1. Introduction

The automation of industrial processes very often requires the handling of small [

1,

2,

3] and micro items [

4], which include mechanical and electrical components used in the assembly processes, finite products that have to be packaged, and row materials that have to be processed. In many industrial scenarios, these small items have to be transported, oriented, and sorted. Nowadays, vibratory systems are very common, because they allow handling small items in a versatile and efficient way. They have a simple and sturdy construction and are suited to handle dusty and hot materials as well. For these reasons, some researchers have studied the kinematics and dynamics of vibratory conveying, orienting, and sorting. In 1963, Taniguchi et al. [

5] carried out a pioneering study that highlighted the role of friction and clearly stated the differences between the gliding and hopping motions of a machine part on a vibrating conveyor, in which the machine part was considered a point mass. The influence of directional friction characteristics was analyzed in [

6], assuming a point mass model of the vibrating part. In [

7], the mechanical part was modeled as a rigid body with six degrees-of-freedom (DOFs) and the contact mechanics were deeply analyzed; however, the rolling motion was neglected, since a block-shaped component was studied. The dynamics of a block moving along the spiral track of a vibratory bowl feeder were studied in [

8], and the block was modeled as a point mass. Some recent studies dealt with the design of the conveyor [

9,

10,

11]; also in these studies, the part was modeled as a point mass, and no rolling motion was considered.

Cylindrical parts, similar to pins and plugs, are very common in electrical and mechanical industry; also, a screw is better represented by a cylinder than by a block. Other manufacturing processes require the handling of cylindrical and quasi-cylindrical parts, e.g., the pharmaceutical industry has to convey cylindrical pills and phials. Cylindrical parts are processed by classical conveyors, if their axes of rotation form a small angle with the direction of conveying [

12]. When this condition is not satisfied, they begin to roll down the track. Most of the scientific literature dealing with conveyors neglects this rolling motion [

1], because sometimes, this phenomenon does not have a significant effect on the process. For example, in orientation processes, often a cylindrical part that can roll also has a wrong orientation and it has to be rejected both if it slides and if it rolls. Nevertheless, in some applications, the cylindrical part has to travel a larger distance, and the rolling motion strongly influences the process.

Thus, this paper focuses on the dynamics of cylindrical parts in a vibrating conveyor, with the aim of explaining the basic differences between the vibration conveying of a block and of a rolling cylinder. The scientific literature in this field is rather scarce. Some papers [

13,

14] analyzed the probabilities of natural resting aspects of cylinders and parts with curved surfaces in vibratory bowl feeders. In [

15], a preliminary numerical analysis of the motion of a cylindrical part on a conveyor was carried out, and the possibility of rolling, sliding, and hopping motions was highlighted. This paper is an extension of the previous research [

15] that includes analytical studies, a more detailed mathematical model that considers impacts, and a wide parametric analysis.

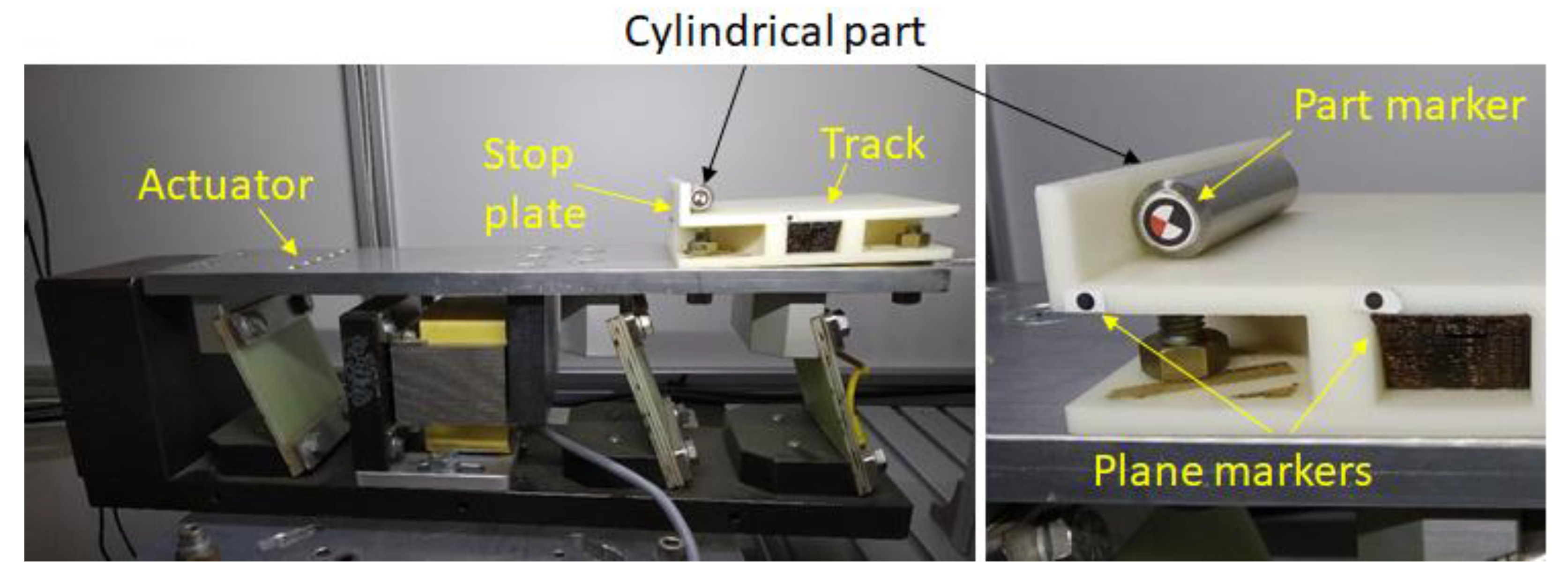

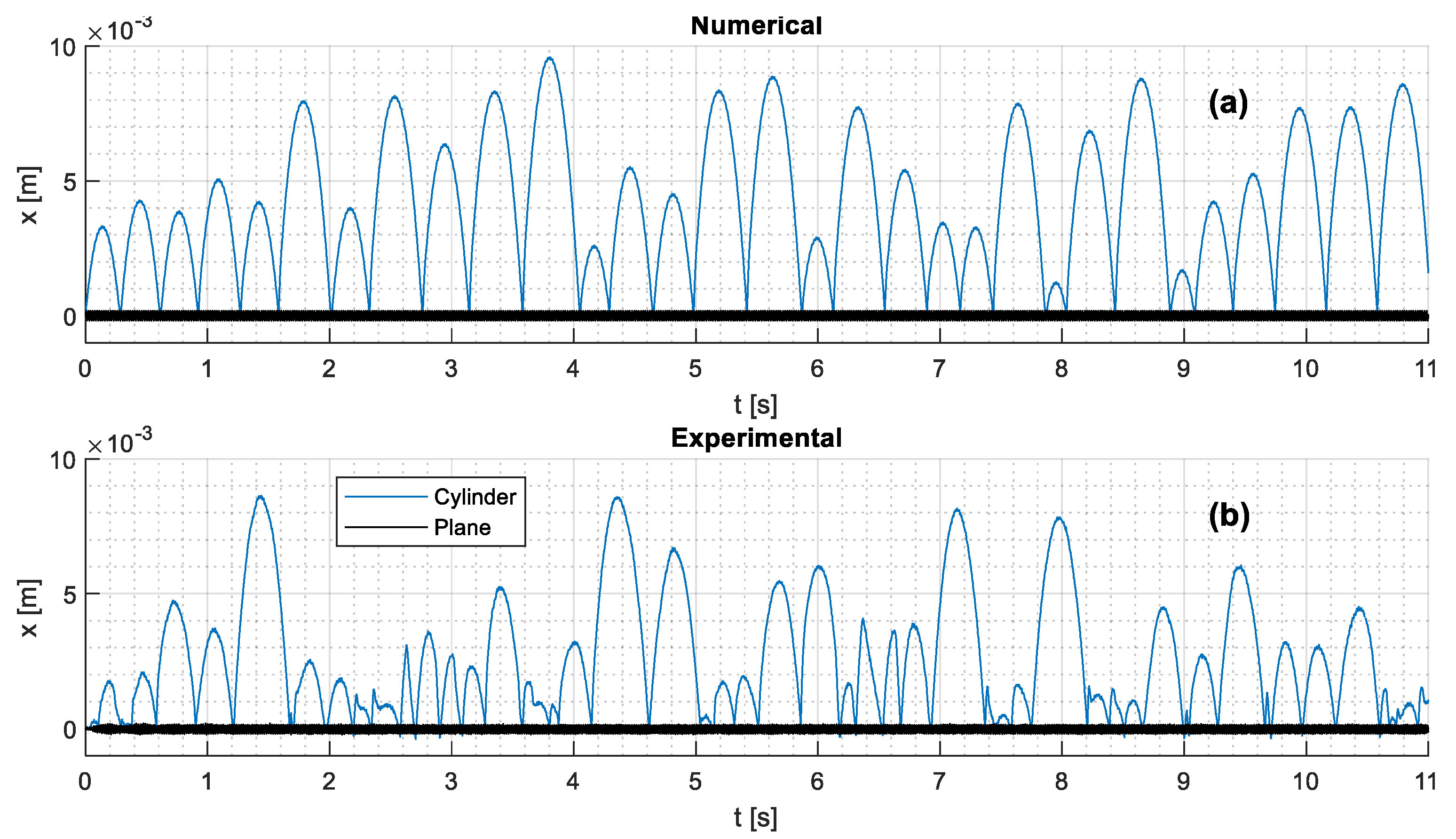

The paper is organized as follows. First, the dynamic equations governing the rolling motion of a cylindrical part are analytically derived, the differences between vibratory conveying of rolling and non-rolling parts are highlighted, and the parameters with the largest influence on the rolling motion are found. Then, a two-dimensional (2D) non-linear numerical model is developed that takes into account the transition between pure rolling and rolling with sliding and the impacts of the cylindrical parts with the edge of the conveyor. Series of numerical simulations are carried out, which show the effects of variations in the system’s parameters on the motion of the cylindrical part. Finally, testing equipment composed of a vibrating conveyor and a vision system that monitors the motion of a cylinder is presented. Numerical results are compared with experimental results, and the benefits and limits of 2D simulations are discussed.

2. Theoretical Basis

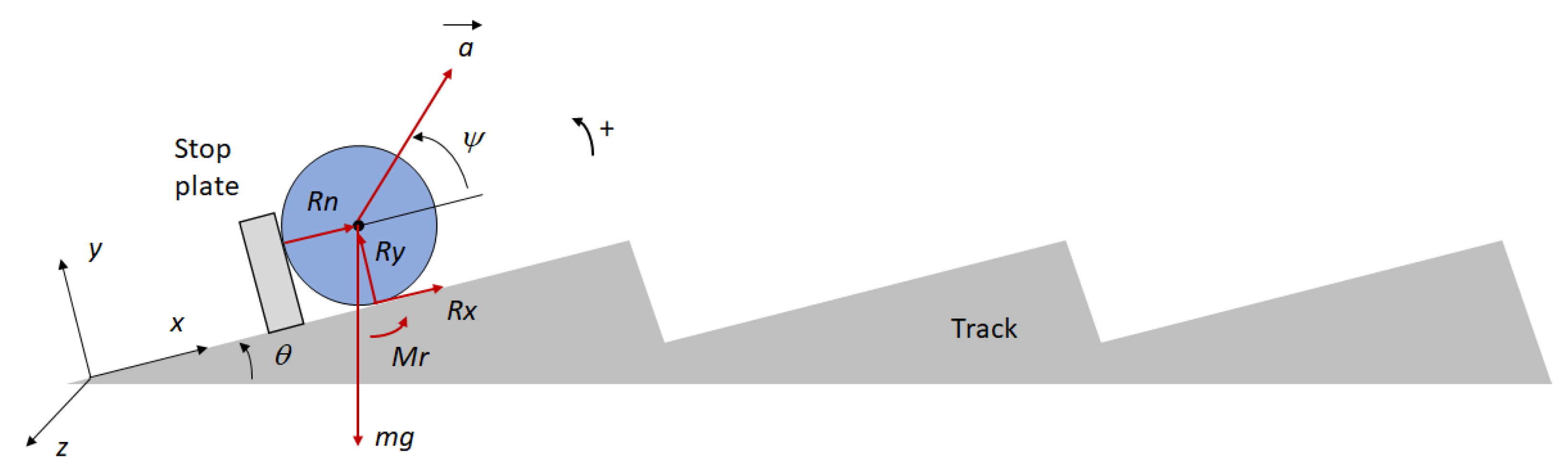

There are very important differences between the vibration conveying of parts that can roll on the conveyor track and parts that cannot roll. A 2D model with the plane of motion perpendicular to the axis of the cylinder is enough to point out these differences.

Vibration conveying of non-rolling parts is a dynamic phenomenon dominated by dry friction.

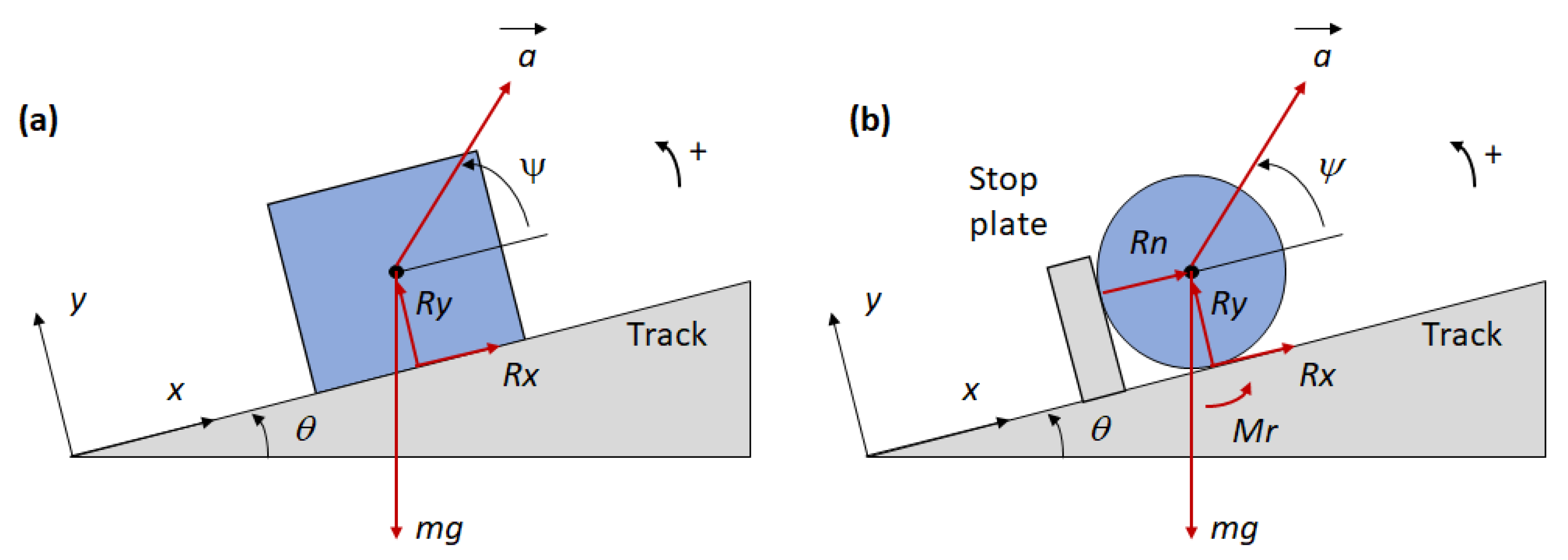

Figure 1a shows a small block on the track of the conveyor, which is tilted by angle

with respect to the horizontal direction. A fixed reference frame with axis

parallel to the track and axis

perpendicular to track is introduced.

and

are the components of the reaction force exerted by the track surface on the block (the positive direction is represented); they are related by the static Coulomb friction coefficient

and by the kinetic Coulomb friction coefficient

. Acceleration (

) of the conveyor is tilted by angle

with respect to the conveyor track. If the motion of the conveyor is harmonic with amplitude

and angular frequency

, the components of the acceleration are:

Angle

is essential for the vibration conveying of non-rolling parts. When acceleration has the direction shown in

Figure 1a, the inertia force adds to the weight of the block, the reaction force

is large, the modulus of the demanded tangential reaction force |

Rx| is smaller than the maximum static friction force (

, and the block cannot slide backwards. Conversely, when acceleration

changes its direction, the inertia force tends to cancel the weight force,

decreases, and the modulus of the demanded tangential reaction force

may become larger than the maximum static friction force; hence, the block moves, and forwards sliding begins. This condition repeats at every period of the harmonic motion and eventually the block moves forwards with respect to the track.

The scenario drastically changes when the part has a cylindrical shape, as depicted in

Figure 1b. A stop-plate is introduced, and

is the reaction force exerted by the stop plate on the cylinder (the positive direction is represented),

is the rolling resistance torque (the positive direction is represented),

is the cylinder mass, and

is the gravity force (the actual direction is represented).

First, the cylindrical part is assumed to be steady on the vibrating conveyor, and the dynamic conditions that make possible the beginning of the relative motion are analyzed. The equations of motion in the

and

directions are:

In Equations (3) and (4), and are the two components of the acceleration of the center of mass of the cylindrical part.

When there is no relative motion,

and

coincide with the components of acceleration of the conveyor (

and

); therefore, the equations of motion become:

The perpendicular reaction force con be calculated from Equation (6).

The contact between the cylinder and the track is unilateral; hence,

. When

tends to zero, the cylinder separates from the track, and the hopping motion begins. The hopping motion can be avoided decreasing the vibration acceleration, and this solution leads to a noise reduction [

9]. Thus, this kind of motion is not considered in the framework of this research.

The angular momentum equation about the center of mass of the cylindrical part is:

Reaction force

does not appear in Equation (8), because it passes through the center of mass of the cylinder.

is the moment of inertia about the center of mass,

r is the cylinder radius,

is the coefficient of rolling resistance in static condition,

is the angular acceleration,

is the angular velocity, and

is the signum function. Since the beginning of the rolling motion is considered,

and

, because after the beginning of relative motion, a negative rolling velocity will take place:

. Tangential reaction force

Rx can be calculated from the angular momentum equation:

The term is the non-dimensional rolling friction coefficient in static condition, which is named .

The reaction force that the stop plate exerts on the cylinder (

) can be calculated from Equations (5) and (9). The contact between the cylinder and the stop plate is unilateral

. Hence, the condition

in conjunction with the adoption of the maximum rolling friction coefficient in Equation (9) defines the beginning of the relative motion between the cylinder and the conveyor track:

If Equation (6) is introduced into Equation (10), the following condition for the beginning of rolling motion is obtained:

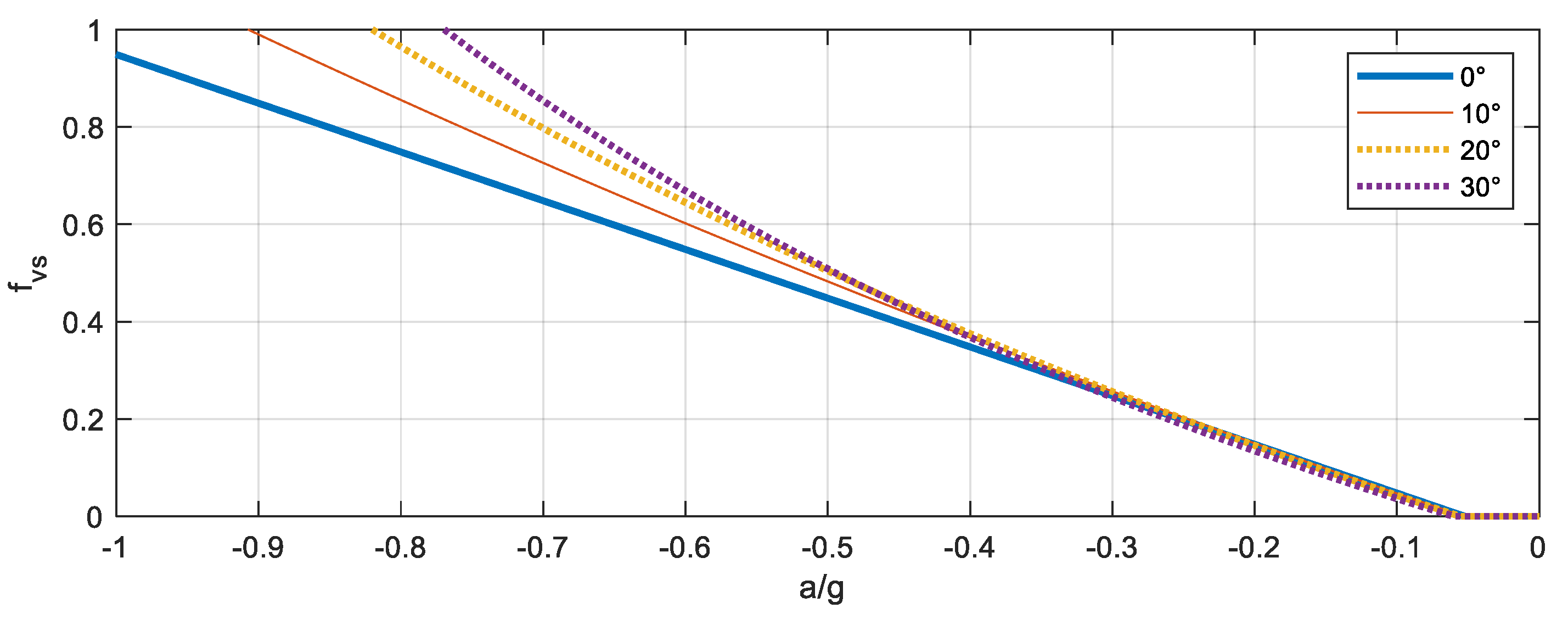

Figure 2 depicts the values of the static rolling friction coefficient (

that prevents the rolling motion against non-dimensional acceleration (

) for parametric values of

. Only negative values of acceleration are considered, since a negative acceleration is required to begin the rolling motion; the maximum value of non-dimensional acceleration is

since for larger values, the resultant of the gravity and inertia forces pushes the cylinder against the stop plate.

Figure 2 shows that very large and unrealistic values [

16] of static rolling friction coefficient (

) are needed to prevent the beginning of the rolling motion. When

is lower than −0.35, the increase in angle

increases the value of

.

Hypothetically, the cylindrical part excited by conveyor vibrations could begin a sliding motion as well. The following condition for the beginning of the sliding motion can be derived:

It is worth noticing that this condition is the same that holds true for non-cylindrical parts [

1]. Equation (12) is similar to Equation (11), but

is substituted by

μs, which is the static Coulomb friction coefficient. For most of the materials used in industrial applications [

16], the static Coulomb friction coefficient is much larger than the non-dimensional rolling friction coefficient in static condition. Therefore, the negative acceleration needed to begin the sliding motion is much larger (in modulus) than the one needed to begin the rolling motion.

The evolution of the rolling motion is now analyzed. The equations of motion are:

Moreover, during pure rolling, the following kinematic condition has to be fulfilled:

can be calculated from Equation (14); then, Equations (13), (15), and (16) can be solved to calculate

,

, and

. Taking into account that for a cylinder

, the following results are obtained:

It is worth noticing that when the cylinder rolls forwards (

), the rolling friction term in Equation (19) adds to the gravity term. The motion of the cylinder on the conveyor track can be studied integrating Equations (18) and (19); the input is

acos(

ψ). Generally speaking, a numerical integration is needed (see

Section 3) owing to the

function. Nevertheless,

in most industrial processes, and an approximation of the integrals of Equations (18) and (19) can be obtained assuming

.

According to Equation (11), the forward motion begins when . Since in normal conveying applications angle is rather small, another simplification can be made assuming that the forward rolling motion begins when becomes negative. This assumption simplifies the initial conditions, because in the harmonic motion vibration, the acceleration changes its sign when the displacement is zero and the velocity has the maximum positive value (x0ω).

The integration of Equation (18) with the above-mentioned simplifications and initial conditions leads to the following equations for the absolute velocity (

) and displacement (

) of the center of mass of the cylinder:

From the point of view of conveying, the most important parameter is the relative velocity

between the part and the track of the conveyor:

The relative velocity includes a positive and constant term due to initial velocity (); a harmonic term due to the vibration of the conveyor plate, whose integral over a period () is zero; and a negative term due to gravity that increases (in modulus) with time.

If

(horizontal conveying), the average conveying velocity in the period (

) is constant and equal to

. If

the average conveying velocity decreases, and at the nth period it assumes the value:

When

becomes negative, the cylindrical part rolls backwards and eventually impacts the stop plate.

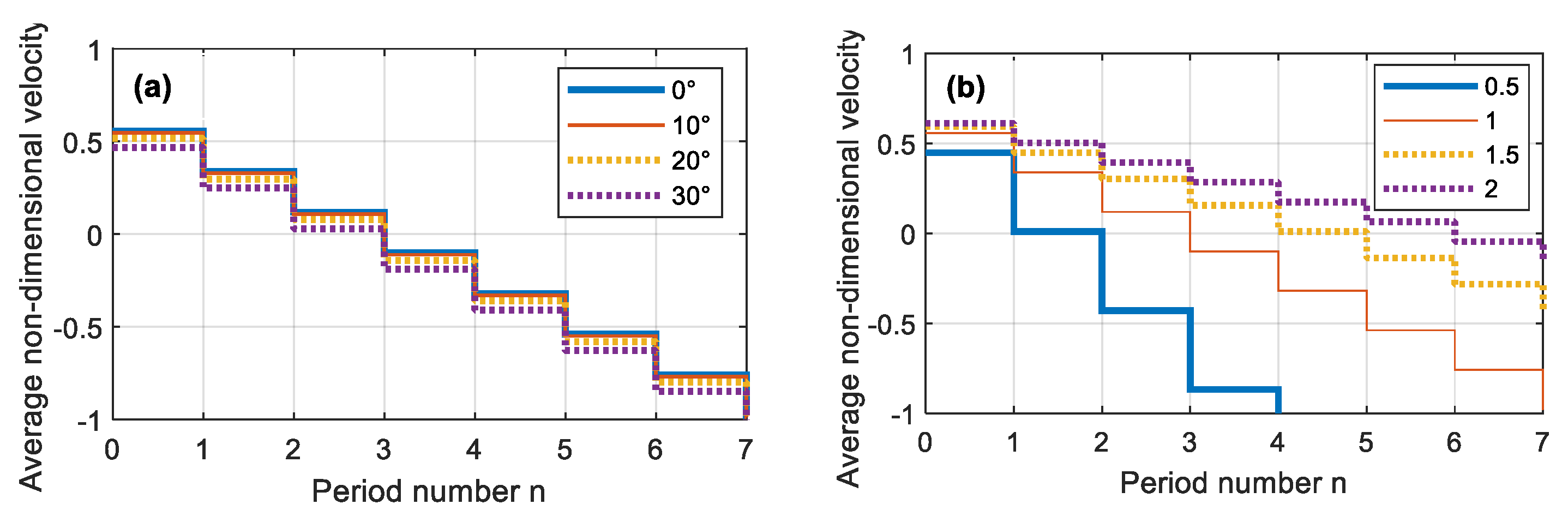

Figure 3 depicts the ratio between

and the maximum vibration speed (

) versus period number (

) for

θ = 3°. In

Figure 3a, the ratio between the vibration acceleration and gravity acceleration (

) is 1 and the parametric values of angle

are considered; the increase in

ψ has a negative effect on the conveying speed. In

Figure 3b,

ψ is set to zero, and the parametric values of the ratio

a/

g are considered; the increase in vibration acceleration has a positive effect on vibration conveying.

Equation (24) holds true with the assumption . If rolling resistance is present, it contributes to decreasing the average conveying speed in the period.

During pure rolling motion, the reaction force

given by Equation (17) is needed to guarantee equilibrium.

has to be smaller than the maximum static friction force (

). Hence, the ratio

has the meaning of static friction coefficient needed to guarantee equilibrium during pure rolling.

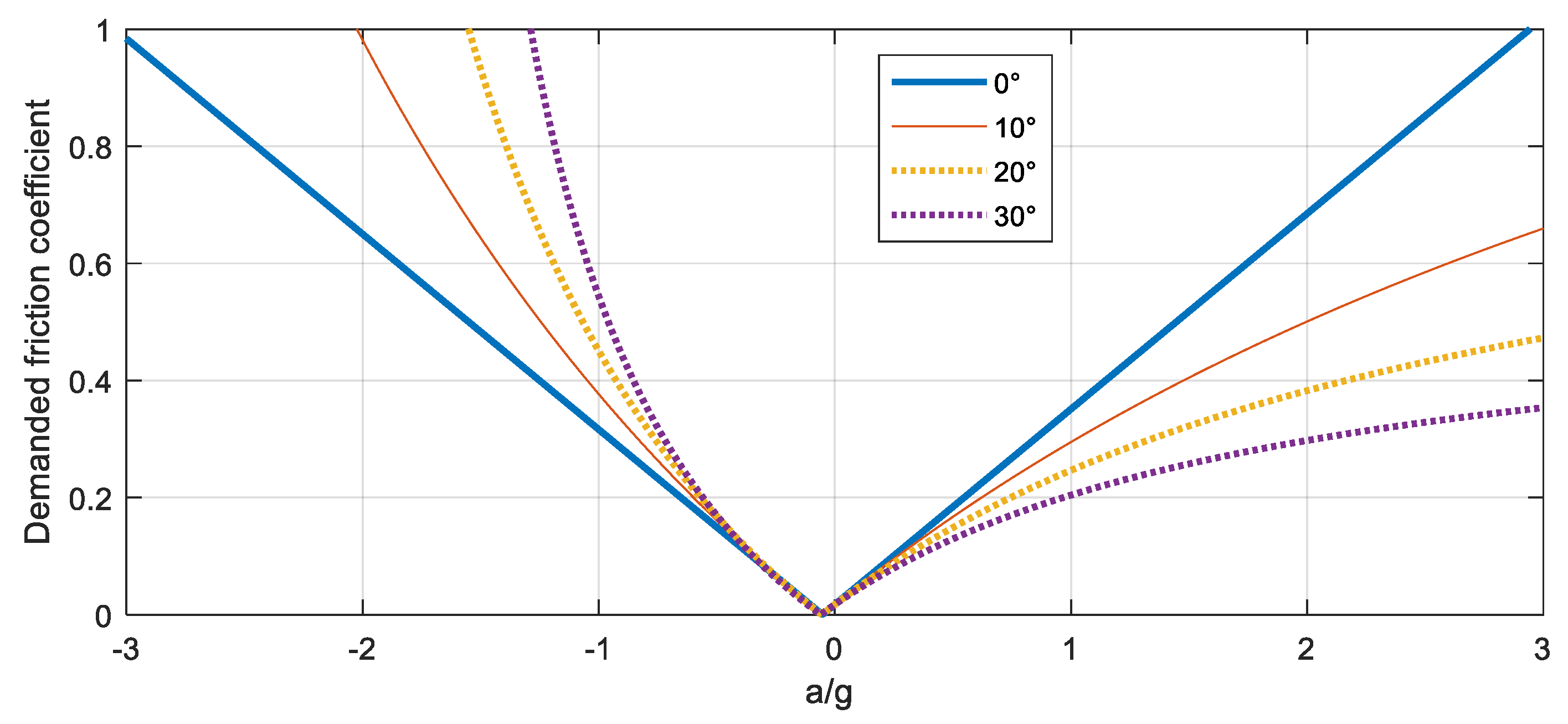

Figure 4 shows the ratio

against non-dimensional acceleration (

) for

and parametric values of

.

With , the friction coefficient needed to guarantee the pure rolling motion is only slightly influenced by the versus of acceleration.

With

, the friction coefficient needed to guarantee the pure rolling motion is significantly smaller when the conveyor acceleration is positive than when acceleration is negative. This phenomenon happens because when acceleration changes sign, the decrease in reaction force

(Equation (7)) is not compensated by the decrease in

(Equation (17)), and this effect becomes even more important when

is large. Since in most industrial material

is in the range of 0.6 ÷ 1 [

1], the transition from a pure rolling motion to a rolling with sliding can take place only in the presence of large negative accelerations of the vibration conveyor.

When the cylindrical part rolls backwards, it may impact the stop plate; in this case, the equation of motion in the x direction becomes:

in which

is the impact force, which has the same direction of

in

Figure 1.

strongly increases

; hence, the ratio

/

may reach very large values, and the sliding motion can begin.

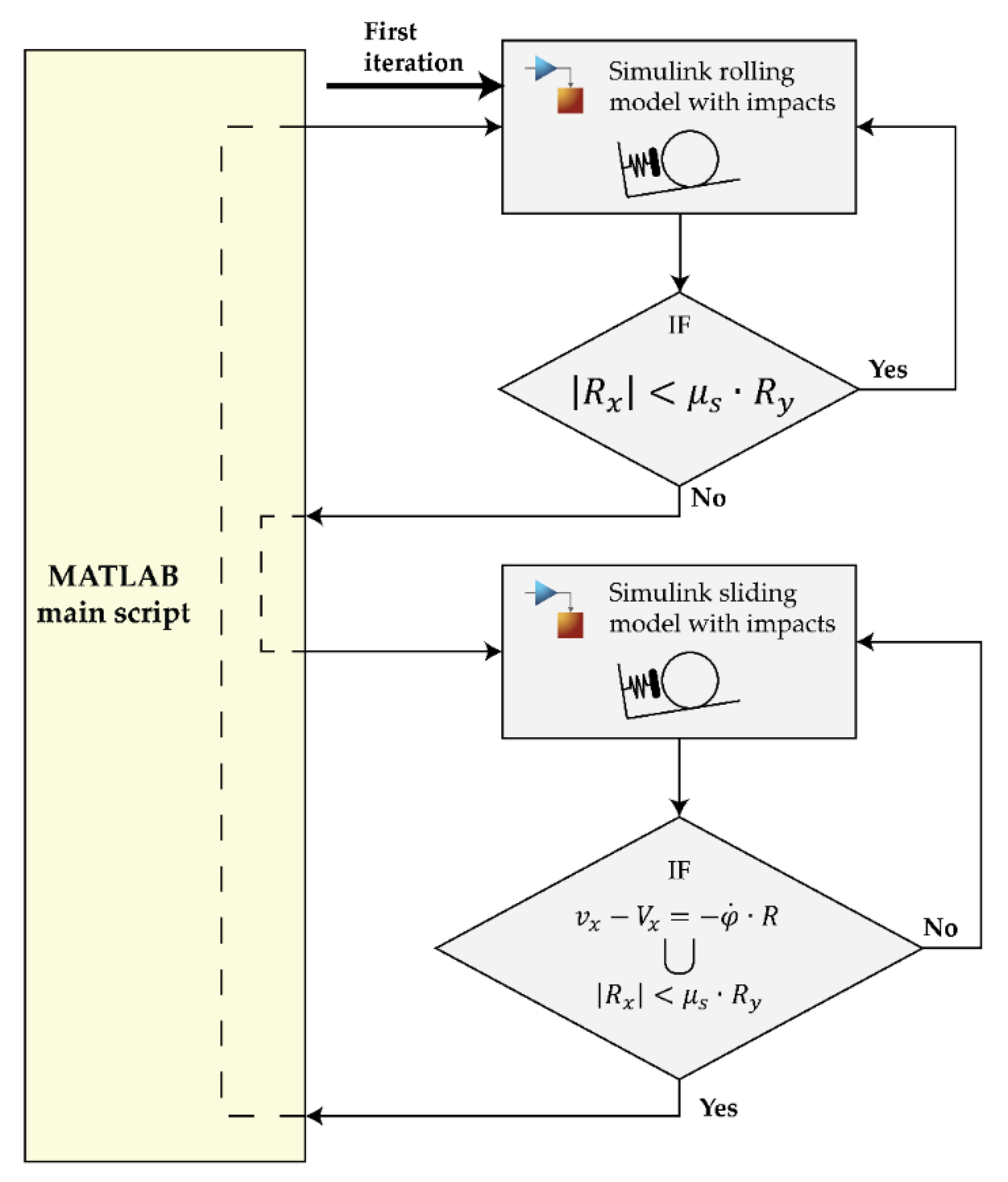

4. Numerical Results

Numerical simulations aimed at exploring the dynamics of vibration conveying of cylindrical parts beyond the limits of the analytical model of

Section 2. In particular, numerical simulations made it possible to analyze the effect of the impacts of the cylindrical part on the stop plate.

A realistic reference case was defined, which is characterized by the following parameters of the vibratory conveyor: = 0.0002 m, 314 rad/s (frequency 50 Hz), 3°, 0°. The maximum modulus of conveyor acceleration is 19.72 m/s2 ).

The rolling part has a radius

0.007 m and mass

0.096 kg. The friction parameters are

0.005,

, and

. The value of the rolling resistance is more than twice that of the typical rolling elements of bearings [

16] and takes into account that the cylindrical part may be rough or dirty. The kinetic Coulomb friction coefficient value is inside the typical range of values found in vibratory conveyors [

1,

6,

9]. The static Coulomb friction coefficient was set to be twice the kinetic coefficient [

17]. Finally, the impact stiffness was set to

N/m; this value made it possible to obtain values of contact forces similar to the measured ones (about 60 ÷ 80 N).

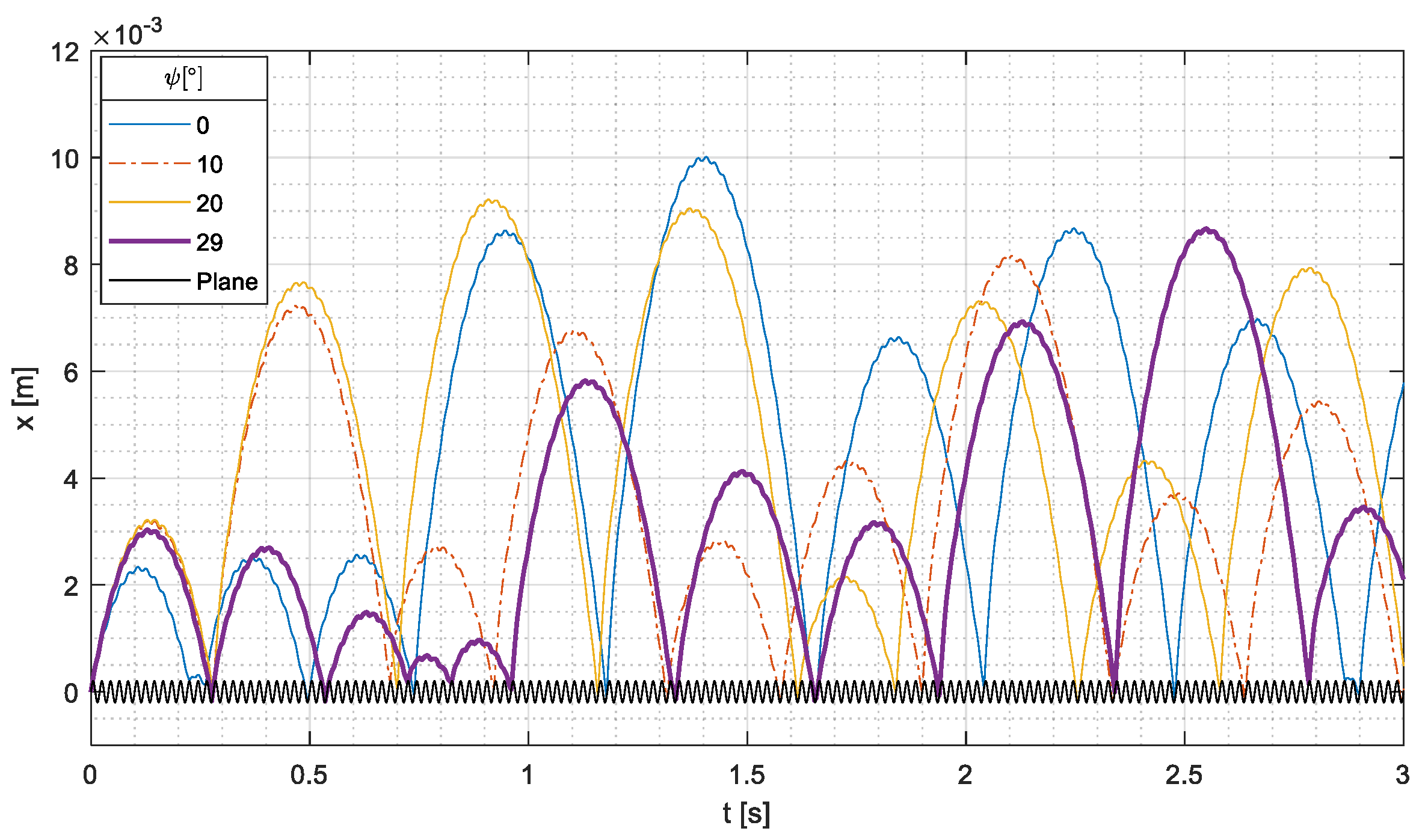

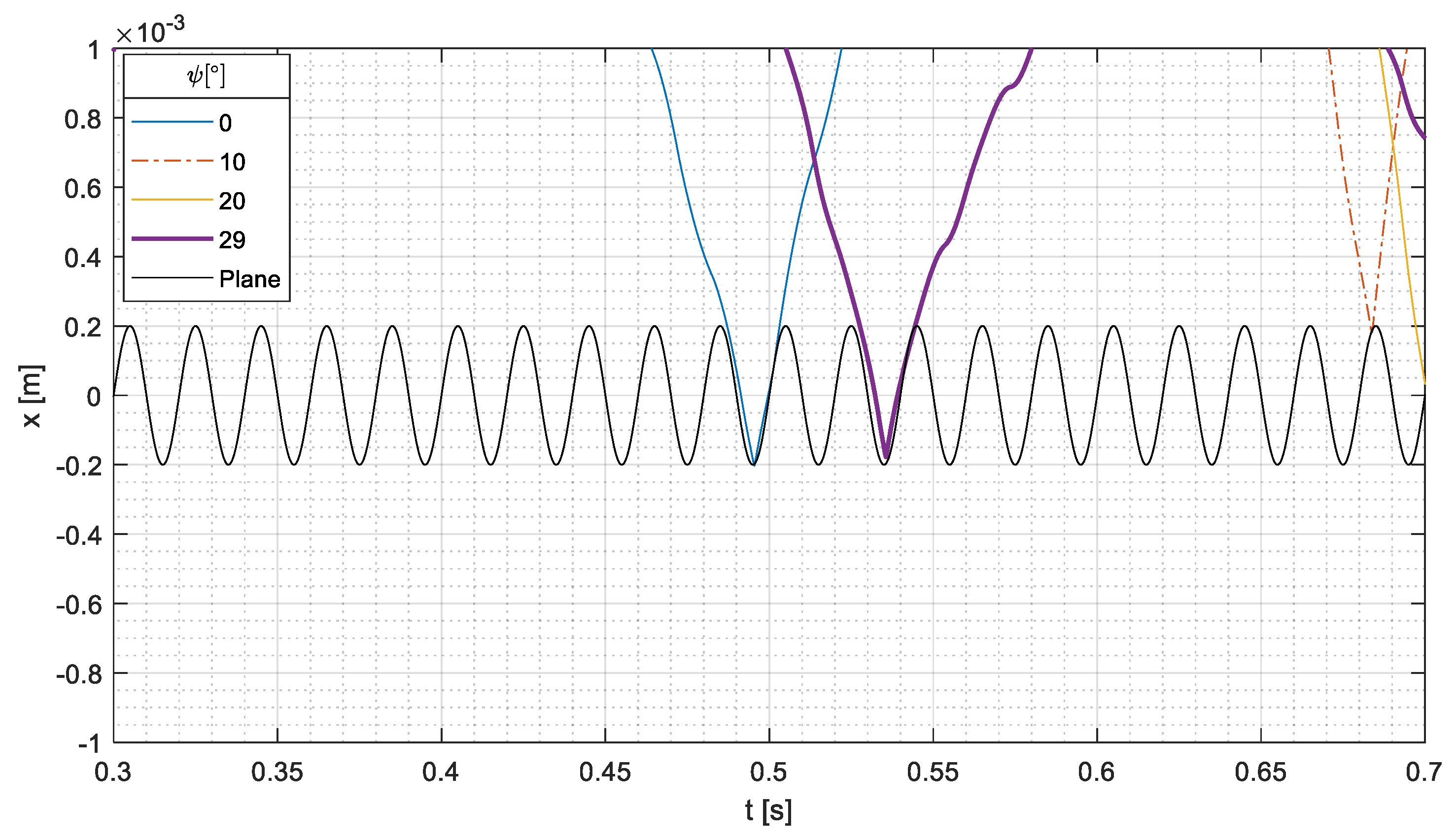

The first parametric simulations aimed at analyzing the effect of angle

;

Figure 6 shows numerical results in terms of the absolute displacement of the cylinder center of the mass. In the same figure, for comparison, the displacement of the conveyor is represented (along the direction tilted by

with respect to the

axis).

In the plots of

Figure 6, two different phases can be identified. The first phase (phase 1), which ends at about 0.25 s and includes 10

vibration periods, is the initial motion of the cylindrical part without impacts. As foreseen by theoretical analysis, the cylindrical parts begins its motion at

owing to the initial velocity given by the conveyor, reaches the maximum displacement, and eventually impacts the stop plate. The maximum displacement is rather small (about 0.003 m), and this value is in agreement with the theoretical predictions (Equation (21)).

In this phase, the increase in the angle up to 20° leads to an increase in the traveled distance, a further increase leads to a reduction in the traveled distance. This particular behavior is due by the presence of two opposite effects.

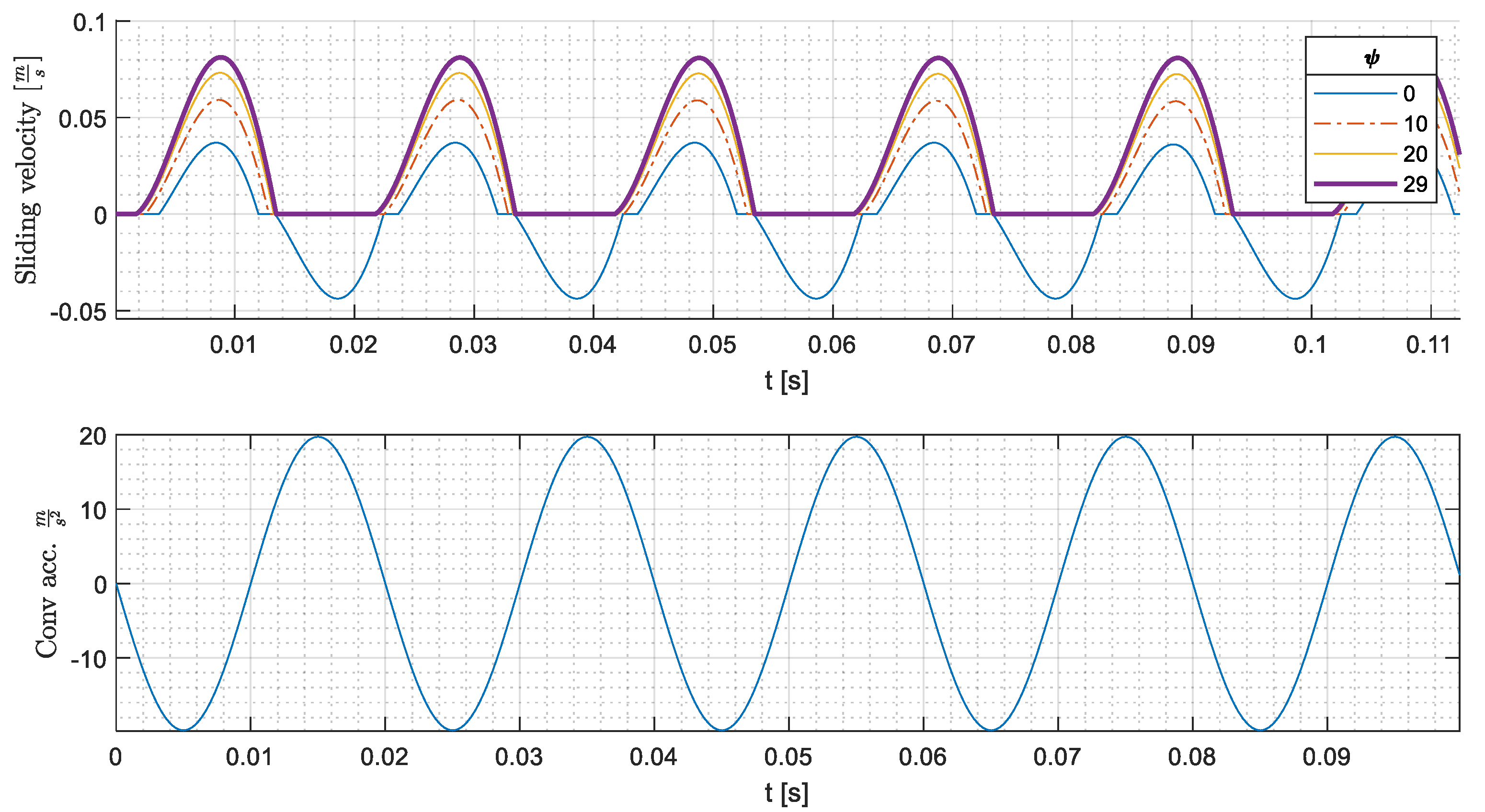

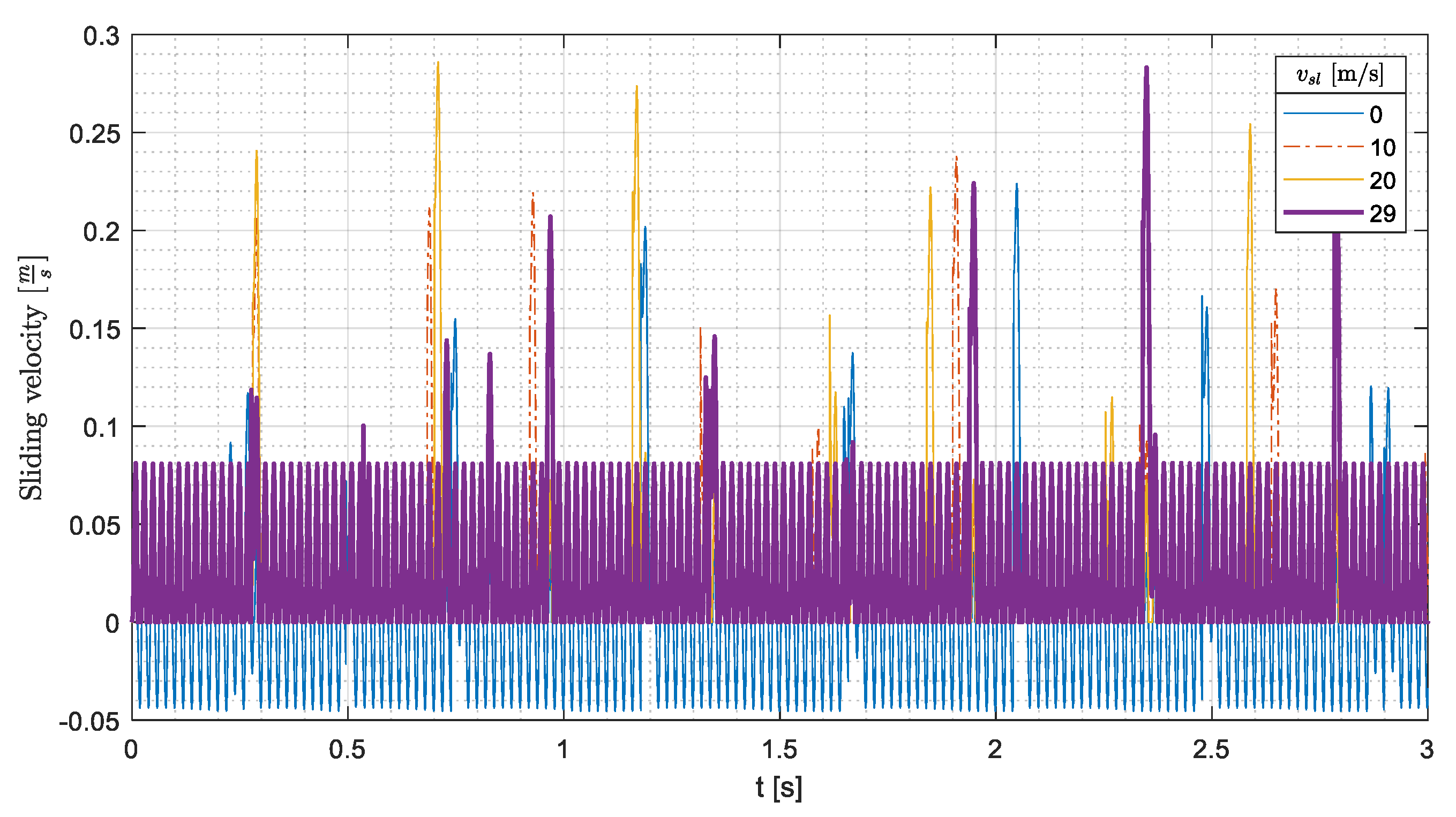

The first effect can be understood looking at the sliding velocity (

) of the cylindrical part:

which is plotted in

Figure 7 with conveyor acceleration. If

, the cylindrical part slides both when the conveyor acceleration is negative and positive (forwards and backwards sliding, respectively). Backwards sliding causes a reduction in the traveled distance. This phenomenon is in agreement with the analytical results of

Figure 4, which show that for

, the static friction coefficient needed to guarantee the pure rolling motion is larger than

both for negative (−2) and for positive (+2) values of non-dimensional acceleration.

Conversely,

Figure 7 shows that if

increases, there is only forwards sliding, since the static friction coefficient is able to prevent backwards sliding when the conveyor acceleration becomes positive, and the cylindrical part behaves similar to a block. It is worth noticing that this behavior is in agreement with the analytical results of

Figure 4.

The second effect is the decrease in the initial velocity of the cylindrical part when increases; see Equation (20). In summary, for small values of , the first effect is dominant, and the traveled distance increases, whereas for large values of , the second effect reduces the traveled distance.

The second phase of the motion (phase 2, 0.25 s) is dominated by the impacts of the cylindrical part on the stop plate.

The cylindrical part reaches the maximum displacement in this phase, and this value chiefly depends on impact mechanics. If the relative velocity (Equation (22)) is large, because the cylindrical part and the conveyor move in opposition, the conveyor transfers a lot of energy to the cylindrical part, which has a large rebound after the impact. This phenomenon occurs at

for

.

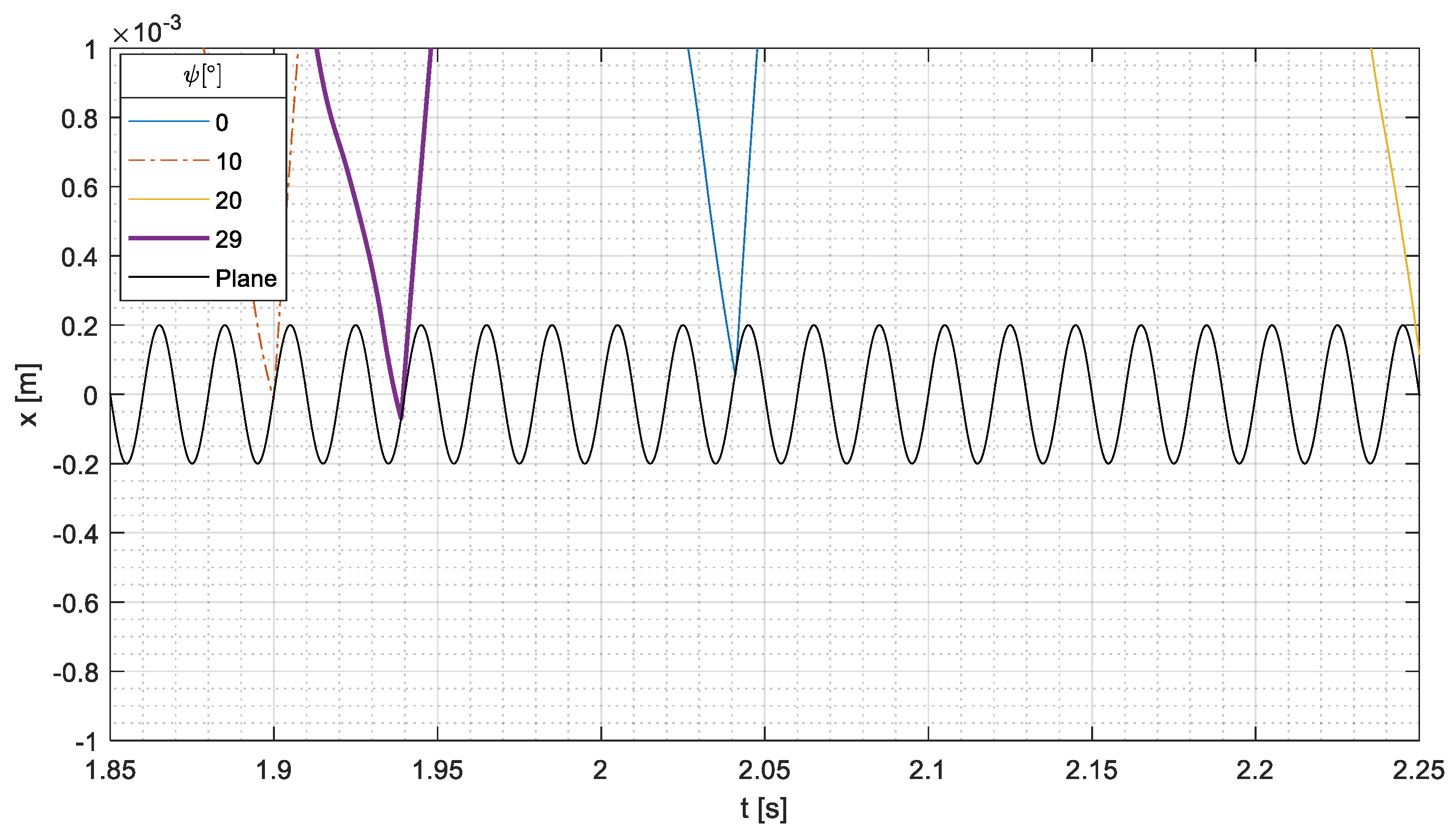

Figure 8, which is a zoom of

Figure 6 of about

, shows that the impact occurs when the conveyor has the maximum positive velocity, whereas the velocity of the cylindrical part is negative. Conversely, if the relative velocity is small, because the cylindrical part and the conveyor move in phase, the conveyor transfers less energy to the cylindrical part, and a smaller rebound occurs. This phenomenon takes place at

for

, since

Figure 9 shows that the cylindrical part impacts the conveyor when it has a negative velocity.

The angle of conveyor acceleration (

) has a negligible effect on the second phase (impact dominated) of the motion of the cylindrical part on the conveyor, since the relative velocity at the impact depends much more on the previous motion than on conveyor maximum velocity, which slightly decreases if

increases. Actually, after some impacts, the relative velocity at the impact changes randomly. Thus, the motion of the cylindrical part on the conveyor is similar to the motion of a bouncing ball that impacts a vibrating table, which may exhibit a chaotic behavior [

18,

19].

Figure 10 shows for the same cases of

Figure 6 the sliding velocity of the cylindrical part and highlights that, owing to the large value of non-dimensional acceleration (

2), very often the cylinder slides on the conveyor track. The largest sliding velocities take place just after the impacts.

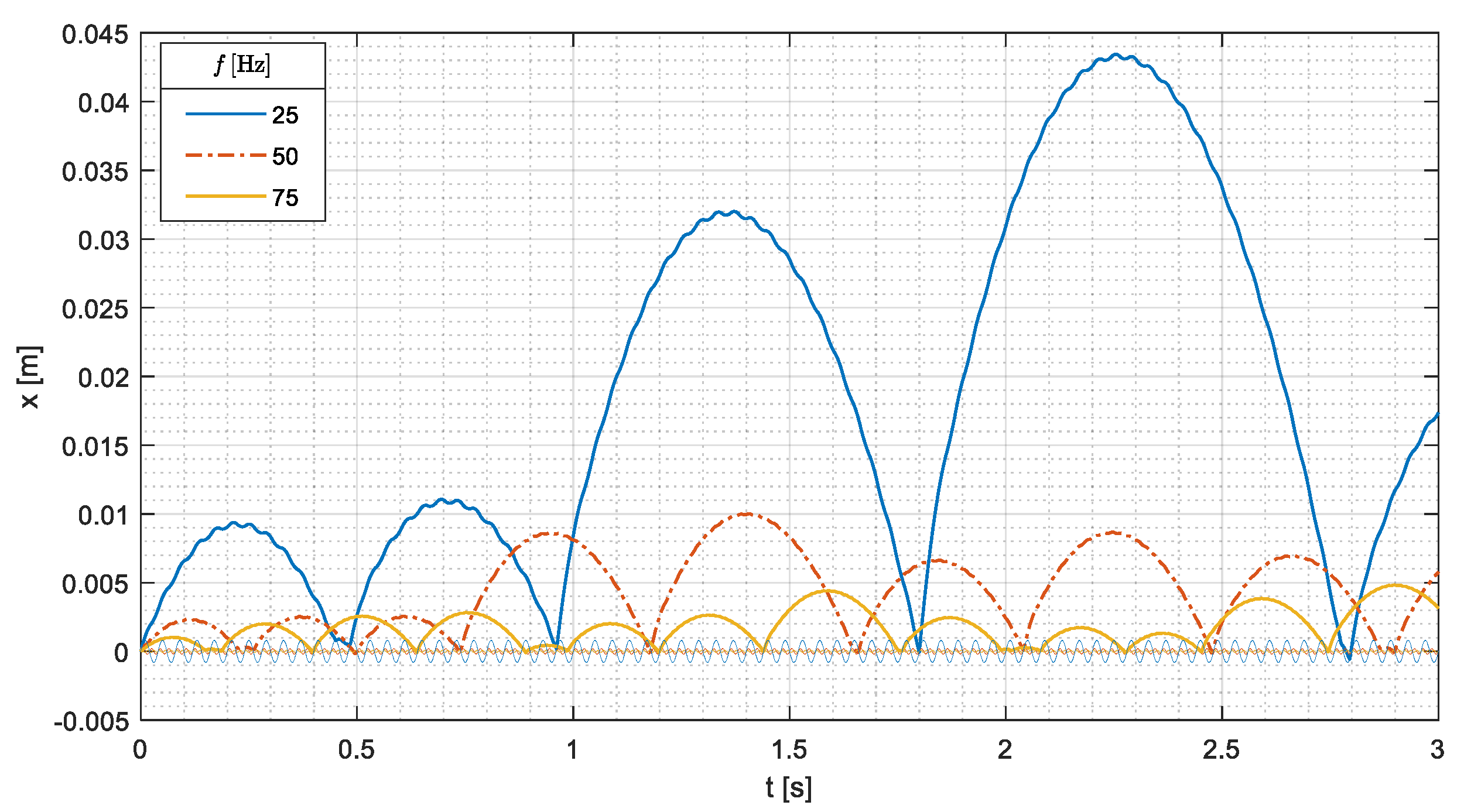

The second parametric simulation aimed at analyzing the effect of conveyor vibration frequency. Conveyor acceleration was kept equal to the previous value (

2); therefore, an increase in frequency led to a decrease in velocity according to this equation:

Figure 11 clearly shows that the increase in the frequency has a negative effect on the motion of the cylindrical part both before and after the first impact. The first effect takes place because the initial velocity is smaller, while the second effect takes place because the relative velocity at the impact is smaller. If the vibration frequency decreases to 25 Hz, the traveled distance increases up to 0.043 m. It is worth noticing that even if the dynamics of conveying of block-shaped parts and cylindrical parts are very different, the decrease in vibration frequency has a positive effect in both cases [

1].

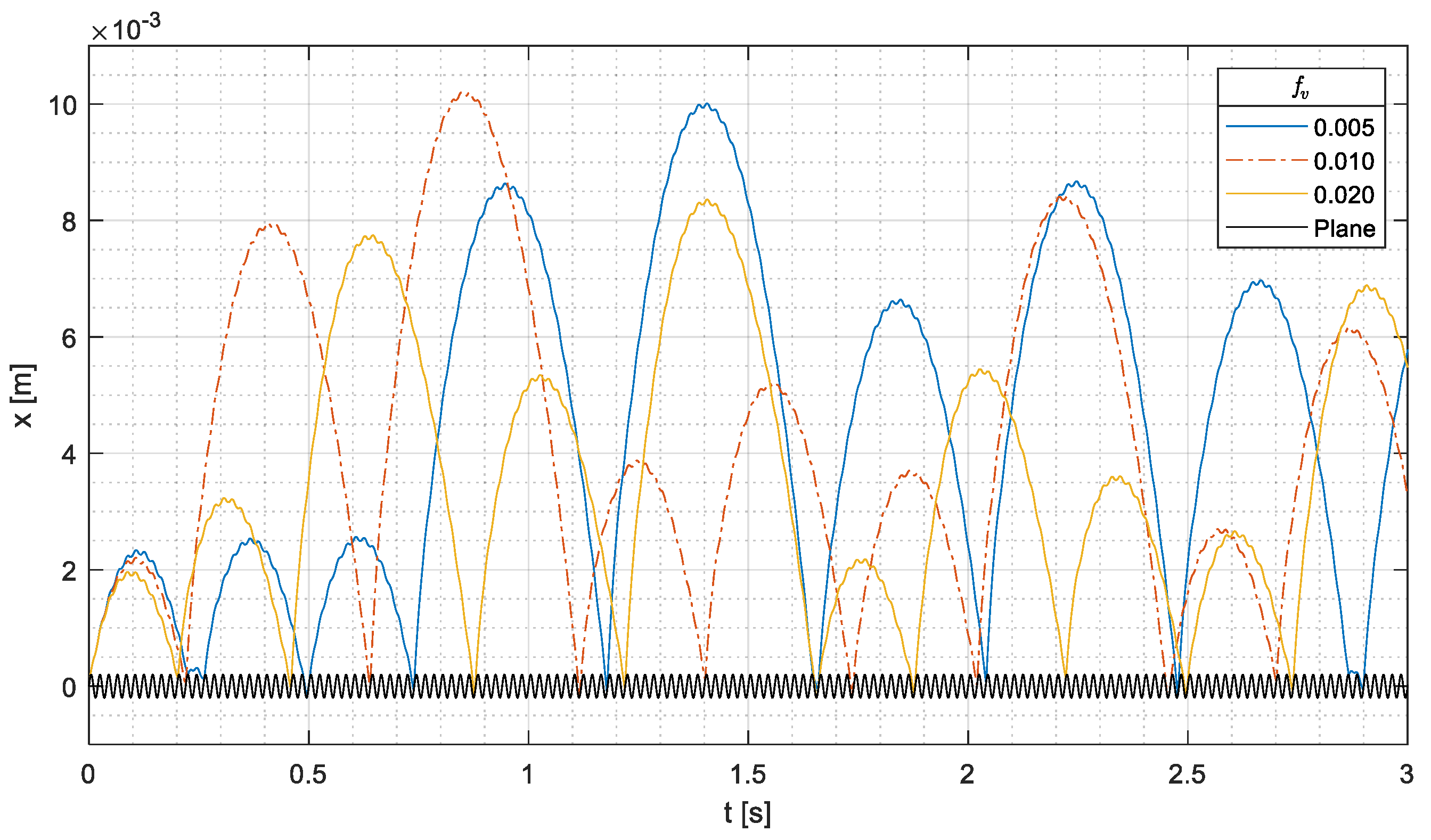

Then, the effect of rolling friction coefficient was investigated by means of numerical simulations. The results, which are presented in

Figure 12, show that realistic variations in

have a negligible effect on the conveying of cylindrical parts. Before the first impact (phase 1), the decrease in

causes a very small increase in the traveled distance. After the first impact (phase 2), the variation in the rolling friction coefficient changes the instants in which the most energetic impacts take place, but the traveled distance does not significantly change.

Figure 13 shows the effect of contact stiffness on the conveying of cylindrical parts. The contact stiffness does not affect phase 1, and it does not have a clear effect on the traveled distance in phase 2. This phenomenon agrees with physical intuition, because the contact stiffness is another factor that contributes to randomly varying the relative velocity at the impact, which is the main factor influencing the rebound of the cylindrical part.

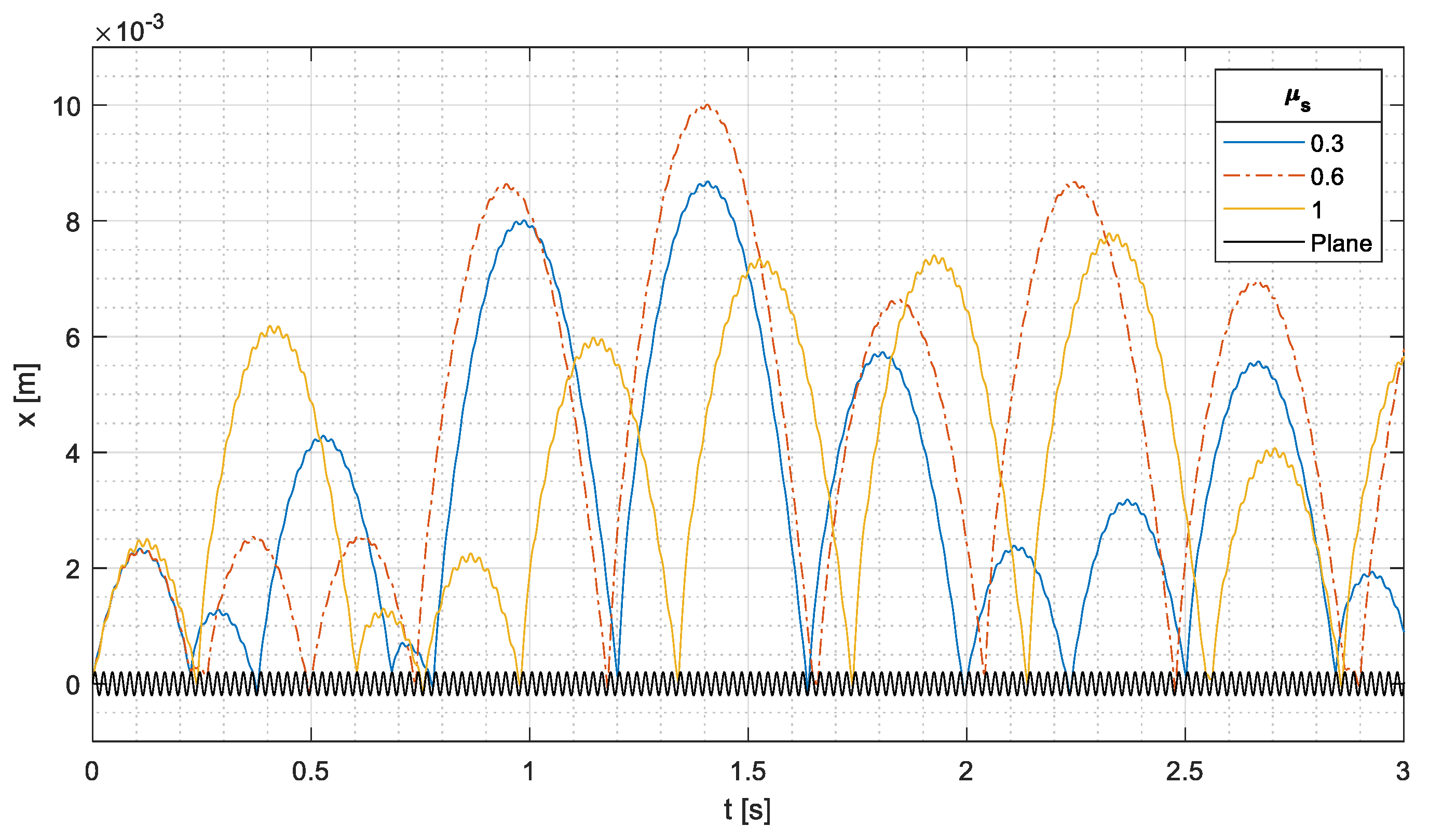

Finally, the effect of friction coefficients was investigated.

Figure 14 shows that

has a small effect on phase 1: if the static friction coefficient increases above 0.6, the traveled distance increases. This phenomenon can be explained looking at

Figure 15, which shows the sliding speed for the same values of

. With

during phase 1, the cylinder does not slide at all, and the traveled distance increases, since the pure rolling motion dissipates less energy than the rolling with sliding motion. It is worth noticing that this result agrees with the analytical results of

Figure 4.

After the first rebound, the impacts take place at random instants and, again, the relative velocity at the impact has the largest effect.

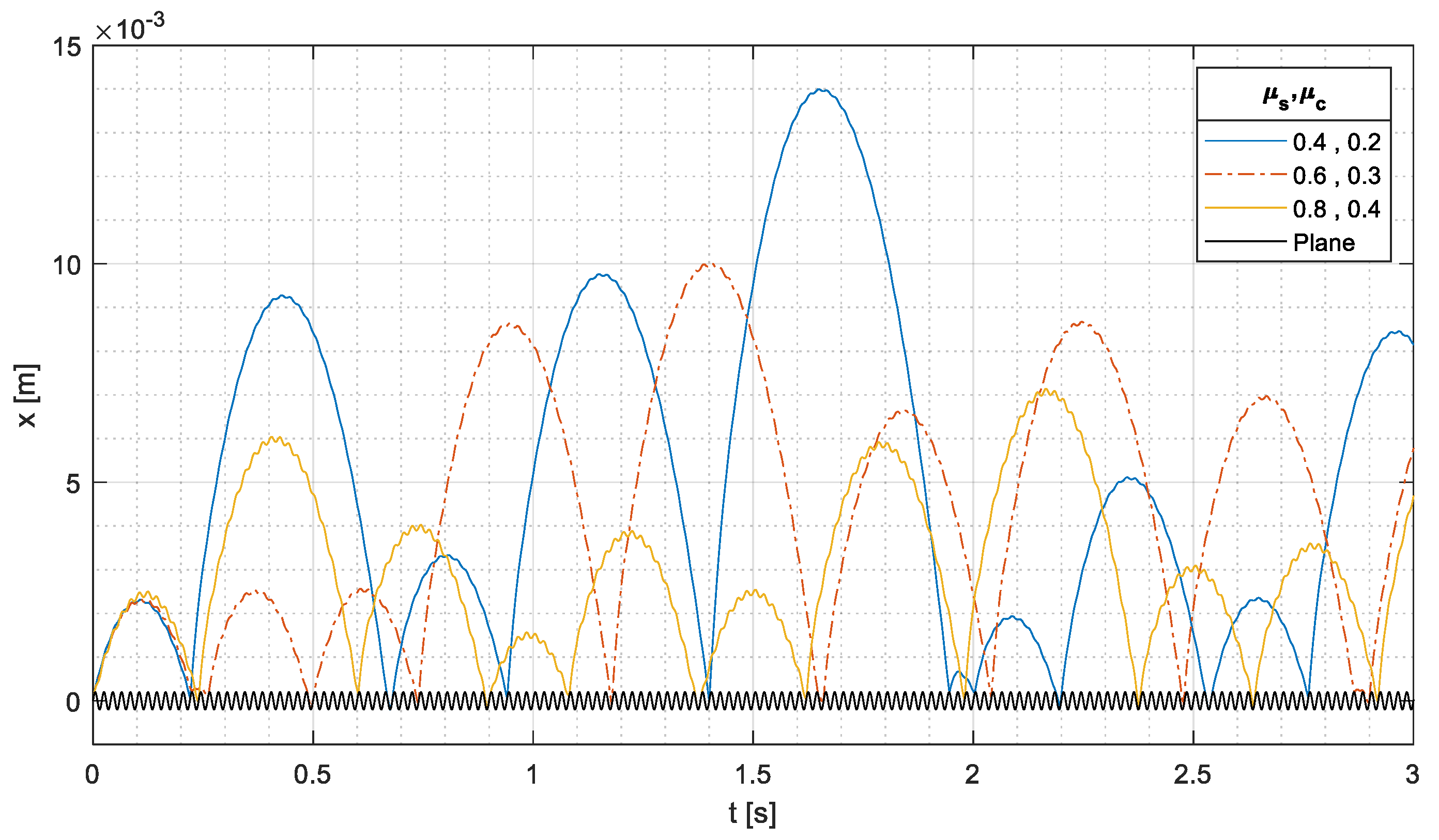

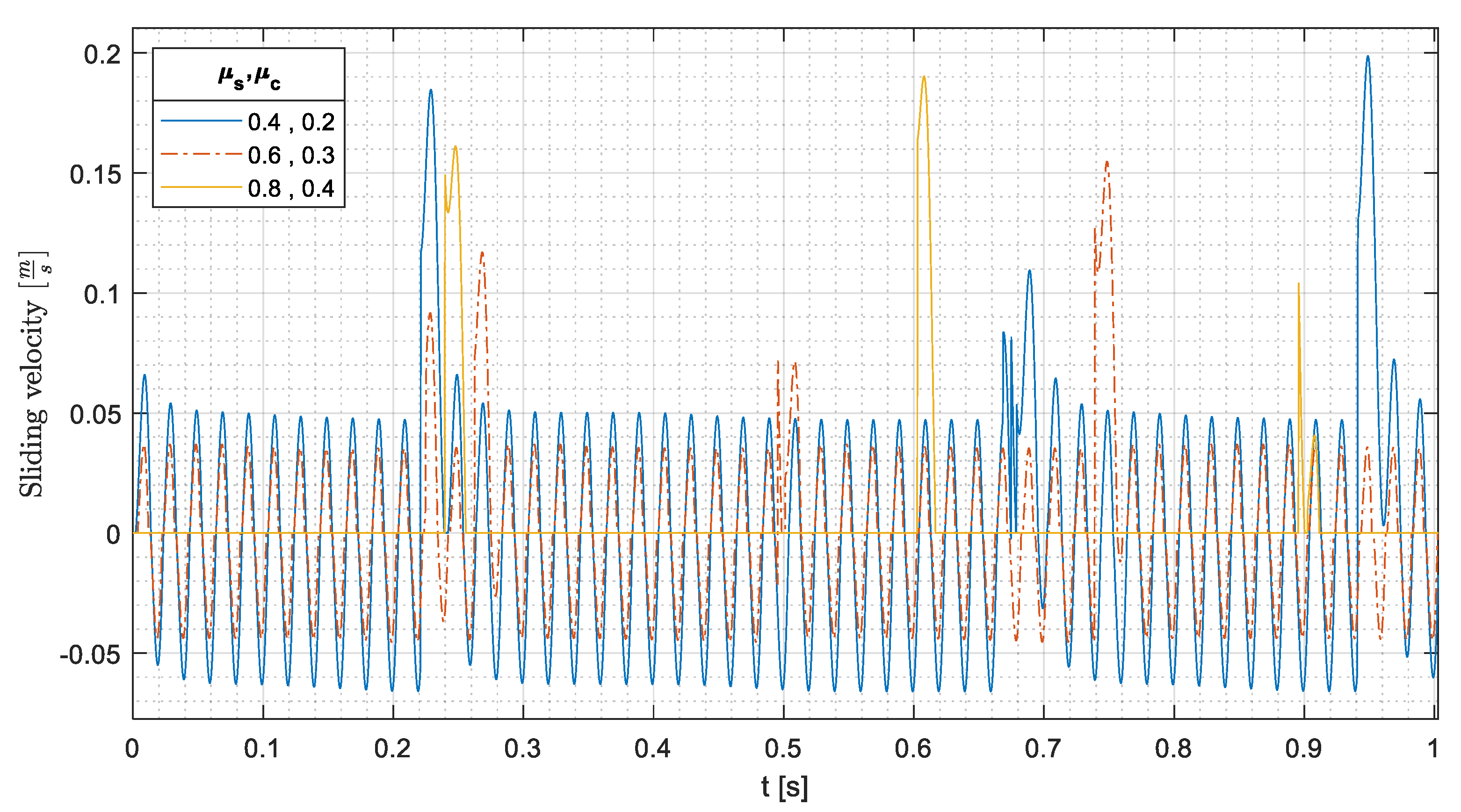

The effect of a proportional variation of both friction coefficients (

and

) is presented in

Figure 16. In phase 1, the cylinder with the highest

reaches the largest distance because it rolls without sliding, as shown in

Figure 17. After the first impact (phase 2), the motion is dominated by the relative velocity at the impact; nevertheless, a decrease in

leads to an average increase in the traveled distance. With

, there are 4 rebounds with a traveled distance larger than 0.008 m, whereas with

, there is no rebound with a traveled distance larger than 0.008 m. This phenomenon occurs because for every value of

and

, there are large sliding velocities (

Figure 17) after the impacts, and a reduction in

leads to a reduction in energy dissipation.

The numerical results presented in this section clearly highlight that only the decrease in the vibration frequency can significantly increase the distance traveled by the cylindrical part. Nevertheless, even the largest traveled distances foreseen by simulations (0.043 m), which corresponds to about six times the cylinder radius, is not enough to cover the distances requested in many automatic manufacturing processes. For this reason, the development of a saw-teeth grooved surface of the conveyor track is highly recommended (see

Figure 18). In this case, a traveled distance equal to 5 ÷ 6 times the cylinder radius is enough to move the cylindrical part from one grove to the following grove and to generate a sequential motion.