Optimisation of a Heat Source for Infrared Thermography Measurements: Comparison to Mehler Engineering + Service-Heater

Abstract

Featured Application

Abstract

1. Introduction

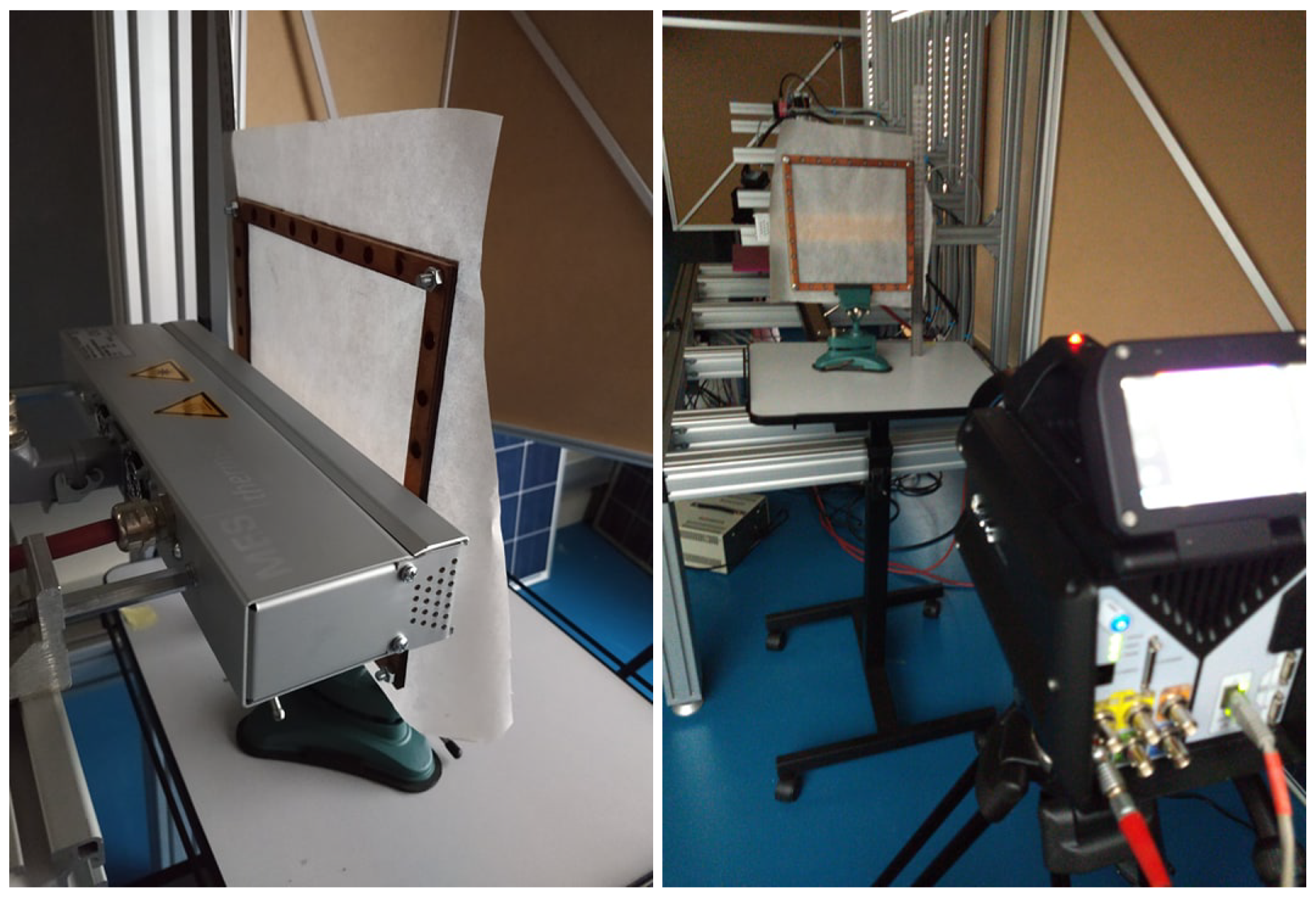

2. Methodology

2.1. Requirements

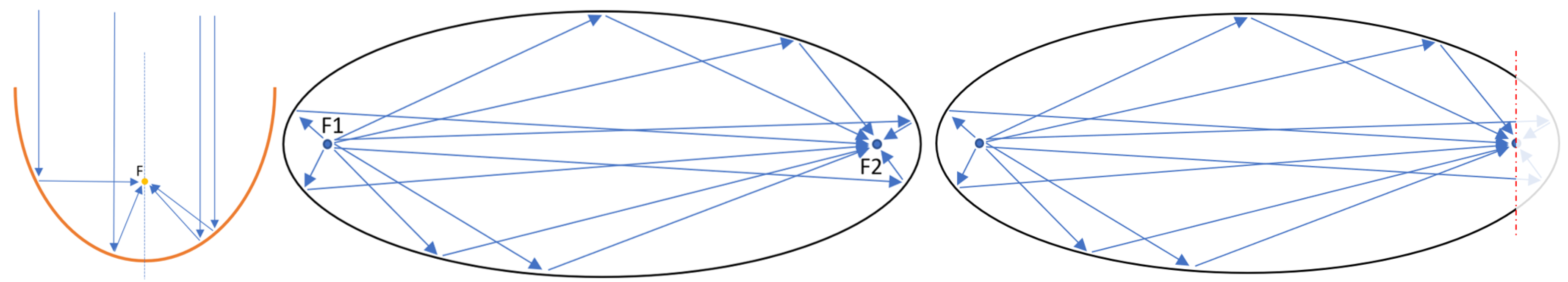

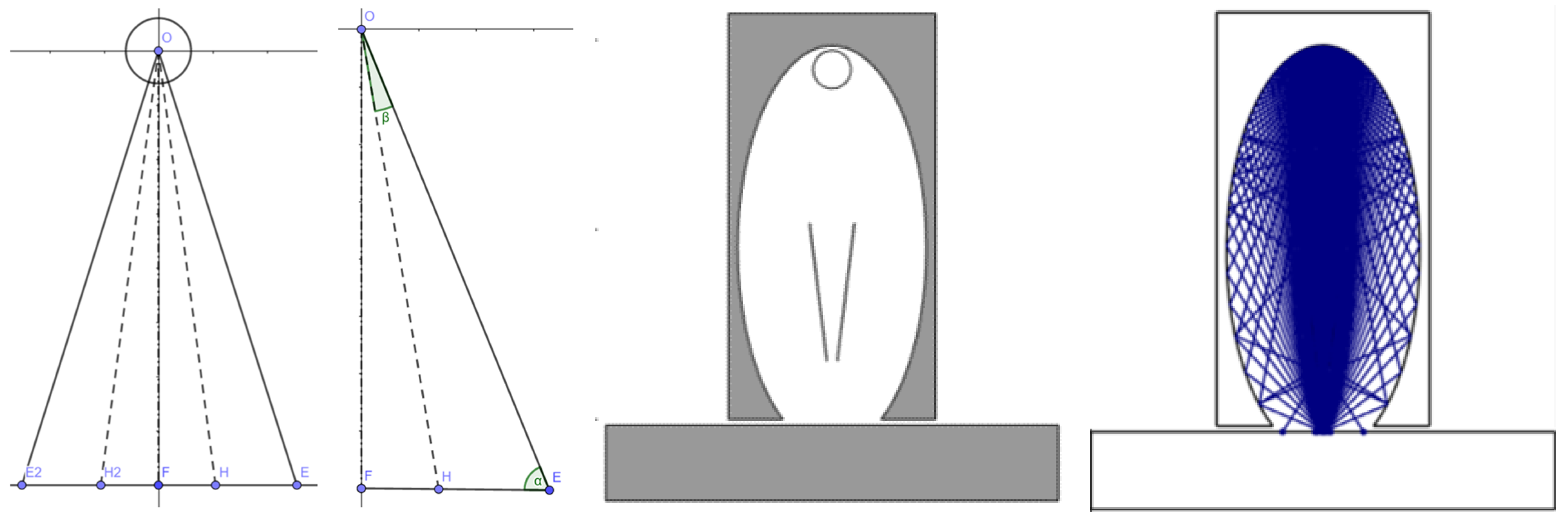

2.2. Geometry

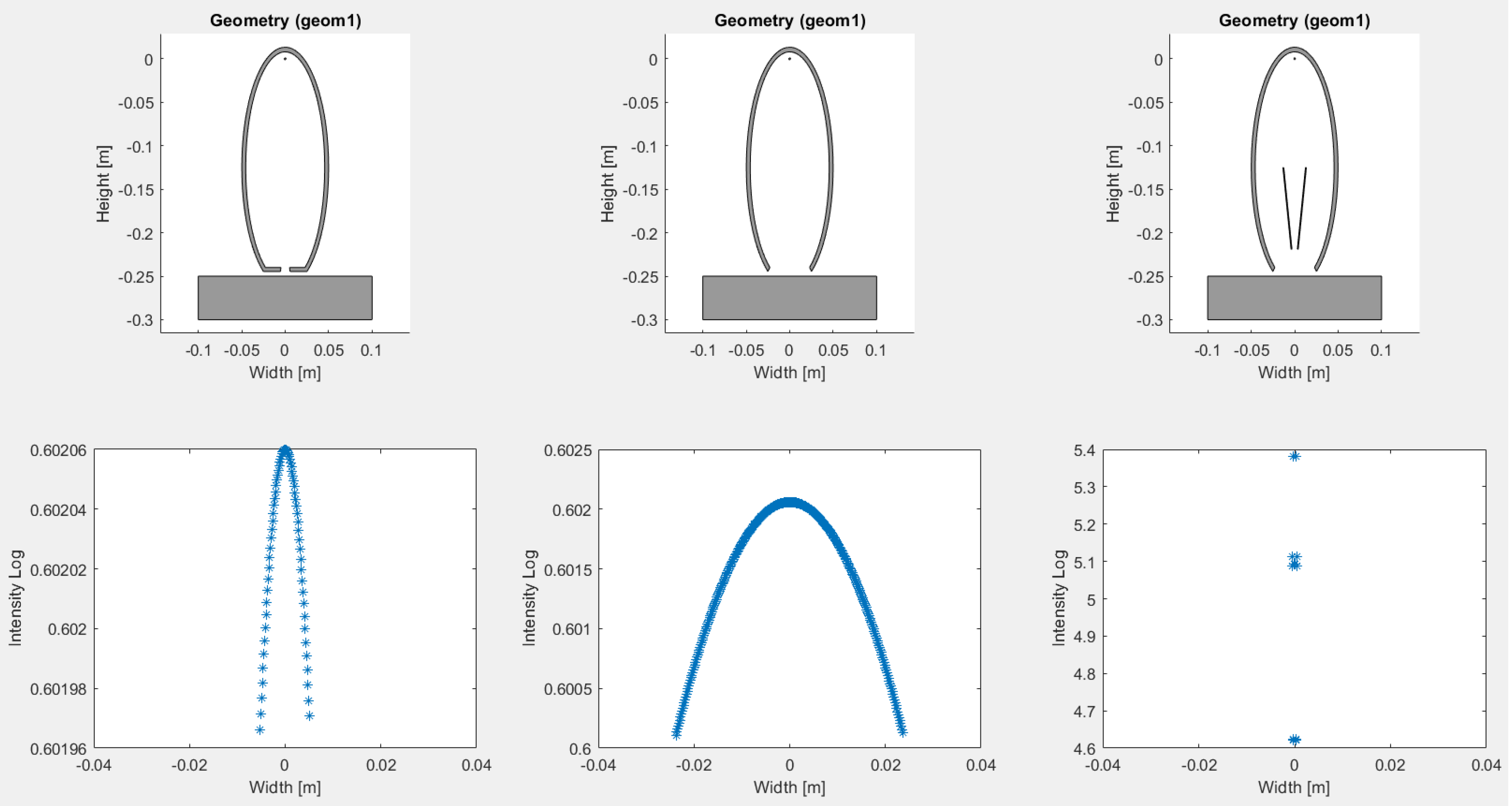

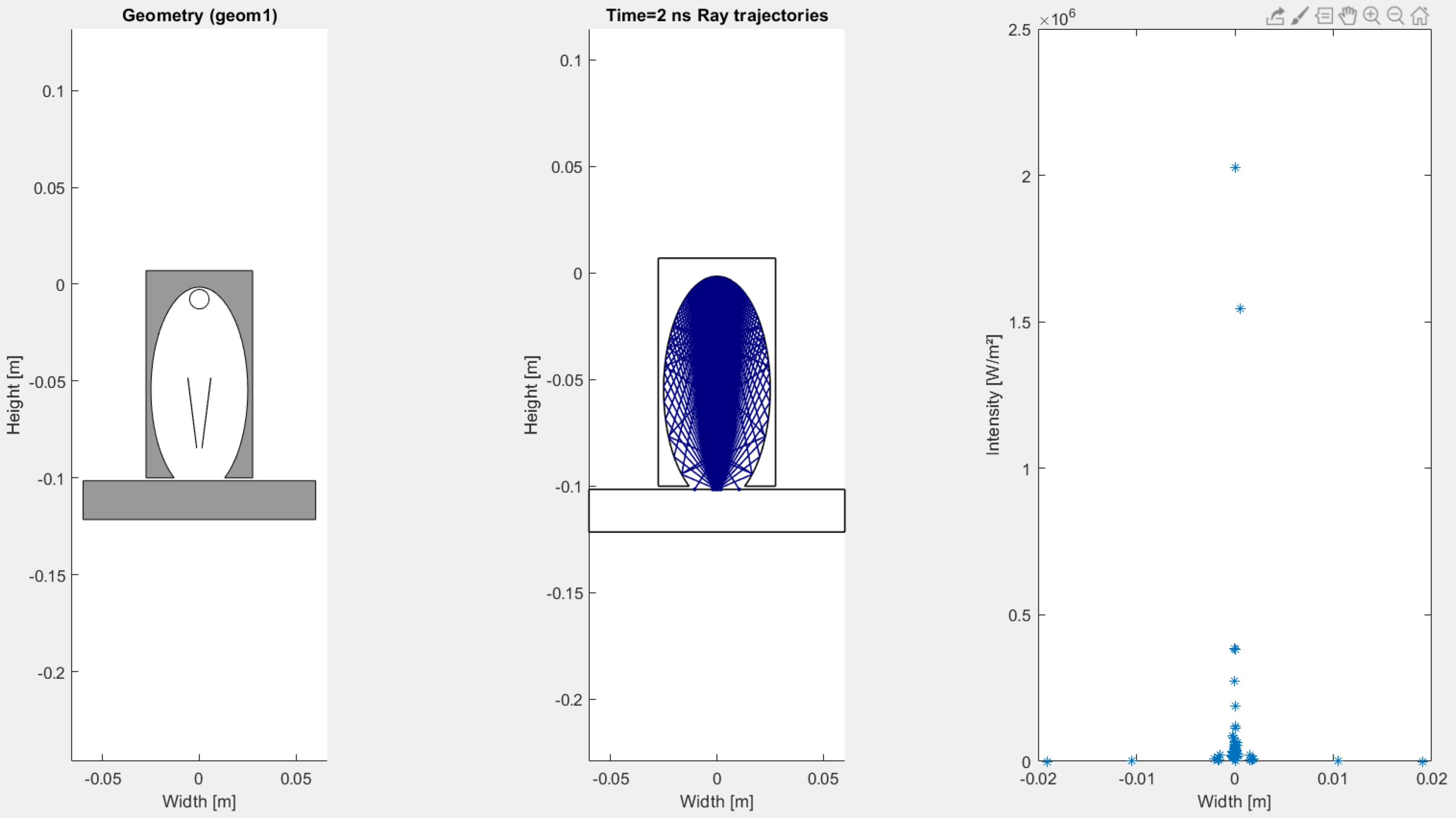

2.3. Simulation

- The reflector is made of aluminium.

- The surface finish is very smooth, ensuring a reflection coefficient around 1.

- The halogen tube lamp emits electromagnetic-radiation uniform along its length.

- The heating source and reflector shape are considered to be indefinitely so the sides can be neglected.

2.3.1. Ray-Tracing Model

2.3.2. Automated Batch-Script

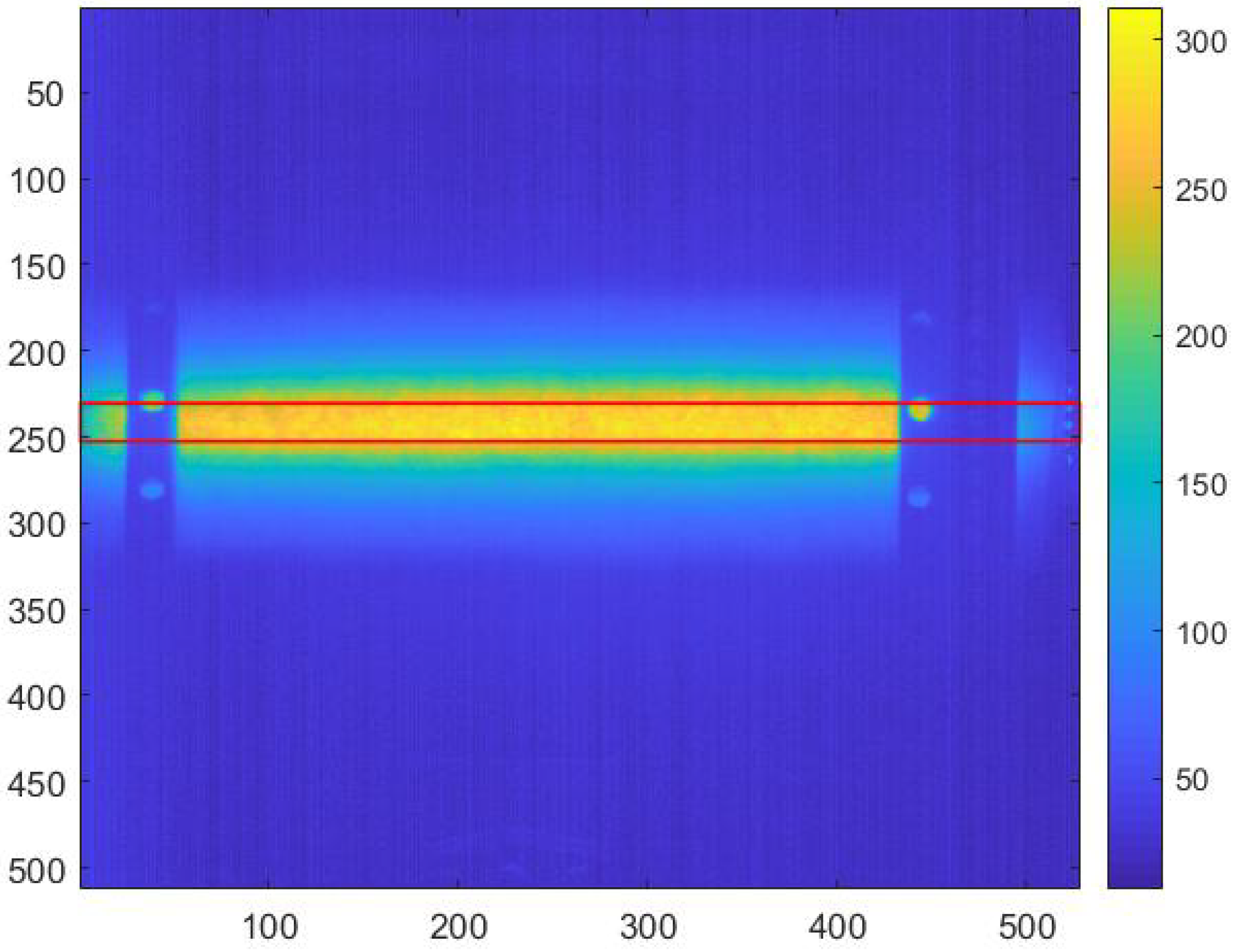

3. Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maldague, X.P. Theory and Practice of Infrared Thermography for Nondestructive Testing; Wiley: New York, NY, USA, 2001. [Google Scholar]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent Advances in Active Infrared Thermography for Non-Destructive Testing of Aerospace Components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yang, L.; Zhang, Z.; Wei, J.; Yang, J. Optimization of a uniform solar concentrator with absorbers of different shapes. Sol. Energy 2017, 158, 396–406. [Google Scholar] [CrossRef]

- Oommen, R.; Jayaraman, S. Development and performance analysis of compound parabolic solar concentrators with reduced gap losses—‘V’ groove reflector. Renew. Energy 2002, 27, 259–275. [Google Scholar] [CrossRef]

- Tian, M.; Su, Y.; Zheng, H.; Pei, G.; Li, G.; Riffat, S. A review on the recent research progress in the compound parabolic concentrator (CPC) for solar energy applications. Renew. Sustain. Energy Rev. 2018, 82, 1272–1296. [Google Scholar] [CrossRef]

- Lee, E.H.; Yang, D.Y.; Yang, W.H. Numerical modeling and experimental validation of focused surface heating using near-infrared rays with an elliptical reflector. Int. J. Heat Mass Transf. 2014, 78, 240–250. [Google Scholar] [CrossRef]

- Lee, E.H.; Hwang, J.S.; Lee, C.W.; Yang, D.Y.; Yang, W.H. A local heating method by near-infrared rays for forming of non-quenchable advanced high-strength steels. J. Mater. Process. Technol. 2014, 214, 784–793. [Google Scholar] [CrossRef]

- Unvala, B.A.; Maries, A. Radiant heating using an ellipsoidal reflector. J. Phys. E Sci. Instrum. 1974, 7, 4385–4390. [Google Scholar] [CrossRef]

- Mehler Engineering Service. Industrial Infrared Line Heater. Available online: https://www.m-e-s.de/en/infrared-drying-technology/infrared-line-radiators/ (accessed on 16 December 2019).

- Rashed, R. A Pioneer in Anaclastics: Ibn Sahl on Burning Mirrors and Lenses. Isis 1990, 81, 464–491. [Google Scholar] [CrossRef]

- Holland, F. The Reflective Property of a Parabola. Ir. Math. Soc. Bull. 2010, 66, 87–90. [Google Scholar]

- Williams, R.C.; By, E.; Hutchinson, J.P.; Wagon, S. A Proof of the Reflective Property of the Parabola. Am. Math. 1987, 94, 667–668. [Google Scholar] [CrossRef]

- Waghmare, S.A.; Gulhane, N.P. Design and ray tracing of a compound parabolic collector with tubular receiver. Sol. Energy 2016, 137, 165–172. [Google Scholar] [CrossRef]

- Berendonk, S. Proving the Reflective Property of an Ellipse. Math. Mag. 2014, 87, 276–279. [Google Scholar] [CrossRef]

- LineIR: Radiant Infrared Line Heater. Available online: http://www.researchinc.com/products/lineir (accessed on 3 February 2020).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Verspeek, S.; Ribbens, B.; Maldague, X.; Steenackers, G. Optimisation of a Heat Source for Infrared Thermography Measurements: Comparison to Mehler Engineering + Service-Heater. Appl. Sci. 2020, 10, 1285. https://doi.org/10.3390/app10041285

Verspeek S, Ribbens B, Maldague X, Steenackers G. Optimisation of a Heat Source for Infrared Thermography Measurements: Comparison to Mehler Engineering + Service-Heater. Applied Sciences. 2020; 10(4):1285. https://doi.org/10.3390/app10041285

Chicago/Turabian StyleVerspeek, Simon, Bart Ribbens, Xavier Maldague, and Gunther Steenackers. 2020. "Optimisation of a Heat Source for Infrared Thermography Measurements: Comparison to Mehler Engineering + Service-Heater" Applied Sciences 10, no. 4: 1285. https://doi.org/10.3390/app10041285

APA StyleVerspeek, S., Ribbens, B., Maldague, X., & Steenackers, G. (2020). Optimisation of a Heat Source for Infrared Thermography Measurements: Comparison to Mehler Engineering + Service-Heater. Applied Sciences, 10(4), 1285. https://doi.org/10.3390/app10041285