Wire Arc Additive Manufacturing of Stainless Steels: A Review

Abstract

Featured Application

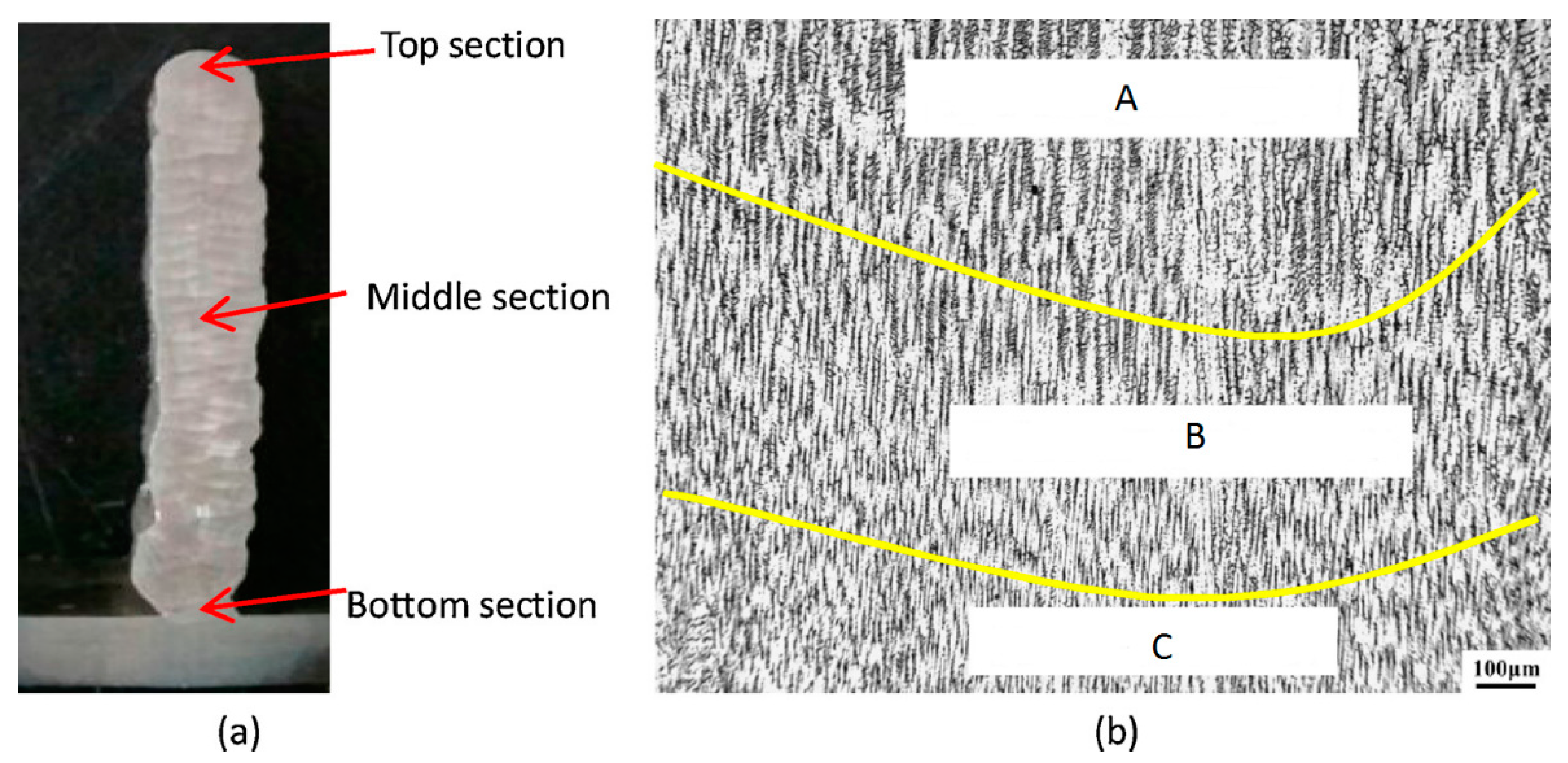

Abstract

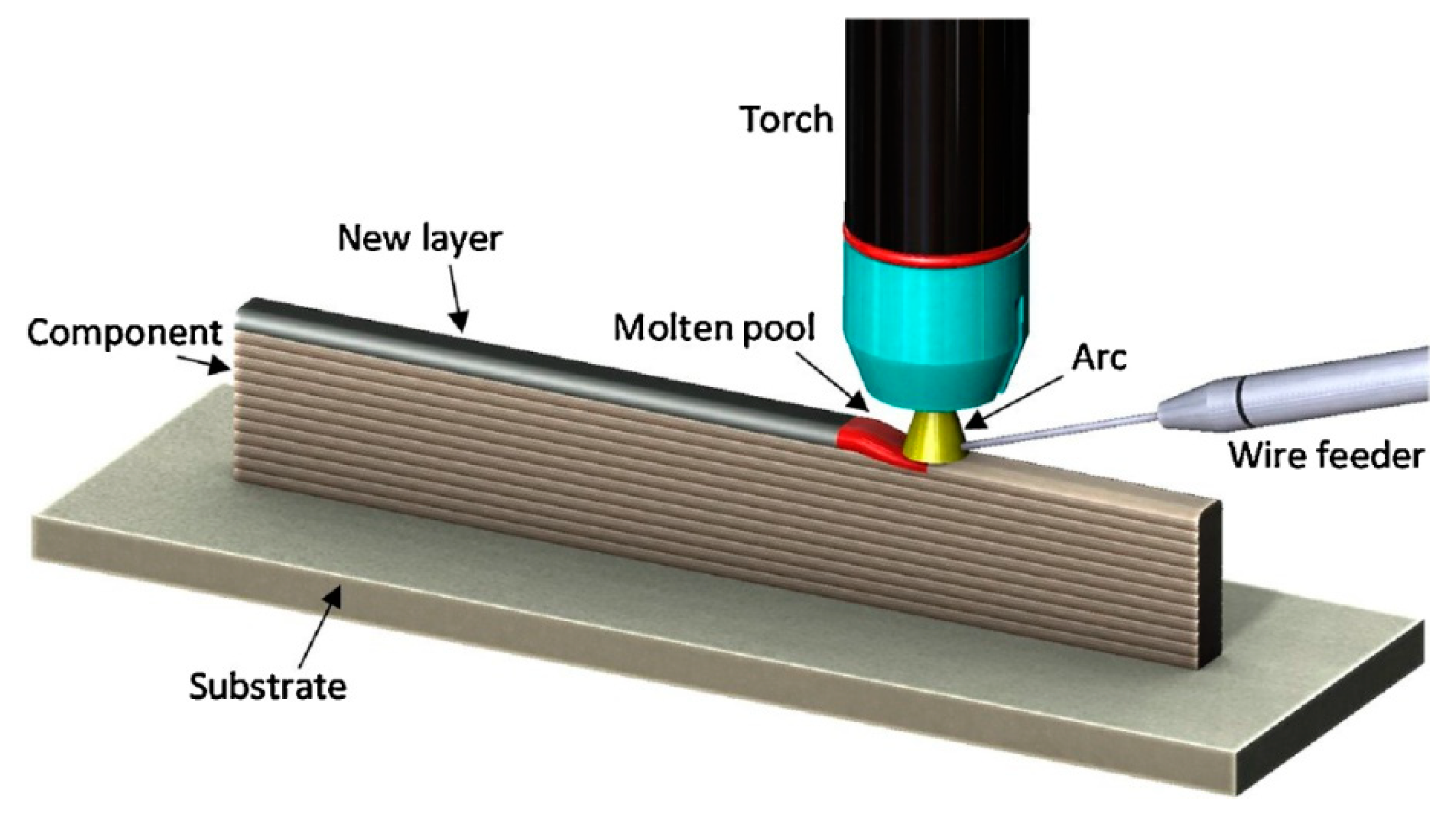

1. Introduction

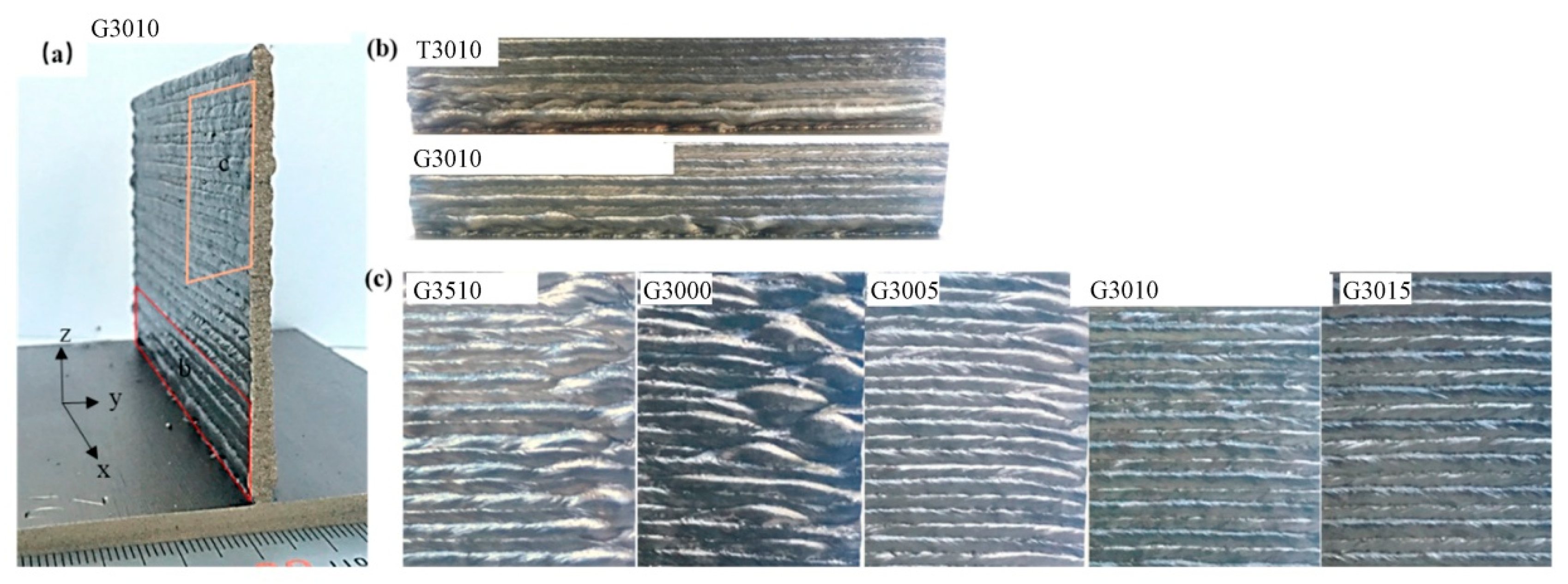

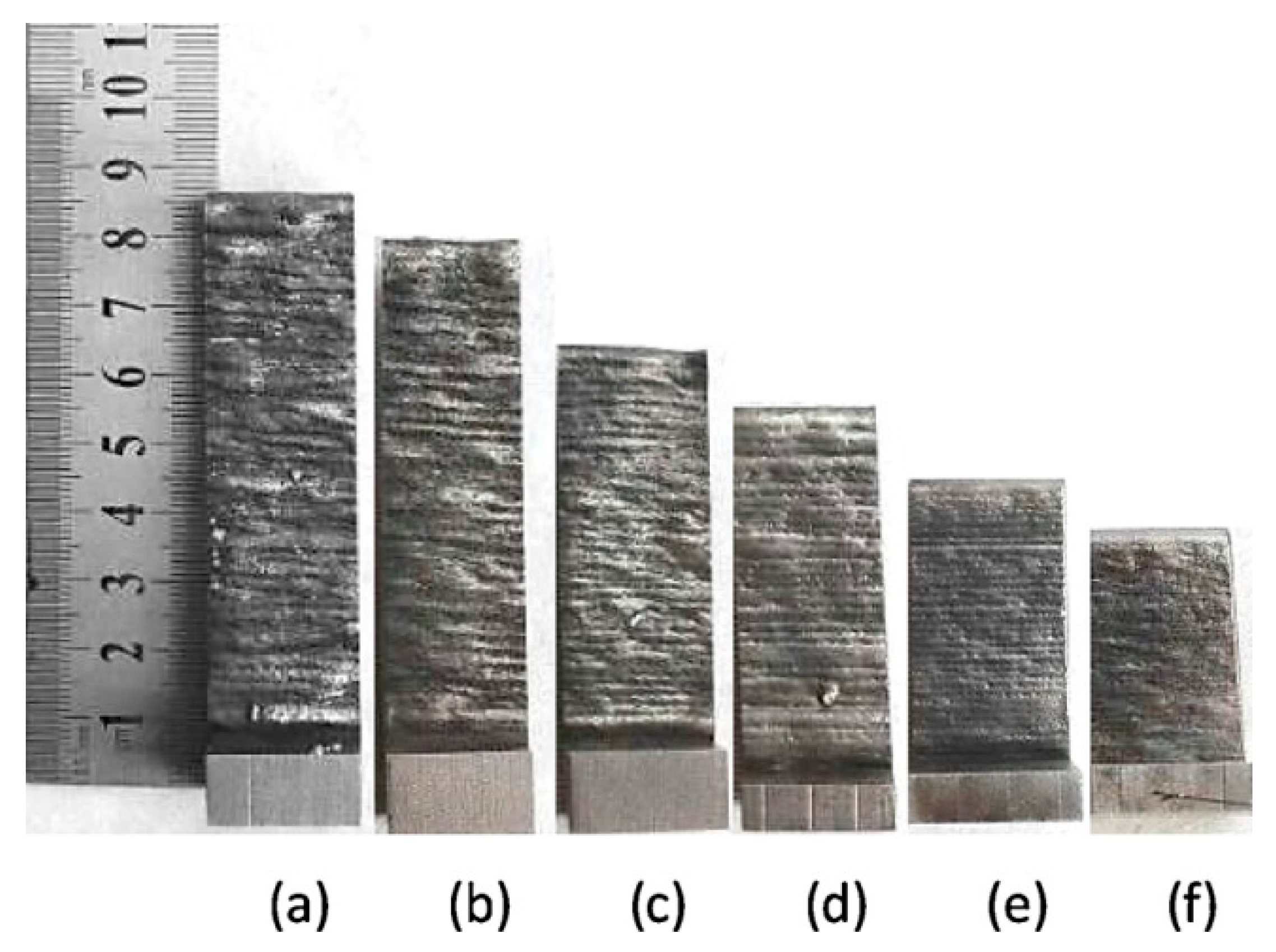

2. Macroscopic Characteristics of Samples

3. Microstructure

4. Residual Stresses and Distortion

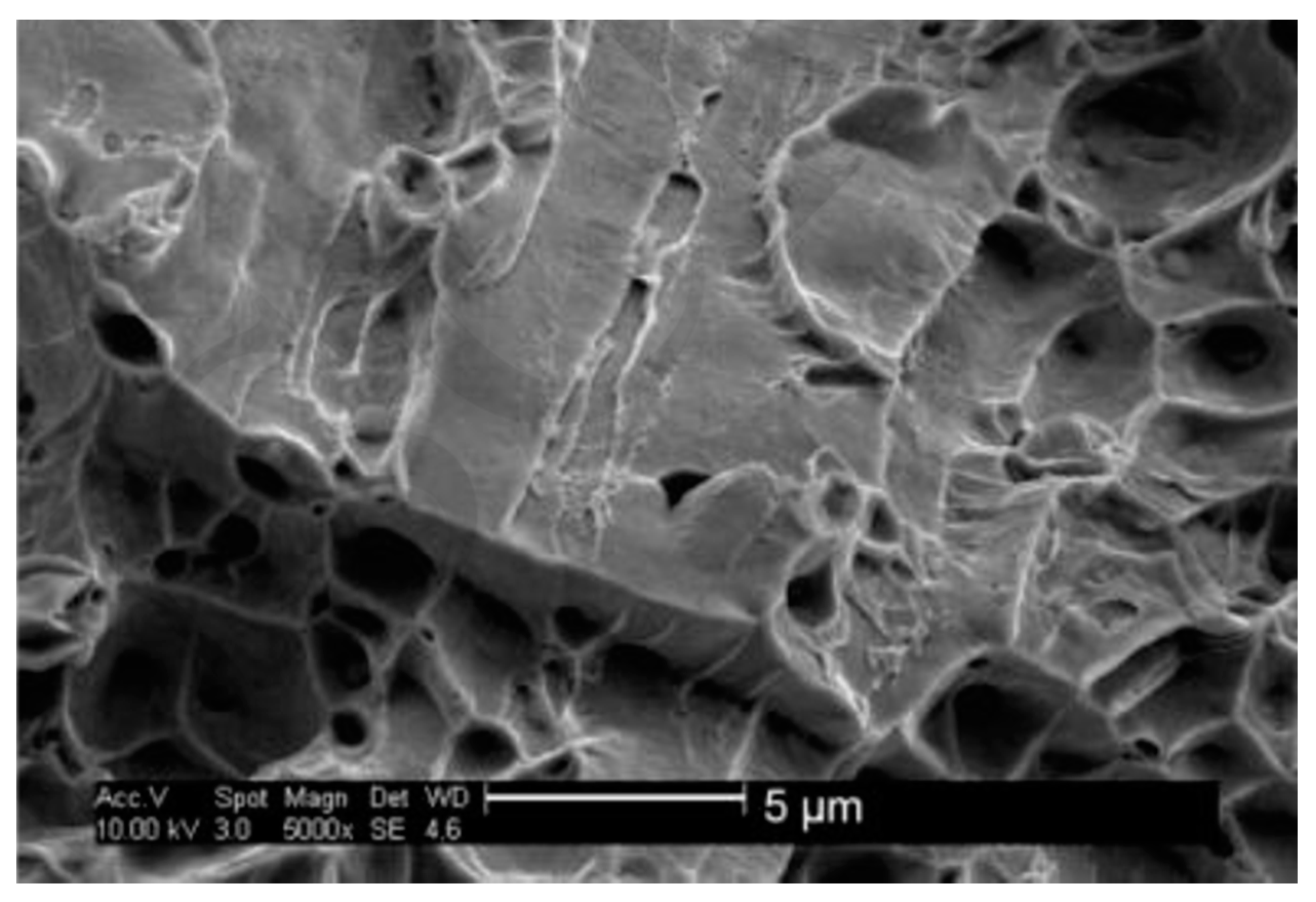

5. Defects

6. Mechanical Properties

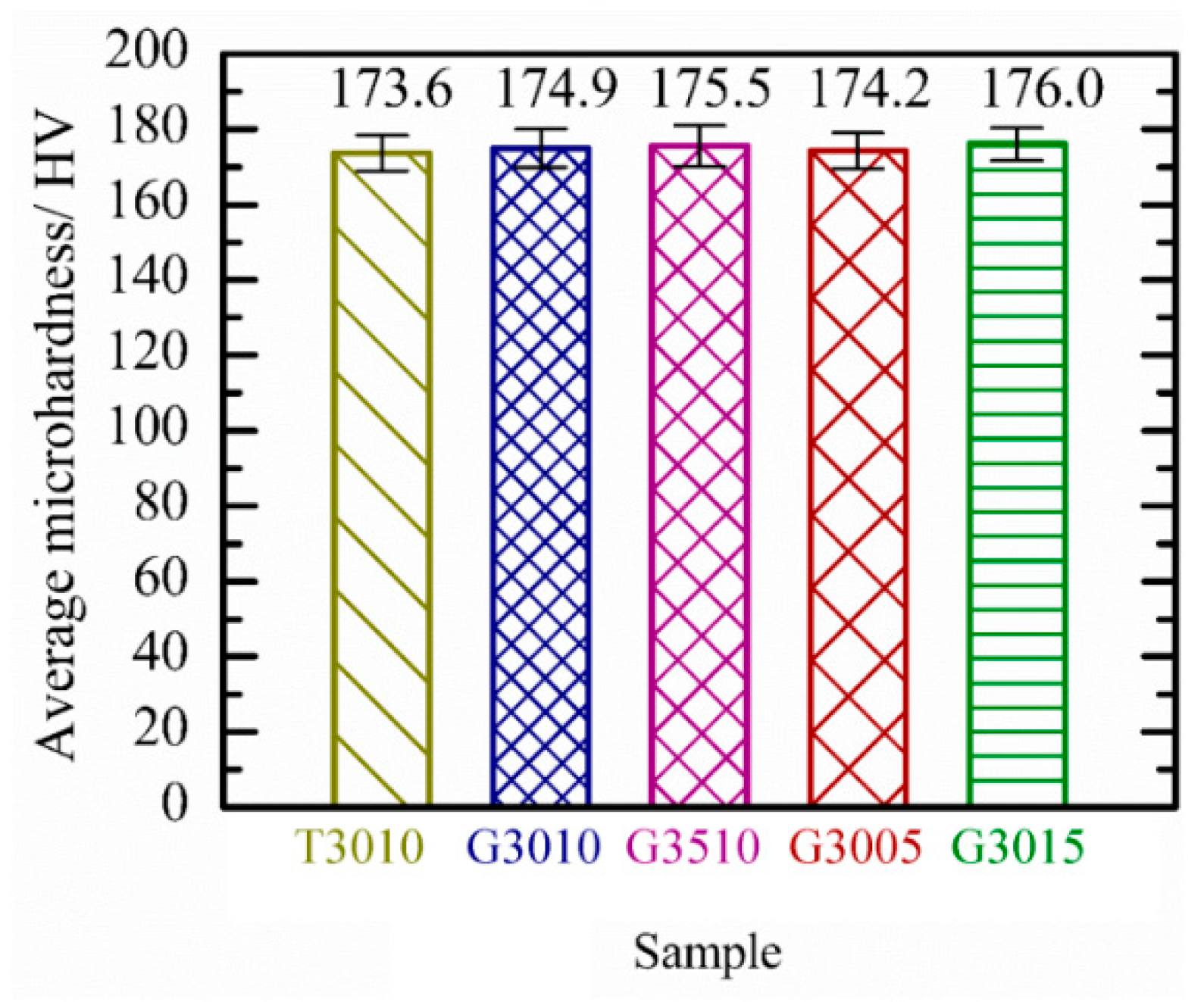

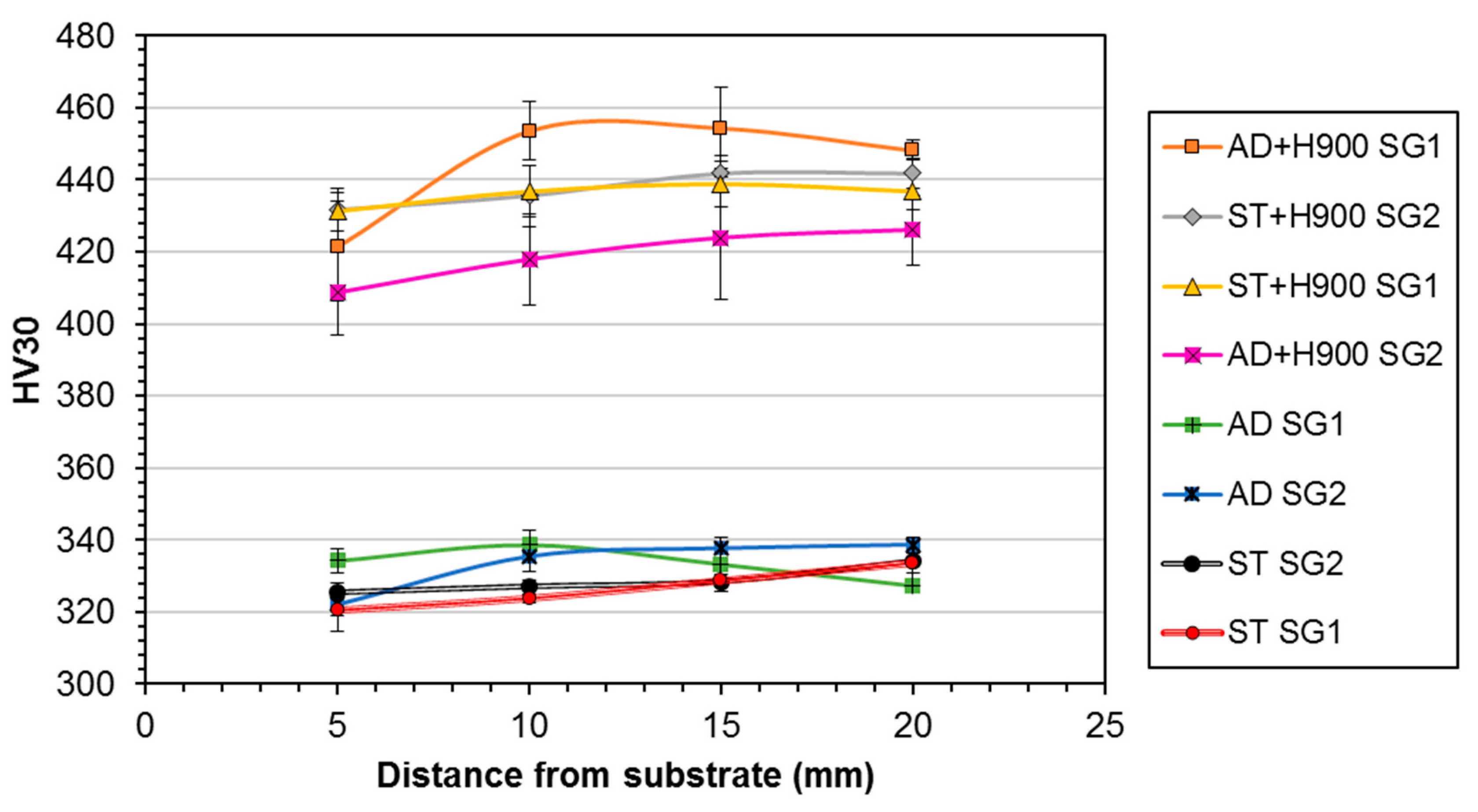

6.1. Hardness Distribution

6.2. Tensile Strength

7. Summary and Outlook

- (1)

- Macroscopic characteristics of WAAMed stainless steel parts are closely related to wire feeding speed and scanning speed, welding current mode, cooling time, and interlay temperature. Further studies on optimizing the above-mentioned process parameters are needed for achieving better dimensional accuracy and surface quality of WAAM parts.

- (2)

- Thermal history in WAAM processes plays an important role in controlling the microstructure, such as the ratio of austenite and ferrite phases. Thus, it is feasible to control the microstructure by controlling the process parameters. Modifying the material compositions, such as using double wires, is another effective approach to achieve desirable final microstructures. Post heat treatments can also significantly influence and change the final microstructure. Therefore, in order to obtain desirable microstructures in WAAM stainless steel parts, it is very necessary to thoroughly understand the solidification behaviors [104] and phase transformations in complex WAAM thermal cycles, and the correlation between material compositions, process parameters, heat treatment parameters, and the final microstructure.

- (3)

- Residual stresses and thermal history have a significant impact on the distortion of WAAM parts. The effect of both becomes more pronounced as the component volume increases [116]. The residual stresses can cause deformation, decrease in dimensional accuracy, defects, as well as worsening of mechanical properties of the components. Phase transformation (especially martensitic phase transformation) has a significant impact on reducing residual stress [111]. Proper deposition path planning can also significantly reduce residual stresses [114]. Therefore, further efforts should be made to optimize the WAAM deposition path, the thermal history, and control the phase transformation during WAAM to reduce the residual stress and distortion through both modelling and experimental studies.

- (4)

- Defects, such as lack of fusion, cracks, and porosity, need to be controlled to a minimum level to achieve sound mechanical properties. Precise control of heat input and thermal history, proper shielding gas and tight gas seals, high quality feedstock, and clean substrate surfaces are helpful to reduce defects during stainless steel WAAM process.

- (5)

- WAAM techniques, material compositions, process parameters, shielding gas composition, post heat treatments, microstructure, and defects can significantly influence the mechanical properties of WAAM stainless steels. Further understanding on the correlation between these factors and precise control of them, especially the final microstructure, are important for better controlling the mechanical properties of WAAM stainless steels.

- (6)

- WAAM samples often show considerable anisotropy in terms of tensile strength and microstructure due to the directionality of layer wise deposition process. It is useful to develop new processes, such as in-situ rolling + WAAM, to solve the anisotropy problems caused by the coarse columnar crystals in the deposition direction. In-situ rolling + WAAM also can reduce the residual stress in WAAM parts.

- (7)

- The main limitation of the paper is that the numerical modelling of the WAAM process was not sufficiently discussed in this paper.

- (8)

- For future industrial applications, fatigue properties, and corrosion behaviors of WAAMed stainless steels need to be deeply studied.

- (9)

- Additionally, further efforts should be made to improve the WAAM process to achieve faster deposition rates and better quality control.

Author Contributions

Funding

Conflicts of Interest

References

- ASTM-International. ISO/ASTM52900-15 Standard Terminology for Additive Manufacturing—General Principles—Terminology; ASTM-International: West Conshohocken, PA, USA, 2015; Volume 3, p. 5. [Google Scholar]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A multi-bead overlapping model for robotic wire and arc additive manufacturing (WAAM). Robot. Comput. Manuf. 2015, 31, 101–110. [Google Scholar] [CrossRef]

- Chen, B.; Mazumder, J. Role of process parameters during additive manufacturing by direct metal deposition of Inconel 718. Rapid Prototyp. J. 2017, 23, 919–929. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef]

- Martin, A.A.; Calta, N.P.; Khairallah, S.A.; Wang, J.; Depond, P.J.; Fong, A.Y.; Thampy, V.; Guss, G.M.; Kiss, A.M.; Stone, K.H.; et al. Dynamics of pore formation during laser powder bed fusion additive manufacturing. Nat. Commun. 2019, 10, 1987. [Google Scholar] [CrossRef]

- Seede, R.; Shoukr, D.; Zhang, B.; Whitt, A.; Gibbons, S.; Flater, P.; Elwany, A.; Arroyave, R.; Karaman, I. An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: Densification, microstructure, and mechanical properties. Acta Mater. 2020, 186, 199–214. [Google Scholar] [CrossRef]

- Polonsky, A.; Lenthe, W.C.; Echlin, M.P.; Livescu, V.; Gray, G.T.; Pollock, T.M. Solidification-driven orientation gradients in additively manufactured stainless steel. Acta Mater. 2020, 183, 249–260. [Google Scholar] [CrossRef]

- Smith, T.; Sugar, J.D.; Marchi, C.S.; Schoenung, J.M. Strengthening mechanisms in directed energy deposited austenitic stainless steel. Acta Mater. 2019, 164, 728–740. [Google Scholar] [CrossRef]

- Hou, H.; Simsek, E.; Ma, T.; Johnson, N.S.; Qian, S.; Cissé, C.; Stasak, D.; Al Hasan, N.; Zhou, L.; Hwang, Y.; et al. Fatigue-resistant high-performance elastocaloric materials made by additive manufacturing. Science 2019, 366, 1116–1121. [Google Scholar] [CrossRef]

- Thapliyal, S. Challenges associated with the wire arc additive manufacturing (WAAM) of aluminum alloys. Mater. Res. Express 2019, 6, 112006. [Google Scholar] [CrossRef]

- Segura-Cárdenas, E.; Ramirez-Cedillo, E.; Robles, J.A.S.; Ruiz-Huerta, L.; Caballero-Ruiz, A.; Siller, H. Permeability Study of Austenitic Stainless Steel Surfaces Produced by Selective Laser Melting. Metals 2017, 7, 521. [Google Scholar] [CrossRef]

- Antunes, F.; Santos, L.; Capela, C.; Ferreira, J.; Costa, J.; Jesus, J.; Prates, P. Fatigue Crack Growth in Maraging Steel Obtained by Selective Laser Melting. Appl. Sci. 2019, 9, 4412. [Google Scholar] [CrossRef]

- Everhart, W.; Newkirk, J. Grain Size Effects in Selective Laser Melted Fe-Co-2V. Appl. Sci. 2019, 9, 3701. [Google Scholar] [CrossRef]

- Nguyen, D.-S.; Park, H.-S.; Lee, C.-M. Applying Selective Laser Melting to Join Al and Fe: An Investigation of Dissimilar Materials. Appl. Sci. 2019, 9, 3031. [Google Scholar] [CrossRef]

- Santos, L.; Jesus, J.A.D.S.D.; Ferreira, J.; Costa, J.; Capela, C. Fracture Toughness of Hybrid Components with Selective Laser Melting 18Ni300 Steel Parts. Appl. Sci. 2018, 8, 1879. [Google Scholar] [CrossRef]

- Barros, R.; Silva, F.; Gouveia, R.; Saboori, A.; Marchese, G.; Biamino, S.; Salmi, A.; Atzeni, E. Laser Powder Bed Fusion of Inconel 718: Residual Stress Analysis Before and After Heat Treatment. Metals 2019, 9, 1290. [Google Scholar] [CrossRef]

- Denti, L.; Sola, A. On the Effectiveness of Different Surface Finishing Techniques on A357.0 Parts Produced by Laser-Based Powder Bed Fusion: Surface Roughness and Fatigue Strength. Metals 2019, 9, 1284. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Chen, C.; Wu, Q.; Chen, X.; Jiping, L. Performance of High Layer Thickness in Selective Laser Melting of Ti6Al4V. Materials 2016, 9, 975. [Google Scholar] [CrossRef]

- Tian, Z.; Zhang, C.; Wang, D.; Liu, W.; Fang, X.; Wellmann, D.; Zhao, Y.; Tian, Y. A Review on Laser Powder Bed Fusion of Inconel 625 Nickel-Based Alloy. Appl. Sci. 2019, 10, 81. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, C.; Jia, D.; Wellmann, D.; Liu, W. Corrosion Behaviors of Selective Laser Melted Aluminum Alloys: A Review. Metals 2020, 10, 102. [Google Scholar] [CrossRef]

- Mohr, G.; Altenburg, S.J.; Ulbricht, A.; Heinrich, P.; Baum, D.; Maierhofer, C.; Hilgenberg, K. In-Situ Defect Detection in Laser Powder Bed Fusion by Using Thermography and Optical Tomography—Comparison to Computed Tomography. Metals 2020, 10, 103. [Google Scholar] [CrossRef]

- Debroy, T.; Mukherjee, T.; Milewski, J.O.; Elmer, J.W.; Ribic, B.; Blecher, J.J.; Zhang, W. Scientific, technological and economic issues in metal printing and their solutions. Nat. Mater. 2019, 18, 1026–1032. [Google Scholar] [CrossRef] [PubMed]

- Lin, T.-C.; Cao, C.; Sokoluk, M.; Jiang, L.; Wang, X.; Schoenung, J.M.; Lavernia, E.J.; Li, X. Aluminum with dispersed nanoparticles by laser additive manufacturing. Nat. Commun. 2019, 10, 4124–4129. [Google Scholar] [CrossRef] [PubMed]

- Zai, L.; Zhang, C.; Wang, Y.; Guo, W.; Wellmann, D.; Tong, X.; Tian, Y. Laser Powder Bed Fusion of Precipitation-Hardened Martensitic Stainless Steels: A Review. Metals 2020, 10, 255. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, C.; Wang, D.; Nie, L.; Wellmann, D.; Tian, Y. Additive manufacturing of WC-Co hardmetals: A review. Int. J. Adv. Manuf. Technol. 2020, in press. [Google Scholar]

- Mukherjee, T.; Debroy, T. Printability of 316 stainless steel. Sci. Technol. Weld. Join. 2019, 24, 412–419. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Zhang, D.; Bermingham, M.J.; Lui, E.W.; Brandt, M.; StJohn, D.H.; Qian, M. Grain structure control during metal 3D printing by high-intensity ultrasound. Nat. Commun. 2020, 11, 142–149. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2015, 34, 369–385. [Google Scholar] [CrossRef]

- Syed, W.U.H.; Pinkerton, A.; Li, L. A comparative study of wire feeding and powder feeding in direct diode laser deposition for rapid prototyping. Appl. Surf. Sci. 2005, 247, 268–276. [Google Scholar] [CrossRef]

- McAndrew, A.; Rosales, M.A.; Colegrove, P.; Hönnige, J.R.; Ho, A.; Fayolle, R.; Eyitayo, K.; Stan, I.; Sukrongpang, P.; Crochemore, A.; et al. Interpass rolling of Ti-6Al-4V wire + arc additively manufactured features for microstructural refinement. Addit. Manuf. 2018, 21, 340–349. [Google Scholar] [CrossRef]

- Korzhyk, V.; Khaskin, V.; Voitenko, O.; Sydorets, V.; Dolianovskaia, O. Welding Technology in Additive Manufacturing Processes of 3D Objects. Mater. Sci. Forum 2017, 906, 121–130. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Jandric, Z.; Labudovic, M.; Kovacevic, R. Effect of heat sink on microstructure of three-dimensional parts built by welding-based deposition. Int. J. Mach. Tools Manuf. 2004, 44, 785–796. [Google Scholar] [CrossRef]

- Song, Y.-A.; Park, S.; Choi, D.; Jee, H. 3D welding and milling: Part I–a direct approach for freeform fabrication of metallic prototypes. Int. J. Mach. Tools Manuf. 2005, 45, 1057–1062. [Google Scholar] [CrossRef]

- Song, Y.-A.; Park, S.; Chae, S.-W. 3D welding and milling: Part II—Optimization of the 3D welding process using an experimental design approach. Int. J. Mach. Tools Manuf. 2005, 45, 1063–1069. [Google Scholar] [CrossRef]

- Kwak, Y.-M.; Doumanidis, C. Geometry Regulation of Material Deposition in Near-Net Shape Manufacturing by Thermally Scanned Welding. J. Manuf. Process. 2002, 4, 28–41. [Google Scholar] [CrossRef]

- Katou, M.; Oh, J.; Miyamoto, Y.; Matsuura, K.; Kudoh, M. Freeform fabrication of titanium metal and intermetallic alloys by three-dimensional micro welding. Mater. Des. 2007, 28, 2093–2098. [Google Scholar] [CrossRef]

- Baufeld, B.; Biest, O.; Gault, R. Additive manufacturing of Ti–6Al–4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Clark, D.; Bache, M.; Whittaker, M.T. Shaped metal deposition of a nickel alloy for aero engine applications. J. Mater. Process. Technol. 2008, 203, 439–448. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Gao, H.; Wu, L. Modeling of bead section profile and overlapping beads with experimental validation for robotic GMAW-based rapid manufacturing. Robot. Comput. Manuf. 2013, 29, 417–423. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Qiu, Z.; Li, Y. Vision-sensing and bead width control of a single-bead multi-layer part: Material and energy savings in GMAW-based rapid manufacturing. J. Clean. Prod. 2013, 41, 82–88. [Google Scholar] [CrossRef]

- Yang, D.; He, C.; Zhang, G. Forming characteristics of thin-wall steel parts by double electrode GMAW based additive manufacturing. J. Mater. Process. Technol. 2016, 227, 153–160. [Google Scholar] [CrossRef]

- Aiyiti, W.; Zhao, W.; Lu, B.; Tang, Y. Investigation of the overlapping parameters of MPAW-based rapid prototyping. Rapid Prototyp. J. 2006, 12, 165–172. [Google Scholar] [CrossRef]

- Suryakumar, S.; Karunakaran, K.; Bernard, A.; Chandrasekhar, U.; Raghavender, N.; Sharma, D. Weld bead modeling and process optimization in Hybrid Layered Manufacturing. Comput. Des. 2011, 43, 331–344. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A tool-path generation strategy for wire and arc additive manufacturing. Int. J. Adv. Manuf. Technol. 2014, 73, 173–183. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. A practical path planning methodology for wire and arc additive manufacturing of thin-walled structures. Robot. Comput. Manuf. 2015, 34, 8–19. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H.; Larkin, N. Adaptive path planning for wire-feed additive manufacturing using medial axis transformation. J. Clean. Prod. 2016, 133, 942–952. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Li, H.; Pan, Z.; Shen, C. The effect of postproduction heat treatment on γ-TiAl alloys produced by the GTAW-based additive manufacturing process. Mater. Sci. Eng. A 2016, 657, 86–95. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Li, P.; Chen, Y.; Male, A.T. Automated system for welding-based rapid prototyping. Mechatronics 2002, 12, 37–53. [Google Scholar] [CrossRef]

- Wang, H.; Jiang, W.; Valant, M.; Kovacevic, R. Microplasma powder deposition as a new solid freeform fabrication process. In Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture; SAGE Publications: Newcastle upon Tyne, UK, 2003; Volume 217, pp. 1641–1650. [Google Scholar]

- Zhang, Y.M.; Chen, Y.; Li, P.; Male, A.T. Weld deposition-based rapid prototyping: A preliminary study. J. Mater. Process. Technol. 2003, 135, 347–357. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G. Adaptive control of deposited height in GMAW-based layer additive manufacturing. J. Mater. Process. Technol. 2014, 214, 962–968. [Google Scholar] [CrossRef]

- Ahn, D.-G. Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. Int. J. Precis. Eng. Manuf. Technol. 2016, 3, 381–395. [Google Scholar] [CrossRef]

- Posch, G.; Chladil, K.; Chladil, H. Material properties of CMT—Metal additive manufactured duplex stainless steel blade-like geometries. Weld. World 2017, 61, 873–882. [Google Scholar] [CrossRef]

- Spencer, J.D.; Dickens, P.M.; Wykes, C.M. Rapid prototyping of metal parts by three-dimensional welding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1998, 212, 175–182. [Google Scholar] [CrossRef]

- Fronius International GmbH. Schweißpraxis Aktuell: CMT-Technologie; WEKA Media GmbH: Kissing, Germany, 2013. [Google Scholar]

- Fronius International GmbH. Current Welding Practice CMT Technology; DVS Media GmbH: Düsseldorf, Germany, 2014. [Google Scholar]

- Bruckner, J.; Himmelbauer, K. Cold Metal Transfer—Ein neuer Prozess in der Fügetechnik; DVS-Berichte Band 237; DVS Media GmbH: Düsseldorf, Germany, 2005. [Google Scholar]

- Zhang, H.; Feng, J.; He, P.; Zhang, B.; Chen, J.; Wang, L. The arc characteristics and metal transfer behaviour of cold metal transfer and its use in joining aluminium to zinc-coated steel. Mater. Sci. Eng. A 2009, 499, 111–113. [Google Scholar] [CrossRef]

- Pickin, C.; Williams, S.; Lunt, M. Characterisation of the cold metal transfer (CMT) process and its application for low dilution cladding. J. Mater. Process. Technol. 2011, 211, 496–502. [Google Scholar] [CrossRef]

- Ayarkwa, K.; Williams, S.; Ding, J. Assessing the effect of TIG alternating current time cycle on aluminium wire + arc additive manufacture. Addit. Manuf. 2017, 18, 186–193. [Google Scholar] [CrossRef]

- Ma, Y.; Cuiuri, D.; Hoye, N.; Li, H.; Pan, Z. The effect of location on the microstructure and mechanical properties of titanium aluminides produced by additive layer manufacturing using in-situ alloying and gas tungsten arc welding. Mater. Sci. Eng. A 2015, 631, 230–240. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.R.; Colegrove, P. Wire + Arc Additive Manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. Titanium and Titanium Alloys: Fundamentals and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Kim, T.B.; Yue, S.; Zhang, Z.; Jones, E.; Jones, J.R.; Lee, P. Additive manufactured porous titanium structures: Through-process quantification of pore and strut networks. J. Mater. Process. Technol. 2014, 214, 2706–2715. [Google Scholar] [CrossRef]

- Wu, B.; Pan, Z.; Li, S.; Cuiuri, D.; Ding, D.; Li, H. The anisotropic corrosion behaviour of wire arc additive manufactured Ti-6Al-4V alloy in 3.5% NaCl solution. Corros. Sci. 2018, 137, 176–183. [Google Scholar] [CrossRef]

- Gu, J.; Ding, J.; Williams, S.; Gu, H.; Bai, J.; Zhai, Y.; Ma, P. The strengthening effect of inter-layer cold working and post-deposition heat treatment on the additively manufactured Al–6.3Cu alloy. Mater. Sci. Eng. A 2016, 651, 18–26. [Google Scholar] [CrossRef]

- Brice, C.; Shenoy, R.; Kral, M.; Buchannan, K. Precipitation behavior of aluminum alloy 2139 fabricated using additive manufacturing. Mater. Sci. Eng. A 2015, 648, 9–14. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Yan, L. Wire and Arc Addictive Manufacture (WAAM) Reusable Tooling Investigation. 2013. Available online: https://dspace.lib.cranfield.ac.uk/handle/1826/12308 (accessed on 23 February 2020).

- Xu, F.; Lv, Y.; Liu, Y.; Shu, F.; He, P.; Xu, B. Microstructural Evolution and Mechanical Properties of Inconel 625 Alloy during Pulsed Plasma Arc Deposition Process. J. Mater. Sci. Technol. 2013, 29, 480–488. [Google Scholar] [CrossRef]

- Bressan, J.; Daros, D.; Sokolowski, A.; Mesquita, R.; Barbosa, C. Influence of hardness on the wear resistance of 17-4 PH stainless steel evaluated by the pin-on-disc testing. J. tianMater. Process. Technol. 2008, 205, 353–359. [Google Scholar] [CrossRef]

- Knapp, G.; Mukherjee, T.; Zuback, J.; Wei, H.; Palmer, T.; De, A.; Debroy, T. Building blocks for a digital twin of additive manufacturing. Acta Mater. 2017, 135, 390–399. [Google Scholar] [CrossRef]

- Mukherjee, T.; Manvatkar, V.; De, A.; Debroy, T. Dimensionless numbers in additive manufacturing. J. Appl. Phys. 2017, 121, 064904. [Google Scholar] [CrossRef]

- Mukherjee, T.; Debroy, T. A digital twin for rapid qualification of 3D printed metallic components. Appl. Mater. Today 2019, 14, 59–65. [Google Scholar] [CrossRef]

- Xu, X.; Mi, G.; Luo, Y.; Jiang, P.; Shao, X.; Wang, C. Morphologies, microstructures, and mechanical properties of samples produced using laser metal deposition with 316 L stainless steel wire. Opt. Lasers Eng. 2017, 94, 1–11. [Google Scholar] [CrossRef]

- Gray, G.T.; Livescu, V.; Rigg, P.; Trujillo, C.; Cady, C.; Chen, S.; Carpenter, J.; Lienert, T.; Fensin, S.J. Structure/property (constitutive and spallation response) of additively manufactured 316L stainless steel. Acta Mater. 2017, 138, 140–149. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of stainless steel parts by Laser Metal Deposition Shaping. Mater. Des. 2014, 55, 104–119. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Wang, X.; Deng, D.; Yi, H.; Xu, H.; Yang, S.; Zhang, H. Influences of pulse laser parameters on properties of AISI316L stainless steel thin-walled part by laser material deposition. Opt. Laser Technol. 2017, 92, 5–14. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Guss, G.; Wu, S.; Matthews, M.; Schoenung, J.M. In-situ characterization of laser-powder interaction and cooling rates through high-speed imaging of powder bed fusion additive manufacturing. Mater. Des. 2017, 135, 385–396. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Manvatkar, V.; De, A.; Debroy, T. Heat transfer and material flow during laser assisted multi-layer additive manufacturing. J. Appl. Phys. 2014, 116, 124905. [Google Scholar] [CrossRef]

- Caiazzo, F.; Alfieri, V. Laser-Aided Directed Energy Deposition of Steel Powder over Flat Surfaces and Edges. Materials 2018, 11, 435. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Cheng, X.; He, B.; Wang, H.; Huang, Z. Microstructure and mechanical properties of the austenitic stainless steel 316L fabricated by gas metal arc additive manufacturing. Mater. Sci. Eng. A 2017, 703, 567–577. [Google Scholar] [CrossRef]

- Yadollahi, A.; Shamsaei, N.; Thompson, S.M.; Seely, D.W. Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater. Sci. Eng. A 2015, 644, 171–183. [Google Scholar] [CrossRef]

- Rodriguez, N.; Vázquez, L.; Huarte, I.; Arruti, E.; Tabernero, I.; Álvarez, P. Wire and arc additive manufacturing: A comparison between CMT and TopTIG processes applied to stainless steel. Weld. World 2018, 62, 1083–1096. [Google Scholar] [CrossRef]

- Stützer, J.; Totzauer, T.; Wittig, B.; Zinke, M.; Jüttner, S. GMAW Cold Wire Technology for Adjusting the Ferrite–Austenite Ratio of Wire and Arc Additive Manufactured Duplex Stainless Steel Components. Metals 2019, 9, 564. [Google Scholar] [CrossRef]

- Wang, L.; Xue, J.; Wang, Q. Correlation between arc mode, microstructure, and mechanical properties during wire arc additive manufacturing of 316L stainless steel. Mater. Sci. Eng. A 2019, 751, 183–190. [Google Scholar] [CrossRef]

- Caballero, A.; Ding, J.; Ganguly, S.; Williams, S. Wire + Arc Additive Manufacture of 17-4 PH stainless steel: Effect of different processing conditions on microstructure, hardness, and tensile strength. J. Mater. Process. Technol. 2019, 268, 54–62. [Google Scholar] [CrossRef]

- Ding, D.; Pan, Z.; Cuiuri, D.; Li, H. Wire-feed additive manufacturing of metal components: Technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Yang, D.; Wang, G.; Zhang, G. Thermal analysis for single-pass multi-layer GMAW based additive manufacturing using infrared thermography. J. Mater. Process. Technol. 2017, 244, 215–224. [Google Scholar] [CrossRef]

- Xiong, J. Forming Characteristics in Multi-Layer Single-Bead GMA Additive Manufacturing and Control for Deposition Dimension. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2014. [Google Scholar]

- Xiong, J.; Li, Y.; Li, R.; Yin, Z. Influences of process parameters on surface roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. J. Mater. Process. Technol. 2018, 252, 128–136. [Google Scholar] [CrossRef]

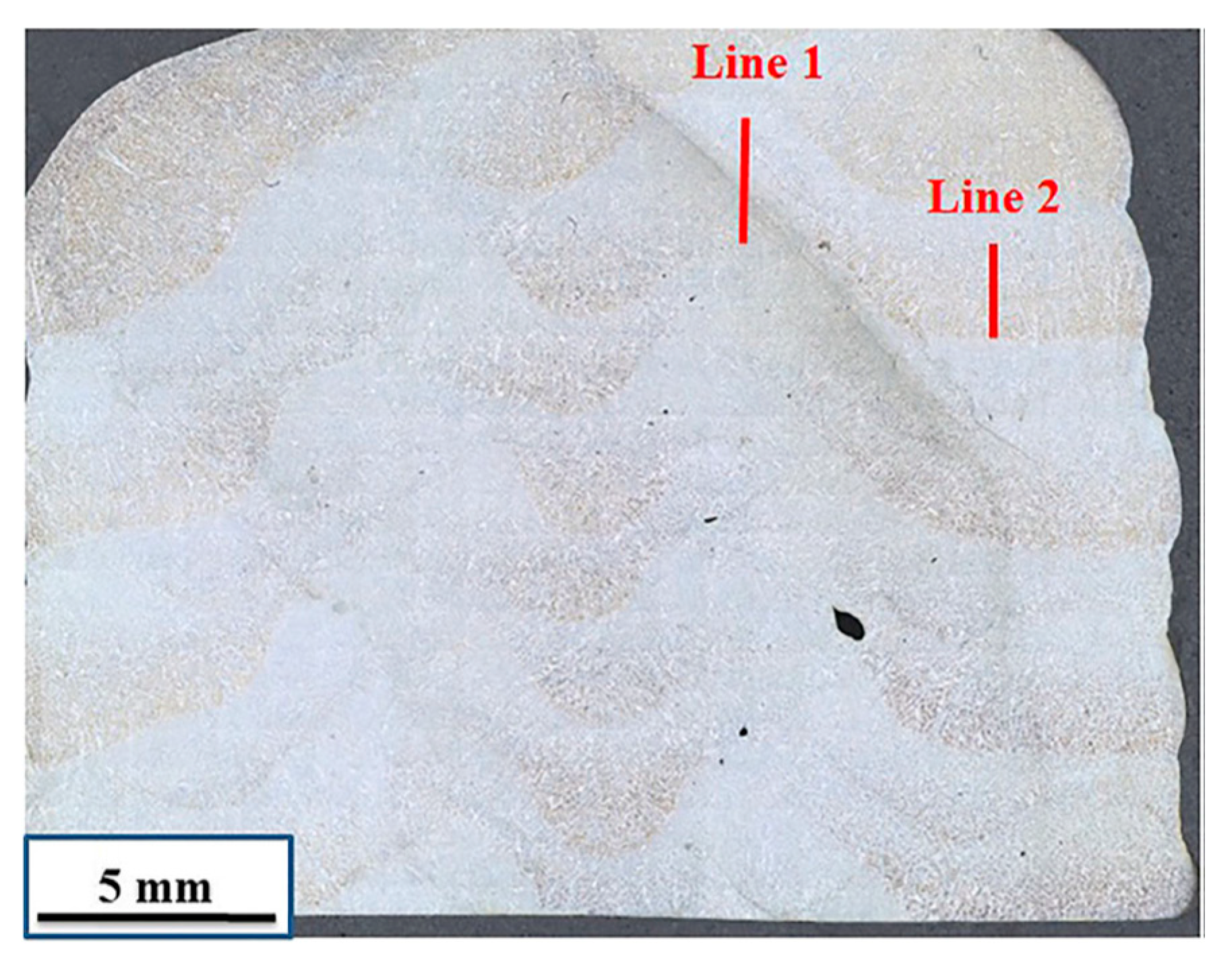

- Wu, W.; Xue, J.; Wang, L.; Zhang, Z.; Hu, Y.; Dong, C. Forming Process, Microstructure, and Mechanical Properties of Thin-Walled 316L Stainless Steel Using Speed-Cold-Welding Additive Manufacturing. Metals 2019, 9, 109. [Google Scholar] [CrossRef]

- Eriksson, M.; Lervåg, M.; Sørensen, C.; Robertstad, A.; Brønstad, B.M.; Nyhus, B.; Aune, R.; Ren, X.; Akselsen, O. Additive manufacture of superduplex stainless steel using WAAM. MATEC Web Conf. 2018, 188, 03014. [Google Scholar] [CrossRef]

- Bermingham, M.J.; StJohn, D.H.; Krynen, J.; Tedman-Jones, S.; Dargusch, M. Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing. Acta Mater. 2019, 168, 261–274. [Google Scholar] [CrossRef]

- Lin, J.; Lv, Y.; Liu, Y.; Sun, Z.; Wang, K.; Li, Z.; Wu, Y.; Xu, B. Microstructural evolution and mechanical property of Ti-6Al-4V wall deposited by continuous plasma arc additive manufacturing without post heat treatment. J. Mech. Behav. Biomed. Mater. 2017, 69, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Zhan, B.; He, J.; Wang, K. The double-wire feed and plasma arc additive manufacturing process for deposition in Cr-Ni stainless steel. J. Mater. Process. Technol. 2018, 259, 206–215. [Google Scholar] [CrossRef]

- Hosseini, V.; Högström, M.; Hurtig, K.; Bermejo, M.A.V.; Stridh, L.-E.; Karlsson, L. Wire-arc additive manufacturing of a duplex stainless steel: Thermal cycle analysis and microstructure characterization. Weld. World 2019, 63, 975–987. [Google Scholar] [CrossRef]

- Baufeld, B.; Biest, O.; Gault, R. Microstructure of Ti-6Al-4V specimens produced by shaped metal deposition. Int. J. Mater. Res. 2009, 100, 1536–1542. [Google Scholar] [CrossRef]

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; Wiley-VCH: Hoboken, NJ, USA, 2005; p. 376. [Google Scholar]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Hejripour, F.; Binesh, F.; Hebel, M.; Aidun, D.K. Thermal modeling and characterization of wire arc additive manufactured duplex stainless steel. J. Mater. Process. Technol. 2019, 272, 58–71. [Google Scholar] [CrossRef]

- Ziewiec, A.; Zielinska-Lipiec, A.; Tasak, E. Microstructure of Welded Joints of X5CrNiCuNb16-4 (17-4 PH) Martensitic Stainlees Steel after Heat Treatment. Arch. Met. Mater. 2014, 59, 965–970. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, K.; Zhou, Q.; Ding, J.; Ganguly, S.; Marzio, G.; Yang, D.; Xu, X.; Dirisu, P.; Williams, S.W. Microstructure and mechanical properties of TOP-TIG-wire and arc additive manufactured super duplex stainless steel (ER2594). Mater. Sci. Eng. A 2019, 762, 138097. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Almeida, P.S.; Wang, F.; Williams, S. Thermo-mechanical analysis of Wire and Arc Additive Layer Manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef]

- Colegrove, P.; Coules, H.; Fairman, J.; Martina, F.; Kashoob, T.; Mamash, H.; Cozzolino, L.D. Microstructure and residual stress improvement in wire and arc additively manufactured parts through high-pressure rolling. J. Mater. Process. Technol. 2013, 213, 1782–1791. [Google Scholar] [CrossRef]

- Sames, W.; List, F.A.; Pannala, S.; Dehoff, R.; Babu, S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Fang, J.; Dong, S.; Wang, Y.; Xu, B.; Zhang, Z.; Xia, D.; He, P. The effects of solid-state phase transformation upon stress evolution in laser metal powder deposition. Mater. Des. 2015, 87, 807–814. [Google Scholar] [CrossRef]

- Masubuchi, K. Analysis of Welded Structures: Residual Stresses, Distortion, and Their Consequences; Elsevier: Amsterdam, The Netherlands, 2013; Volume 33. [Google Scholar]

- Deng, D.; Murakawa, H. FEM prediction of buckling distortion induced by welding in thin plate panel structures. Comput. Mater. Sci. 2008, 43, 591–607. [Google Scholar] [CrossRef]

- Lee, Y.; Bandari, Y.; Nandwana, P.; Gibson, B.; Richardson, B.; Simunovic, S. Effect of Interlayer Cooling Time, Constraint and Tool Path Strategy on Deformation of Large Components Made by Laser Metal Deposition with Wire. Appl. Sci. 2019, 9, 5115. [Google Scholar] [CrossRef]

- Martina, F.; Ding, J.; Williams, S.; Caballero, A.; Pardal, G.R.; Quintino, L. Tandem metal inert gas process for high productivity wire arc additive manufacturing in stainless steel. Addit. Manuf. 2019, 25, 545–550. [Google Scholar] [CrossRef]

- Gordon, J.V.; Harlow, D.G. Statistical Modeling of Wire and Arc Additive Manufactured Stainless Steel 304: Microstructure and Fatigue. Int. J. Reliab. Qual. Saf. Eng. 2019, 26, 1950016. [Google Scholar] [CrossRef]

- Tian, Y.; Ouyang, B.; Gontcharov, A.; Gauvin, R.; Lowden, P.; Brochu, M. Microstructure evolution of Inconel 625 with 0.4 wt% boron modification during gas tungsten arc deposition. J. Alloy. Compd. 2017, 694, 429–438. [Google Scholar] [CrossRef]

- Dong, B.; Pan, Z.; Shen, C.; Ma, Y.; Li, H. Fabrication of Copper-Rich Cu-Al Alloy Using the Wire-Arc Additive Manufacturing Process. Met. Mater. Trans. A 2017, 48, 3143–3151. [Google Scholar] [CrossRef]

- Geng, H.; Li, J.; Xiong, J.; Lin, X.; Zhang, F. Optimization of wire feed for GTAW based additive manufacturing. J. Mater. Process. Technol. 2017, 243, 40–47. [Google Scholar] [CrossRef]

- Scotti, A.; Ponomarev, V.; Lucas, W. Interchangeable metal transfer phenomenon in GMA welding: Features, mechanisms, classification. J. Mater. Process. Technol. 2014, 214, 2488–2496. [Google Scholar] [CrossRef]

- Scotti, A.; Ponomarev, V.; Lucas, W. A scientific application oriented classification for metal transfer modes in GMA welding. J. Mater. Process. Technol. 2012, 212, 1406–1413. [Google Scholar] [CrossRef]

- Yi, H.; Qi, L.; Luo, J.; Zhang, D.; Li, N. Direct fabrication of metal tubes with high-quality inner surfaces via droplet deposition over soluble cores. J. Mater. Process. Technol. 2019, 264, 145–154. [Google Scholar] [CrossRef]

- Thompson, S.M.; Bian, L.; Shamsaei, N.; Yadollahi, A. An overview of Direct Laser Deposition for additive manufacturing; Part I: Transport phenomena, modeling and diagnostics. Addit. Manuf. 2015, 8, 36–62. [Google Scholar] [CrossRef]

- Wang, P.; Nai, M.L.S.; Tan, X.; Sin, W.J.; Tor, S.B.; Wei, J. Anisotropic Mechanical Properties in a Big-Sized Ti-6Al-4V Plate Fabricated by Electron Beam Melting. In TMS 2016: 145th Annual Meeting & Exhibition: Supplemental Proceedings; Springer: Berlin/Heidelberg, Germany, 2016; pp. 5–12. [Google Scholar] [CrossRef]

- Cain, V.; Thijs, L.; Van Humbeeck, J.; Van Hooreweder, B.; Knutsen, R. Crack propagation and fracture toughness of Ti6Al4V alloy produced by selective laser melting. Addit. Manuf. 2015, 5, 68–76. [Google Scholar] [CrossRef]

| Abbreviations | Phrases |

|---|---|

| 3D | Three-dimensional |

| AD | As-deposited |

| AD+H900 | As-deposited plus H900 ageing treatment |

| AM | Additive manufacturing |

| BJ | Binder jetting |

| CGEF | Complete grown equiaxed ferrite |

| CMT | Cold metal transfer welding |

| DED | Directed energy deposition |

| DED-GMA | Directed energy deposition with gas metal arc |

| DED-L | Directed energy deposition-laser |

| DSS | Duplex stainless steel |

| DWF-PAM | Double-wire feed and plasma additive manufacturing |

| EL | Elongations |

| GMAW | Gas metal arc welding |

| GMAW–CMT | Gas metal arc welding with the cold metal transfer process |

| GTAW | Gas tungsten arc welding |

| H | Horizontal |

| IGEF | Incomplete grown equiaxed ferrite |

| LMPD | Laser metal powder deposition |

| ME | Material extrusion |

| MJ | Material jetting |

| PAW | Plasma arc welding |

| PBF | Powder bed fusion |

| PBF-L | Powder bed fusion-laser |

| RP | Rapid prototyping |

| SG | Shielding gas |

| SG1 | Shielding gas1 |

| SG2 | Shielding gas 2 |

| SL | Sheet lamination |

| SLM | Selective laser melting |

| ST | As-deposited followed by solution treatment only |

| ST+H900 | As-deposited followed by solution treatment and H900 ageing |

| SWF-PAM | Single-wire feed and plasma additive manufacturing |

| UTS | Ultimate tensile strength |

| V | Vertical |

| VP | Vat photo-polymerization |

| WAAM | wire arc additive manufacturing |

| YS | Yield strength |

| Company | Model | Details | Country |

|---|---|---|---|

| Gefertec GmbH | GTarc3000-3 WAAM machine | A three-axis system for the production of parts up to 3 m3 with a maximum mass of 3000 kg. | Germany |

| Mazak | VARIAXIS j-600AM | Applied to the production and repair of aerospace parts, molds, and dies and oil-drilling components. | Japan |

| Addilan | Addilan VO.1 | A closed loop control system and an inert chamber with a special loading and unloading system. | Spain |

| Nanjing Enigma Automation CO., Ltd. | ArcMan-600 | Building Dimensions: 400 × 400 × 600 mm | China |

| Layer thickness resolution: 0.5–0.25 mm | |||

| Nanjing Zhongke Raycham Laser Technology Co., Ltd. | RC-WAAM-3000 | Building Dimensions: 3000 × 2000 × 1000 mm | China |

| Max wire feed rate: 1–5 m/min |

| Country | Research Groups | Synonyms of Wire Arc Additive Manufacturing (WAAM) | Ref. |

|---|---|---|---|

| United States | Southern Methodist University | Rapid prototyping (RP) based on gas tungsten arc welding (GTAW) | Jandric et al. [34] |

| Tufts University | Near-Net Shape Manufacturing | Kwak et al. [37] | |

| South Korea | Korea Institute of Science and Technology | 3D welding | Song et al. [35,36] |

| Japan | Osaka University | 3D micro welding | Katou et al. [38] |

| United Kingdom | University of Sheffield | Shaped metal deposition | Baufeld et al. [39] |

| Cranfield University | Wire Arc Additive Manufacturing | Williams et al. | |

| University of Manchester | Wire Arc Additive Manufacturing | Prangnell et al. | |

| Coventry University | Wire Arc Additive Manufacturing | Biswal et al. | |

| University of Wales Swansea | Shaped metal deposition | Clark et al. [40] | |

| China | Harbin Institute of Technology | GMAW-based rapid manufacturing | Xiong et al. [41,42] |

| Harbin Institute of Technology | GMAW based additive manufacturing | Yang et al. [43] | |

| Xi An Jiao Tong University | MPAW—based rapid prototyping | Aiyiti et al. [44] | |

| India | Indian Institute of Technology | Hybrid Layered Manufacturing | Suryakumar et al. [45] |

| Australia | University of Wollongong | Wire and arc additive manufacturing (WAAM) | Ding et al. [46,47] |

| Wire-feed additive manufacturing | Ding et al. [48] | ||

| GTAW based-additive manufacturing | Ma et al. [49] |

| Sample | Scanning Speed/cm.min−1 | Cooling Time/s | Bottom Current Mode |

|---|---|---|---|

| G3010 | 30 | 10 | Gradual reduction of bottom current |

| T3010 | 30 | 10 | Transient reduction of bottom current |

| G3510 | 35 | 10 | Gradual reduction of bottom current |

| G3000 | 30 | 0 | |

| G3005 | 30 | 5 | |

| G3015 | 30 | 15 |

| WAAM Techniques | Material | Linear Energy Density/Heat Input | Reported by |

|---|---|---|---|

| GMAW-CMT | Duplex stainless steel-G 25 94 | 0.4–0.87 KJ/mm | Eriksson et al. [97] |

| GTAW | Ti-6Al-4V | 0.186–1.492 KJ/mm | Bermingham et al. [98] |

| PAW | Ti-6Al-4V | 0.655–1.302 KJ/mm | Lin et al. [99] |

| WAAM Techniques | Material | Process Parameters | Macroscopic Characteristics | Reported by | |

|---|---|---|---|---|---|

| MIG | 316L (austenitic) stainless steel | Welding current mode | Gradual reduction of bottom current | Improves bottom formation | Wu et al. [96] |

| Increasing scanning speed | Unevenness of both ends | ||||

| PAM | H00Cr21Ni10 (austenitic) stainless steel | SWF-PAM: single-wire feed and plasma additive manufacturing | Slightly better surface-quality than that of Double-wire feed and plasma additive manufacturing | Feng et al. [100] | |

| DWF-PAM: double-wire feed and plasma additive manufacturing | / | ||||

| PAM: SWF-PAM, DWF-PAM | Increasing scanning speed | Better surface quality | |||

| GMAW | Type-2209 (duplex) stainless steel | Deposition path | Alternating direction deposition path | Uniform layer height | Hosseini et al. [101] |

| One-direction deposition path | Uneven sides: the start side was higher than the end side. | ||||

| GMAW | H08Mn2Si low-carbon steel | Decreasing interlay temperature | Surface roughness decreases | Xiong et al. [95] | |

| Increasing scanning speed | Surface roughness increases | ||||

| Increasing wire feeding speed | Surface roughness increases | ||||

| Process | Materials | Process Factors | Microstructure | YS (MPa) | UTS (MPa) | EL (%) | Hardness (HV) | Reported by |

|---|---|---|---|---|---|---|---|---|

| DWF-PAM | H00Cr21Ni10 (austenitic) stainless steel | Scanning speed | A lot of complete grown equiaxed ferrite (CGEF) grains | / | About 550, similar in the vertical and horizontal directions | 44.7–58.7 | ~193 | Feng et al. [100] |

| SWF-PAM | A number of incomplete grown equiaxed ferrite (IGEF) grains, and a few CGEF grains | / | Around 510, similar in the vertical and horizontal directions | 20.5–35.4 | ~187 | Feng et al. [100] | ||

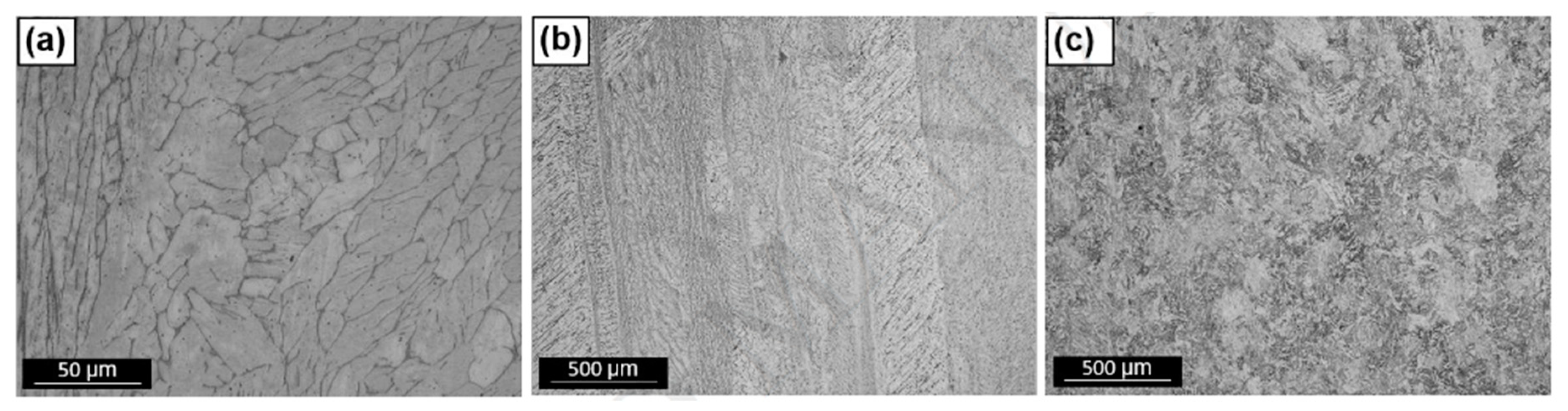

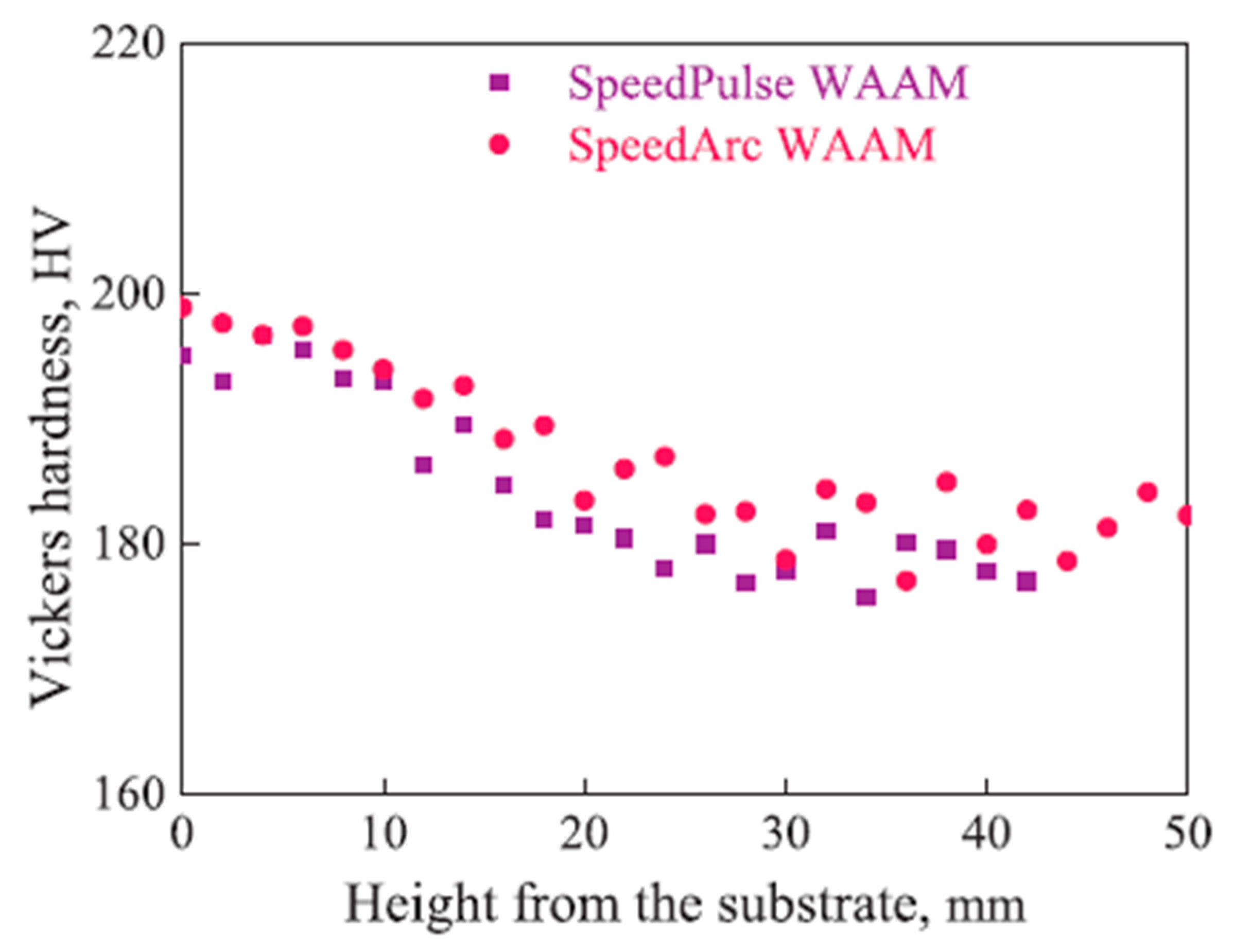

| SpeedPulse WAAM | 316 (austenitic) stainless steel | Heat input, cooling rate | Coarser secondary dendrite arm spacing | Horizontal 418.0 | Horizontal 550 ± 6 | / | / | Wang et al. [90] |

| SpeedArc WAAM | Smaller secondary dendrite arm spacing | Horizontal 417.9 | Horizontal 553 ± 2 | / | Higher than the hardness of SpeedPulse WAAM parts | Wang et al. [90] | ||

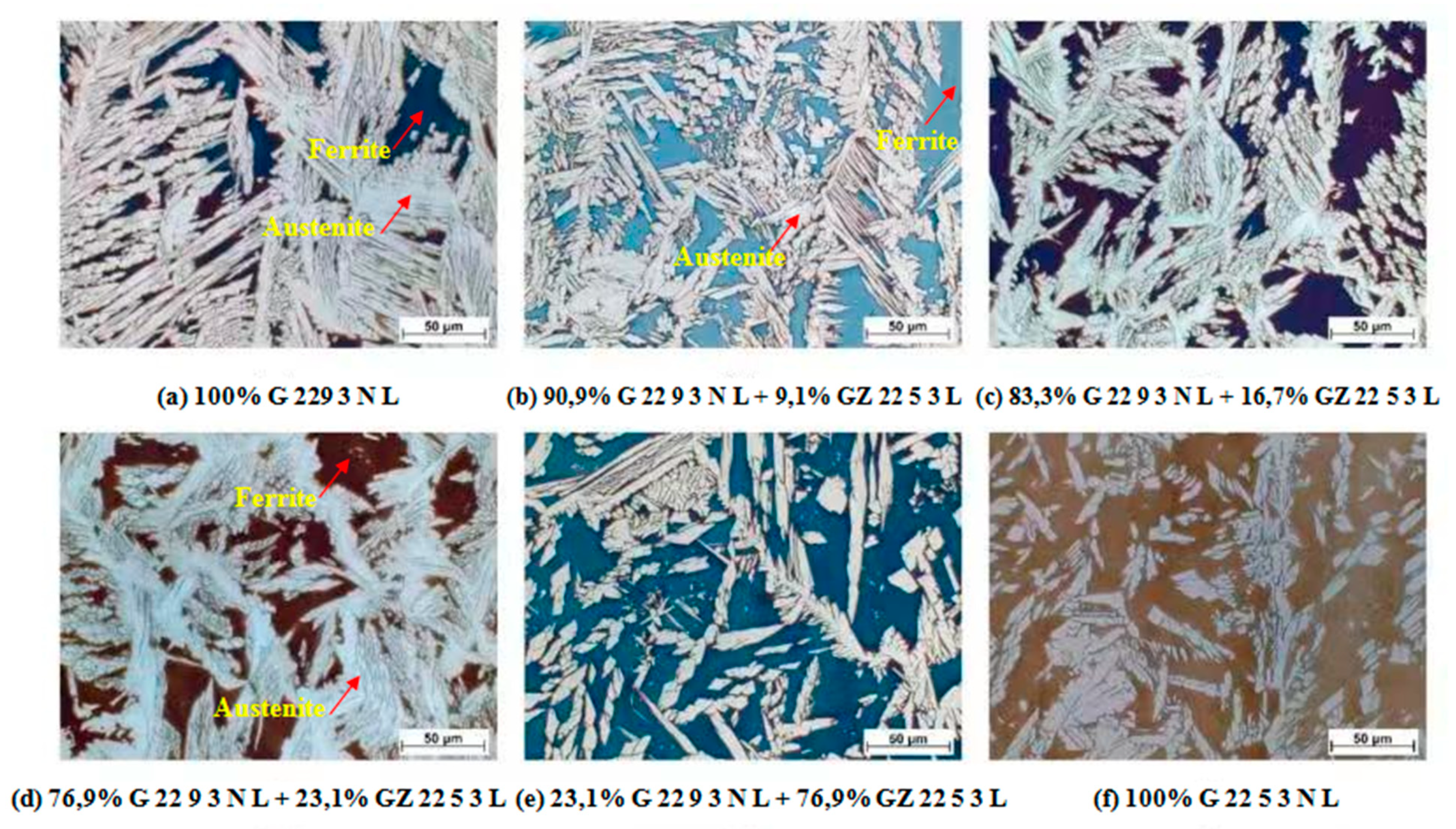

| GMAW–CMT | Duplex Stainless Steel | Chemical composition of feedstock | As the nickel content reduces, the austenite plates become smaller in size and less in content. | / | / | / | / | Stützer et al. [89] |

| CMT | 17-4 PH (martensitic) stainless steel | As-built, Shielding gas 1 (SG1): 38% He + 2% CO2 + Ar | Higher percentage of retained austenite: 0.85%, area percentage. Mainly a dendritic martensite-δ ferrite microstructure | / | Average 994 | Average 11.9 | ~330 | Caballero et al. [91] |

| As-built, Shielding gas 2 (SG2) composition: 2.5% CO2+Ar | Lower percentage of retained austenite: 0.12%, area percentage | / | / | / | ~340 | |||

| CMT | 17-4 PH stainless steel | SG1+post-deposition heat treatment: AD+H900 | Columnar microstructure | / | Average 1208 | Average 7.3 | ~450 | Caballero et al. [91] |

| CMT | 17-4 PH stainless steel | SG1+post-deposition heat treatment: ST+H900 | A columnar microstructure | / | Average 1352 | Average 13.8 | ~440 | Caballero et al. [91] |

| CMT | 17-4 PH stainless steel | SG1+ Solution treated | N/A | / | Average 1003 | Average 12.6 | ~330 | Caballero et al. [91] |

| WAAM Techniques | Material | Defects | Reasons | Reported by | |

|---|---|---|---|---|---|

| WAAM | 304 stainless steel | Porosity | Insufficient energy for complete melting the layers; gas generation. | Gordon et al. [116] | |

| WAAM | Metals (Steel, Al, Ti, etc.) | Porosity | Raw material-induced | Contaminants of wire and substrate | Wu et al. [33] |

| Process-induced | Insufficient fusion or spatter ejection | ||||

| Delamination | Incomplete melting or insufficient re-melting of the underlying solid between layers | ||||

| GTAW | Inconel 625 | Solidification cracking | Existence of liquid film at terminal solidification | Tian et al. [117] | |

| GTAW | Intermetallic Al/Cu | Grain boundary crack | Intermetallic phase-equilibrium is freely broken | Dong et al. [118] | |

| Process | Materials | Sample | YS (MPa) | UTS (MPa) | EL (%) | Reported by | |

|---|---|---|---|---|---|---|---|

| SpeedPulse WAAM | 316 (austenitic) stainless steel | Horizontal | As-deposited | 418.0 | 550 ± 6 | / | Wang et al. [90] |

| SpeedArc WAAM | 316 (austenitic) stainless steel | Horizontal | As-deposited | 417.9 | 553 ± 2 | / | Wang et al. [90] |

| Wrought (cold finished) | 316 (austenitic) stainless steel | / | Cold finished | 255–310 | 525–623 | / | Yadollahi et al. [87] |

| Speed-cold-welding additive manufacturing | 316 (austenitic) stainless steel | T3010-H1 | As-deposited | 335.00 | 537.40 | / | Wu et al. [96] |

| T3010-H2 | 310.00 | 498.77 | / | ||||

| T3010-H3 | 336.83 | 563.78 | / | ||||

| T3010-V1 | 370.33 | 628.19 | / | ||||

| T3010-V2 | 371.11 | 616.07 | / | ||||

| T3010-V3 | 342.56 | 585.83 | / | ||||

| G3010-H1 | 330.17 | 541.08 | / | ||||

| G3010-H2 | 345.67 | 561.38 | / | ||||

| G3010-H3 | 327.17 | 570.56 | / | ||||

| G3010-V1 | 369.17 | 628.04 | / | ||||

| G3010-V2 | 364.17 | 606.68 | / | ||||

| G3010-V3 | 339.50 | 574.68 | / | ||||

| G3510-H1 | 307.33 | 524.30 | / | ||||

| G3510-H2 | 306.17 | 525.75 | / | ||||

| G3510-H3 | 336.67 | 593.59 | / | ||||

| G3510-V1 | 359.56 | 634.47 | / | ||||

| G3510-V2 | 336.67 | 602.56 | / | ||||

| G3510-V3 | 336.67 | 621.44 | / | ||||

| G3015-H1 | 333.33 | 564.69 | / | ||||

| G3015-H2 | 335.83 | 558.86 | / | ||||

| G3015-H3 | 353.00 | 619.28 | / | ||||

| G3015-V1 | 373.00 | 637.98 | / | ||||

| G3015-V2 | 345.83 | 609.24 | / | ||||

| G3015-V3 | 365.50 | 595.88 | / | ||||

| CMT technology in continuous modes | 316L (austenitic) stainless steel | Horizontal | As-deposited | 364.3 ± 13.9 | 577.3 ± 4.0 | 43.4 ± 4.7 | Rodriguez et al. [88] |

| Vertical | 336.9 ± 1.7 | 574.1 ± 7.9 | 42.0 ± 3.7 | ||||

| CMT technology in pulsed modes | Horizontal | 374.0 ± 11.2 | 588.0 ± 5.7 | 45.1 ± 3.5 | |||

| Vertical | 331.7 ± 5.4 | 536.0 ± 15.3 | 45.6 ± 16.7 | ||||

| TopTIG technology in continuous mode | Horizontal | 365.5 ± 8.7 | 590.3 ± 3.6 | 42.3 ± 2.7 | |||

| Vertical | 322.2 ± 2.7 | 539.9 ± 14.7 | 43.1 ± 6.9 | ||||

| CMT | 17-4 PH (martensitic) stainless steel | Horizontal | Post-deposition heat treatment: AD+H900 | / | 1293 | 8.2 | Caballero et al. [91] |

| Vertical | Post-deposition heat treatment: AD+H900 | 1124 | 6.5 | ||||

| Horizontal | Post-deposition heat treatment: ST+H900 | / | 1353 | 13.8 | |||

| Vertical | Post-deposition heat treatment: ST+H900 | 1351 | 13.8 | ||||

| Horizontal | As-deposited (AD) | / | 1009 | 11.6 | |||

| Vertical | As-deposited (AD) | 979 | 12.2 | ||||

| Horizontal | Post-deposition heat treatment: ST | / | 1000 | 12.8 | |||

| Vertical | Post-deposition heat treatment: ST | 1006 | 12.4 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, W.; Zhang, C.; Jin, S.; Tian, Y.; Wellmann, D.; Liu, W. Wire Arc Additive Manufacturing of Stainless Steels: A Review. Appl. Sci. 2020, 10, 1563. https://doi.org/10.3390/app10051563

Jin W, Zhang C, Jin S, Tian Y, Wellmann D, Liu W. Wire Arc Additive Manufacturing of Stainless Steels: A Review. Applied Sciences. 2020; 10(5):1563. https://doi.org/10.3390/app10051563

Chicago/Turabian StyleJin, Wanwan, Chaoqun Zhang, Shuoya Jin, Yingtao Tian, Daniel Wellmann, and Wen Liu. 2020. "Wire Arc Additive Manufacturing of Stainless Steels: A Review" Applied Sciences 10, no. 5: 1563. https://doi.org/10.3390/app10051563

APA StyleJin, W., Zhang, C., Jin, S., Tian, Y., Wellmann, D., & Liu, W. (2020). Wire Arc Additive Manufacturing of Stainless Steels: A Review. Applied Sciences, 10(5), 1563. https://doi.org/10.3390/app10051563