1. Introduction

In the process of iron and steel smelting, as one of the by-products, steel slag emission is about 15%–20% of the total crude steel production and is increasing rapidly along with the increase of steel production in the world. Taking China as an example, according to the China economic network, crude steel output in 2018 was 928 million tons, and the steel slag output was about 150 million tons. As a kind of solid waste, steel slag stacking not only takes up land, but also brings a series of ecological environmental pollution problems, and also causes the waste of precious resources to a certain extent. With the increase in its total amount, it has greatly hindered the sustainable development of the environment.

Self-compacting concrete (SCC) is one of the key research directions of the high-performance concrete industry because it flows under its own weight, can completely fill the formwork without mechanical compaction, and has the advantages of fast construction, easy pouring, high efficiency, etc. The research and application of SCC have attracted attention all over the world [

1,

2,

3]. The concept of SCC and related scientific tests were first proposed and tested in Tokyo University, Japan, by Okamura et al. [

4,

5], and they also started to analyze and study the design method of SCC mix proportion through conducting a lot of experimental research. This mix proportion design method of SCC is called the ‘Japanese prototype method’ or ‘step-by-step method’. In this method, the target performance of SCC is determined, firstly, by the mix proportion of the mixture being initially designed, secondly after selecting the raw materials required in construction, and then the mix proportion is adjusted to meet the performance and construction requirements according to the related experiment. Petersson et al. [

6,

7] proposed the liquid criterion theory and blocking criterion theory, based on the interaction between aggregate particle system and cement paste in SCC, to design the mix proportion of SCC. Su et al. [

8] proposed the SCC mix proportion design method based on the compactness between aggregates by introducing an aggregate compaction factor. Moreover, other SCC design methods have been proposed including the fixed aggregate content method [

9], the computer-aided design method [

10,

11], and the mathematical statistics factor method [

12], etc.

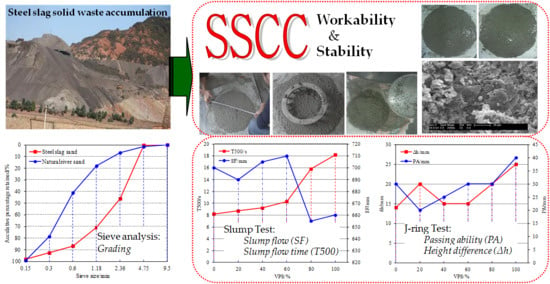

It is difficult to use a single index or test method to assess the workability of fresh SCC mixture comprehensively. Generally, the workability of SCC mainly comprises filling ability, passing ability, and segregation resistance. The segregation resistance is often considered as the index of stability of SCC, which also can be classified as static stability and dynamic stability. At present, the evaluation and test methods of the workability of SCC mainly includes a slump flow (SF) test incorporating slump flow time (T500) measurements [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26], a V-funnel test [

14,

15,

17,

19,

20,

21,

22,

24,

26], a L-box test [

13,

15,

19,

21,

23,

24,

26], a U-shape meter test [

14,

17,

22], and a J-ring test [

15,

16,

17,

18,

19,

24,

25], etc. Stability tests conducted for SCC mixture involved a sieve analysis test [

15,

17,

20,

25], flow table test [

27], segregation probe test [

20], and static settlement column test [

20,

23], etc. Zhu et al. [

13] studied the influence of manufactured sand and lightweight sand on the workability of fresh self-compacting lightweight concrete (SCLC) by the slump flow test incorporating T500 measurement and the L-box test. The experimental results indicated that higher manufactured sand and lightweight sand ratios can reduce the flowing ability of SCC. Rios et al. [

27] used a flow table test to investigate the self-compacting properties and the consistency of fresh SCC using air-cooled blast furnace slag to replace coarse and fine natural aggregate. The results show that with the increase of slag content, the self-compacting performance of concrete gradually reduces, and when the replacement rate is low, the self-compacting performance of concrete still remains. Valizadeh et al. [

18] used magnetite aggregate to replace the natural coarse aggregate of SCC and general concrete with the volume ratio of 50%, 75% and 100% in the study of heavyweight SCC. The slump test and J-ring test results show that the workability of fresh concrete decreases gradually with the increase of the amount of magnetite aggregate. Khan et al. [

19] used the slump flow test, V-funnel test, L-box test and J-ring test to study and analyze the workability of SCC with ethylene vinyl acetate (EVA) and ladle furnace slag (LFS) instead of cement and natural sand. The results show that adding EVA increases the workability of SCC, while LFS decreases that.

In recent years, quite a few researchers have begun to explore the application of steel slag in the preparation of SCC [

20,

21,

22,

23,

24,

25,

26]. Sheen et al. [

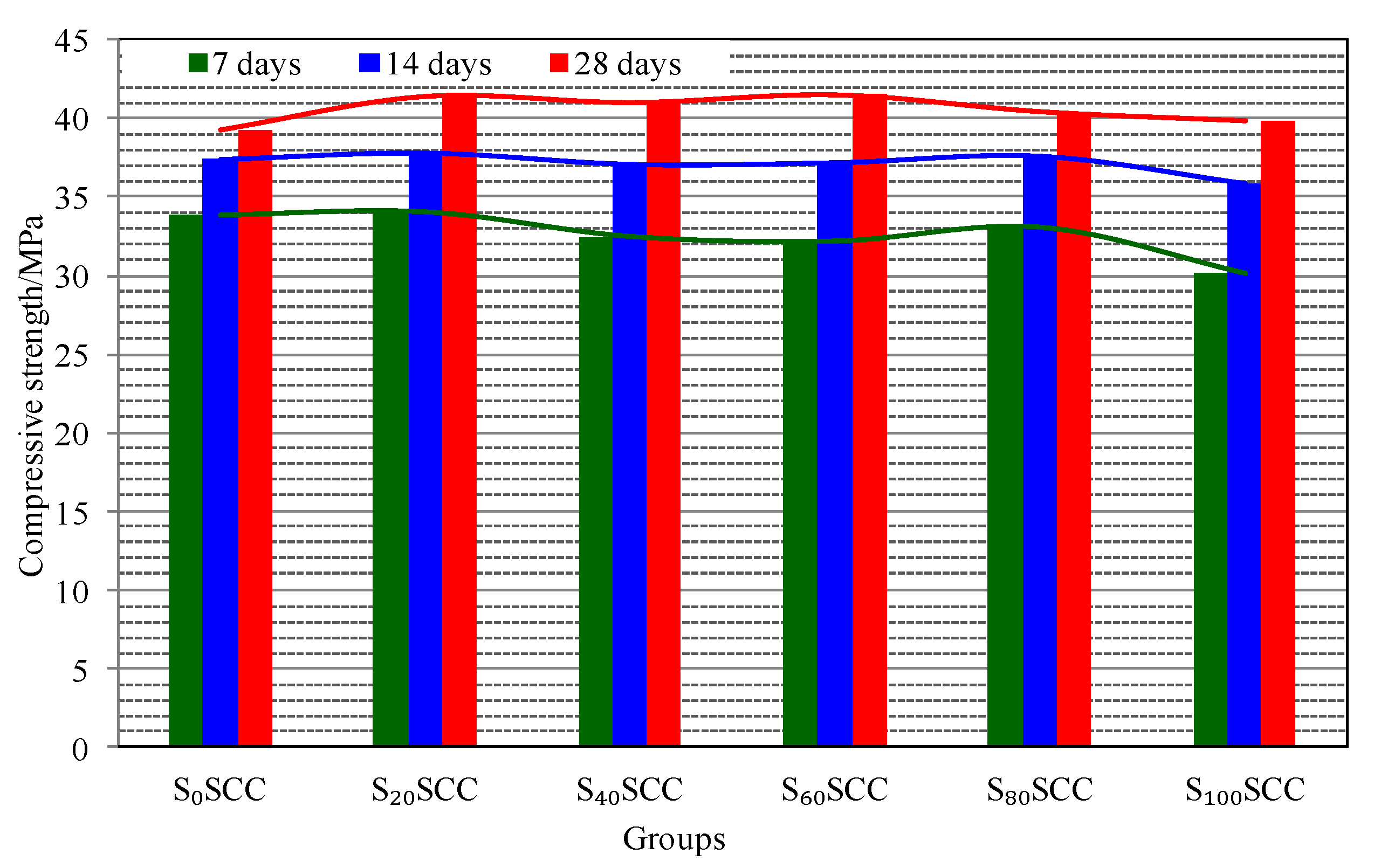

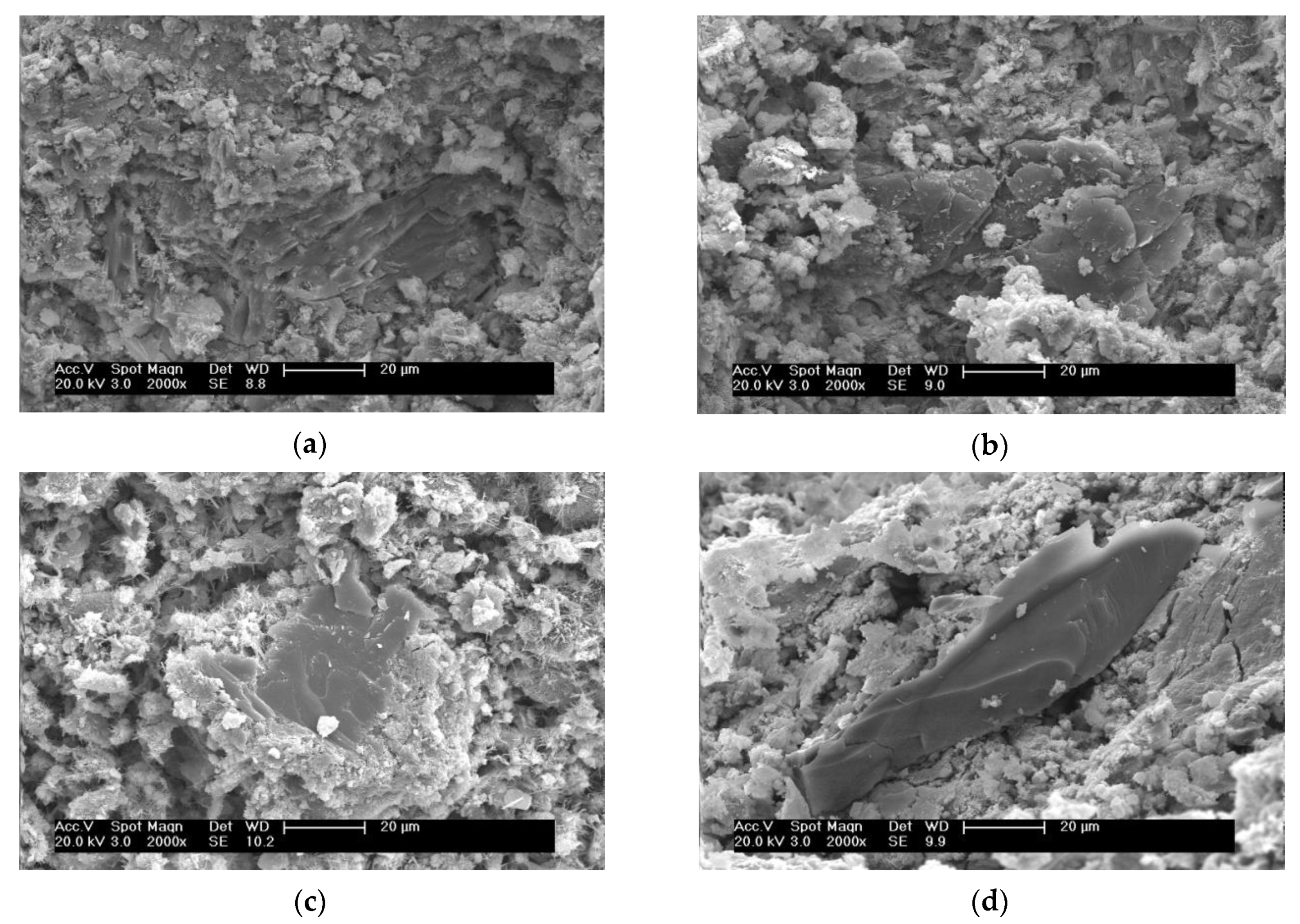

20] developed SCC containing stainless steel oxidizing slag (SSOS, partial substitution of fine and coarse aggregate) and stainless steel reducing slag (SSRS, partial substitution of cement). Results showed that the stainless steel slag-based SCC can accelerate the hardening process, the compressive strength of SCC prepared with SSOS replacement in full exhibits slightly better or at least similar results to that of the control while potentially volumetric instability. Santamaría et al. [

21,

23], investigated the mix design, in-fresh and hardened properties of SCC incorporating electric arc-furnace steelmaking slag as aggregate, and concluded that it is possible to prepare SCC using electric arcfurnace slag as coarse and fine aggregate, using appropriate doses and compatible chemical admixtures. Hisham [

22] investigated the effect of steel slag replacing natural aggregate on SCC, and the slump flow test, V-shaped funnel test, column segregation test, sieve analysis test, segregation probe test and U-shaped box test were used to comprehensively evaluate the influence. The results show that steel slag aggregate can be used in SCC, but the workability of SCC will be greatly affected when the substitution rate of steel slag is over 50%. Rehman [

24], investigated the combined influence of glass powder and granular steel slag on fresh and mechanical properties of SCC, and found that the workability of SCC decreases with the increase in granular steel slag content which may be attributed to the porous and rough texture of steel slag. Pan et al. [

25] investigated the effects of steel slag powder on the properties of SCC with recycled aggregates and found that steel slag powder improved the filling ability and passing ability of SCC, but adversely affected segregation resistance. Sosa et al. [

26] investigated the feasibility of high-performance SCC prepared with electric arc furnace slag (EAFS) aggregate and cupola slag powder based on the rheological and physical-mechanical experiments of SCC. The experimental results showed that it is possible to obtain a very homogeneous, symmetrical, and stable distributed mixture without segregation or concentration of coarse aggregates. EAFS reduces concrete slump and passing ability by 10%, reduced the flow rates more noticeably compared to reference mixes due to their high viscosity.

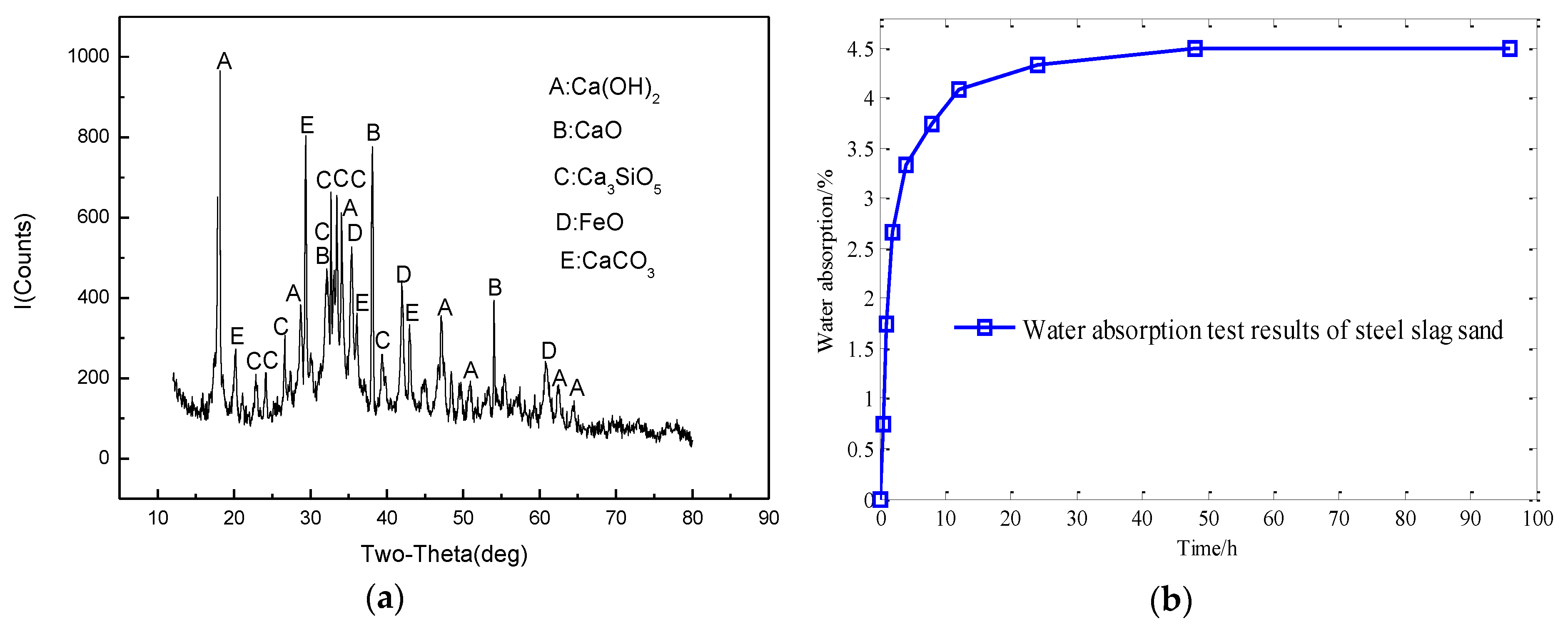

Use of industrial wastes as cement or aggregate replacement can play vital role in reducing the utilization of natural resources, besides decreasing land and air pollution [

24]. Although there are many works on steel slag use as aggregates or mineral admixture in concrete and its advantageous properties have been reported, the research on the utilization of steel slag in SCC preparation has only begun in recent years to some extent because the high water absorption of steel slag is unfavorable to the fluidity of the concrete mixture. Moreover, it is not enough to encourage the use of a steel slag in the construction industry without misgivings or concerns if the technical opinion is not supported by sufficient characterization and performance testing [

28]. Analyzing the aforementioned research on the use of steel slag in SCC, it found that the steel slag was mainly used to replaces the coarse aggregate [

22,

26] or both coarse and fine aggregate [

20,

21,

23]. Meanwhile, the substitution rate is relatively high, for instance, all coarse aggregate was replaced [

21,

22,

23,

26], the substitution rate is of 0%, 50%, 100% for both coarse and fine aggregates [

20]. The steel slag was also used as powder replacing the cement (fixed substitution rate of 30%) [

25], as a fine aggregate (substitution rate is 0, 40%, 60%, 80%) together with the glass powder [

24]. The research work that has been carried out mainly focuses on workability and mechanical properties of steel slag self-compaction concrete (SSCC). However, the expansion potential of steel slag has always been an important factor restricting its large-scale application in building materials [

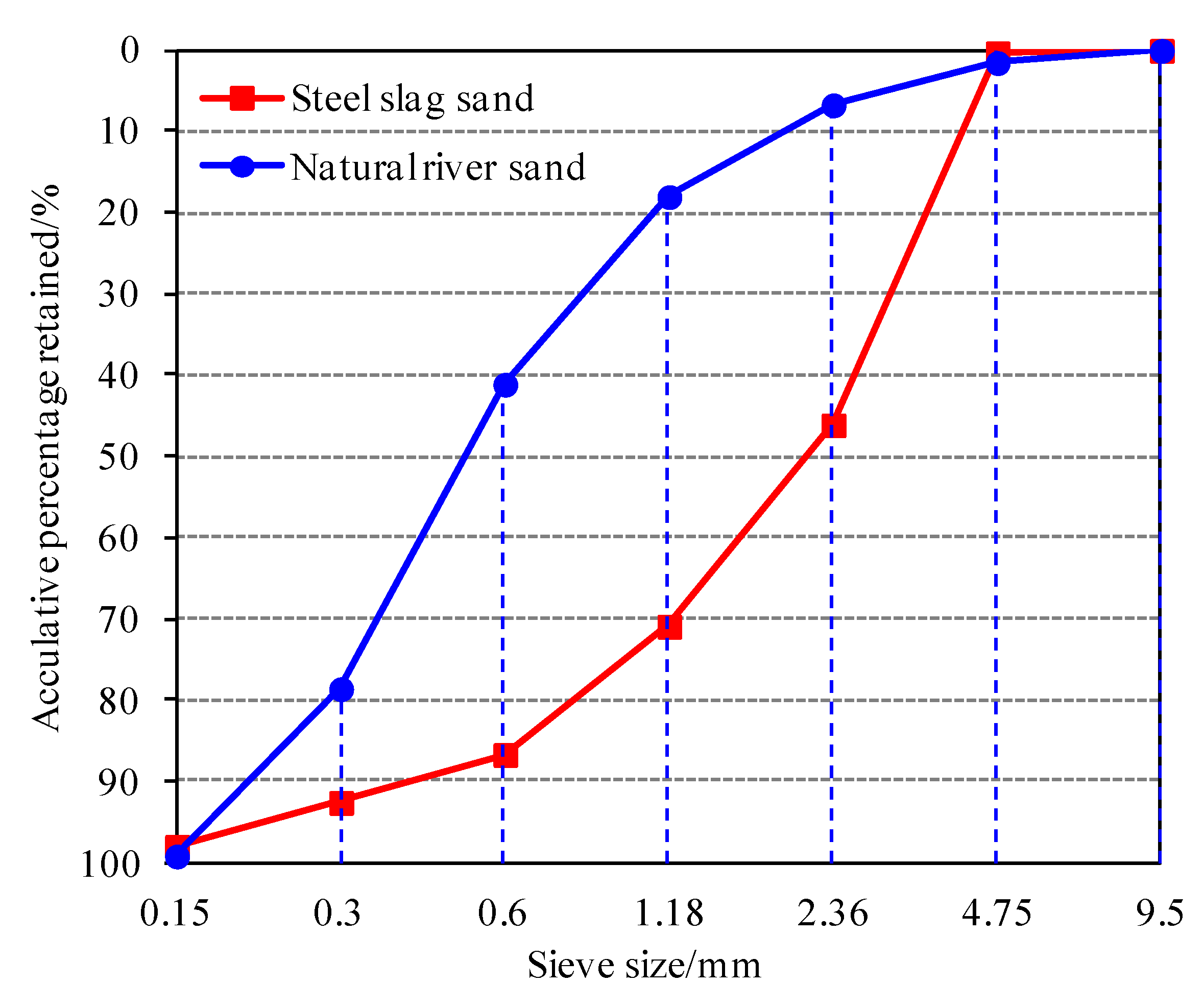

28], and it is easier to cause inhomogeneous expansion stress for large-size coarse aggregates.

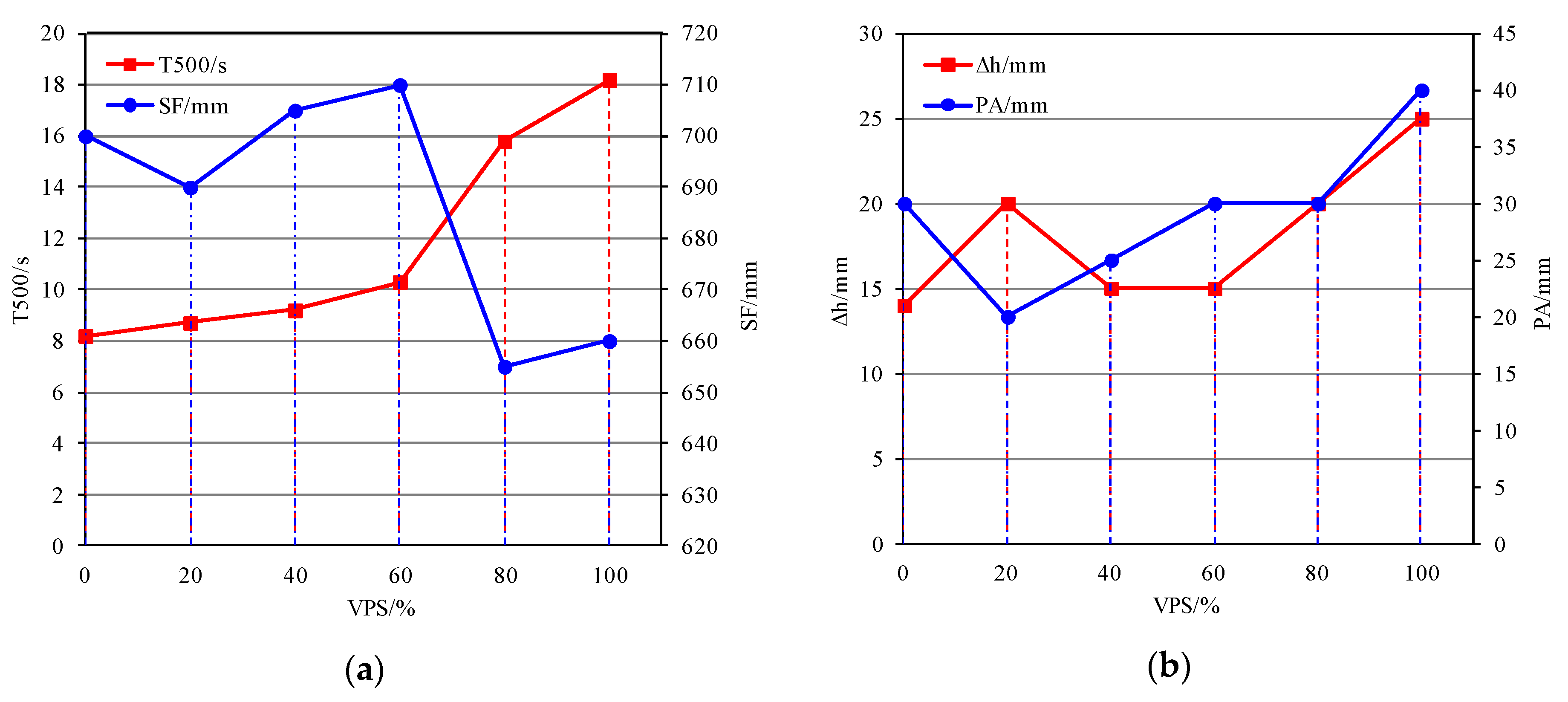

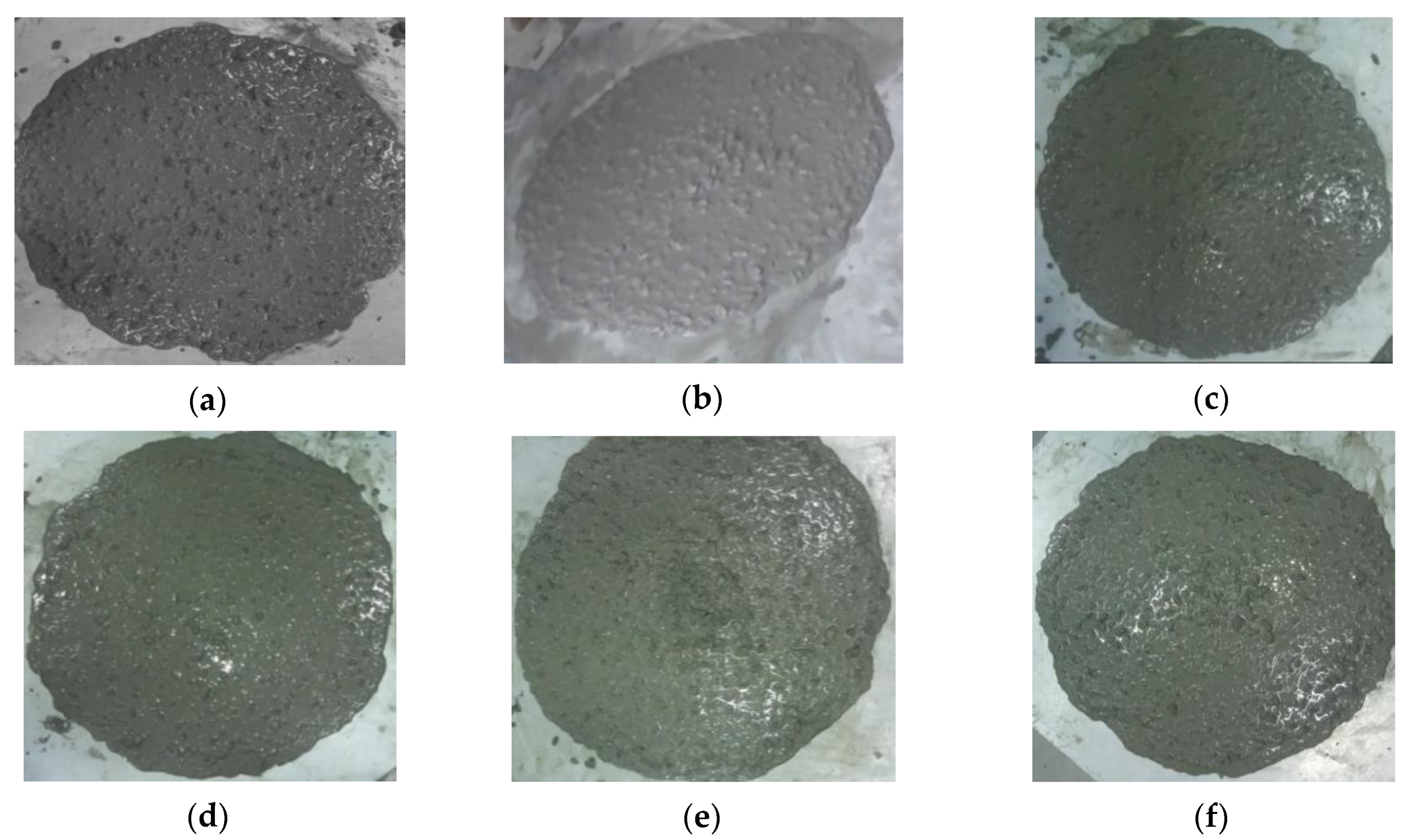

Therefore, this paper focuses on the use of steel slag as fine aggregate, and the aged steel slag used in incorporating fly ash in SSCC, which is of benefit to reduce the expansion effect of steel slag and inhomogeneous expansion stress. The present work is to investigate the filling ability, passing ability, dynamic stability and static stability of a fresh mixture of SSCC with steel slag as the fine aggregate, and is expected to systematically investigate SSCC workability to promote the wide application of steel slag in SCC for traditional material saving and sustainable development.