Model-Based Design and Simulation of Paraxial Ray Optics Systems

Abstract

1. Introduction

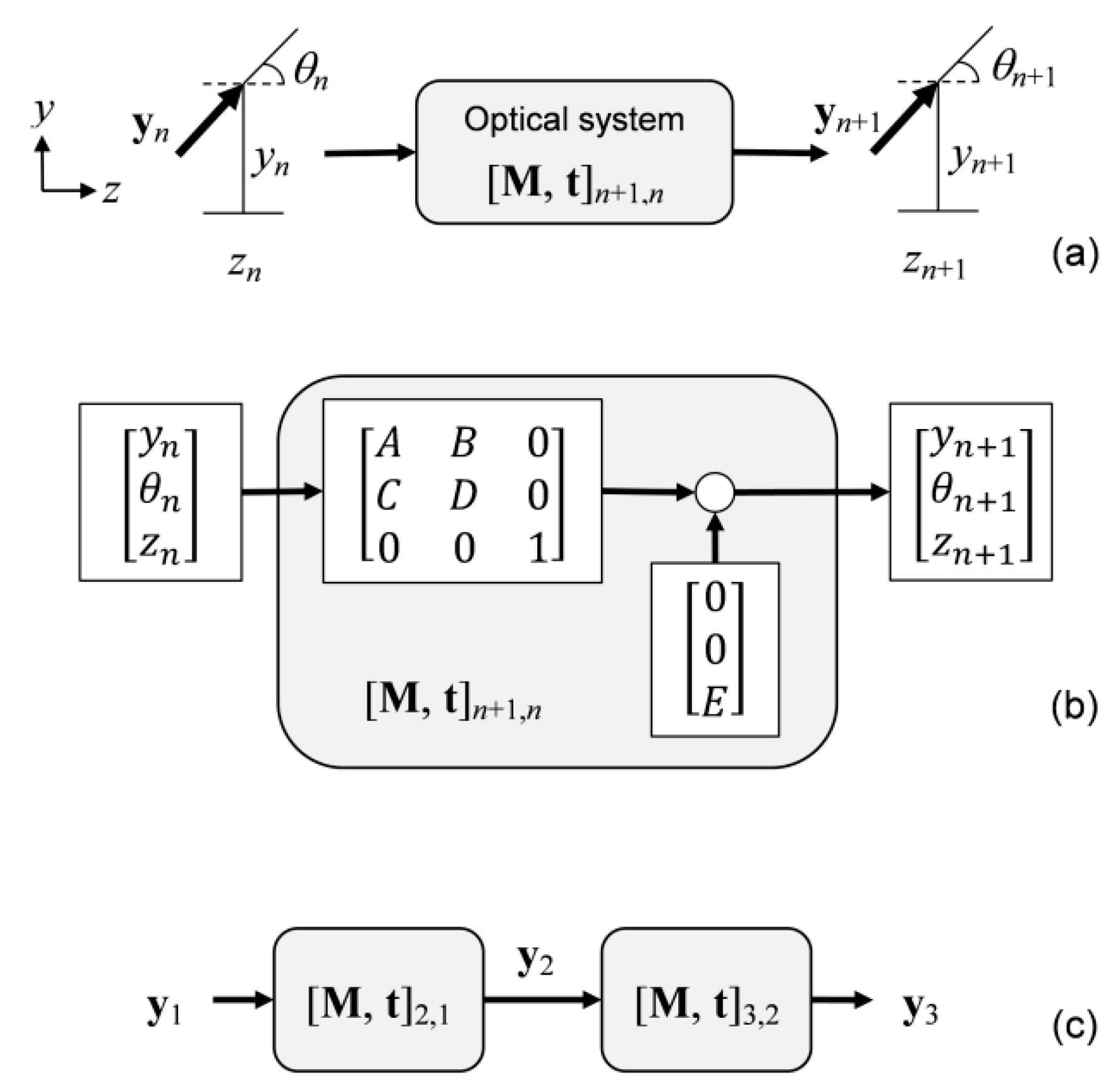

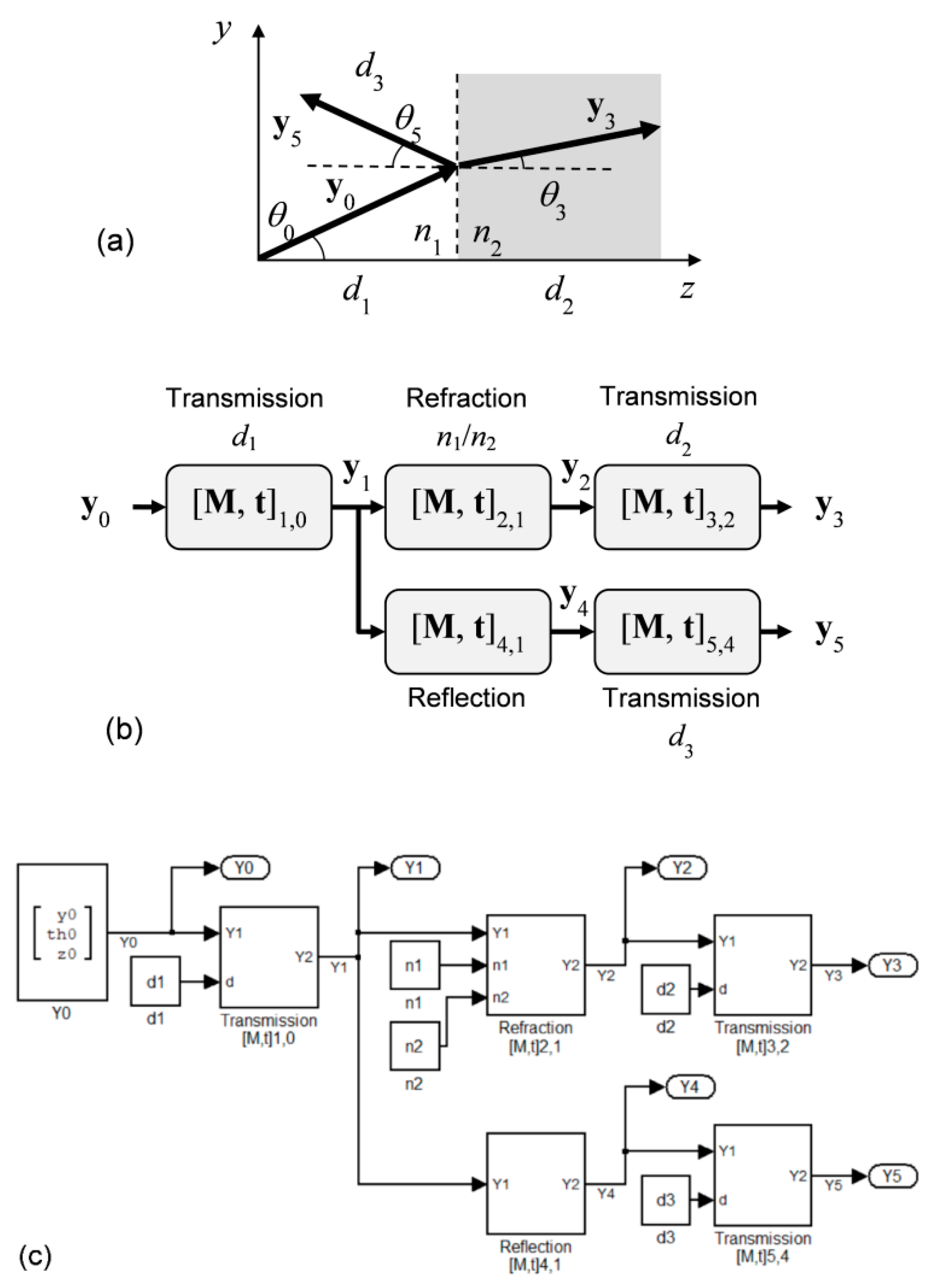

2. Ray Transfer Matrix

3. Implementation

4. Results and Discussion

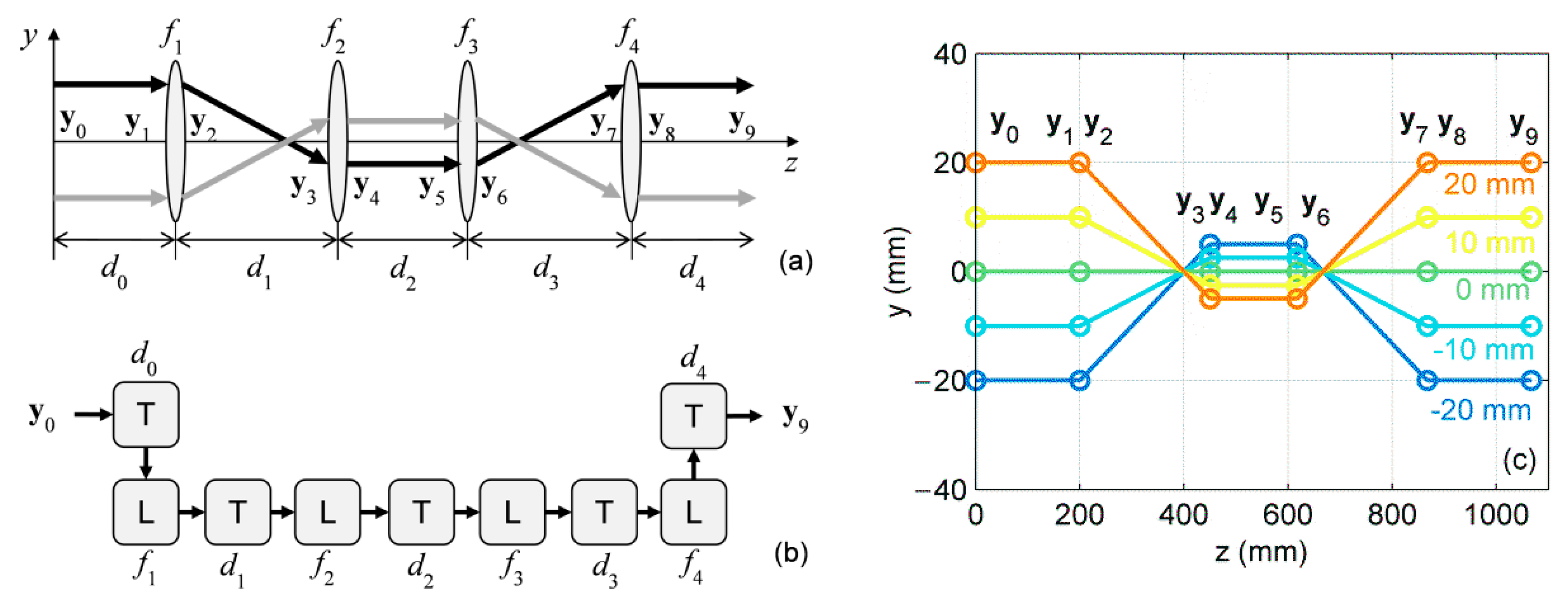

4.1. Paraxial Cloaking

4.2. Optical Fiber

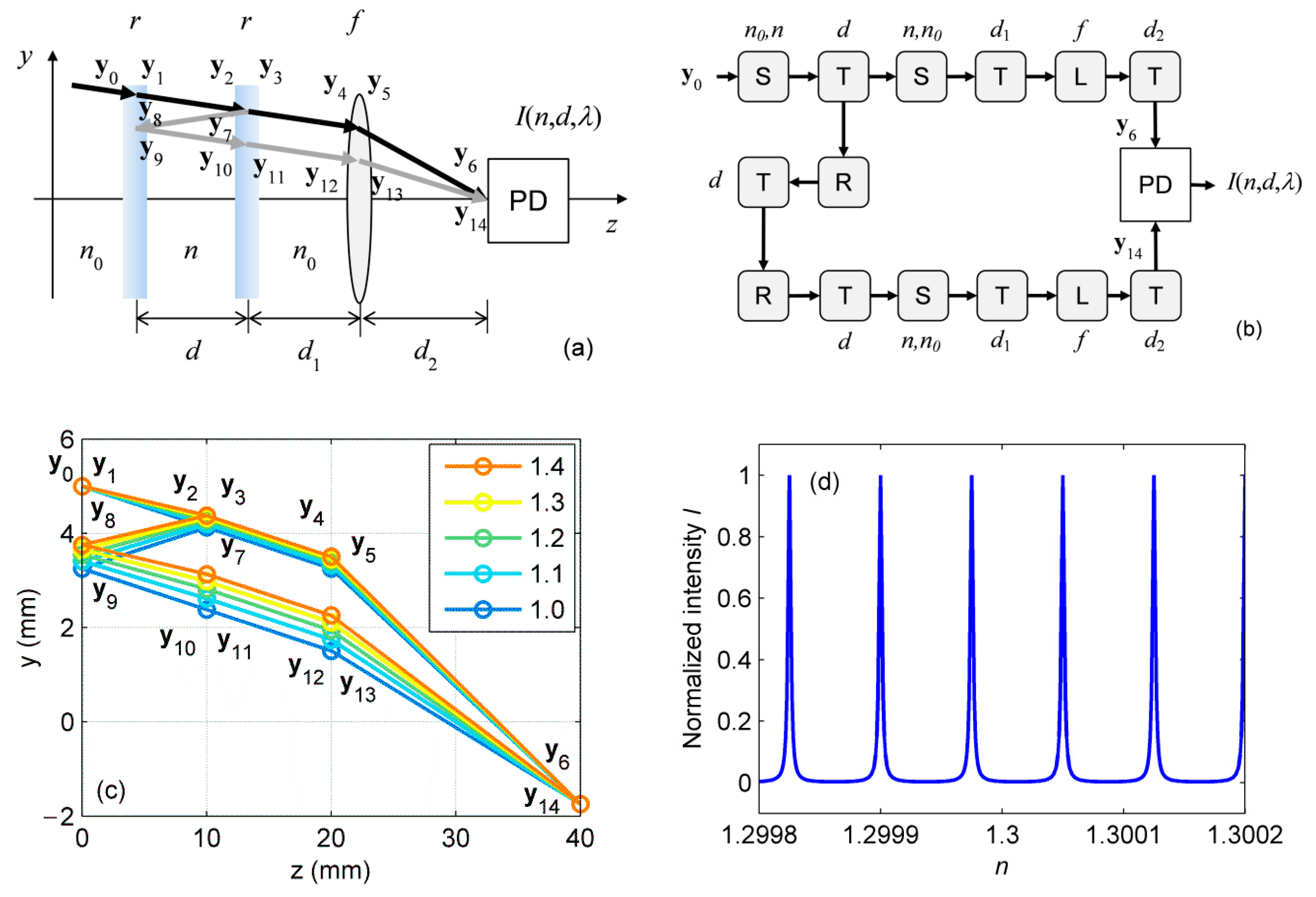

4.3. Fabry–Perot Interferometer

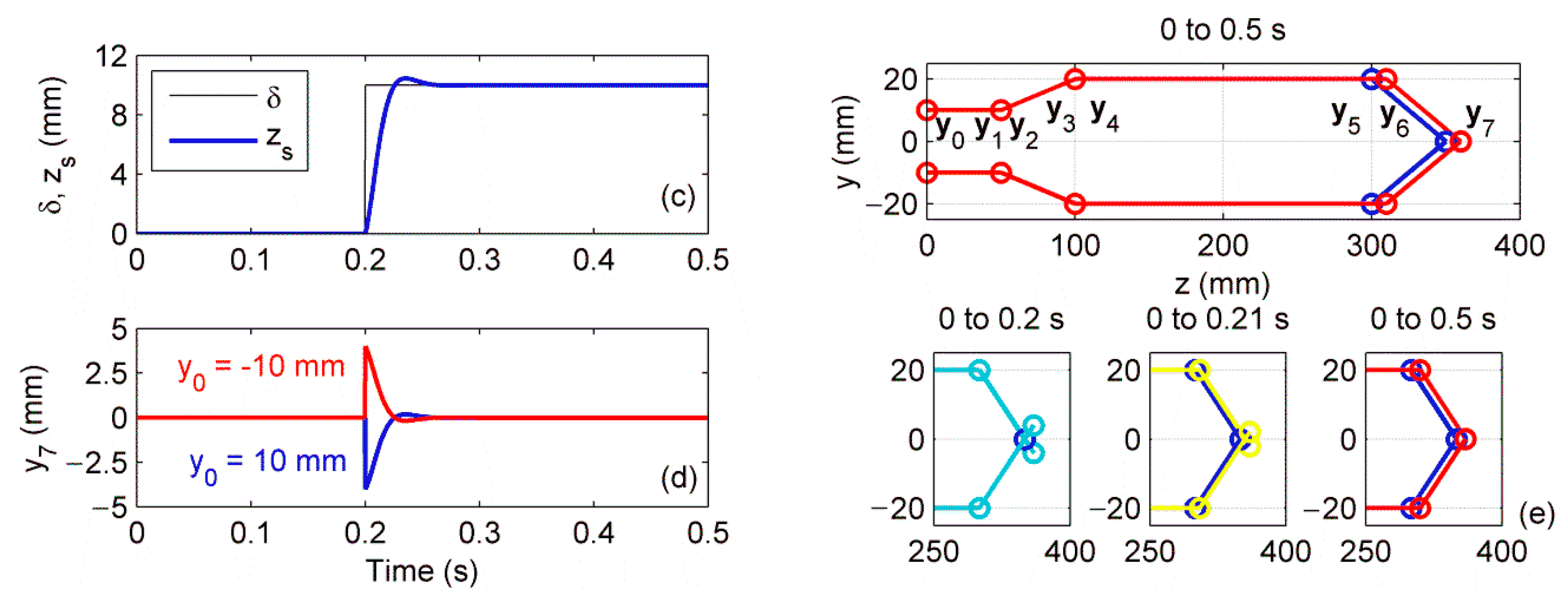

4.4. Automatic Focusing System

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cabrera, A.A.A.; Foeken, M.J.; Tekin, O.A.; Woestenenk, K.; Erden, M.S.; De Schutter, B.; van Tooren, M.J.L.; Rabuška, R.; van Houten, F.J.A.M.; Tomiyama, T. Towards automation of control software: A review of challenges in mechatronic design. Mechatronics 2010, 20, 876–886. [Google Scholar] [CrossRef]

- Gamo, J. Assessing a virtual laboratory in optics as a complement to on-site teaching. IEEE Trans. Educ. 2019, 62, 119–126. [Google Scholar] [CrossRef]

- Verlage, E.; Saini, S.; Agarwal, A.; Serna, S.; Kosciolek, R.; Morrisey, T.; Kimerling, L.C. Web-based interactive simulations and virtual lab for photonics education. In Proceedings of the Fifteenth Conference on Education Training in Optics and Photonics (ETOP 2019), Quebec City, QC, Canada, 21–24 May 2019; OSA: Washington, DC, USA, 2019; p. 11143_136. [Google Scholar] [CrossRef]

- Sanchez del Rio, M.; Canestrari, N.; Jiang, F.; Cerrina, F. SHADOW3: A new version of the synchrotron X-ray optics modelling package. J. Synchrotron Radiat. 2011, 18, 708–716. [Google Scholar] [CrossRef] [PubMed]

- Cohen, D.K.; Gee, W.H.; Ludeke, M.; Lewkowicz, J. Automatic focus control: The astigmatic lens approach. Appl. Opt. 1984, 23, 565–570. [Google Scholar] [CrossRef] [PubMed]

- Logozzo, S.; Valigi, M.C.; Canella, G. Advances in optomechatronics: An automated tilt-rotational 3D scanner for high-quality reconstructions. Photonics 2018, 5, 42. [Google Scholar] [CrossRef]

- Cho, H.; Kim, M.Y. Optomechatronic technology: The characteristics and perspectives. IEEE Trans. Ind. Electron. 2005, 52, 932–943. [Google Scholar] [CrossRef]

- Knight, J.S.; Acton, D.S.; Lightsey, P.; Barto, A. Integrated telescope model for the James Webb space telescope. In Proceedings of the SPIE Astronomical Telescopes + Instrumentation, Proceedings of SPIE 8449, Amsterdam, The Netherlands, 1–6 July 2012; SPIE: Bellingham, WA, USA, 2012; p. 84490V. [Google Scholar] [CrossRef]

- Wittkopf, S.; Grobe, L.O.; Geisler-Moroder, D.; Compagnon, R.; Kämpf, J.; Linhart, F.; Scartezzini, J.-L. Ray tracing study for non-imaging daylight collectors. Sol. Energy 2010, 84, 986–996. [Google Scholar] [CrossRef]

- González, G.D.; Castillo, M.D.I. Model of the human eye based on ABCD matrix. In Proceedings of the 6th Ibero-American Conference on Optics/9th Latin-American Meeting on Optics, Lasers and Applications, AIP Conference Proceedings 992, Campinas, Brazil, 21–26 October 2007; AIP: Melville, NY, USA, 2007; pp. 108–113. [Google Scholar] [CrossRef]

- Parker, S.G.; Bigler, J.; Dietrich, A.; Friedrich, H.; Hoberock, J.; Luebke, D.; McAllister, D.; McGuire, M.; Morley, K.; Robinson, A.; et al. OptiX: A general purpose ray tracing engine. ACM Trans. Graph. 2010, 29, 66. [Google Scholar] [CrossRef]

- Osório, T.; Horta, P.; Larcher, M.; Pujol-Nadal, R.; Hertel, J.; van Rooyen, D.W.; Heimsath, A.; Schneider, S.; Benitez, D.; Frein, A.; et al. Ray-tracing software comparison for linear focusing solar collectors. In Proceedings of the International Conference on Concentrating Solar Power and Chemical Energy Systems, AIP Conference Proceedings 1734, Cape Town, South Africa, 13–16 October 2015; AIP: Melville, NY, USA, 2016; p. 020017. [Google Scholar] [CrossRef]

- Mauch, F.; Gronle, M.; Lyda, W.; Osten, W. Open-source graphics processing unit-accelerated ray tracer for optical simulation. Opt. Eng. 2016, 52, 053004. [Google Scholar] [CrossRef][Green Version]

- Savage, N. Optical design software. Nat. Photonics 2007, 1, 598–599. [Google Scholar] [CrossRef]

- Poon, T.-C.; Kim, T. Engineering Optics with MATLAB; World Scientific Publishing: Hackensack, NJ, USA, 2006. [Google Scholar]

- Anterrieu, E.; Perez, J.-P. MOTO: A Matlab object-oriented programming toolbox for optics. In Proceedings of the Education Training in Optics and Photonics, Ottawa, ON, Canada, 3 June 2007; OSA: Washington, DC, USA, 2007; p. ETD3. [CrossRef]

- Crowther, B.G.; Wassom, S.R. Toward end-to-end optical system modeling and optimization: A step forward in optical design. In Proceedings of the Optical Science and Technology, the SPIE 49th Annual Meeting, Proceedings of SPIE 5524, Denver, CO, USA, 2–6 August 2004; SPIE: Bellingham, WA, USA, 2004; pp. 196–204. [Google Scholar] [CrossRef]

- Wilson, W.C.; Atkinson, G.M. MOEMS Modeling Using the Geometrical Matrix Toolbox, NASA Technical Reports Server. 2005. Available online: https://ntrs.nasa.gov/search.jsp?R=20050237975 (accessed on 12 October 2020).

- Tarsaria, H.; Alvarenga, J.; Desai, A.; Rad, K.; Boussalis, H. Ray tracing visualization using LabVIEW for precision pointing architecture of a segmented reflector testbed. In Proceedings of the 19th Mediterranean Conference on Control & Automation, Corfu, Greece, 20–23 June 2011; IEEE: Bellingham, WA, USA, 2011; pp. 1367–1372. [Google Scholar] [CrossRef]

- Delano, E. First-order design and the y, ӯ diagram. Appl. Opt. 1963, 12, 1251–1256. [Google Scholar] [CrossRef]

- Schwab, M.; Herkommer, A. The Delano diagram, a powerful design tool. In Proceedings of the Optical Systems Design, Proceedings of SPIE 7100, Glasgow, Scotland, UK, 2–5 September 2008; SPIE: Bellingham, WA, USA, 2008; p. 71000U. [Google Scholar] [CrossRef]

- Saleh, B.E.A.; Teich, M.C. Fundamentals of Photonics; John Wiley & Sons: New York, NY, USA, 1991. [Google Scholar]

- Choi, J.S.; Howell, J.C. Paraxial ray optics cloaking. Opt. Express 2014, 22, 29465–29478. [Google Scholar] [CrossRef] [PubMed]

- Keiser, G. Optical Fiber Communications; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Snyder, A.W.; Pask, C.; Mitchell, D.J. Light-acceptance property of an optical fiber. J. Opt. Soc. Am. 1973, 63, 59–64. [Google Scholar] [CrossRef] [PubMed]

- Tekelioglu, M.; Wood, B.D. Prediction of light-transmission losses in plastic optical fibers. Appl. Opt. 2005, 44, 2318–2326. [Google Scholar] [CrossRef]

- Lomer, M.; Arrue, J.; Jauregui, C.; Aiestaran, P.; Zubia, J.; López-Higuera, J.M. Lateral polishing of bends in plastic optical fibres applied to a multipoint liquid-level measurement sensor. Sens. Actuators A Phys. 2007, 137, 68–73. [Google Scholar] [CrossRef]

- Beard, P.C. Interrogation of free-space Fabry-Perot sensing interferometers by angle tuning. Meas. Sci. Technol. 2003, 14, 1998–2005. [Google Scholar] [CrossRef]

- Jovanov, V.; Bunte, E.; Stiebig, H.; Knipp, D. Transparent Fourier transform spectrometer. Opt. Lett. 2011, 36, 274–276. [Google Scholar] [CrossRef]

- Chu, C.-L.; Lin, C.-H. Development of an optical accelerometer with a DVD pick-up head. Meas. Sci. Technol. 2005, 16, 2498–2502. [Google Scholar] [CrossRef]

- Kasukurti, A.; Potcoava, M.; Desai, S.A.; Eggleton, C.; Marr, D.W.M. Single-cell isolation using a DVD optical pickup. Opt. Express 2011, 19, 10377–10386. [Google Scholar] [CrossRef]

- Thorlabs. Z8 Series Motorized DC Servo Actuators—User Guide. 2018. Available online: www.thorlabs.com/thorproduct.cfm?partnumber=Z825B (accessed on 13 October 2020).

- Yue, M.S.; Shiue, S.-G.; Lu, M.-H. Two-optical-component method for designing zoom system. Opt. Eng. 1995, 34, 1826–1834. [Google Scholar] [CrossRef]

- Wick, D.V.; Martinez, T. Adaptative optical zoom. Opt. Eng. 2004, 43, 8–9. [Google Scholar] [CrossRef]

| Element | Coefficients | Notes |

|---|---|---|

| Transmission through a medium | d is the path length. Refractive index of the medium is constant. | |

| Refraction at a planar interface | n1 and n2 are the refractive indices of incident and refracting media, respectively. yn is perpendicular to the interface. | |

| Reflection at a planar interface | yn is perpendicular to the interface. | |

| Thin lens | f is the focal length (positive for convex and negative for concave lens). yn is perpendicular to the interface. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fujiwara, E.; Cordeiro, C.M.B. Model-Based Design and Simulation of Paraxial Ray Optics Systems. Appl. Sci. 2020, 10, 8278. https://doi.org/10.3390/app10228278

Fujiwara E, Cordeiro CMB. Model-Based Design and Simulation of Paraxial Ray Optics Systems. Applied Sciences. 2020; 10(22):8278. https://doi.org/10.3390/app10228278

Chicago/Turabian StyleFujiwara, Eric, and Cristiano M. B. Cordeiro. 2020. "Model-Based Design and Simulation of Paraxial Ray Optics Systems" Applied Sciences 10, no. 22: 8278. https://doi.org/10.3390/app10228278

APA StyleFujiwara, E., & Cordeiro, C. M. B. (2020). Model-Based Design and Simulation of Paraxial Ray Optics Systems. Applied Sciences, 10(22), 8278. https://doi.org/10.3390/app10228278