An Experimental Study on the Defect Detectability of Time- and Frequency-Domain Analyses for Flash Thermography

Abstract

1. Introduction

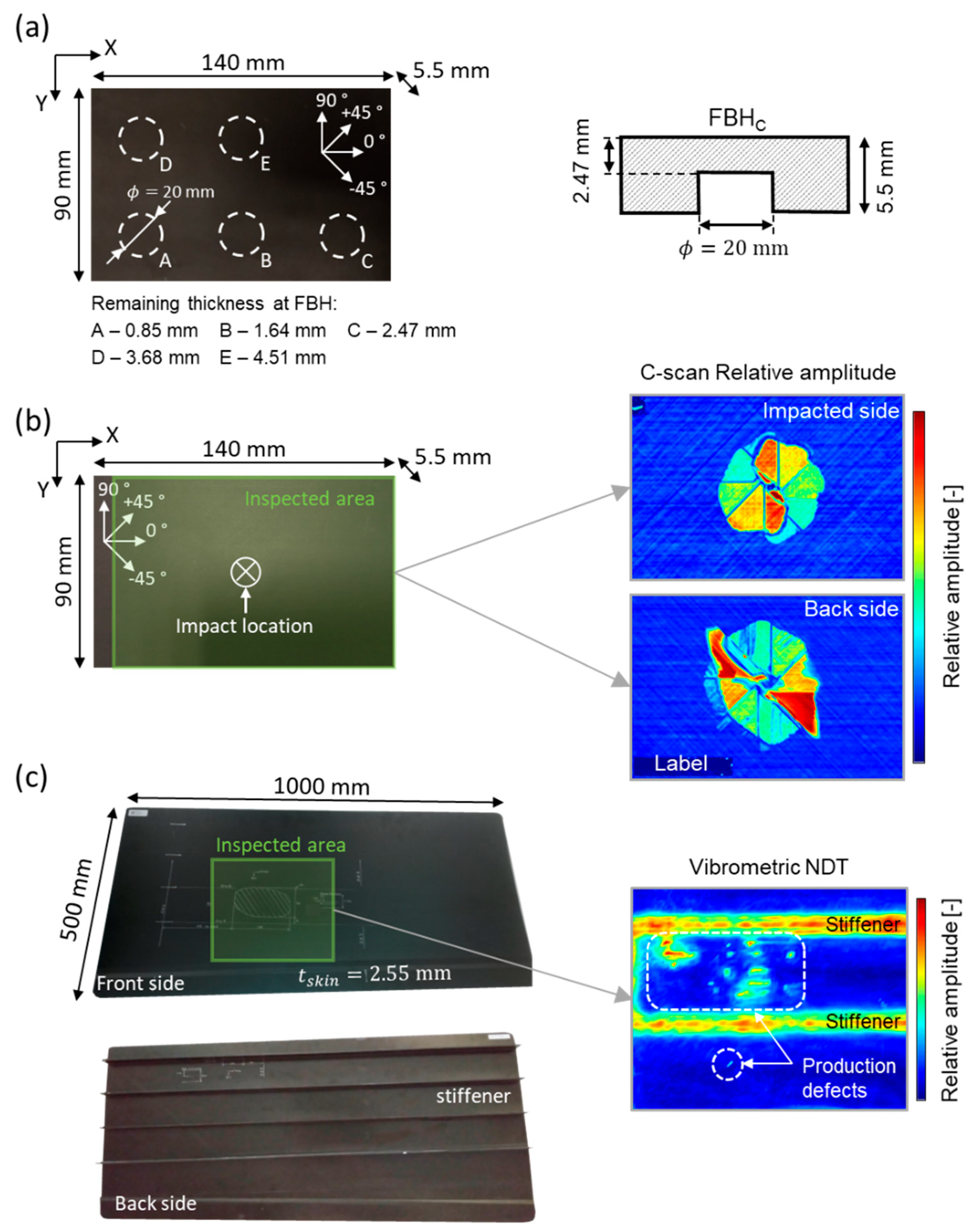

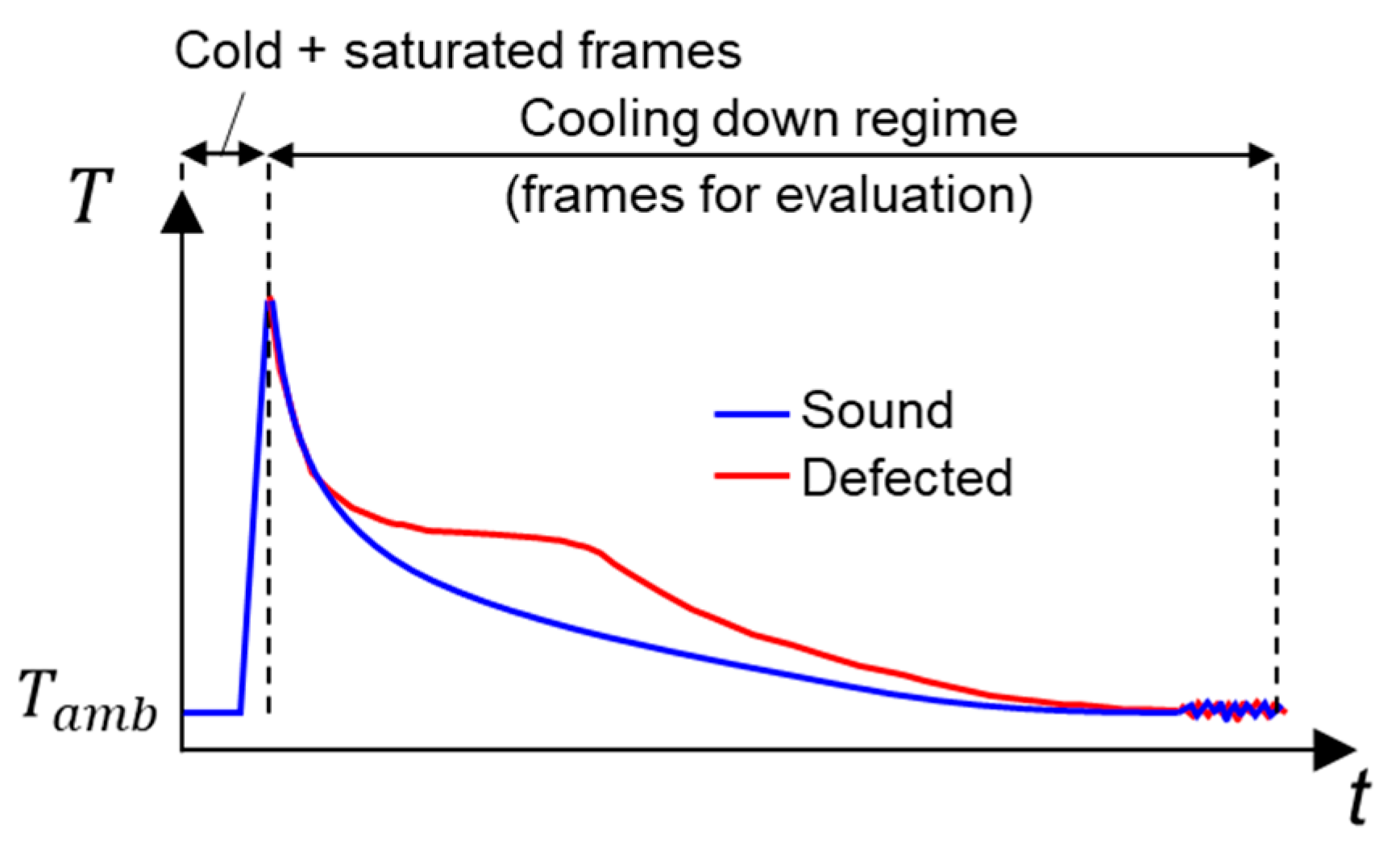

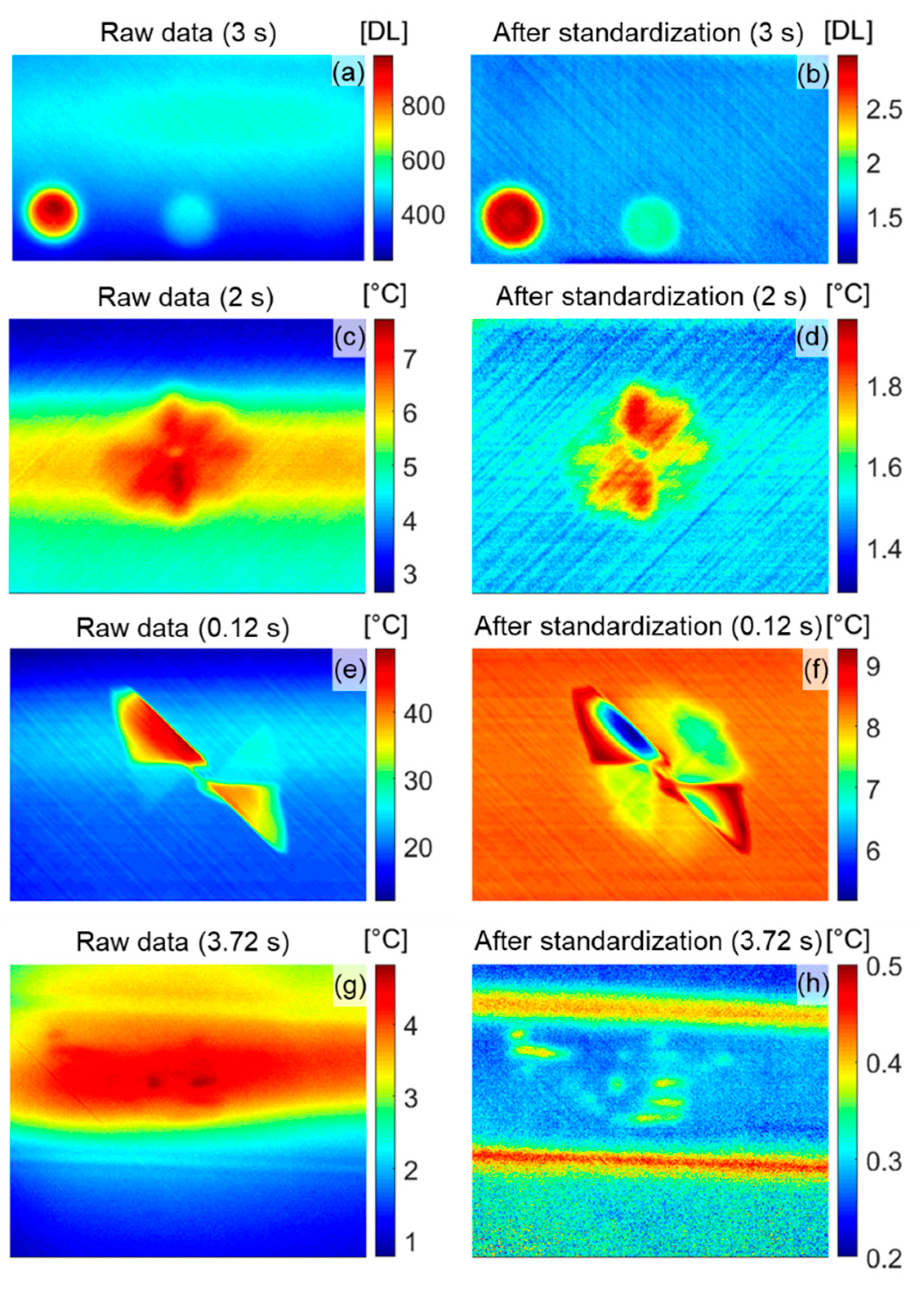

2. Materials and Methods

3. Post-Processing Methodologies

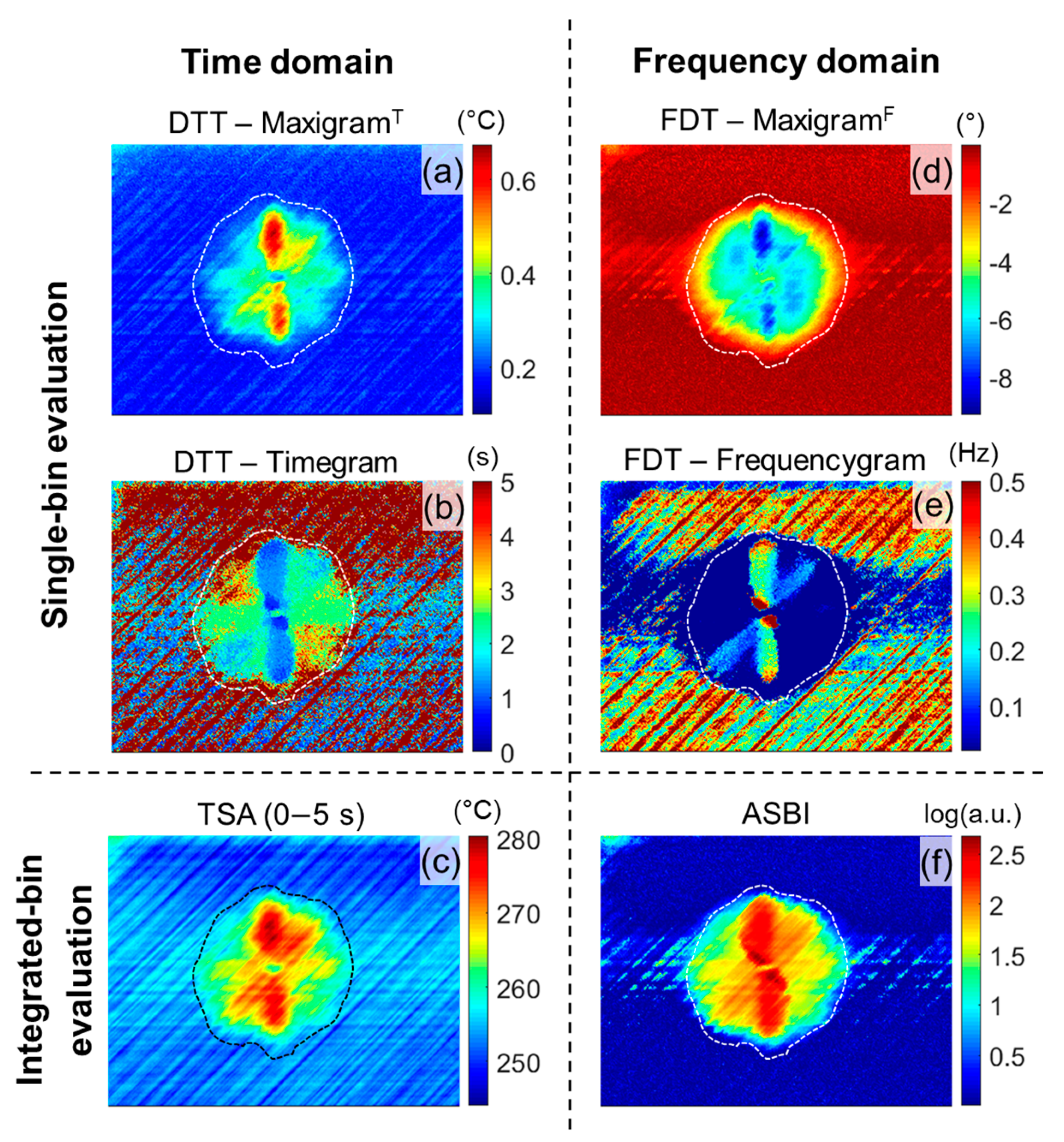

3.1. Time-Domain Analysis

3.1.1. Single-Bin Evaluation: Dynamic Thermal Tomography (DTT)

3.1.2. Integrated-Bin Evaluation: Thermal Signal Area (TSA)

3.2. Frequency-Domain Analysis

3.2.1. Single-Bin Evaluation: Frequency-Domain Tomography (FDT)

3.2.2. Integrated-Bin Evaluation: Adaptive Spectral Band Integration (ASBI)

4. Results

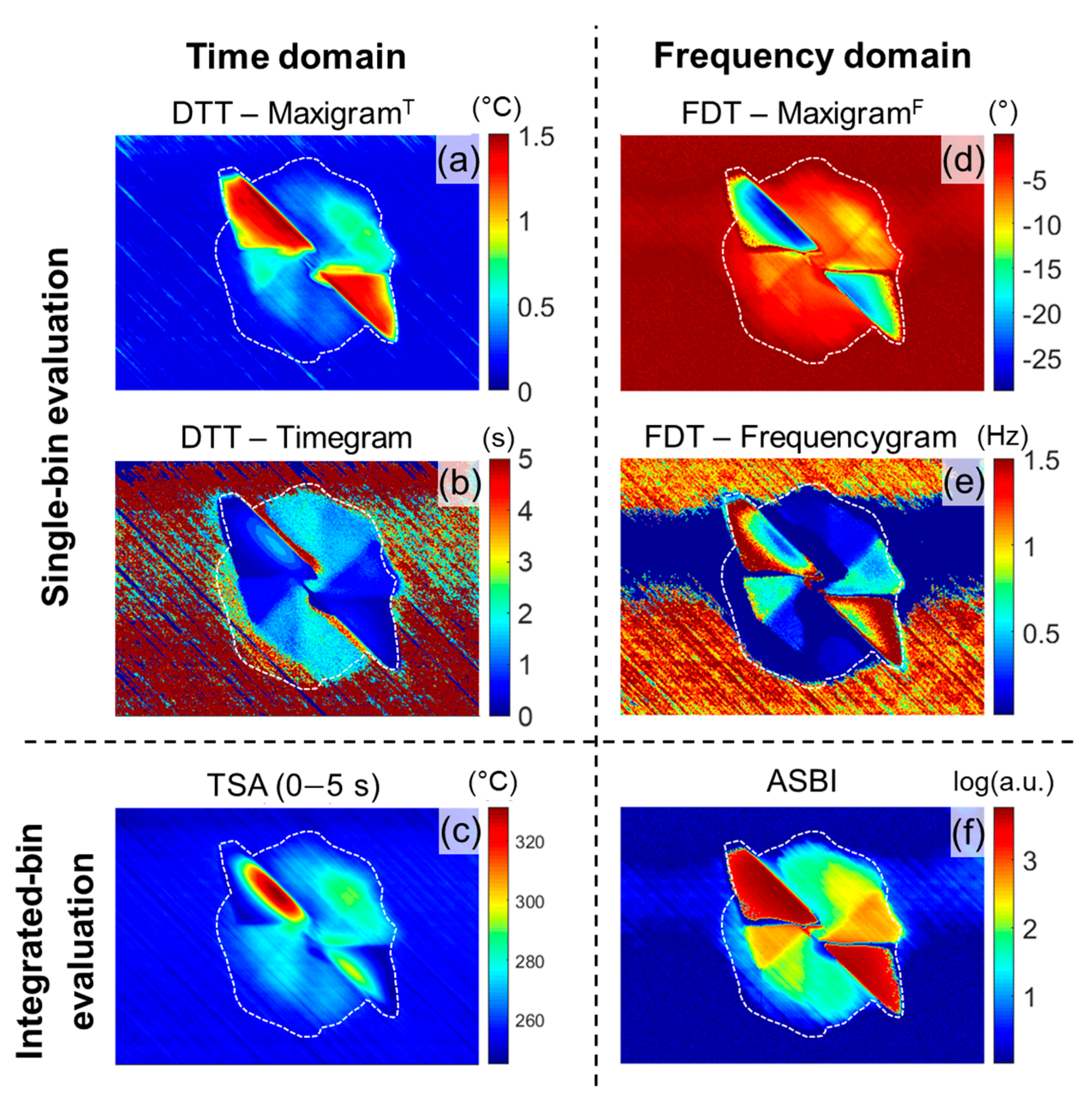

4.1. CFRPFBH Coupon

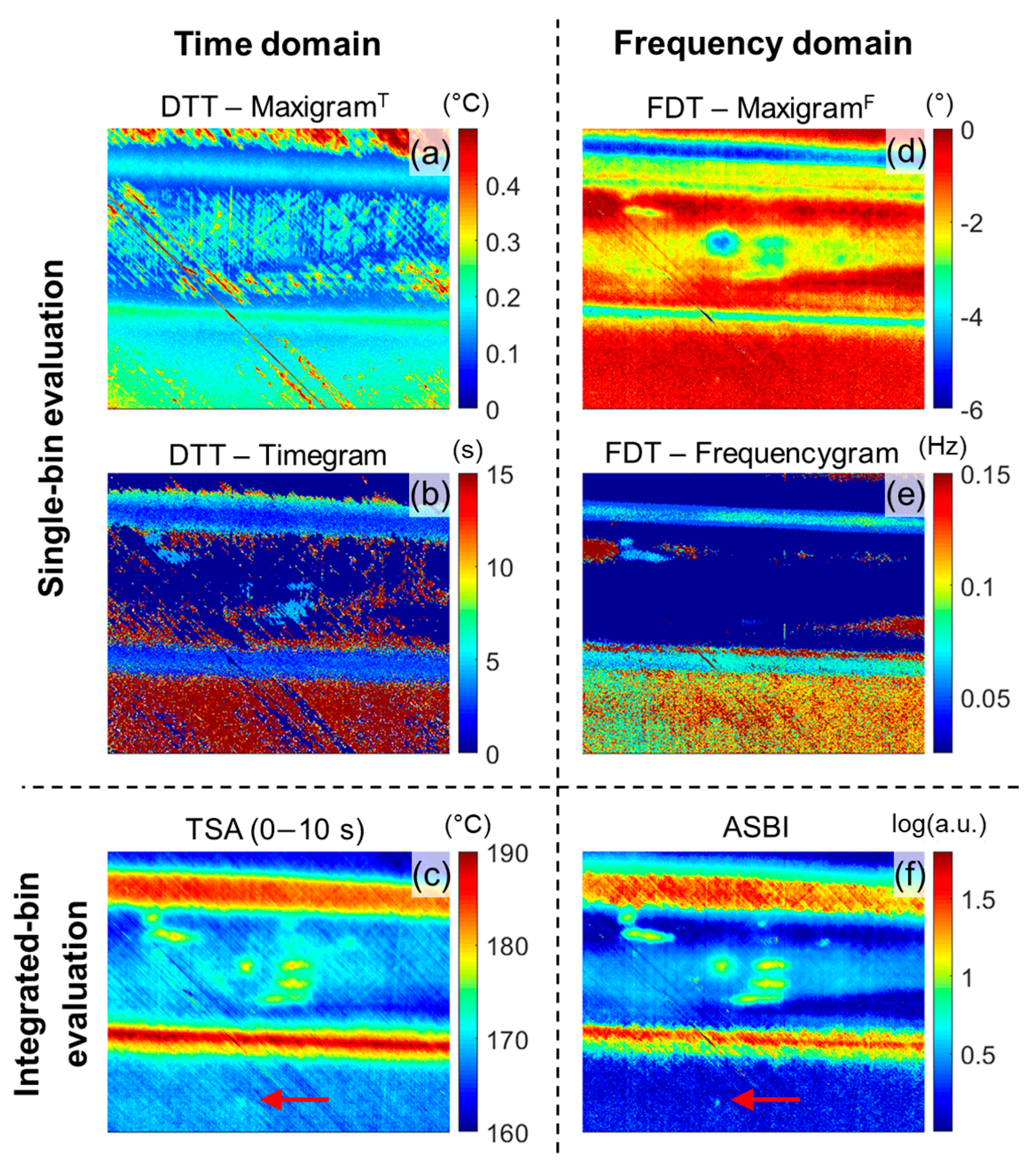

4.2. CFRPBVID Coupon

4.3. CFRPPROD Aircraft Panel

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maierhofer, C.; Röllig, M.; Gower, M.; Lodeiro, M.; Baker, G.; Monte, C.; Adibekyan, A.; Gutschwager, B.; Knazowicka, L.; Blahut, A. Evaluation of Different Techniques of Active Thermography for Quantification of Artificial Defects in Fiber-Reinforced Composites Using Thermal and Phase Contrast Data Analysis. Int. J. Thermophys. 2018, 39. [Google Scholar] [CrossRef]

- Milne, M.J.; Reynolds, W.N. The non-destructive evaluation of composites and other materials by thermal pulse video thermography. In Proceedings of the Thermosense VII: Thermal Infrared Sensing for Diagnostics and Control, Cambridge, MA, USA, 23–26 October 1984; Volume 0520, pp. 119–1222. [Google Scholar]

- Vavilov, V.P.; Burleigh, D.D. Review of pulsed thermal NDT: Physical principles, theory and data processing. NDT Int. 2015, 73, 28–52. [Google Scholar] [CrossRef]

- Yang, R.; He, Y. Optically and non-optically excited thermography for composites: A review. Infrared Phys. Technol. 2016, 75, 26–50. [Google Scholar] [CrossRef]

- Chatterjee, K.; Tuli, S.; Pickering, S.; Almond, D.P. A comparison of the pulsed, lock-in and frequency modulated thermography nondestructive evaluation techniques. NDT E Int. 2011, 44, 655–667. [Google Scholar] [CrossRef]

- Busse, G.; Wu, D.; Karpen, W. Thermal wave imaging with phase sensitive modulated thermography. J. Appl. Phys. 1992, 71, 3962–3965. [Google Scholar] [CrossRef]

- Hedayatrasa, S.; Poelman, G.; Segers, J.; Van Paepegem, W.; Kersemans, M. Performance of frequency and/or phase modulated excitation waveforms for optical infrared thermography of CFRPs through thermal wave radar: A simulation study. Compos. Struct. 2019, 225, 111177. [Google Scholar] [CrossRef]

- Hedayatrasa, S.; Poelman, G.; Segers, J.; Van Paepegem, W.; Kersemans, M. Novel discrete frequency-phase modulated excitation waveform for enhanced depth resolvability of thermal wave radar. Mech. Syst. Signal Process. 2019, 132, 512–522. [Google Scholar] [CrossRef]

- Hedayatrasa, S.; Poelman, G.; Segers, J.; Van Paepegem, W.; Kersemans, M. On the application of an optimized Frequency-Phase Modulated waveform for enhanced infrared thermal wave radar imaging of composites. Optics Lasers Eng. 2021, 138, 106411. [Google Scholar] [CrossRef]

- Tabatabaei, N.; Mandelis, A. Thermal-wave radar: A novel subsurface imaging modality with extended depth-resolution dynamic range. Rev. Sci. Instrum. 2009, 80, 034902. [Google Scholar] [CrossRef]

- Tabatabaei, N.; Mandelis, A. Thermal coherence tomography using match filter binary phase coded diffusion waves. Phys. Rev. Lett. 2011, 107, 165901. [Google Scholar] [CrossRef]

- Burgholzer, P.; Hendorfer, G. Limits of Spatial Resolution for Thermography and Other Non-destructive Imaging Methods Based on Diffusion Waves. Int. J. Thermophys. 2013, 34, 1617–1632. [Google Scholar] [CrossRef] [PubMed]

- Groz, M.-M.; Abisset, E.; Meziane, A.; Sommier, A.; Pradère, C. Three-Dimensional Reconstruction of Thermal Volumetric Sources from Surface Temperature Fields Measured by Infrared Thermography. Appl. Sci. 2019, 9, 5464. [Google Scholar] [CrossRef]

- Erazo-Aux, J.; Loaiza-Correa, H.; Restrepo-Girón, A. Histograms of oriented gradients for automatic detection of defective regions in thermograms. Appl. Optics 2019, 58, 3620–3629. [Google Scholar] [CrossRef] [PubMed]

- Ibarra-Castanedo, C.; Gonzalez, D.; Klein, M.; Pilla, M.; Vallerand, S.; Maldague, X. Infrared image processing and data analysis. Infrared Phys. Technol. 2004, 46, 75–83. [Google Scholar] [CrossRef]

- Poelman, G.; Hedayatrasa, S.; Segers, J.; Van Paepegem, W.; Kersemans, M. Multi-scale gapped smoothing algorithm for robust baseline-free damage detection in optical infrared thermography. NDT E Int. 2020, 112, 102247. [Google Scholar] [CrossRef]

- Ciampa, F.; Mahmoodi, P.; Pinto, F.; Meo, M. Recent Advances in Active Infrared Thermography for Non-Destructive Testing of Aerospace Components. Sensors 2018, 18, 609. [Google Scholar] [CrossRef]

- Ibarra-Castanedo, C.; Maldague, X. Pulsed phase thermography reviewed. Quant. InfraRed Thermograph. J. 2004, 1, 47–70. [Google Scholar] [CrossRef]

- Poelman, G.; Hedayatrasa, S.; Segers, J.; Van Paepegem, W.; Kersemans, M. Adaptive spectral band integration in flash thermography: Enhanced defect detectability and quantification in composites. Compos. Part B Eng. 2020, 202, 108305. [Google Scholar] [CrossRef]

- Popow, V.; Gurka, M. Full factorial analysis of the accuracy of automated quantification of hidden defects in an anisotropic carbon fibre reinforced composite shell using pulse phase thermography. NDT E Int. 2020, 116, 102359. [Google Scholar] [CrossRef]

- Vavilov, V.; Shiryaev, V.; Kuimova, M. Time- and Phase-Domain Thermal Tomography of Composites. Photonics 2018, 5, 31. [Google Scholar] [CrossRef]

- Vavilov, V.P.; Kuimova, M.V. Dynamic Thermal Tomography of Composites: A Comparison of Reference and Reference-Free Approaches. J. Nondestruct. Eval. 2018, 38, 2. [Google Scholar] [CrossRef]

- Benítez, H.D.; Ibarra-Castanedo, C.; Bendada, A.; Maldague, X.; Loaiza, H.; Caicedo, E. Definition of a new thermal contrast and pulse correction for defect quantification in pulsed thermography. Infrared Phys. Technol. 2008, 51, 160–167. [Google Scholar] [CrossRef]

- Moradi, M.; Safizadeh, M.S. Detection of edge debonding in composite patch using novel post processing method of thermography. NDT E Int. 2019, 107, 102153. [Google Scholar] [CrossRef]

- Maldague, X.; Marinetti, S. Pulse phase infrared thermography. J. Appl. Phys. 1996, 79, 2694–2698. [Google Scholar] [CrossRef]

- Oswald-Tranta, B. Time and frequency behaviour in TSR and PPT evaluation for flash thermography. Quant. InfraRed Thermograph. J. 2017, 14, 164–184. [Google Scholar] [CrossRef]

- Netzelmann, U.; Müller, D. Modified pulse-phase thermography algorithms for improved contrast-to-noise ratio from pulse-excited thermographic sequences. NDT E Int. 2020, 116, 102325. [Google Scholar] [CrossRef]

- Rajic, N. Principal component thermography for flaw contrast enhancement and flaw depth characterisation in composite structures. Compos. Struct. 2002, 58, 521–528. [Google Scholar] [CrossRef]

- Rajic, N. DSTO-TR-1298, Principal Component Thermography; DSTO Aeronautical and Maritime Research Laboratory: Fishermans bend, Victoria, Australia, 2002; p. 38. [Google Scholar]

- Madruga, F.J.; Ibarra-Castanedo, C.; Conde, O.M.; López-Higuera, J.M.; Maldague, X. Infrared thermography processing based on higher-order statistics. NDT E Int. 2010, 43, 661–666. [Google Scholar] [CrossRef]

- Shepard, S.M. Temporal Noise Reduction, Compression and Analysis of Thermographic Data Sequences; Thermal Wave Imaging, Inc.: Ferndale, MI, USA, 2003. [Google Scholar]

- Spronk, S.W.F.; Kersemans, M.; De Baerdemaeker, J.; Gilabert, F.A.; Sevenois, R.; Garoz, D.; Kassapoglou, C.; Van Paepegem, W. Comparing damage from low-velocity impact and quasi-static indentation in automotive carbon/epoxy and glass/polyamide-6 laminates. Polymer Test. 2018, 65, 231–241. [Google Scholar] [CrossRef]

- Segers, J.; Hedayatrasa, S.; Poelman, G.; Van Paepegem, W.; Kersemans, M. Robust and baseline-free full-field defect detection in complex composite parts through weighted broadband energy mapping of mode-removed guided waves. Mech. Syst. Signal Process. 2021, 151. [Google Scholar] [CrossRef]

- Sun, J.G. Analysis of Pulsed Thermography Methods for Defect Depth Prediction. J. Heat Transfer 2006, 128. [Google Scholar] [CrossRef]

- Vavilov, V.P. Dynamic thermal tomography: Recent improvements and applications. NDT E Int. 2015, 71, 23–32. [Google Scholar] [CrossRef]

- Theodorakeas, P.; Koui, M. Depth Retrieval Procedures in Pulsed Thermography: Remarks in Time and Frequency Domain Analyses. Appl. Sci. 2018, 8, 409. [Google Scholar] [CrossRef]

- Welvaert, M.; Rosseel, Y. On the definition of signal-to-noise ratio and contrast-to-noise ratio for FMRI data. PLoS ONE 2013, 8, e77089. [Google Scholar] [CrossRef]

- Segers, J.; Hedayatrasa, S.; Poelman, G.; Van Paepegem, W.; Kersemans, M. Probing the limits of full-field linear local defect resonance identification for deep defect detection. Ultrasonics 2020, 105, 106130. [Google Scholar] [CrossRef]

- Saintey, M.B.; Almond, D.P. Defect sizing by transient thermography II: A numerical treatment. J. Phys. D Appl. Phys. 1995, 28, 2539–2546. [Google Scholar] [CrossRef]

| Contrast-to-Noise Ratio (dB) | |||||

|---|---|---|---|---|---|

| Time-Domain | Frequency-Domain | ||||

| Depth (mm) | DTT MaxigramT | TSA (0–50 s) | FDT MaxigramF | ASBI | |

| FBHA | 0.85 | 25.8 | 37.1 | 45.6 | 73.8 |

| FBHB | 1.64 | 21.34 | 35.9 | 42.7 | 59.0 |

| FBHC | 2.47 | 14.3 | 30.7 | 38.0 | 47.5 |

| FBHD | 3.68 | −0.7 | 19.7 | 28.8 | 30.7 |

| FBHE | 4.51 | −8.1 | 13.1 | 18.6 | 18.0 |

| Defect-to-Background Ratio (–) | |||||

|---|---|---|---|---|---|

| Time-Domain | Frequency-Domain | ||||

| Depth (mm) | DTT MaxigramT | TSA (0–50 s) | FDT MaxigramF | ASBI | |

| FBHA | 0.85 | 10.3 | 3.9 | 174.7 | 6341.0 |

| FBHB | 1.64 | 6.5 | 3.5 | 126.5 | 1159.4 |

| FBHC | 2.47 | 3.5 | 2.4 | 73.4 | 307.3 |

| FBHD | 3.68 | 1.4 | 1.4 | 26.2 | 45.5 |

| FBHE | 4.51 | 1.2 | 1.2 | 8.8 | 11.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Poelman, G.; Hedayatrasa, S.; Segers, J.; Van Paepegem, W.; Kersemans, M. An Experimental Study on the Defect Detectability of Time- and Frequency-Domain Analyses for Flash Thermography. Appl. Sci. 2020, 10, 8051. https://doi.org/10.3390/app10228051

Poelman G, Hedayatrasa S, Segers J, Van Paepegem W, Kersemans M. An Experimental Study on the Defect Detectability of Time- and Frequency-Domain Analyses for Flash Thermography. Applied Sciences. 2020; 10(22):8051. https://doi.org/10.3390/app10228051

Chicago/Turabian StylePoelman, Gaétan, Saeid Hedayatrasa, Joost Segers, Wim Van Paepegem, and Mathias Kersemans. 2020. "An Experimental Study on the Defect Detectability of Time- and Frequency-Domain Analyses for Flash Thermography" Applied Sciences 10, no. 22: 8051. https://doi.org/10.3390/app10228051

APA StylePoelman, G., Hedayatrasa, S., Segers, J., Van Paepegem, W., & Kersemans, M. (2020). An Experimental Study on the Defect Detectability of Time- and Frequency-Domain Analyses for Flash Thermography. Applied Sciences, 10(22), 8051. https://doi.org/10.3390/app10228051