Effect of Holes on Dynamic Crack Propagation under Impact Loading

Abstract

:1. Introduction

2. Experiment

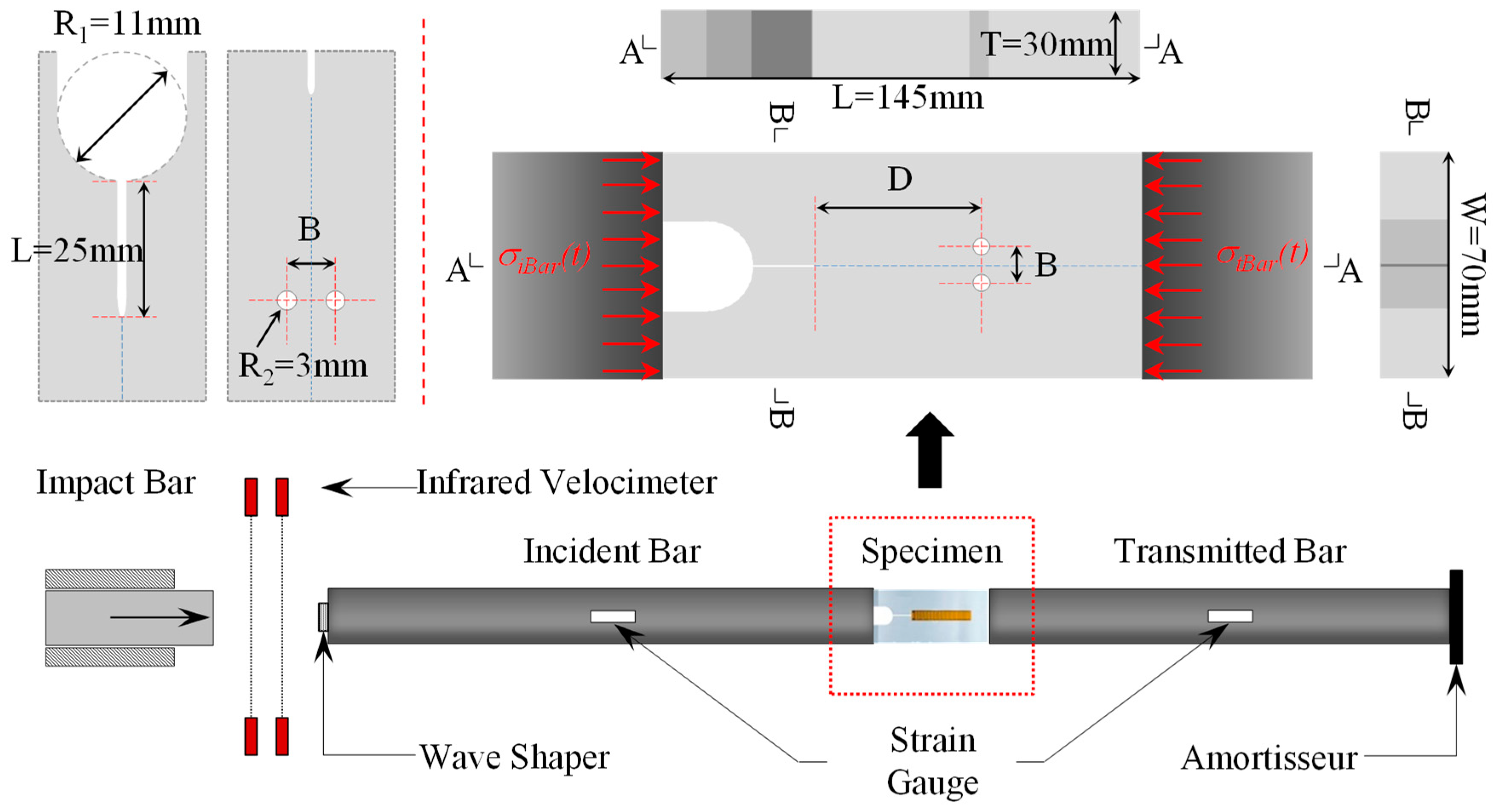

2.1. Test System and Specimen

2.2. Material Parameters

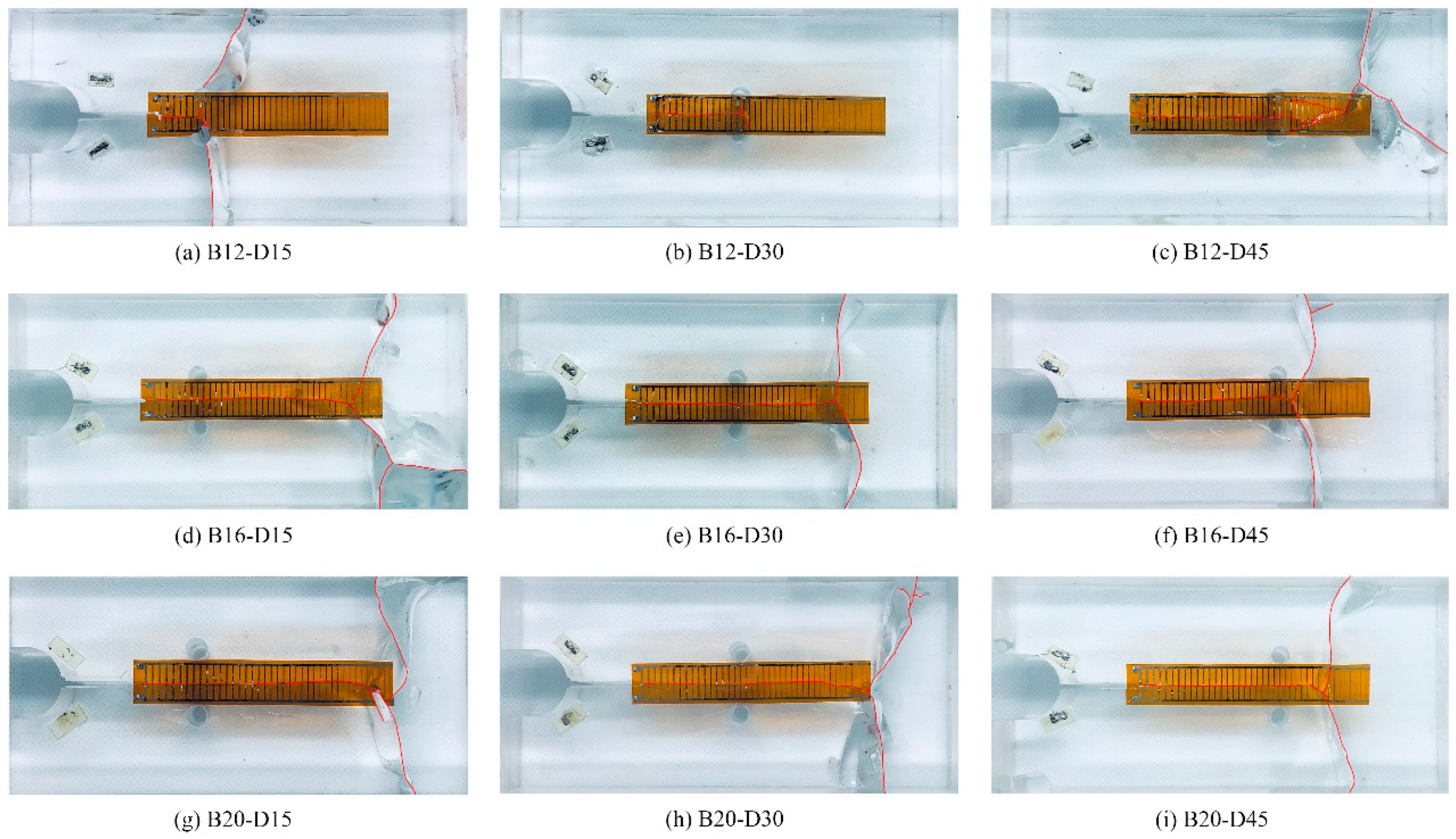

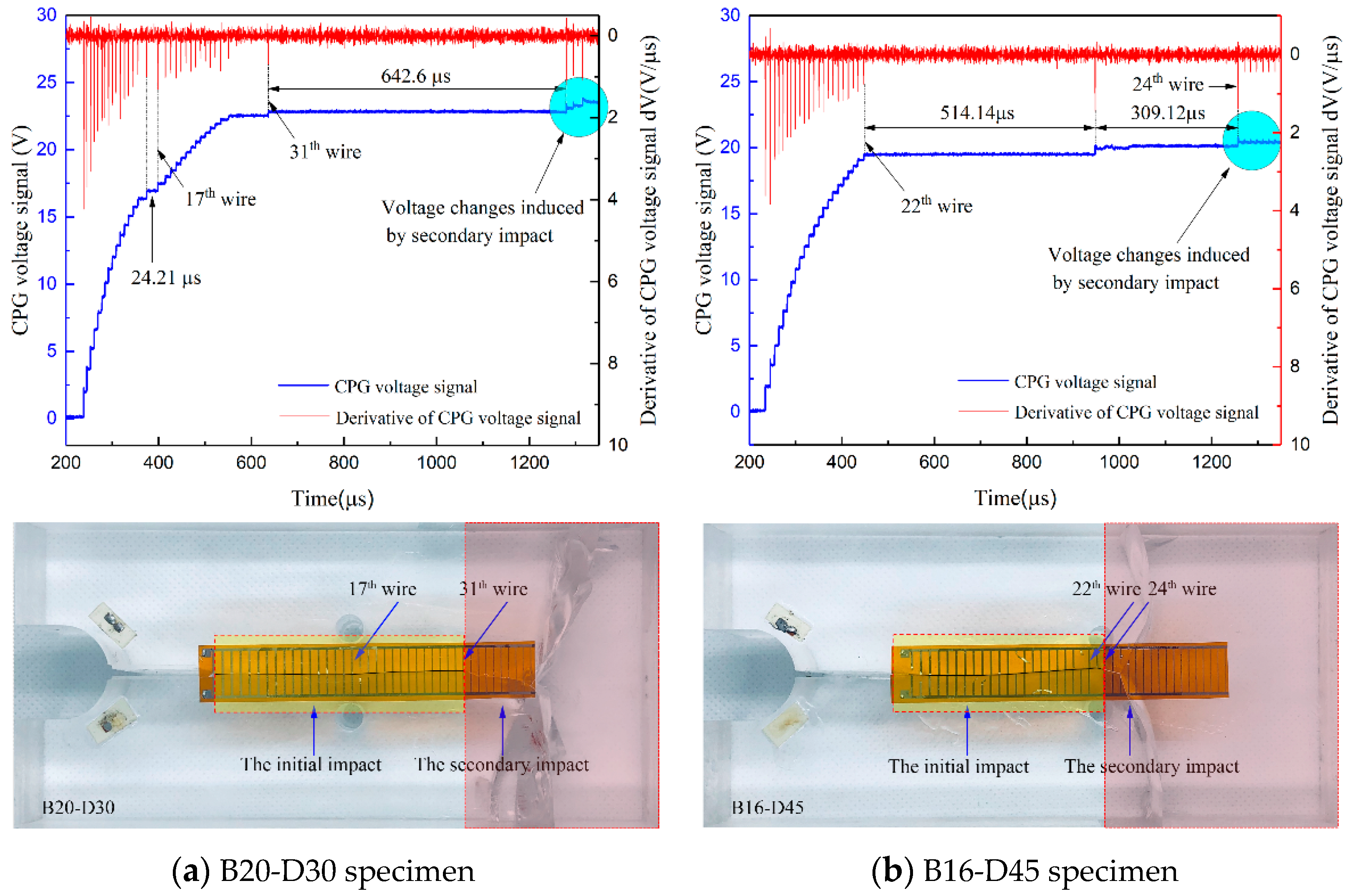

2.3. Experiment Results and Discussion

3. Numerical Method

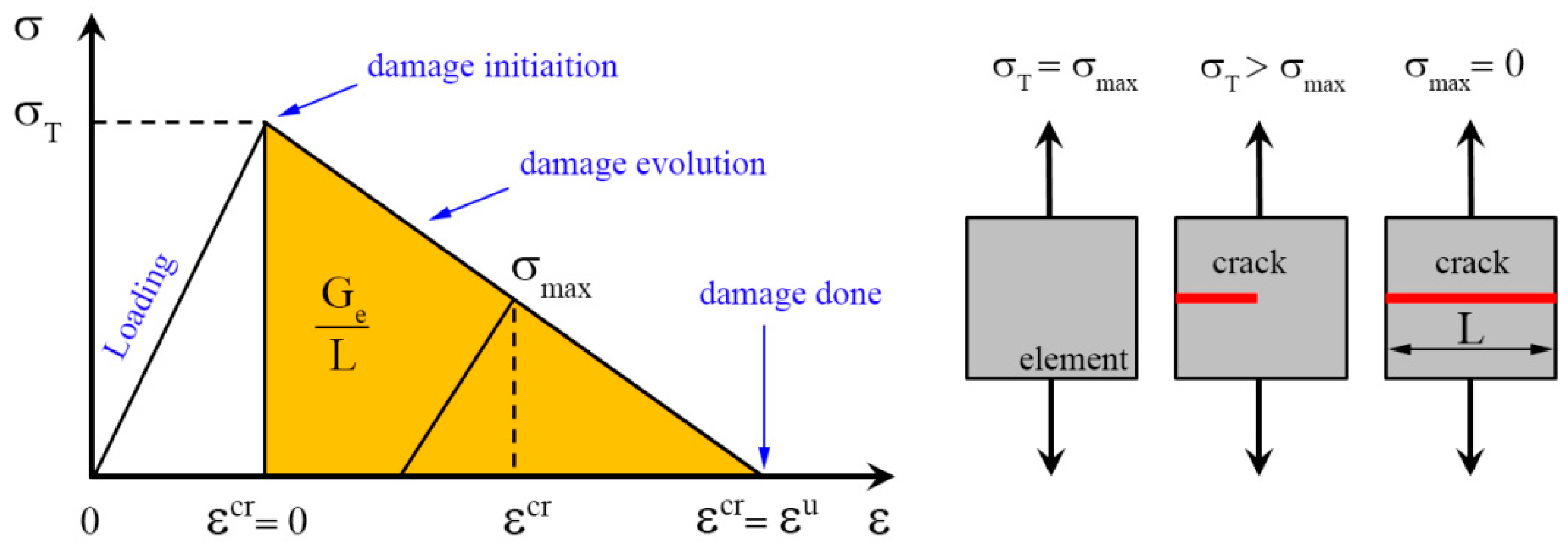

3.1. Introduction of the Algorithm in AUTODYN

3.2. Numerical Damage Mode

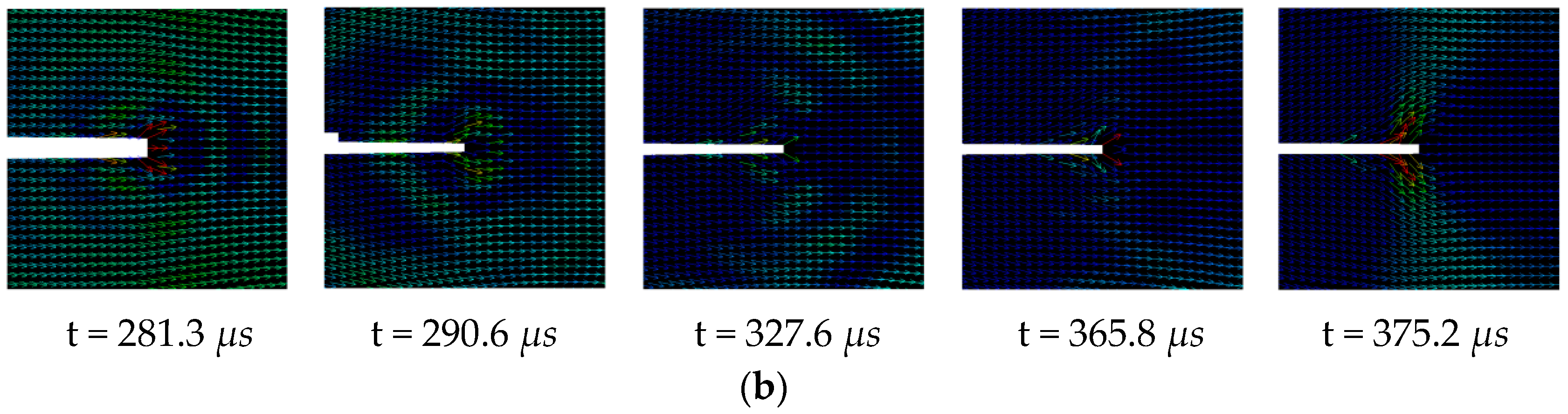

3.3. Numerical Simulation Results

3.4. Discussion of Mechanism

4. Conclusions

- The crack may be arrested by two symmetrical holes when propagating between the holes. Furthermore, the main crack may bifurcate to two sub-cracks and connect with the holes when the distance between the holes is very small, or the extending crack may be transitorily restrained by the holes when the propagation velocity decreases sharply.

- The effect of the holes has a sensitive relationship with the distance between the holes and the distance of the holes to the crack tip.

- The effect of the holes is dependent on the compressive stress field caused by the deformation of the holes during the crack propagation process. Moreover, the compressive stress perpendicular to the crack is the dominant factor influencing the crack propagation behavior.

- The finite difference code AUTODYN has an advantage in solving dynamic fracture problems, and it can be applied in investigating the crack propagation behavior of brittle materials.

Author Contributions

Funding

Conflicts of Interest

References

- Gómez, F.J.; Elices, M.; Berto, F.; Lazzarin, P. Local strain energy to assess the static failure of U-notches in plates under mixed mode loading. Int. J. Fract. 2007, 145, 29–45. [Google Scholar] [CrossRef]

- Cook, N.G.W. Natural joints in rock-mechanical, hydraulic and seismic behavior and properties under normal stress. Int. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 198–223. [Google Scholar] [CrossRef]

- Soh, A.K.; Yang, C.H. Numerical modeling of interactions between a macro-crack and a cluster of micro-defects. Eng. Fract. Mech. 2004, 71, 193–217. [Google Scholar] [CrossRef]

- Mishuris, G.; Movchan, A.; Movchan, N.; Piccolroaz, A. Interaction of an interfacial crack with linear small defects under out-of-plane shear loading. Comput. Mater. Sci. 2012, 52, 226–230. [Google Scholar] [CrossRef] [Green Version]

- Simonov, I.V.; Karihaloo, B.L. Dislocation model of an asymmetric weak zone for problems of interaction between crack-like defects. Philos. Mag. 2005, 85, 1847–1864. [Google Scholar] [CrossRef] [Green Version]

- Jiang, C.; Zhao, G.F.; Zhu, J.B.; Zhao, Y.X.; Shen, L.M. Investigation of Dynamic Crack Coalescence Using a Gypsum-Like 3D Printing Material. Rock Mech. Rock Eng. 2016, 49, 3983–3998. [Google Scholar] [CrossRef]

- Gao, D.W.; Zhang, C.W. Theoretical and numerical investigation on in-plane impact performance of chiral honeycomb core structure. J. Struct. Integr. Maint. 2018, 3, 95–105. [Google Scholar] [CrossRef]

- Zhang, C.W.; Gholipour, G.; Mousavi, A.A. Nonlinear dynamic behavior of simply-supported RC beams subjected to combined impact-blast loading. Eng. Struct. 2019, 181, 124–142. [Google Scholar] [CrossRef]

- Theocaris, P.S.; Milios, J. Crack Arrest Modes of a Transverse Crack Going Through a Longitudinal Crack or a Hole. J. Eng. Mater. Technol. 1981, 103, 177–182. [Google Scholar] [CrossRef]

- Milios, J.; Spathis, G. Dynamic interaction of a propagating crack with a hole boundary. Acta Mech. 1988, 72, 283–295. [Google Scholar] [CrossRef]

- Murdani, A.; Makabe, C.; Saimoto, A.; Kondou, R. A crack-growth arresting technique in aluminum alloy. Eng. Fail. Anal. 2008, 15, 302–310. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Razavi, S.M.J.; Yahya, M.Y. Mixed mode fatigue crack initiation and growth in a CT specimen repaired by stop hole technique. Eng. Fract. Mech. 2015, 145, 115–127. [Google Scholar] [CrossRef]

- Chen, N.Z. A stop-hole method for marine and offshore structures. Int. J. Fatigue 2016, 88, 49–57. [Google Scholar] [CrossRef]

- Yang, R.S.; Xu, P.; Yue, Z.W.; Chen, C. Dynamic fracture analysis of crack-defect interaction for mode I running crack using digital dynamic caustics method. Eng. Fract. Mech. 2016, 161, 63–75. [Google Scholar] [CrossRef]

- Wang, Y.B.; Yang, R.S.; Zhao, G.F. Influence of empty hole on crack running in PMMA plate under dynamic loading. Polym. Test. 2017, 58, 70–85. [Google Scholar] [CrossRef]

- Zhu, Z.; Mohanty, B.; Xie, H. Numerical investigation of blasting-induced crack initiation and propagation in rocks. Int. J. Rock Mech. Min. Sci. 2007, 44, 412–424. [Google Scholar] [CrossRef]

- Zhu, Z. Numerical prediction of crater blasting and bench blasting. Int. J. Rock Mech. Min. Sci. 2009, 46, 1088–1096. [Google Scholar] [CrossRef]

- Wang, M.; Zhu, Z.; Dong, Y.; Lei, Z. Study of mixed-mode I/II fractures using single cleavage semicircle compression specimens under impacting loads. Eng. Fract. Mech. 2017, 177, 33–44. [Google Scholar] [CrossRef]

- Wang, M.; Wang, F.; Zhu, Z.; Dong, Y.; Mousavi Nezhad, M.; Zhou, L. Modelling of crack propagation in rocks under SHPB impacts using a damage method. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1699–1710. [Google Scholar] [CrossRef]

- Zhu, Z.; Chao, W.; Kang, J.; Li, Y.; Meng, W. Study on the mechanism of zonal disintegration around an excavation. Int. J. Rock Mech. Min. Sci. 2014, 67, 88–95. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A Review of Dynamic Experimental Techniques and Mechanical Behaviour of Rock Materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef] [Green Version]

- Shin, H.; Kim, D. One-dimensional analyses of striker impact on bar with different general impedance. Proc. Inst. Mech. Eng. Part C J. Eng. Mech. Eng. Sci. 2019. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, Z.; Meng, W.; Peng, Y.; Lei, Z.; Dong, Y. Study of rock dynamic fracture toughness by using VB-SCSC specimens under medium-low speed impacts. Eng. Fract. Mech. 2017, 181, 52–64. [Google Scholar] [CrossRef]

- Rossmanith, H.P.; Daehnke, A.; Knasmillner, R.E.; Kouzniak, N.; Ohtsu, M.; Uenishi, K. Fracture mechanics applications to drilling and blasting. Fatigue Fract. Eng. Mater. Struct. 1997, 20, 1617–1636. [Google Scholar] [CrossRef]

- Yue, Z.W.; Yang, L.Y.; Wang, Y.B. Experimental study of crack propagation in polymethyl methacrylate material with double holes under the directional controlled blasting. Fatigue Fract. Eng. Mater. Struct. 2013. [Google Scholar] [CrossRef]

- Eringen, A.C.; Suhubi, E.S.; Chao, C.C. Elastodynamics, Vol. II, Linear Theory. J. Appl. Mech. 1978, 45, 229. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.Z.; Yang, J.R.; Zhang, C.G.; Zhou, Y.; Li, L.; Wu, L.Z.; Huang, R.Q. Determination of Dynamic Crack Initiation and Propagation Toughness of a Rock Using a Hybrid Experimental-Numerical Approach. J. Eng. Mech. 2016, 142, 9. [Google Scholar] [CrossRef]

| Name | Material | Length (mm) | Diameter (mm) | ρ (kg/m3) | Ed (GPa) | νd |

|---|---|---|---|---|---|---|

| Incident Bar | 40CrmoV | 3000 | 80 | 7600 | 210 | 0.25 |

| Transmitted Bar | 40CrmoV | 2000 | 80 | 7600 | 210 | 0.25 |

| Specimen | D = 15 mm | D = 30 mm | D = 45 mm |

|---|---|---|---|

| B = 12 mm | B12-D15 | B12-D30 | B12-D45 |

| B = 16 mm | B16-D15 | B16-D30 | B16-D45 |

| B = 20 mm | B20-D15 | B20-D30 | B20-D45 |

| Material | Cd (m/s) | Cs (m/s) | ρ (kg/m3) | Ed (GPa) | Κ (GPa) | νd |

|---|---|---|---|---|---|---|

| PMMA | 2382 | 1305 | 1187 | 5.61 | 4.35 | 0.28 |

| Specimen | AT μs | Vmin m/s | Vavg m/s | specimen | AT μs | Vmin m/s | Vavg m/s | Specimen | AT μs | Vmin m/s | Vavg m/s |

|---|---|---|---|---|---|---|---|---|---|---|---|

| B12-D15 | 85.87 | 23.29 | 205.95 | B12-D30 | 51.77 | 38.63 | 164.46 | B12-D45 | 338.98 | 5.90 | 152.82 |

| B16-D15 | 56.60 | 35.33 | 186.69 | B16-D30 | 99.90 | 20.02 | 208.30 | B16-D45 | 309.11 | 6.47 | 183.93 |

| B20-D15 | 14.40 | 138.88 | 212.32 | B20-D30 | 24.20 | 82.64 | 205.18 | B20-D45 | 50.80 | 39.37 | 225.88 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, F.; Wang, M. Effect of Holes on Dynamic Crack Propagation under Impact Loading. Appl. Sci. 2020, 10, 1122. https://doi.org/10.3390/app10031122

Wang F, Wang M. Effect of Holes on Dynamic Crack Propagation under Impact Loading. Applied Sciences. 2020; 10(3):1122. https://doi.org/10.3390/app10031122

Chicago/Turabian StyleWang, Fei, and Meng Wang. 2020. "Effect of Holes on Dynamic Crack Propagation under Impact Loading" Applied Sciences 10, no. 3: 1122. https://doi.org/10.3390/app10031122

APA StyleWang, F., & Wang, M. (2020). Effect of Holes on Dynamic Crack Propagation under Impact Loading. Applied Sciences, 10(3), 1122. https://doi.org/10.3390/app10031122