1. Introduction

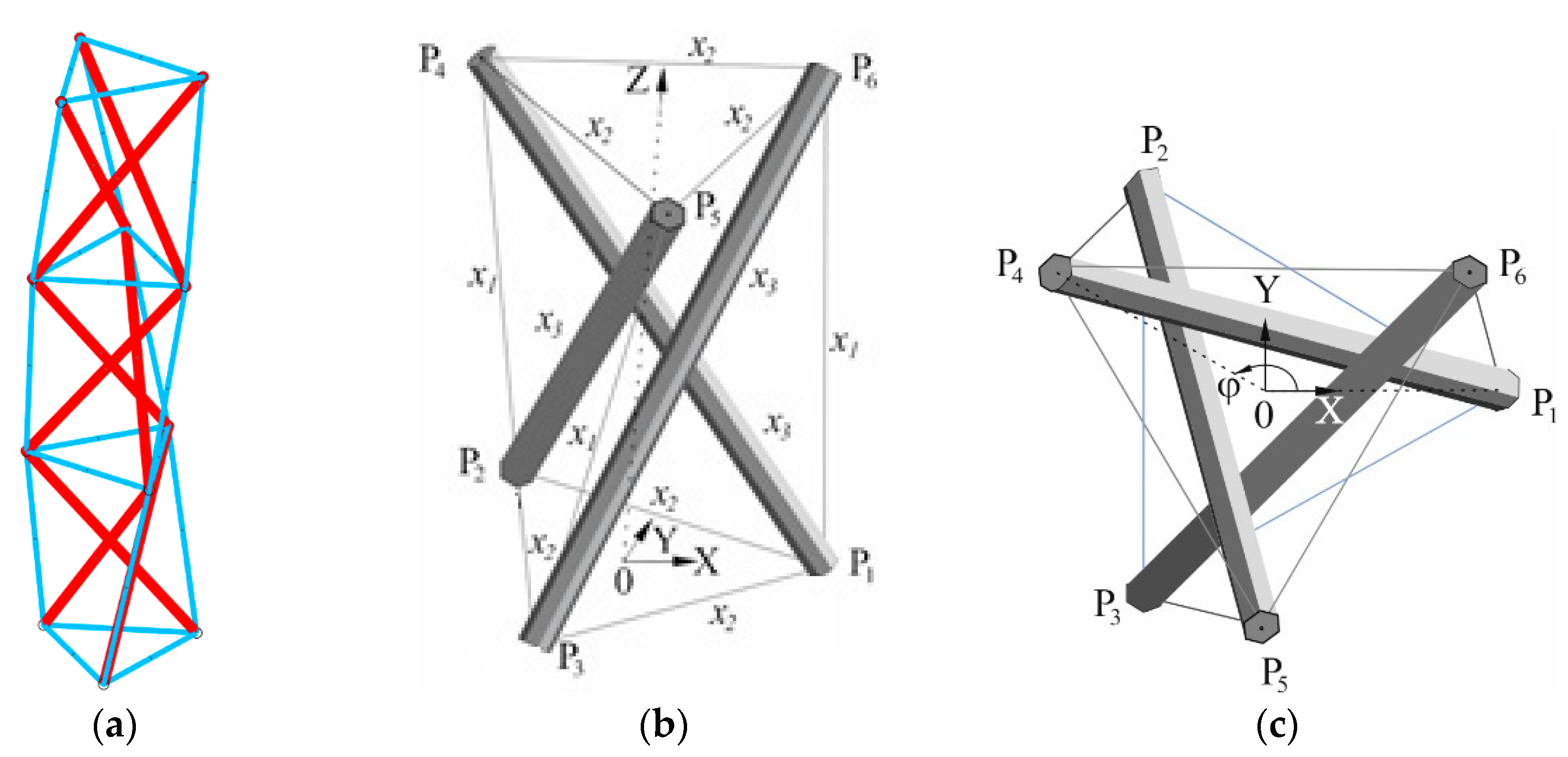

Tensegrity structures are built from compressed struts and tensioned cables. External loads can only be applied at the nodes, which connect elements using ball joints. The system stability and load-bearing capacity is obtained after inducing the prestressing force in its elements. Therefore, from the mechanical point of view, tensegrities can be regarded as a special class of spatial truss. A known example of these types of structure is a tensegrity column composed of several moduli, each of them being a tensegrity simplex (

Figure 1). The tensegrity simplex as the fundamental three-dimensional module of low complexity is often called the regular minimal tensegrity prism [

1]. It is constructed with three struts and nine cables. Six cables form two equilateral triangles which create horizontal bases of the module. The bases are interconnected between themselves by three other cables and three struts.

The history of tensegrity structures starts from the year 1921 when a sculpture of Karl Ioganson was presented at an exhibition in Moscow [

2]. Better known in the west is the artist Kenneth Snelson, creator of his X-Piece structure from 1948 [

3,

4]. Following the pattern of sculptures by Snelson, the architect Richard Buckminster Fuller patented a class of cable-bar assemblages in 1961, which he named tensegrity structures as an abbreviation of tensile integrity [

5].

Although elements forming tensegrity structures can deform in the range of small strains, the structure as a whole can experience large displacements. Therefore, their analysis needs to take into account geometrical non-linearity, where the equilibrium path is a function of the pre-stress level. The response of the Simplex to uniaxial compression was studied numerically in [

6] and, further, experimentally in [

7]. Both surveys have proven that the module may experience softening or stiffening type of response, as well as that it is a dependent on geometry, prestress level and stiffness of the members. Simplex module design examples, built from highly-elastic polyamide ropes and taking into account geometric nonlinearity, were shown in [

8,

9] with an incremental-iterative script written in Matlab programming language. Despite the non-linear approach, after inducing the prestress to the structure at a designed magnitude, the computational task can often be linearized, as in many simulation approaches. After the prestressing, small vibrations around the equilibrium points may be analyzed i.e., modal analysis can be used with linearization of these vibrations. This kind of a preliminary research of the simplex with innovative cables was presented in [

10]. Determined natural frequencies and modes can further be used to calibrate or validate numerical solutions. In tensegrity structures, the function of the first natural frequency vs. the magnitude of prestress is utilized in vibrational health monitoring or active stiffness control using servomechanisms.

In 1986 Rene Motro conducted a study [

11] on a tensegrity simplex, in terms of static and dynamic analysis. The equilibrium path of the axially loaded module, as well as six natural frequencies, were determined. The module was, however, not prestressed. In [

12] the relation between the pre-stress and natural frequencies was studied numerically for two-dimensional tensegrity trusses. The results stated that the change of pre-stress level causes the natural frequencies to either rise or fall. The effect of the self-stress on the dynamic properties of the basic spatial tensegrity modules was analyzed in the papers [

13,

14,

15,

16]. A dynamic model of the simplex as a system of single-degree-of-freedom subjected to rotation about its vertical axis was discussed in [

17]. An active controlled tensegrity was analyzed dynamically in [

18], which was a part of a Tensarch project [

19]. A solution to attenuate the first natural frequency in order to diminish the response of the analyzed structure was proposed. A five-module tensegrity was studied experimentally and numerically in [

20] by means of vibrational behavior, taking into account the effect of active strut movement. The pre-stress effect on the response of the tensegrity structures was also numerically studied, recently in [

21] and in [

22], with an emphasis on a road bridge appliance. Numerical analyses of statically and dynamically loaded structures was also analyzed in [

23]. The effect of the self-stressing force on self-diagnosis, self-repair and active control of a tensegrity structures and modules were analyzed numerically in [

24], where it was proven that it is possible to compensate potential damage of the structure by adjusting the prestress level.

The vast majority of presented surveys were of the numerical type, and there were no experimental validations of obtained results. On the other hand, Motro’s experimental analysis did not consider different prestress levels, while the Tensarch project investigations were performed on the different tensegrity grid and were focused on the structural control. Therefore, this study aims to fill the literature gap in terms of experimental identification of modal parameters, taking into account the prestress level of the tensegrity simplex and the contemporary method of measurement.

The utilized method is the experimental modal analysis. The method is used in many areas, e.g., for dissipation estimation in materials [

25], and for fatigue assessment of tools [

26]. However, a majority of tests are considered with structural behavior i.e., determining the damping ratios, natural frequencies and corresponding modes—see, e.g., [

27]. In this study, recorded data from an impact hammer strike were post-processed with a system identification method and further extracted using a Matlab [

28] toolbox [

29].

The article is written in the following order:

Section 2 presents the self-stress states of the analyzed module and the description of the physical model,

Section 3 includes the process of the experimental modal analysis with its results and the

Section 4 includes a discussion with conclusions.

2. The Prestressability of the Experimental Model and Vibration Measurements

Symmetrical prestressable configurations of the left-handed tensegrity simplex are considered. The symmetrical configuration is commonly used in theoretical models of the simplex and it can be described by three variables, e.g.,: the radius

or the side length

of the triangles, the height

denoting the distance between the horizontal triangles, and the twist angle

between the projection of the line

onto the horizontal plane and the

-axis (

Figure 1). The stable equilibrium configuration is for the angle

and it is taken as the reference configuration. In the Cartesian coordinate system

, with the origin at the center of the bottom triangle, we can identify coordinates of the nodes

as:

from which additional geometrical parameters can be calculated, e.g., the lengths

s and

b of the cross-cables and the bars, respectively:

The tensegrity simplex is characterized by the one self-stress state that ensures its stability by activating the geometrical stiffness. The self-stress state introduced initially in the members before applying loads has a direct impact on the structural response depending on its level. Together with the cross-sectional areas of tensioned and compressed members, the initial self-stresses are the design parameters that affect the structural performance and cost of a tensegrity structure. The self-stress level

, which describes the general self-stress state in the tensegrity simplex can be defined as a normal elongation of the cross-cables, i.e., as the strain:

where the cross-cable length

is calculated based on the formula (2) for the angle

at which the tensegrity equilibrium occurs. It follows from (3) that after pre-stressing at a level

, the length of the cross-cables is equal to

. The other lengths, i.e., the length of the base triangles

and the length of the bar

can be computed from the analytical model—see [

6,

8] as:

where

are the Young’s moduli and

are the cross-section areas of the cross and horizontal cables, respectively. When using the finite element method, we can obtain these lengths by iterative procedures, while having a physical model, by measurements.

Figure 1 shows, that it is possible to calculate the self-stress state of module, without external loading and without any supports in terms of an arbitrary chosen

force density i.e., the ratio between the member force and the member length as

in the cross-cables,

in the bars and

in the horizontal cables, because for the tensegrity simplex in the equilibrium configuration

without any external loads, the following relationship can be written:

where the force density

, i.e., it is assumed to be negative if the bars are under compression.

After the prestressing, the normal forces in the cross-cables

, the horizontal cables

and the bars

are:

where

,

and

and denote the force densities acting in the cross-cables, horizontal cables and bars, respectively.

Taking in the formulas (6) , the self-stress state can be also expressed in terms of the force in the cross-cables as the parameter . It is worth mentioning, that the unknown three force densities need to be known, when the deformation of the module preserves the parallelism of the two base triangles, e.g., when the module is under uniform and axial loading.

The coordinates, element numerations, and lengths of the simplex used in the survey are presented in

Table 1, as well as, the self-stress state according to the symmetrical theoretical model.

The experiments were performed on the full-scale physical module. The view of the model and some technical details are presented in

Figure 2. The bars made of a steel S355 were built from rods of the circular hollow section 42.4 × 2 mm, in which M20 bars were welded into edge parts. The linear density of the bars, i.e., the masses per length of both used sections are similar. The bearing capacity of the bars under compression is sufficient high to withstand expected in experiments the pre-stress levels. The cross and horizontal cables were created using a 3 mm nominal diameter steel line made of 19 wires and thimbled on each side. The net area of the cross-sections of the line is given in

Table 2, where materials, cross sections and masses of the physical model are gathered. The equivalent moduli of elasticity are presented in

Table 2 for the cross and horizontal cables, since they are made apart from steel lines, also of force transducers, roman screws and shackles. The moduli were established based on experimental uniaxial tension tests.

The minimal failure force, given by the manufacturer, is equal to 7.26 kN. The design value of 6.30 kN can be assumed as the bearing capacity after taking a partial material factor. Each cable had attached a force sensor (

Figure 2c), while three cross-cables had also additionally attached a roman screw in order to implement and control the prestress level. Nodes were laser cut out of a 20 mm thick stainless steel sheet and further countersigned for M8 bolts, which held the cables. A connection of the bars and nodes was created by regulation of two steel nuts, while a connection of cables and nodes was created using M8 screws (

Figure 2b). Crafted specially for the model, the force sensors were attached to all nine cables (

Figure 2c). The mass of a single joint was 0.897 kg. They were designed to work with electro-resistive strain gauges, where two active arms are placed on the opposite sides of the four-arm bridge (so called Wheatstone half bridge configuration). The body of the sensor was precisely water cut out of 6 mm thick stainless steel sheet and further processed to obtain a clear surface. The strain gauges were mounted on the two inner sides of the body, with special attention to manufacturers’ requirements [

30]. The finisher force sensors were also calibrated for the force using the strain gauge bridge and a universal testing machine to obtain the force-strain function and for the temperature using the strain gauge bridge and climate chamber to obtain the temperature-strain function. This enabled proper readouts on the force during the tests to be obtained, where also temperature variations were taken into account.

The testing standpoint was composed of the simplex module with three attached, triaxial piezoelectric accelerometers on top of its three nodes, a strain gauge bridge with the force sensors, a dynamic analyzer and impulse hammer (

Figure 3). The strain gauge bridge was used to control the values of forces in nine cables—three cross-cables and six horizontal cables in the top and bottom triangle. The dynamic recorder was used to record the values of applied impulses induced by the modal hammer and accelerations of the three, tri-axial accelerometers attached to the upper nodes of the simplex.

The methodology of the test was based on the method of the experimental modal analysis, where both types of signal—the force and accelerations are recorded in the time domain—from the modal hammer impulse and from the accelerometers in the upper nodes. The method utilizes all signals recorded in the test, i.e., all forces that are applied to the structure are measured. Ambient forces such as wind or traffic can be excluded. This method is based on obtaining both the impulse signal and the acceleration signal. At the excitation, piezoelectric transducers change the mechanical vibration energy into an analogous electrical signal, which is afterwards amplified by the amplifier. Furthermore, the analyzer digitizes the analogous signal into discrete series. The time resolution (number of samples measured in time) is dependent on the sampling rate, while the resolution of the recorded magnitudes is dependent on the bit depth.

A complete measuring system is usually composed of three elements: an excitation mechanism, a power amplifier, an analyzer and at least one transducer.

The study was performed using a data acquisition and recording system TEAC brand, model LX-110, using the dedicated software [

31]. The acceleration transducers are of the typical, triaxial type consisting of a seismic mass and piezoelectric crystals enclosed in one body. Their parameters are listed in [

32]. The hammer is built of a handle connected with a striking head. The idea is similar to the accelerometers, yet providing data on the force values. A detachable mass, as well as, a set of hammer tips with different stiffness enables to adjust the induced frequency of the structure. Generally, the heavier the hammer and softer the tip, the lower the frequencies that are induced. Data on hammer utilized in the test are available in [

33].

Figure 3b presents the experimental global coordinate system, where it was possible to measure accelerations of nine signals 4x, 4y, 4z, 5x, 5y, 5z, 6x, 6y, 6z in the one strike of the impulse hammer, as a source of excitation, together with this one force signal induced by this hammer at each pre-stress level. The directions of the strikes are shown also in

Figure 3b. One hundred and thirty five acceleration signals and 15 force signals were recorded for each prestress level. The 13 different prestress levels were applied on the whole as shown in

Table 3 in terms of the measured forces in the cross and horizontal (base) cables.

A distribution of the member forces between elements of the same type, i.e., the lower horizontal cables (1–3), the upper horizontal cables (7–9) and the cross-cables (4–6) for exemplary 4th and 13th prestress levels are presented in

Figure 4 and correspond with numeration in

Table 1. The forces are closely related with each other among each of the three groups during the prestressing process. The theoretical distribution of the member forces seems to be preserved with typical experimental fluctuations connected with crafting and measuring accuracy of the physical model.

4. Discussion

The first frequency depends on the self-stress state. This is due the fact that in the simplex one infinitesimal mechanism can be identified. The phenomenon is known in the literature. In the absence of prestressing, the first natural frequency should be zero, and after introducing the self-stress state, it increases. The tendency of rising the natural frequency is clearly visible in the experimental test in the first rotational mode. Successive frequencies are practically insensitive to changes of the prestress level. The rotational modes do depend mainly on the geometrical stiffness matrix, which is a function of the prestress level. Other modes are dependent only on the elastic stiffness matrix, which is dependent on the material, cross section, geometry and boundary conditions.

If the equilibrium equations of the representative node

of the simplex are considered under the applied torque

associated to the rotation

and under the uniform axial loading

, the summation of all the forces acting in current configuration can be written as:

where the vectors of the total vertical force

and of the moment

are acting along the

Z-axis.

Solving the system of Equation (13) with respect to the torque

and for

leads to the following constitutive law for the angle

:

where the linear elastic stiffness and the geometrically non-linear constitutive model of the cross-cable

are assumed. If the cross-cables are elastic, while the horizontal triangles are rigid, the length

, and the response of the rigid-elastic model of the simplex is obtained in (14) in the form of the system of a single degree of freedom, which is a function of the self-stress level

. The same constitutive law as in (14) was derived in [

35] starting from the model of a single degree of freedom by means of the energy expression. The derivative of (14)

with respect the angle

gives the tangent torsional stiffness of the model and the initial modulus of the elastic response

as:

where the initial tangent torsional modulus

is zero if there is no prestress.

Using the modulus

, the first rotational frequency of the simplex at small amplitude can be written as:

where the effective torsional stiffness

(15

1) is written depending on the prestress tension force in the cross-cable

, the mass moment of inertia about the simplex vertical axis for the three nodal masses is

and

denotes

the reduced mass of one node.

Figure 9 presents the comparison between the experimental results and the formula (16) and the results from the FEM. Additionally, the relationship between the square frequency and the force in the cross-cable is shown. The curve (16) is fitted into the experimental results by means of the curve fitting procedure performed in Matlab [

28]. The excellent fit is achieved for the reduced mass

, where the mass of the one node

is calculated by dividing the weight of the experimental model by six. In the curve fitting procedure, the formula (16) was treated as a parametric equation with the mass

as the parameter. The fitting procedure was constructed by changing the mass

to match the theoretical solution (16) to the experimental data. The non-linear least-squares fitting procedure was used, in which the best fit was found for the sum of squares to errors

and for the square of the multiple correlation the R-square

. The statistics

SSE is indicating a better fit with a value closer to zero. For the

R-square statistics the better the fit, the closer the values to one. The sensitivity of the frequency to the self-stress state is high enough to be successfully used to control the dynamic properties of the simplex.

The results from the FEM are presented for a lumped-mass idealization of the finite element mass matrix with the diagonal terms and for the consistent-mass formulation with the calculated effective mass of the cables based on the weight of the experimental model. Very good agreement with formula (16) and with the experiment was found for the lumped-mass approach. In the case of the consistent-mass approach, the agreement is worse, although the change of the frequency has similar, non-linear characteristics during the prestress in the experiments and FEM calculations. In the FEM calculations the first frequency increases in proportion to the square root of the prestress force in the cross-cable. The difference between the experiments and numerical calculations for the consistent mass matrix decreases with the increase of the prestressing from approximately 60% for the first level through 30% for the fourth to 20% for the 13th level. For the level greater than 1.5 kN the difference is less than 25%, which may be acceptable at the moment, considering the very complex mass distributions in the physical model. It was observed in the experiments when the structure was not prestressed, the gravity caused heavy elements such as nodes to create a little prestress, which is not taken into account in the numerical analysis. Considering both the FEM calculation, quite good agreement was found between results of the finite element method and experimental tests.

It seems that the external loads should act similar to the prestressing. They cause the additional prestress. However, their effect should be greater with the lower prestress level due to the fact that with the increase of the prestressing the member forces caused by the external load gradually decrease relative to the prestress and their effect on the vibration frequency decreases.

Although non-linear analysis should be used to calculate the static load response of the tensegrity structure, the dynamic response can often be linearized around the equilibrium state corresponding to a designed prestress level and small vibrations can be analyzed. It was shown in the paper that the natural frequencies and modes of the simplex can be obtained using the experimental modal analysis approach. Also, usage of the finite element method in numerical simulations, allows to control the stiffness by regulating the level of pre-stressing. However, practice shows that there are some difficulties and an experimental validation can bring useful information, especially if the natural frequencies of the structure are measured and filtered from the whole experimental vibration spectrum.

The effect of self-stress on the overall stiffness of the tensegrity simplex was shown experimentally. The tendency of increasing the first natural frequency with an increase of the prestressing is clear visible in the experiments. It was also shown that adjustment of self-stress levels by means of the prestressing can also be used to control the dynamic properties of tensegrity simplex as the structures with one infinitesimal mechanism.

The vulnerability of tensegrities to dynamic excitation can be an important design issue due to their slenderness and lightness. The experimental validation of designed parameters, in particular modal ones, is essential for proper design in terms of load-bearing capacity and serviceability. Moreover, it serves as a quality control indicator for structural health monitoring purposes.