Numerical Investigation of the Collapse of a Steel Truss Roof and a Probable Reason of Failure

Abstract

1. Introduction

2. Theory and Case Study

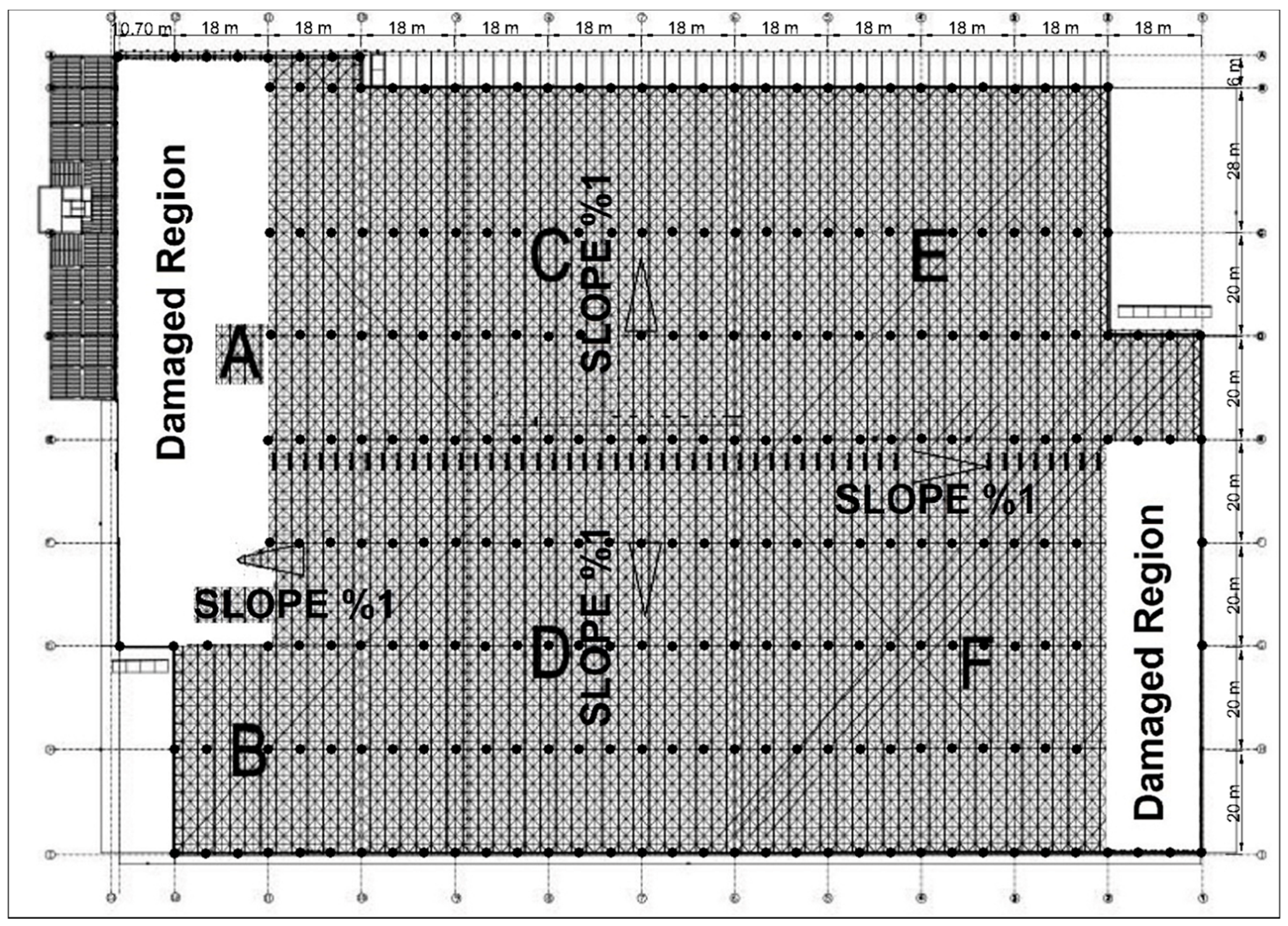

2.1. Overview of the Structure and the Case

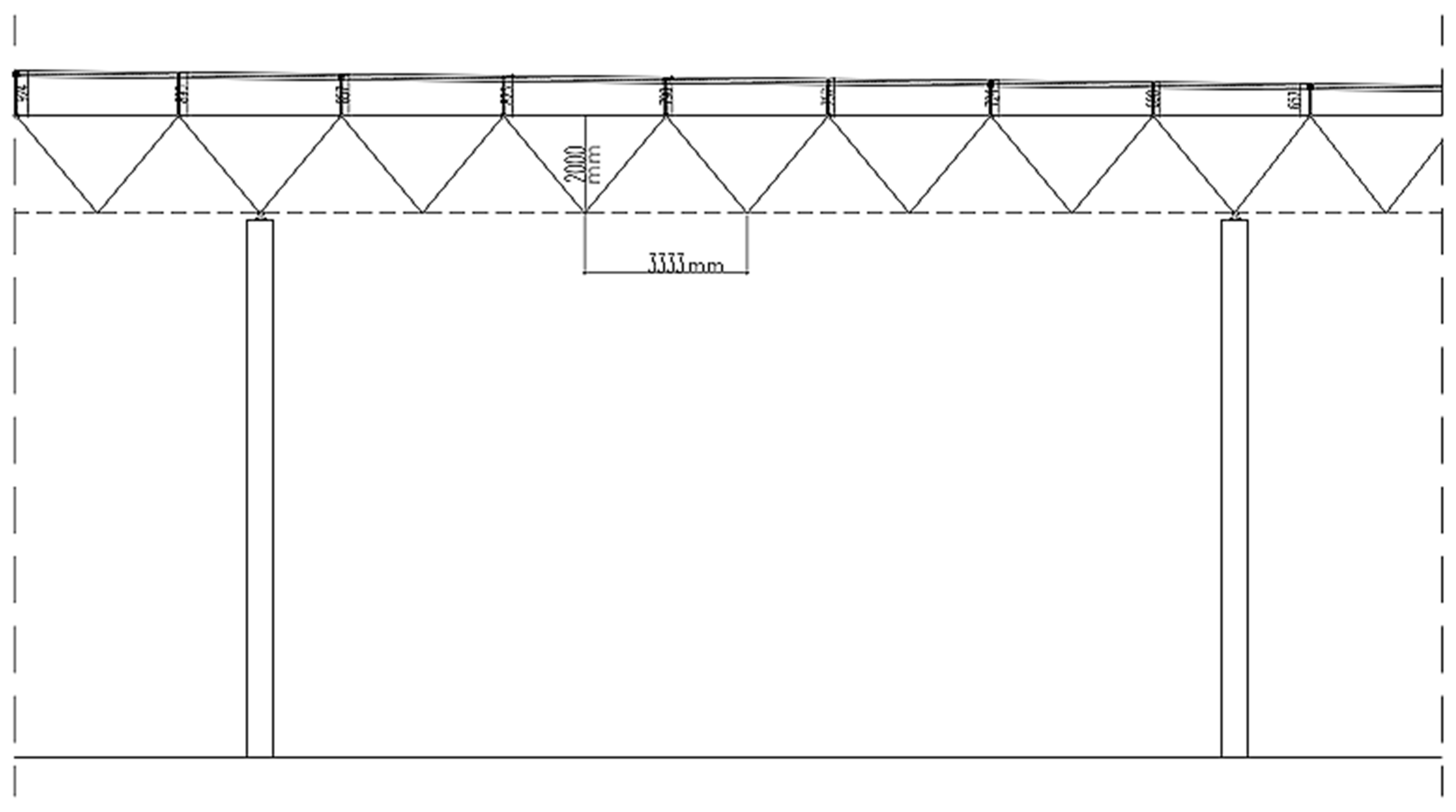

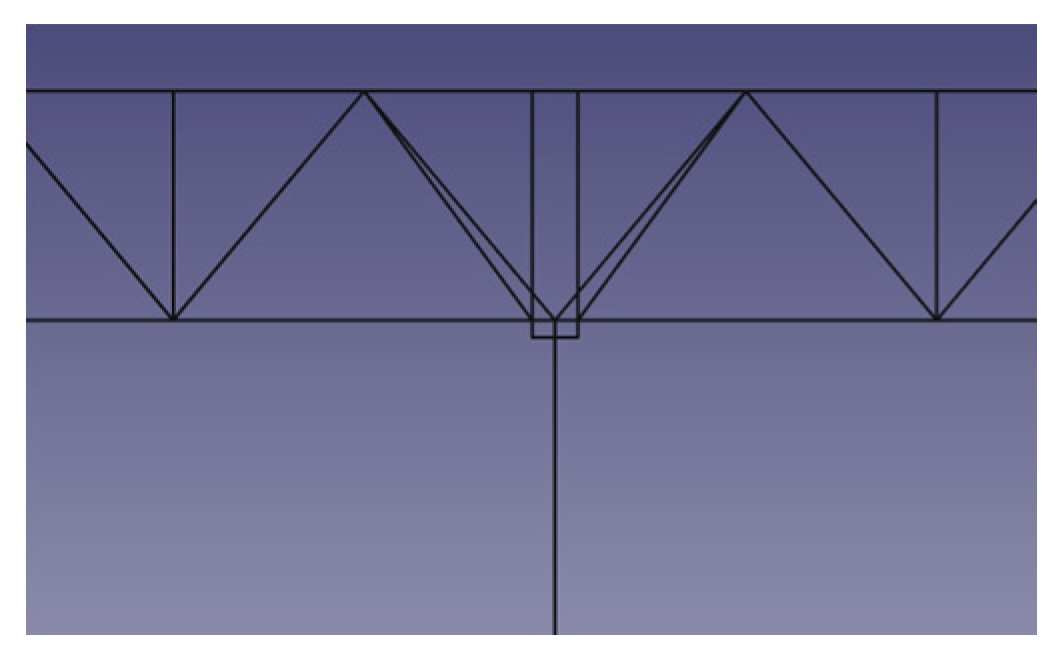

2.2. Structural Members

3. Analysis

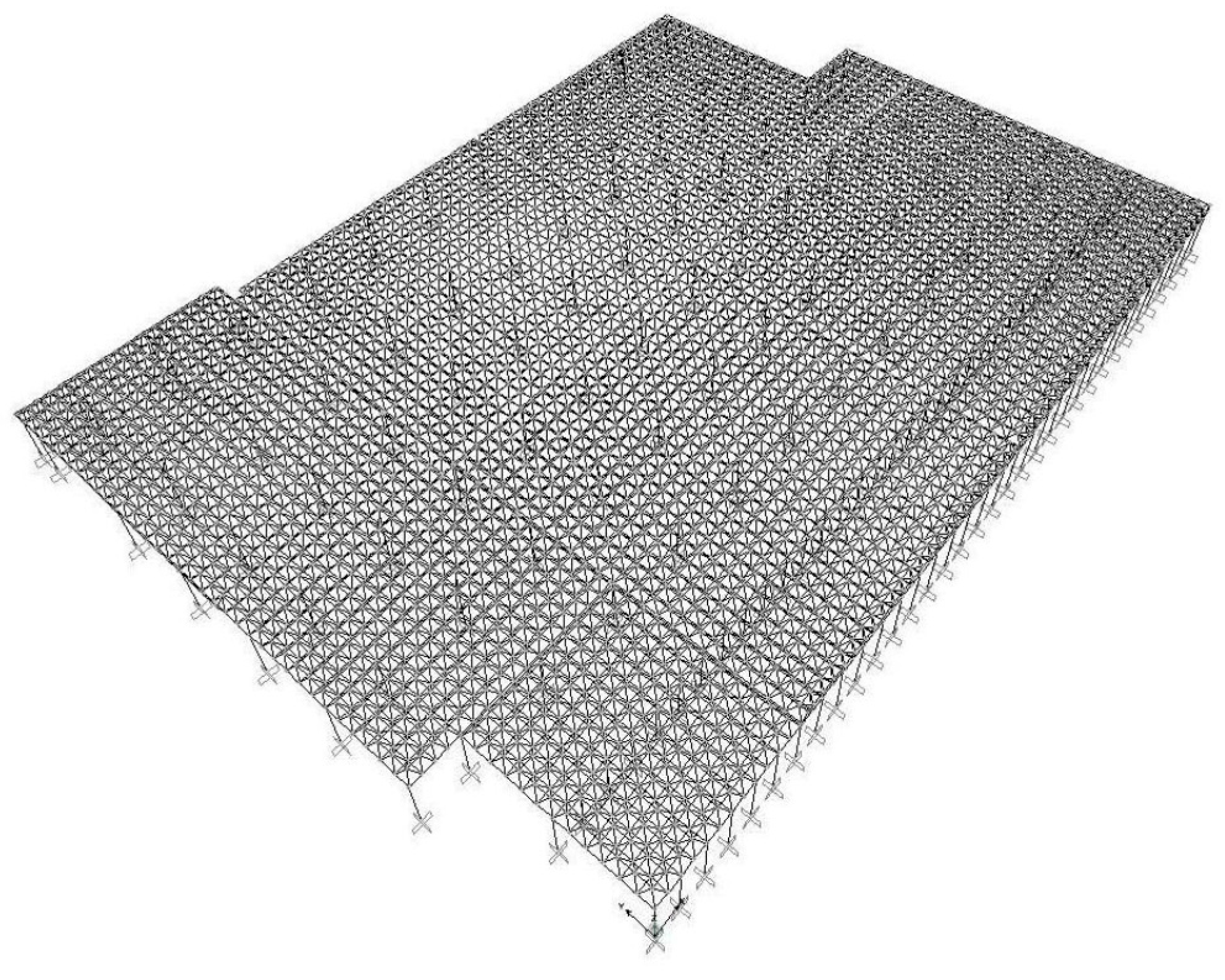

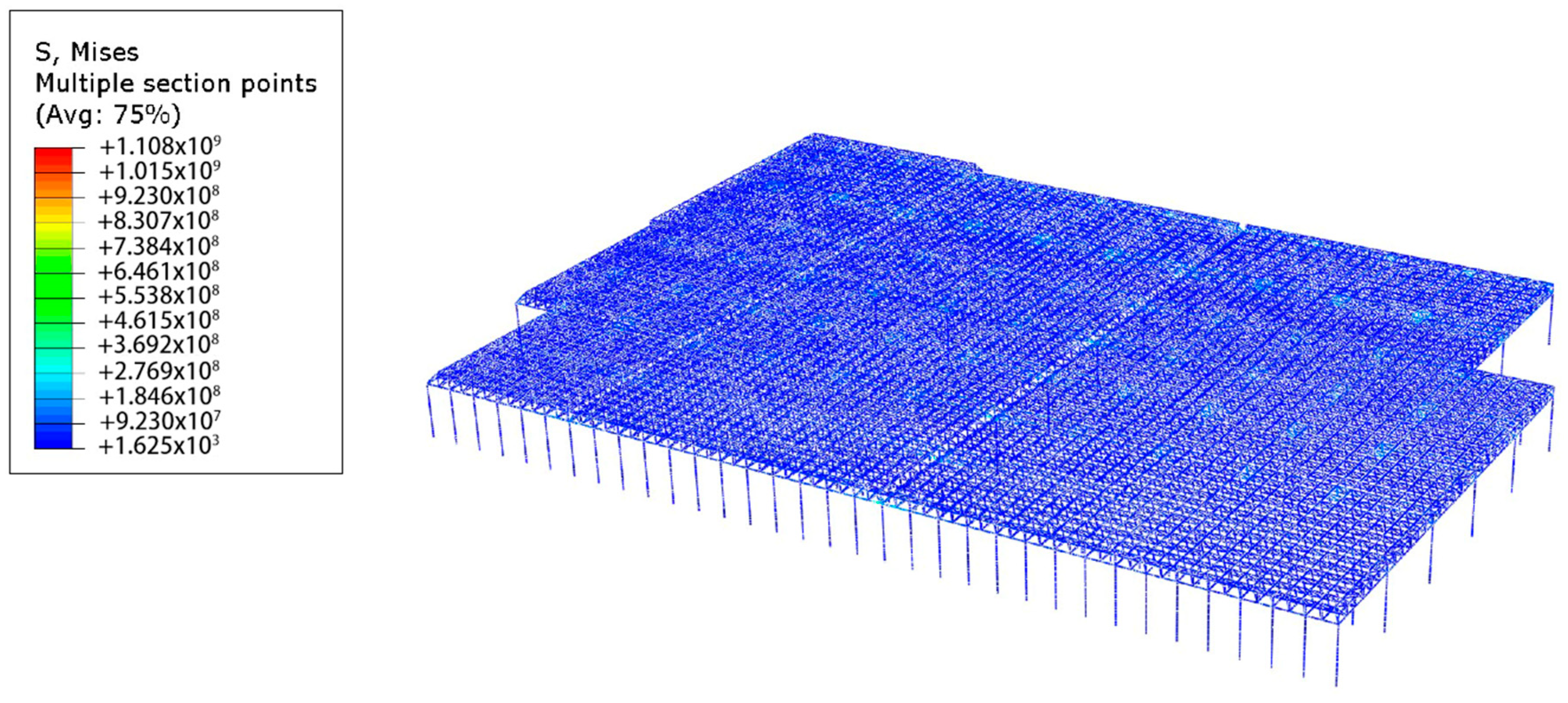

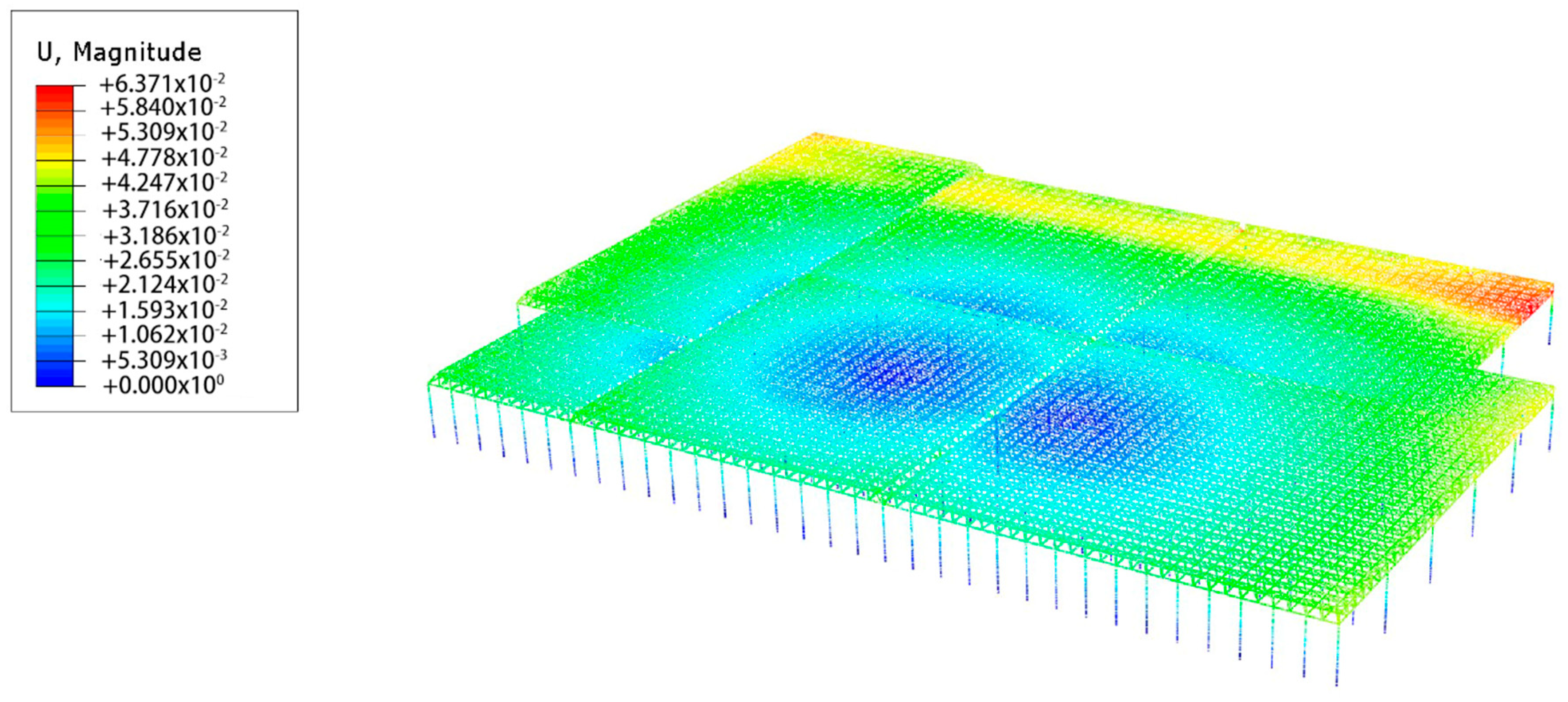

3.1. Global Analysis

3.2. Analysis of the Columns and Supports

3.2.1. Analysis of the Steel-Reinforced Columns

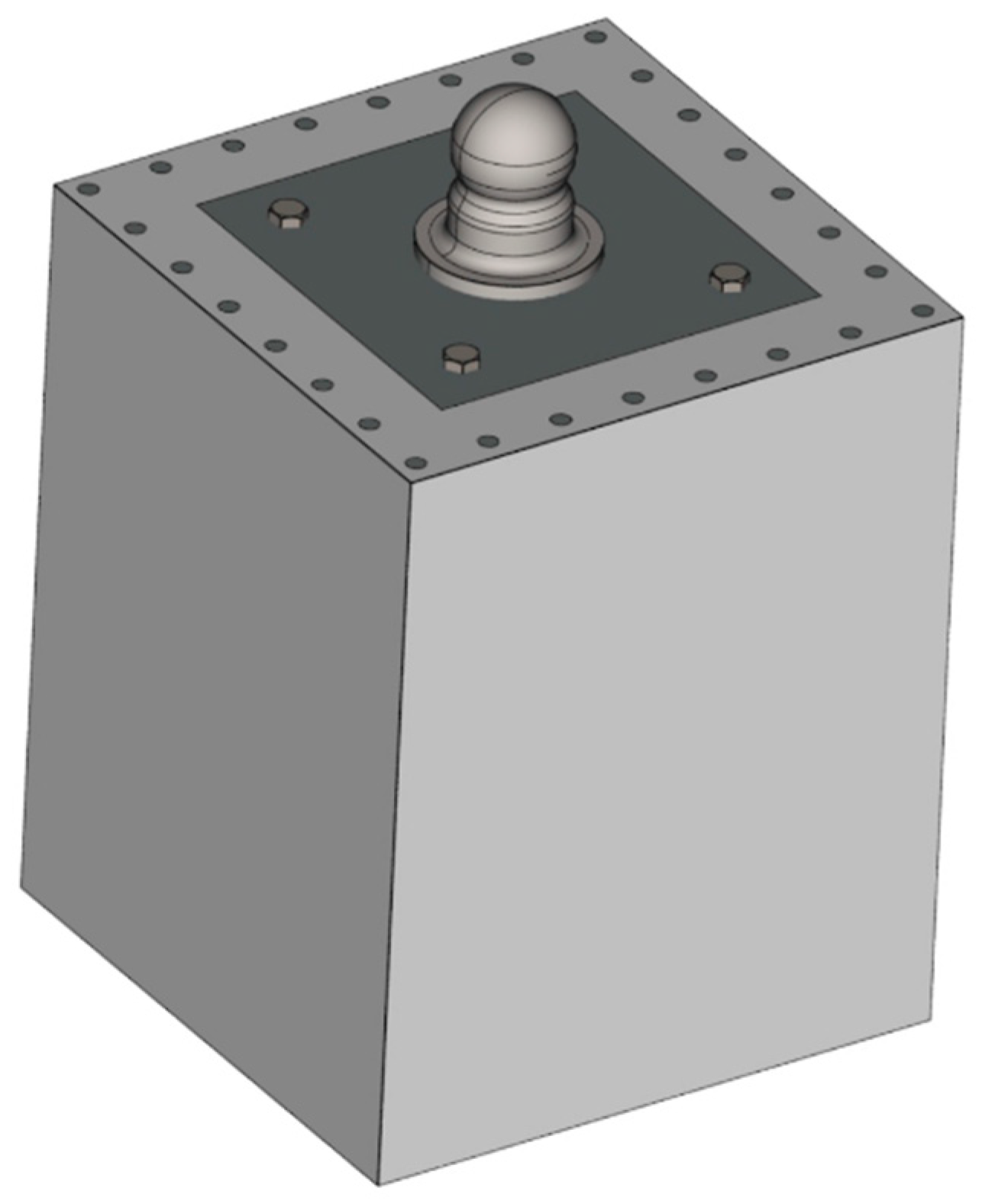

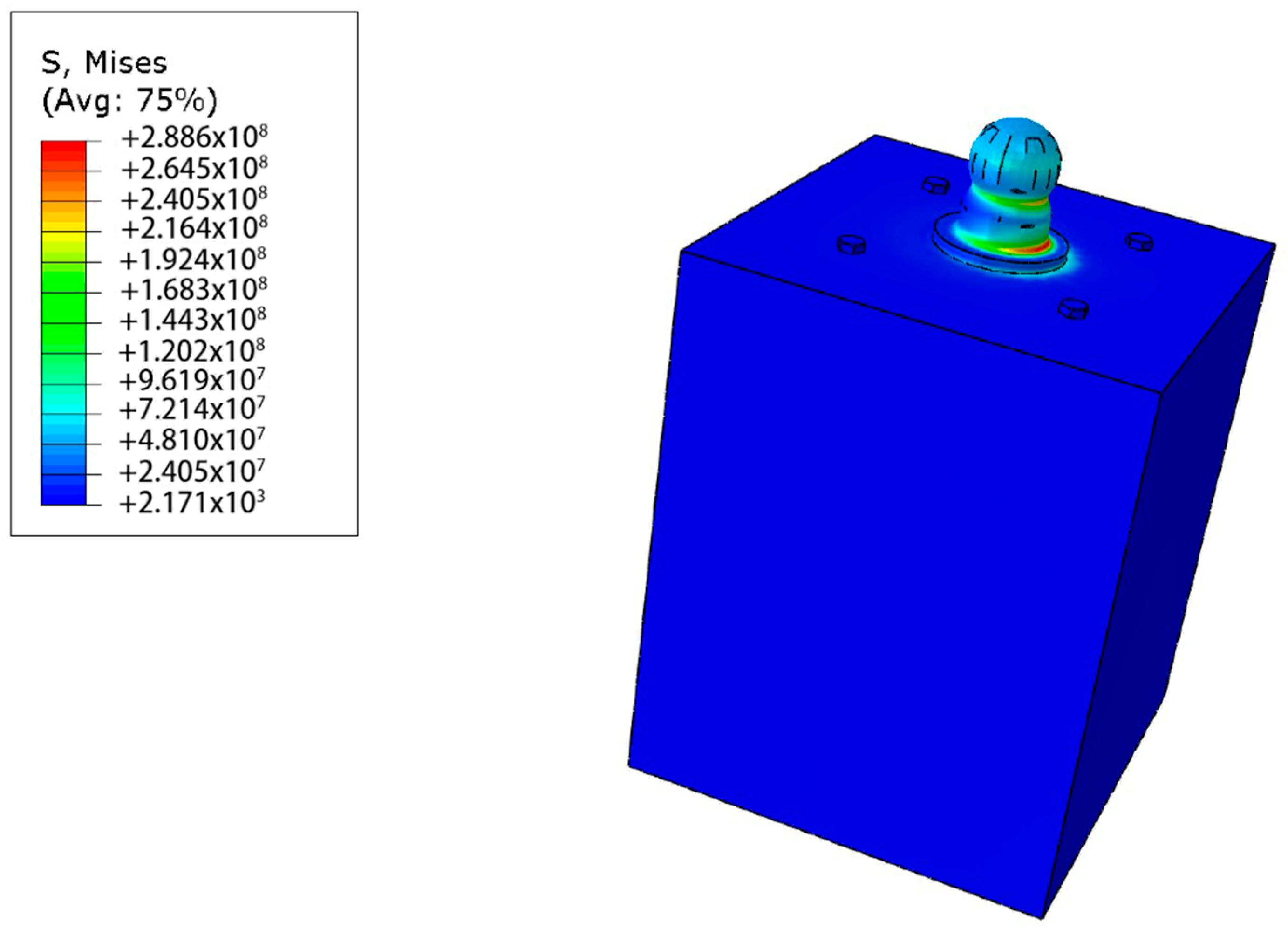

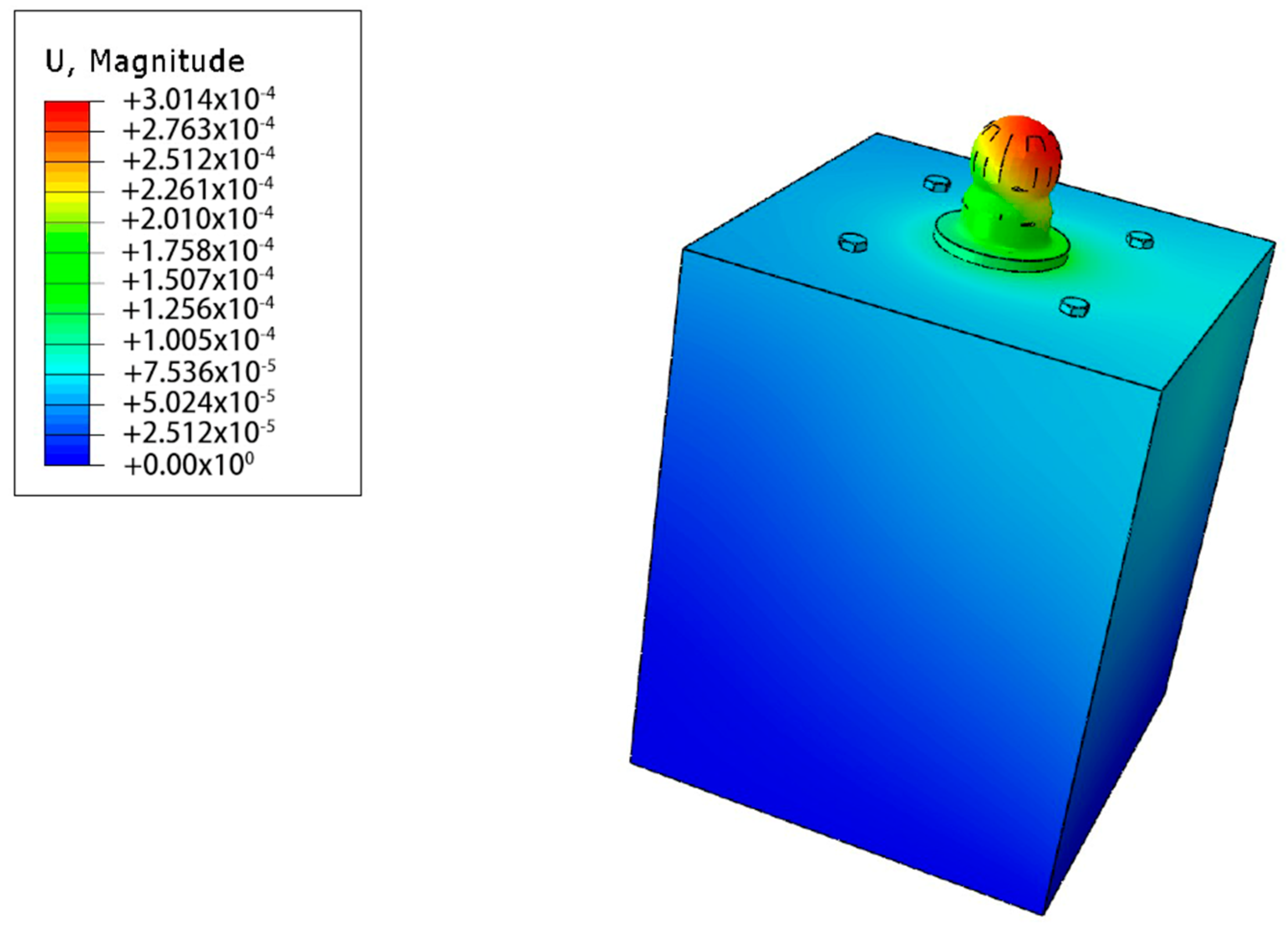

3.2.2. Analysis of the Spherical Support with Steel-Reinforced Columns

4. Results and Discussion

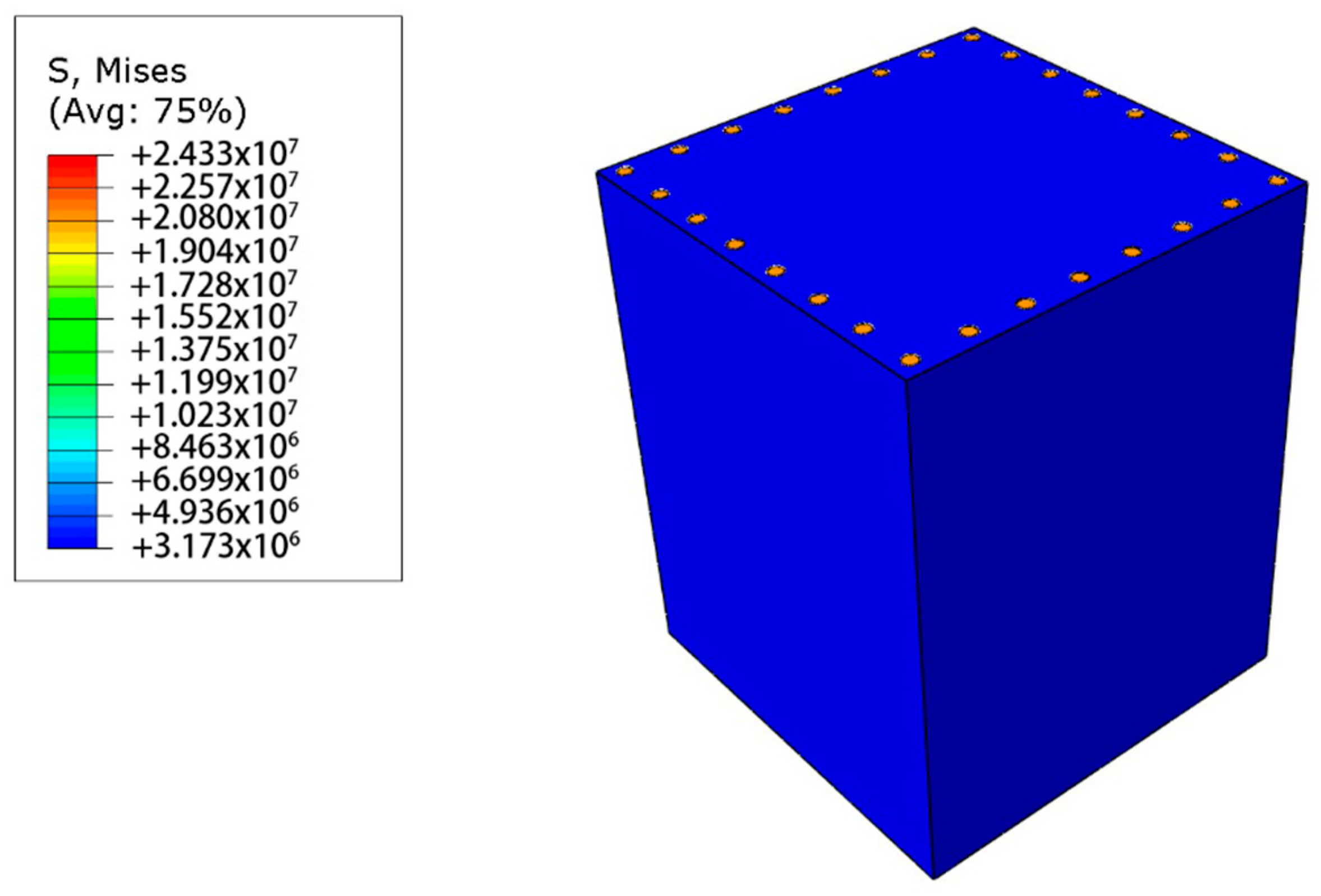

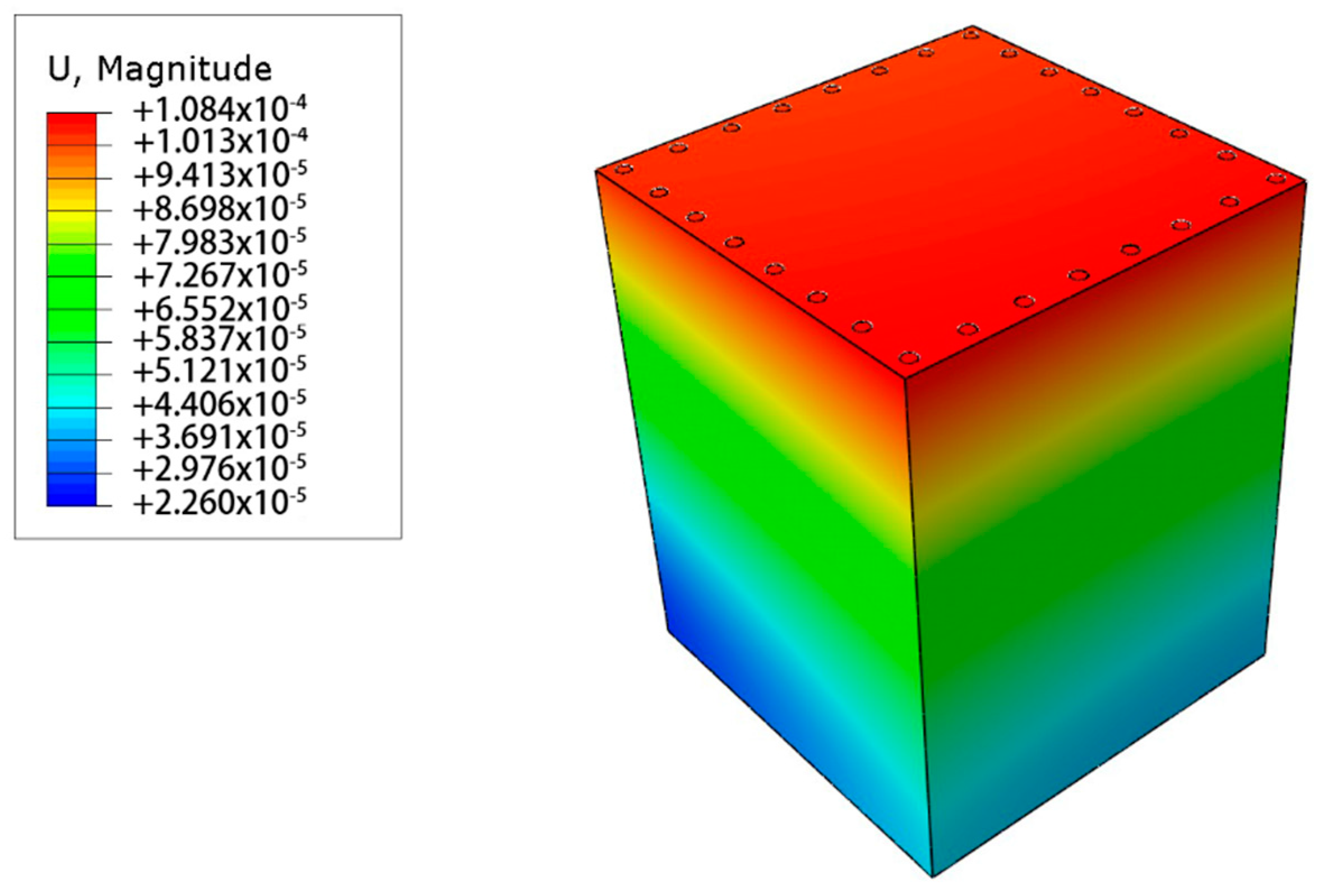

4.1. Analysis of the Steel-Reinforced Columns

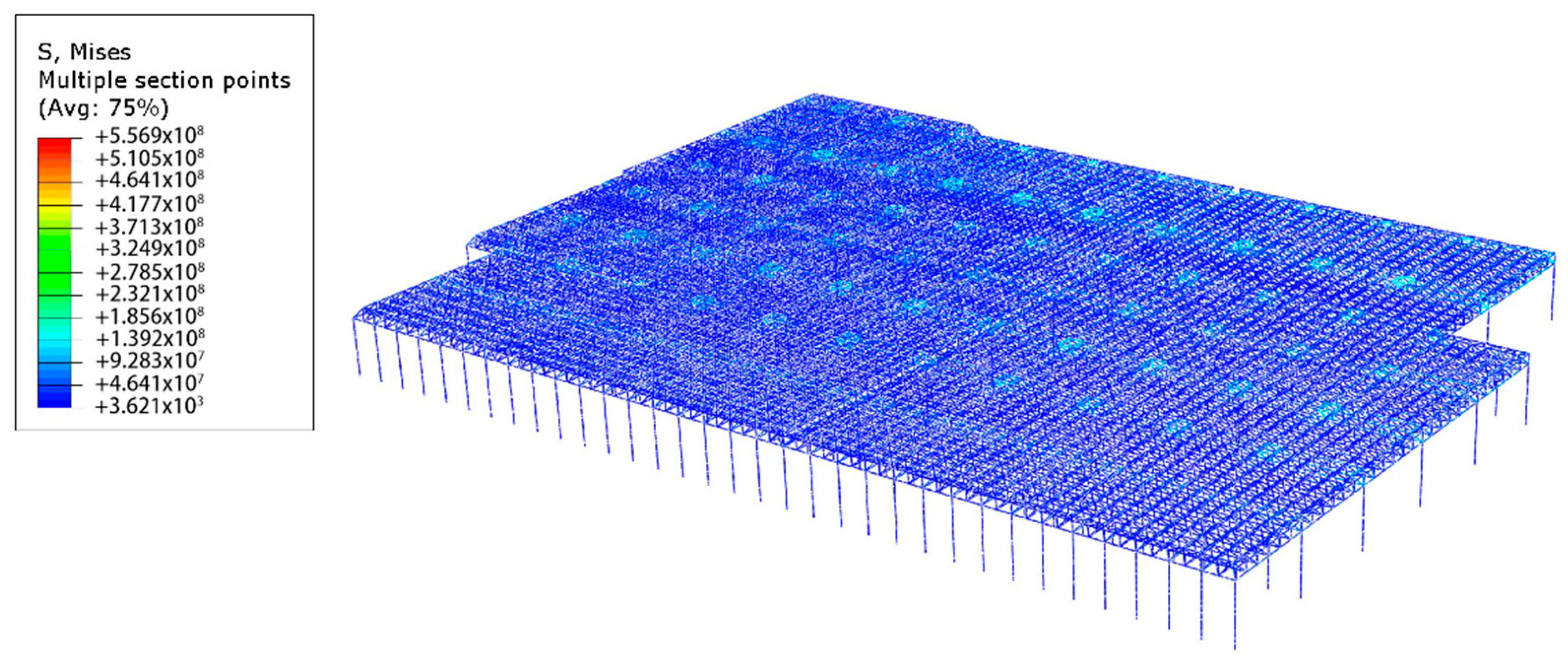

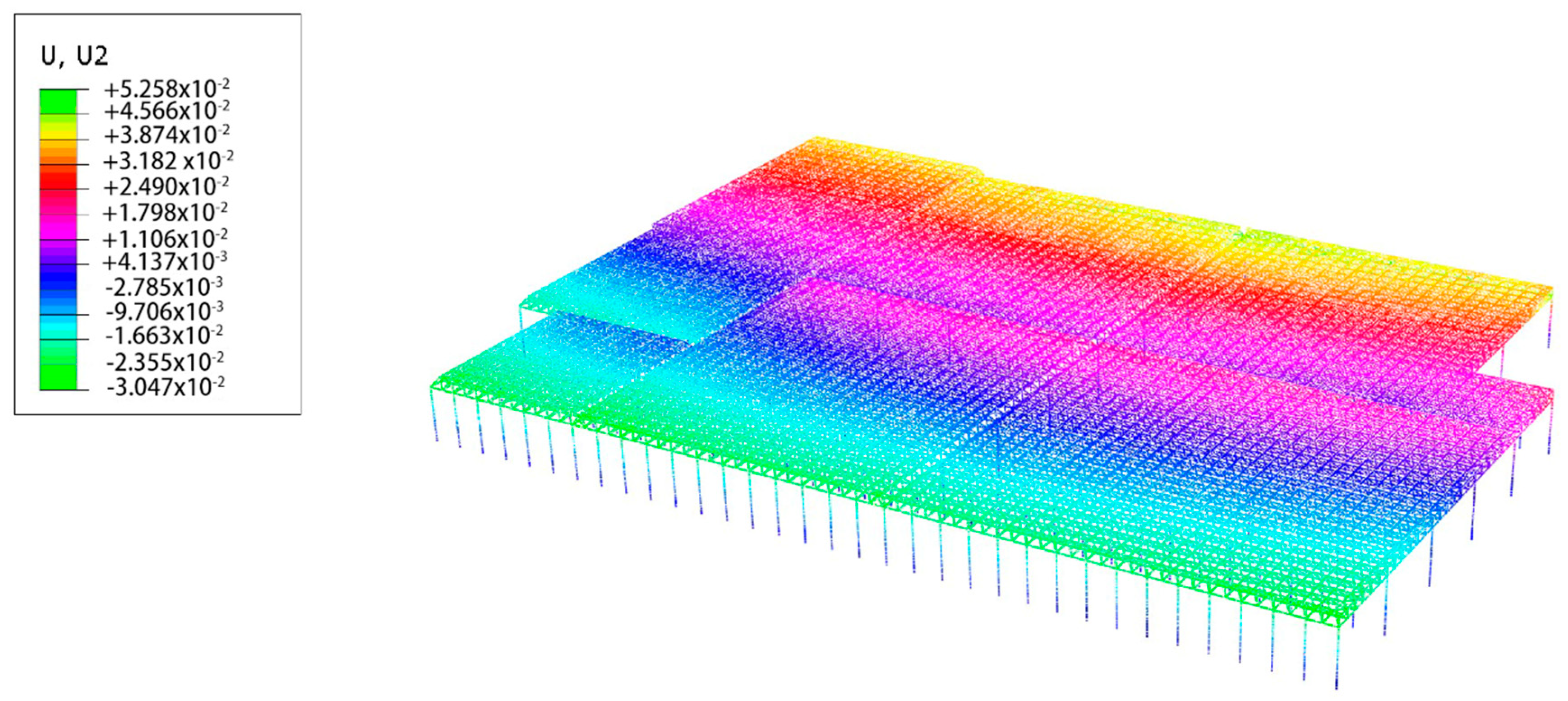

4.2. Global Analysis with Only Mechanical Loads

4.3. Analysis of the Spherical Support with Steel-Reinforced Columns

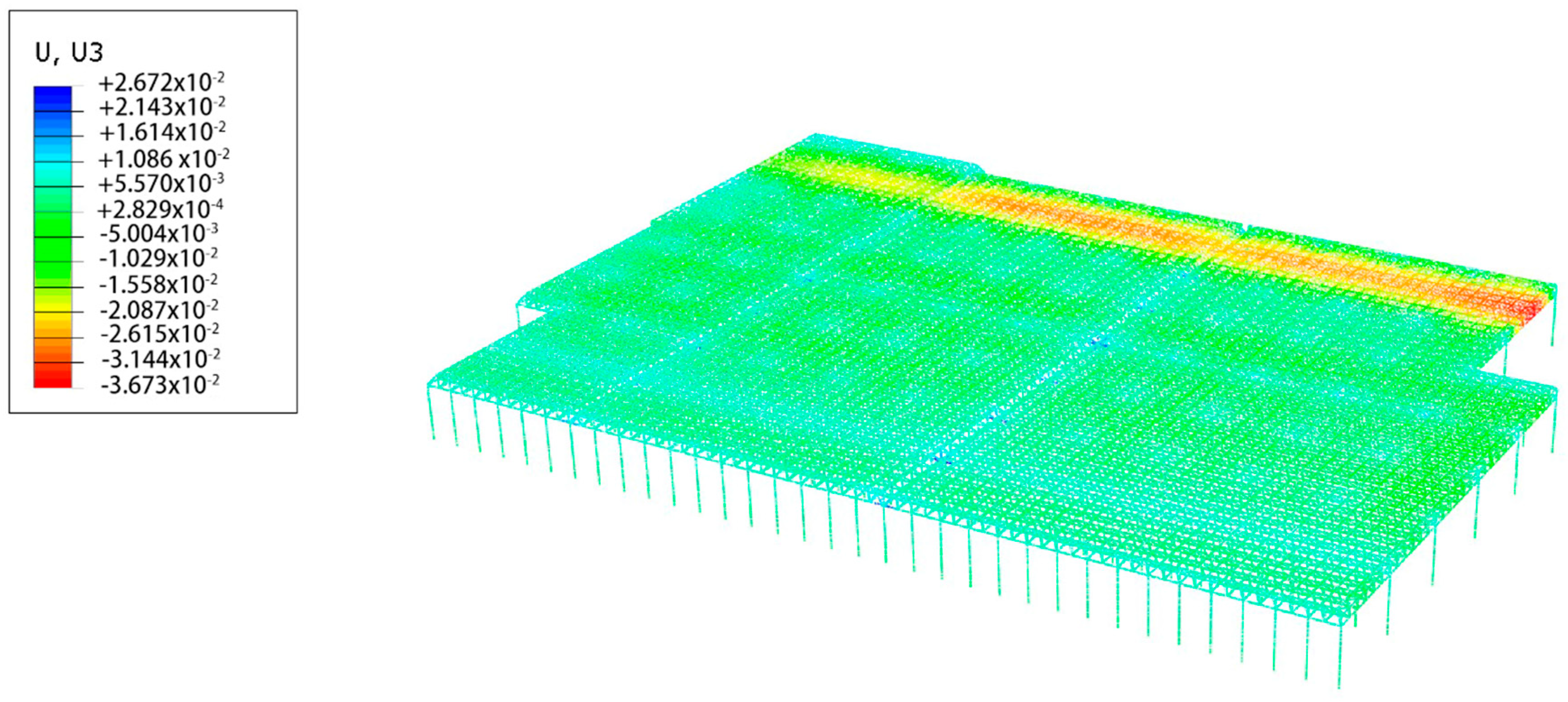

4.4. Global Analysis with Mechanical Loads and Thermal Effects

5. Conclusions

- −

- According to the global analysis, the structure is quite strong and insensitive to the vertical dead loads (rain, snow, etc.) even at some higher values, which are judged to be extreme and unrealistic. The most dangerous region of the space frame system in terms of vertical loads is the corridor with the largest column span in the A, C, and E blocks. However, this region is still safe, and the damage occurred somewhere else.

- −

- Using the results of the global analysis, the most critical support connection was individually investigated and found safe, although it is more sensitive to horizontal forces. However, in the analysis, all the effects that create lateral forces caused by the wind and similar homogeneous distributed loads could not make the structure exceed the safety limits and cause any damage in the locations where the real damage occurred.

- −

- It is judged that the thermal expansion of structural members increases the horizontal forces at the supports and the stresses at the members. The temperature change was assumed to be caused by lightning strikes. To investigate the effects of the temperature change, a simplified analysis with a uniform temperature rise was conducted and produced results that point out critical regions that are the same as the real damaged zones.

- −

- The significant change of temperature of the air surrounding the lightning channel and the electric current that passes through the structure may cause heating of the roof system rapidly and locally. The lightning at the scene may also cause a sudden pressure change that can be amplified by the presence of water on top of the structural surface. In addition to the thermal expansion, it is judged possible that the blast effect may have a significant role in the failure of the structure.

- −

- Testing the idea of temperature change, the damage prediction was found to be consistent with the real failure mode. It was concluded that the bolts and the bolted members attached to the supports in the real damaged regions of the space truss roof system were overloaded and damaged, as it can be seen in Figure 15.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wu, Z.; Rong, J.; Liu, C.; Liu, Z.; Shi, W.; Xin, P.; Li, W. Dynamic analysis of spatial truss structures including sliding joint based on the geometrically exact beam theory and isogeometric analysis. Appl. Sci. 2020, 10, 1231. [Google Scholar] [CrossRef]

- Hadipriono, F.C. Analysis of Events in Recent Structural Failures. J. Struct. Eng. 1985, 111, 1468–1481. [Google Scholar] [CrossRef]

- Klasson, A.; Björnsson, I.; Crocetti, R.; Hansson, E.F. Slender Roof Structures—Failure Reviews and a Qualitative Survey of Experienced Structural Engineers. Structures 2018, 15, 174–183. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Fleck, N.A. Collapse of truss core sandwich beams in 3-point bending. Int. J. Solids Struct. 2001, 38, 6275–6305. [Google Scholar] [CrossRef]

- Ballarini, R.; La Mendola, L.; Le, J.L.; Monaco, A. Computational study of failure of hybrid steel trussed concrete beams. J. Struct. Eng. 2017, 143, 1–13. [Google Scholar] [CrossRef]

- Wu, Y.; Xiao, Y. Steel and glubam hybrid space truss. Eng. Struct. 2018, 171, 140–153. [Google Scholar] [CrossRef]

- Sun, W.; Zhang, Q. Universal equivalent static wind loads of fluctuating wind loads on large-span roofs based on compensation of structural frequencies and modes. Structures 2020, 26, 92–104. [Google Scholar] [CrossRef]

- Piroglu, F.; Ozakgul, K.; Iskender, H.; Trabzon, L.; Kahya, C. Site investigation of damages occurred in a steel space truss roof structure due to ponding. Eng. Fail. Anal. 2014, 36, 301–313. [Google Scholar] [CrossRef]

- Goto, Y.; Kawanishi, N.; Honda, I. Dynamic stress amplification caused by sudden failure of tension members in steel truss bridges. J. Struct. Eng. 2011, 137, 850–861. [Google Scholar] [CrossRef]

- Geis, J.; Strobel, K.; Liel, A. Snow-Induced Building Failures. J. Perform. Constr. Facil. 2012, 26, 377–388. [Google Scholar] [CrossRef]

- Altunişik, A.C.; Ateş, Ş.; Hüsem, M. Lateral buckling failure of steel cantilever roof of a tribune due to snow loads. Eng. Fail. Anal. 2017, 72, 67–78. [Google Scholar] [CrossRef]

- Thai, H.T.; Kim, S.E. Nonlinear inelastic time-history analysis of truss structures. J. Constr. Steel Res. 2011, 67, 1966–1972. [Google Scholar] [CrossRef]

- Shivarudrappa, R.; Nielson, B.G.; Asce, M. Sensitivity of load distribution in light-framed wood roof systems due to typical modeling parameters. J. Perform. Constr. Facil. 2013, 27, 222–234. [Google Scholar] [CrossRef]

- Malla, R.B.; Nalluri, B.B. Dynamic effects of member failure on response of truss-type space structures. J. Spacecr. Rockets 1995, 32, 545–551. [Google Scholar] [CrossRef]

- Parisi, M.A.; Piazza, M. Seismic behavior and retrofitting of joints in traditional timber roof structures. Soil Dyn. Earthq. Eng. 2002, 22, 1183–1191. [Google Scholar] [CrossRef]

- Pollino, M.; Bruneau, M. Seismic testing of a bridge steel truss pier designed for controlled rocking. J. Struct. Eng. 2010, 136, 1523–1532. [Google Scholar] [CrossRef]

- Sosorburam, P.; Yamaguchi, E. Seismic retrofit of steel truss bridge using buckling restrained damper. Appl. Sci. 2019, 9, 2791. [Google Scholar] [CrossRef]

- Chou, C.C.; Chen, J.H. Seismic tests of post-tensioned self-centering building frames with column and slab restraints. Front. Archit. Civ. Eng. China 2011, 5, 323–334. [Google Scholar] [CrossRef]

- Zhao, H.; Ding, Y.; Nagarajaiah, S.; Li, A. Longitudinal displacement behavior and girder end reliability of a jointless steel-truss arch railway bridge during operation. Appl. Sci. 2019, 9, 2222. [Google Scholar] [CrossRef]

- Rezaei, S.; Akbari Hamed, A.; Basim, M.C. Seismic performance evaluation of steel structures equipped with dissipative columns. J. Build. Eng. 2020, 29. [Google Scholar] [CrossRef]

- Qu, W.L.; Chen, Z.H.; Xu, Y.L. Dynamic Analysis of Wind Excited Truss Tower With Friction Dampers. Comput. Struct. 2001, 79, 2817–2831. [Google Scholar] [CrossRef]

- Spyrakos, C.C.; Raftoyiannis, I.G.; Ermopoulos, J.C. Condition assessment and retrofit of a historic steel-truss railway bridge. J. Constr. Steel Res. 2004, 60, 1213–1225. [Google Scholar] [CrossRef]

- Zheng, H.D.; Fan, J. Analysis of the progressive collapse of space truss structures during earthquakes based on a physical theory hysteretic model. Thin-Walled Struct. 2018, 123, 70–81. [Google Scholar] [CrossRef]

- Maraveas, C.; Tsavdaridis, K.D. Assessment and retrofitting of an existing steel structure subjected to wind-induced failure analysis. J. Build. Eng. 2019, 23, 53–67. [Google Scholar] [CrossRef]

- Foraboschi, P. Lateral load-carrying capacity of steel columns with fixed-roller end supports. J. Build. Eng. 2019, 26. [Google Scholar] [CrossRef]

- Rakov, V.A. The physics of lightning. Surv. Geophys. 2013, 34, 701–729. [Google Scholar] [CrossRef]

- Hartono, Z.A.; Ibrahim, R. A database of lightning damage caused by bypasses of air terminals on buildings in Kuala Lumpur, Malaysia. In Proceedings of the VI International Symposium on Lightning Protection, Santos, Brazil, 19–23 November 2001. [Google Scholar]

- Bothma, J.G. Transmission line tower collapse investigation: A case study. In Proceedings of the IEEE Power and Energy Society Conference and Exposition in Africa: Intelligent Grid Integration of Renewable Energy Resources (PowerAfrica), Johannesburg, South Africa, 9–13 July 2012. [Google Scholar] [CrossRef]

- Mills, B.; Unrau, D.; Pentelow, L.; Spring, K. Assessment of lightning-related damage and disruption in Canada. Nat. Hazards 2010, 52, 481–499. [Google Scholar] [CrossRef]

- Zhang, W.; Meng, Q.; Ma, M.; Zhang, Y. Lightning casualties and damages in China from 1997 to 2009. Nat. Hazards 2011, 57, 465–476. [Google Scholar] [CrossRef]

- Krausmann, E.; Renni, E.; Campedel, M.; Cozzani, V. Industrial accidents triggered by earthquakes, floods and lightning: Lessons learned from a database analysis. Nat. Hazards 2011, 59, 285–300. [Google Scholar] [CrossRef]

- Patel, K. Effect of Lightning on Building and Its Protection Measures. Int. J. Eng. Adv. Technol. 2013, 2, 182. [Google Scholar]

- Blong, R. Residential building damage and natural perils: Australian examples and issues. Build. Res. Inf. 2004, 32, 379–390. [Google Scholar] [CrossRef]

- Shivalli, S. Lightning Phenomenon, Effects and Protection of Structures from Lightning Sanketa Shivalli. IOSR J. Electr. Electron. Eng. 2016, 11, 44–50. [Google Scholar]

- Zhivlyuk, Y.; Mandel’shtam, S. On the temperature of lightning and force of thunder. Sov. Phys. JETP 1961, 13, 338–340. [Google Scholar]

- Mu, Y.; Yuan, P.; Wang, X.; Dong, C. Temperature distribution and evolution characteristic in lightning return stroke channel. J. Atmos. Solar-Terrestrial Phys. 2016, 145, 98–105. [Google Scholar] [CrossRef]

- Elsom, D.M.; Webb, J.D.C. Lightning Impacts in the United Kingdom and Ireland. In Extreme Weather; Wiley-Blackwell: Hoboken, NJ, USA, 2016; pp. 195–207. [Google Scholar]

- Holle, R.L.; López, R.E.; Arnold, L.J.; Endres, J. Insured Lightning-Caused Property Damage in Three Western States. J. Appl. Meteorol. 1996, 35, 1344–1351. [Google Scholar] [CrossRef][Green Version]

- Kmet, S.; Tomko, M.; Demjan, I.; Pesek, L.; Priganc, S. Analysis of a damaged industrial hall subjected to the effects of fire. Struct. Eng. Mech. 2016, 58, 757–781. [Google Scholar] [CrossRef]

- Usmani, A.S. Stability of the world trade center twin towers structural frame in multiple floor fires. J. Eng. Mech. 2005, 131, 654–657. [Google Scholar] [CrossRef]

- Behnam, B. Fire Structural Response of the Plasco Building: A Preliminary Investigation Report. Int. J. Civ. Eng. 2019, 17, 563–580. [Google Scholar] [CrossRef]

- Mwangi, S. Why Broadgate Phase 8 composite floor did not fail under fire: Numerical investigation using ANSYS® FEA code. J. Struct. Fire Eng. 2017, 8, 238–257. [Google Scholar] [CrossRef]

- Usmani, A.S.; Chung, Y.C.; Torero, J.L. How did the WTC towers collapse: A new theory. Fire Saf. J. 2003, 38, 501–533. [Google Scholar] [CrossRef]

- Meppelink, J. The Impact of a lightning Stroke on a Flat Roof When the Building is Filled with Water. In Proceedings of the ICLP ‘98, 24th International Conference on Lightning Protection, Birmingham, UK, 14–18 September 1998; pp. 826–831. [Google Scholar]

- Li, H.; Wu, G. Fatigue evaluation of steel bridge details integrating multi-scale dynamic analysis of coupled train-track-bridge system and fracture mechanics. Appl. Sci. 2020, 10, 3261. [Google Scholar] [CrossRef]

- Blandford, G.E. Progressive failure analysis of inelastic space truss structures. Comput. Struct. 1996, 58, 981–990. [Google Scholar] [CrossRef]

- Blandford, G.E. Review of Progressive Failure Analyses for Truss Structures. J. Struct. Eng. 1997, 123, 122–129. [Google Scholar] [CrossRef]

- Malla, R.B.; Agarwal, P.; Ahmad, R. Dynamic analysis methodology for progressive failure of truss structures considering inelastic postbuckling cyclic member behavior. Eng. Struct. 2011, 33, 1503–1513. [Google Scholar] [CrossRef]

- Machaly, E.S.B. Buckling contribution to the analysis of steel trusses. Comput. Struct. 1986, 22, 445–458. [Google Scholar] [CrossRef]

- Murtha-Smith, E. Alternate Path Analysis of Space Trusses for Progressive Collapse. J. Struct. Eng. 1999, 114, 1978–1999. [Google Scholar] [CrossRef]

- Astaneh-Asl, A. Progressive collapse of steel truss bridges, the case of I-35W collapse. In Proceedings of the International Conference on Steel Bridges, Guimarăes, Portugal, 4–6 June 2008; pp. 1–10. [Google Scholar]

- Tanzer, A. High school gymnasium roof truss support collapse. J. Fail. Anal. Prev. 2011, 11, 208–214. [Google Scholar] [CrossRef]

- Park, S.; Yun, C.B.; Roh, Y. Damage diagnostics on a welded zone of a steel truss member using an active sensing network system. NDT E Int. 2007, 40, 71–76. [Google Scholar] [CrossRef]

- Riasat Azim, M.; Gül, M. Damage Detection of Steel-Truss Railway Bridges Using Operational Vibration Data. J. Struct. Eng. 2020, 146, 1–12. [Google Scholar] [CrossRef]

- Wood, J.V.; Dawe, J.L. Full-scale test behavior of cold-formed steel roof trusses. J. Struct. Eng. 2006, 132, 616–623. [Google Scholar] [CrossRef]

- Fülöp, A.; Iványi, M. Experimentally analyzed stability and ductility behaviour of a space-truss roof system. Thin-Walled Struct. 2004, 42, 309–320. [Google Scholar] [CrossRef]

- Caglayan, O.; Yuksel, E. Experimental and finite element investigations on the collapse of a Mero space truss roof structure—A case study. Eng. Fail. Anal. 2008, 15, 458–470. [Google Scholar] [CrossRef]

- Piroglu, F.; Ozakgul, K. Partial collapses experienced for a steel space truss roof structure induced by ice ponds. Eng. Fail. Anal. 2016, 60, 155–165. [Google Scholar] [CrossRef]

- Pieraccini, L.; Palermo, M.; Trombetti, T.; Baroni, F. The role of ductility in the collapse of a long-span steel roof in North Italy. Eng. Fail. Anal. 2017, 82, 243–265. [Google Scholar] [CrossRef]

| Property | Steel | Concrete |

|---|---|---|

| Young’s modulus (E) | 210 GPa | 32 GPa |

| Poisson’s ratio (ν) | 0.28 | 0.20 |

| Thermal expansion coefficient (α) | 13 μm/(m K) | 11.5 μm/(m K) |

| Load Description | Value |

|---|---|

| Weight of the space truss system | 140 N/m2 |

| Dead loads | 350 N/m2 |

| (240 N/m2 given in design calculations) | |

| Snow load | 2000 N/m2 |

| (1000 N/m2 given in design calculations.) | |

| Vertical wind loads | 960 N/m2 |

| Equivalent earthquake vertical load | 950 N/m2 |

| Equivalent earthquake horizontal load | 200 N/m2 |

| (180 N/m2 given in design calculations) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tüfekci, M.; Tüfekci, E.; Dikicioğlu, A. Numerical Investigation of the Collapse of a Steel Truss Roof and a Probable Reason of Failure. Appl. Sci. 2020, 10, 7769. https://doi.org/10.3390/app10217769

Tüfekci M, Tüfekci E, Dikicioğlu A. Numerical Investigation of the Collapse of a Steel Truss Roof and a Probable Reason of Failure. Applied Sciences. 2020; 10(21):7769. https://doi.org/10.3390/app10217769

Chicago/Turabian StyleTüfekci, Mertol, Ekrem Tüfekci, and Adnan Dikicioğlu. 2020. "Numerical Investigation of the Collapse of a Steel Truss Roof and a Probable Reason of Failure" Applied Sciences 10, no. 21: 7769. https://doi.org/10.3390/app10217769

APA StyleTüfekci, M., Tüfekci, E., & Dikicioğlu, A. (2020). Numerical Investigation of the Collapse of a Steel Truss Roof and a Probable Reason of Failure. Applied Sciences, 10(21), 7769. https://doi.org/10.3390/app10217769