Biogas Potential of Wastes and By-Products of the Alcoholic Beverage Production Industries in the Spanish Region of Cantabria

Abstract

Featured Application

Abstract

1. Introduction

1.1. Generalities

1.2. Historical and Current Situation

- -

- Among solids, grape marc, raw or fermented and distilled from wine and orujo production, as well as apple pomace from cider manufacturing; brewers and distillers spent grains in beer breweries and from ethyl alcohol of agricultural origin production (the basis for a number of spirits); and botanics and aromatics for some distilled beverages.

- -

- Among liquids, trub from breweries; pot ales and washes from distillation; and wash and process waters.

2. Materials and Methods

2.1. Substrates

2.2. Inoculum and Conductive Material

2.3. Experimental Set-up: Batch Experiments

2.4. Analytical Techniques

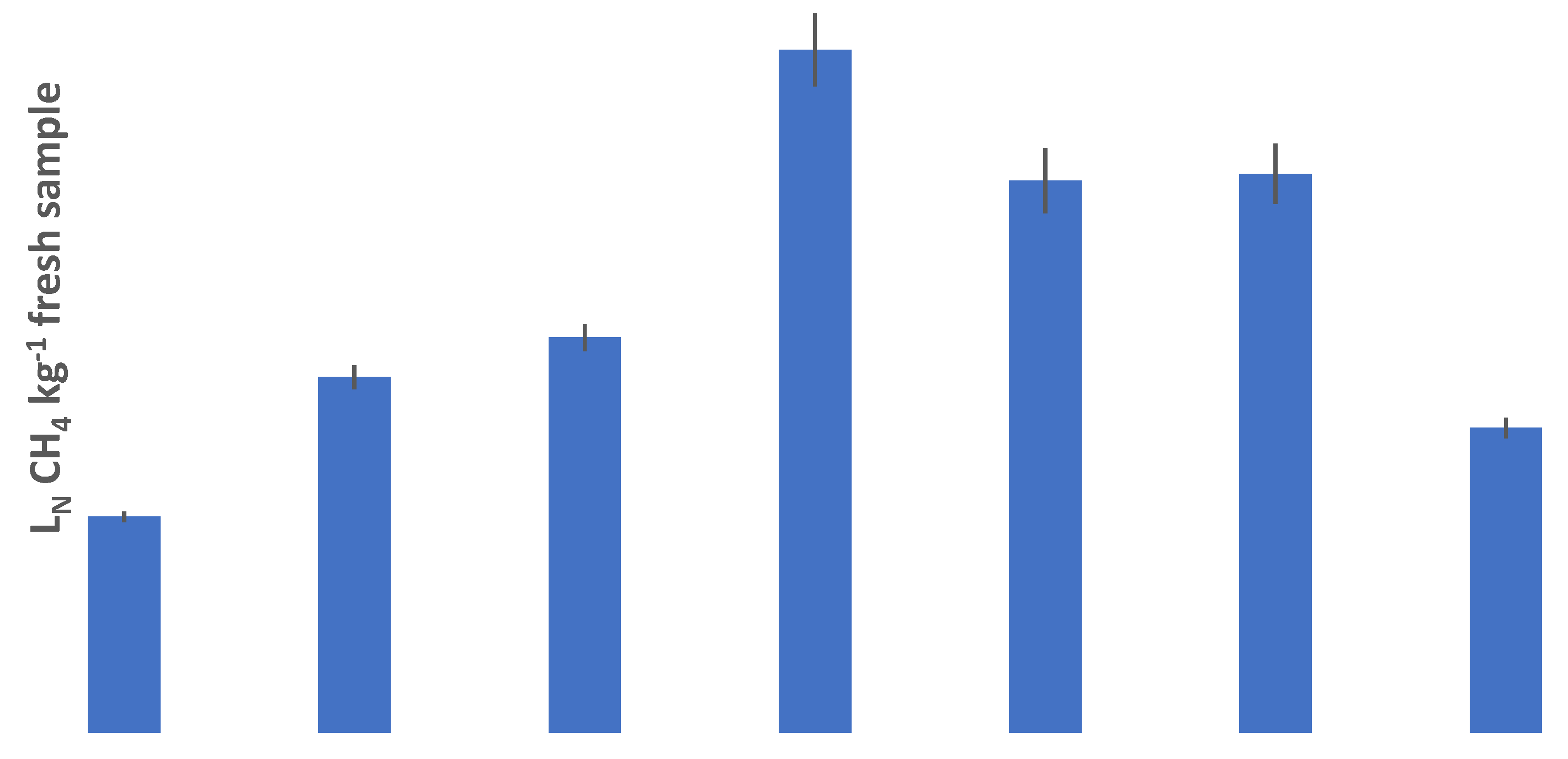

3. Results

4. Discussion

4.1. Wastes and By-Products: Generation and Characteristics

4.2. Practical Application of the Results of the BMP Tests

- Total methane potential: TMP = 57,951 m3 CH4/year

- Amount of possible electricity generation from methane: ebio = 231,804 kWh/year

- Emission reduction from electricity generation: ERe l= 516,993 kg CO2/year

- Total emission reduction: TER = 1,476,578 kg CO2/year

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| AD | Short for anaerobic digestion. |

| BMP | Short for biochemical methanogenic potential. |

| COD | Short for chemical oxygen demand. |

| ebio | Amount of possible electricity generation from biomethane. Expressed in kWh/year. |

| ERel | Emission reduction from electricity generation (using biomethane). Expressed in kg CO2/year. |

| GDP | Short for gross domestic product. |

| LN CH4 kg VS−1 | Liters of methane in standard conditions per kilogram of volatile solids in the feedstock. Out of convenience and as usual in literature, it is the unit of choice to express methane yield. To translate into SI units (m3N CH4 kg VS−1), the values should be multiplied by 10−3. |

| η | Electricity conversion efficiency factor. |

| PAC | Short for powdered activated charcoal. |

| TAN | Short for total ammonia nitrogen. Out of convenience and as usual in literature, it is expressed in g NH4+-N l−1. |

| TER | Total emission reduction (using biomethane). Expressed in kg CO2/year. |

| TMP | Short for total methane potential. |

| TS | Short for total solids. Expressed as a percentage of the mass of a solution. |

| TKN | Total Kjeldahl nitrogen. Out of convenience and as usual in literature, it is expressed in g/kg TS. To translate into SI units (kg/kg TS), the values should be multiplied by 10−3. |

| VFA | Short for volatile fatty acids. |

| VS | Volatile solids. Expressed as a percentage, either of the mass of a solution (as in this work) or of the total solids in the solution. |

References

- ICANE InstitutoCántabro de Estadística. Available online: https://www.icane.es/ (accessed on 12 April 2020).

- INE Instituto Nacional de Estadística. EncuestaSobreGeneración de Residues en el Sector Industrial. Serie 2012–2016. Available online: https://www.ine.es/dynt3/inebase/es/index.htm?type=pcaxis&path=/t26/e068/p02/serie&file=pcaxis (accessed on 12 April 2020).

- Springer, N.P.; Schmitt, J. The price of byproducts: Distinguishing co-products from waste using the rectangular choice-of-technologies model. Resour. Conserv. Recycl. 2018, 138, 231–237. [Google Scholar] [CrossRef]

- Laso, J.; Margallo, M.; García-Herrero, I.; Fullana, P.; Bala, A.; Gazulla, C.; Polettini, A.; Kahhat, R.; Vázquez-Rowe, I.; Irabien, A.; et al. Combined application of Life Cycle Assessment and linear programming to evaluate food waste-to-food strategies: Seeking for answers in the nexus approach. Waste Manage. 2018, 80, 186–197. [Google Scholar] [CrossRef] [PubMed]

- Banias, G.; Achillas, C.; Vlachokostas, C.; Moussiopoulos, N.; Stefanou, M. Environmental impacts in the life cycle of olive oil: A literature review. J. Sci. Food Agric. 2017, 97, 1686–1697. [Google Scholar] [CrossRef] [PubMed]

- Teigiserova, D.A.; Hamelin, L.; Thomsen, M. Review of high-value food waste and food residues biorefineries with focus on unavoidable wastes from processing. Resour. Conserv. Recycl. 2019, 149, 413–426. [Google Scholar] [CrossRef]

- Sharma, P.; Gaur, V.K.; Kim, S.-H.; Pandey, A. Microbial strategies for bio-transforming food waste into resources. Bioresour. Technol. 2020, 299, 122580. [Google Scholar] [CrossRef] [PubMed]

- Mussatto, S.I.; Moncada, J.; Roberto, I.C.; Cardona, C.A. Techno-economic analysis for brewer’s spent grains use on a biorefinery concept: The Brazilian case. Bioresour. Technol. 2013, 148, 302–310. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Garcia, G.; Rahimifard, S. Life-cycle environmental impacts of barley straw valorisation. Resour. Conserv. Recycl. 2019, 149, 1–11. [Google Scholar] [CrossRef]

- Rico, C.; Montes, J.A.; Lobo, A. Dry batch anaerobic digestion of food waste in a box-type reactor system: Inoculum preparation and reactor performance. J. Clean Prod. 2020, 251, 119751. [Google Scholar] [CrossRef]

- De Palomares, J.I.S.; de Galarreta Gómez, J.I.R.; Azpitarte, E.R.; Díaz, E.M. La Viden Cantabria: Prospección y Caracterización de VariedadesAutóctonas; Muriedas: Centro de Investigación y FormaciónAgrarias (CIFA): Muriedas, Spain, 2005; 178p, ISBN 84-689-3884-X. [Google Scholar]

- Ruescas, J.T. El Trujal: Historia, Leyendas y NotasSobre la Manzana y la Sidra en Cantabria, 1st ed.; Torrelavega: Cantabria Tradicional, Torrelavega, Spain, 2007; 212p, ISBN 978-8496042469. [Google Scholar]

- Iñigo, P.P. Historia de las Cervecerías Españolas Raíces de Cervezas de Santander, SA y Unión cervecera, SA (1a parte). Cerveza y Malta 2002, 156, 65–76. [Google Scholar]

- EUR-LEX, Official Website of European Union Law. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1556781080548&uri=CELEX:32008R0110 (accessed on 12 April 2020).

- BOC. BoletínOficial de Cantabria. Official Gazette of the Autonomous Community of Cantabria. Available online: https://boc.cantabria.es/boces/verAnuncioAction.do?idAnuBlob=186396 (accessed on 12 April 2020).

- Olajire, A.A. The brewing industry and environmental challenges. J. CleanProd. 2020, 256, 102817. [Google Scholar] [CrossRef]

- Montalvo, S.; Martinez, J.; Castillo, A.; Huiliñir, C.; Borja, R.; García, V.; Salazar, R. Sustainable energy for a winery through biogas production and its utilization: A Chilean case study. Sustain. Energy Technol. Assess. 2020, 37, 100640. [Google Scholar] [CrossRef]

- Bocci, E.; Di Carlo, A.; McPhail, J.; Gallucci, K.; Foscolo, P.U.; Moneti, M.; Villarini, M.; Carlini, M. Biomass to fuel cells state of the art: A review of the most innovative technology solutions. Int. J. Hydrog. Energy 2014, 39, 21876–21895. [Google Scholar] [CrossRef]

- Papurello, D.; Silvestri, S.; Lanzini, A. Biogas cleaning: Trace compounds removal with model validation. Sep. Purif. Technol. 2019, 210, 80–92. [Google Scholar] [CrossRef]

- Papurello, D.; Chiodo, V.; Maisano, S.; Lanzini, A.; Santarelli, M. Catalytic stability of a Ni-Catalyst towards biogas reforming in the presence of deactivating trace compounds. Renew. Energy 2018, 127, 481–494. [Google Scholar] [CrossRef]

- Martinez, S.; Michaux, G.; Salagnac, P.; Bouvier, J.L. Micro-combined heat and power systems (micro-CHP) based on renewable energy sources. Energy Conv. Manag. 2017, 254, 262–285. [Google Scholar] [CrossRef]

- García, N.H.; Mattioli, A.; Gil, A.; Frison, N.; Battista, F.; Bolzonella, D. Evaluation of the methane potential of different agricultural and food processing substrates for improved biogas production in rural areas. Renew. Sustain. Energ. Rev. 2019, 112, 1–10. [Google Scholar] [CrossRef]

- Filho, M.G.; Lumi, M.; Hasan, C.; Marder, M.C.S.; Leite, L.; Konrad, O. Energy recovery from wine sector wastes: A study about the biogas generation potential in a vineyard from Rio Grande do Sul, Brazil. Sustain. Energy Technol. Assess. 2018, 29, 44–49. [Google Scholar] [CrossRef]

- Ferreira-Leitão, V.S.; Cammarota, M.C.; Aguieiras, E.C.G.; de Sá, L.R.V.; Fernandez-Lafuente, R.; Freire, D.M.G. The Protagonism of Biocatalysis in Green Chemistry and Its Environmental Benefits. Catalysts 2017, 7, 9. [Google Scholar] [CrossRef]

- Rajagopal, R.; Saadi, N.M.C.; Torrijos, M.; Thanikal, J.V.; Hung, Y.T. Sustainable Agro-Food Industrial Wastewater Treatment Using High Rate Anaerobic Process. Water 2013, 5, 292–311. [Google Scholar] [CrossRef]

- Valero, D.; Alzate-Gaviria, L.; Montes, J.A.; Rico, C. Influence of a Conductive Material and Different Anaerobic Inocula on Biochemical Methane Potential of Substrates from Alcoholic Beverage Production. Waste Biomass Valorization 2020, 11, 5957–5964. [Google Scholar] [CrossRef]

- Valero, D.; Montes, J.A.; Rico, J.L.; Rico, C. Influence of headspace pressure on methane production in Biochemical Methane Potential (BMP) tests. Waste Manage. 2016, 48, 193–198. [Google Scholar] [CrossRef] [PubMed]

- Muhlack, R.A.; Potumarthi, R.; Jeffery, D.W. Sustainable wineries through waste valorisation: A review of grape marc utilisation for value-added products. Waste Manage. 2018, 72, 99–118. [Google Scholar] [CrossRef] [PubMed]

- Barrena, R.; Traub, J.E.; Gil, C.R.; Goodwin, J.A.S.; Harper, A.J.; Willoughby, N.A.; Sánchez, A.; Aspray, T.J. Batch anaerobic digestion of deproteinated malt whisky pot ale using different source inocula. Waste Manag. 2018, 71, 675–682. [Google Scholar] [CrossRef] [PubMed]

- Vitanza, R.; Cortesi, A.; Gallo, V.; Colussi, I.; De Arana-Sarabia, M.E. Biovalorization of brewery waste by applying anaerobic digestion. Chem. Biochem. Eng. Q. 2016, 30, 351–357. [Google Scholar] [CrossRef]

- Bochmann, G.; Drosg, B.; Fuchs, W. Anaerobic digestion of thermal pretreated brewers’ spent grains. Environ. Prog. Sustain. Energy 2015, 34, 1092–1096. [Google Scholar] [CrossRef]

- Oliveira, J.V.; Alves, M.M.; Costa, J.C. Biochemical methane potential of brewery by-products. Clean Technol. Environ. Policy 2018, 20, 435–440. [Google Scholar] [CrossRef]

- Dinuccio, E.; Balsari, P.; Gioelli, F.; Menardo, S. Evaluation of the biogas productivity potential of some Italian agro-industrial biomasses. Bioresour. Technol. 2010, 101, 3780–3783. [Google Scholar] [CrossRef]

- Hungría, J.; Siles, J.A.; Gil, A.; Gutiérrez, M.C.; Martín, M.A. Revalorization of grape marc waste from liqueur wine: Biomethanization. J. Chem. Technol. Biotechnol. 2019, 94, 1499–1508. [Google Scholar] [CrossRef]

- Fabbri, A.; Bonifazi, G.; Serranti, S. Micro-scale energy valorization of grape marcs in winery production plants. Waste Manag. 2015, 36, 156–165. [Google Scholar] [CrossRef]

- Da Ros, C.; Cavinato, C.; Bolzonella, D.; Pavan, P. Renewable energy from thermophilic anaerobic digestion of winery residue: Preliminary evidence from batch and continuous lab-scale trials. Biomass Bioenerg. 2016, 91, 150–159. [Google Scholar] [CrossRef]

- Montes, J.A.; Leivas, R.; Martínez-Prieto, D.; Rico, C. Biogas production from the liquid waste of distilled gin production: Optimization of UASB reactor performance with increasing organic loading rate for co-digestion with swine wastewater. Bioresour. Technol. 2019, 274, 43–47. [Google Scholar] [CrossRef] [PubMed]

- Feiz, R.; Ammenberg, J. Assessment of feedstocks for biogas production, part I—A multi-criteria approach. Resour. Conserv. Recycl. 2017, 122, 373–387. [Google Scholar] [CrossRef]

- Ammenberg, J.; Feiz, R. Assessment of feedstocks for biogas production, part II—Results for strategic decision making. Resour. Conserv. Recycl. 2017, 122, 388–404. [Google Scholar] [CrossRef]

- Vlachokostas, C.; Achillas, C.; Agnantiaris, I.; Michailidou, A.V.; Pallas, C.; Feleki, E.; Moussiopoulos, N. Decision support system to implement units of alternative biowaste treatment for producing bioenergy and boosting local bioeconomy. Energies 2020, 13, 2306. [Google Scholar] [CrossRef]

- Failla, S.; Restuccia, A. Methane potentials from grape marc by a laboratory scale plant. Appl. Math. Sci. 2014, 8, 6665–6678. [Google Scholar] [CrossRef]

- Oliveira, M.; Duarte, E. Integrated approach to winery waste: Waste generation and data consolidation. Front. Env. Sci. Eng. 2016, 10, 168–176. [Google Scholar] [CrossRef]

- Devesa-Rey, R.; Vecino, X.; Varela-Alende, J.L.; Barral, M.T.; Cruz, J.M.; Moldes, A.B. Valorization of winery waste vs. the costs of not recycling. Waste Manage. 2011, 31, 2327–2335. [Google Scholar] [CrossRef]

- ODECA. Oficina de CalidadAlimentaria. Gobierno de Cantabria. Available online: https://www.alimentosdecantabria.com/inicio (accessed on 12 April 2020).

- Lorenz, H.; Fischer, P.; Schumacher, B.; Adler, P. Current EU-27 technical potential of organic waste streams for biogas and energy production. Waste Manage. 2013, 33, 2434–2448. [Google Scholar] [CrossRef] [PubMed]

- Muster-Slawitsch, B.; Weiss, W.; Schnitzer, H.; Brunner, C. The green brewery concept-Energy efficiency and the use of renewable energy sources in breweries. Appl. Therm. Eng. 2011, 31, 2123–2134. [Google Scholar] [CrossRef]

- Johnson, P.; Paliwal, J.; Cenkowski, S. Issues with utilisation of brewers’ spent grain. Stewart Postharvest Rev. 2010, 6, 1–8. [Google Scholar] [CrossRef]

- Mallick, P.; Akunna, J.C.; Walker, G.M. Anaerobic digestion of distillery spent wash: Influence of enzymatic pre-treatment of intact yeast cells. Bioresour. Technol. 2010, 101, 1681–1685. [Google Scholar] [CrossRef]

- Rico, C.; Rico, J.L.; Tejero, I.; Muñoz, N.; Gómez, B. Anaerobic digestion of the liquid fraction of dairy manure in pilot plant for biogas production: Residual methane yield of digestate. Waste Manag. 2011, 31, 2167–2173. [Google Scholar] [CrossRef]

- Ministerio de Agricultura, Pesca y Alimentación. Gobierno de España. Encuestas de Viñedo. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/agricultura/encuestas-de-vinedo/ (accessed on 12 April 2020).

- Ministerio de Agricultura, Pesca y Alimentación. Gobierno de España. Superficies y ProduccionesAnuales de Cultivos–DatosAvances de ViñedoAño. 2017. Available online: https://www.mapa.gob.es/es/estadistica/temas/estadisticas-agrarias/agricultura/superficies-producciones-anuales-cultivos/ (accessed on 12 April 2020).

- Ministerio de Agricultura, Pesca y Alimentación. Gobierno de España. Datos Denominaciones de Origen e Indicaciones Geográficas Protegidas. Available online: https://www.mapa.gob.es/es/alimentacion/temas/calidad-agroalimentaria/calidad-diferenciada/dop/htm/cifrasydatos.aspx (accessed on 12 April 2020).

- Jasko, J.; Skripsts, E.; Dubrovskis, V. Biogas production of winemaking waste in anaerobic fermentation process. In Proceedings of the 11th International Scientific Conference Engineering For Rural Development, Jelgava, Latvia, 24–25 May 2012; pp. 576–579. [Google Scholar]

- Spigno, G.; Marinoni, L.; Garrido, G.D. State of the Art in Grape Processing ByProducts. In Handbook of Grape Processing By-Products: Sustainable Solutions; Galanakis, C.M., Ed.; Academic Press: San Diego, CA, USA, 2017; pp. 1–27. ISBN 9780128098707. [Google Scholar]

- Toscano, G.; Riva, G.; Duca, D.; Pedrretti, E.F.; Corinaldesi, F.; Rossini, G. Analysis of the characteristics of the residues of the wine production chain finalized to their industrial and energy recovery. Biomass Bioenerg. 2013, 55, 260–267. [Google Scholar] [CrossRef]

- Sturm, B.; Butcher, M.; Wang, Y.; Huang, Y.; Roskilly, T. The feasibility of the sustainable energy supply from bio wastes for a small scale brewery-A case study. Appl. Therm. Eng. 2012, 39, 45–52. [Google Scholar] [CrossRef]

- Özer, B. Biogas energy opportunity of Ardahan city of Turkey. Energy 2017, 139, 1144–1152. [Google Scholar] [CrossRef]

- Skornia, K.; Safferman, S.I.; Rodriguez-Gonzalez, L.; Ergas, S.J. Treatment of winery wastewater using bench-scale columns simulating vertical flow constructed wetlands with adsorption media. Appl. Sci.-Basel 2020, 10, 1063. [Google Scholar] [CrossRef]

- Ali, M.Y.; Hassan, M.; Rahman, M.A.; Al Kafy, A.; Ara, I.; Javed, A.; Rahman, M.R. Life cycle energy and cost analysis of small scale biogás plant and solar PV system in rural areas of Bangladesh. Energy Procedia 2019, 160, 277–284. [Google Scholar] [CrossRef]

- Menind, A.; Olt, J. Biogas plant investment analysis, cost benefit and main factors. In Proceedings of the 8th International Scientific Conference Engineering For Rural Development, Jelgava, Latvia, 28–29 May 2009; pp. 339–343. [Google Scholar]

- Achinas, S.; Euverink, G.J.W. Feasibility study of biogas production from hardly degradable material in co-inoculated bioreactor. Energies 2019, 12, 1040. [Google Scholar] [CrossRef]

| Wastes and By-Products | TS (%) | VS (%) | TKN (g/kg TS) | P (g/kg TS) |

|---|---|---|---|---|

| Pot ale | 6.06 | 5.55 | - | - |

| Trub | 9.51 | 8.69 | - | - |

| Gin spent wash | 8.32 | 7.68 | 1.44 | 0.36 |

| Gin spent botanics | 35.6 | 34.3 | 1.56 | 0.17 |

| Brewers’ spent grains | 25.2 | 24.2 | 3.59 | 0.56 |

| Grape marc | 44.1 | 38.3 | 2.21 | 0.22 |

| Exhausted grape marc | 31.9 | 29.1 | 2.43 | 0.24 |

| Inoculum | |

|---|---|

| TS (%) | 2.23 |

| VS (%) | 1.16 |

| COD (g L−1) | --- |

| pH | 7.9 |

| Alkalinity (g CaCO3 L−1) | 12.1 |

| TAN (g NH4+-N L−1) | 2.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montes, J.A.; Rico, C. Biogas Potential of Wastes and By-Products of the Alcoholic Beverage Production Industries in the Spanish Region of Cantabria. Appl. Sci. 2020, 10, 7481. https://doi.org/10.3390/app10217481

Montes JA, Rico C. Biogas Potential of Wastes and By-Products of the Alcoholic Beverage Production Industries in the Spanish Region of Cantabria. Applied Sciences. 2020; 10(21):7481. https://doi.org/10.3390/app10217481

Chicago/Turabian StyleMontes, Jesús A., and Carlos Rico. 2020. "Biogas Potential of Wastes and By-Products of the Alcoholic Beverage Production Industries in the Spanish Region of Cantabria" Applied Sciences 10, no. 21: 7481. https://doi.org/10.3390/app10217481

APA StyleMontes, J. A., & Rico, C. (2020). Biogas Potential of Wastes and By-Products of the Alcoholic Beverage Production Industries in the Spanish Region of Cantabria. Applied Sciences, 10(21), 7481. https://doi.org/10.3390/app10217481