1. Introduction

Concrete is widely used in the construction industry. The material requires sufficient strength and durability to be used in building construction for different types of structural members, such as foundations, beams, walls, slabs, or columns. During the concrete’s placement, it is important to monitor its status throughout the entire concrete formwork process, until the material cures. The formwork must remain in place to support a concrete structure during the construction. This process must consider factors such as the class of concrete, cement type or grade, humidity, temperature, and size/type of the structural components [

1,

2,

3]. The formwork removal time is critical to the concrete gaining sufficient strength, as well as to the cost and time management of the entire construction project; this is because early removal leads to rework, which leads to project delays [

4,

5]. The current state of practice has established a standard time to remove concrete formworks during a construction project [

6,

7,

8]. Tailored time determination involves employing a concrete maturity method that estimates the mechanical properties of the concrete, based on the temperature during curing concrete [

9,

10]. This approach involves monitoring the concrete’s temperature and using the data acquired to estimate its strength and the time needed for the formwork [

11].

To monitor the temperature and strength of concrete, the current state of practice uses a mobile-based or wireless sensor-embedded monitoring system [

9,

12,

13]. Such studies have focused only on the schematic design for monitoring and collecting sensor data. The concrete formwork is placed for all concrete structural elements such as columns, walls, and slabs. Therefore, sensor data regarding the concrete’s maturity obtained from different elements can be stored and managed in the building information modeling (BIM) environment because BIM can store geometric and semantic information of the construction project. Previous systems have focused only on collecting data and monitoring the condition of the concrete, and not providing real-time information about the appropriate time to remove the formwork. To address this concern, the present research expanded BIM’s interoperability to monitor concrete’s maturity and determine the formwork removal time by using wireless sensor data.

BIM is capable of integrating all stages of construction into a single digital model, achieving high-quality construction, accurate performance and cost estimates, and continuous monitoring and control, as well as maintaining an up-to-date information source that facilitates project stakeholders achieving a clear overview of the project for use in informed decision-making [

14,

15]. This study incorporates BIM and a sensor-based concrete maturity method to monitor and manage data related to various concrete-based structural components (e.g., slabs, walls, columns) and their strengths. This research used a module and wireless sensors embedded in fresh concrete, measured the concrete’s temperature, and then automatically calculated its maturity so that its strength would be predictable. To expand BIM’s interoperability, a BIM application programming interface (API) was applied that can transfer data related to the concrete’s maturity to the BIM environment from sensors in real-time. All information about the temperature and maturity of the concrete can be monitored through planted sensors to the BIM environment, and stored in an industry foundation class (IFC) format. To test the interoperability, this research conducted a field case study in a building construction project in Iran. The results showed that BIM was able to interoperate with the data collected from the sensors, receive data related to the concrete’s maturity, and calculate the appropriate concrete formwork removal time. The time to remove the formwork was less than what would have resulted from using the standardized regulation alone, and still clearly ensured the necessary level of strength. Thus, this interoperable BIM system contributes to monitoring the concrete curing conditions, receiving maturity data from the sensors, reducing concrete formwork removal times, and positively preventing wasted time and cost from reworks resulting from concrete failing to gain the necessary strength.

2. Literature Review

2.1. Concrete Maturity Method

The concrete maturity approach generally assumes that concrete’s strength and durability depend on its temperature and moisture [

16,

17]. These parameters significantly affect how concrete’s properties (such as strength, elastic modulus, deformation, and shrinkage) develop during the early stages of a formwork [

18]. Since concrete maturity is calculated based on the temperature of the concrete between its place and form, the in situ concrete’s strength and time of removal can be estimated in real-time if it is possible to collect temperature data at the construction site [

11,

19,

20]. Among the various properties of concrete, strength is particularly critical to measuring and evaluating its quality and performance [

21]. To measure the performance, a sample is tested to see if the concrete can bear the maximum load it should be able to resist. However, this direct measurement method consumes both time and money because it requires a number of samples and the test must be repeated until an allowable strength is acquired [

22]. The process may also ignore the time and temperature of mature concrete. Moreover, results based on this type of manual test can be affected by external or environmental factors such as human mistakes, errors in sample specifications, and problems with loading configurations and settings [

23]. To overcome this challenge, a maturity index for calculating in situ concrete’s strength during construction can be used to test field-cured concrete cylinders. It is also important to predict and document the concrete’s strength from the early work stages, in order to reduce the time for removing the concrete formwork [

24,

25].

2.2. Wireless Concrete Monitoring Systems and Formwork Removal

Over the years, studies have tried to implement indirect methods of evaluating the strength performance of concrete, developing sensor-based systems to monitor environmental conditions and identifying the parameters affecting concrete’s performance [

23,

26,

27,

28,

29,

30]. For example, temperature data can be collected while the concrete is forming by using temperature sensors and radio frequency identification (RFID) tags or resistance rigidity thermometers [

31]. Kumbhar and Chaudhari [

32] proposed a wireless sensor for measuring temperatures in early-age concrete structures in order to determine the concrete’s strength. That study found that this sensor-based method could be used to predict concrete’s maturity. Cabezas et al. also presented a new embedded sensor system for monitoring the status of concrete [

33]. Such sensor-based maturity methods are very effective at estimating the properties of concrete, based on data collected via temperature monitoring [

33,

34]. Dong et al. [

35] conducted a case study measuring the temperature of concrete on a highway construction project by using a sensor network system. The temperature data obtained allowed researchers to continuously estimate the concrete’s strength and maturity throughout the project’s lifecycle, showing that the sensor-based maturity method could also be used to estimate the appropriate time to detach the concrete mold, based on the temperature [

35]. Such interdisciplinary research has shown new techniques based on wireless sensor systems that allow for the continuous measurement and real-time monitoring of both the temperature and humidity level of concrete [

24,

36]. As a result, these sensor systems have underscored the potential to compute more accurate and consistent outputs based on concrete’s various properties. However, it should be noted that sensor-based systems embedded in concrete are still not reliable in terms of the concrete’s stability, lifespan, signal transmission requirements, and protection against various types of damage [

37].

Several standards are widely used to concrete formworks suggest removal at different structural ranges [

6,

7,

8]. Vertical structural elements require a shorter amount of time to form than do horizontal components with large spans (greater than six meters) that require at least 14 to 28 days. The standards dictate that large structures (greater than six meters) must acquire about 85% of the recommended strength level before formwork removal [

3]. Several studies have reported that for vertical elements the formwork can be detached earlier, before what is recommended in the standard [

20,

38,

39]. However, the manual maturity method does not provide sufficient information about the ideal time to remove the formwork. In addition, it requires workers to follow the standard even if they could remove the formwork earlier without any damage. This can cause significant delays in a panel’s removal because there is still the possibility of serious damage during the early formwork stages [

20].

2.3. Concrete Formwork Applications in BIM

In the construction industry, BIM has recently been used to facilitate the integration of the design and construction processes, saving both cost and time [

14,

40]. BIM can store and manage geometric and semantic information for design components and integrate all descriptions of visualized objects and related data during a construction project. Many BIM applications have focused on pre-construction planning activities [

41]. A few studies have tried to develop BIM applications for decision support systems facilitating construction project control and operation [

42,

43]. Particularly for concrete formwork, Romanovskyi et al. [

44] recently proposed a BIM-based decision support system for concrete formwork design that managed all information needed and collected during the concrete formwork construction process. BIM has been implemented to help the design and planning process, as well as simulate the designed formwork. Meadati et al. [

45] provided a conceptual overview of a knowledge repository for concrete formworks via BIM. The initial concept was to connect 3D models and associated information, saving on parameters related to cost and concrete formwork materials such as unit price, specifications, and quantity [

45]. Kannan and Santhi [

46] developed a BIM-based automated concrete formwork layout and simulation system that could predict construction schedules based on a BIM formwork simulation. Another study in this domain developed a BIM-based concrete formwork management system for improving the efficiency of formwork use, such as by optimizing reuse and maximizing return-on-investment [

47]. The current state of knowledge has contributed significantly to developing BIM-based management systems, especially in terms of concrete formwork design and planning during the pre-construction step [

44,

46,

47]. However, the end-users of such systems employ static data instead of real-time information collected by sensors or other information technologies during the construction process [

48]. Real-time data collected in BIM can support project stakeholders’ decision-making by controlling and interpreting data pattern changes and trends [

44,

47,

48,

49]. Current research has focused on using BIM for concrete formwork planning and design rather than monitoring and calculating the maturity of concrete during the formwork process [

44,

47,

48,

49,

50].

Therefore, the present study expanded the interoperability of BIM for real-time monitoring of the maturity of concrete by using sensor data and calculations conducted through the API interface, in addition to conveying the possible formwork opening time that does not risk damage to the concrete’s structural elements. The interoperability of exchanging BIM models and sensor data can also extract all computed outcomes to an IFC data format in the BIM environment.

3. Research Methodology

This study consisted of three steps: (1) creating a sensor-based monitoring system (both module and application design), (2) developing a BIM-integrated data exchange system through a Revit API add-in, and (3) applying and validating the BIM-integrated system in a building construction project (i.e., a case study). This work employed three sensors (i.e., SHT21, Ds18b20, and LM3) to develop the sensor-based monitoring system. The first sensor, SHT21, collected temperature and humidity data, while the other two were only capable of measuring the temperature of the concrete. In the first step, the sensors’ hardware and software modules were designed, allowing for the retrieval of two types of data that could be stored on an SD card. The software module was designed based on Java and .NET frameworks in order to allow for visualization of the temperature and humidity data collected by the sensors. Through Wi-Fi, the data on the SD card could be forwarded to the application developed for this step. The information in this application could then be used to calculate the concrete’s maturity and estimate its strength. The second step involved the development of a Revit add-in to extend the BIM interoperability for calculating the concrete’s maturity and storing all information in a database as an IFC format (i.e., Maturity 1, Maturity 2, and Maturity 3). In the final step, a case study was conducted at a construction project in Iran to apply and validate the interoperability and system.

Figure 1 shows an overview of the research methodology.

3.1. Sensor Module Design and Application Development

This study used three different sensors to collect humidity and temperature data from the tested concrete. The first sensor was an SHT21, which can collect both temperature and humidity information and produce digital output according to an I2C communication protocol. This sensor has a 14-bit resolution for temperature and 12-bit resolution for humidity. Its operating range is −40 °C to 125 °C for temperature and 0% to 100% for humidity. The Ds18b20 sensor can measure temperatures between −55 °C and 125 °C. It operates based on a one-wire communication protocol connected to a board via three wires (i.e., VCC, GND, and Date). This sensor has a nominal error of ±0.5 °C in the temperature range of −10 °C to 85 °C and an error rate of up to ±2 °C in the rest of its operating range [

51]. The third sensor was an LM35, which can produce the analog output. The voltage output increases linearly by 10mV with each 10 °C increase in temperature. It has an error of ±0.5 °C at 25 °C. After connecting the LM35 to a micro-analog/digital converter, the voltage outputs can be turned into temperature data with 12-bit resolution [

29]. The combination of these three sensors made the proposed system capable of monitoring temperatures ranging between 0 °C and 80 °C while the concrete cured. High-performance sensors capable of indicating high or low temperatures between −100 °C and 300 °C were not required for this research. The sensors used in this study have a relatively high rate of precision with regards to temperature (±0.5 °C); the level of accuracy required is at least ±1 °C to determine the concrete’s maturity. Also, these sensors resist changes to the properties of the concrete that occur during hardening; previous studies have also used these sensors for similar purposes.

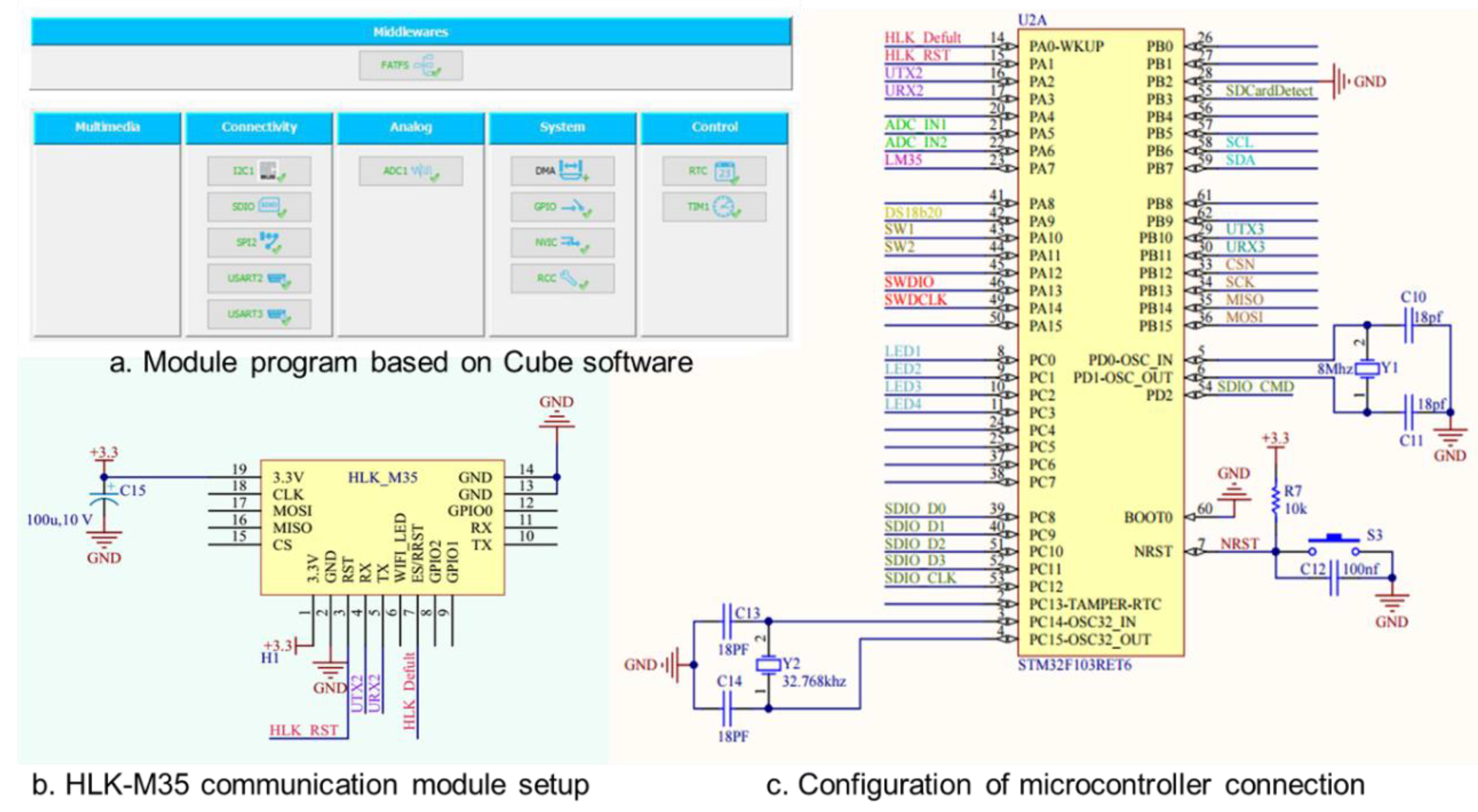

The hardware module consisted of data acquisition, data storage, and wireless transmission circuits. The module stored the retrieved information on an SD card mounted on the board. The data were processed by software designed with a .NET framework, using Android for visualization of the server or mobile device. This small module was equipped with a self-designed ad-hoc board appropriate for concrete formwork on construction sites. The module program was developed using Cube software (see

Figure 2a). The microcontroller employed on the board was a STM32F130RET6, which is a 32-bit microcontroller from the Cortex M3 family. The microcontroller had an operating frequency of 72MHz and enjoyed very high processing speed and precision. The IEEE 802.11 (Wi-Fi) topology and, specifically, an HLK-M35 module were used to establish a connection with the computer or smartphone. The module used the TCP/IP operating protocol and universal asynchronous receiver/transmitter communication protocol to link with the microcontroller.

Figure 2 shows the HLK-M35 communication module setup (see

Figure 2b) and the configuration of the microcontroller connection (see

Figure 2c). The Wi-Fi module was connected to the microcontroller through the serial port, which was specified on the PA0 to PA3 bases. Two analog inputs were inserted into PA5 and PA6 to connect the sensors. A one-wire protocol was used on the PA9 base to connect the DS18b20 sensor. The SDIO protocol developed by STMicroelectronics was connected through the PC to PC12 bases for connection with the SD card. Pull-up 47K resistors were used to reduce noise.

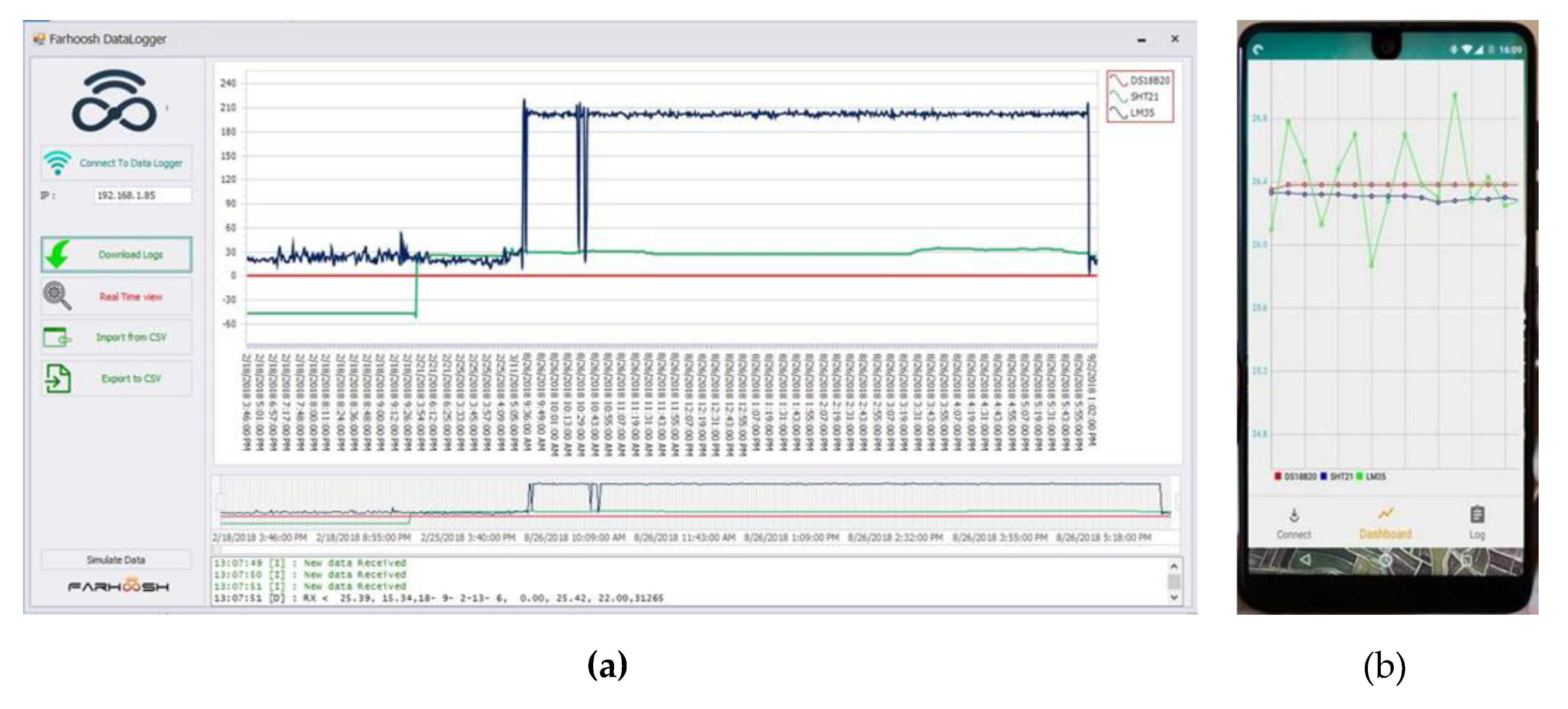

The data logger system was designed in Visual Studio with C#, and the DevExpress software suite was used alongside to improve the user interface (UI) design. The developed program could not be directly executed on the operating system and needed the .NET framework to function. This framework is preinstalled on all newer versions of Windows. Communication with the board was designed using .NET Framework sockets, which is a package for network-managed communications. Software performance was improved for multithread processing, which while making the coding more difficult, leading to easier event management and execution. In the next stage, a mobile application was developed to monitor the output temperature via a smartphone. The UIs of data logger and mobile application are shown in

Figure 3a,b, respectively. The application was designed in Android Studio based on the Navigation Drawer platform. The design was accomplished with through Java, using the model-view-controller pattern and consisting entirely of object-oriented components. The model-view-controller is an architectural pattern commonly used in UI design; it partitions a program into three parts: the model, view, and controller. After connecting through Wi-Fi (by clicking on the Connect button), the program automatically connected to the electronic circuit and relayed the ReqData command to initiate information retrieval from the data logger. The information received from the data logger was then uploaded to the software dashboard. Fragment design was used to optimize RAM usage and increase program performance. Hence, the program contained three fragments managed by the program once the Main Activity was executed. Keeping every page in memory, this structure prevented unnecessary opening and closing and improved the software efficiency. The Dashboard component was built using the well-known MPAndroidChart library, which allows developers to create a variety of different charts. The Android app consisted of four main components. The first, Main Activity, was the main UI for the program and where views such as the bottom navigation bar and fragment holders were maintained. The second component, Connection Fragment, involved wireless communication and related codes. The third component was the Dashboard Fragment, which displayed the data charts. The fourth was the Log Fragment, which logged the program events for later review and analysis.

3.2. Extending BIM Interoperability for Concrete Maturity Calculation

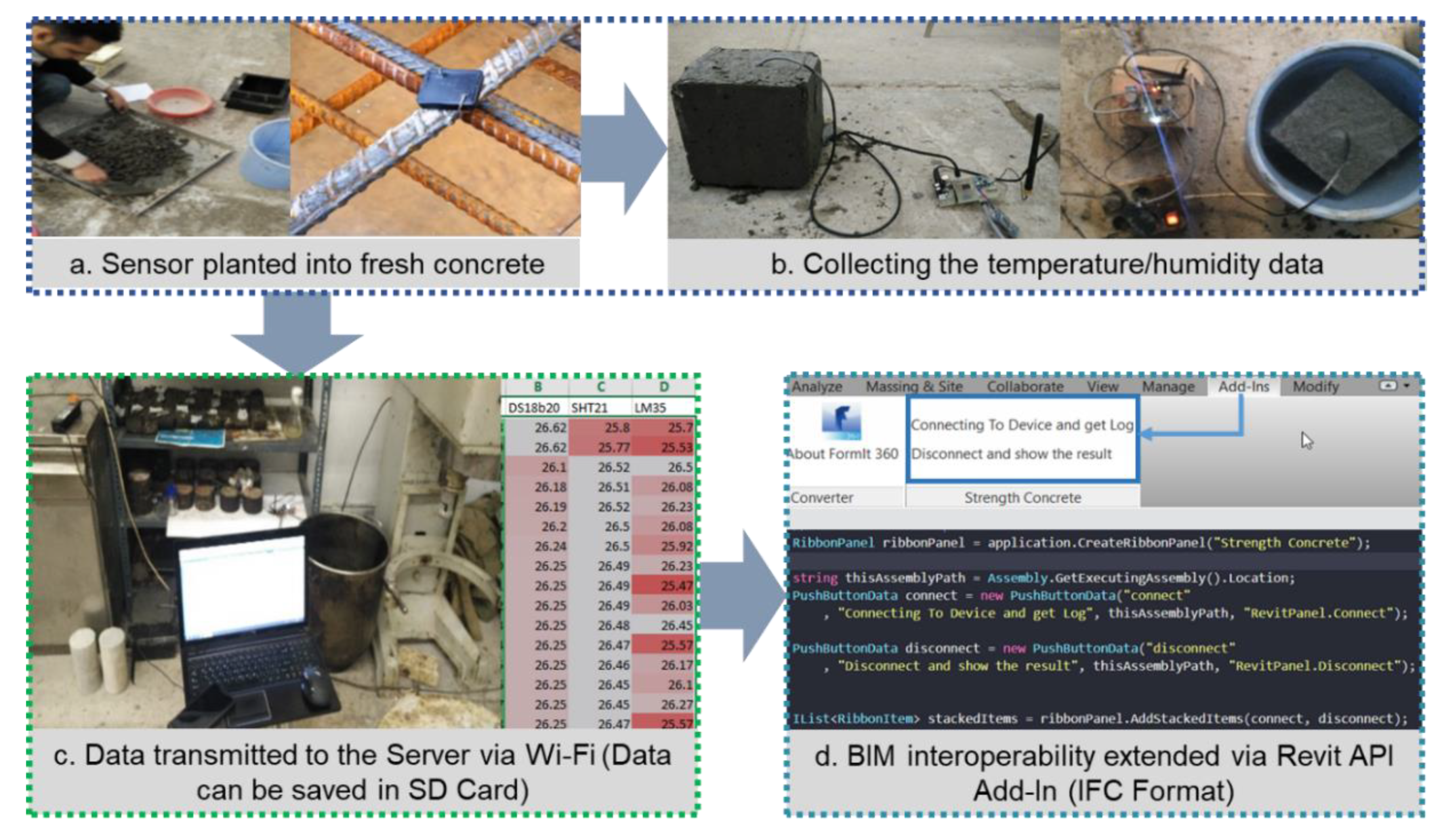

This study developed a BIM API add-in to bring the temperature data from the developed module and calculate the concrete formwork removal time.

Figure 4 shows the process to link the BIM environment and the sensors. The process consists of sending the concrete temperature data from the sensors to the BIM model over Wi-Fi. The sensors planted in fresh concrete can collect the temperature data and convey the data to the module system (see

Figure 4a,b). All data can be sent to the server via Wi-Fi (see

Figure 4c). Once the sensor module is connected to the BIM, two extra buttons appear in the Add-Ins pane in Revit (see

Figure 4d). The BIM can receive the sensor data from the module, and those data can then be analyzed to compute the concrete maturity on the associated sections in the 3D model. Since the sensor data are constantly transmitted to the BIM, this system monitors the concrete’s strength in real-time. To create a link between the module and the BIM-based system (see

Figure 4d), an object was defined as the Socket during the coding process. Once the systems were connected, two queues were also defined to command the system: DataRXQueue for incoming and DataTXQueue for outgoing commands. The information was placed in DataTXQueue to automatically transmit the data. To receive data, the information was simply read from the queue. The data were processed and listed as a record that could be accessed at any time. Since the commands received were added to the end of the buffer, short interruptions occurred and caused premature connection termination, as well as an #Enddata message to be displayed before the data were completely received. This meant that the system would start to send partial data before collecting the entire dataset. Therefore, a timer was set up to process the data during the designated time. The time interval was computed to be two seconds, so a multi-second delay was applied after reading each data line. Data processing began when no new data were received during this period. The system could calculate the concrete’s maturity by using the data collected. This conveyed the maturity as determined by each sensor. The Revit add-in system was designed to log the data hourly in an IFC format through a computed command. Then, each value from each sensor could be computed:

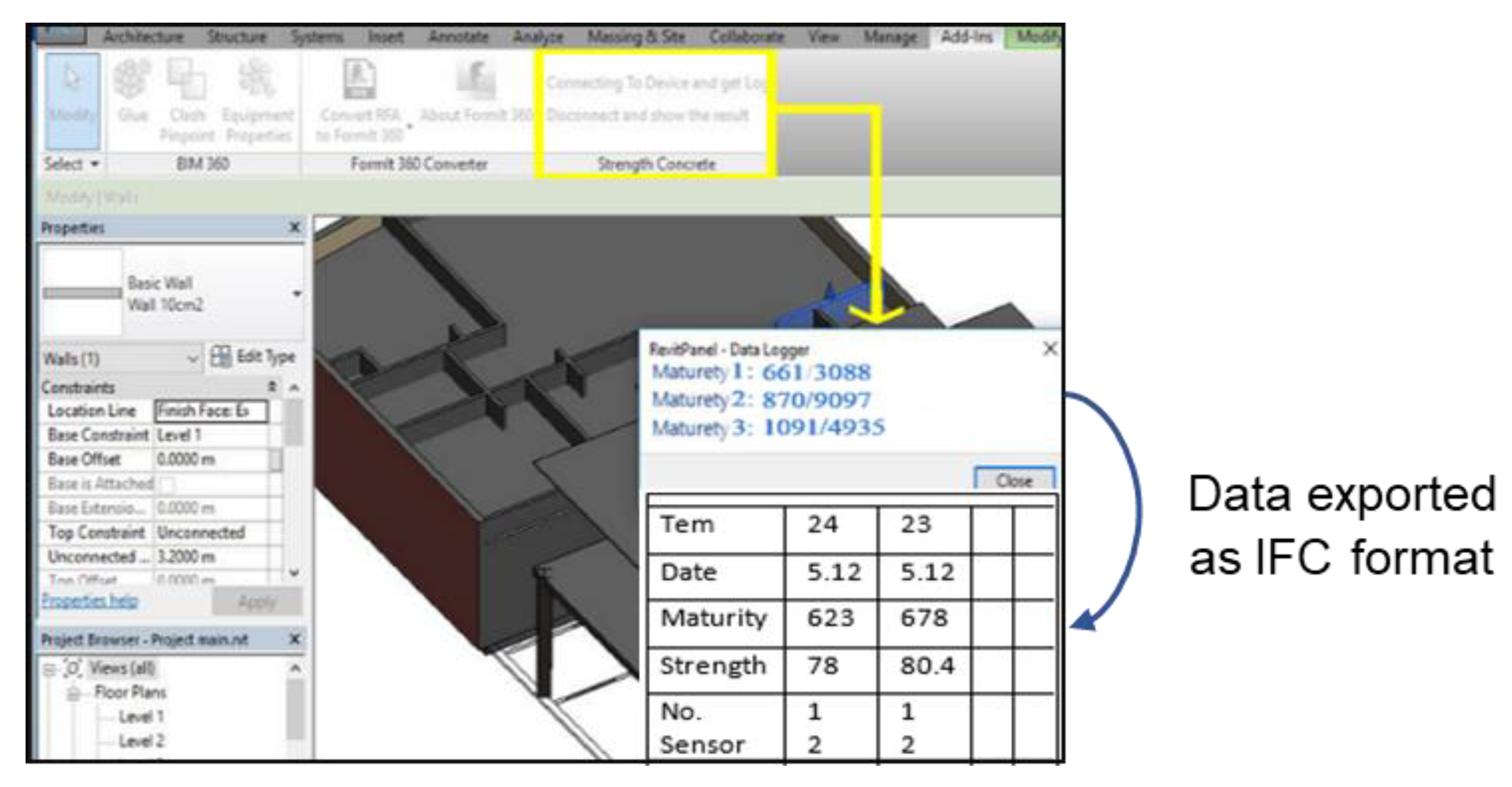

Based on the data received, it was possible to compute the concrete’s maturity based on the temperature in the maturity index, according to ASTM C1074 [

11]. The result was displayed on the associated structural members (e.g., slab, column, wall) of the 3D BIM model. Finally, the system could determine the time for formwork removal based on comparing the standard strength and computed values. The information regarding the status of the concrete could then be exported to an IFC format. Based on this, BIM’s interoperability through IFC can be extended to communicate temperature data for concrete collected from embedded sensors to an objective 3D model in the BIM.

4. System Validation and Case Study

To apply and validate the developed BIM-based concrete formwork control system, a case study was conducted on a beam with a span of seven meters in a building construction project (the Baran building) in Mashhad, Iran. A geometric 3D model of the Baran building was developed in BIM. The module was simultaneously connected to three sensors. During the construction project execution, the sensors were embedded in the concrete, and the temperature data was collected during the concrete placement. The average of the temperatures measured by these three sensors was used in the calculations.

Figure 5 shows the core temperature of the concrete automatically measured by the SHT21, Lm35, and Ds18b20 sensors at 1-minute intervals. Considering the size of the dataset collected, the figure presented only covers 44 min.

The compressive strength of concrete can be formulated based on the maturity concept, as defined by Carino [

20,

52]. The equivalent age was computed using Equation (1):

(where,

: equivalent age at the temperature;

: activation energy;

: universal gas constant;

: average absolute temperature during interval time,

)

The activation energy was considered to be constant for all cement types (in accordance with the recommendation in Carino and ASTM C1074). Many studies have argued that activation energy can depend on time and temperature [

10,

52,

53,

54,

55]. However, it is customary to assume constant activation energy. The concrete’s strength was estimated using parabolic Equation (2).

(where,

: strength;

: constant rate)

The cement used in the case study was ordinary Portland cement (OPC). As suggested by Carino and Tank [

56], the activation energy for OPC was assumed to be 41 kJ. It should be noted that some researchers have recommended slightly different values for this parameter [

57,

58].

Table 1 shows the performance coefficient and activation energy values used in this case study. By employing Equation (1), the equivalent time t

e24 was calculated for a normal day of the month. The times t

50%, t

70%, and t

85% were required for the concrete to gain 50%, 70%, and 85% of its designed compressive strength, respectively, at the reference temperature (i.e., 20 °C); these were calculated using Equation (2). The times t

e50%, t

e70%, and t

e85% were required for the concrete to gain 50%, 70%, and 85% of its designed compressive strength, respectively, at the site temperature.

The t

e value obtained from Equation (1) depended on the cement type (i.e., activation energy) and daily temperature variations. In this case study, particularly for a beam with a span of seven meters were used to test the BIM interoperability developed. For the selected beam element (spanning over six meters), 14 days were indicated in the standard building code as the minimum time required before formwork removal (BS8110:1997) and 28 days are required as the maximum time to strike the formwork (PN-B-06251:1963). The results of the t

e calculations for the selected beam are presented in

Table 2. Temperature data have been collected through three sensors during two tests. It is assumed that the concrete should gain at least 85% of its design strength before the formwork can be removed [

8]. As a result, the formwork removal time was computed as 9.6 days, ensuring 85% of the designed concrete strength at the second test.

The developed BIM-based system predicted that the formwork could be removed 4.4 days earlier than the requirement in the BS 8110:1997 (31.4% time-saving), 11.4 days earlier than the standard of IS 456:2000 (54.3% time-saving), and 18.4 days earlier than the PN-B-06251:1963’s formwork strike standard time (65.8% time-saving). In addition to the beam, the case study also conducted at the slab with a span of less than 4.5 m. The calculated time for removing the formwork was 6.9 days, which can reduce the time about 50.7% in maximum and minimum 1.4%. In the case of the slab more than 4.5 m, the computed time was indicated as 11.3 days. This reduced the time about 18.6% based on both IS456:2000 and BS8110:1997 standards. The results indicate that the proposed BIM interoperability in this study can aim in monitoring the concrete curing status based on the temperature data received from the sensors and computing the removal strike time based on the maturity method. Also, the BIM model could receive and compute the concrete maturity data through Wi-Fi and the information was exported into the IFC format.

Figure 6 shows the schematic of the BIM’s interoperability to compute the concrete maturity data from the three sensors.

5. Discussion

This study proposed a method for expanding the interoperability of BIM with wireless sensors in order to monitor the concrete maturity and control the concrete formwork process. While previous efforts to create BIM-assisted systems focused on concrete formwork design and the planning process, the system developed in this research targeted a concrete formwork control that potentially affects construction management and project controls. Particularly, the extended capability of BIM allows for the calculation of formwork removal time based on the maturity and strength data collected from planted sensors. In the case study, the overall approach, including wireless sensors, concrete maturity, and formwork removal control, was tested at a real construction project. As a result, this study identified the amount of time reduction in the removal of concrete formwork, as compared to the time given in the standard. Based on the case study, this study has four noteworthy implications.

First, sensor data can be transmitted to the BIM environment via a Wi-Fi signal with a TCP-IP protocol and API add-in interface. Data related to the concrete’s maturity can then be connected to the associated 3D objective model in the BIM environment. Therefore, this system is capable of monitoring the status of concrete and providing maturity data for users of the BIM environment. Therefore, the sensor module and BIM add-in developed in this study contribute to extending BIM’s interoperability in terms of real-time concrete monitoring and formwork process control.

Second, this interoperable BIM-based system can calculate the removal times of concrete formworks according to different parts of a structure (i.e., slab, beam, or column). This system will help practitioners to continuously monitor and control the concrete placement process and deliver an earlier time to remove the formwork. The current standards manually regulates the recommended time for removing the formwork to maintain the concrete’s performance. However, the results of the case study imply that the time for removing the formwork was reduced beyond what was recommended in the current standards. Removing the formwork earlier while still ensuring strength will help to avoid project delays and unnecessary formwork rental expenses. This will lead to reducing the time needed for the concrete formwork process and, consequently, project completion.

Third, it can be noticed that the use of BIM can be expanded from the concrete formwork design and layout to the concrete placement control. The previous studies contributed to documenting the design process of the concrete formwork by using BIM. This research described a proof-of-concept to exchange real-time sensor data in the BIM environment. By integrating two concepts in the BIM environment, it can provide more efficiency to design and control the concrete formwork.

Lastly, the developed BIM interoperability will help to prevent concrete rework from failing to gain the necessary strength. Based on the case study, the system demonstrated less than a 13% difference in concrete strength between the manual and newly developed system-based methods. Also, this implies that using the average temperature data collected from three sensors to calculate the strength and formwork removal time is of low tolerance. Since concrete work can be as high as 40%~60% of the total project cost and concrete formation usually represents over 50% of the entire set of concrete-based tasks in a construction project [

59], minimizing the reworking of concrete jobs is very significant for preventing total cost overruns. Consequently, this system will save time and cost on construction projects.

In this sense, this new BIM interoperability is beneficial for project control and management of construction. However, this study did not consider: (1) that environmental factors may affect concrete formation; (2) that the number of planted sensors may affect the performance of fresh concrete; (3) natural sensor errors, and (4) total cost and time impacts. Based on the limitation and implications documented in this research, it is recommended that this system potentially be integrated with the BIM-integrated concrete formwork layout and planning system proposed in previous studies. In addition, the sensor-embedded BIM interoperability could be also extended to the operation and maintenance steps of the constructed facilities. The sensors will continuously collect the data in terms of the concrete temperature and strength during the life cycle of the project. This will provide a more visible platform for implementation into the construction industry. Also, a deep investigation of the potential cost and time savings resulting from early formwork removal is needed. This would allow for an investigation of how this extended BIM interoperability impacts the total cost and time of a construction project.

6. Conclusions

Removing concrete formwork after a sufficient level of strength has been reached is critical to the quality of the concrete and the consequent safety and health of the structural components. The current study has documented various sensor-based concrete monitoring systems for use during the formwork process. Studies integrating BIM into the concrete formwork process have to date focused on design and planning rather than controlling the project and formwork use. Therefore, this study extended the interoperability of BIM for monitoring the status of curing concrete and computing its maturity and the timing of the formwork during the concrete placement. A sensor module was designed to receive data from three sensors collecting concrete temperature data. The data were conveyed to the associated parts of an objective 3D model via Wi-Fi. A database was then created via the BIM API add-in and based on the concrete’s maturity as computed and the formwork removal time, thus assisting the user’s decision-making with regards to the concrete work. A 3D model of an active construction project in Iran was established to validate the system. During the case study, sensors were planted in various structural components, columns, beams, floors, and slabs. The data collected by the sensors and module were then transmitted to the designed software. The BIM-based system presented here was capable of receiving and documenting data in real-time. The data computed in BIM were automatically stored in an IFC format. These data were capable of describing the strength of the concrete, building codes, and associated criteria, as well as opportunities to remove the formwork. The results of the case study showed that the concrete formwork could be removed approximately 40% earlier than the documented standard time without resulting in any structural damage.

In summary, this study proposed a new form of BIM interoperability for concrete formwork control and monitoring. This work ignored natural errors from the sensors, as well as other external factors affecting the concrete formwork. However, it should be underscored that this research provides extended interoperability for managing project activities, particularly concrete formwork, and the developed system can reduce the time spent before removing concrete formworks while still ensuring the concrete’s strength. In the future, this BIM-based system could be incorporated with BIM-based concrete formwork design and planning processes described in previous studies to improve the efficiency and productivity of concrete formwork use, as well as reduce redundancy. Other future efforts should investigate the economics of this new system’s use, as well as other issues affecting management feasibility. Such efforts will lead to an overall reduction in the time and money consumed by construction projects.

Author Contributions

Conceptualization, M.H. and J.M.S.; methodology, M.H., J.M.S., and S.K.; software, M.M.; validation, M.H., M.M., and J.M.S.; formal analysis, M.H.; investigation, J.M.S. and S.K.; resources, M.M. and J.M.S.; data curation, M.H., M.M., and J.M.S.; writing—original draft preparation, M.H.; writing—review and editing, S.K.; visualization, M.H. and S.K.; supervision, J.M.S. and S.K.; project administration, J.M.S.; All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Johnson, R.P. Composite Structures of Steel and Concrete; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 978-1-405-16839-7. [Google Scholar]

- Hyun, C.; Jin, C.; Shen, Z.; Kim, H. Automated optimization of formwork design through spatial analysis in building information modeling. Autom. Constr. 2018, 95, 193–205. [Google Scholar] [CrossRef]

- Skibicki, S. Optimization of Cost of Building with Concrete Slabs Based on the Maturity Method. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 022061. [Google Scholar]

- Hanna, A.S.; Senouci, A.B. Material Cost Minimization of Concrete Wall Forms. Build. Environ. 1997, 32, 57–67. [Google Scholar] [CrossRef]

- Okafor, F.; Ewa, D. Estimating Formwork Striking Time for Concrete Mixes. Niger. J. Technol. 2015, 35, 1–7. [Google Scholar] [CrossRef][Green Version]

- PN-B-06251:1963. Concrete and Reinforced Concrete Work—Technical Specification (Roboty Betonowe i Żelbetowe—Wymagania Techniczne); Polish Committee for Standardization: Warsaw, Poland, 1963. (In Polish) [Google Scholar]

- Indian Standard, I.S. IS 456 2000: Plain and Reinforced Concrete. Code of Practice, 4th ed.; Bureau of Indian Standards: New Delhi, India, 2000. [Google Scholar]

- British Standards Institution. Structural Use of Concrete—Part 1: Code of Practice for Design and Construction; BSI Press: London, UK, 1998. [Google Scholar]

- Yikici, T.A.; Chen, H.L. Use of maturity method to estimate compressive strength of mass concrete. Constr. Build. Mater. 2015, 95, 802–812. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Karakurt, C. Strength-Maturity Relations of Concrete for Different Cement Types. In International Sustainable Buildings Symposium; Springer: Cham, Switzerland, 2017; pp. 435–443. [Google Scholar]

- American Society for Testing and Materials (ASTM). ASTM C1074-17 Standard Practice for Estimating Concrete Strength by the Maturity Method; ASTM Internationa: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Badawi, Y.; Shamselfalah, A.; Elbadri, A.; Badawi, D.; Abdelazim, M.; Wahid, R.A.; Ali, A.M.; Ahmed, Y. Use of Maturity Sensors to Predict Concrete Compressive Strength in Different Curing and Compaction Regimes. In Proceedings of the 2nd Conference on Civil Engineering, Khartoum, Sudan, 3–5 December 2018; pp. 203–210. [Google Scholar]

- Moon, S. Application of Mobile Devices in Remotely Monitoring Temporary Structures during Concrete Placement. Procedia Eng. 2017, 196, 128–134. [Google Scholar] [CrossRef]

- Akula, M.; Lipman, R.R.; Franaszek, M.; Saidi, K.S.; Cheok, G.S.; Kamat, V.R. Real-time drill monitoring and control using building information models augmented with 3D imaging data. Autom. Constr. 2013, 36, 1–15. [Google Scholar] [CrossRef]

- Joblot, L.; Paviot, T.; Deneux, D.; Lamouri, S. Building Information Maturity Model specific to the renovation sector. Autom. Constr. 2019, 101, 140–159. [Google Scholar] [CrossRef]

- Paulsson, J.; Farhang, A. Measurements on the moisture state in a heavily trafficked concrete flat slab repaired with a bonded conrete overlay. In Proceedings of the Nordic Mini-seminar of the Nordic Concrete Federation, Espoo, Finlad, 22 August 1997; Volume 174, pp. 5–19. [Google Scholar]

- Paroll, H.; Nyknen, E. Measurement of relative humidity and temperature in a new concrete bridge vs. laboratory samples. Nord. Concr. Res. 1999, 23, 116–118. [Google Scholar]

- Kim, J.K.; Lee, C.S. Moisture diffusion of concrete considering self-desiccation at early ages. Cem. Concr. Res. 1999, 29, 1921–1927. [Google Scholar] [CrossRef]

- Klieger, P.; Lamond, J.F. STP 169C Significance of Tests and Properties of Concrete and Concrete-Making Materials; Klieger, P., Lamond, J.F., Eds.; ASTM International: West Conshohocken, PA, USA, 1994; ISBN 0-8031-2053-2. [Google Scholar]

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Sadrossadat, E.; Ghorbani, B.; Hamooni, M.; Moradpoor Sheikhkanloo, M.H. Numerical formulation of confined compressive strength and strain of circular reinforced concrete columns using gene expression programming approach. Struct. Concr. 2018, 19, 783–794. [Google Scholar] [CrossRef]

- Morel, J.C.; Pkla, A.; Walker, P. Compressive strength testing of compressed earth blocks. Constr. Build. Mater. 2007, 21, 303–309. [Google Scholar] [CrossRef]

- Lee, S.-C. Prediction of concrete strength using artificial neural networks. Eng. Struct. 2003, 25, 849–857. [Google Scholar] [CrossRef]

- Norris, A.; Saafi, M.; Romine, P. Temperature and moisture monitoring in concrete structures using embedded nanotechnology/microelectromechanical systems (MEMS) sensors. Constr. Build. Mater. 2008, 22, 111–120. [Google Scholar] [CrossRef]

- Benaicha, M.; Burtschell, Y.; Alaoui, A.H. Prediction of compressive strength at early age of concrete—Application of maturity. J. Build. Eng. 2016, 6, 119–125. [Google Scholar] [CrossRef]

- Schlicke, D.; Kanavaris, F.; Lameiras, R.; Azenha, M. On-site Monitoring of Mass Concrete. In RILEM State-of-the-Art Reports; Springer International Publishing: Berlin/Heidelberg, Germany, 2019; pp. 307–355. ISBN 978-3-319-76616-4. [Google Scholar]

- Providakis, C.; Liarakos, E. T-WiEYE: An early-age concrete strength development monitoring and miniaturized wireless impedance sensing system. Procedia Eng. 2011, 10, 484–489. [Google Scholar] [CrossRef]

- Hue, F.; Serrano, G.; Bolaño, J.A. Öresund Bridge. Temperature and cracking control of the deck slab concrete at early ages. Autom. Constr. 2000, 9, 437–445. [Google Scholar] [CrossRef]

- Lee, H.-S.; Cho, M.-W.; Yang, H.-M.; Lee, S.-B.; Park, W.-J. Curing Management of Early-age Concrete at Construction Site using Integrated Wireless Sensors. J. Adv. Concr. Technol. 2016, 12, 91–100. [Google Scholar] [CrossRef]

- Zekavat, P.R.; Moon, S.; Bernold, L.E. Performance of short and long range wireless communication technologies in construction. Autom. Constr. 2014, 47, 50–61. [Google Scholar] [CrossRef]

- Kang, J.H.; Gandhi, J. Readability test of RFID temperature sensor embedded in fresh concrete. J. Civ. Eng. Manag. 2010, 16, 412–417. [Google Scholar] [CrossRef]

- Kumbhar, D.S.; Chaudhari, H.C. Development of Wireless Sensor Network for Monitoring and Analysis of Concrete Compressive Strength Development in Early Age Concrete Structure. In Proceedings of the International Conference on Functional Materials and Microwaves ICFMM—2015, Aurangabad, India, 28–30 December 2015. [Google Scholar]

- Cabezas, J.; Sánchez-Rodríguez, T.; Gómez-Galán, J.A.; Cifuentes, H.; Carvajal, R.G. Compact embedded wireless sensor-based monitoring of concrete curing. Sensors 2018, 18, 876. [Google Scholar] [CrossRef]

- Lee, S.; Park, S. Development of Integrated Wireless Sensor Network Device with Mold for Measurement of Concrete Temperature. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 129–136. [Google Scholar]

- Dong, Y.; Luke, A.; Vitillo, N.; Ansari, F. In-Place estimation of concrete strength during the construction of a highway bridge by the maturity method. Concr. Int. 2000, 24, 61–66. [Google Scholar]

- Ilc, A.; Turk, G.; Kavčič, F.; Trtnik, G. New numerical procedure for the prediction of temperature development in early age concrete structures. Autom. Constr. 2009, 18, 849–855. [Google Scholar] [CrossRef]

- Chang, C.Y.; Hung, S.S. Implementing RFID and sensor technology to measure temperature and humidity inside concrete structures. Constr. Build. Mater. 2012, 26, 628–637. [Google Scholar] [CrossRef]

- Rudeli, N.; Santilli, A.; Arrambide, F. Striking of vertical concrete elements: An analysis using the maturity method. Eng. Struct. 2015, 95, 40–48. [Google Scholar] [CrossRef]

- Sofi, M.; Mendis, P.A.; Baweja, D. Estimating early-age in situ strength development of concrete slabs. Constr. Build. Mater. 2012, 29, 659–666. [Google Scholar] [CrossRef]

- Charles, M.E.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook: A Guide to Building Information Modeling for Owners, Managers, Designers, Engineers and Contractors; John Wiley & Sons: Hoboken, NJ, USA, 2008; ISBN 978-0-470-18528-5. [Google Scholar]

- Karan, E.P.; Irizarry, J. Extending BIM interoperability to preconstruction operations using geospatial analyses and semantic web services. Autom. Constr. 2015, 53, 1–12. [Google Scholar] [CrossRef]

- Kyungki, K.; Yong, C.; Kinam, K. BIM-Driven Automated Decision Support System for Safety Planning of Temporary Structures. J. Constr. Eng. Manag. 2018, 144, 4018072. [Google Scholar]

- Jeong, W.; Chang, S.; Son, J.; Yi, J.-S. BIM-Integrated Construction Operation Simulation for Just-In-Time Production Management. Sustainability 2016, 8, 1106. [Google Scholar] [CrossRef]

- Romanovskyi, R.; Sanabria Nejia, L.; Rezazadeh Azar, E. BIM-based Decision Support System for Concrete Formwork Design. In Proceedings of the 36th International Association for Automation and Robotics in Construction, Banff, AB, Canada, 21–24 May 2019; pp. 1129–1135. [Google Scholar]

- Meadati, P.; Irizary, J.; Aknoukh, A. BIM and Concrete Formwork Repository. In Proceedings of the 47th Associated School of Construction, Omaha, NE, USA, 6–9 April 2011. [Google Scholar]

- Ramesh, K.M.; Santhi, M.H. Automated Construction Layout and Simulation of Concrete Formwork Systems Using Building Information Modeling. In Proceedings of the 4th International Conference of European Asian Civil Engineering Forum (EACEF), Singapore, 26–28 June 2013; pp. C7–C12. [Google Scholar]

- Mansuri, D.; Chakraborty, D.; Elzarka, H.; Deshpande, A.; Gronseth, T. Building Information Modeling enabled Cascading Formwork Management Tool. Autom. Constr. 2017, 83, 259–272. [Google Scholar] [CrossRef]

- Chen, J.; Bulbul, T.; Taylor, J.E.; Olgun, G. A Case Study of Embedding Real-time Infrastructure Sensor Data to BIM. In Proceedings of the Construction Research Congress (CRC) 2014: Construction in a Global Network, Atlanta, GA, USA, 19–21 May 2014; pp. 269–278. [Google Scholar]

- Kannan, M.R.; Santhi, M.H. Constructability Assessment of Climbing Formwork Systems Using Building Information Modeling. Procedia Eng. 2013, 64, 1129–1138. [Google Scholar] [CrossRef]

- Singh, M.M.; Sawhney, A.; Sharma, V. Utilising Building Component Data from BIM for Formwork Planning. Constr. Econ. Build. 2017, 17, 20–36. [Google Scholar] [CrossRef]

- Runjing, Z.; Hongwei, X.; Guanzhong, R. Design of Temperature Measurement System Consisted of FPGA and DS18B20. In Proceedings of the 2011 International Symposium on Computer Science and Society, Kota Kinabalu, Malaysia, 16–17 July 2011; pp. 90–93. [Google Scholar]

- Xuan, D.; Zhan, B.; Poon, C.S. A maturity approach to estimate compressive strength development of CO2-cured concrete blocks. Cem. Concr. Compos. 2018, 85, 153–160. [Google Scholar] [CrossRef]

- Zhang, J.; Cusson, D.; Monteiro, P.; Harvey, J. New perspectives on maturity method and approach for high performance concrete applications. Cem. Concr. Res. 2008, 38, 1438–1446. [Google Scholar] [CrossRef]

- Yang, K.-H.; Mun, J.-S.; Cho, M.-S. Effect of Curing Temperature Histories on the Compressive Strength Development of High-Strength Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 12. [Google Scholar] [CrossRef]

- Kamkar, S.; Eren, Ö. Evaluation of maturity method for steel fiber reinforced concrete. KSCE J. Civ. Eng. 2018, 22, 213–221. [Google Scholar] [CrossRef]

- Tank, R.C.; Carino, N.J. Rate Constant Functions for Strength Development of Concrete. Mater. J. 1991, 88, 74–83. [Google Scholar]

- Kaszyńska, M. Early age properties of high-strength/high-performance concrete. Cem. Concr. Compos. 2002, 24, 253–261. [Google Scholar] [CrossRef]

- Saul, A.G.A. Principles underlying the steam curing of concrete at atmospheric pressure. Mag. Concr. Res. 1951, 2, 127–140. [Google Scholar] [CrossRef]

- Robert, L. Think Formwork - Reduce Costs. Struct. Mag. 2007, 4, 14–16. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).