Measurement and Evaluation for Interbedded Pore Water Pressure of Saturated Asphalt Pavement under Vehicle Loading

Abstract

:Featured Application

Abstract

1. Introduction

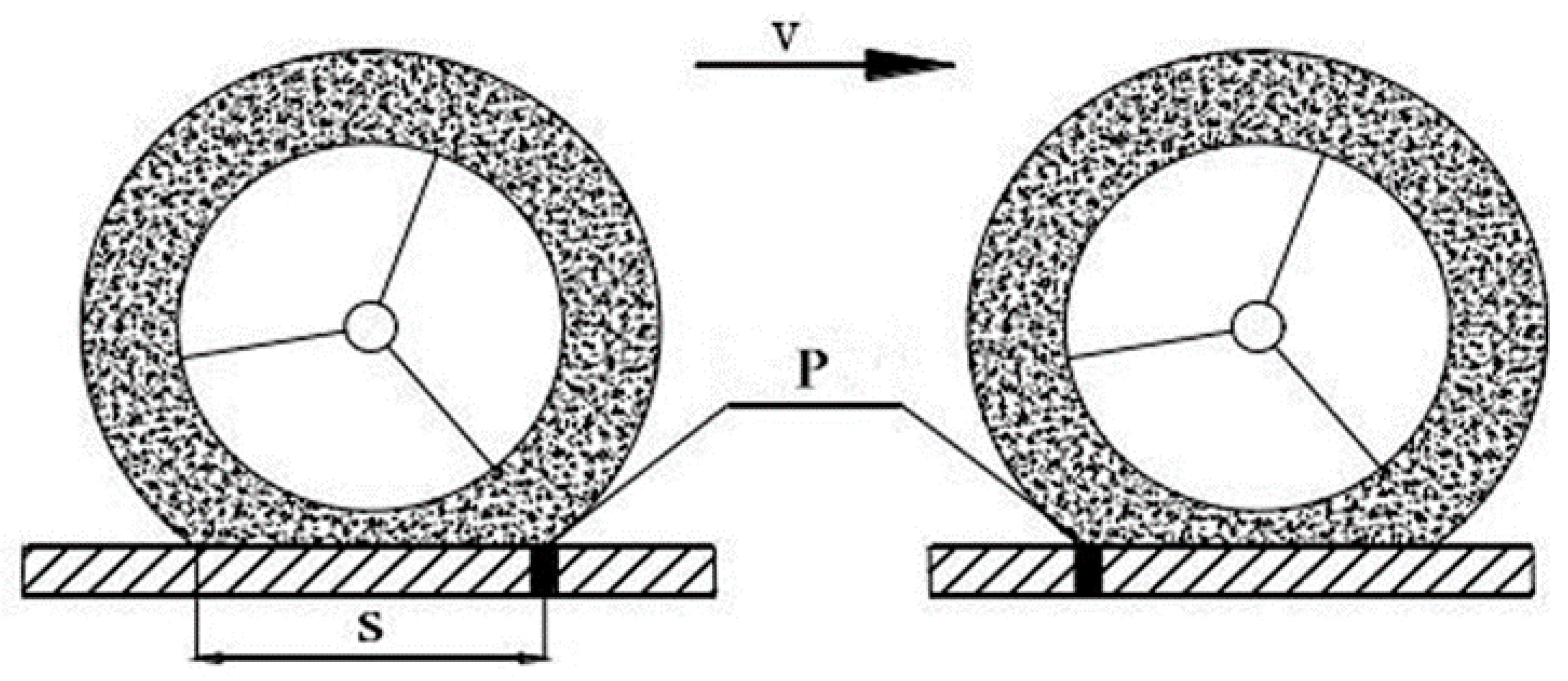

2. Experimental facility

2.1. Requirements of Sensor

2.1.1. Sensor Frequency Requirements

2.1.2. Sensor Range Requirements

2.2. Sensor Selection

- Wide frequency response range and high natural frequency.

- Small size. Due to the integrated circuit process, silicon diaphragm sensitive components can be made very small.

- High precision, good sensitivity, suitable for dynamic measurement.

- Because the piezoresistive pressure sensor is integrally formed, it has the advantages of reliable operation, shock resistance, impact resistance, corrosion resistance, and strong anti-interference ability.

3. Measurement Method Design

3.1. Measurement Method Summary

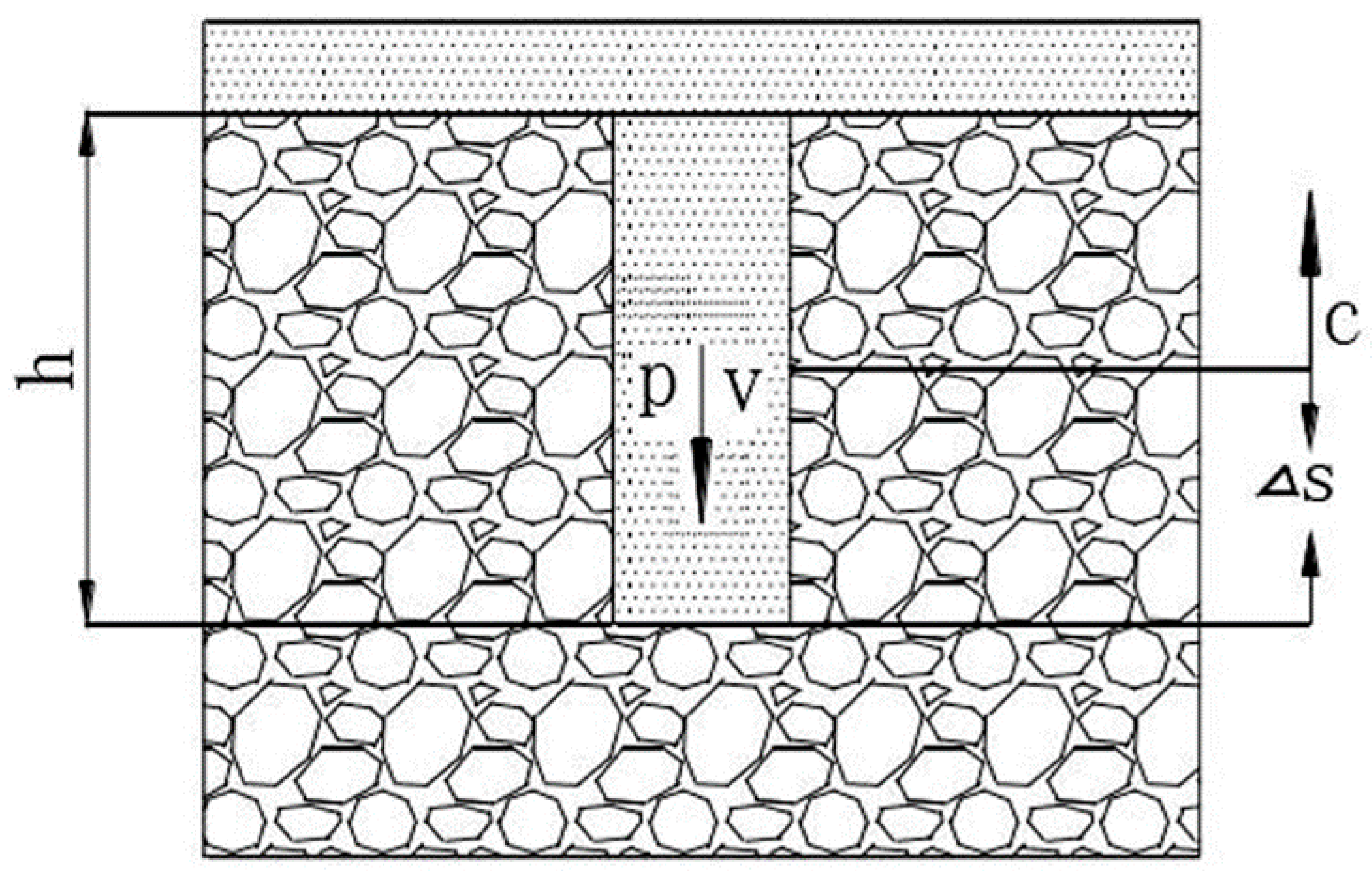

3.2. Design of Pore Water Pressure Measurement Method

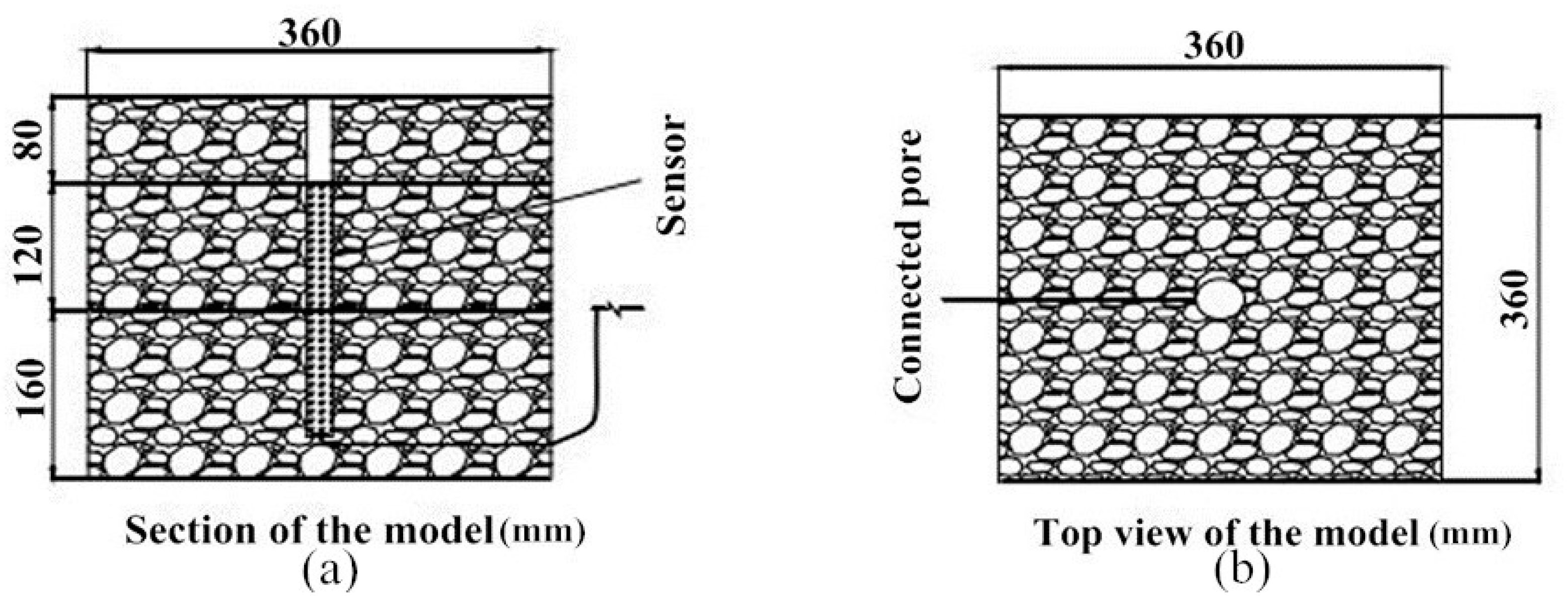

3.2.1. Material Preparation

- According to the gradation and thickness of G12 highway, the plate specimen of the upper layer, the middle surface layer and the lower layer are respectively prepared.

- A connected pore with a diameter of 4 mm that extends vertically through the upper layer are formed at the center of the upper layer by electric drill.

- A vertical hole is drilled in the center of the middle surface layer according to the size of the sensor, so that the sensor can be fixed in the middle surface layer.

- Since the diameter of the data line of the sensor is 8 mm, a vertical hole with a diameter of 10 mm is drilled in the center of the lower layer to ensure the data line can pass through.

- The basic asphalt used in this study is 70# asphalt, which is called “Pan Jin” base asphalt. The basic indicators of the basic asphalt used in this study are summarized in Table 1.

- The road performance of the asphalt mixture used in this study is shown in Table 2.

3.2.2. Model Assembly

- The sensor is placed in the hole of the middle surface layer, and the upper surface of the sensor is kept on the same level as the upper surface of the middle surface layer. The upper surface of the sensor is sealed with tape and 150 °C asphalt binder is poured into the gap between the sensor and the hole until the gap is filled. Then the middle surface layer and the sensor are cooled to the normal temperature so that the sensor can be firmly fixed in the middle surface layer.

- A high-strength fine mesh should be covered on the surface of the sensor to prevent the fine particles from clogging the sensor and affecting the measurement result during the measurement process. Considering that the fine mesh should not only prevent the particles from blocking the sensor, but also not affect the pore water pressure, the pore diameter of fine mesh is selected to be 0.2 mm. Remove the adhesive tape stuck on the sensor surface, and carefully clean the upper surface of the sensor, then cover the surface of the sensor with a fine mesh of appropriate size and press the surrounding of the fine mesh into the asphalt binder into the asphalt binder for fixation.

- After the asphalt binder in the middle surface layer is cooled, the data line is passed through the hole in the lower layer. Here, asphalt binder with 150 °C is evenly applied to the lower surface of the middle surface layer and the upper surface of the lower layer, then the middle surface layer and lower layer are glued together to ensure the central axis of the two is in a straight line. After the asphalt binder is cooled and the two are integrated, the gap between the data line and the hole of the lower layer is filled with asphalt binder according to the above steps.

- After 150 °C asphalt binder is evenly applied to the upper surface of the middle surface layer and the lower surface of the upper layer, then the middle surface layer and upper layer are glued together to ensure the central axis of the connected pore in upper layer and the force diaphragm of the sensor in the middle surface layer are on a straight line. Moreover, the connected pore of the upper layer is covered with a fine mesh to prevent fine particles from blocking the connected pore. The model is prepared after it is kept at 15 °C for 3 days.

3.2.3. Model Embedment

- Communicate with the relevant departments and block the single traffic on the road section.

- The rectangular hole with the same size of the model was dug out on the pavement with asphalt concrete cutting machine, and enough gaps are left for the data line to lead out.

- The sidewalls and the bottom of the hole and the sidewall of the model are heated using a blast burner, then the model is hung into the hole and the data line is drawn along the bottom of the model to the road surface. Then, 150 °C asphalt binder is poured into the gap between the side wall of the model and the side wall of the hole until the gap is filled.

- Lead the data line to the workstation on the roadside, and cut out a slot with width and depth of 1 mm through which the data line passes. Put the data line into the slot and fix the data line in the slot with tape to ensure the vehicle will not damage the data line when it passes by. The model embedding work has been completed, as is shown in Figure 3 and Figure 4.

4. Results and Analysis

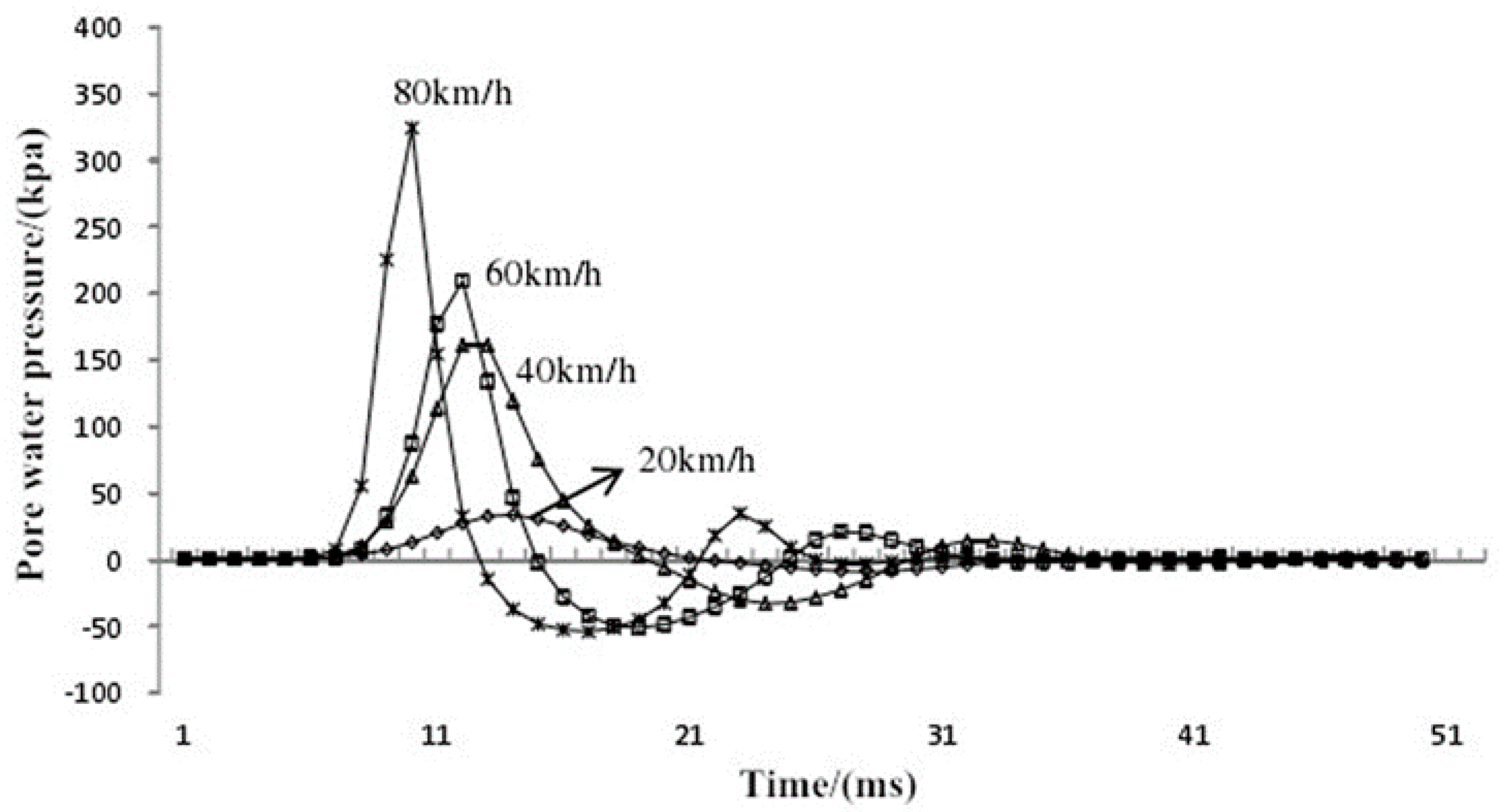

4.1. Analysis of Relationship between Pore Water Pressure and Vehicle Speed

4.2. Analysis of Relationship between Pore water Pressure Response Time and Vehicle Speed

5. Conclusions

- (1)

- A practical pore water pressure test method for saturated asphalt pavement is designed. The advantage is mainly that the structure of the asphalt pavement is less disturbed and the measured data is closer to the actual value.

- (2)

- Based on the analysis of hydrodynamic water hammer theory, it is concluded that the pore water pressure shows a periodic decay phenomenon with time, and the decay phenomenon is analyzed. Finally, the empirical formula of maximum positive pressure with speed and the empirical formula of Abp at different speeds are obtained.

- (3)

- Measurement data show that the pore water pressure gradually increases with increasing vehicle speed, and the pore water pressure response time becomes shorter.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Apeagyei, A.K.; Grenfell, J.R.A.; Airey, G.D. Evaluation of moisture sorption and diffusion characteristics of asphalt mastics using manual and automated gravimetric sorption techniques. J. Mater. Civ. Eng. 2014, 26, 839–844. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Ahmad, M. Evaluating the relationship between permeability and moisture damage of asphalt concrete pavements. J. Mater. Civ. Eng. 2015, 27, 41–72. [Google Scholar] [CrossRef]

- Jahromi, S.G. Investigation of damage and deterioration hazard in asphalt mixtures due to moisture. Proc. Inst. Civ. Eng. Transp. 2018, 171, 98–105. [Google Scholar] [CrossRef]

- Min, H.G.; Zhang, W.P.; Gu, X.L. Effects of load damage on moisture transport and relative humidity response in concrete. Constr. Build. Mater. 2018, 169, 59–68. [Google Scholar] [CrossRef]

- Kim, S.-H.; Kim, N.; Jeong, J.-H. Use of Surface Free Energy Properties to Predict Moisture Damage Potential of Asphalt Concrete Mixture in Cyclic Loading Condition. KSCE J. Civ. Eng. 2003, 7, 381–387. [Google Scholar] [CrossRef]

- Bozorgzad, A.; Kazemi, S.F.; Nejad, F.M. Evaporation-induced moisture damage of asphalt mixtures: Microscale model and laboratory validation. Constr. Build. Mater. 2018, 171, 697–707. [Google Scholar] [CrossRef]

- Abuawad, I.M.A.; Al-Qadi, I.L.; Trepanier, J.S. Mitigation of moisture damage in asphalt concrete: Testing techniques and additives/modifiers effectiveness. Constr. Build. Mater. 2015, 84, 437–443. [Google Scholar] [CrossRef]

- Kringos, N.; Scarpas, A.; Bondt, A.D. Determination of moisture susceptibility of mastic stone bond strength and comparison to thermodynamical properties. Tech. Sess. Assoc. Asph. Paving Technol. 2008, 77, 435–478. [Google Scholar]

- Weldegiorgis, M.T.; Tarefder, R.A. Towards a Mechanistic Understanding of Moisture Damage in Asphalt Concrete. J. Mater. Civ. Eng. 2015, 27, 0899–1561. [Google Scholar] [CrossRef]

- Arambula, E.; Caro, S.; Masad, E. Experimental measurement and numerical simulation of water vapor diffusion through asphalt pavement materials. J. Mater. Civ. Eng. 2010, 22, 588–598. [Google Scholar] [CrossRef]

- Khalili, N.; Selvadurai, A.P.S. On the constitutive modeling of thermo-hydro-mechanical coupling in elastic media with double porosity. In Elsevier Geo-Engineering Book Series; Elsevier: Amsterdam, The Netherlands, 2004; Volume 2, pp. 559–564. [Google Scholar] [CrossRef]

- Kettil, P.; Engstrom, G.; Wiberg, N.E. Coupled hydro-mechanical wave propagation in road structures. Comput. Struct. 2005, 83, 1719–1729. [Google Scholar] [CrossRef]

- Cai, Y.Q.; Cao, Z.G.; Sun, H.L. Dynamic response of pavements on poroelastic half-space soil medium to a moving traffic load. Comput. Geotech. 2009, 36, 52–60. [Google Scholar] [CrossRef]

- Gao, J.; Guo, C.; Liu, Y. Measurement of pore water pressure in asphalt pavement and its effects on permeability. Measurement 2015, 62, 81–87. [Google Scholar] [CrossRef]

- Cui, X.; Zhang, J.; Huang, D. Analysis of Vehicle-Force-Induced Dynamic Pore Pressure in Saturated Pavement with LSPM Drainage Base. J. Test. Eval. 2017, 45, 294–302. [Google Scholar] [CrossRef]

- Novak, M.E.; Birgisson, B.; Mcvay, M. Effects of vehicle speed and permeability on pore pressures in hot- mix asphalt pavement. In Proceedings of the 2nd MIT Conference on Computational Fluid and Solid Mechanics, Cambridge, MA, USA, 17–20 June 2003; pp. 532–536. [Google Scholar]

- Guo, X.D.; Sun, M.Z.; Dai, W.T. Analysis of effective pore pressure in asphalt pavement based on computational fluid dynamics calculation. Adv. Mech. Eng. 2017, 9, 1–14. [Google Scholar] [CrossRef]

- Luo, Z.G.; Ling, J.M.; Zhou, Z.G.; Zheng, J.L. Calculation of interbedded pore water pressure of asphalt concrete pavement. Highway 2005, 50, 86–89. [Google Scholar]

- Luo, S.P.; Dan, H.C.; Li, L. Coupled hydro-mechanical analysis of saturated asphalt pavement under moving traffic loads. J. South China Univ. Technol. 2012, 40, 104–111. [Google Scholar]

- Dong, Z.J.; Tan, Y.Q.; Cao, L.P. Research on pore pressure within asphalt pavement under the coupled moisture-loading action. J. Harbin Inst. Technol. 2007, 39, 1614–1617. [Google Scholar]

- Wang, S.R.; Liu, T.W.; Peng, T.G. Water Hammer Theory and Water Hammer Calculation; Tsinghua University Press: Beijing, China, 1980; Volume 62, pp. 57–98. [Google Scholar]

| Penetration (0.1 mm) | 25 °C Ductility (cm) | Softening Point (°C) | Flash Point (°C) | Density (g·cm−3) |

|---|---|---|---|---|

| 15 °C 25 °C 30 °C | ||||

| 24.7 61.9 106.9 | >100 | 48.7 | 260 | 1.003 |

| GB/T0606- 2011 | GB/T0605- 2011 | GB/T0606- 2011 | GB/T0611- 2011 | GB/T0603- 2011 |

| High Temperature Performance | Low Temperature Performance | Water Stable Performance | |||

|---|---|---|---|---|---|

| Marshall stability (KN) | Dynamic stability (times/mm) | Splitting strength (MPa) | Flexural tensile strength (MPa) | Residual stability of immersed Marshall (%) | Residual Marshall stability after 10 days of freezing and thawing (%) |

| 8.53 | 3261 | 3.79 | 7.51 | 78.7 | 81.3 |

| Vehicle Speed (km/h) | Maximum Positive Pressure (kpa) | Maximum Negative Pressure (kpa) |

| 20 | 34.003 | −8.589 |

| 40 | 161.351 | −32.747 |

| 60 | 209.692 | −51.094 |

| 80 | 324.245 | −53.714 |

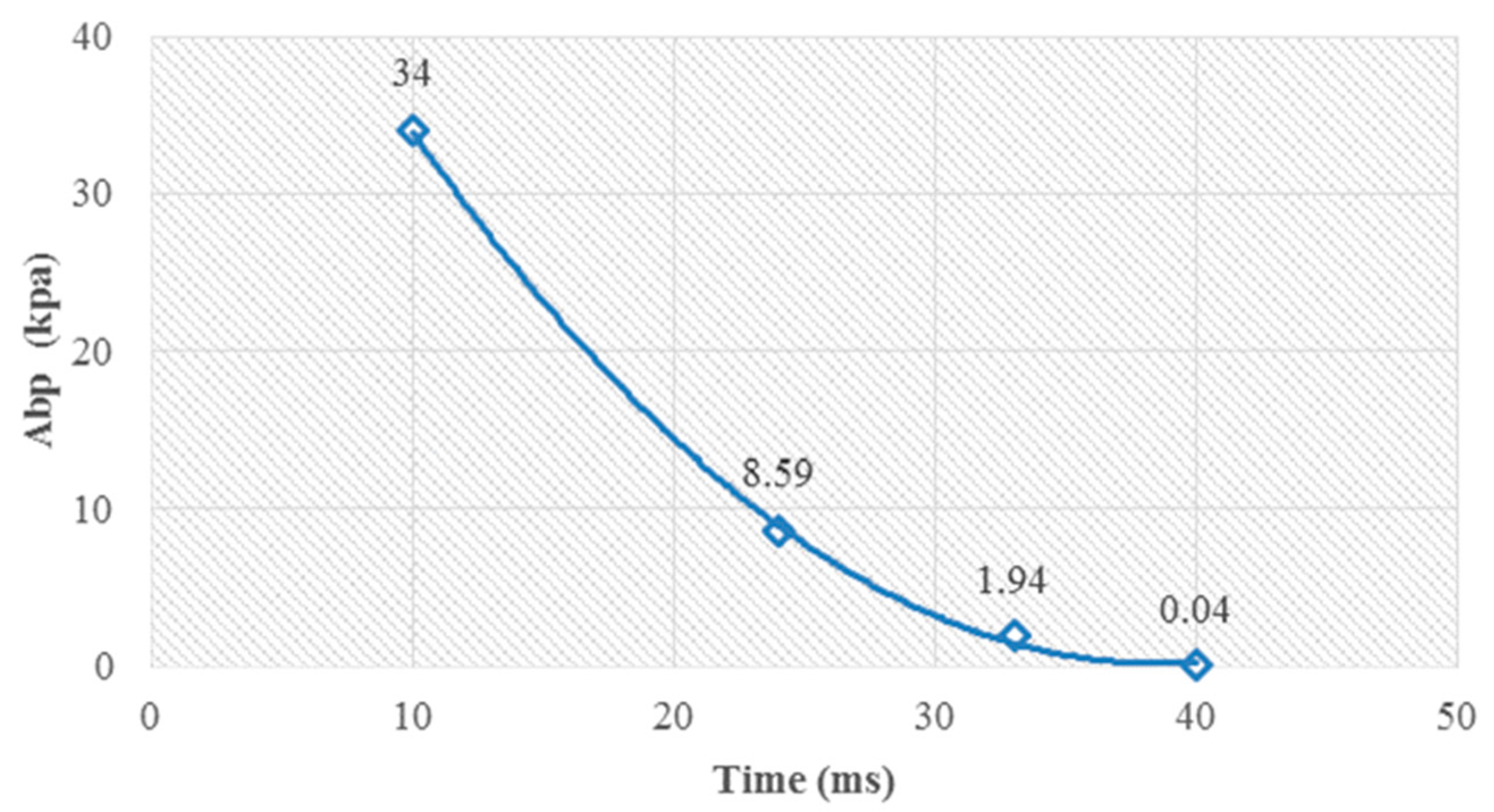

| Cycle | The First Cycle | The Second Cycle | ||

|---|---|---|---|---|

| Response time (ms) | 10 | 24 | 33 | 40 |

| Peaks and troughs (kpa) | 34.00 | −8.59 | 1.94 | −0.04 |

| Vehicle Speed (km/h) | The Regression Equation of Abp | The Correlation Coefficient |

|---|---|---|

| 20 | 0.8378 | |

| 40 | 0.9772 | |

| 60 | 0.9535 | |

| 80 | 0.8994 |

| Vehicle Speed (km/h) | First Cycle Response Time | Second Cycle Response Time | Pore Water Pressure Response Time (ms) | Vehicle Loading Time (ms) |

|---|---|---|---|---|

| 20 | 31 | 18 | 49 | 36.5 |

| 40 | 26 | 15 | 41 | 15.8 |

| 60 | 21 | 15 | 36 | 10.5 |

| 80 | 18 | 9 | 27 | 7.9 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Wang, Z.; Guo, W.; Dai, W. Measurement and Evaluation for Interbedded Pore Water Pressure of Saturated Asphalt Pavement under Vehicle Loading. Appl. Sci. 2020, 10, 1416. https://doi.org/10.3390/app10041416

Chen W, Wang Z, Guo W, Dai W. Measurement and Evaluation for Interbedded Pore Water Pressure of Saturated Asphalt Pavement under Vehicle Loading. Applied Sciences. 2020; 10(4):1416. https://doi.org/10.3390/app10041416

Chicago/Turabian StyleChen, Wuxing, Zhenyong Wang, Wei Guo, and Wenting Dai. 2020. "Measurement and Evaluation for Interbedded Pore Water Pressure of Saturated Asphalt Pavement under Vehicle Loading" Applied Sciences 10, no. 4: 1416. https://doi.org/10.3390/app10041416

APA StyleChen, W., Wang, Z., Guo, W., & Dai, W. (2020). Measurement and Evaluation for Interbedded Pore Water Pressure of Saturated Asphalt Pavement under Vehicle Loading. Applied Sciences, 10(4), 1416. https://doi.org/10.3390/app10041416