Robocasting of Single and Multi-Functional Calcium Phosphate Scaffolds and Its Hybridization with Conventional Techniques: Design, Fabrication and Characterization

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Robocasting

2.1.1. Design of CAD Models

2.1.2. Materials

2.1.3. Scaffolds Fabrication

2.1.4. Scaffolds Characterizations

2.2. Hybrid Technologies: Robocasting Joined with Polymer Processing Routes

2.2.1. Fabrication of Hybrid Ceramic-Polymer Scaffolds

2.2.2. In-Vitro Bacterial Adhesion Assay

3. Results and Discussions

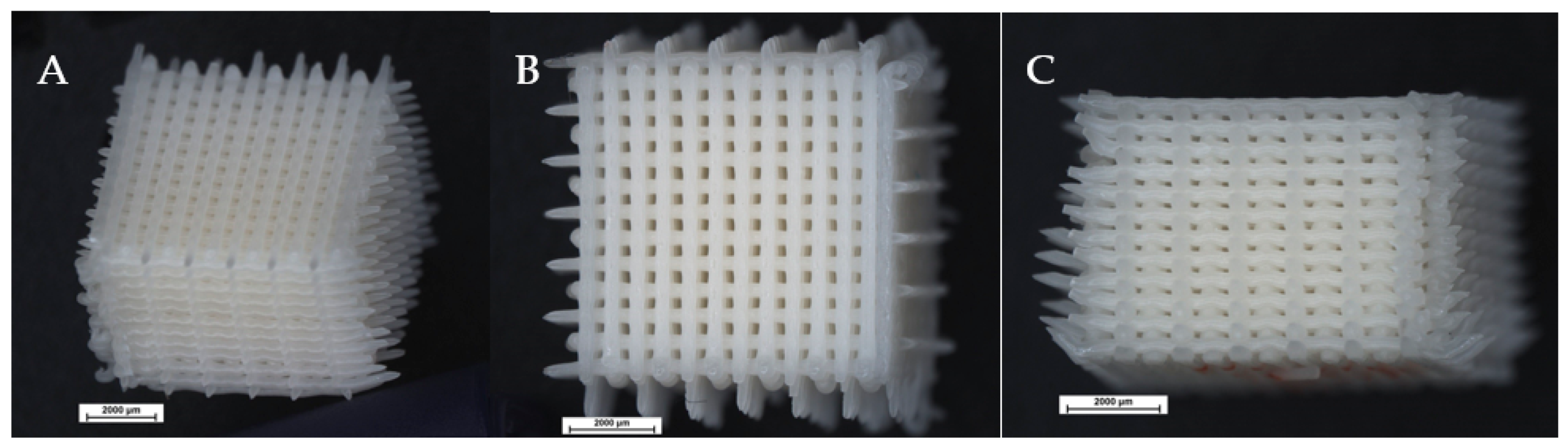

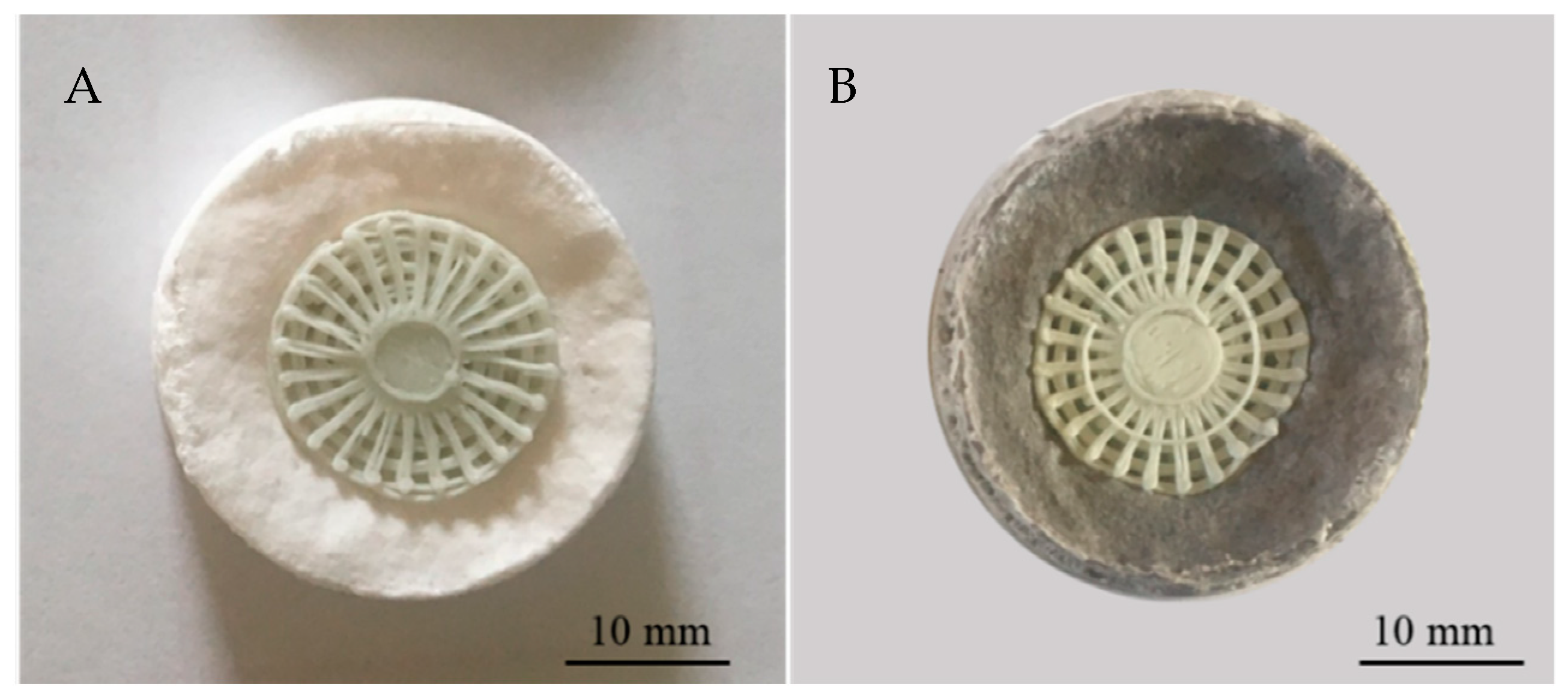

3.1. Robocasting of Lattice, Dense and Bi-Layer Parts

3.1.1. Paste Formulations

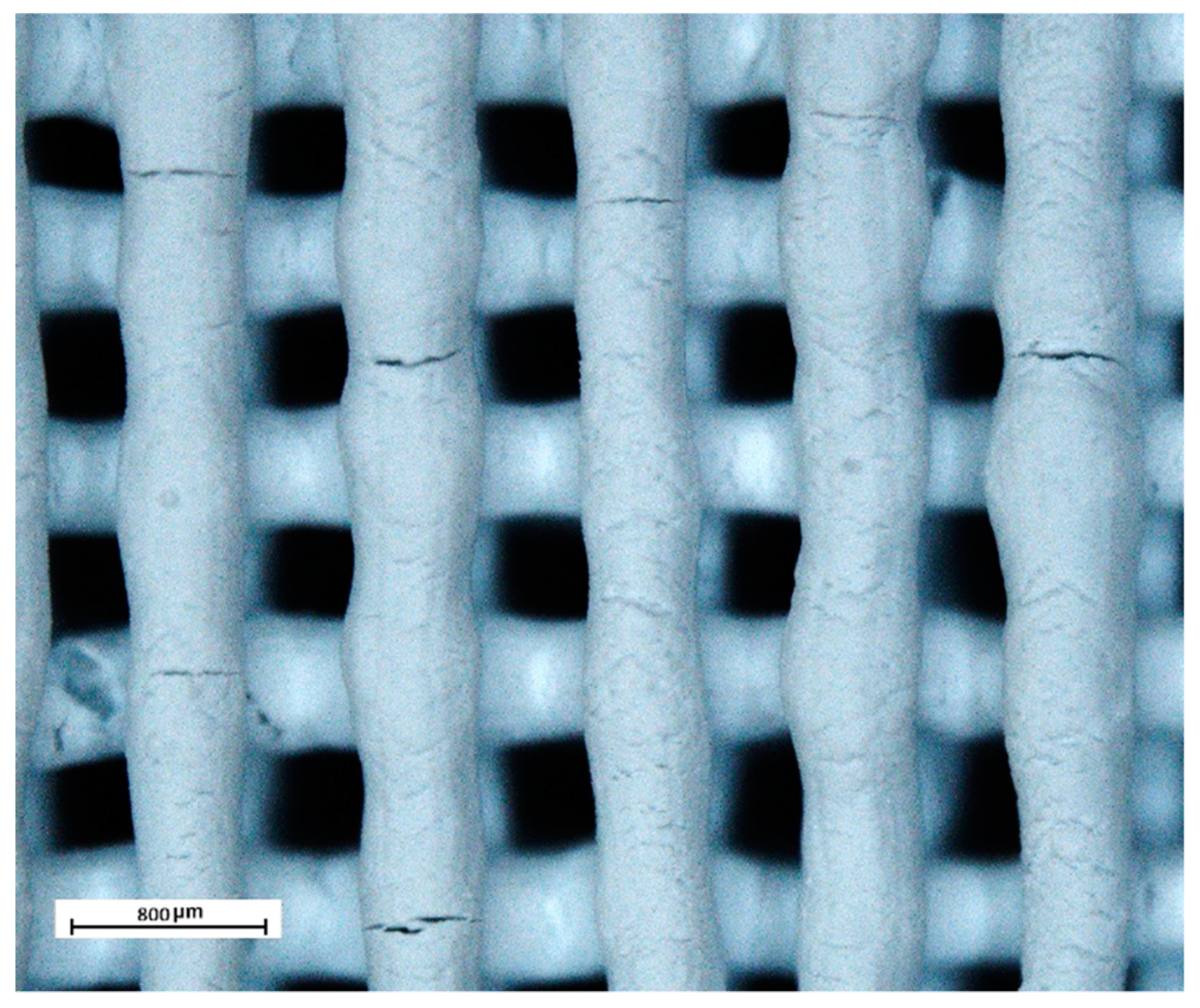

3.1.2. Porous Parts

3.1.3. Dense Parts

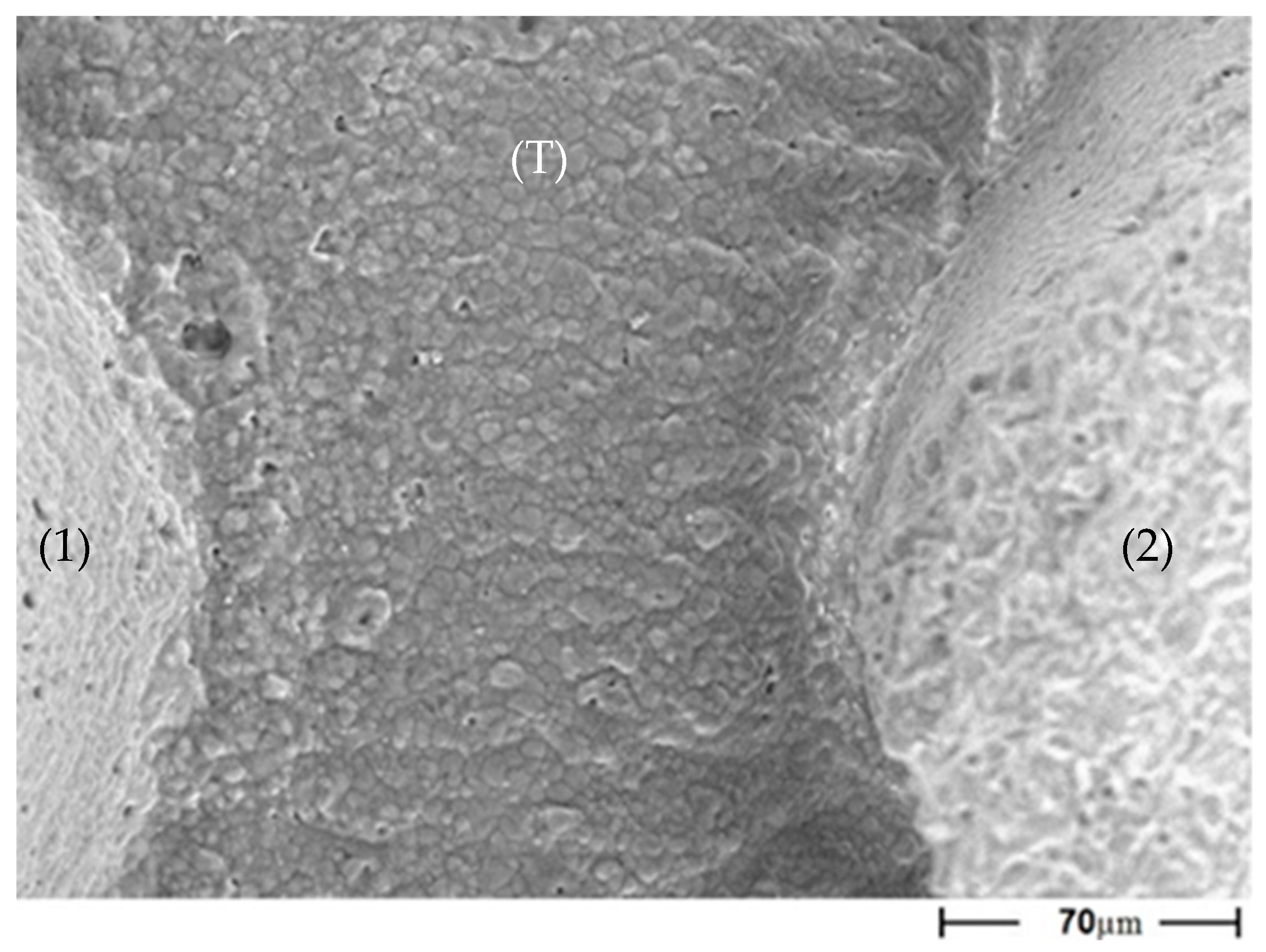

3.1.4. FGM Bi-Layer Parts

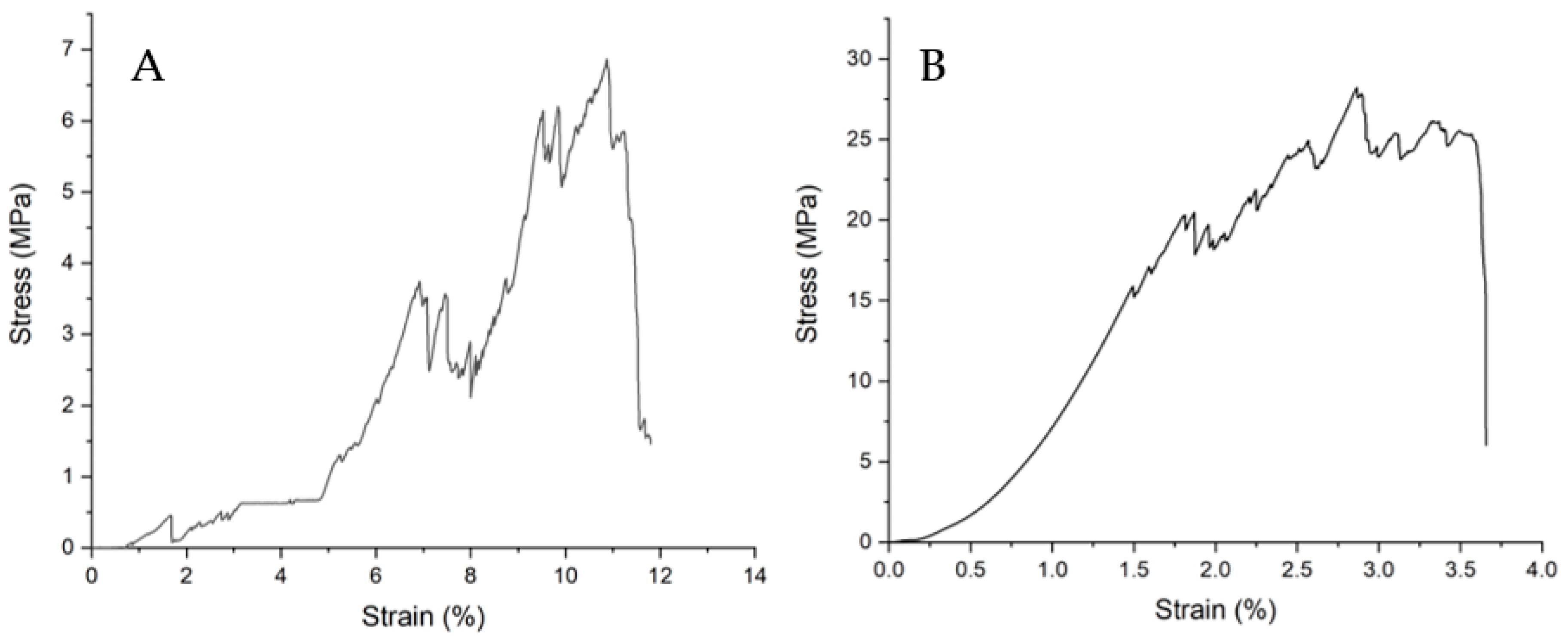

3.1.5. Mechanical Properties

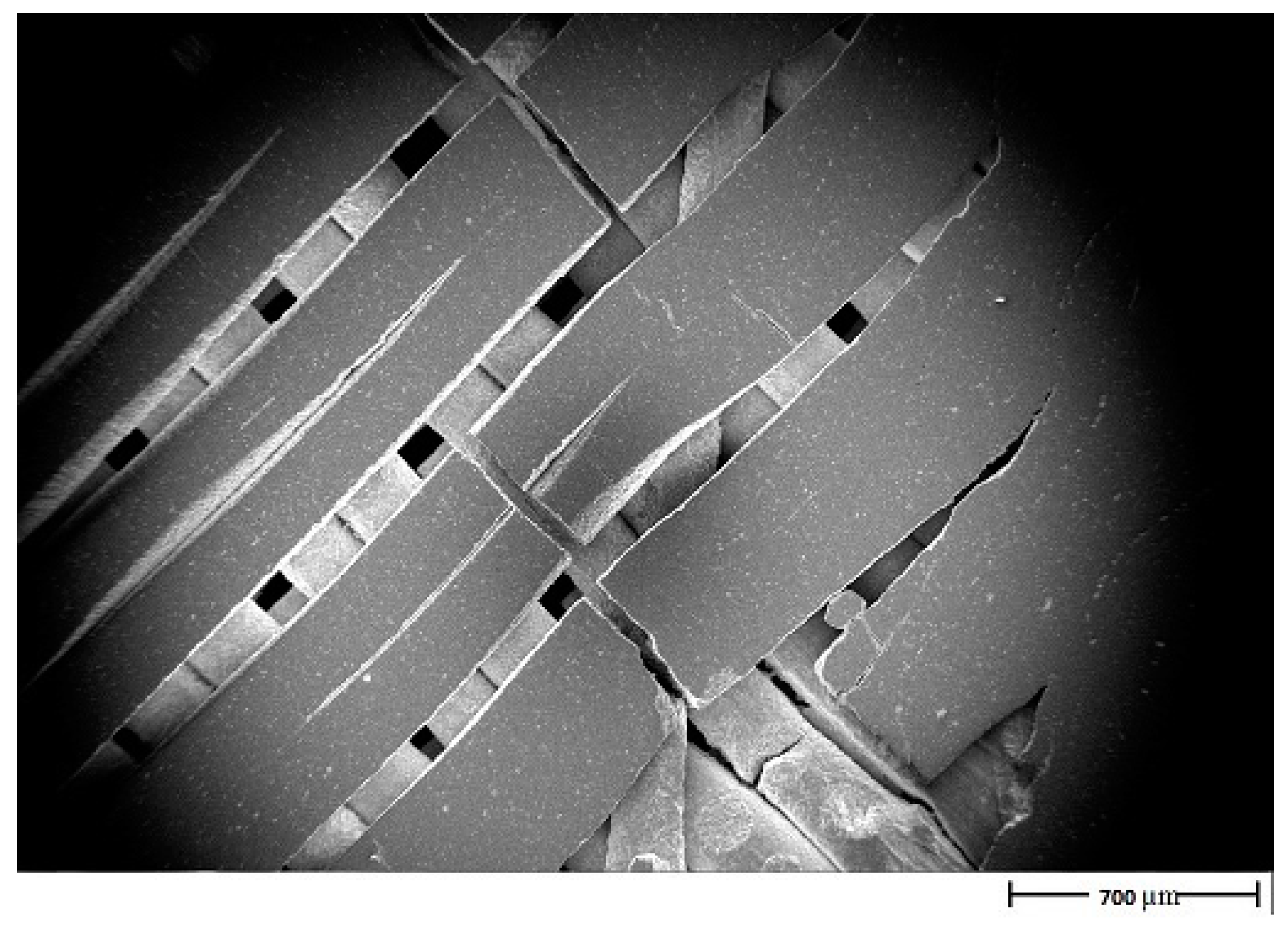

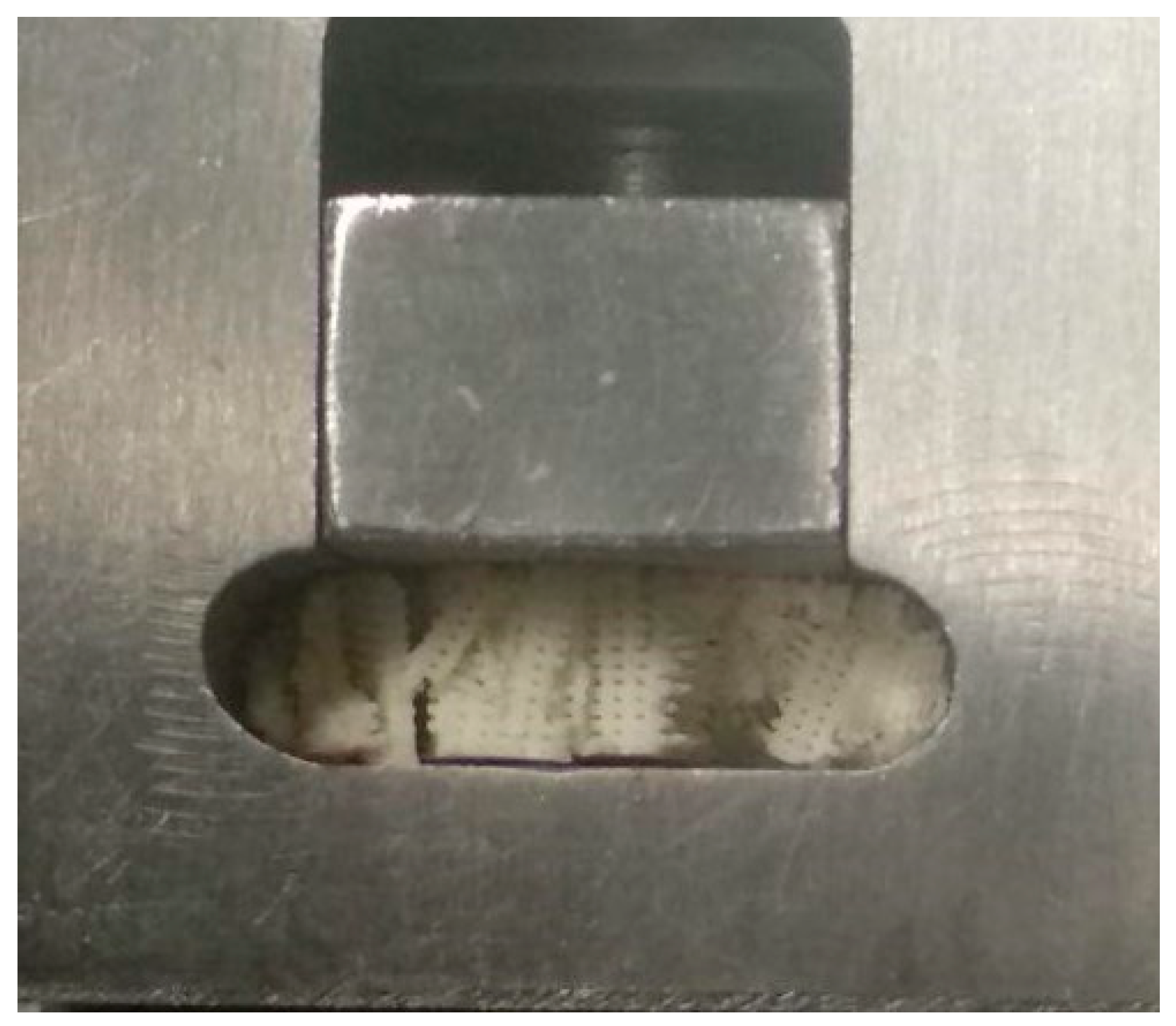

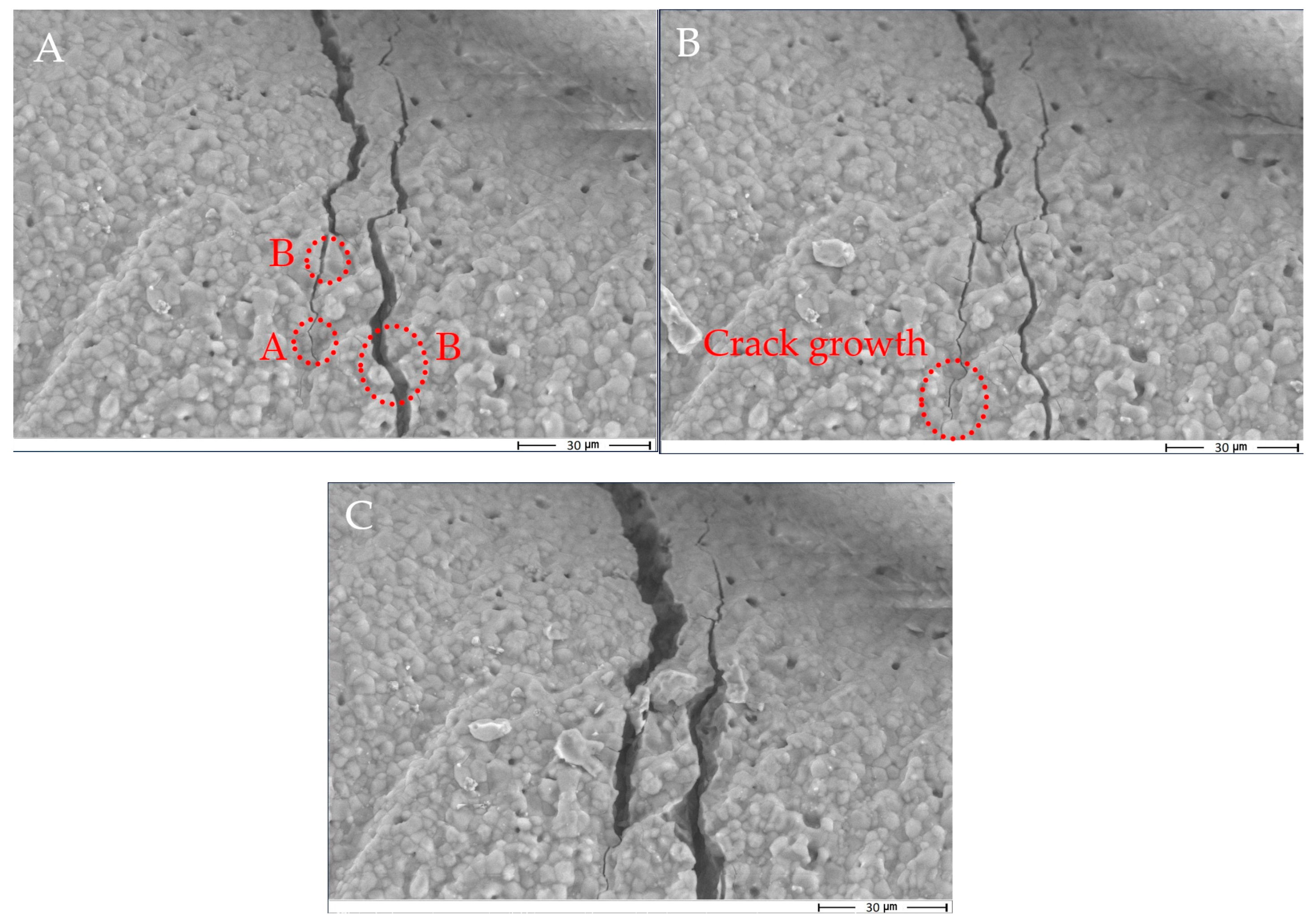

3.1.6. Fracture Mechanism Analysis

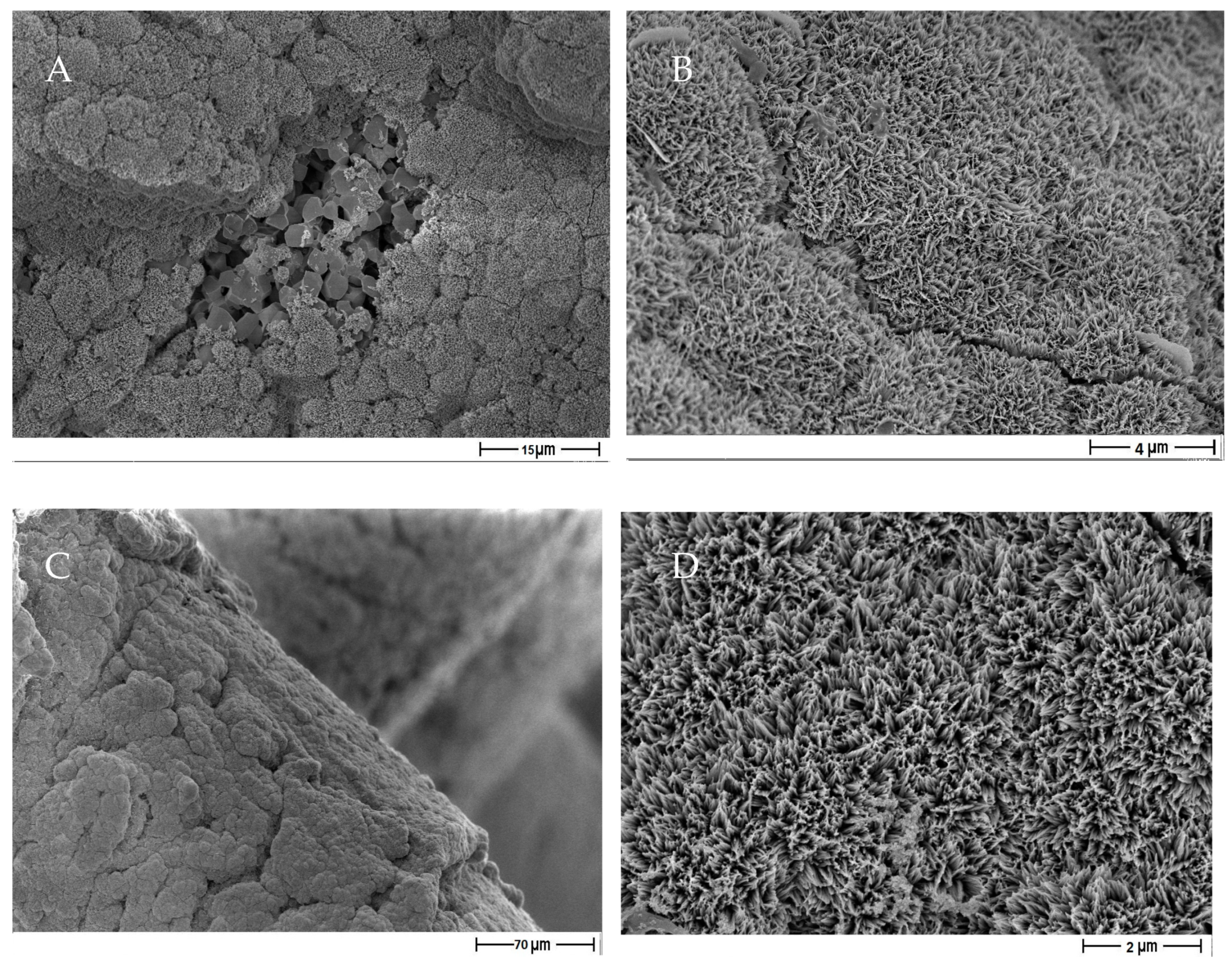

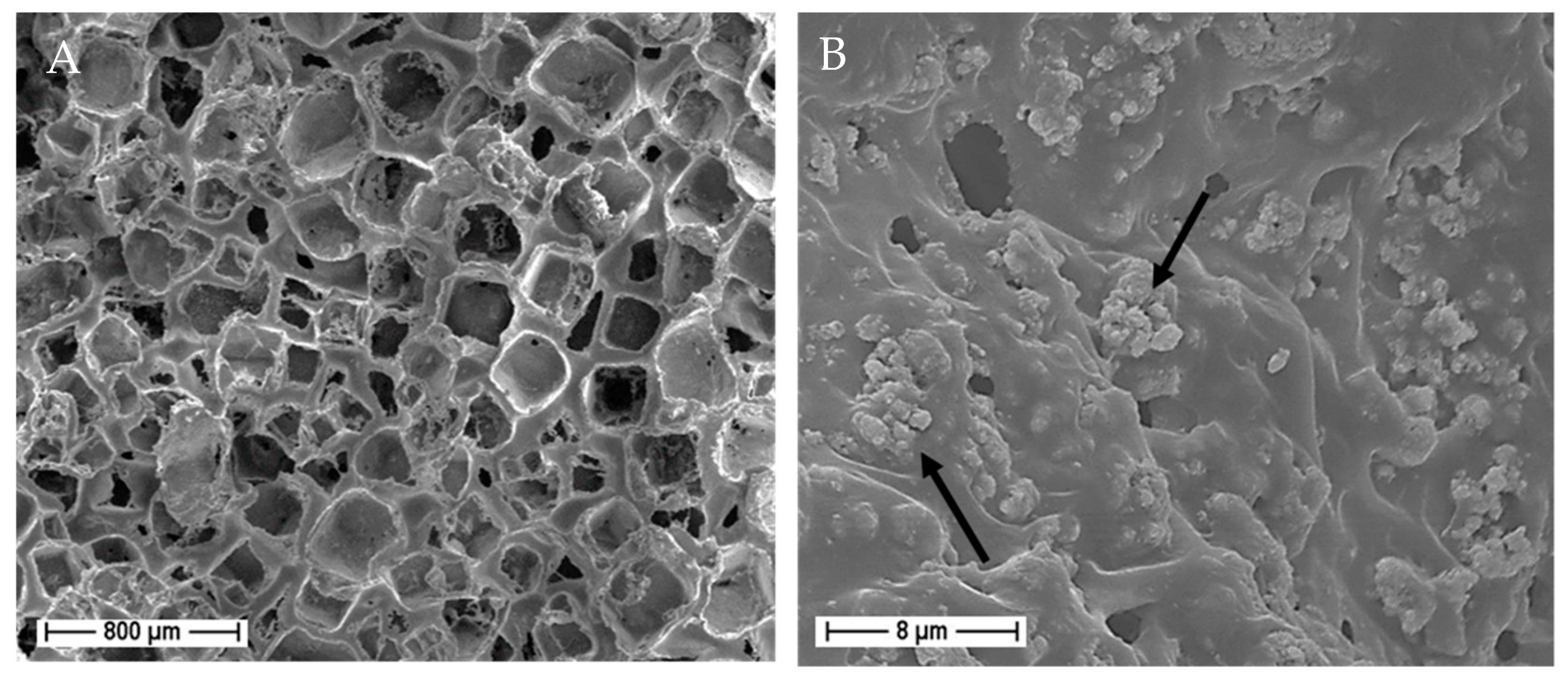

3.1.7. In Vitro Bioactivity Test

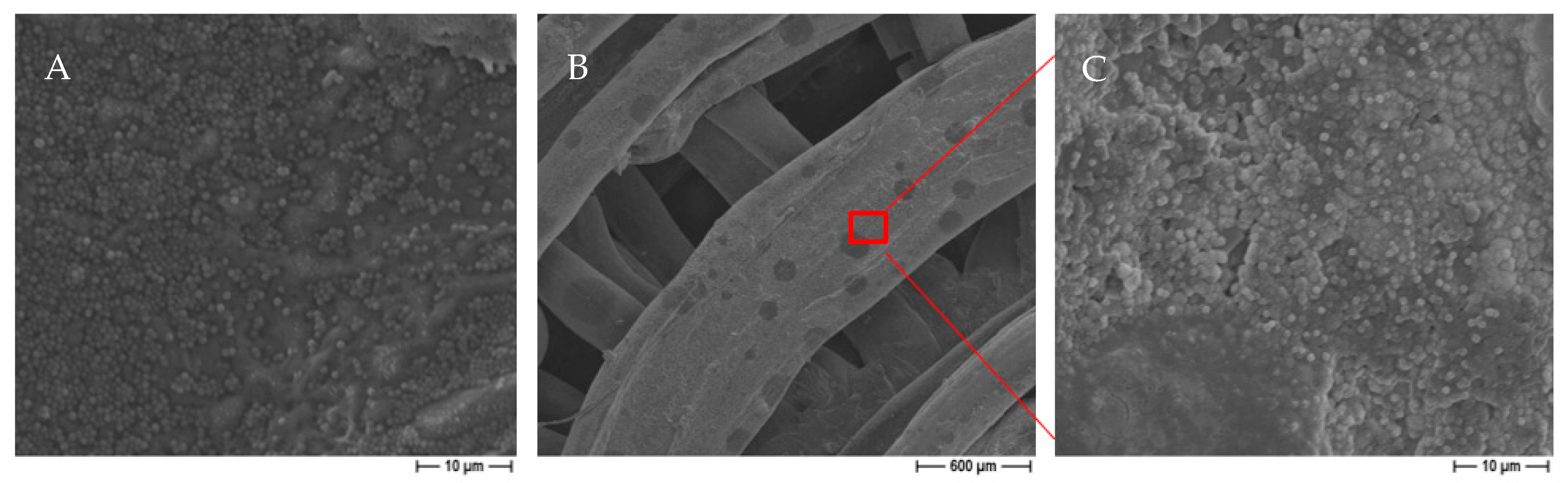

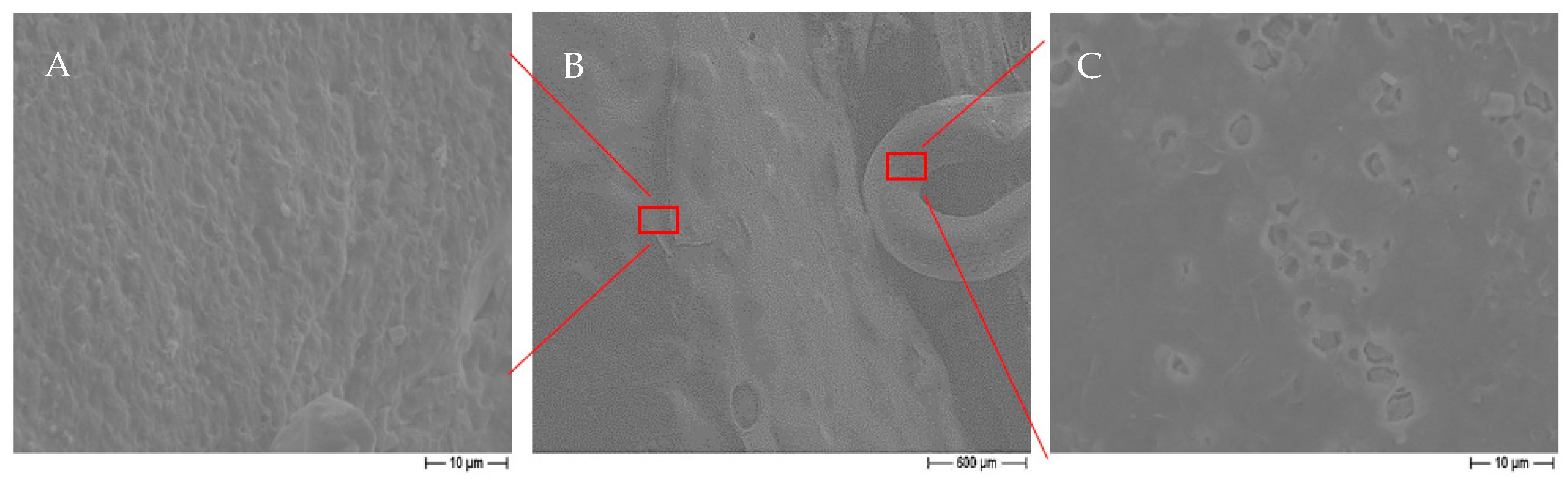

3.2. Hybrid Technologies for Ceramic/Polymer Scaffolds

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sultana, N. Biodegradable Polymer-Based Scaffolds for Bone Tissue Engineering; Springer: Berlin/Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2013. [Google Scholar] [CrossRef]

- Liu, H. Nanocomposites for Musculoskeletal Tissue Regeneration; Woodhead Publishing: Kidlington, UK, 2016. [Google Scholar]

- Brown, O.; McAfee, M.; Clarke, S.; Buchanan, F. Sintering of biphasic calcium phosphates. J. Mater. Sci. Mater. Med. 2010, 21, 2271–2279. [Google Scholar] [CrossRef] [PubMed]

- LeGeros, R.Z. Properties of osteoconductive biomaterials: Calcium phosphates. Clin. Orthop. Relat. Res. 2002, 395, 81–98. [Google Scholar] [CrossRef] [PubMed]

- Hench, L.L. An Introduction to Bioceramics, 2nd ed.; Imperial College Press: London, UK, 2013. [Google Scholar]

- Dorozhkin, S.V. Bioceramics of calcium orthophosphates. Biomaterials 2010, 31, 1465–1485. [Google Scholar] [CrossRef] [PubMed]

- Hwa, L.C.; Rajoo, S.; Mohd Noor, A.; Norhayati, A.; Uday, M. Recent advances in 3D printing of porous ceramics: A review. Curr. Opin. Solid State Mater. Sci. 2017, 21, 323–347. [Google Scholar] [CrossRef]

- Gauthier, O.; Bouler, J.M.; Aguado, E.; Pilet, P. Macroporous biphasic calcium phosphate ceramics: Influence of macropore diameter and macroporosity percentage on bone ingrowth. Biomaterials 1998, 19, 133–139. [Google Scholar] [CrossRef]

- Schephake, H.; Neukam, E.W.; Klosa, D. Influence of pore dimensions on bone ingrowth into porous hydroxylapatite blocks used as bone graft substitutes: A histometric study. Int. J. Oral Maxillofac. Surg. 1991, 20, 53–58. [Google Scholar] [CrossRef]

- Samavedi, S.; Whittington, A.R.; Goldstein, A.S. Calcium phosphate ceramics in bone tissue engineering: A review of properties and their influence on cell behavior. Acta Biomater. 2013, 9, 8037–8045. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium orthophosphate bioceramics. Ceram. Int. 2015, 41, 13913–13966. [Google Scholar] [CrossRef]

- Cyster, L.; Grant, D.; Howdle, S.; Rose, F.; Irvine, D.; Freeman, D.; Scotchford, C.; Shakesheff, K. The influence of dispersant concentration on the pore morphology of hydroxyapatite ceramics for bone tissue engineering. Biomaterials 2005, 26, 697–702. [Google Scholar] [CrossRef]

- Tarafder, S.; Balla, V.K.; Davies, N.M.; Bandyopadhyay, A.; Bose, S. Microwave-sintered 3D printed tricalcium phosphate scaffolds for bone tissue engineering. J. Tissue Eng. Regen. Med. 2013, 7, 631–641. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Lee, H.; Jang, T.S.; Song, J.; Kim, H.E.; Jung, H.D. The production of porous hydroxyapatite scaffolds with graded porosity by sequential freeze-casting. Materials 2017, 10, 367. [Google Scholar] [CrossRef] [PubMed]

- Fu, Q.; Rahaman, M.N.; Dogan, F.; Ba, B.S. Freeze-cast hydroxyapatite scaffolds for bone tissue engineering applications. Biomed. Mater. 2008, 3. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, Q.; Wang, C. Preparation and evaluation of a biomimetic scaffold with porosity gradients in vitro. An. Acad. Bras. Ciênc. 2012, 84, 9–16. [Google Scholar] [CrossRef] [PubMed]

- Chamary, S.; Hautcoeur, D.; Hornez, J.C.; Leriche, A.; Cambier, F. Bio-inspired hydroxyapatite dual core-shell structure for bone substitutes. J. Eur. Ceram. Soc. 2017, 37, 5321–5327. [Google Scholar] [CrossRef]

- Pompe, W.; Worch, H.; Epple, M.; Friess, W.; Gelinsky, M.; Greil, P.; Hempele, U.; Scharnweber, D.; Schulte, K. Functionally graded materials for biomedical applications. Mater. Sci. Eng. A 2003, 362, 40–60. [Google Scholar] [CrossRef]

- Macchetta, A.; Turner, I.G.; Bowen, C.R. Fabrication of HA/TCP scaffolds with a graded and porous structure using a camphene-based freeze-casting method. Acta Biomater. 2009, 5, 1319–1327. [Google Scholar] [CrossRef]

- Sanchez-Salcedo, S.; Werner, J.; Vallet-Regi, M. Hierarchical pore structure of calcium phosphate scaffolds by a combination of gel-casting and multiple tape-casting methods. Acta Biomater. 2008, 4, 913–922. [Google Scholar] [CrossRef]

- Petit, C.; Tulliani, J.M.; Tadier, S.; Meille, S.; Chevalier, J.; Palmero, P. Novel calcium phosphate/PCL graded samples: Design and development in view of biomedical applications. Mater. Sci. Eng. C 2019, 97, 336–346. [Google Scholar] [CrossRef]

- Lewis, J.A.; Gratson, G.M. Direct writing in three dimensions. Mater. Today 2004, 7, 32–39. [Google Scholar] [CrossRef]

- Fu, Z.; Freihart, M.; Wahl, L.; Tobias Fey, T.; Greil, P.; Travitzky, N. Micro- and macroscopic design of alumina ceramics by robocasting. J. Eur. Ceram. Soc. 2017, 37, 3115–3124. [Google Scholar] [CrossRef]

- Marchi, C.S.; Kouzeli, M.; Rao, R.; Lewis, J.; Dunand, D. Alumina–aluminum interpenetrating-phase composites with three-dimensional periodic architecture. Scr. Mater. 2003, 49, 861–866. [Google Scholar] [CrossRef]

- Stanciuc, A.M.; Sprecher, C.M.; Adrien, J.; Roiban, L.I.; Alini, M.; Gremillard, L.; Peroglio, M. Robocast zirconia-toughened alumina scaffolds: Processing, structural characterisation and interaction with human primary osteoblasts. J. Eur. Ceram. Soc. 2018, 18, 845–853. [Google Scholar] [CrossRef]

- Feilden, E.; García-Tunón Blanca, E.; Giuliani, F.; Saiz, E.; Vandeperre, L. Robocasting of structural ceramic parts with hydrogel inks. J. Eur. Ceram. Soc. 2016, 36, 2525–2533. [Google Scholar] [CrossRef]

- Wahl, L.; Lorenz, M.; Biggemann, J.; Travitzky, N. Robocasting of reaction bonded silicon carbide structures. J. Eur. Ceram. Soc. 2019, 39, 4520–4526. [Google Scholar] [CrossRef]

- Eqtesadi, S.; Motealleh, A.; Miranda, P.; Lemos, A.; Rebelo, A.; Ferreira, J.M. A simple recipe for direct writing complex 45S5 Bioglasss 3D scaffolds. Mater. Lett. 2013, 93, 68–71. [Google Scholar] [CrossRef]

- Fu, Q.; Saiz, E.; Tomsia, A.P. Direct ink writing of highly porous and strong glass scaffolds for load-bearing bone defects repair and regeneration. Acta Biomater. 2011, 7, 3547–3554. [Google Scholar] [CrossRef]

- Barberi, J.; Nommeots-Nomm, A.; Fiume, E.; Verne, E.; Massera, J.; Baino, F. Mechanical characterization of pore-graded bioactive glass scaffolds produced by robocasting. Biomed. Glas. 2019, 5, 140–147. [Google Scholar] [CrossRef]

- Smay, J.E.; Nadkarni, S.S.; Xu, J. Direct writing of dielectric ceramics and base metal electrodes. Int. J. Appl. Ceram. Technol. 2007, 4, 47–52. [Google Scholar] [CrossRef]

- Maroulakos, M.; Kamperos, G.; Tayebi, L.; Halazonetis, D.; Ren, Y. Applications of 3D printing on craniofacial bone repair: A systematic review. J. Dent. 2019, 80, 1–14. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Gunster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Michna, S.; Wu, W.; Lewis, J.A. Concentrated hydroxyapatite inks for direct-write assembly of 3-D periodic scaffolds. Biomaterials 2005, 26, 5632–5639. [Google Scholar] [CrossRef] [PubMed]

- Miranda, P.; Pajares, A.; Saiz, E.; Tomsia, A.P.; Guiberteau, F. Mechanical properties of calcium phosphate scaffolds fabricated by robocasting. J. Biomed. Mater. Res. A 2008, 85, 218–227. [Google Scholar] [CrossRef] [PubMed]

- Martínez-Vázquez, F.J.; Perera, F.H.; Miranda, P.; Pajares, A.; Guiberteau, F. Improving the compressive strength of bioceramic robocast scaffolds by polymer infiltration. Acta Biomater. 2010, 6, 4361–4368. [Google Scholar] [CrossRef] [PubMed]

- Franco, J.; Hunger, P.; Launey, M.; Tomsia, A.; Saiz, E. Direct write assembly of calcium phosphate scaffolds using a water-based hydrogel. Acta Biomater. 2010, 6, 218–228. [Google Scholar] [CrossRef]

- Paredes, C.; Martínez-Vázquez, F.J.; Pajares, A.; Miranda, P. Development by robocasting and mechanical characterization of hybrid HA/PCL coaxial scaffolds for biomedical applications. J. Eur. Ceram. Soc. 2019, 39, 4375–4383. [Google Scholar] [CrossRef]

- Roleček, J.; Pejchalová, L.; Martínez-Vázquez, F.; Miranda González, P.; Salamon, D. Bioceramic scaffolds fabrication: Indirect 3D printing combined with ice templating vs. robocasting. J. Eur. Ceram. Soc. 2019, 39, 1595–1602. [Google Scholar] [CrossRef]

- Cesarano, J., III; Dellinger, J.G.; Saavedra, M.P.; Gill, D.D. Customization of load-bearing hydroxyapatite lattice scaffolds. Int. J. Appl. Ceram. Technol. 2005, 2, 212–220. [Google Scholar] [CrossRef]

- Miranda, P.; Pajares, A.; Saiz, E.; Tomsia, A.; Guiberteau, F. Fracture modes under uniaxial compression in hydroxyapatite scaffolds fabricated by robocasting. J. Biomed. Mater. Res. A 2007, 83, 646–657. [Google Scholar] [CrossRef]

- Martinez-Vazquez, F.J.; Perera, F.H.; Meulen, I.V.D.; Heise, A.; Pajares, A.; Miranda, P. Impregnation of b-tricalcium phosphate robocast scaffolds by in situ polymerization. J. Biomed. Mater. Res. A 2013, 101, 3086–3096. [Google Scholar] [CrossRef]

- Sorrentino, R.; Cochis, A.; Azzimonti, B.; Caravaca, C.; Chevalier, J.; Kuntz, M.; Porporati, A.A.; Streicher, R.M.; Rimondini, L. Reduced bacterial adhesion on ceramics used for arthroplasty applications. J. Eur. Ceram. Soc. 2018, 38, 963–970. [Google Scholar] [CrossRef]

- Ou, S.F.; Chung, R.J.; Lin, L.H.; Chiang, Y.C.; Huang, C.F.; Ou, K.L. A mechanistic study on the antibacterial behavior of silver doped bioceramic. J. Alloys Compd. 2015, 629, 362–367. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y.; Yu, J.; Zhen, Z.; Huang, T.; Tang, Q.; Chu, P.K.; Qi, L.; Hongbo, L. Antibacterial and mechanical properties of honeycomb ceramic materials incorporated with silver and zinc. Mater. Des. 2014, 59, 461–465. [Google Scholar] [CrossRef]

- Balamurugan, A.; Balossier, G.; Laurent-Maquin, D.; Pina, S.; Rebelo, A.; Faure, J.; Ferreira, J. An in vitro biological and anti-bacterial study on a sol–gel derived silver-incorporated bioglass system. Dent. Mater. 2008, 24, 1343–1351. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, M.; Tulliani, J.M.; Palmero, P. Fabrication of dense and porous biphasic calcium phosphates: Effect of dispersion on sinterability and microstructural development. Int. J. Appl. Ceram. Technol. 2019, 16, 1797–1806. [Google Scholar] [CrossRef]

- ISO 10545-3. Ceramic tiles—Part 3: Determination of Water Absorption, Apparent Porosity, Apparent Relative Density and Bulk Density; International Organization for Standardization: Geneva, Switzerland, 2018. [Google Scholar]

- ASTM C773-88. Standard Test Method for Compressive (Crushing) Strength of Fired Whiteware Materials; American Society for Testing and Materials: West Conshohocken, PE, USA, 2016.

- Marcassoli, P.; Cabrini, M.; Tirillò, J.; Bartuli, C.; Palmero, P.; Montanaro, L. Mechanical Characterization of Hydroxiapatite Micro/Macro-Porous Ceramics Obtained by Means of Innovative Gel-Casting Process. Key Eng. Mater. 2009, 417, 565–568. [Google Scholar] [CrossRef]

- Benaqqa, C.; Chevalier, J.; Saädaoui, M.; Fantozzi, G. Slow crack growth behaviour of hydroxyapatite ceramics. Biomaterials 2005, 26, 6106–6112. [Google Scholar] [CrossRef]

- Palmero, P.; Fantozzi, G.; Lomello, F.; Bonnefont, G.; Montanaro, L. Creep behaviour of alumina/YAG composites prepared by different sintering routes. Ceram. Int. 2012, 38, 433–441. [Google Scholar] [CrossRef]

- ISO 23317. Ceramic Tiles—Part 3: Implants for Surgery—In Vitro Evaluation for Apatite-Forming Ability of Implant Materials; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Afghah, F.; Ullah, M.; Seyyed Monfared Zanjani, J.; Akkus Sut, P.; Sen, O.; Emanet, M.; Saner Okan, B.; Culha, M.; Menceloglu, M.; Yildiz, M.; et al. 3D printing of silver-doped polycaprolactone-poly(propylene succinate) composite scaffolds for skin tissue engineering. Biomed. Mater. 2020, 15. [Google Scholar] [CrossRef]

- Banche, G.; Allizond, V.; Bracco, P.; Bistolfi, A.; Boffano, M.; Cimino, A.; Brach Del Prever, E.M.; Cuffini, A.M. Interplay between surface properties of standard, vitamin E blended and oxidised ultra high molecular weight polyethylene used in total joint replacement and adhesion of Staphylococcus aureus and Escherichia coli. Bone Jt. J. 2014, 96, 497–501. [Google Scholar] [CrossRef]

- Cazzola, M.; Ferraris, S.; Allizond, V.; Bertea, C.M.; Novara, C.; Cochis, A.; Geobaldo, F.; Bistolfi, A.; Cuffini, A.M.; Rimondini, L.; et al. Grafting of peppermint essential oil to chemically treated Ti6Al4V alloy to counteract bacterial adhesion. Surf. Coat. Technol. 2019, 378, 125011. [Google Scholar] [CrossRef]

- Ferraris, S.; Spriano, S.; Miola, M.; Bertone, E.; Allizond, V.; Cuffini, A.M.; Banche, G. Bioactive and antibacterial titanium surfaces through a modified oxide layer and embedded silver nanoparticles: Effect of reducing/stabilizing agents on precipitation and properties of the nanoparticles. Surf. Coat. Technol. 2018, 344, 177–189. [Google Scholar] [CrossRef]

- Banche, G.; Bracco, P.; Allizond, V.; Bistolfi, A.; Boffano, M.; Cimino, A.; Brach Del Prever, E.M.; Cuffini, A.M. Do crosslinking and vitamin E stabilization influence microbial adhesions on UHMWPE-based biomaterials? Clin. Orthop. Relat. Res. 2015, 473, 974–986. [Google Scholar] [CrossRef]

- Rahaman, M.N. Ceramic Processing, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

- Potoczek, M.; Zima, A.; Paszkiewicz, Z.; Slosarczyk, A. Manufacturing of highly porous calcium phosphate bioceramics via gel-casting using agarose. Ceram. Int. 2009, 35, 2249–2254. [Google Scholar] [CrossRef]

- Roopavath, U.K.; Malferrari, S.; Van Haver, A.; Verstreken, A.; Narayan Rath, S.; Kalaskar, D.M. Optimization of extrusion based ceramic 3D printing process for complex bony design. Mater. Des. 2019, 162, 263–270. [Google Scholar] [CrossRef]

- Martınez-Vazquez, F.; Pajares, A.; Miranda, P. Effect of the drying process on the compressive strength and cell proliferation of hydroxyapatite-derived scaffolds. Int. J. Appl. Ceram. Technol. 2017, 14, 1101–1106. [Google Scholar] [CrossRef]

- Palmero, P. Ceramic–polymer Nanocomposites for Bone-Tissue Regenerarion. In Nanocomposites for Musculoskeletal Tissue Regeneration; Woodhead Publishing: Duxford, UK, 2016; pp. 331–367. [Google Scholar]

- Seitz, H.; Rieder, W.; Irsen, S.; Leukers, B.; Tille, C. Three-dimensional printing of porous ceramic scaffolds for bone tissue engineering. J. Biomed. Mater. Res. B 2005, 74, 782–788. [Google Scholar] [CrossRef]

- Xin, R.; Leng, Y.; Chen, J.; Zhang, Q. A comparative study of calcium phosphate formation on bioceramics in vitro and in vivo. Biomaterials 2005, 26, 6477–6486. [Google Scholar] [CrossRef]

- Lu, X.; Leng, Y. Theoretical analysis of calcium phosphate precipitation in simulated body fluid. Biomaterials 2005, 26, 1097–1108. [Google Scholar] [CrossRef]

- Eidelman, N.; Chow, L.C.; Brown, W.E. Calcium phosphate saturation levels in ultrafiltered serum. Calcif. Tiss. Int. 1987, 40, 71–78. [Google Scholar] [CrossRef]

- Leeuwenburgh, S.C.; Wolke, J.G.; Siebers, M.C.; Schoonman, J.; Jansen, J.A. In vitro and in vivo reactivity of porous, electrosprayed calcium phosphate coatings. Biomaterials 2006, 27, 3368–3378. [Google Scholar] [CrossRef]

- Leng, Y.; Chen, J.; Qu, S. TEM study of calcium phosphate precipitation on HA/TCP ceramics. Biomaterials 2003, 24, 2125–2131. [Google Scholar] [CrossRef]

- Poh, P.S.; Hutmacher, D.W.; Holzapfel, B.M.; Solanki, A.K.; Stevens, M.M.; Woodruff, M.A. In vitro and in vivo bone formation potential of surface calcium phosphate-coated polycaprolactone and polycaprolactone/bioactive glass composite scaffolds. Acta Biomater. 2016, 30, 319–333. [Google Scholar] [CrossRef]

- Dziadek, M.; Stodolak-Zych, E.; Cholewa-Kowalska, K. Biodegradable ceramic-polymer composites for biomedical applications: A review. Mater. Sci. Eng. C 2017, 71, 1175–1191. [Google Scholar] [CrossRef]

- Chen, W.; Oh, S.; Ong, A.; Oh, N.; Liu, Y.; Courtney, H.; Appleford, M.; Ong, J. Antibacterial and osteogenic properties of silver-containing hydroxyapatite coatings produced using a sol gel process. J. Biomed. Mater. Res. 2007, 82A, 899–906. [Google Scholar] [CrossRef]

- Chen, W.; Liu, Y.; Courtney, H.; Bettenga, M.; Agrawal, C.; Bumgardner, J.; Ong, J. In vitro anti-bacterial and biological properties of magnetron co-sputtered silver-containing hydroxyapatite coating. Biomaterials 2006, 27, 5512–5517. [Google Scholar] [CrossRef]

- Karlov, A.; Shakhov, V.; Kolobov, J. Definition of silver concentration in calcium phophate coatings on titanium implants ensuring balancing of bactericidity and cytotoxicity. Key Eng. Mater. 2000, 192, 207–210. [Google Scholar] [CrossRef]

| Scaffold Type | Paste Code | Solid Loading (vol%) | Dispersant (%) | Methocel (%) | PEI (%) | Printing Speed (mm/min) |

|---|---|---|---|---|---|---|

| Lattice | P1 | 49.2 | 4 | 6.5 | 16 | 290 |

| P2 | 49.2 | 4 | 3.5 | 8 | 290 | |

| P3 | 51.0 | 4 | 6.5 | 8 | 290 | |

| Dense | P3 | 51.0 | 4 | 6.5 | 8 | 226 |

| Bi-layer | P3 | 51.0 | 4 | 6.5 | 8 | 129 |

| Scaffold Type | Strut Size (µm) | Pore Size (µm) | Apparent Density (g/cm3) | Density of Solid Part (g/cm3) | Relative Density of Solid (%) | Total Porosity (%) | Open Porosity (%) |

|---|---|---|---|---|---|---|---|

| Lattice | 341 ± 7 | 275 ± 8 | 2.06 ± 0.10 | 2.97 ± 0.01 | 95 | 34.1 | 30.7 ± 3.4 |

| Dense | - | - | 2.69 ± 0.20 | 2.95 ± 0.01 | 95 | 13.9 | 8.7 ± 1.6 |

| Bi-layer | 619 ± 21 | 605 ± 55– 1040 ± 31 | 2.19 ± 0.10 | 2.99 ± 0.01 | 96 | 29.9 | 26.8 ± 2.6 |

| External Diameter (mm) | Mean Pore Size (µm) | ||||||

|---|---|---|---|---|---|---|---|

| Core | 1° ring | 2° ring | 3° ring | 4° ring | 1° ring | 2° ring | 3° ring |

| 5.48 ± 0.11 | 7.92 ± 0.13 | 10.43 ± 0.15 | 13.02 ± 0.18 | 15.49 ± 0.35 | 605 ± 55 | 896 ± 52 | 1040 ± 31 |

| Ca | P | O | Si | Mg | Na | Ca/P |

|---|---|---|---|---|---|---|

| 15.44 | 11.63 | 71.4 | 0.32 | 0.56 | 0.65 | 1.33 |

| Sample Type | Ag-Doped Sample | Control Sample | R (%) |

|---|---|---|---|

| Adhered bacteria | 7.16 × 104 ± 3.5 × 104 | 3.22 × 109 ± 3.07 × 108 | 100.00 |

| Planktonic bacteria | 4.31 × 104 ± 1.70 × 104 | 2.97 × 109 ± 3.82 × 108 | 100.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammadi, M.; Pascaud-Mathieu, P.; Allizond, V.; Tulliani, J.-M.; Coppola, B.; Banche, G.; Chaput, C.; Cuffini, A.M.; Rossignol, F.; Palmero, P. Robocasting of Single and Multi-Functional Calcium Phosphate Scaffolds and Its Hybridization with Conventional Techniques: Design, Fabrication and Characterization. Appl. Sci. 2020, 10, 8677. https://doi.org/10.3390/app10238677

Mohammadi M, Pascaud-Mathieu P, Allizond V, Tulliani J-M, Coppola B, Banche G, Chaput C, Cuffini AM, Rossignol F, Palmero P. Robocasting of Single and Multi-Functional Calcium Phosphate Scaffolds and Its Hybridization with Conventional Techniques: Design, Fabrication and Characterization. Applied Sciences. 2020; 10(23):8677. https://doi.org/10.3390/app10238677

Chicago/Turabian StyleMohammadi, Mehdi, Patricia Pascaud-Mathieu, Valeria Allizond, Jean-Marc Tulliani, Bartolomeo Coppola, Giuliana Banche, Christophe Chaput, Anna Maria Cuffini, Fabrice Rossignol, and Paola Palmero. 2020. "Robocasting of Single and Multi-Functional Calcium Phosphate Scaffolds and Its Hybridization with Conventional Techniques: Design, Fabrication and Characterization" Applied Sciences 10, no. 23: 8677. https://doi.org/10.3390/app10238677

APA StyleMohammadi, M., Pascaud-Mathieu, P., Allizond, V., Tulliani, J.-M., Coppola, B., Banche, G., Chaput, C., Cuffini, A. M., Rossignol, F., & Palmero, P. (2020). Robocasting of Single and Multi-Functional Calcium Phosphate Scaffolds and Its Hybridization with Conventional Techniques: Design, Fabrication and Characterization. Applied Sciences, 10(23), 8677. https://doi.org/10.3390/app10238677