A Real-Time Thermal Model for the Analysis of Tire/Road Interaction in Motorcycle Applications

Abstract

1. Introduction

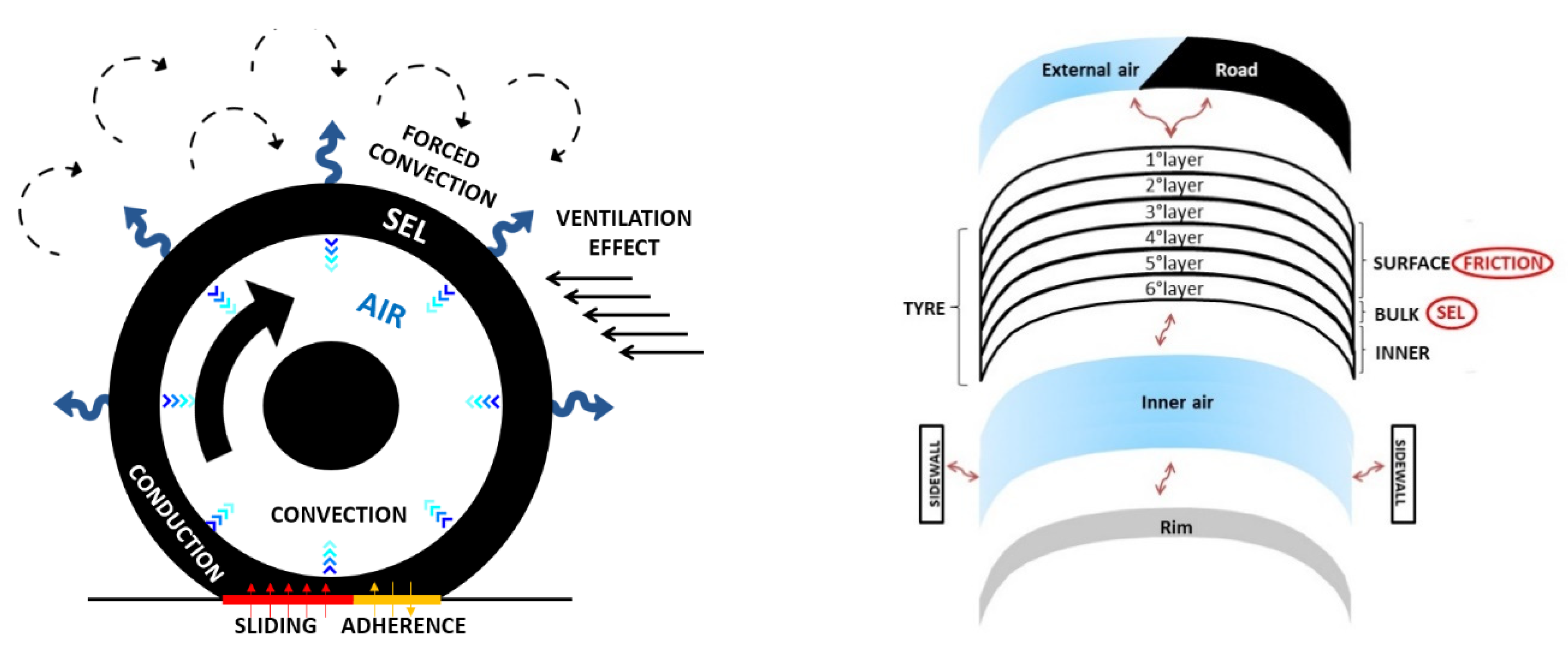

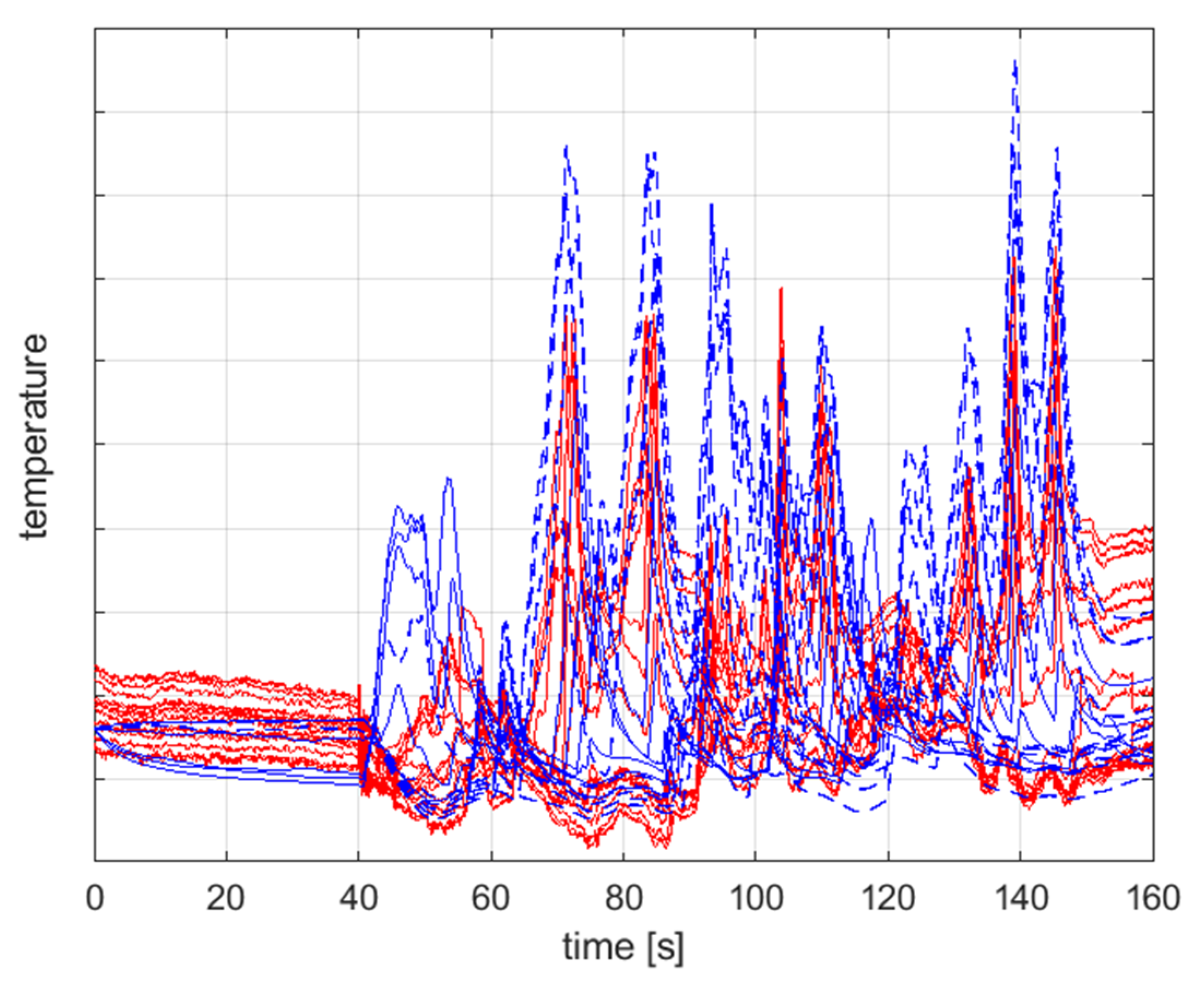

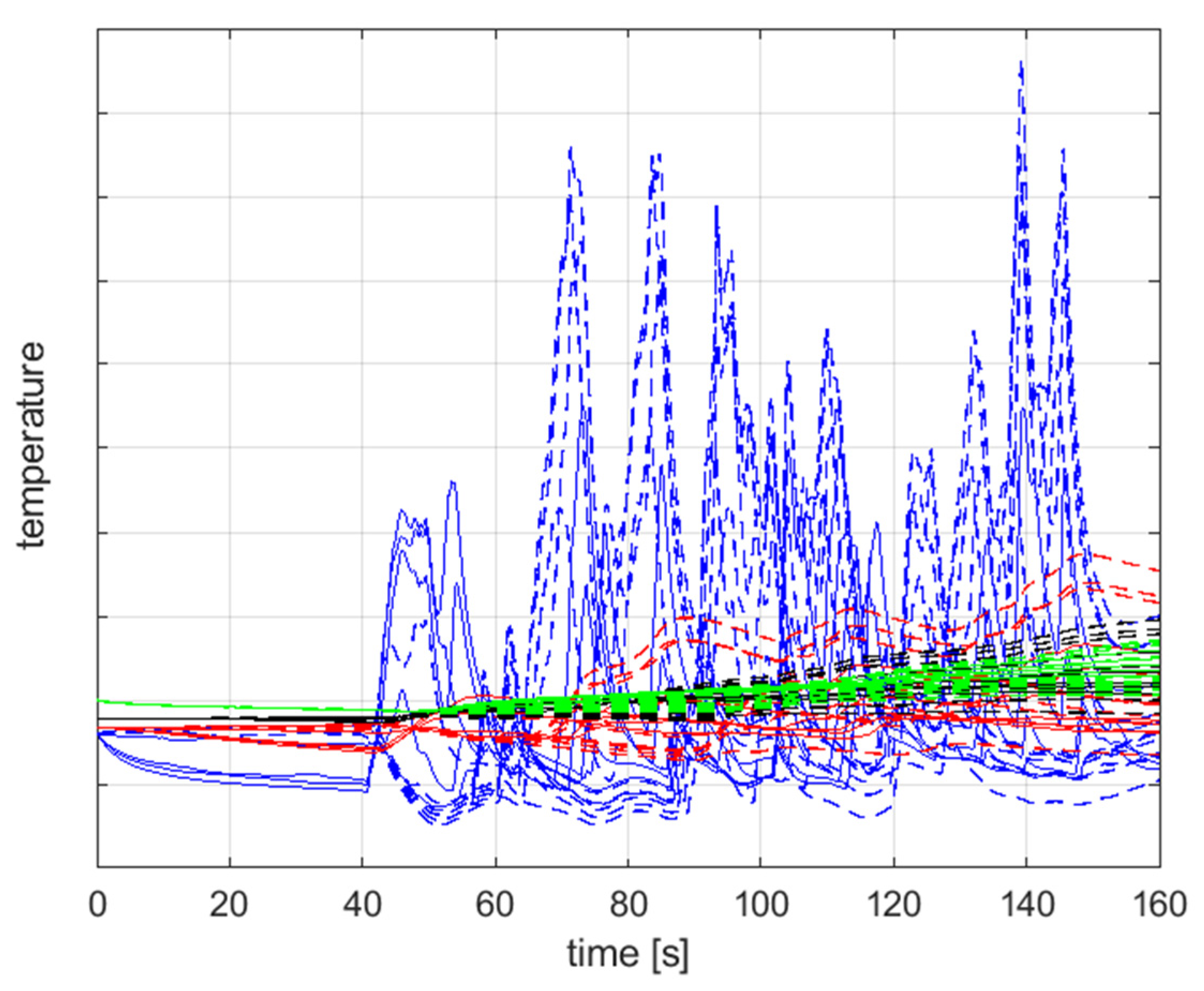

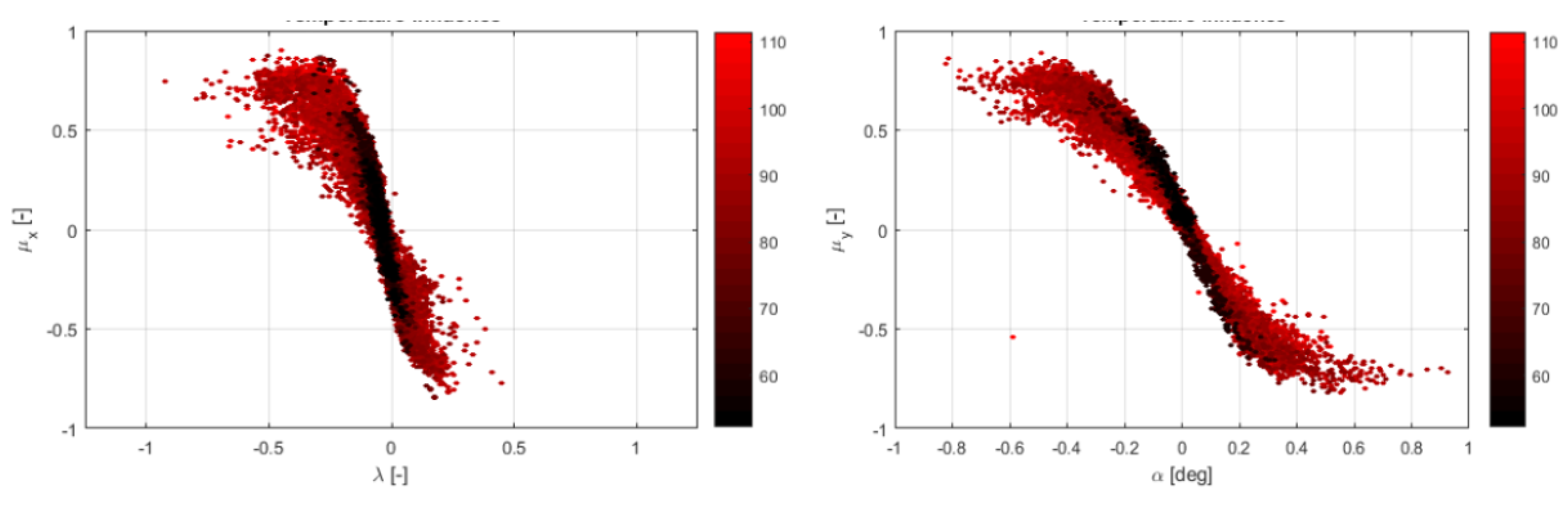

2. thermoRIDE–Tire Thermodynamic Model

- Heat generation within the tire structure due to:

- Tire/road tangential interaction, known as FP (friction power);

- Effect of tire cyclic deformation during the tire rolling, known as SEL (strain energy loss).

- Heat exchange with the external environment due to:

- Thermal conduction between the tire tread and the road pavement;

- Thermal convection of the tread surface with the external air;

- Thermal convection of the inner liner surface with the inner air.

- Heat conduction between the tire nodes due to the temperature gradient.

2.1. Mathematical Model

- q is the local heat flux density, in [;

- k is the material’s conductivity, in ;

- ∇T is the temperature gradient, in .

- Heat exchanged through the outer surface of the volume dV;

- Heat generated inside it.

- is the heat amount generated per unit time and per unit volume, in

- is the normal unit vector respectively to the faces of the volume element.

2.2. Physical Model

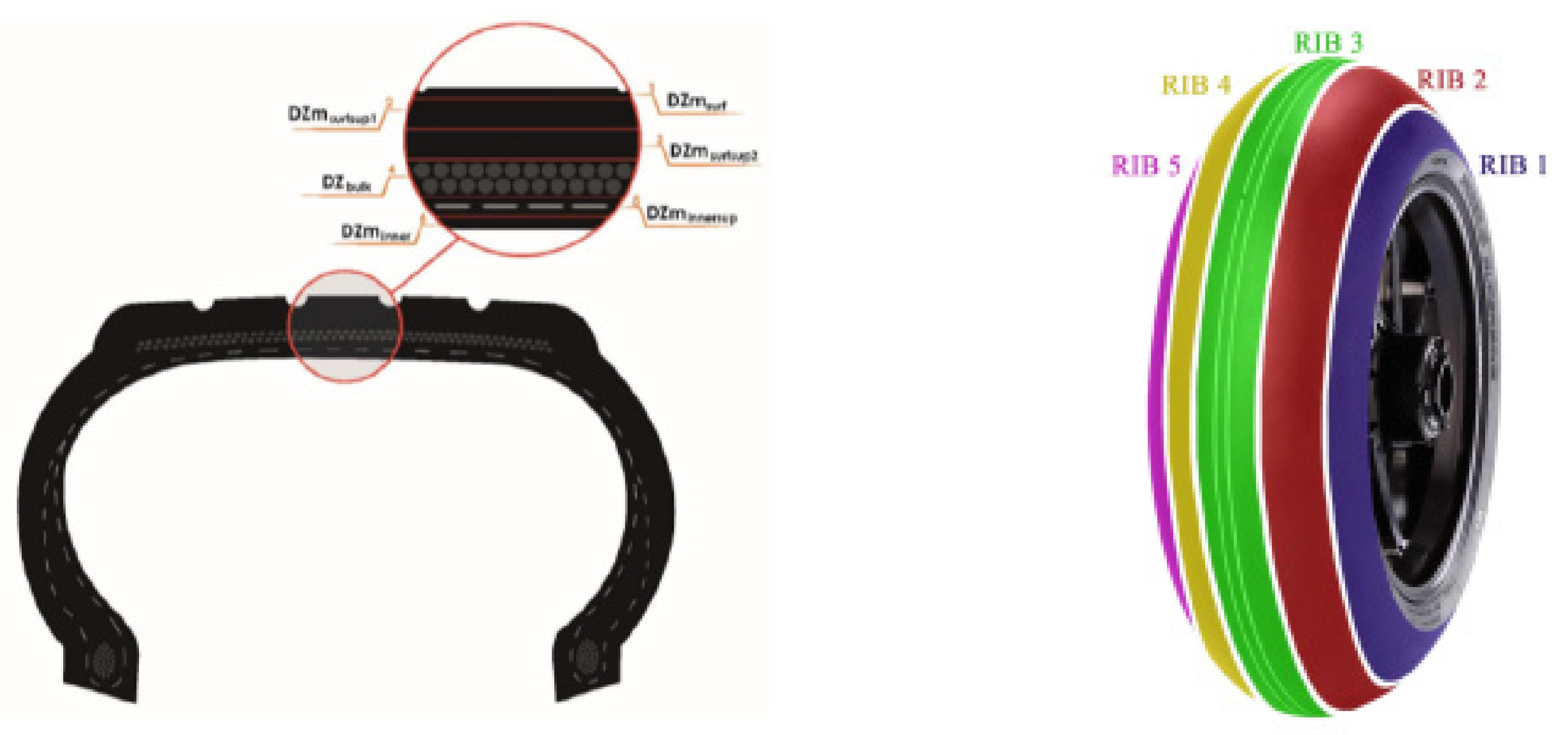

2.2.1. Tire Structural Model

- Tread surface, which is the most external part of the tread, the one which is in contact with the tarmac and the external air;

- Tread core is just below the surface and it is strictly connected with the grip level the tire is able to provide but it affects also the tire stiffness;

- Tread base is the deepest part of the tread, the last part before the belt; its temperature is more linked to the tire stiffness rather than the grip level;

- Belt is just below the Tread Base and it gives a big contribution to the SEL;

- Plies which is the last layer of the tire structure, it is another important contributor to the SEL, thanks to the energy dissipated by the friction among different plies and within the plies;

- Inner liner is the layer in contact with the inner air, which is not contributing to SEL dissipation neither linked to tire stiffness and grip.

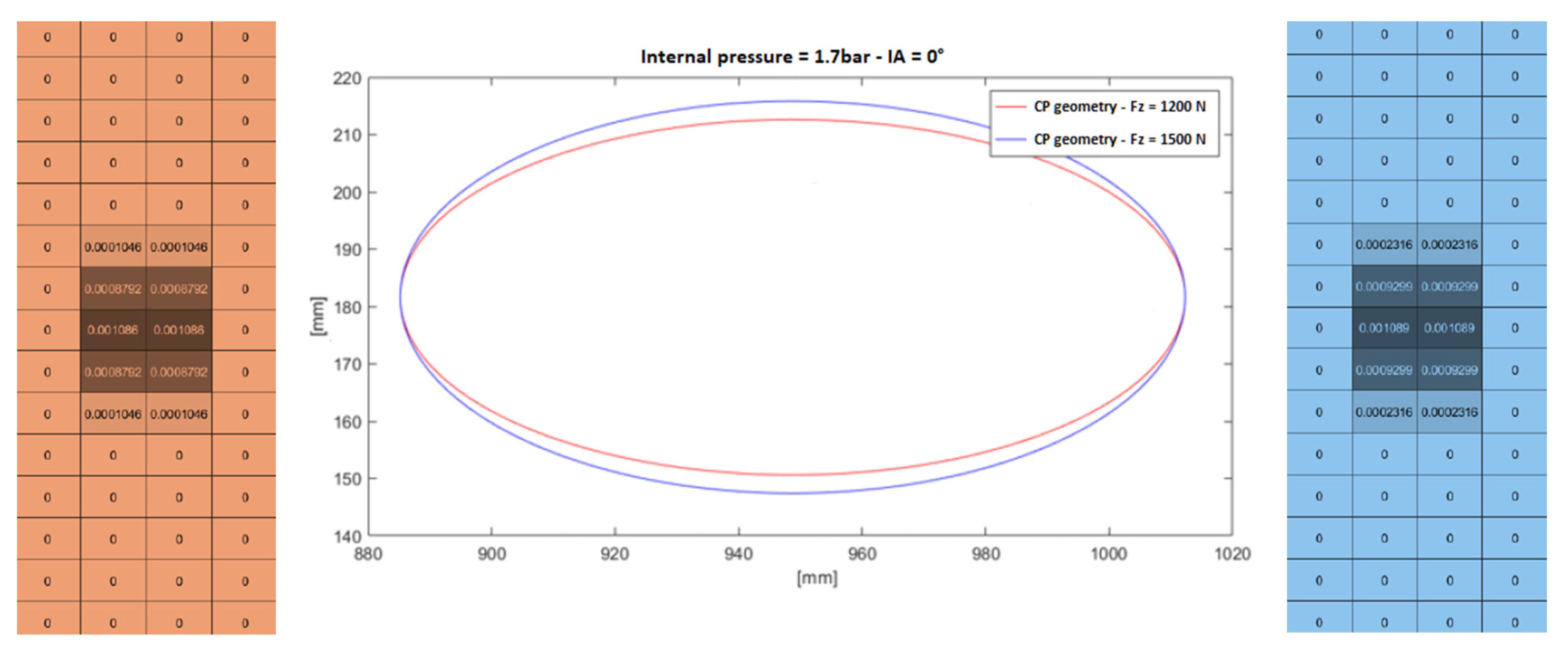

2.2.2. Contact Patch Evaluation

2.2.3. Heat Exchange with Road Surface

- is the convective heat transfer coefficient, estimated for the track testing conditions, in ;

- is the track temperature [K].

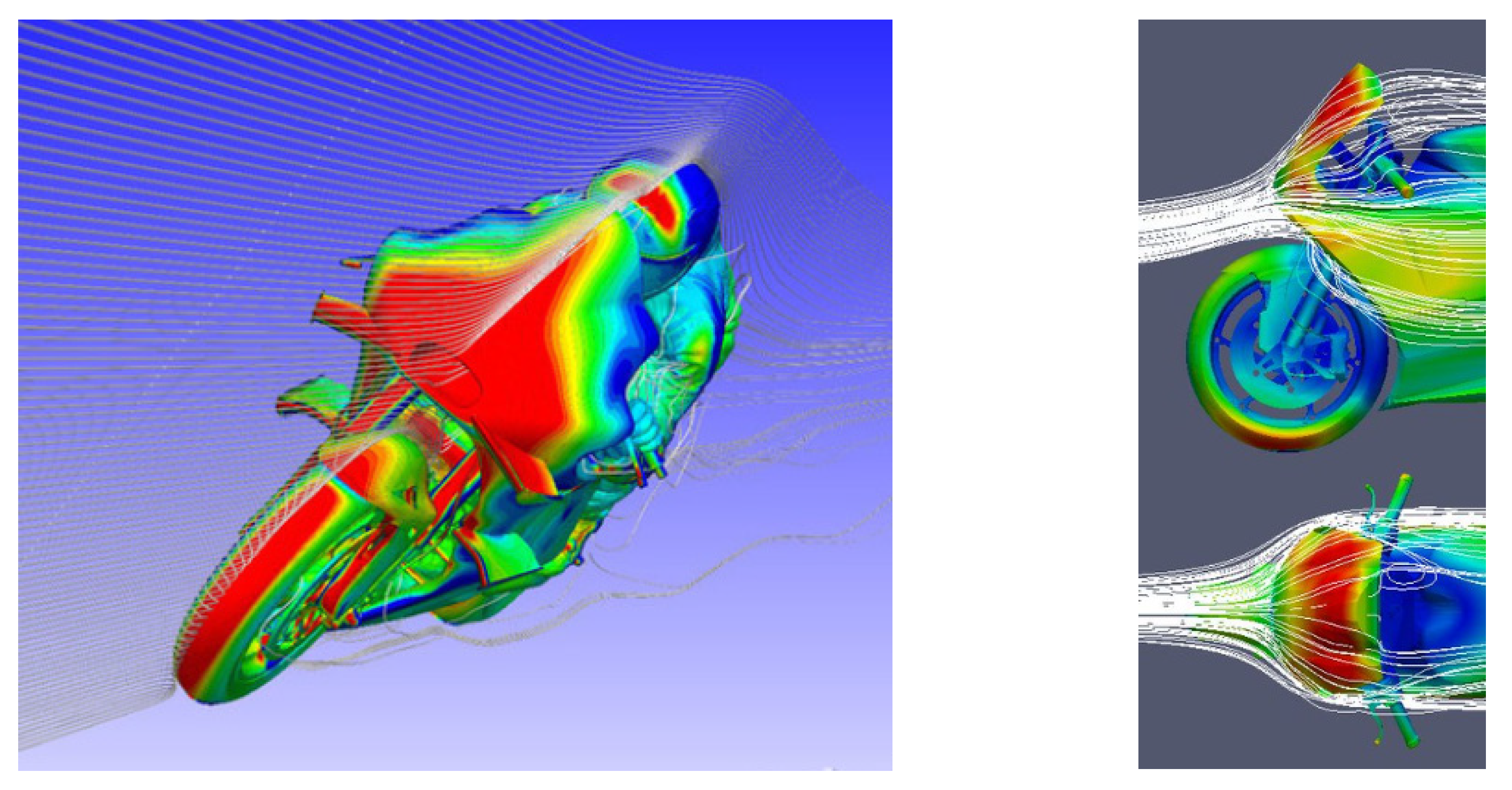

2.2.4. Heat Exchange with External/Inside Air

- is air conductivity, evaluated at an average temperature between the effective air one and outer tire surface one, in ;

- Vx is considered to be equal to the forward speed, in ;

- is the kinematic viscosity of air, in ;

- L is the characteristic length of the heat transfer surface, in [m];

- is the arithmetic mean between the temperatures of the tire outer surface and the external air in relative motion, in [K].

2.2.5. Hysteretic Generative Term

- F is the average interaction force at the contact patch, in [N];

- ω is the wheel rotation frequency, in [rad/s];

- γ is the wheel alignment camber angle, in [rad];

- is the gauge pressure within the wheel internal chamber, in [bar].

2.2.6. Model Input/Output Interface

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cossalter, V.; Lot, R.; Massaro, M. Modelling, Simulation and Control of Two-Wheeled Vehicles; John Wiley & Sons: Hoboken, NJ, USA, 2014; pp. 1–42. [Google Scholar]

- Gargallo, L.; Radic, D. Physicochemical Behavior and Supramolecular Organization of Polymers; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2009; pp. 43–162. [Google Scholar]

- Smith, R.H. Analyzing Friction in the Design of Rubber Products and Their Paired Surfaces; CRC Press: Boca Raton, FL, USA, 2008. [Google Scholar]

- Heinrich, G.; Klüppel, M. Rubber Friction, Tread Deformation and Tire Traction. Wear 2008, 265, 1052–1060. [Google Scholar] [CrossRef]

- Farroni, F.; Russo, R.; Timpone, F. Theoretical and Experimental Estimation of the Hysteretic Component of Friction for a Visco-Elastic Material Sliding on a Rigid Rough Surface. Int. Rev. Mech. Eng. 2013, 6, 3. [Google Scholar]

- Ferry, J.D.; Myers, H.S. Viscoelastic Properties of Polymers. J. Electrochem. Soc. 2007, 41, 53–62. [Google Scholar]

- Radford, D.W.; Fitzhorn, P.A.; Senan, A.; Peterson, M.L. Application of Dynamic Mechanical Analysis to the Evaluation of Tire Compounds. SAE Technical Pap. Ser. 2002, 111, 2492–2496. [Google Scholar]

- Kern, W.J.; Futamura, S. Effect of Tread Polymer Structure on Tyre Performance. Polymer 1988, 29, 1801–1806. [Google Scholar] [CrossRef]

- Mavros, G. A Thermo-Frictional Tyre Model Including the Effect of Flash Temperature. Veh. Syst. Dyn. 2019, 57, 721–751. [Google Scholar] [CrossRef]

- Segers, J. Analysis Techniques for Racecar Data Acquisition, 2nd ed.; SAE Technical Paper: Warrendale, PA, USA, 2014. [Google Scholar]

- Sharp, R.S.; Gruber, P.; Fina, E. Circuit Racing, Track Texture, Temperature and Rubber Friction. Veh. Syst. Dyn. 2016, 54, 510–525. [Google Scholar] [CrossRef]

- Angrick, C.; van Putten, S.; Prokop, G. Influence of Tire Core and Surface Temperature on Lateral Tire Characteristics. SAE Int. J. Passeng. Cars Mech. Syst. 2014, 7, 468–481. [Google Scholar] [CrossRef]

- Farroni, F.; Sakhnevych, A.; Timpone, F. Physical Modelling of Tire Wear for the Analysis of the Influence of Thermal and Frictional Effects on Vehicle Performance. J. Mater. Des. Appl. 2017, 231, 151–161. [Google Scholar] [CrossRef]

- Kelly, D.P.; Sharp, R.S. Time-Optimal Control of the Race Car: Influence of a Thermodynamic Tyre Model. Veh. Syst. Dyn. 2012, 50, 641–662. [Google Scholar] [CrossRef]

- Ozerem, O.; Morrey, D. A Brush-Based Thermo-Physical Tyre Model and Its Effectiveness in Handling Simulation of a Formula SAE Vehicle. J. Automob. Eng. 2019, 233, 107–120. [Google Scholar] [CrossRef]

- Février, P.; Blanco Hague, O.; Schick, B.; Miquet, C. Advantages of a Thermomechanical Tire Model for Vehicle Dynamics. ATZ Worldw. 2010, 112, 33–37. [Google Scholar] [CrossRef]

- Farroni, F.; Giordano, D.; Russo, M.; Timpone, F. TRT: Thermo Racing Tyre a Physical Model to Predict the Tyre Temperature Distribution. Meccanica 2014, 49, 707–723. [Google Scholar] [CrossRef]

- Wang, Z. Finite Element Analysis of Mechanical and Temperature Field for a Rolling Tire. In Proceedings of the IEEE 2010 International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 13–14 March 2010; IEEE: Piscataway, NJ, USA. [Google Scholar]

- Farroni, F.; Russo, M.; Sakhnevych, A.; Timpone, F. TRT EVO: Advances in Real-Time Thermodynamic Tire Modeling for Vehicle Dynamics Simulations. J. Automob. Eng. 2019, 233, 121–135. [Google Scholar] [CrossRef]

- Cossalter, V.; Doria, A. The Relation between Contact Patch Geometry and the Mechanical Properties of Motorcycle Tyres. Veh. Syst. Dyn. 2005, 43, 156–164. [Google Scholar] [CrossRef]

- Farroni, F.; Rocca, E.; Timpone, F. A Full Scale Test Rig to Characterize Pneumatic Tyre Mechanical Behaviour. Int. Rev. Mech. Eng. 2013, 7, 841–846. [Google Scholar]

| Physical Quantity | Description |

|---|---|

| Vertical interaction force | |

| Longitudinal interaction force | |

| Lateral interaction force | |

| Wheel hub longitudinal velocity | |

| Slip ratio | |

| Slip angle | |

| Wheel angular velocity | |

| Inclination angle | |

| Ambient air temperature | |

| Road pavement temperature |

| Physical Quantity | Description |

|---|---|

| Tread surface temperature | |

| Tread core temperature | |

| Tread base temperature | |

| Inner liner temperature | |

| Internal air temperature | |

| Internal air pressure | |

| Ambient air convection | |

| Chamber air convection | |

| Road pavement conduction | |

| Longitudinal friction | |

| Lateral friction | |

| Strain Energy Loss |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farroni, F.; Mancinelli, N.; Timpone, F. A Real-Time Thermal Model for the Analysis of Tire/Road Interaction in Motorcycle Applications. Appl. Sci. 2020, 10, 1604. https://doi.org/10.3390/app10051604

Farroni F, Mancinelli N, Timpone F. A Real-Time Thermal Model for the Analysis of Tire/Road Interaction in Motorcycle Applications. Applied Sciences. 2020; 10(5):1604. https://doi.org/10.3390/app10051604

Chicago/Turabian StyleFarroni, Flavio, Nicolò Mancinelli, and Francesco Timpone. 2020. "A Real-Time Thermal Model for the Analysis of Tire/Road Interaction in Motorcycle Applications" Applied Sciences 10, no. 5: 1604. https://doi.org/10.3390/app10051604

APA StyleFarroni, F., Mancinelli, N., & Timpone, F. (2020). A Real-Time Thermal Model for the Analysis of Tire/Road Interaction in Motorcycle Applications. Applied Sciences, 10(5), 1604. https://doi.org/10.3390/app10051604