1. Introduction

Serious damages of subway stations and tunnels were observed in the Kobe earthquake, indicating that underground structures were vulnerable under severe earthquake excitations [

1]. The Daikai station was the first large-scale underground structure that almost collapsed in the earthquake. Therefore, researchers all around the world gave their explanations about the damage process of the Daikai station, both numerically and experimentally. Such investigations shed light on the damage process and the failure mode of the Daikai station [

2]. Actually, a consensus on the seismic responses of a typical subway station has not been reached. Investigations on the damage process of a typical subway station require more work. Therefore, innovate numerical methods and experimental methods should be proposed to study the dynamic responses of a typical subway station.

Generally, two kinds of methods, namely numerical methods and experimental methods, are developed to study the seismic behavior of subway stations. With respect to numerical modelling, the finite element method is widely used in time-history analysis. The nonlinear mechanical behavior of the underground structure, adjacent geotechnical media, and soil-structure interaction could be considered in time-history analysis. The propagation process of seismic waves in the infinite region would be reproduced with a reasonable boundary. Therefore, up to now, numerical analysis is the main way to study the seismic performance of subway stations, especially for failure progress [

3,

4,

5,

6,

7]. Such investigations give clues to the design of typical underground structures.

Yasuo et al. [

3] used the equivalent linearized constitutive model for soil modeling. The viscous boundary was selected at the bottom of the finite element (FE) model. The transmission boundary was selected laterally. The rigid beam element and elastic beam element were selected for the structure modelling. The results showed that the shear force of the center column reached the bearing capacity during the earthquake and brittle failure happened. Due to the damage of the concrete, the vertical bearing capacity of the central column decreased, and the thrust exceeded the bearing capacity, which caused the center column to fail. The upper end of the side walls and the upper roof reached the ultimate bending capacity after the center column crushed. Huo et al. [

4] applied an equivalent linearized constitutive material for soil modelling. The rigid boundary was applied on the bottom side, and the free boundary was selected on the lateral sides. The results showed that the soil-structure stiffness ratio was significant in the seismic analysis. The station with a lower stiffness ratio suffered more severe damage. As the Daikai station was designed subject to static loading only, the stirrup reinforcement ratio was relatively low, and brittle failure occurred due to the insufficient shear capacity. After the shear failure, the compressive bearing capacity of the central column decreased. In fact, the Daikai station had a large span. After the center column failed, the entire station collapsed due to the increased thrust of the central column. Lu et al. [

5] proposed a simplified approach to consider the nonlinear behavior of the station with FLAC-2D. The nonlinear constitutive models were applied to consider the nonlinear interaction between the soil and structure accurately. Based on the proposed framework, the failure process of the Daikai station can be traced by the dynamic time-history analysis. In order to decrease the seismic responses of the Daikai station, Chen et al. [

6,

7] proposed a self-centering energy dissipation column for the Daikai station. 3D time-history analysis results showed that the self-centering energy dissipation column would effectively decrease the internal forces of the central column and the peak and residual drift. To be specific, the drift would be reduced by 4–5%. Replaceable energy dissipating devices provide supplementary energy dissipation capacity to relieve the development of structural plasticity [

8,

9,

10,

11]. Therefore, the enhanced behavior of the central column would avoid the occurrence and development of a plastic hinge under earthquake excitation.

Actually, further work should be conducted to validate the accuracy of the numerical method. With respect to experimental research, Chen et al. [

12] conducted a series of shaking table tests to investigate the effect of pulse-like ground motion on a typical multi-story subway station. Dynamic responses including structural forces, story drift, settlement, and deformation of the soil were obtained and analyzed. Central columns were verified as the vulnerable component of the multi-story subway station. Moreover, the propagation of earthquake motions in soils was explored based on the test results of another series of large-scale shaking table tests [

13]. It was found that the site amplified the frequency components of dynamic excitation in specific frequency bands. Pulse-like earthquake motions with a long pulse duration and multiple pulse cycles would lead to remarkable resonance-like phenomena of soils. Chen et al. [

14] conducted a series of shaking table tests based on a typical three-story and three-span subway station made of plaster in order to investigate the seismic failure process of an underground subway station on the liquefiable ground. The dynamic responses of the structure and ground soil were studied. Sand boiling, waterspout phenomena, ground surface cracks, and earthquake-induced ground surface settlements were observed in the test. The results of the aforementioned shaking table tests gave people new sights into the seismic damage development process and failure mechanism of the subway station.

It should be noted that the scale issue always exists in the shaking table test of underground structures. In light of the above-mentioned research, this paper aims at studying the seismic behavior of a typical station with a hybrid simulation technique. The hybrid simulation technique is a kind of test method that combines numerical modelling and experimental research. Hybrid simulation could take advantage of both numerical methods and test methods. Therefore, hybrid simulation would achieve a complete representation of the real-world problem [

15]. With respect to the application of hybrid simulation to the underground infrastructure, Yang et al. [

16] applied the virtual hybrid simulation method in the seismic issue of a typical station. In addition, a self-designed steel column was used to validate the hybrid simulation process. Tessari [

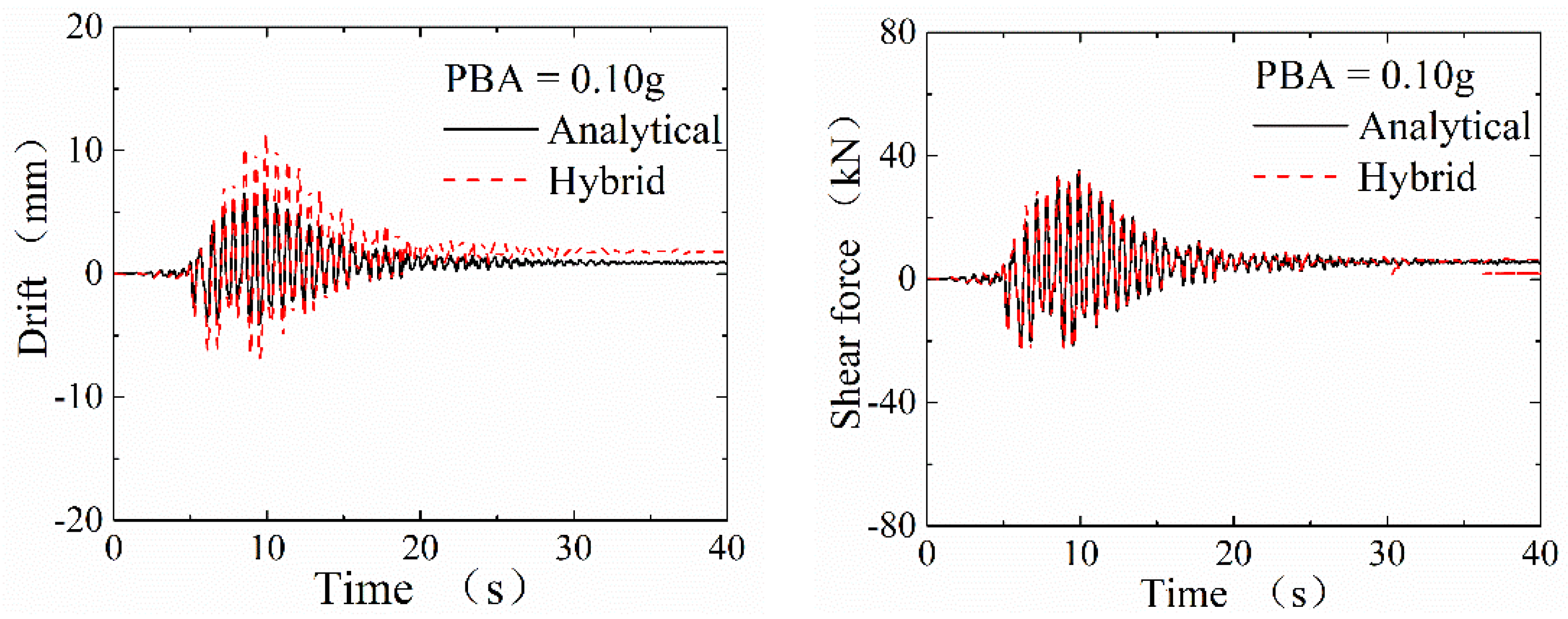

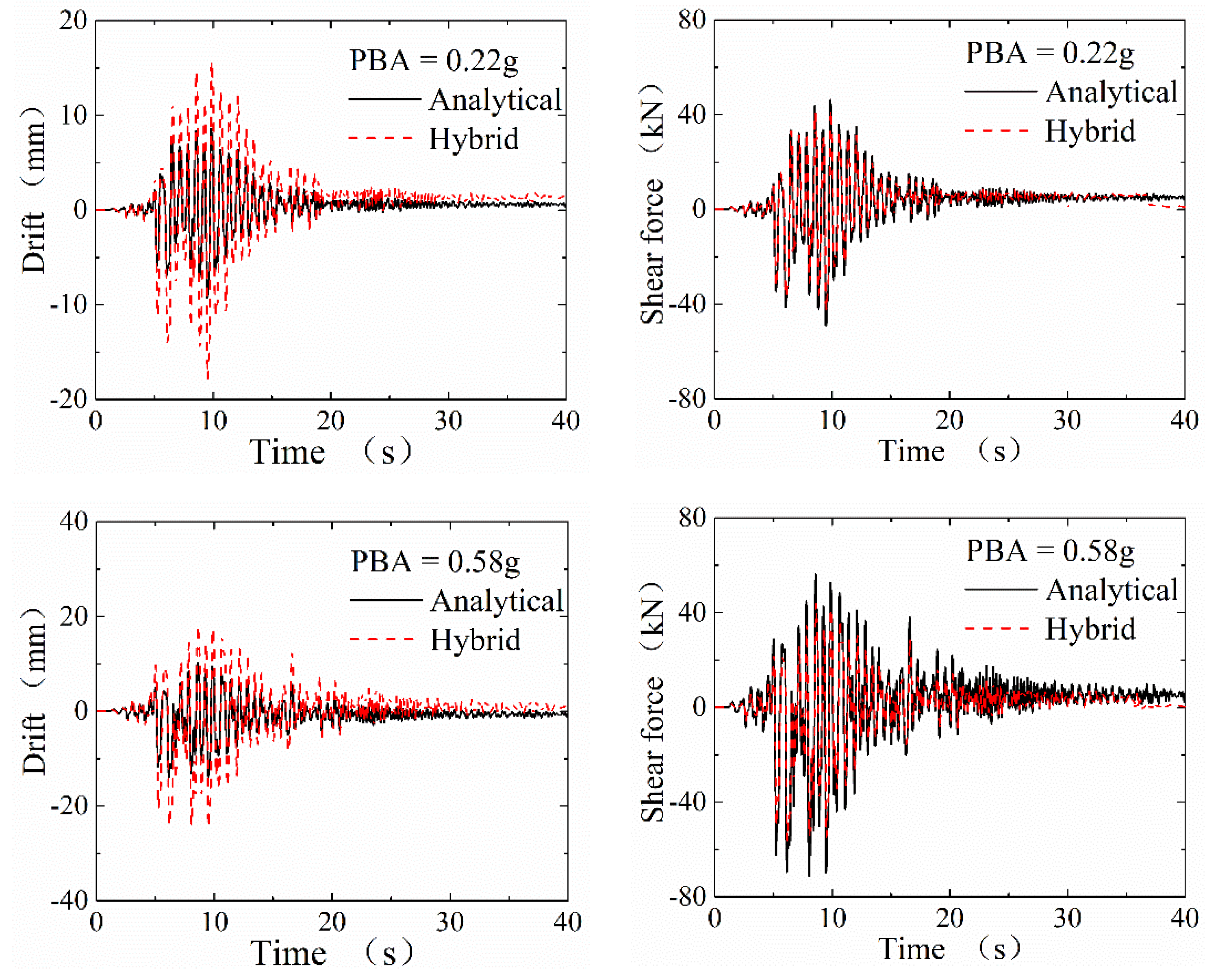

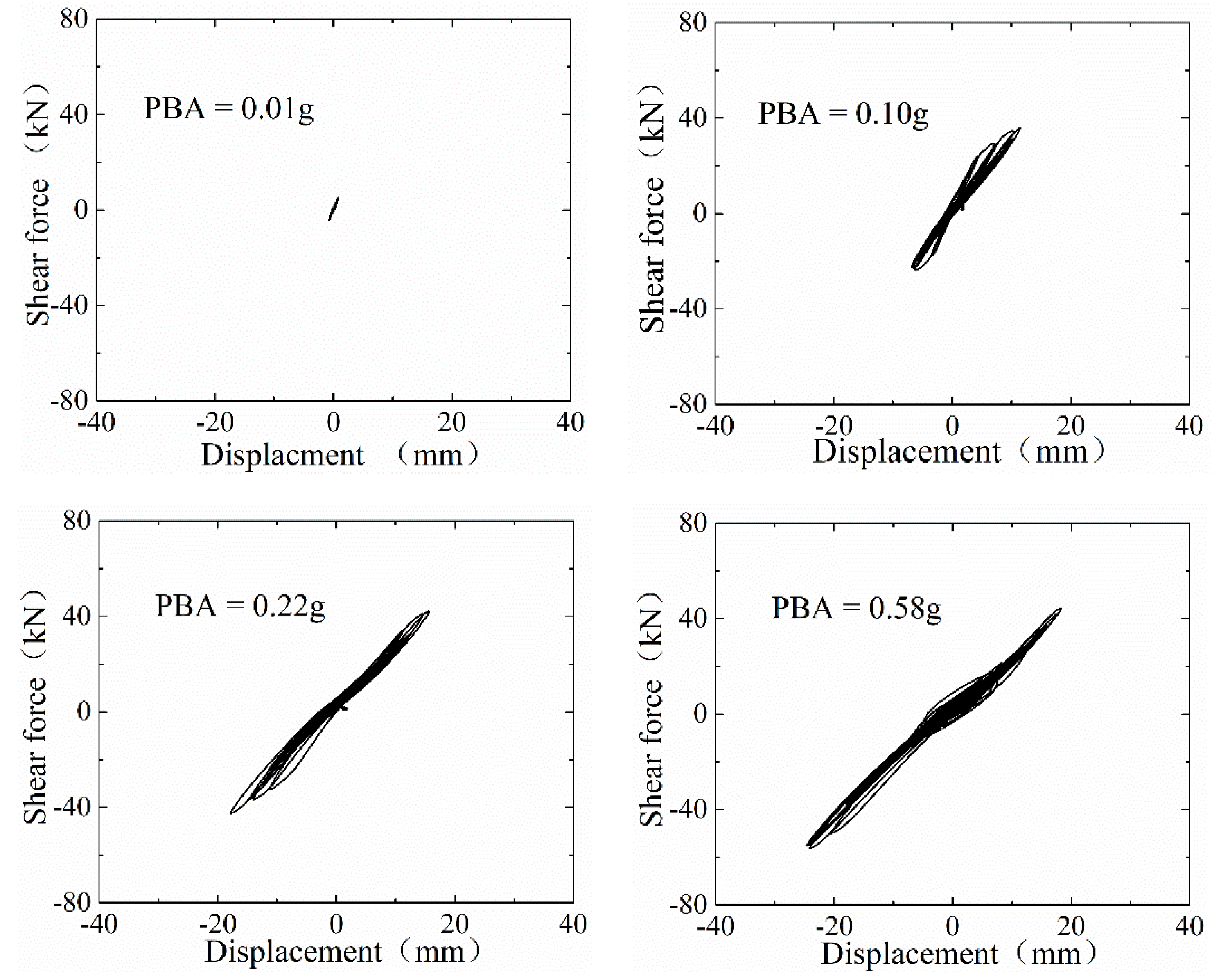

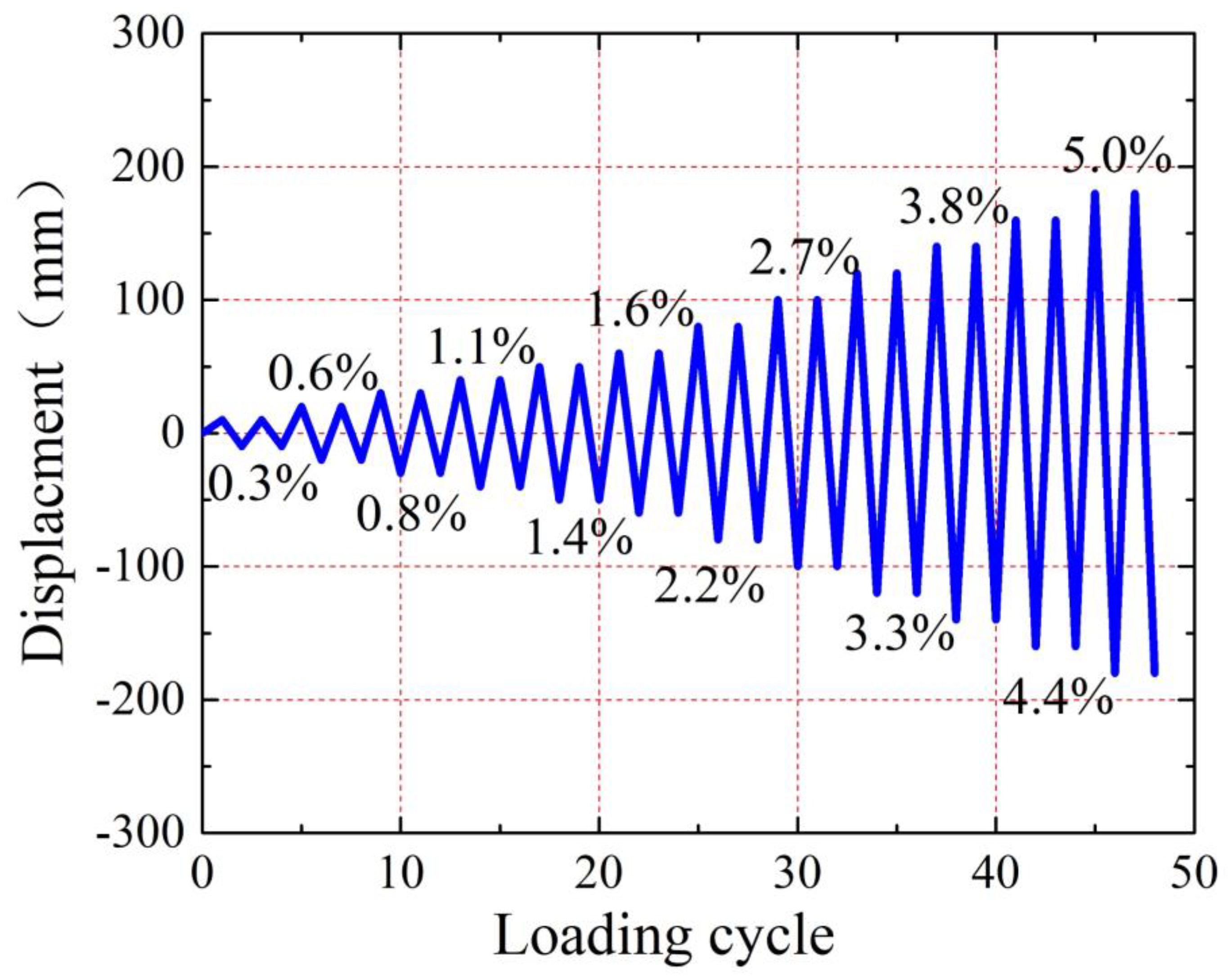

17] utilized a shaking table and an actuator to analyze the soil structure interaction issue with the hybrid simulation test method. The soil domain was tested by the shaking table, and the effects of structure-foundation interactions were realized by the actuator. Based on the previous research, the critical part of the model, such as the central column of the subway station, could be adopted as the physical substructure, while the remaining parts of the station and the soil domain could be taken as the numerical substructure. In this paper, an RC (reinforced concrete) column specimen is selected to study the seismic performance of the central column of a typical station. The pressure-dependent multi-yield-surface J2 plasticity material model is applied to model the deposit. The hybrid simulation system is composed of OpenSees, OpenFresco, and the MTS loading system. The Kobe excitation (peak ground acceleration = 0.01 g, 0.1g, 0.22 g, 0.58 g) is applied in the hybrid simulation process, then the quasi-static test is conducted after the hybrid simulation process. The shear forces and drift responses of the central column are analyzed further to illustrate the characteristics of the central column after the earthquake excitation.

2. Substructure Hybrid Simulation

Hybrid simulation is one kind of experimental method that consists both of physical testing and numerical modelling. The concept originated from the PsD (pseudo-dynamic) test method. In the PsD test method, the mass and damping of the model are numerically calculated while the stiffness is obtained physically from the test specimen. In this paper, the substructure pseudo dynamic test method is adopted to evaluate the seismic performance of a typical station. The concept of the substructure pseudo dynamic test allows the critical part of the structure (typically with a highly nonlinear response) to be physically tested and the rest of the structure to be simultaneously numerically modeled [

18]. The dynamic equation of motion can be written as follows.

where

is the mass matrix,

is the damping matrix,

is the nodal acceleration vector,

is the nodal velocity vector,

is the restoring force vector for the numerical substructure,

is the restoring force vector for the experimental substructure, and

is the external load vector. During the analysis process,

is obtained by calculation, whilst

is derived from the test results. At each integration step, the displacement is calculated numerically and sent to the experimental substructure. Equation (1) is solved for the displacement

at the interface between the experimental substructure and numerical substructure. The restoring forces

are then fed back to the numerical substructure where the displacement is calculated for the next integration step. Such a procedure would be repeated until the end of the test.

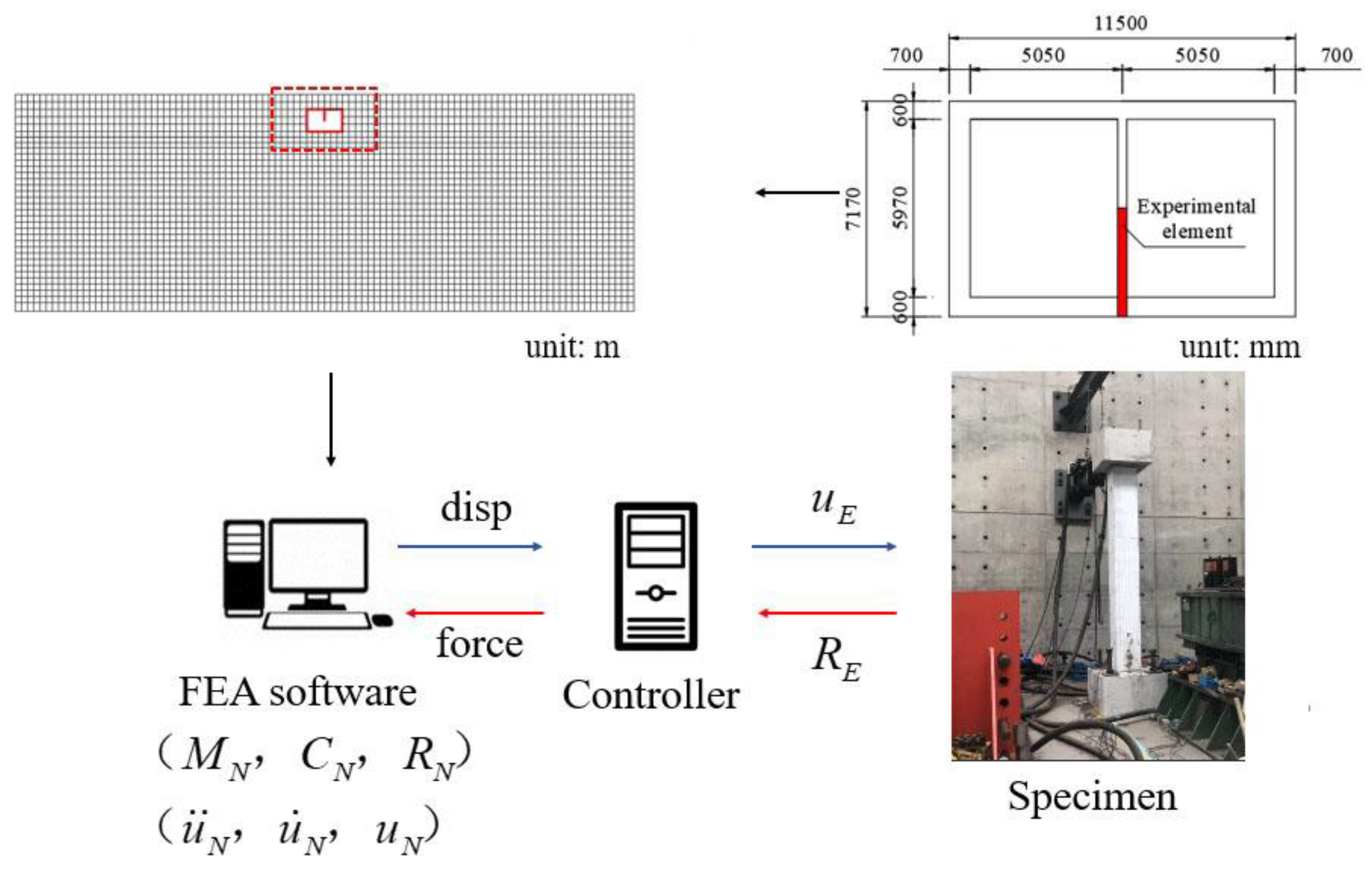

OpenFresco is the middleware that allows the communication between the finite element software (OpenSees) and the experimental hardware (MTS actuator(s)). Displacement and force signals are transmitted and transformed on the OpenFresco platform. OpenFresco builds a bridge between the numerical model and the experimental specimen to fulfill the hybrid simulation process. OpenFresco is used to define the stiffness of the physical substructure, and in this way, the experimental substructure can be regarded as a part of the numerical model. The stiffness matrix would be updated based on the feedback force. The equation of motion could be solved with the updated stiffness matrix for the next integration step.

3. Numerical Substructure

3.1. Soil Modeling

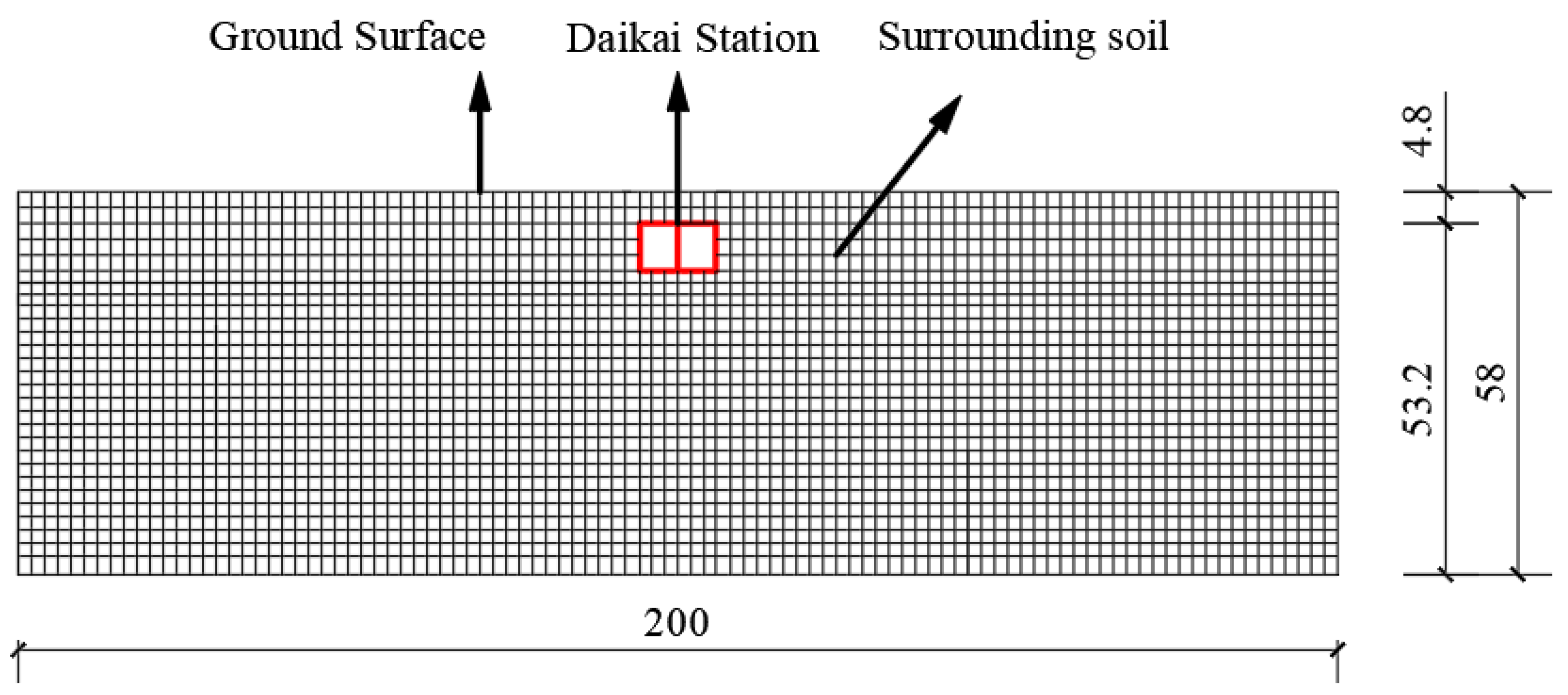

The FE model was established by the object-oriented and open source software OpenSees, with a width of 200 m (11.7 times of structural width) and a height of 58 m, as shown in

Figure 1. The thickness of plane-strain model was 3.5 m because the column spacing was 3.5 m [

19]. The central column was located at the center position of the model along the out-of-plane direction. The ground surface was set to be free. The fixed boundary was set at the bottom of the FEA model. The boundaries at the lateral sides of the model were set as the equal displacement boundary in order to reduce the impact of seismic wave reflection. All boundaries were supposed to be undrained.

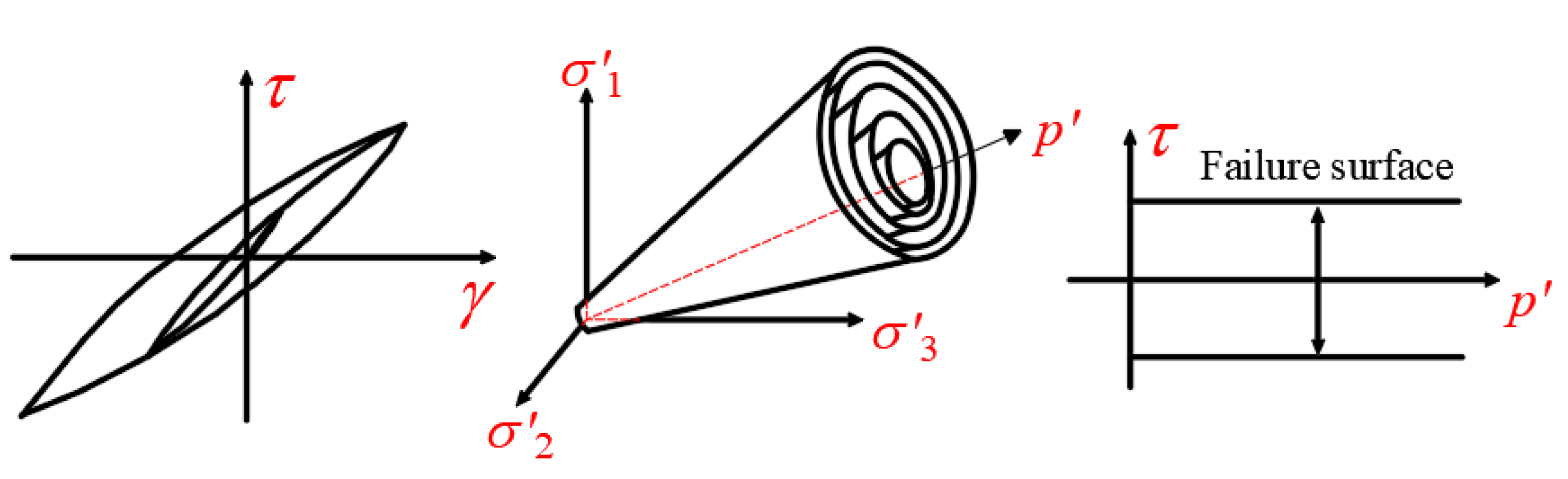

The soil was modeled with the pressure-dependent multi-yield-surface J2 plasticity material model [

20]. In the multi-yield-surface clay model, it was postulated that the shear behavior was dependent on the soil confining pressure. In this constitutive model, a set of von Mises yield surfaces with different sizes formed a hardening zone, as shown in

Figure 2. The outermost surface defined the shear strength (or failure) envelope. Nonlinear kinematic hardening and associative flow rules were employed to reproduce the Masing-type hysteretic behavior. The soil layers and parameters of the site are listed in

Table 1.

The quad elements were applied to simulate the deposit, and such quad elements were four-node plane strain elements. The size of the soil elements should be less than one-eighth of the wavelength corresponding to the maximum frequency of the input seismic wave [

21]. The Rayleigh damping model was applied in the analysis procedure. To be specific, the target damping ratio was set as 0.02. The stiffness parameter and the mass parameter were determined by Equation (2). The frequencies of first order and third order were derived to determine the damping coefficients.

where

is the mass parameter,

is the stiffness parameter,

is the damping ratio,

is the angular frequency of the first mode, and

is the angular frequency of the third mode.

3.2. Structure Modeling

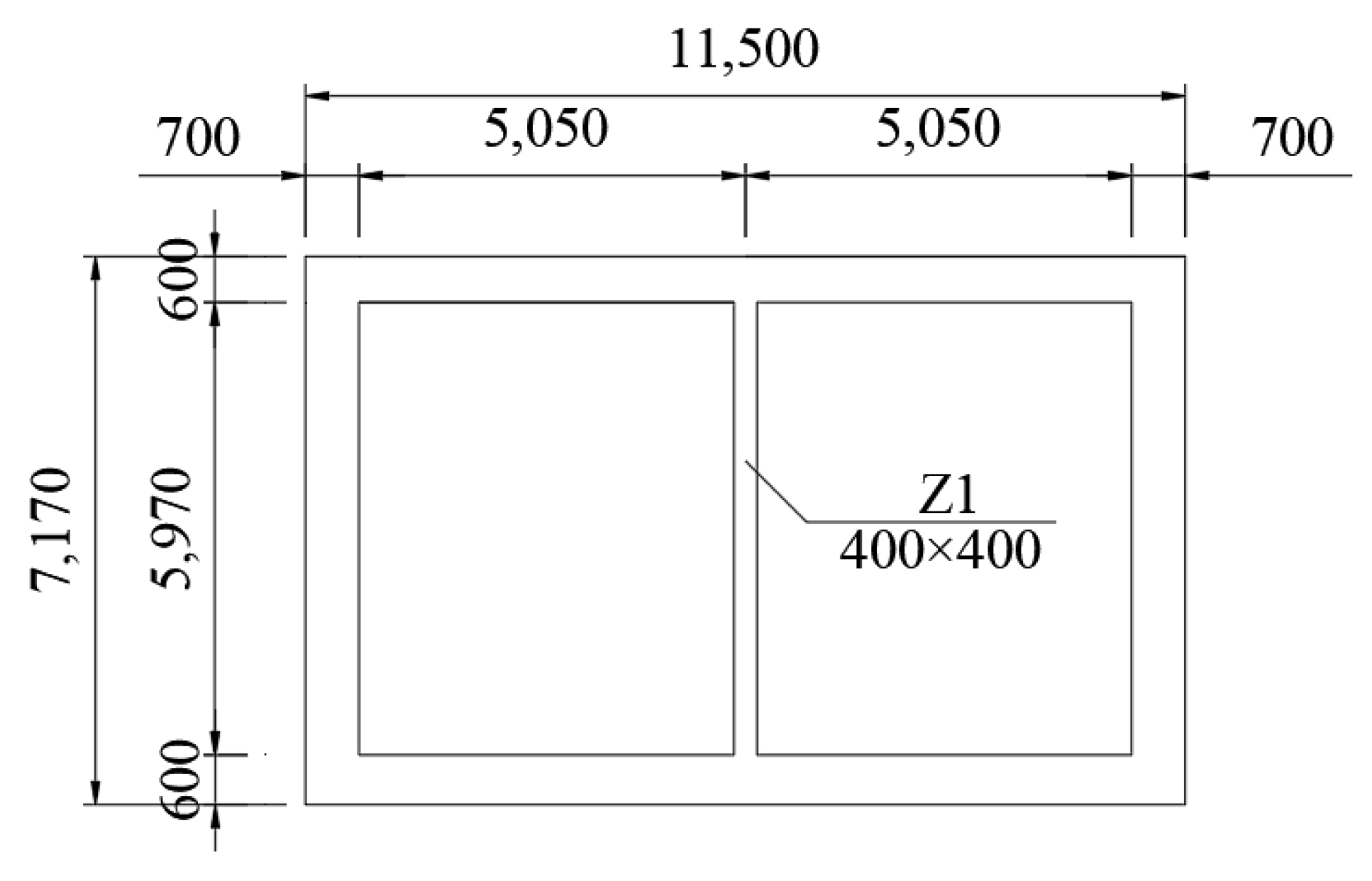

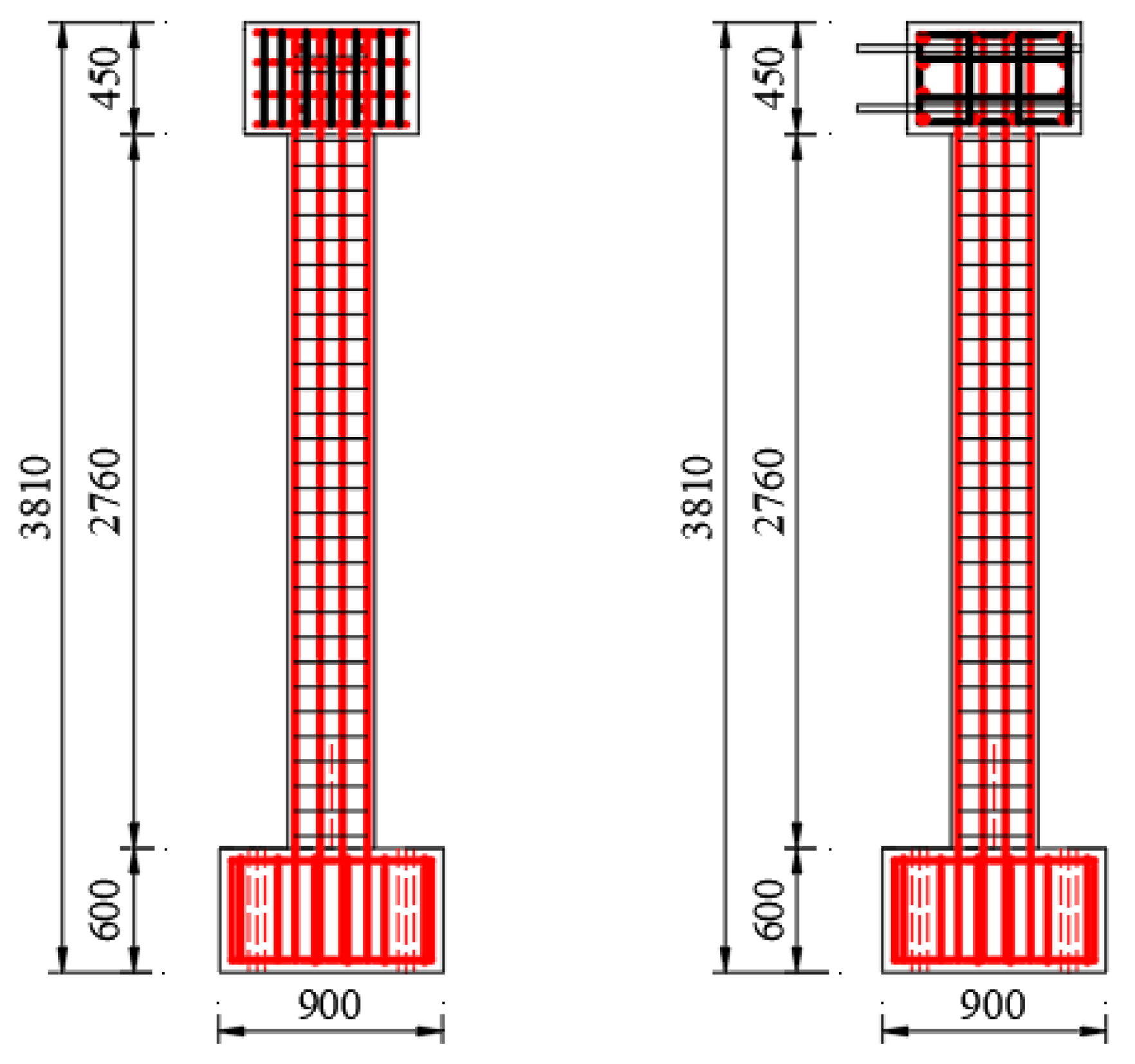

The finite element model of the stratum-station is shown in

Figure 1. The subway station was a one-story two-bay RC frame with section dimensions given in

Figure 3. The cross-section of the subway station measured 11.5 m × 7.17 m. The buried depth of the station structure was 4.8 m, and the column spacing was 3.5 m. The thickness of the station roof was 0.8 m, and the thickness of the bottom plate was 0.85 m, while the thickness of the sidewalls was 0.7 m. The cross-section of the center column measured 0.4 m × 0.4 m. The structure elements and the surrounding soil elements were fixed together, and the sliding effect of soil and structure was neglected in the analysis.

The subway station was modeled with distributed plasticity Euler–Bernoulli beam elements, which had four Gauss–Legendre integration points. The displacement based element was adopted to simulate the slabs, lateral walls, and central column. The element assumed the displacement field derived the formulation through the virtual displacement principle. For a given element displacement vector

, the section deformation vector

at location

is approximated as below [

22],

where

is the displacement interpolation function, and the Hermite polynomials can be used here. Then, the section force vector

can be obtained through the fiber section model,

where

is the section stiffness matrix. According to the virtual displacement principle, the element resisting force

and stiffness

are expressed by Equation (5),

where the integral can be computed through Gauss quadrature.

The Concrete 01 constitutive model as used to construct a uniaxial Kent–Scott–Park concrete material object with degraded linear unloading/reloading stiffness. In addition, no tensile strength was considered for such concrete material. The Concrete 01 model was utilized for the concrete, whilst the Steel 02 model was utilized for the reinforcements of the central column specimen. The whole structure had a density of 25 kN/m3, a Poisson’s ratio of 0.2, and a Young’s modulus of 32,500 MPa. The main parameters of the Concrete 01 model were the peak compressive yielding stress 36.4 MPa and peak strain 0.002, while the extreme compressive yielding stress 7.3 MPa and peak strain 0.004. The longitudinal reinforcements in the central column had a density of 7800 kN/m3, a Poisson’s ratio of 0.3, a Young’s modulus of 200 GPa, and a yielding stress of 431.5 MPa. The hardening ratio was set to be 0.01.

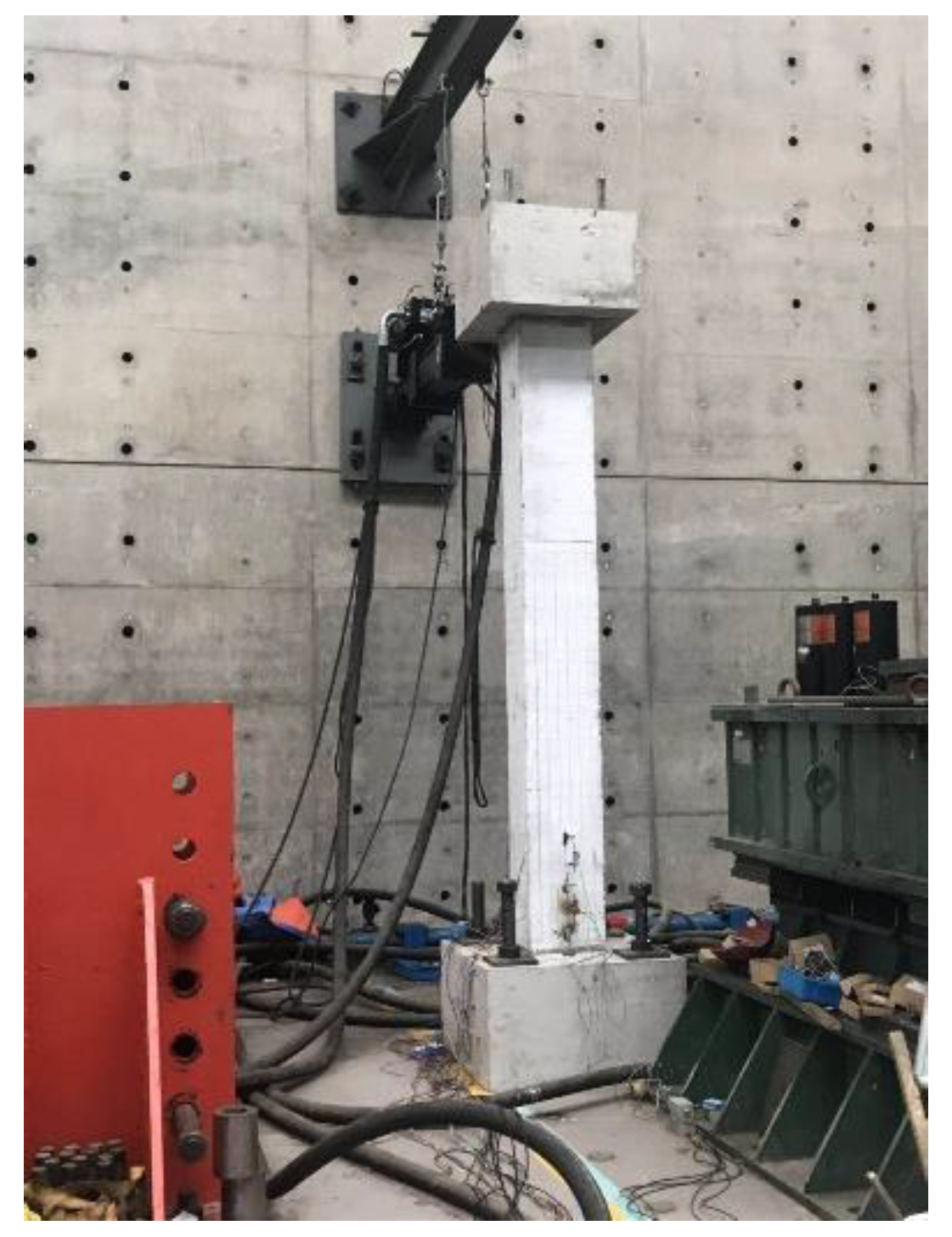

During the hybrid simulation process, the appropriate experimental substructure should be adopted to satisfy the boundary conditions.

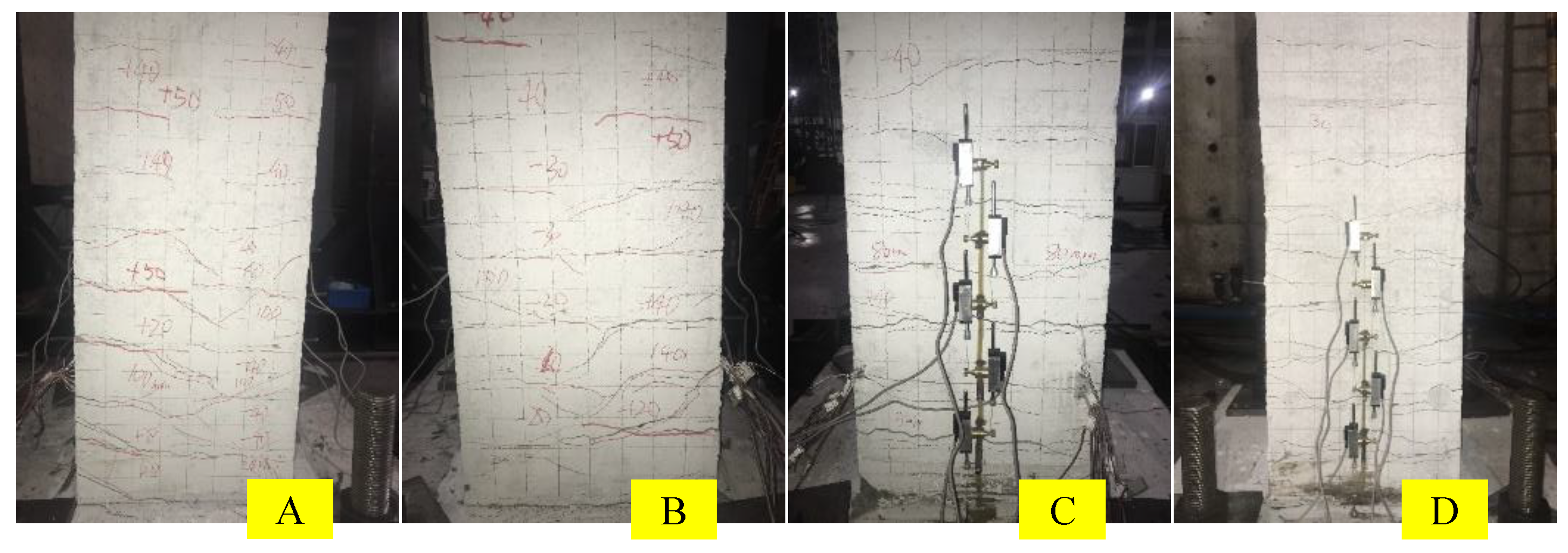

Figure 4 shows that the experimental specimen was selected based on the inflection point of the central column. It was assumed that the inflection point of the central column was located in the center. Therefore, the half bottom central column was adopted as the experimental substructure with a height of 3.56 m.

Two analysis steps should be involved. Firstly, geostatic analysis procedure should be carried out to balance the gravity load. Then, the dynamic analysis procedure should be carried out with the designated accelerations. Actually, only the dynamic process was conducted in this study because thrust was not applied on the top of the column specimen.

The end point of the Euler–Bernoulli beam element shared three degrees of freedom, corresponding to the axial direction, tangential direction, and rotational direction. Therefore, axial force, shear force, and bending moment should be taken into consideration in the traditional substructure hybrid simulation. In the hypothetical model, the top point of the column was the inflection point, and the position of inflection point did not change in the hybrid simulation test. Based on the assumptions mentioned above, shear force could be considered. However, both bending moment and thrust were neglected in the test.

3.3. Input Motions

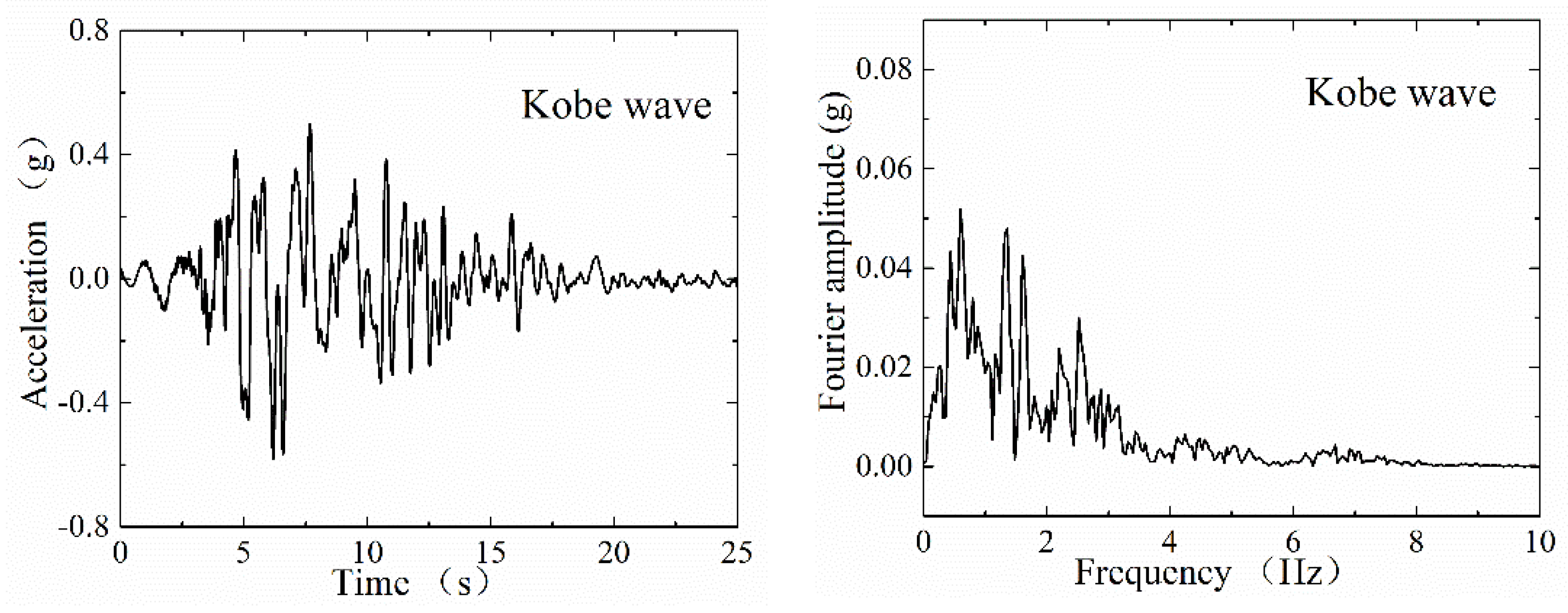

The Kobe wave, which was recorded at Port island, was adopted as the input earthquake motion.

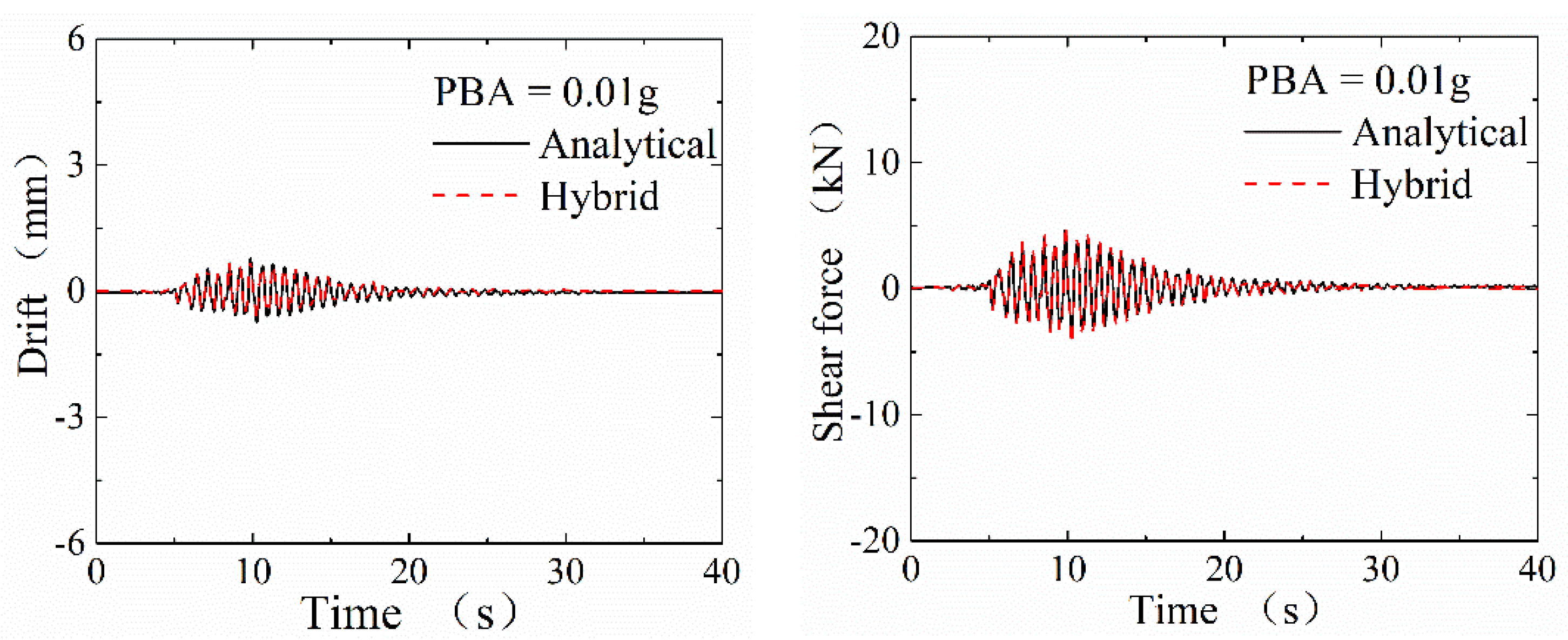

Figure 5 shows the seismic acceleration time histories and spectra. The frequency content of the Kobe wave was mainly below 10 Hz, and the dominant frequency ranged from 0.60 to 1.36 Hz based on the results of Fourier transformation. The PBA (peak base acceleration) of the Kobe wave was scaled to 0.01 g, 0.10 g, 0.22 g, and 0.58 g in this paper. The accelerations were applied on the bedrock face, which was 58 m away from the ground surface level.

The 2D numerical model had a width of 200 m and a depth of 58 m. The width of the site was large enough that the influence of the reflected wave near the lateral boundary could be ignored. The lateral boundary was set as an equal-displacement and impermeable boundary. Vertically polarized shear waves (SV seismic waves) could be appropriately considered by setting the equal-displacement boundary.

7. Conclusions

Although the hybrid simulation technique with RC specimens could be applied to reproduce the seismic behavior of the typical subway station, there were still some shortcomings that need to be overcome. The first shortcoming was the application of thrust. As thrust was not applied in the test, gravity analysis was not performed. Such a loading condition did not coincide with the real condition. The second shortcoming was the assumption of the inflection point. The bottom half column was adopted as the physical substructure on the condition that the position of the inflection point would not change during the test. Limited to the laboratory conditions, such an assumption was made to meet the requirements of the hybrid test. The third shortcoming was the constitutive model of the deposit. The parameters of the soil constitutive model should be calibrated with the corresponding test results. However, such work was not promoted in this paper. Hence, the aforementioned three factors could be used as predictors to further improve the accuracy of the hybrid simulation and estimate the seismic behavior of the typical station.

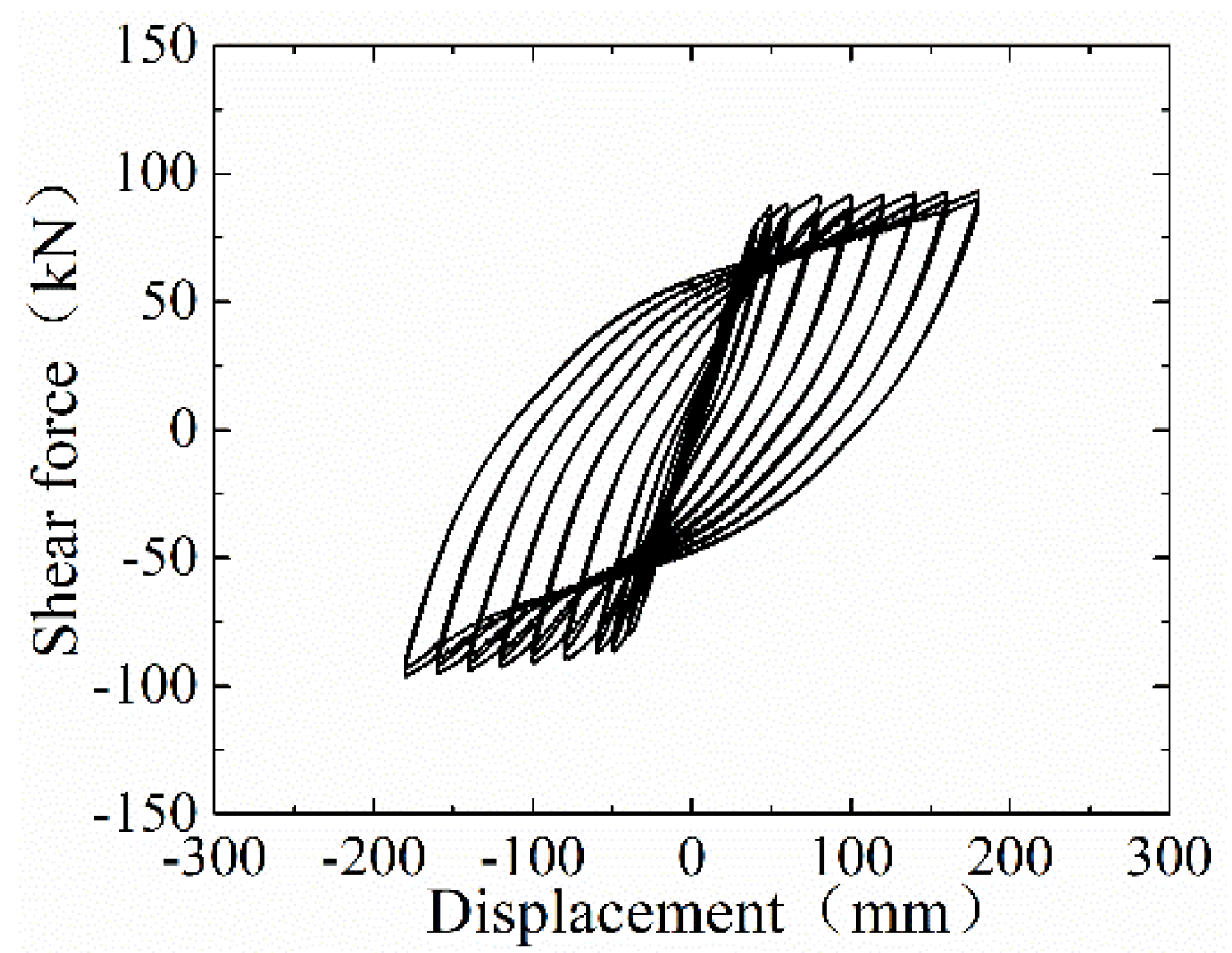

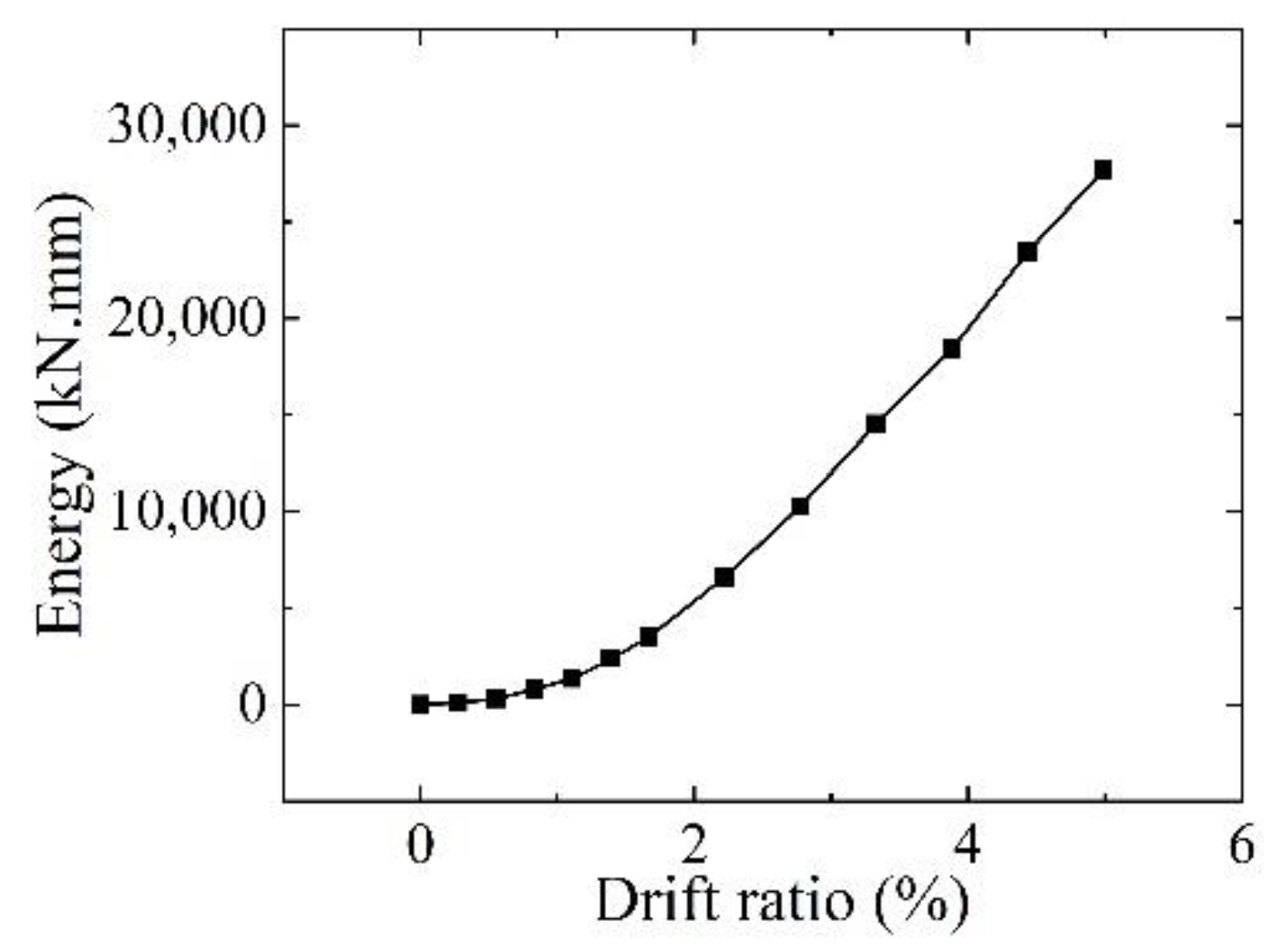

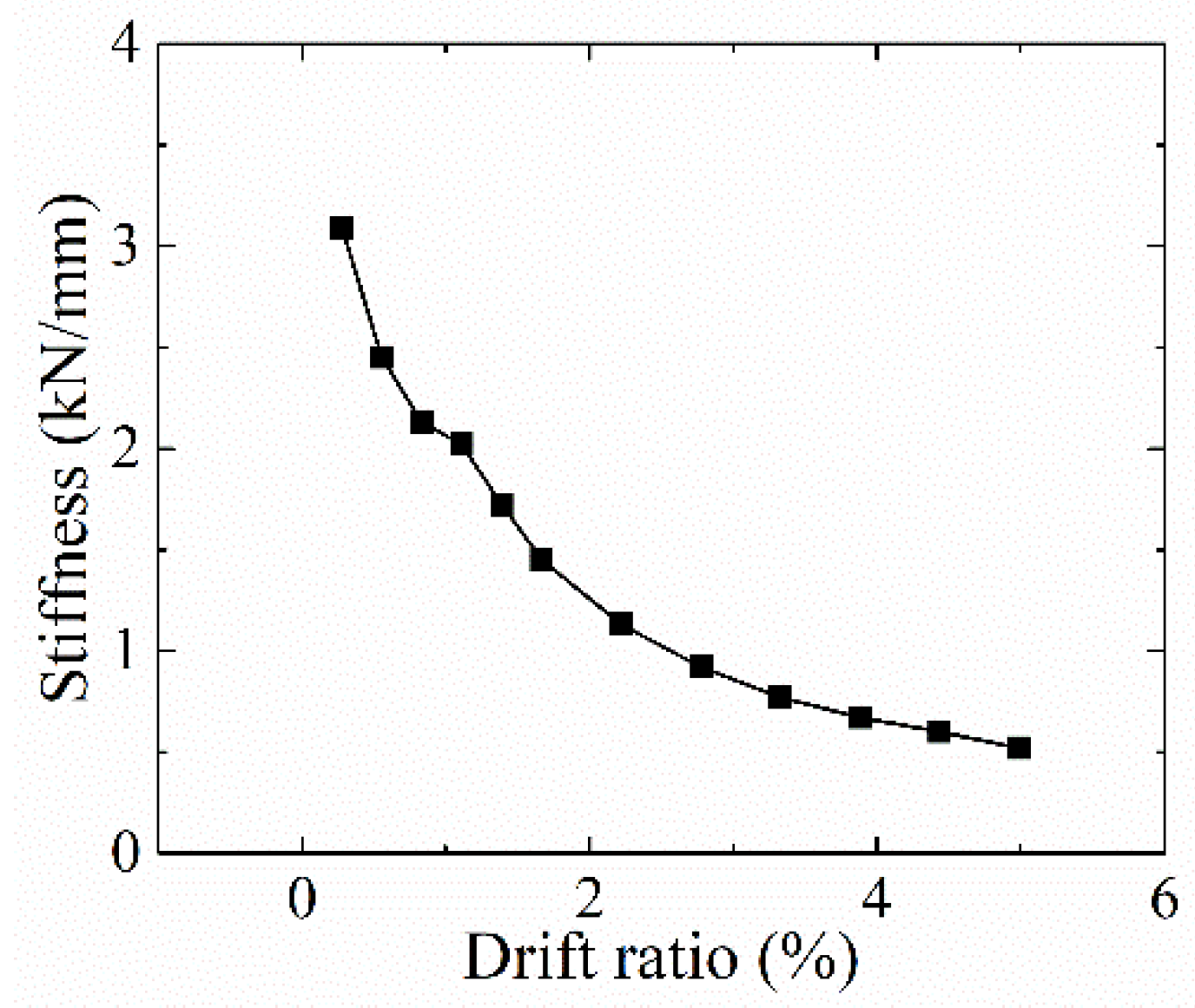

The hybrid simulation technique was shown to be a feasible solution of conducting large-scale or full-scale seismic tests of underground structures. In this paper, a series of tests, composed of hybrid tests and quasi-static tests, were performed on the central column of the typical subway station. The physical substructure was an RC column, while the numerical substructure was the rest of the model. After the definition of the experimental beam-column elements in OpenFresco, the lateral stiffness of the central column was represented. With the proposed evaluation index, the test results showed a good agreement with the numerical results in the elastic stage. Therefore, hybrid simulation was proven to be a suitable way to assess the seismic performance of a typical subway station. It should be noted that in the hybrid simulation cases of 0.22 g and 0.58 g, the ultimate shear forces were smaller than the corresponding analytical results whilst the peak drifts were larger. The stiffness of the central column decreased, and the central column gradually entered its plastic state in the aforementioned hybrid simulation cases.