A Coupled Effect Model of Two-Position Local Geometric Deviations on Subsonic Blade Aerodynamic Performance

Abstract

1. Introduction

2. Computation Methods

3. Results and Analysis

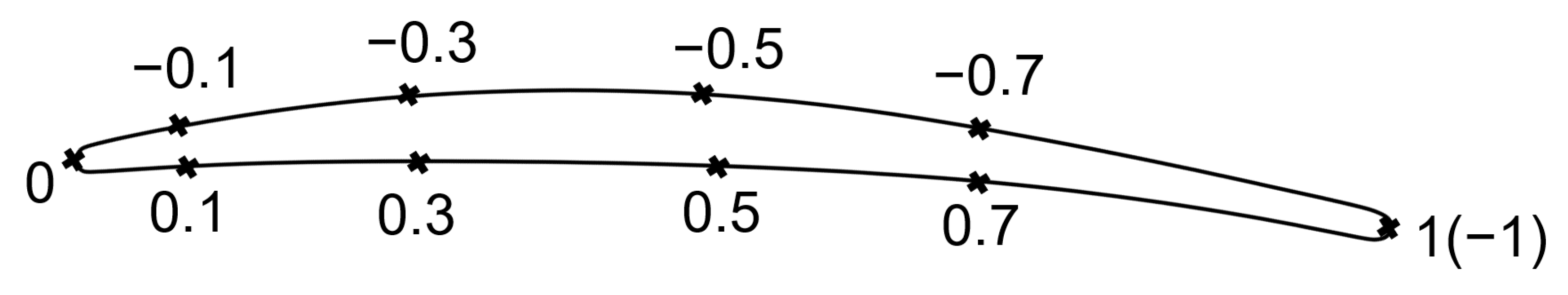

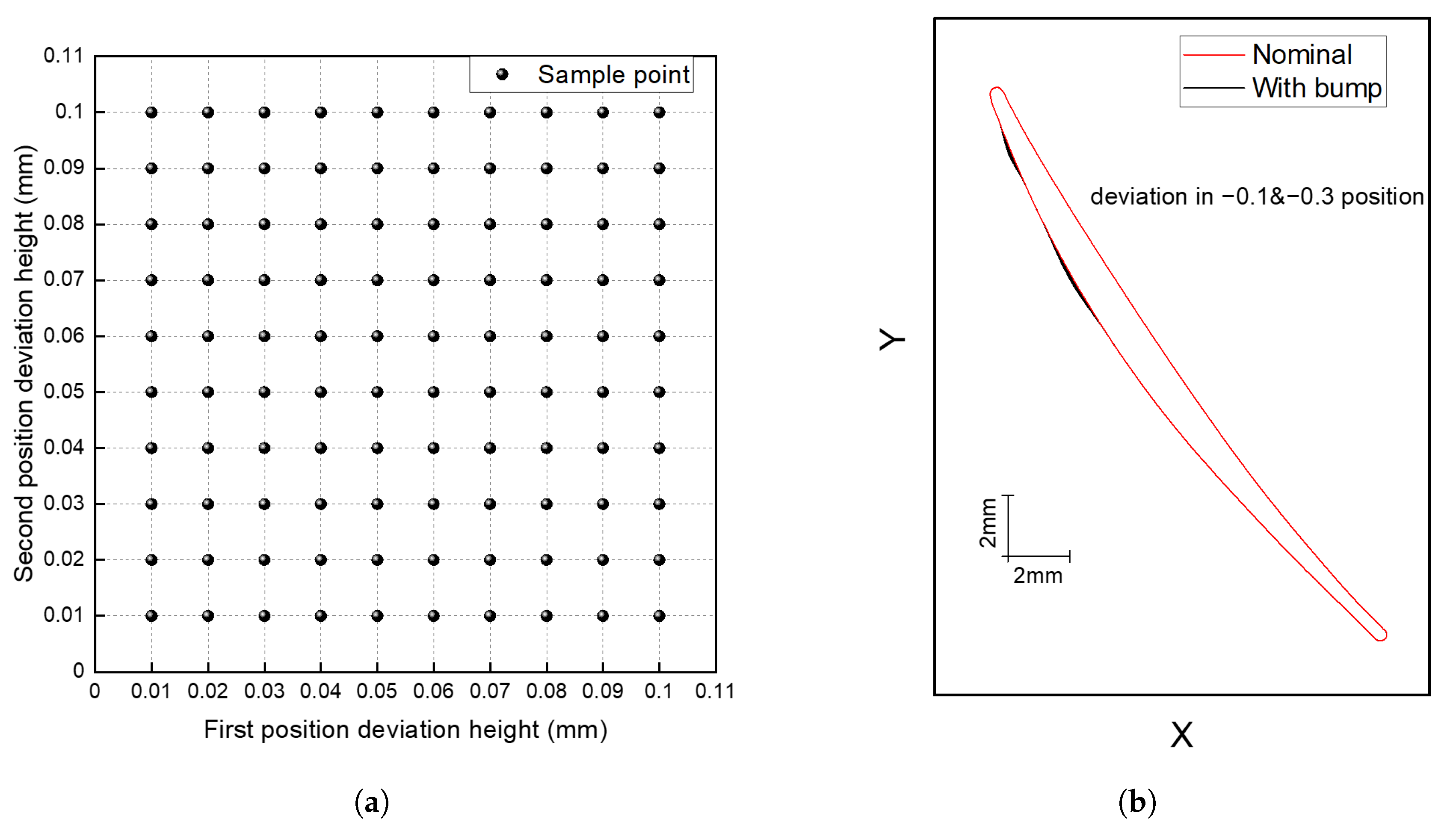

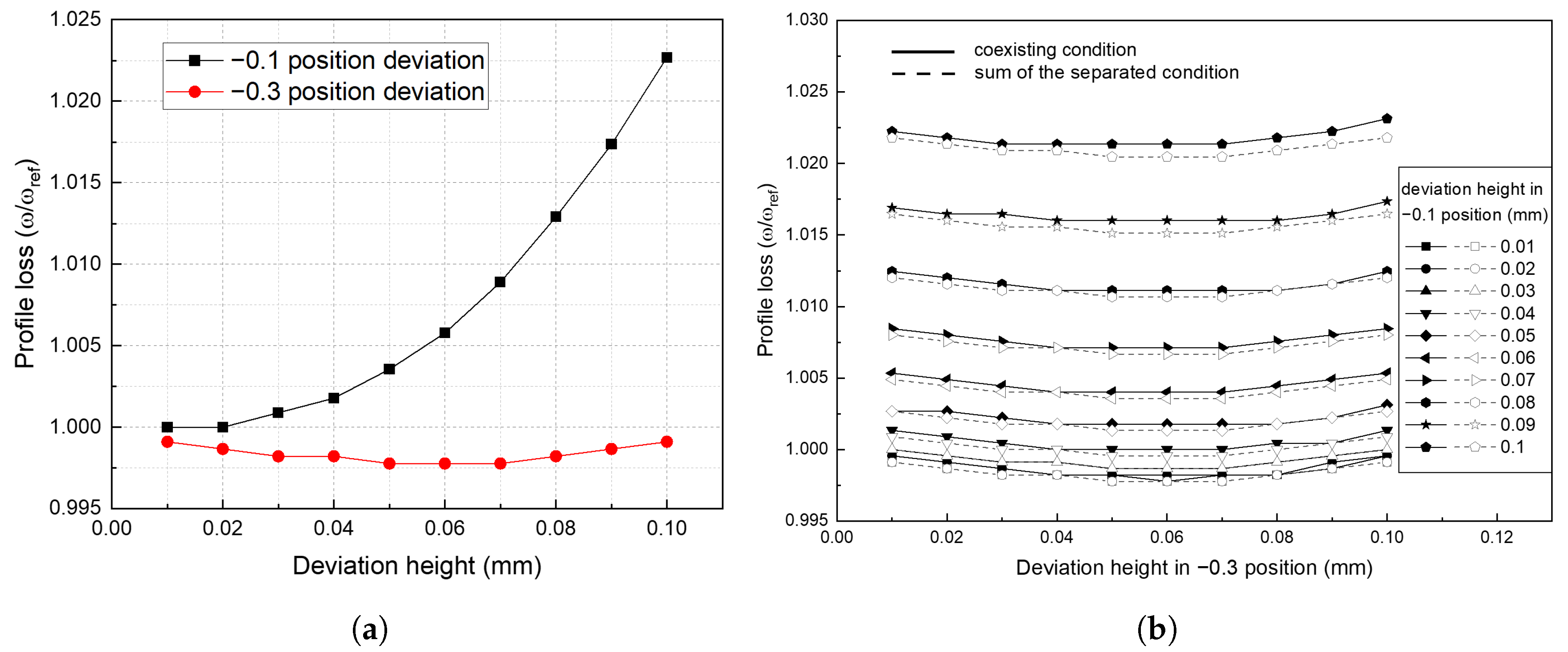

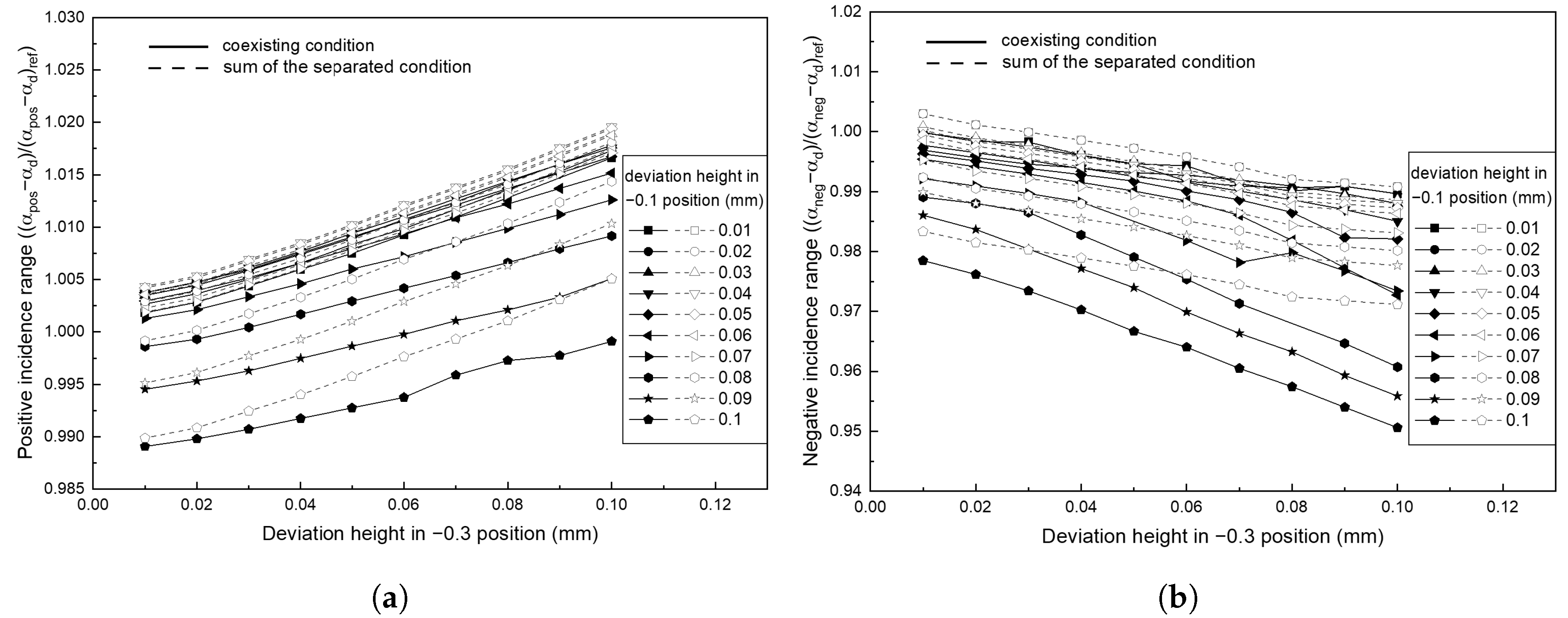

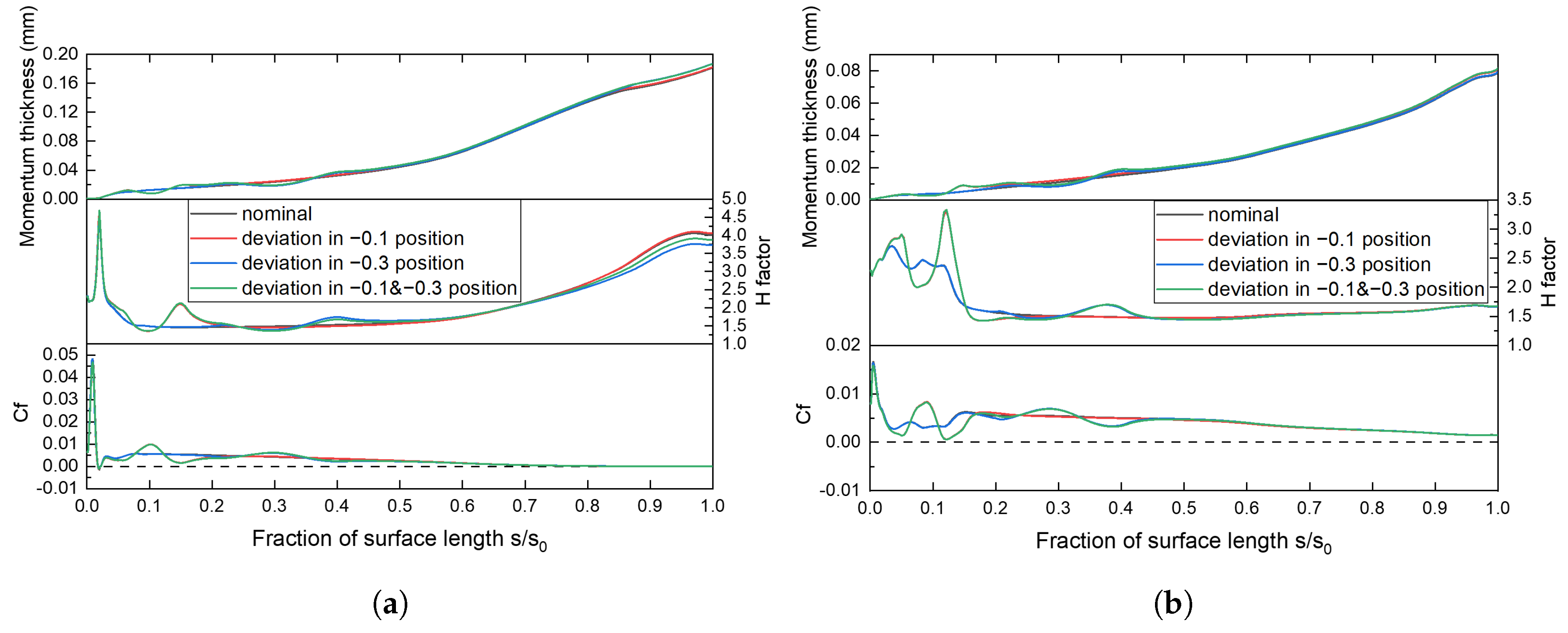

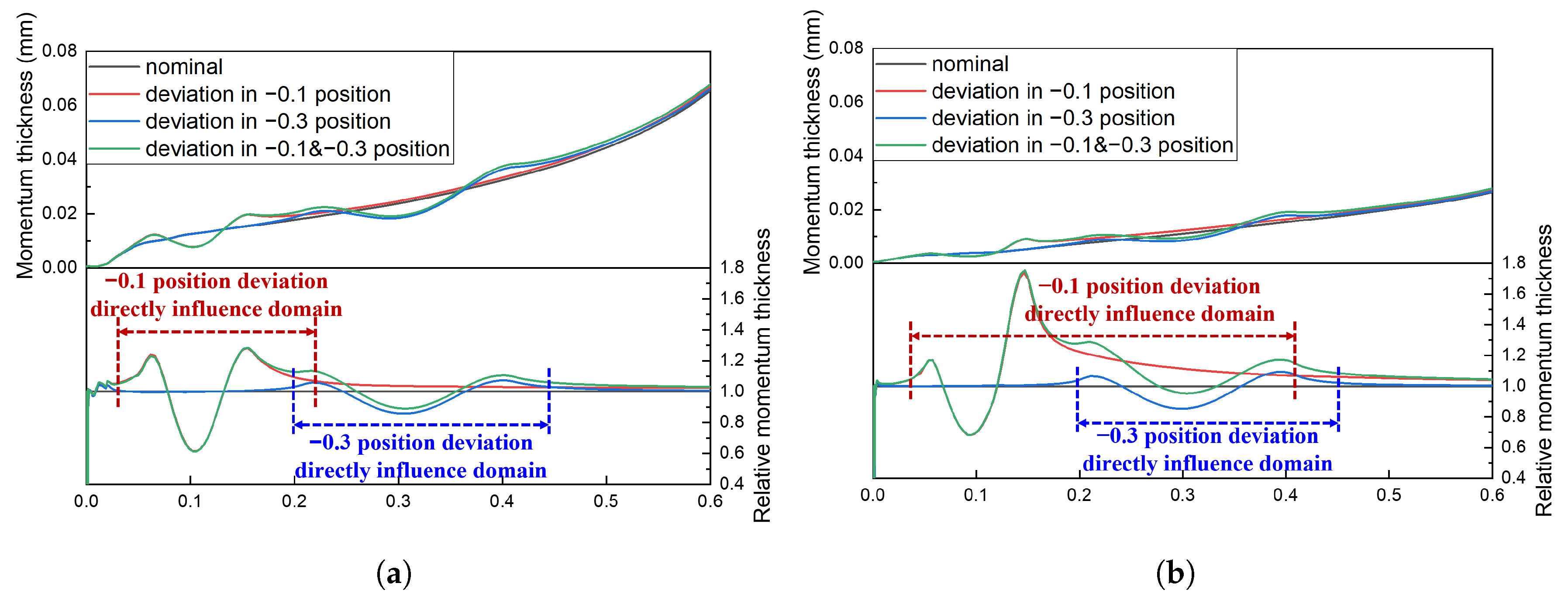

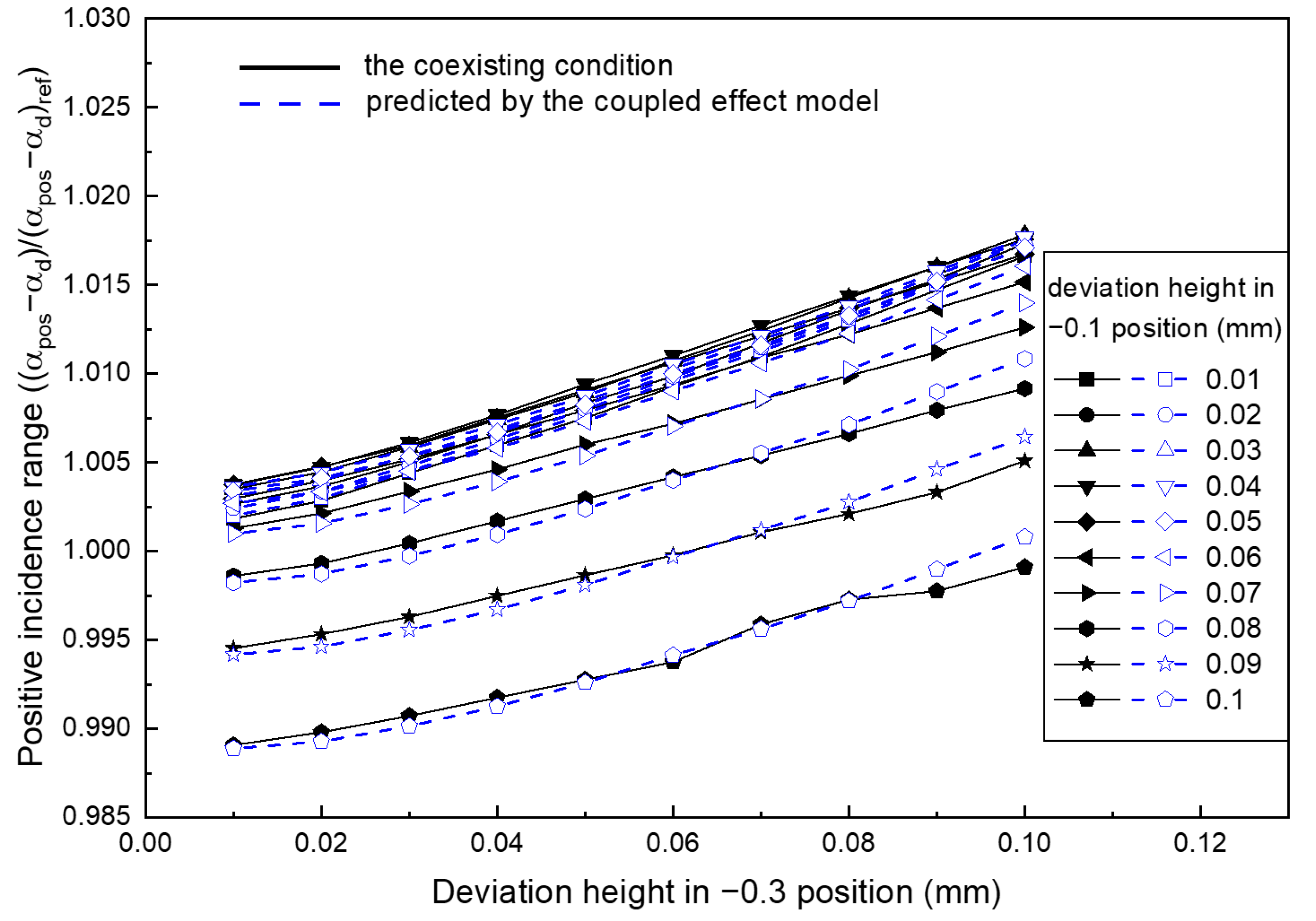

3.1. Analysis of Blade Performance and Model Establishment

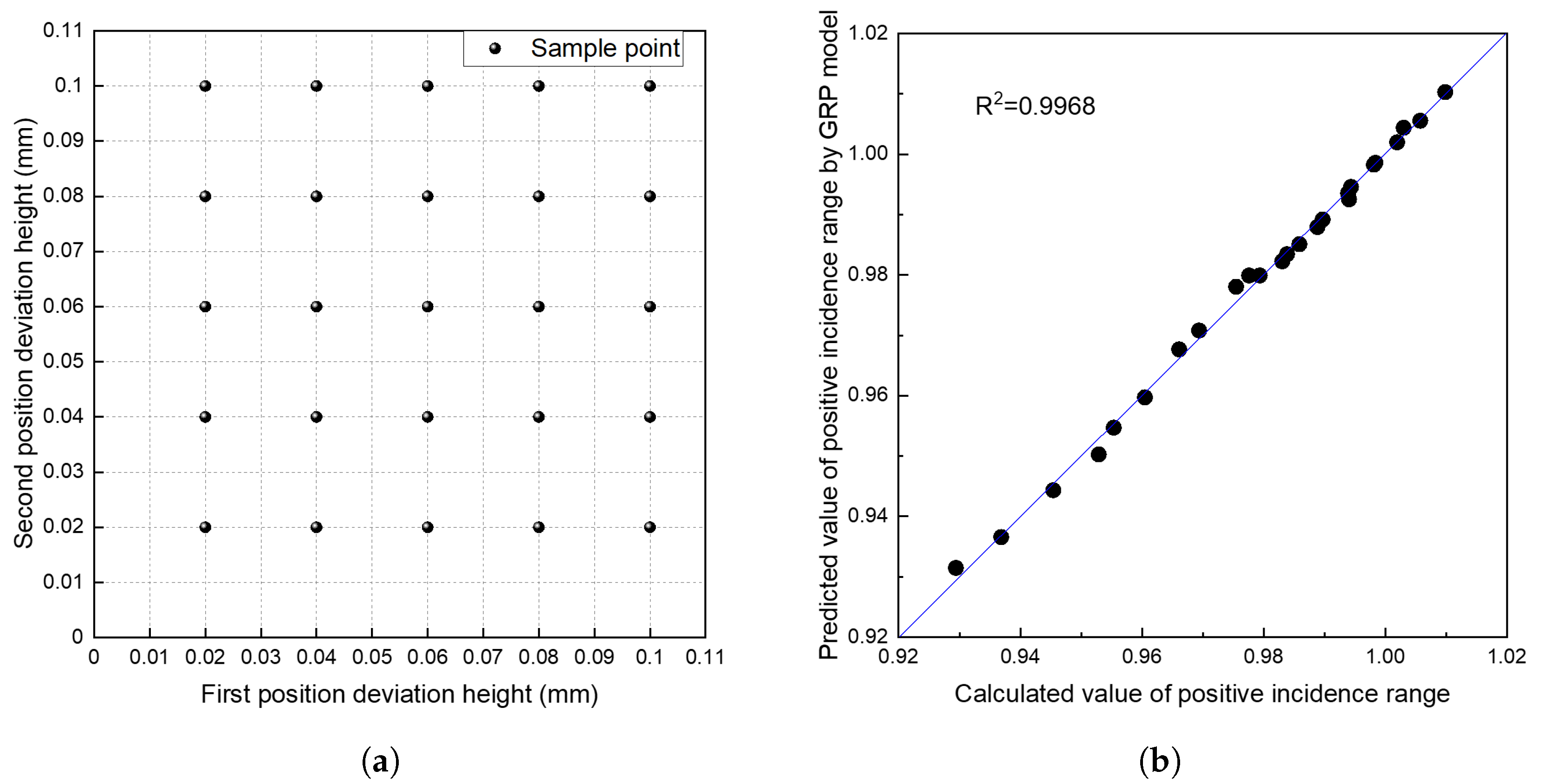

3.2. Model Verification

4. Discussion and Conclusions

- The aerodynamic performance influences of the blade local geometric deviations in different positions are not isolated from each other. In addition, there is a big difference in the incidence range between the sum of the separated condition and the coexisting condition. When solving the aerodynamic sensitivity of the blade profile, the impact of deviations in other positions should also be considered.

- The coupled effect between deviations is related to the deviation heights, the thickness of the boundary layer and the distance between the deviations. When the upstream boundary layer thickens, the effect of the downstream deviation will be weakened.

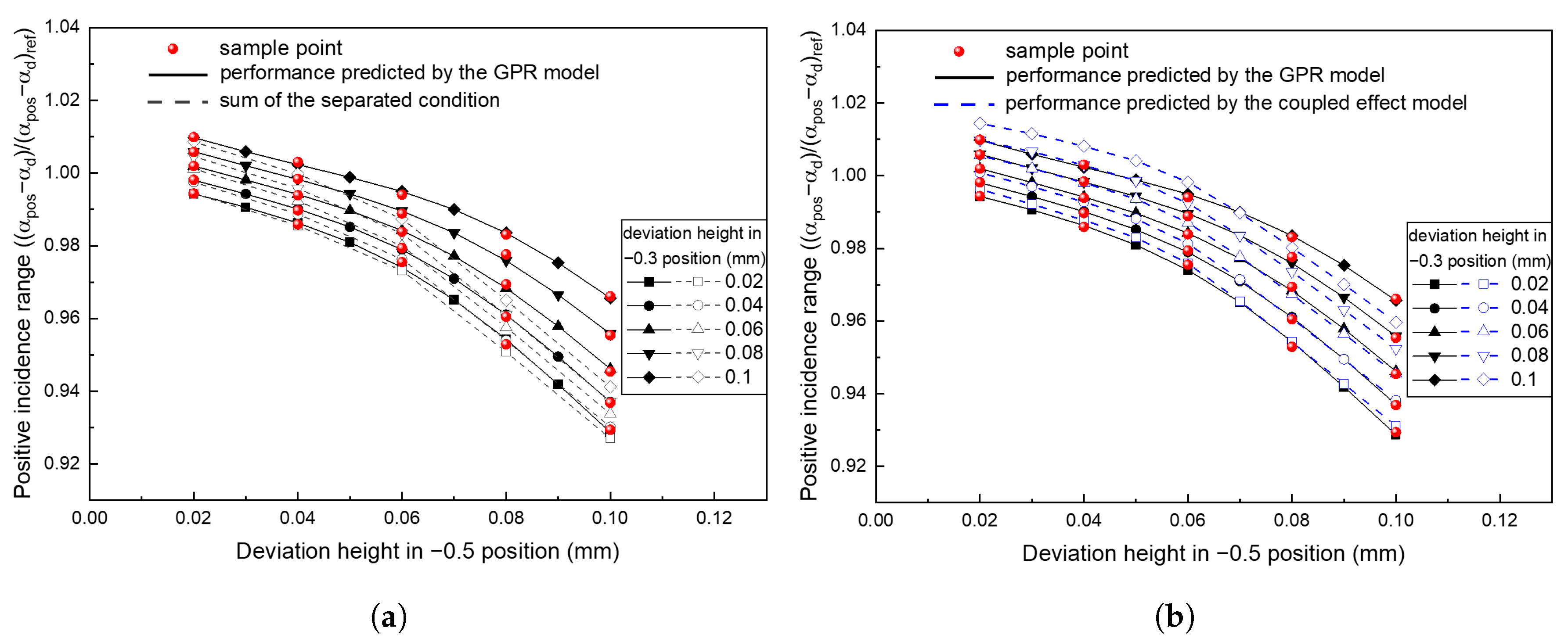

- By introducing the condition of a thick boundary layer and the assumption of exponential weakening effect, the coupled effect model was created to model the weakening effect of the downstream deviation. The accuracy of the model is proven by predicting the positive incidence range when the deviations are located on the suction surface. This model provides a new approach for the performance evaluation of the blade profile with multi-position deviations.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| Inlet Mach number | |

| Reynolds number | |

| Turbulivity | |

| Total pressure loss coeffcient | |

| Flow angle measured from axial | |

| Momentum thickness of boundary layer | |

| H | Shape factor |

| Blade surface friction coefficient | |

| s | Surface distance from leading-edge |

| Total surface length |

References

- Klapproth, J.F. Approximate Relative-Total-Pressure Losses of An Infinite Cascade of Supersonic Blades with Finite Leading-Edge Thickness; NASA: Washington, DC, USA, 1950.

- Reid, L.; Urasek, D. Experimental Evaluation of the Effects of a Blunt Leading Edge on the Performance of a Transonic Rotor. J. Eng. Power 1973, 95, 199. [Google Scholar] [CrossRef]

- Suder, K.L.; Chima, R.V.; Strazisar, A.J.; Roberts, W.B. The Effect of Adding Roughness and Thickness to a Transonic Axial Compressor Rotor. J. Turbomach. 1995, 117. [Google Scholar] [CrossRef]

- Garzon, V.; Darmofal, D. Using computational fluid dynamics in probabilistic engineering design. In Proceedings of the 15th AIAA Computational Fluid Dynamics Conference, Anaheim, CA, USA, 11–14 June 2001; p. 2526. [Google Scholar]

- Garzon, V.E. Probabilistic Aerothermal Design of Compressor Airfoils. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Lamb, C.M. Probabilistic Performance-Based Geometric Tolerancing of Compressor Blades. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2005. [Google Scholar]

- Goodhand, M.N.; Miller, R.J. Compressor leading edge spikes: A new performance criterion. J. Turbomach. 2011, 133, 021006. [Google Scholar] [CrossRef]

- Goodhand, M.N.; Miller, R.J.; Lung, H.W. The sensitivity of 2D compressor incidence range to in-service geometric variation. In Proceedings of the ASME Turbo Expo 2012: Power for Land, Sea, and Air, Copenhagen, Denmark, 11–15 June 2012; pp. 159–170. [Google Scholar]

- Goodhand, M.N.; Miller, R.J.; Lung, H.W. The impact of geometric variation on compressor two-dimensional incidence range. J. Turbomach. 2015, 137, 021007. [Google Scholar] [CrossRef]

- Dow, E.A. Robust Design and Tolerancing of Compressor Blades. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2015. [Google Scholar]

- Liu, B.; Liu, J.; Yu, X.; Meng, D. Influence mechanisms of manufacture variations on supersonic/transonic blade aerodynamic performances. In Proceedings of the ASME 2020: Turbomachinery Technical Conference and Exposition, London, UK, 22–26 June 2020; pp. 2020–15485. [Google Scholar]

- Lange, A.; Voigt, M.; Vogeler, K.; Johann, E. Principal component analysis on 3D scanned compressor blades for probabilistic CFD simulation. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1762. [Google Scholar]

- Tang, X.; Luo, J.; Liu, F. Adjoint aerodynamic optimization of a transonic fan rotor blade with a localized two-level mesh deformation method. Aerosp. Sci. Technol. 2018, 72, 267–277. [Google Scholar] [CrossRef]

- Wunsch, D.; Hirsch, C.; Nigro, R.; Coussement, G. Quantification of combined operational and geometrical uncertainties in turbo-machinery design. In Proceedings of the ASME Turbo Expo 2015: Power for Land, Sea, and Air, Montreal, QC, Canada, 15–19 June 2015; p. V02CT45A018. [Google Scholar]

- Dow, E.A.; Wang, Q. Simultaneous robust design and tolerancing of compressor blades. In Proceedings of the ASME Turbo Expo 2014: Power for Land, Sea, and Air, Düsseldorf, Germany, 16–20 June 2014; p. V02BT45A007. [Google Scholar]

- Hicks, R.M.; Henne, P.A. Wing design by numerical optimization. J. Aircr. 1978, 15, 407–412. [Google Scholar] [CrossRef]

- Nair, P.; Choudhury, A.; Keane, A. A Bayesian framework for uncertainty analysis using deterministic black-box simulation codes. In Proceedings of the 42nd AIAA/ASME/ASCE/AHS/ASC Structures, Seattle, WA, USA, 16–19 April 2001; p. 1677. [Google Scholar]

| Deviation Position | Parameter | Min/(mm) | Max/(mm) | Sample Interval/(mm) |

|---|---|---|---|---|

| Leading edge | Height | 0.01 | 0.1 | 0.01 |

| Width | 10% Chord length | |||

| Profile body | Height | 0.01 | 0.1 | 0.01 |

| Width | 20% Chord length | |||

| Parameter | Value |

|---|---|

| Local/average spacing ratios in leading edge | 0.1 |

| Local/average spacing ratios in trailing edge | 0.9 |

| Inlet and outlet grid type | H-type |

| Number of inlet points | 50 |

| Number of outlet points | 30 |

| Number of streamlines | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, X.; Li, M.; An, G.; Liu, B. A Coupled Effect Model of Two-Position Local Geometric Deviations on Subsonic Blade Aerodynamic Performance. Appl. Sci. 2020, 10, 8976. https://doi.org/10.3390/app10248976

Yu X, Li M, An G, Liu B. A Coupled Effect Model of Two-Position Local Geometric Deviations on Subsonic Blade Aerodynamic Performance. Applied Sciences. 2020; 10(24):8976. https://doi.org/10.3390/app10248976

Chicago/Turabian StyleYu, Xianjun, Mingzhi Li, Guangfeng An, and Baojie Liu. 2020. "A Coupled Effect Model of Two-Position Local Geometric Deviations on Subsonic Blade Aerodynamic Performance" Applied Sciences 10, no. 24: 8976. https://doi.org/10.3390/app10248976

APA StyleYu, X., Li, M., An, G., & Liu, B. (2020). A Coupled Effect Model of Two-Position Local Geometric Deviations on Subsonic Blade Aerodynamic Performance. Applied Sciences, 10(24), 8976. https://doi.org/10.3390/app10248976