Characterization of Responsive Plasters for Passive Moisture and Temperature Control

Abstract

1. Introduction

2. Materials and Methods

2.1. Studied Materials

2.2. Experimental Methods

3. Results and Discussion

4. Conclusions

- Application of selected admixtures influenced the basic material properties to a minor extent, namely, a slight increase in the total open porosity should be noted;

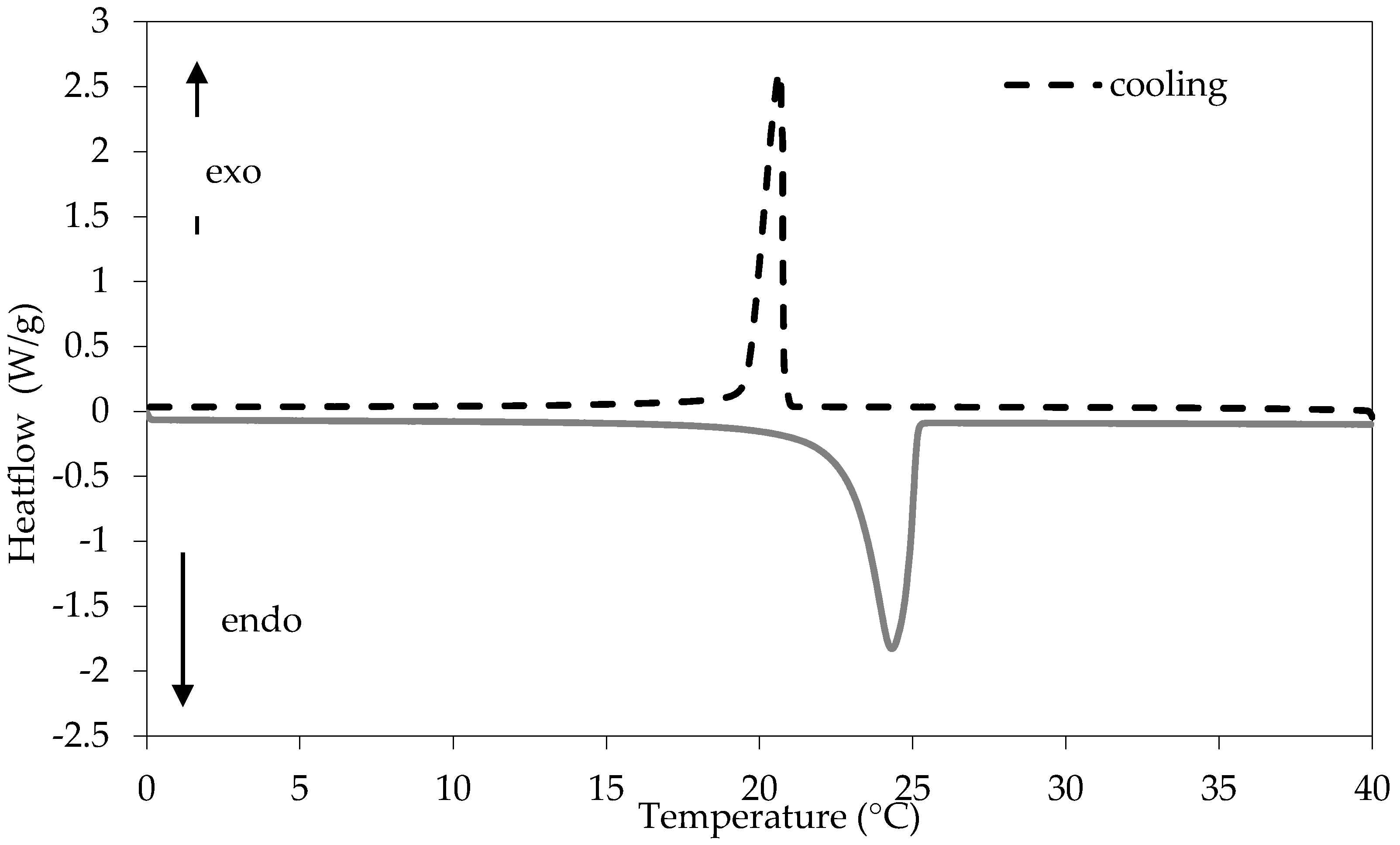

- The incorporation of the diatomite-based PCM composite into plaster did not affect the phase change transition in terms of the temperature range. The phase change enthalpy was increased proportionally to the applied dosage;

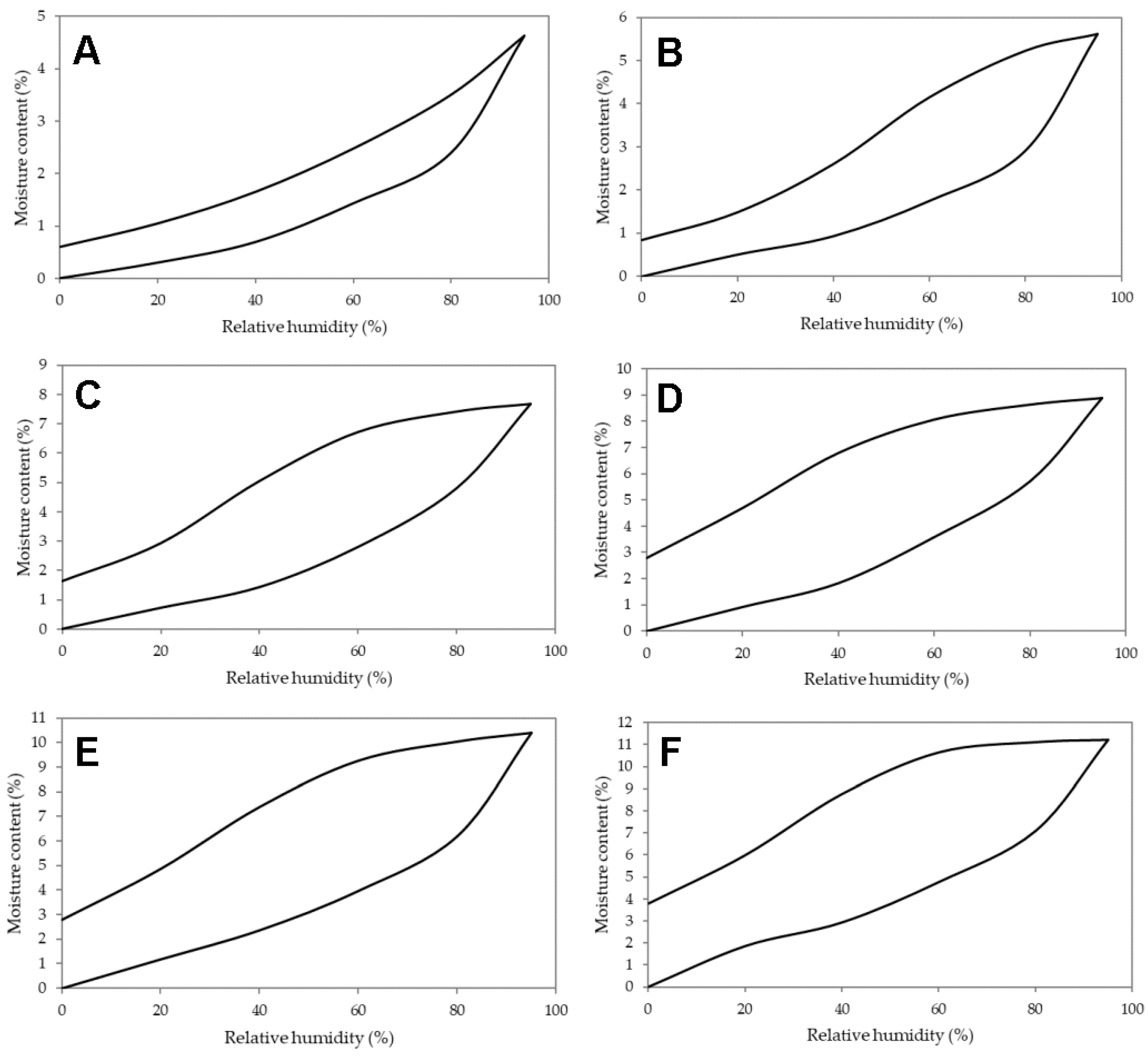

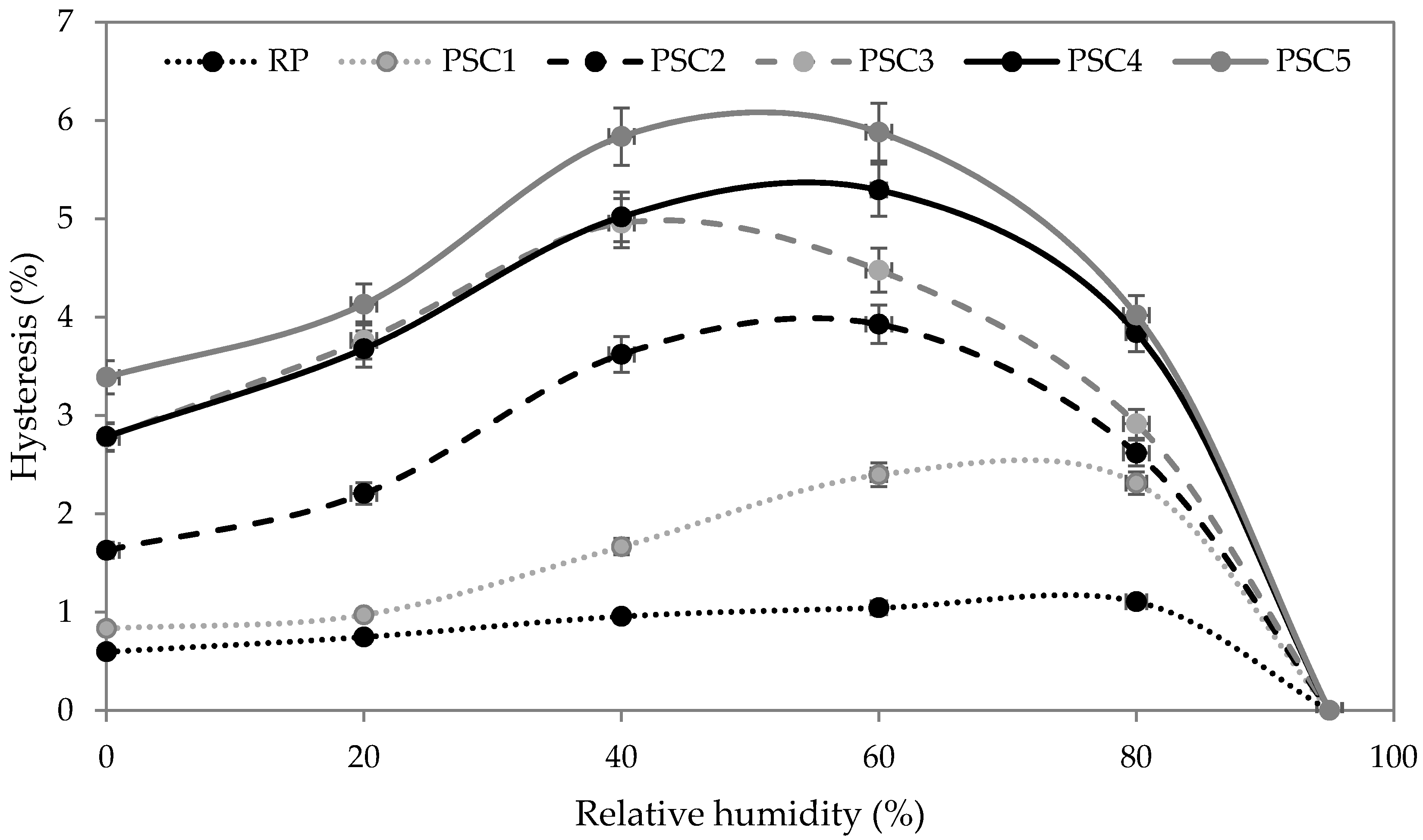

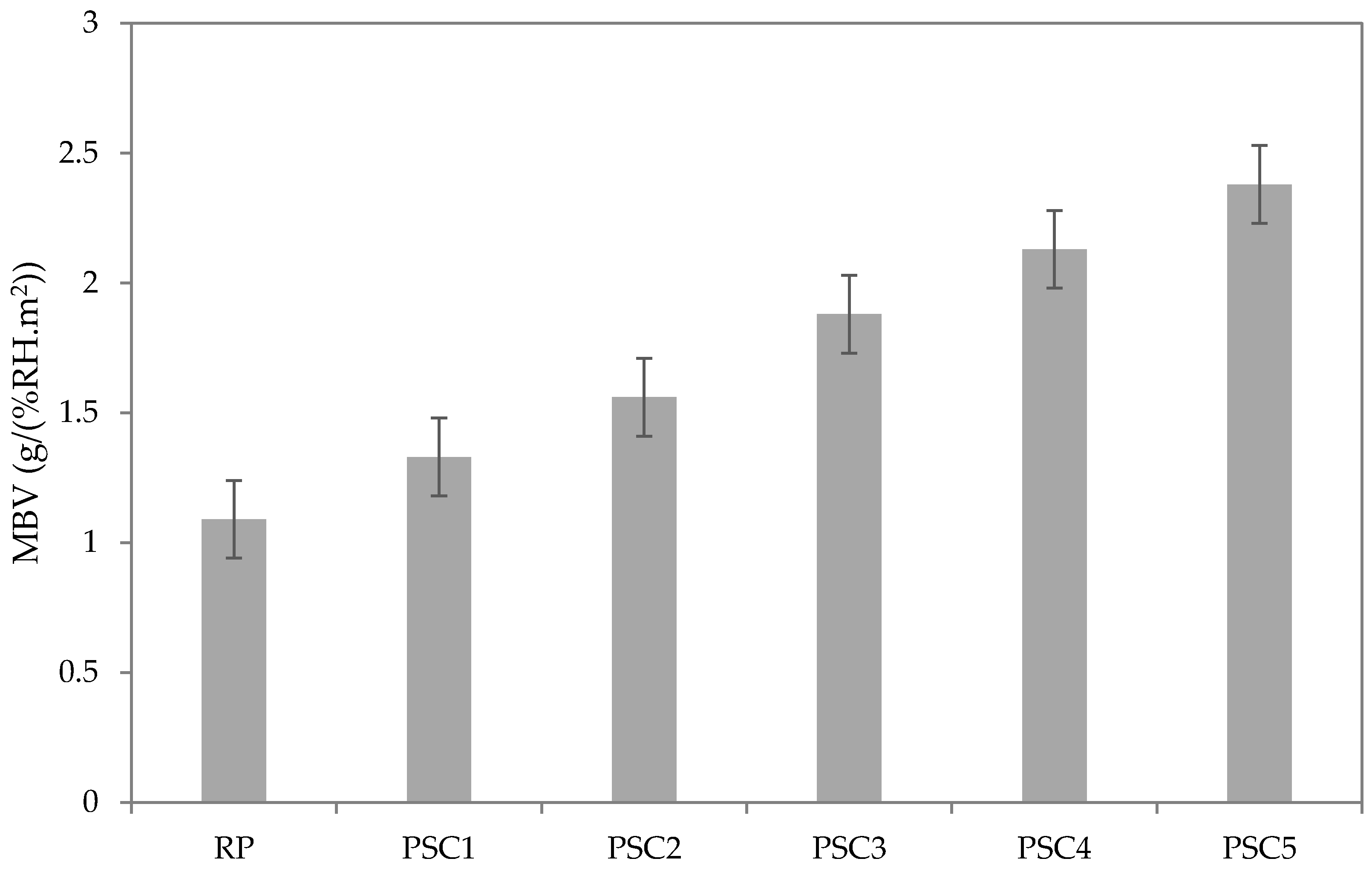

- Modifications in the hygric properties, and sorption characteristics in particular, point to the beneficial effect of the highly hygroscopic SAP admixture. In fact, the water vapor storage capability was tripled, although the hysteresis was shifted substantially;

- The humidity control performance accessed by MBV increased up to 2.38 g/(%RHm2), which corresponds to excellent moisture buffering, according to Nordtest classification, thanks to the synergic effect of both applied admixtures;

- The obtained results show the energy-saving potential of the developed phase change, humidity control plaster due to extended functionality.

Author Contributions

Funding

Conflicts of Interest

References

- Park, J.Y.; Wilson, E.; Parker, A.; Nagy, Z. The good, the bad, and the ugly: Data-driven load profile discord identification in a large building portfolio. Energy Build. 2020, 215, 19. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ballarini, I.; Corrado, V.; Evangelisti, L.; Grazieschi, G.; Guattari, C. Energy and environmental payback times for an NZEB retrofit. Build. Environ. 2019, 147, 461–472. [Google Scholar] [CrossRef]

- Brambilla, A.; Salvalai, G.; Imperadori, M.; Sesana, M.M. Nearly zero energy building renovation: From energy efficiency to environmental efficiency, a pilot case study. Energy Build. 2018, 166, 271–283. [Google Scholar] [CrossRef]

- Koci, J.; Koci, V.; Madera, J. Uncertainty in Moisture Transport Modelling and its Effect on Ice Formation in Porous Building Materials. In Proceedings of the Thermophysics 2018, Terchova, Slovakia, 7–9 November 2018; Trnik, A., Matiasovsky, P., Medved, I., Eds.; 2018; Volume 1988. [Google Scholar]

- Mazhoud, B.; Collet, F.; Pretot, S.; Chamoin, J. Hygric and thermal properties of hemp-lime plasters. Build. Environ. 2016, 96, 206–216. [Google Scholar] [CrossRef]

- Pavlik, Z.; Fort, J.; Pavlikova, M.; Pokorny, J.; Trnik, A.; Cerny, R. Modified lime-cement plasters with enhanced thermal and hygric storage capacity for moderation of interior climate. Energy Build. 2016, 126, 113–127. [Google Scholar] [CrossRef]

- Lee, H.; Ozaki, A.; Lee, M.; Yamamoto, T. Humidity control effect of vapor-permeable walls employing hygroscopic insulation material. Indoor Air 2020, 30, 346–360. [Google Scholar] [CrossRef]

- Johra, H.; Heiselberg, P.; Le Dreau, J. Influence of envelope, structural thermal mass and indoor content on the building heating energy flexibility. Energy Build. 2019, 183, 325–339. [Google Scholar] [CrossRef]

- Alam, M.; Singh, H.; Suresh, S.; Redpath, D.A.G. Energy and economic analysis of Vacuum Insulation Panels (VIPs) used in non-domestic buildings. Appl. Energy 2017, 188, 1–8. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Shukla, S.K.; Gupta, N.K. Potential of microencapsulated PCM for energy savings in buildings: A critical review. Sustain. Cities Soc. 2020, 53, 21. [Google Scholar]

- Mofijur, M.; Mahlia, T.M.I.; Silitonga, A.S.; Ong, H.C.; Silakhori, M.; Hasan, M.H.; Putra, N.; Rahman, S.M.A. Phase Change Materials (PCM) for Solar Energy Usages and Storage: An Overview. Energies 2019, 12, 3167. [Google Scholar] [CrossRef]

- Navarro, L.; Sole, A.; Martin, M.; Barreneche, C.; Olivieri, L.; Tenorio, J.A.; Cabeza, L.F. Benchmarking of useful phase change materials for a building application. Energy Build. 2019, 182, 45–50. [Google Scholar] [CrossRef]

- Urgessa, G.; Yun, K.K.; Yeon, J.; Yeon, J.H. Thermal responses of concrete slabs containing microencapsulated low-transition temperature phase change materials exposed to realistic climate conditions. Cem. Concr. Compos. 2019, 104, 8. [Google Scholar] [CrossRef]

- Essid, N.; Loulizi, A.; Neji, J. Compressive strength and hygric properties of concretes incorporating microencapsulated phase change material. Constr. Build. Mater. 2019, 222, 254–262. [Google Scholar] [CrossRef]

- Fort, J.; Novotny, R.; Trnik, A.; Cerny, R. Preparation and Characterization of Novel Plaster with Improved Thermal Energy Storage Performance. Energies 2019, 12, 3318. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, Z.M.; Yuan, Y.; Wang, Y.J.; Lei, J.X.; Zhou, C.L. Fabrication and characterization of fatty acid/wood-flour composites as novel form-stable phase change materials for thermal energy storage. Energy Build. 2018, 171, 88–99. [Google Scholar]

- Tao, Y.B.; He, Y.L. A review of phase change material and performance enhancement method for latent heat storage system. Renew. Sustain. Energy Rev. 2018, 93, 245–259. [Google Scholar] [CrossRef]

- Stritih, U.; Tyagi, V.V.; Stropnik, R.; Paksoy, H.; Haghighat, F.; Joybari, M.M. Integration of passive PCM technologies for net-zero energy buildings. Sustain. Cities Soc. 2018, 41, 286–295. [Google Scholar] [CrossRef]

- Fateh, A.; Borelli, D.; Weinlader, H.; Devia, F. Cardinal orientation and melting temperature effects for PCM-enhanced light-walls in different climates. Sustain. Cities Soc. 2019, 51, 19. [Google Scholar] [CrossRef]

- Li, Z.X.; Al-Rashed, A.; Rostamzadeh, M.; Kalbasi, R.; Shahsavar, A.; Afrand, M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: Effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers. Manag. 2019, 195, 43–56. [Google Scholar] [CrossRef]

- Koci, J.; Fort, J.; Cerny, R. Energy efficiency of latent heat storage systems in residential buildings: Coupled effects of wall assembly and climatic conditions. Renew. Sustain. Energy Rev. 2020, 132, 12. [Google Scholar] [CrossRef]

- Orlik-Kozdon, B.; Steidl, T. Experimental and analytical determination of water vapour transmission properties of recyclable insulation material. Constr. Build. Mater. 2018, 192, 798–807. [Google Scholar] [CrossRef]

- Kumaran, M.K.; Lackey, J.C.; Normandin, N.; Tariku, F.; van Reenen, D. Heat, air, and moisture transport properties of several North American bricks and mortar mixes. J. Test. Eval. 2004, 32, 383–389. [Google Scholar] [CrossRef]

- Brzyski, P.; Suchorab, Z. Capillary Uptake Monitoring in Lime-Hemp-Perlite Composite Using the Time Domain Reflectometry Sensing Technique for Moisture Detection in Building Composites. Materials 2020, 13, 1677. [Google Scholar] [CrossRef] [PubMed]

- Ivanic, A.; Kravanja, G.; Kidess, W.; Rudolf, R.; Lubej, S. The Influences of Moisture on the Mechanical, Morphological and Thermogravimetric Properties of Mineral Wool Made from Basalt Glass Fibers. Materials 2020, 13, 2392. [Google Scholar] [CrossRef]

- Bajno, D.; Bednarz, L.; Matkowski, Z.; Raszczuk, K. Monitoring of Thermal and Moisture Processes in Various Types of External Historical Walls. Materials 2020, 13, 505. [Google Scholar] [CrossRef]

- Jiang, Y.H.; Phelipot-Mardele, A.; Collet, F.; Lanos, C.; Lemke, M.; Ansell, M.; Hussain, A.; Lawrence, M. Moisture buffer, fire resistance and insulation potential of novel bio-clay plaster. Constr. Build. Mater. 2020, 244, 10. [Google Scholar] [CrossRef]

- Nizovtsev, M.I.; Letushko, V.N.; Borodulin, V.Y.; Sterlyagov, A.N. Experimental studies of the thermo and humidity state of a new building facade insulation system based on panels with ventilated channels. Energy Build. 2020, 206, 12. [Google Scholar] [CrossRef]

- Esty, B.; Permaul, P.; DeLoreto, K.; Baxi, S.N.; Phipatanakul, W. Asthma and Allergies in the School Environment. Clin. Rev. Allergy Immunol. 2019, 57, 415–426. [Google Scholar] [CrossRef]

- Nakayama, Y.; Nakaoka, H.; Suzuki, N.; Tsumura, K.; Hanazato, M.; Todaka, E.; Mori, C. Prevalence and risk factors of pre-sick building syndrome: Characteristics of indoor environmental and individual factors. Environ. Health Prev. Med. 2019, 24, 10. [Google Scholar] [CrossRef]

- Kreiger, B.K.; Srubar, W.V. Moisture buffering in buildings: A review of experimental and numerical methods. Energy Build. 2019, 202, 17. [Google Scholar] [CrossRef]

- McGregor, F.; Fabbri, A.; Ferreira, J.; Simoes, T.; Faria, P.; Morel, J.C. Procedure to determine the impact of the surface film resistance on the hygric properties of composite clay/fibre plasters. Mater. Struct. 2017, 50, 13. [Google Scholar] [CrossRef]

- Goncalves, H.; Goncalves, B.; Silva, L.; Raupp-Pereira, F.; Senff, L.; Labrincha, J.A. Development of porogene-containing mortars for levelling the indoor ambient moisture. Ceram. Int. 2014, 40, 15489–15495. [Google Scholar] [CrossRef]

- Buratti, C.; Belloni, E.; Merli, F. Water vapour permeability of innovative building materials from different waste. Mater. Lett. 2020, 265, 4. [Google Scholar] [CrossRef]

- Park, J.H.; Kang, Y.J.; Lee, J.; Wi, S.; Chang, J.D.; Kim, S. Analysis of walls of functional gypsum board added with porous material and phase change material to improve hygrothermal performance. Energy Build. 2019, 183, 803–816. [Google Scholar] [CrossRef]

- Senff, L.; Ascensao, G.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. Assessment of the single and combined effect of superabsorbent particles and porogenic agents in nanotitania-containing mortars. Energy Build. 2016, 127, 980–990. [Google Scholar] [CrossRef]

- Fort, J.; Sal, J.; Koci, J.; Cerny, R. Energy Efficiency of Novel Interior Surface Layer with Improved Thermal Characteristics and Its Effect on Hygrothermal Performance of Contemporary Building Envelopes. Energies 2020, 13, 2012. [Google Scholar] [CrossRef]

- Fort, J.; Trnik, A.; Pavlikova, M.; Pavlik, Z.; Cerny, R. Fabrication of Dodecanol/Diatomite Shape-Stabilized PCM and Its Utilization in Interior Plaster. Int. J. Thermophys. 2018, 39, 11. [Google Scholar] [CrossRef]

- Fort, J.; Koci, J.; Pokorny, J.; Cerny, R. Influence of Superabsorbent Polymers on Moisture Control in Building Interiors. Energies 2020, 13, 2009. [Google Scholar] [CrossRef]

- Patra, S.K.; Swain, S.K. Swelling Study of Superabsorbent PAA-co-PAM/Clay Nanohydrogel. J. Appl. Polym. Sci. 2011, 120, 1533–1538. [Google Scholar] [CrossRef]

- Li, A.; Wang, A.Q.; Chen, J.M. Studies on poly(acrylic acid)/attapulgite superabsorbent composite. I. Synthesis and characterization. J. Appl. Polym. Sci. 2004, 92, 1596–1603. [Google Scholar] [CrossRef]

- Qi, X.H.; Liu, M.Z.; Chen, Z.B.; Liang, R. Preparation and properties of diatomite composite superabsorbent. Polym. Adv. Technol. 2007, 18, 184–193. [Google Scholar] [CrossRef]

- Koci, V.; Fort, J.; Madera, J.; Scheinherrova, L.; Trnik, A.; Cerny, R. Correction of Errors in DSC Measurements Using Detailed Modeling of Thermal Phenomena in Calorimeter-Sample System. IEEE Trans. Instrum. Meas. 2020, 69, 8178–8186.40. [Google Scholar] [CrossRef]

- McGregor, F.; Heath, A.; Shea, A.; Lawrence, M. The moisture buffering capacity of unfired clay masonry. Build. Environ. 2014, 82, 599–607. [Google Scholar] [CrossRef]

- Mignon, A.; Graulus, G.J.; Snoeck, D.; Martins, J.; De Belie, N.; Dubruel, P.; Van Vlierberghe, S. pH-sensitive superabsorbent polymers: A potential candidate material for self-healing concrete. J. Mater. Sci. 2015, 50, 970–979. [Google Scholar] [CrossRef]

- He, Z.M.; Shen, A.Q.; Guo, Y.C.; Lyu, Z.H.; Li, D.S.; Qin, X.; Zhao, M.; Wang, Z.L. Cement-based materials modified with superabsorbent polymers: A review. Constr. Build. Mater. 2019, 225, 569–590. [Google Scholar] [CrossRef]

- Chen, Z.; Qin, M.H. Preparation and hygrothermal properties of composite phase change humidity control materials. Appl. Therm. Eng. 2016, 98, 1150–1157. [Google Scholar] [CrossRef]

- Mankel, C.; Caggiano, A.; Konig, A.; Schicchi, D.S.; Sam, M.N.; Koenders, E. Modelling the Thermal Energy Storage of Cementitious Mortars Made with PCM-Recycled Brick Aggregates. Materials 2020, 13, 1064. [Google Scholar] [CrossRef]

- Thongtha, A.; Khongthon, A.; Boonsri, T.; Chan, H.Y. Thermal Effectiveness Enhancement of Autoclaved Aerated Concrete Wall with PCM-Contained Conical Holes to Reduce the Cooling Load. Materials 2019, 12, 2170. [Google Scholar] [CrossRef]

- Sari, A.; Bicer, A.; Karaipekli, A.; Al-Sulaiman, F.A. Preparation, characterization and thermal regulation performance of cement based-composite phase change material. Sol. Energy Mater. Sol. Cells 2018, 174, 523–529. [Google Scholar] [CrossRef]

- Colinart, T.; Vinceslas, T.; Lenormand, H.; De Menibus, A.H.; Hamard, E.; Lecompte, T. Hygrothermal properties of light-earth building materials. J. Build. Eng. 2020, 29, 10. [Google Scholar] [CrossRef]

- Pavlik, Z.; Jerman, M.; Fort, J.; Cerny, R. Monitoring Thermal Performance of Hollow Bricks with Different Cavity Fillers in Difference Climate Conditions. Int. J. Thermophys. 2015, 36, 557–568. [Google Scholar] [CrossRef]

- Wan, H.; Sun, Z.W.; Huang, G.S.; Xu, X.H.; Yu, J.H. Calculation of the maximum moisture buffering thickness of building wall layer of hygroscopic material. Build. Environ. 2019, 160, 11. [Google Scholar] [CrossRef]

- Wu, Z.M.; Qin, M.H.; Zhang, M.J. Phase change change humidity control material and its impact on building energy consumption. Energy Build. 2018, 174, 254–261. [Google Scholar] [CrossRef]

- Shi, C.N.; Zhang, H.B.; Xuan, Y.L. Experimental investigation of thermal properties and moisture buffering performance of composite interior finishing materials under different airflow conditions. Build. Environ. 2019, 160, 10. [Google Scholar] [CrossRef]

- Senff, L.; Modolo, R.C.E.; Ascensao, G.; Hotza, D.; Ferreira, V.M.; Labrincha, J.A. Development of mortars containing superabsorbent polymer. Constr. Build. Mater. 2015, 95, 575–584. [Google Scholar] [CrossRef]

- Yang, H.L.; Peng, Z.Q.; Zhou, Y.; Zhao, F.; Zhang, J.; Cao, X.Y.; Hu, Z.W. Preparation and performances of a novel intelligent humidity control composite material. Energy Build. 2011, 43, 386–392. [Google Scholar] [CrossRef]

- Vieira, J.; Senff, L.; Goncalves, H.; Silva, L.; Ferreira, V.M.; Labrincha, J.A. Functionalization of mortars for controlling the indoor ambient of buildings. Energy Build. 2014, 70, 224–236. [Google Scholar] [CrossRef]

- Hou, P.M.; Qin, M.H.; Cui, S.Q.; Zu, K. Preparation and characterization of metal-organic framework/microencapsulated phase change material composites for indoor hygrothermal control. J. Build. Eng. 2020, 31, 11. [Google Scholar] [CrossRef]

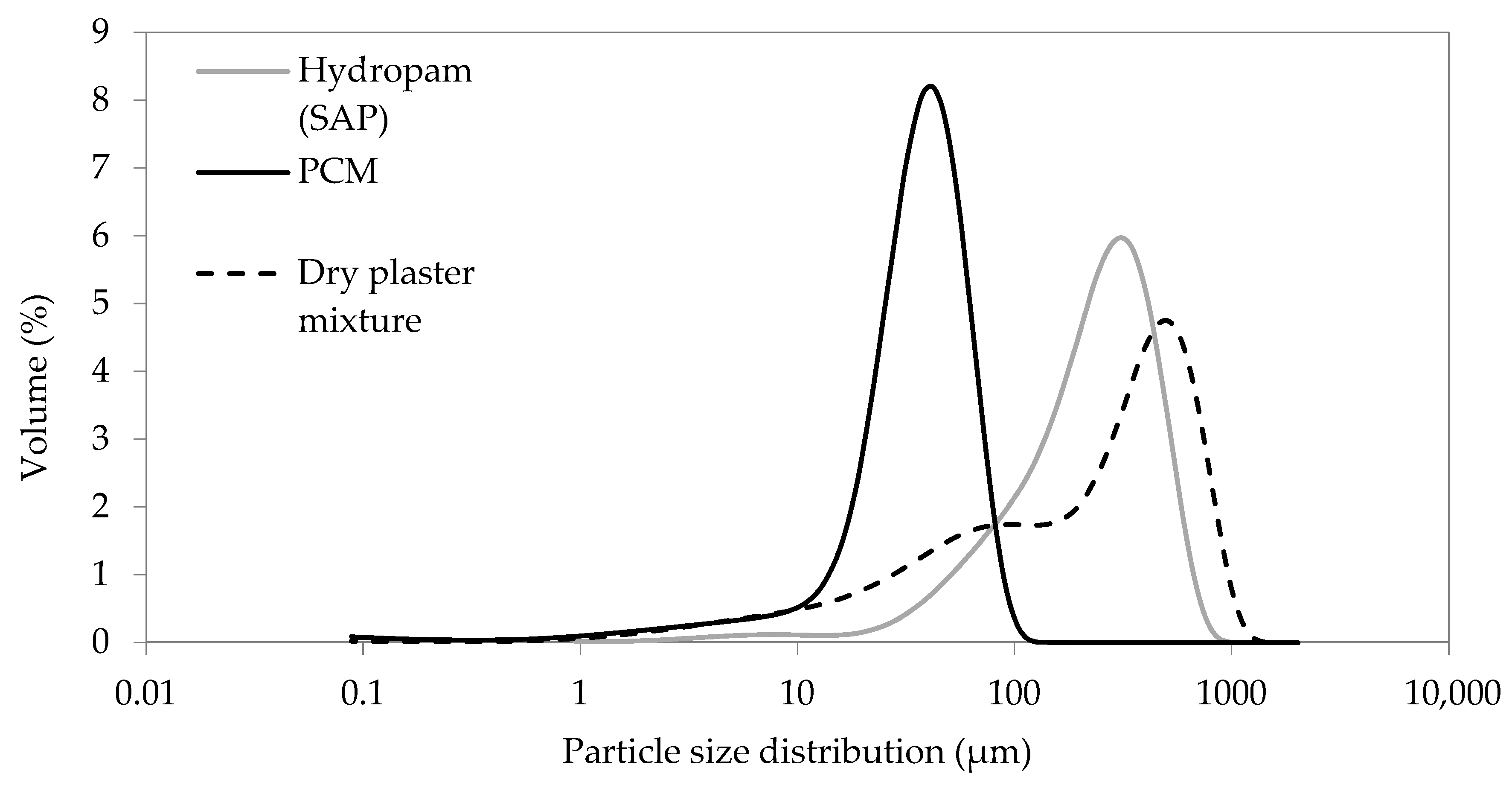

| Dry Plaster Mixture (kg) | w/p | PCM (kg) | SAP (kg) | |

|---|---|---|---|---|

| RP | 10 | 0.23 | 0 | 0 |

| PSC1 | 10 | 0.24 | 0.5 | 0.1 |

| PSC2 | 10 | 0.27 | 1 | 0.2 |

| PSC3 | 10 | 0.29 | 1.5 | 0.3 |

| PSC4 | 10 | 0.32 | 2 | 0.4 |

| PSC5 | 10 | 0.35 | 2.5 | 0.5 |

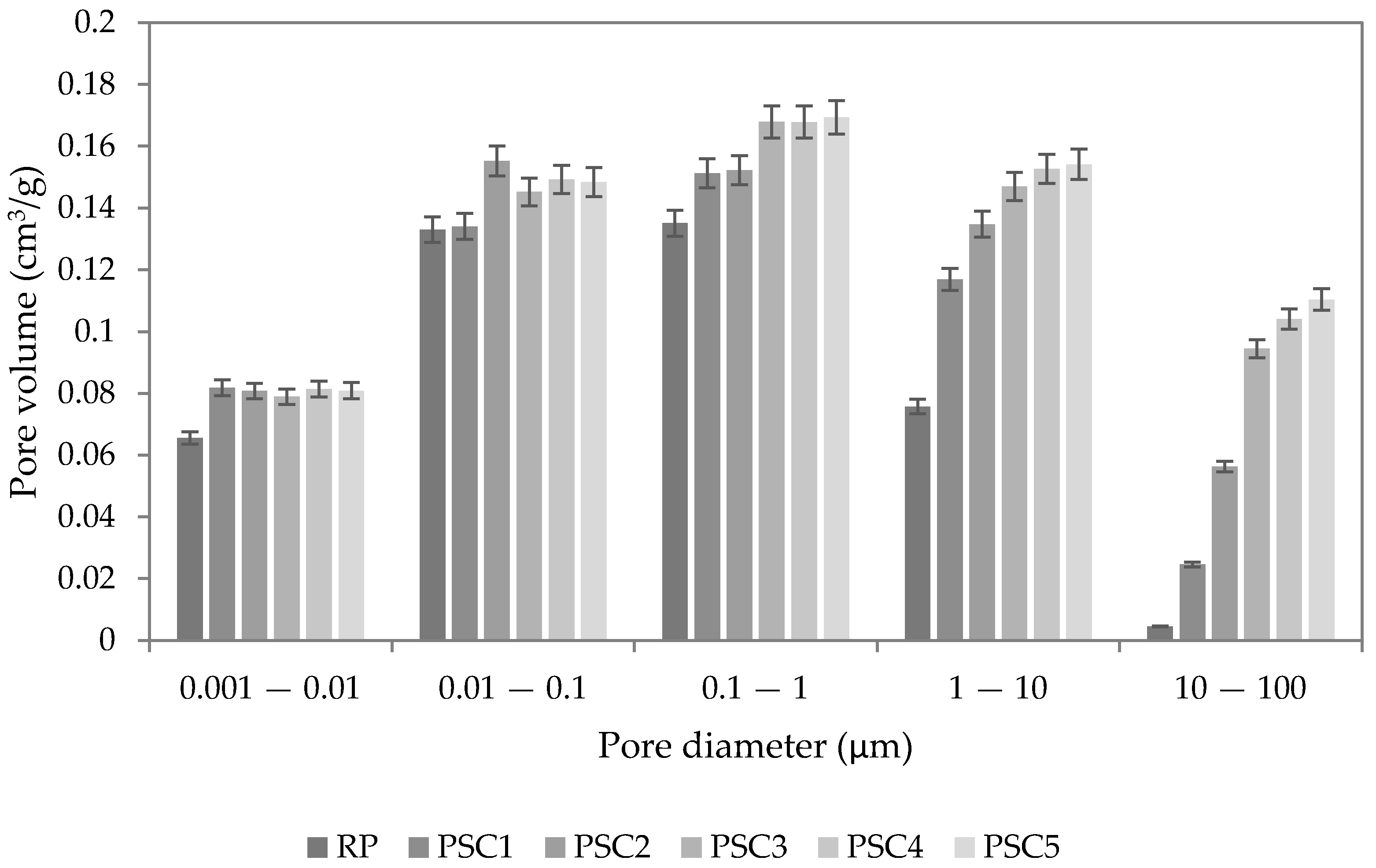

| Mixture | Bulk Density (kg/m3) | Matrix Density (kg/m3) | Total Open Porosity (%) |

|---|---|---|---|

| RP | 1604 ± 39 | 2506 ± 13 | 35.99 ± 1.57 |

| PSC1 | 1516 ± 36 | 2492 ± 16 | 39.17 ± 0.95 |

| PSC2 | 1476 ± 41 | 2441 ± 14 | 39.53 ± 1.23 |

| PSC3 | 1419 ± 23 | 2413 ± 12 | 41.19 ± 1.32 |

| PSC4 | 1372 ± 45 | 2356 ± 13 | 41.77 ± 1.08 |

| PSC5 | 1362 ± 24 | 2311 ± 15 | 41.06 ± 1.11 |

| Phase Change Temperature (°C) | ||||

|---|---|---|---|---|

| Heating | Cooling | |||

| Mixture | Onset | Endset | Onset | Endset |

| RP | - | - | - | - |

| PSC1 | 21.96 ± 0.36 | 24.78 ± 0.43 | 20.12 ± 0.33 | 18.47 ± 0.29 |

| PSC2 | 22.13 ± 0.24 | 24.89 ± 0.38 | 20.08 ± 0.35 | 18.96 ± 0.33 |

| PSC3 | 22.07 ± 0.52 | 25.14 ± 0.61 | 20.74 ± 0.52 | 19.11 ± 0.47 |

| PSC4 | 21.87 ± 0.51 | 25.01 ± 0.59 | 20.68 ± 0.62 | 19.06 ± 0.42 |

| PSC5 | 22.16 ± 0.45 | 25.43 ± 0.50 | 20.39 ± 0.36 | 19.21 ± 0.35 |

| Mixture | Thermal Conductivity (W/(mK)) | Thermal Diffusivity (m2/s) |

|---|---|---|

| RP | 0.543 ± 0.004 | 0.365 ± 0.003 |

| PSC1 | 0.532 ± 0.004 | 0.333 ± 0.004 |

| PSC2 | 0.533 ± 0.004 | 0.351 ± 0.002 |

| PSC3 | 0.514 ± 0.005 | 0.330 ± 0.003 |

| PSC4 | 0.505 ± 0.003 | 0.324 ± 0.003 |

| PSC5 | 0.480 ± 0.004 | 0.312 ± 0.004 |

| Mixture | Water Absorption Coefficient (kg/m2 s1/2) | Moisture Diffusivity (m2/s) |

|---|---|---|

| RP | 0.112 ± 0.011 | 1.61 × 10−8 ± 0.078 × 10−8 |

| PSC1 | 0.136 ± 0.009 | 3.02 × 10−8 ± 0.09 × 10−8 |

| PSC2 | 0.176 ± 0.012 | 8.46 × 10−8 ± 0.17 × 10−8 |

| PSC3 | 0.226 ± 0.014 | 2.63 × 10−7 ± 0.07 × 10−7 |

| PSC4 | 0.254 ± 0.024 | 4.90 × 10−7 ± 0.16 × 10−7 |

| PSC5 | 0.294 ± 0.023 | 7.95 × 10−7 ± 0.21 × 10−7 |

| Mixture | Water Vapor Resistance Factor (-) | Water Vapor Diffusivity (m2/s) |

|---|---|---|

| RP | 9.31 ± 0.60 | 2.66 × 10−6 ± 0.14 × 10−6 |

| PSC1 | 8.63 ± 0.31 | 2.87 × 10−6 ± 0.10 × 10−6 |

| PSC2 | 8.36 ± 0.34 | 2.98 × 10−6 ± 0.12 × 10−6 |

| PSC3 | 8.22 ± 0.41 | 3.01 × 10−6 ± 0.15 × 10−6 |

| PSC4 | 8.30 ± 0.44 | 2.98 × 10−6 ± 0.14 × 10−6 |

| PSC5 | 7.92 ± 0.29 | 3.13 × 10−6 ± 0.11 × 10−6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fořt, J.; Kočí, J.; Pokorný, J.; Podolka, L.; Kraus, M.; Černý, R. Characterization of Responsive Plasters for Passive Moisture and Temperature Control. Appl. Sci. 2020, 10, 9116. https://doi.org/10.3390/app10249116

Fořt J, Kočí J, Pokorný J, Podolka L, Kraus M, Černý R. Characterization of Responsive Plasters for Passive Moisture and Temperature Control. Applied Sciences. 2020; 10(24):9116. https://doi.org/10.3390/app10249116

Chicago/Turabian StyleFořt, Jan, Jan Kočí, Jaroslav Pokorný, Luboš Podolka, Michal Kraus, and Robert Černý. 2020. "Characterization of Responsive Plasters for Passive Moisture and Temperature Control" Applied Sciences 10, no. 24: 9116. https://doi.org/10.3390/app10249116

APA StyleFořt, J., Kočí, J., Pokorný, J., Podolka, L., Kraus, M., & Černý, R. (2020). Characterization of Responsive Plasters for Passive Moisture and Temperature Control. Applied Sciences, 10(24), 9116. https://doi.org/10.3390/app10249116