A Machine Learning Model for Predicting Noise Limits of Motor Vehicles in UNECE R51 Regulations

Abstract

:1. Introduction

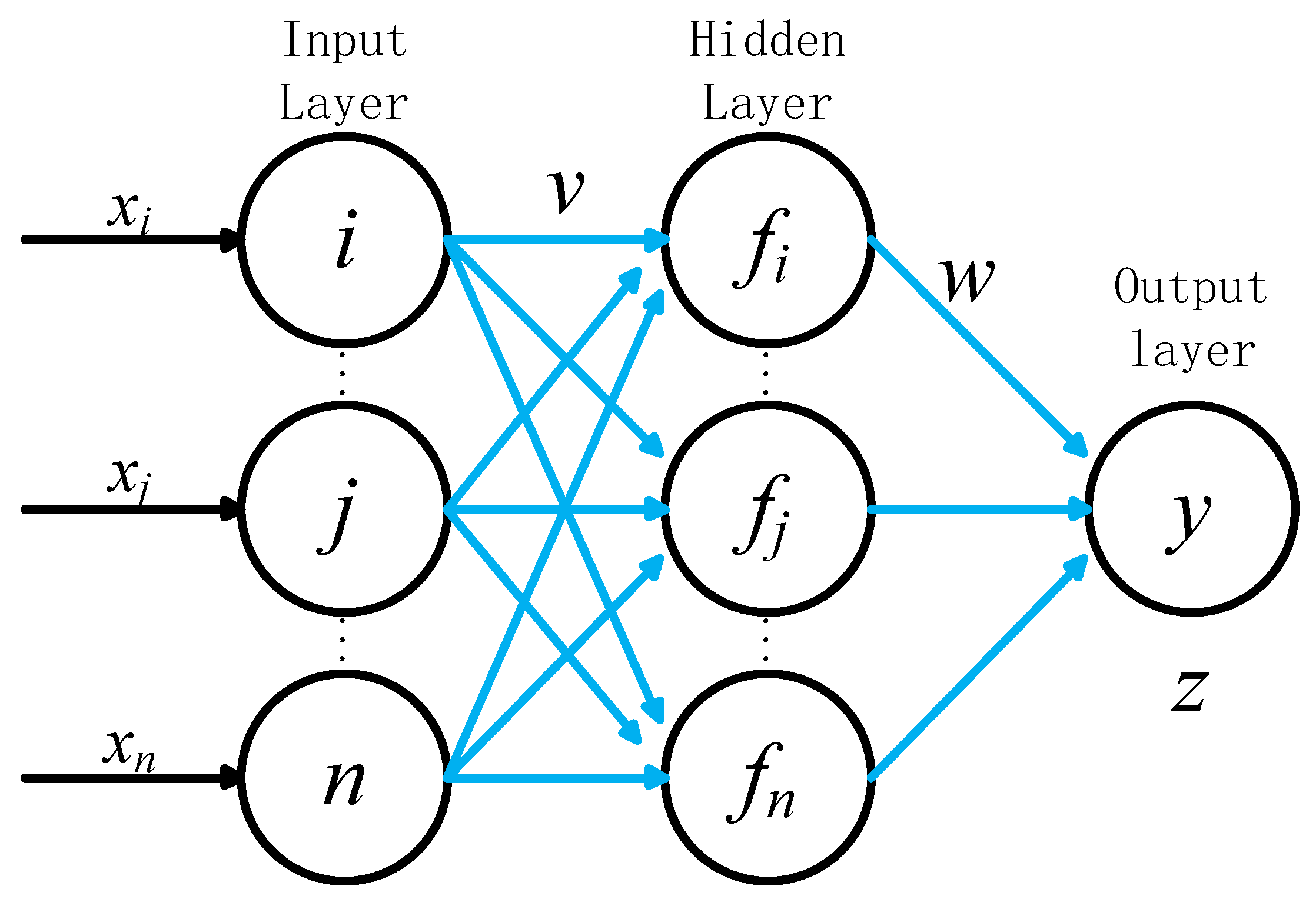

2. Artificial Neural Network

2.1. Principles and Basic Architecture

2.2. Neural Network Learning

3. BPNN Model for Noise Limits Prediction during Vehicle Acceleration

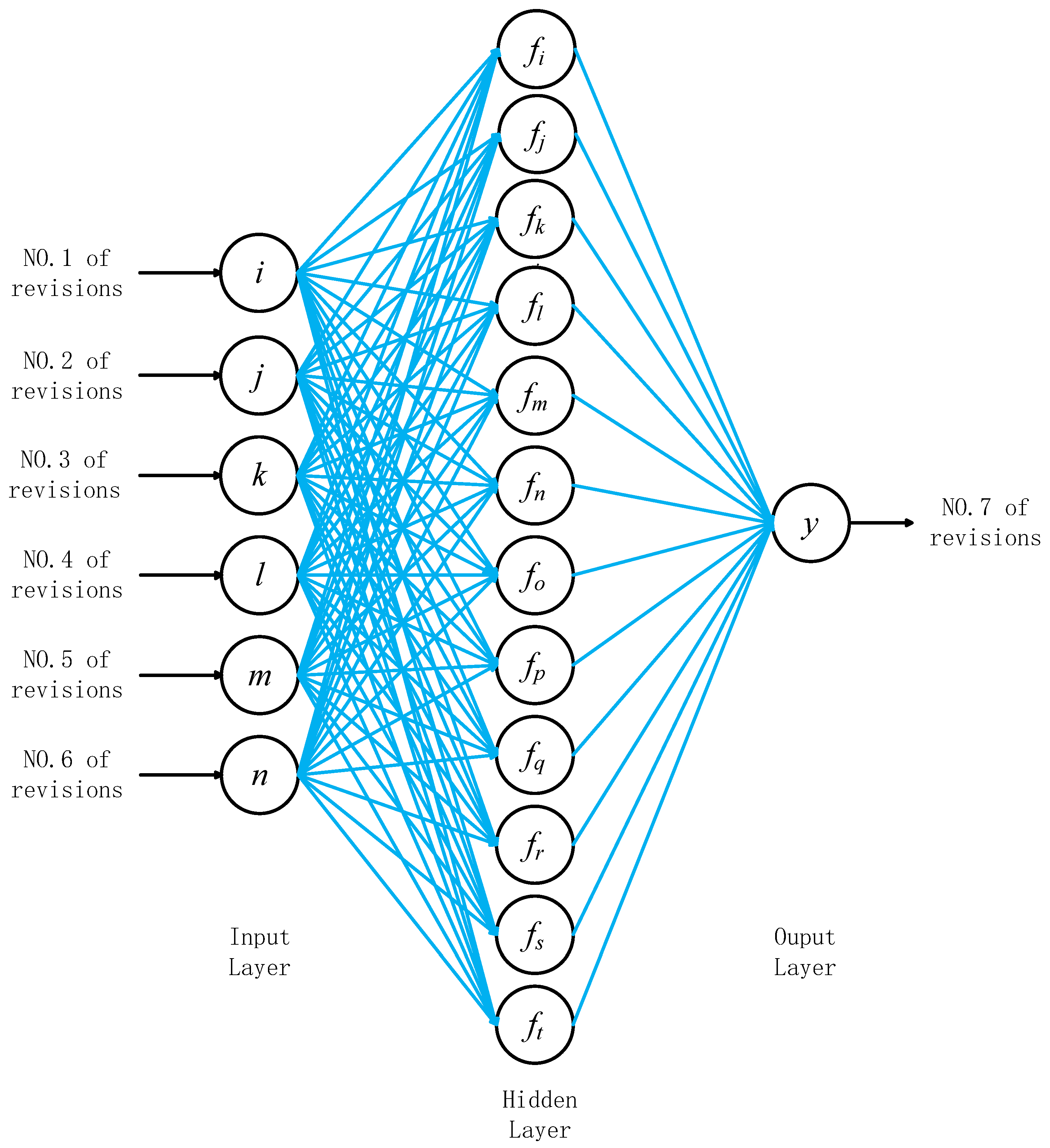

3.1. Architecture of the Proposed BPNN Model

3.1.1. Data Normalisation and Classification

3.1.2. Development of Back-Propagation Neural Network

3.2. Training of the Neural Networks

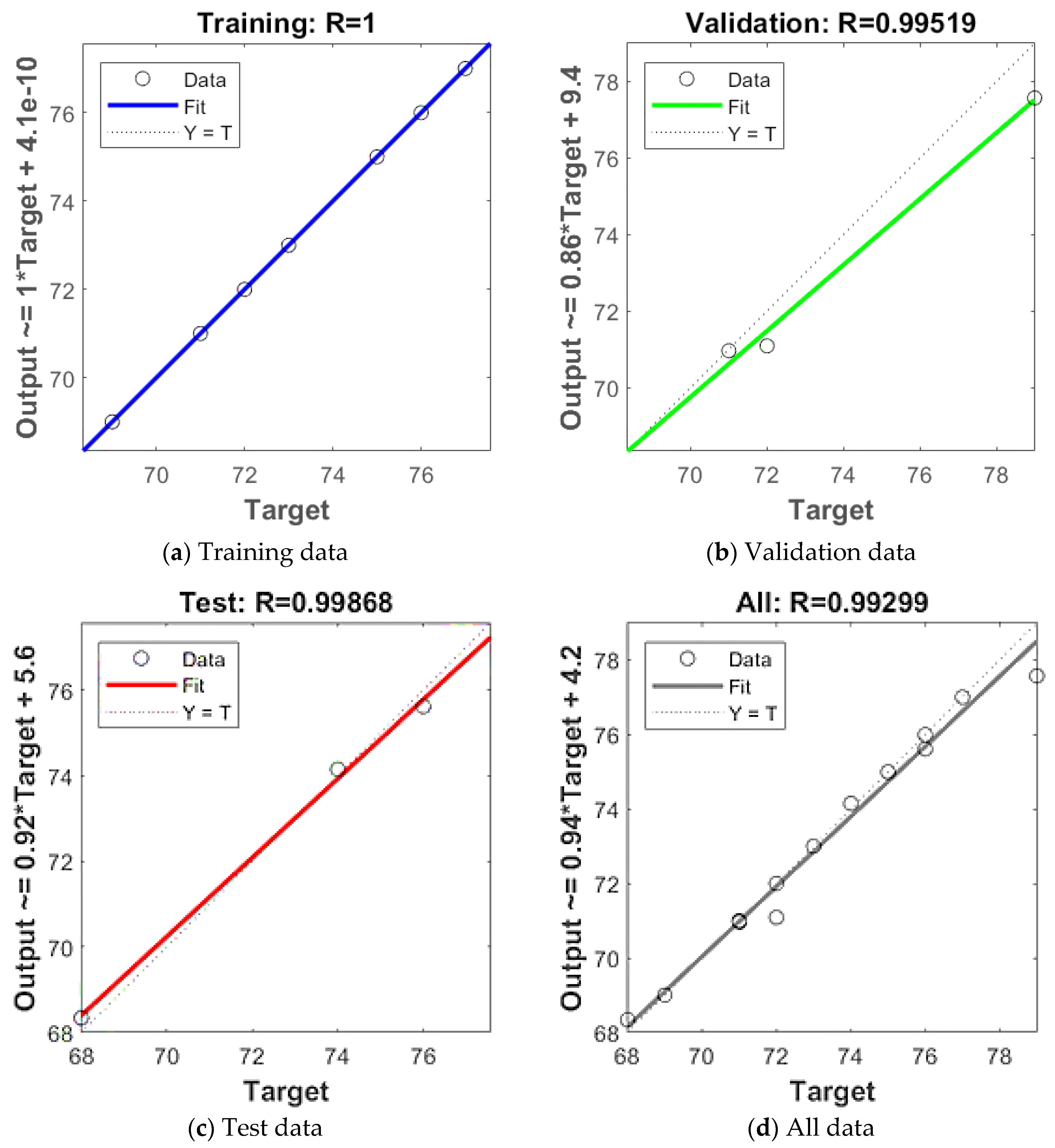

3.3. Performance Analysis on Machine Learning Models

4. Prediction of Acceleration Noise Limits by Using the Proposed BPNN Model

4.1. Validation of Noise Limit Outputs

- (1)

- For the training data, the predicted values by using the proposed BPNN model with network learning is almost the same as the values of the current noise limits except for one case for N3 with a percentage error of 1.81%. The quadratic regression model extracted the predicted values with much higher errors from −5.44% to 1.73%. It demonstrated the proposed BPNN model was accurate.

- (2)

- As for those validation data and test data, since there was no network learning, the predicted values have much larger errors compared with those training data. However, the maximum deviation is still smaller than the results obtained by the quadratic regression model in most cases. Again, the proposed BPNN model provides a better accuracy than the quadratic regression model in the prediction of noise limits during vehicle acceleration.

- (3)

- The proposed BPNN model can predict noise limits for all learned categories of vehicles, which are only related to historic values of the noise limits of a vehicle, but not depending on its category. Differently, the quadratic regression model is strongly related to both historic values of noise limits of a vehicle and its vehicle category.

- (4)

- The proposed BPNN model has a migration ability on the prediction of noise limits and can be used to predict the backward trend of noise limits defined in the UNECE regulations. If the inputs of the BPNN model are moved one unit backward, it provides predicted values of noise limits in the next revisions of the UNECE regulations.

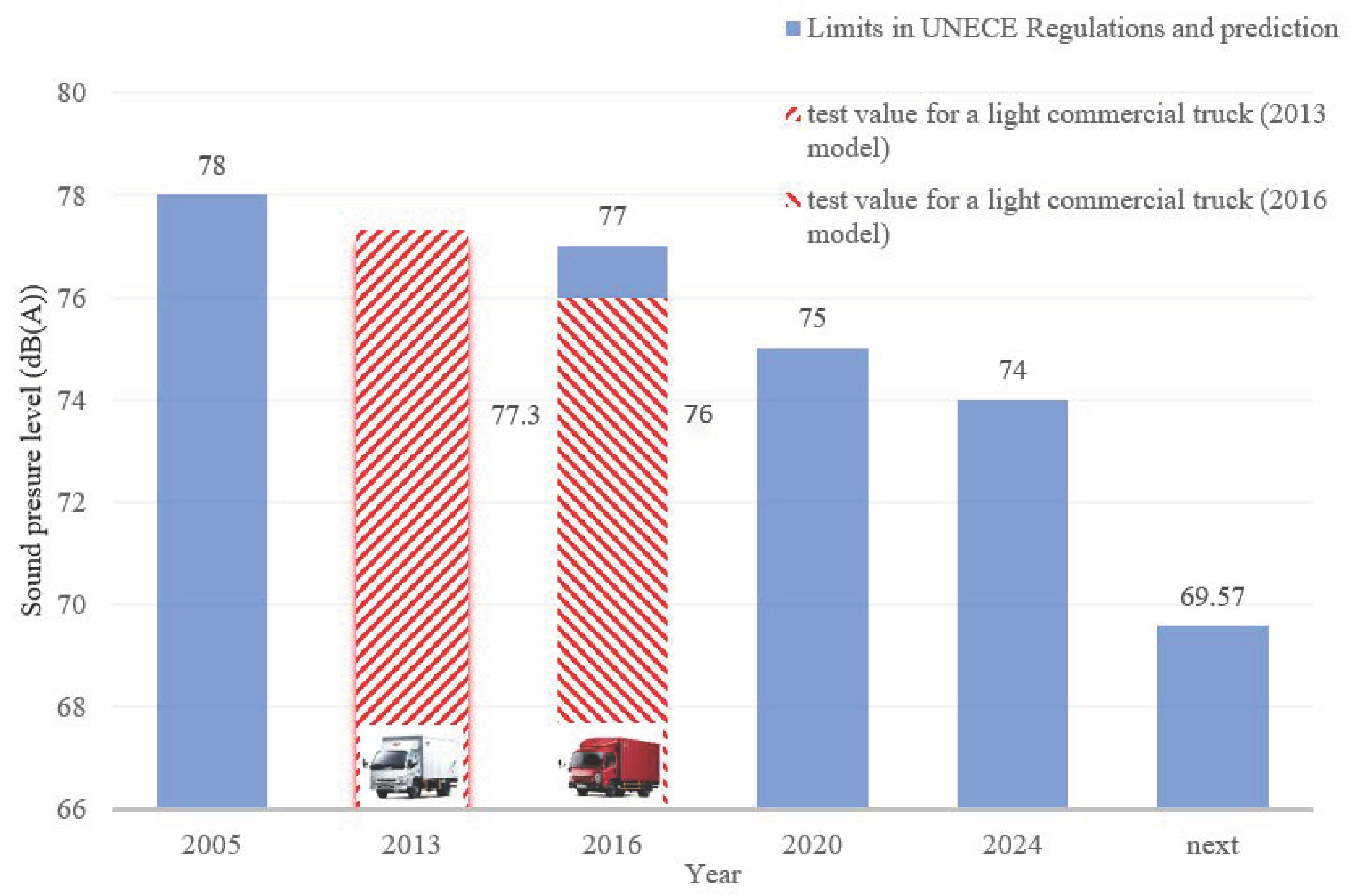

4.2. Prediction of Noise Limits for Future Revision of UNECE Regulations

4.3. A Case Study of Noise Control for a Light Commercial Truck

5. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Singh, N.; Davar, S.C. Noise pollution-sources, effects and control. J. Hum. Ecol. 2004, 16, 181. [Google Scholar] [CrossRef]

- Moore, D. Development of ECE R51. 03 Noise Emission Regulation; SAE Technical Paper 2017-01-1893; SAE International: Warrendale, PA, USA, 2017. [Google Scholar] [CrossRef]

- Roo, F.D. New EU and UN/ECE Vehicle noise emission limits and associated measurement methods. In Proceedings of the 42nd International Congress and Exposition on Noise Control Engineering-Noise Control for Quality of Life-INTER-NOISE 2013, Innsbruck, Austria, 15–18 September 2013; pp. 6415–6430. [Google Scholar]

- Sottek, R.; Krebber, W.; Genuit, K. Simulation of vehicle exterior noise. In Proceedings of the Inter-Noise 2001—International Congress and Exhibition on Noise Control Engineering, The Hague, The Netherlands, 28–30 August 2001; pp. 2371–2374. [Google Scholar]

- McBride Granda, S.M. A Wave Propagation Approach for Prediction of Tire-Pavement Interaction Noise. Ph.D. Thesis, Virginia Tech, Blacksburg, VA, USA, 2019. [Google Scholar]

- Sarkan, B.; Stopka, O.; Li, C. The issues of measuring the exterior and interior noise of road vehicles. Commun. Sci. Lett. Univ. Zilina 2017, 19, 50. [Google Scholar]

- Phan, V.L.; Tanaka, H.; Nagatani, T.; Wakamatsu, M.; Yasuki, T. A CFD analysis method for prediction of vehicle exterior wind noise. Sae Int. J. Passeng. Cars Mech. Syst. 2017, 10, 286. [Google Scholar] [CrossRef]

- Baudet, G.; Dutrion, C.; Lorenzi, R.; Gendre, F.; Geng, S. Calculation Process with Lattice Boltzmann and Finite Element Methods to Choose the Best Exterior Design for Wind Noise. In Proceedings of the Noise and Vibration Conference & Exhibition, Grand Rapids, MI, USA, 10−13 June 2017. [Google Scholar]

- Nygren, J.; Boij, S.; Rumpler, R.; O’Reilly, C.J. A study of the interaction between vehicle exterior noise emissions and vehicle energy demands for different drive cycles. In Proceedings of the 23rd International Congress on Acoustics, ICA, Aachen, Germany, 9–13 September 2019. [Google Scholar]

- Kerber, S. The importance of vehicle exterior noise levels in urban traffic for pedestrian—Vehicle interaction. Atz Worldw. 2006, 108, 19. [Google Scholar] [CrossRef]

- Tousignant, T.; Eisele, G.; Govindswamy, K.; Steffens, C.; Tomazic, D. Optimization of Electric Vehicle Exterior Noise for Pedestrian Safety and Sound Quality. In Proceedings of the INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Grand Rapids, MI, USA, 12–14 June 2017; Institute of Noise Control Engineering: Reston, VA, USA; pp. 245–252. [Google Scholar]

- Qi, J.; Du, J.; Siniscalchi, S.M.; Ma, X.; Lee, C.H. Analyzing Upper Bounds on Mean Absolute Errors for Deep Neural Network Based Vector-to-Vector Regression. IEEE Trans. Signal Process. 2020, 68, 3411–3422. [Google Scholar] [CrossRef]

- Nourani, V.; Gökçekuş, H.; Umar, I.K.; Najafi, H. An emotional artificial neural network for prediction of vehicular traffic noise. Sci. Total Environ. 2020, 707, 136134. [Google Scholar] [CrossRef]

- Jiménez-Romero, F.J.; Guijo-Rubio, D.; Lara-Raya, F.R.; Ruiz-González, A.; Hervás-Martínez, C. Validation of artificial neural networks to model the acoustic behaviour of induction motors. Appl. Acoust. 2020, 166, 107332. [Google Scholar] [CrossRef]

- Lu, H.; Wang, T. An Automobile Noise Prediction Model Based on Extension Data Mining Algorithm. Rev. D’intelligence Artif. 2019, 33, 341. [Google Scholar] [CrossRef]

- Çelebi, K.; Uludamar, E.; Tosun, E.; Yıldızhan, Ş.; Aydın, K.; Özcanlı, M. Experimental and artificial neural network approach of noise and vibration characteristic of an unmodified diesel engine fuelled with conventional diesel, and biodiesel blends with natural gas addition. Fuel 2017, 197, 159. [Google Scholar] [CrossRef]

- Huang, B.; Pan, Z.; Liu, Z.; Hou, G.; Yang, H. Acoustic amenity analysis for high-rise building along urban expressway: Modeling traffic noise vertical propagation using neural networks. Transp. Res. Part D Transp. Environ. 2017, 53, 63. [Google Scholar] [CrossRef]

- Steinbach, L.; Altinsoy, M.E. Prediction of annoyance evaluations of electric vehicle noise by using artificial neural networks. Appl. Acoust. 2019, 145, 149. [Google Scholar] [CrossRef]

- Werbos, P.J. Beyond Regression: New Tools for Prediction and Analysis in the Behavioral Sciences. Ph.D. Thesis, Harvard University, Cambridge, MA, USA, 1974. [Google Scholar]

- Bhat, N.; McAvoy, T.J. Use of neural nets for dynamic modeling and control of chemical process systems. Comput. Chem. Eng. 1990, 14, 573. [Google Scholar] [CrossRef]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning representations by back-propagating errors. Nature 1986, 323, 533. [Google Scholar] [CrossRef]

- Khashei, M.; Bijari, M. An artificial neural network (p, d, q) model for timeseries forecasting. Expert Syst. Appl. 2010, 37, 479. [Google Scholar] [CrossRef]

- Han, J.; Moraga, C. The influence of the sigmoid function parameters on the speed of backpropagation learning. In International Workshop on Artificial Neural Networks; Springer: Berlin, Germany, 1995; p. 195. [Google Scholar]

- Kreinovich, V.; Sirisaengtaksin, O. 3-layer neural networks are universal approximations for functions and for control strategies. Neural Parallel Sci. Comp. 1993, 1, 325. [Google Scholar]

- Beheshti, M.; Berrached, A.; de Korvin, A.; Hu, C.; Sirisaengtaksin, O. On interval weighted three-layer neural networks. In Proceedings of the 31st Annual Simulation Symposium, Boston, MA, USA, 5–9 April 1998; IEEE: Piscataway Township, NJ, USA, 1998; p. 188. [Google Scholar]

- Gavin, H.P. The Levenberg-Marquardt Algorithm for Nonlinear Least Squares Curve-Fitting Problems. Department of Civil and Environmental Engineering, Duke University. Available online: http://people.duke.edu/~hpgavin/ce281/lm.pdf (accessed on 1 October 2020).

- Mirri, S.; Delnevo, G.; Roccetti, M. Is a COVID-19 Second Wave Possible in Emilia-Romagna (Italy)? Forecasting a Future Outbreak with Particulate Pollution and Machine Learning. Computation 2020, 8, 74. [Google Scholar] [CrossRef]

- Joachims, T. Learning to Classify Text Using Support Vector Machines; Springer Science & Business Media: Berlin, Germany, 2002. [Google Scholar]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273. [Google Scholar] [CrossRef]

- Williams, C.K.; Rasmussen, C.E. Gaussian Processes for Machine Learning; MIT Press: Cambridge, MA, USA, 2006. [Google Scholar]

- Rasmussen, C.E. Gaussian processes in machine learning. In Summer School on Machine Learning; Springer: Berlin, Germany, 2003; p. 63. [Google Scholar]

- Dietterich, T.G. Ensemble methods in machine learning. In International Workshop on Multiple Classifier Systems; Springer: Berlin, Germany, 2000; p. 1. [Google Scholar]

- Sagi, O.; Rokach, L. Ensemble learning: A survey. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2018, 8, e1249. [Google Scholar] [CrossRef]

- Steinberg, D.; Colla, P. CART: Classification and regression trees. Top Ten Algorithms Data Min. 2009, 9, 179. [Google Scholar]

- Rodriguez-Galiano, V.; Sanchez-Castillo, M.; Chica-Olmo, M.; Chica-Rivas, M. Machine learning predictive models for mineral prospectivity: An evaluation of neural networks, random forest, regression trees and support vector machines. Ore Geol. Rev. 2015, 71, 804. [Google Scholar] [CrossRef]

| UNECE Regulations | Limits of Motor Vehicle During Acceleration (dB(A)) | |||||||

|---|---|---|---|---|---|---|---|---|

| Categories of vehicles | Regulation No. | R9/00 | R51/00 | R51/01 | R51/02 | R51/03I | R51/03II | R51/03III |

| Year | 1969 | 1982 | 1988 | 2005 | 2016 | 2020 | 2024 | |

| Revision No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

| M1 | PMR ≤ 120 | 82 | 80 | 77 | 74 | 72 | 70 | 68 |

| 120 < PMR ≤ 160 | 82 | 80 | 77 | 74 | 73 | 71 | 69 | |

| PMR > 160 | 82 | 80 | 77 | 74 | 75 | 73 | 71 | |

| M2 | M ≤ 2.5 t | 84 | 81 | 77 | 74 | 72 | 70 | 69 |

| 2.5 t < M ≤ 3.5 t | 84 | 81 | 77 | 74 | 74 | 72 | 71 | |

| M > 3.5 t; Pn ≤ 135 kW | 89 | 82 | 80 | 78 | 75 | 73 | 72 | |

| M > 3.5 t; Pn > 135 kW | 91 | 85 | 83 | 80 | 75 | 74 | 72 | |

| M3 | Pn ≤ 150 kW | 89 | 82 | 80 | 78 | 76 | 74 | 73 |

| 150 kW < Pn ≤ 250 kW | 91 | 85 | 83 | 80 | 78 | 77 | 76 | |

| Pn > 250 kW | 91 | 85 | 83 | 80 | 80 | 78 | 77 | |

| N1 | M ≤ 2.5 t | 84 | 81 | 78 | 76 | 72 | 71 | 69 |

| M > 2.5 t | 84 | 81 | 79 | 77 | 74 | 73 | 71 | |

| N2 | Pn ≤135 kW | 89 | 86 | 83 | 78 | 77 | 75 | 74 |

| Pn > 135 kW | 89 | 86 | 84 | 80 | 78 | 76 | 75 | |

| N3 | Pn ≤ 150 kW | 89 | 86 | 83 | 78 | 79 | 77 | 76 |

| 150 kW < Pn ≤ 250 kW | 92 | 88 | 84 | 80 | 81 | 79 | 77 | |

| Pn > 250 kW | 92 | 88 | 84 | 80 | 82 | 81 | 79 | |

| Number of Hidden Layers | Training Data | Validation Data | Test Data | |||

|---|---|---|---|---|---|---|

| MSE | Regression Values | MSE | Regression Values | MSE | Regression Values | |

| 6 | 0.601 | 0.996 | 0.340 | 0.950 | 2.08 | 0.999 |

| 7 | 9.61 × 10−3 | 0.999 | 1.39 | 0.905 | 2.26 | 0.899 |

| 8 | 3.92 × 10−3 | 0.999 | 7.27 × 10−2 | 0.996 | 2.36 | 0.976 |

| 9 | 0.167 | 0.992 | 3.92 | 0.772 | 1.28 | 0.999 |

| 10 | 0.127 | 0.995 | 2.88 | 0.965 | 2.25 | 0.945 |

| 11 | 4.74 × 10−2 | 0.999 | 2.22 | −0.694 | 2.39 | −0.761 |

| 12 | 3.64 × 10−2 | 0.999 | 1.20 | 0.995 | 1.18 | 0.999 |

| 13 | 9.61 × 10−2 | 0.995 | 1.23 | 0.915 | 0.536 | 0.991 |

| 14 | 1.86 × 10−7 | 0.999 | 0.178 | 0.999 | 1.12 | 0.969 |

| 15 | 0.133 | 0.998 | 0.785 | 0.999 | 1.77 | 0.997 |

| 16 | 0.1.0040 | 0.993 | 8.99×10−2 | 0.997 | 1.45 | 0.974 |

| 17 | 9.99 × 10−4 | 0.999 | 0.439 | 0.999 | 1.25 | 0.997 |

| 18 | 2.97 × 10−8 | 0.999 | 0.869 | 0.927 | 1.44 | 0.946 |

| 19 | 5.03 × 10−5 | 0.999 | 1.09 | 0.992 | 0.899 | 0.981 |

| 20 | 9.77 × 10−12 | 0.999 | 1.49 | 0.994 | 1.49 | 0.976 |

| 21 | 0.219 | 0.994 | 0.957 | 0.952 | 1.99 | 0.997 |

| 22 | 0.857 | 0.971 | 1.31 | 0.998 | 1.16 | 0.999 |

| 23 | 1.32 × 10−4 | 0.999 | 0.619 | 0.998 | 1.21 | 0.995 |

| 24 | 0.277 | 0.998 | 0.488 | 0.999 | 1.07 | 0.999 |

| Machine Learning | Kernel Function | MSE | Model Type |

|---|---|---|---|

| SVM | Linear | 0.663 | |

| Quadratic | 0.599 | ||

| Cubic | 0.997 | ||

| Fine Gaussian | 8.65 | Kernel scale: 0.61 | |

| Medium Gaussian | 1.59 | Kernel scale: 2.4 | |

| Coarse Gaussian | 2.02 | Kernel scale: 9.8 | |

| GPR | Rational Quadratic | 0.331 | |

| Squared Exponential | 0.312 | ||

| Matern 5/2 | 0.524 | ||

| Exponential | 0.876 | ||

| ET | Boosted Trees | 23.6 | Minimum leaf size: 8; Number of learners: 30; learning rate: 0.1 |

| Bagged Trees | 14.8 | Minimum leaf size: 8; Number of learners: 30 | |

| RT | Fine Tree | 4.76 | Minimum leaf size: 4 |

| Medium Tree | 14.4 | Minimum leaf size: 12 | |

| Coarse Tree | 14.4 | Minimum leaf size: 36 | |

| BPNN | Levenberg-Marquardt algorithm | 0.444 | Hidden layer units: 12 |

| Categories of Vehicle | CNL | BPNN Model | Quadratic Regression Model | |||||

|---|---|---|---|---|---|---|---|---|

| Data Classification | PV | PE | Prediction Model | PV | PE | |||

| M1 | 1 | 68 | Test data | 68.34 | −0.50% | y = 0.0714x2 − 2.9857x + 85.2 | 67.80 | 0.30% |

| 2 | 69 | Training data | 69.00 | 0.00% | y = 0.1429x2 − 3.2571x + 85.4 | 69.60 | −0.86% | |

| 3 | 71 | Validation data | 70.96 | 0.05% | y = 0.2857x2 − 3.8000x + 85.8 | 73.20 | −3.10% | |

| M2 | 1 | 69 | Training data | 69.00 | 0.00% | y = 0.2321x2 − 4.4821x + 88.5 | 68.50 | 0.73% |

| 2 | 71 | Training data | 71.00 | 0.00% | y = 0.3750x2 − 5.0250x + 88.9 | 72.10 | −1.55% | |

| 3 | 72 | Training data | 72.00 | 0.00% | y = 0.3750x2 − 5.5679x + 93.3 | 72.70 | −0.97% | |

| 4 | 72 | Validation data | 71.09 | 1.26% | y = 0.2321x2 − 4.9964x + 95.3 | 71.70 | 0.42% | |

| M3 | 1 | 73 | Training data | 73.00 | 0.00% | y = 0.4464x2 − 5.8393x + 93.5 | 74.50 | −2.05% |

| 2 | 76 | Test data | 75.61 | 0.51% | y = 0.4464x2 − 5.8107x + 95.9 | 77.10 | −1.45% | |

| 3 | 77 | Training data | 77.00 | 0.00% | y = 0.5000x2 − 5.8714x + 95.8 | 79.20 | −2.86% | |

| N1 | 1 | 69 | Training data | 69.00 | 0.00% | y = 0.1071x2 − 3.4357x + 87.4 | 68.60 | 0.58% |

| 2 | 71 | Training data | 71.00 | 0.00% | y = 0.1071x2 − 2.9786x + 86.8 | 71.20 | −0.28% | |

| N2 | 1 | 74 | Test data | 74.15 | −0.21% | y = 0.2321x2 − 4.5393x + 93.7 | 73.30 | 0.95% |

| 2 | 75 | Training data | 75.00 | 0.00% | y = 0.0893x2 − 3.2821x + 92.3 | 73.70 | 1.73% | |

| N3 | 1 | 76 | Training data | 76.00 | 0.00% | y = 0.3750x2 − 5.0821x + 94.1 | 76.90 | −1.18% |

| 2 | 77 | Validation data | 77.00 | 0.00% | y = 0.5357x2 − 6.3214x + 98.0 | 79.99 | −3.90% | |

| 3 | 79 | Training data | 77.57 | 1.81% | y = 0.6964x2 − 7.0750x + 98.7 | 83.30 | −5.44% | |

| Item | Training Data | Validation Data | Test Data | All Data | ||||

|---|---|---|---|---|---|---|---|---|

| BPNN | Regression | BPNN | Regression | BPNN | Regression | BPNN | Regression | |

| Correlation | 1 | 0.995 | 0.995 | 0.999 | 0.999 | 0.987 | 0.993 | 0.952 |

| Two-tailed test | 0.000 | 0.000 | 0.013 | 0.006 | 0.006 | 0.013 | 0.009 | 0.007 |

| Categories of Vehicle | Current Noise Limits with Revision Number 7 | Predicted Noise Limits for Next Revision (Revision Number 8) | CR | |

|---|---|---|---|---|

| M1 | 1 | 68 | 69.14 | 1.68% |

| 2 | 69 | 69.40 | 0.58% | |

| 3 | 71 | 69.83 | −1.65% | |

| M2 | 1 | 69 | 69.89 | 1.28% |

| 2 | 71 | 69.95 | −1.48% | |

| 3 | 72 | 69.59 | −3.34% | |

| 4 | 72 | 69.82 | −3.03% | |

| M3 | 1 | 73 | 70.45 | −3.49% |

| 2 | 76 | 72.23 | −4.97% | |

| 3 | 77 | 72.26 | −6.15% | |

| N1 | 1 | 69 | 69.19 | 0.27% |

| 2 | 71 | 69.16 | −2.59% | |

| N2 | 1 | 74 | 69.57 | −5.99% |

| 2 | 75 | 70.73 | −5.70% | |

| N3 | 1 | 76 | 70.63 | −7.07% |

| 2 | 77 | 73.03 | −5.15% | |

| 3 | 79 | 73.75 | −6.64% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, G.; Chen, Q.; Li, C.; Yang, R. A Machine Learning Model for Predicting Noise Limits of Motor Vehicles in UNECE R51 Regulations. Appl. Sci. 2020, 10, 8092. https://doi.org/10.3390/app10228092

Tan G, Chen Q, Li C, Yang R. A Machine Learning Model for Predicting Noise Limits of Motor Vehicles in UNECE R51 Regulations. Applied Sciences. 2020; 10(22):8092. https://doi.org/10.3390/app10228092

Chicago/Turabian StyleTan, Gangping, Qingshuang Chen, Changyin Li, and Richard (Chunhui) Yang. 2020. "A Machine Learning Model for Predicting Noise Limits of Motor Vehicles in UNECE R51 Regulations" Applied Sciences 10, no. 22: 8092. https://doi.org/10.3390/app10228092

APA StyleTan, G., Chen, Q., Li, C., & Yang, R. (2020). A Machine Learning Model for Predicting Noise Limits of Motor Vehicles in UNECE R51 Regulations. Applied Sciences, 10(22), 8092. https://doi.org/10.3390/app10228092

_Yang.png)