The Modification Mechanism of Nano-Liquids on Streamer Morphology and Breakdown Strength under Microsecond Pulse

Abstract

1. Introduction

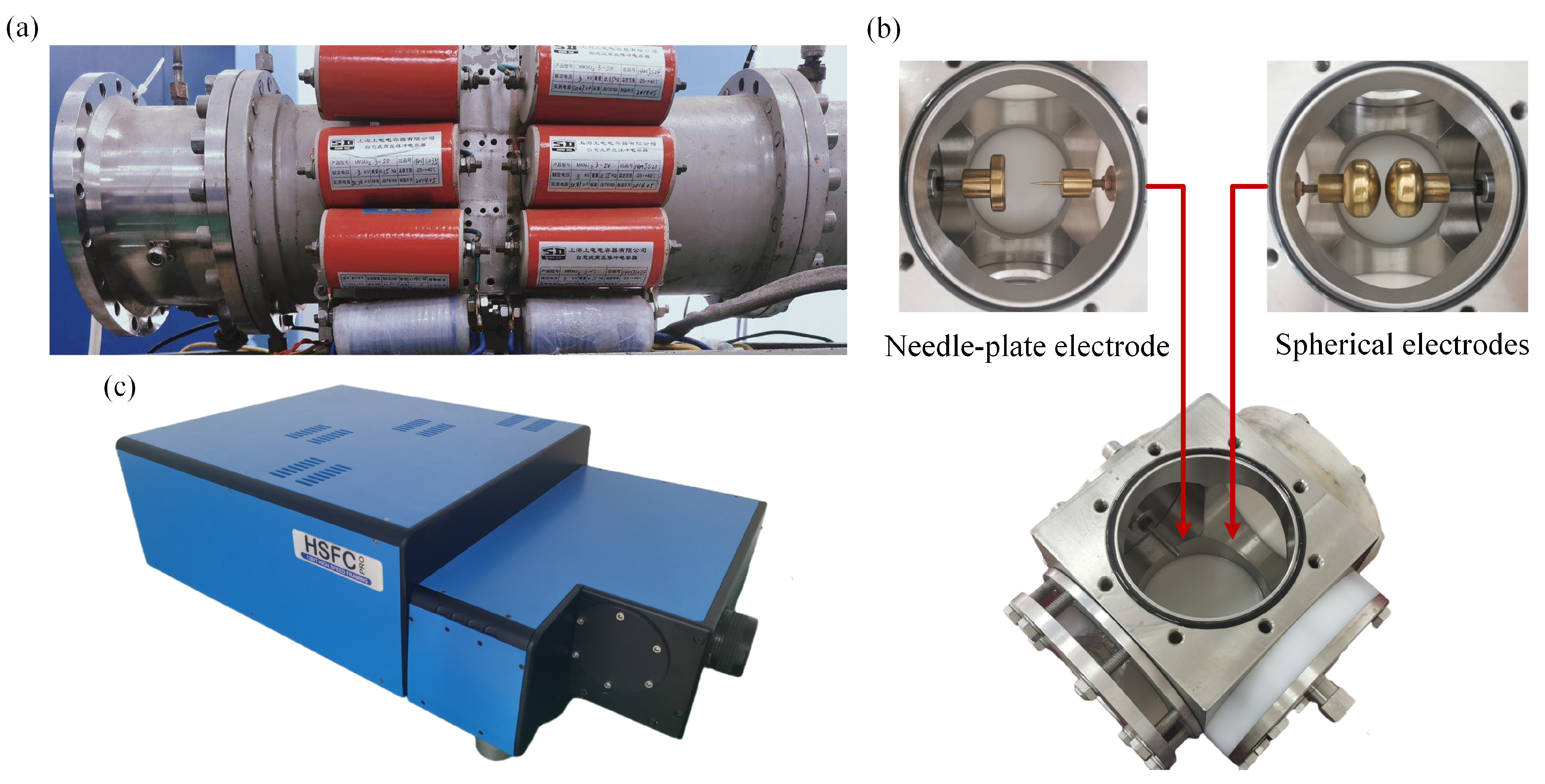

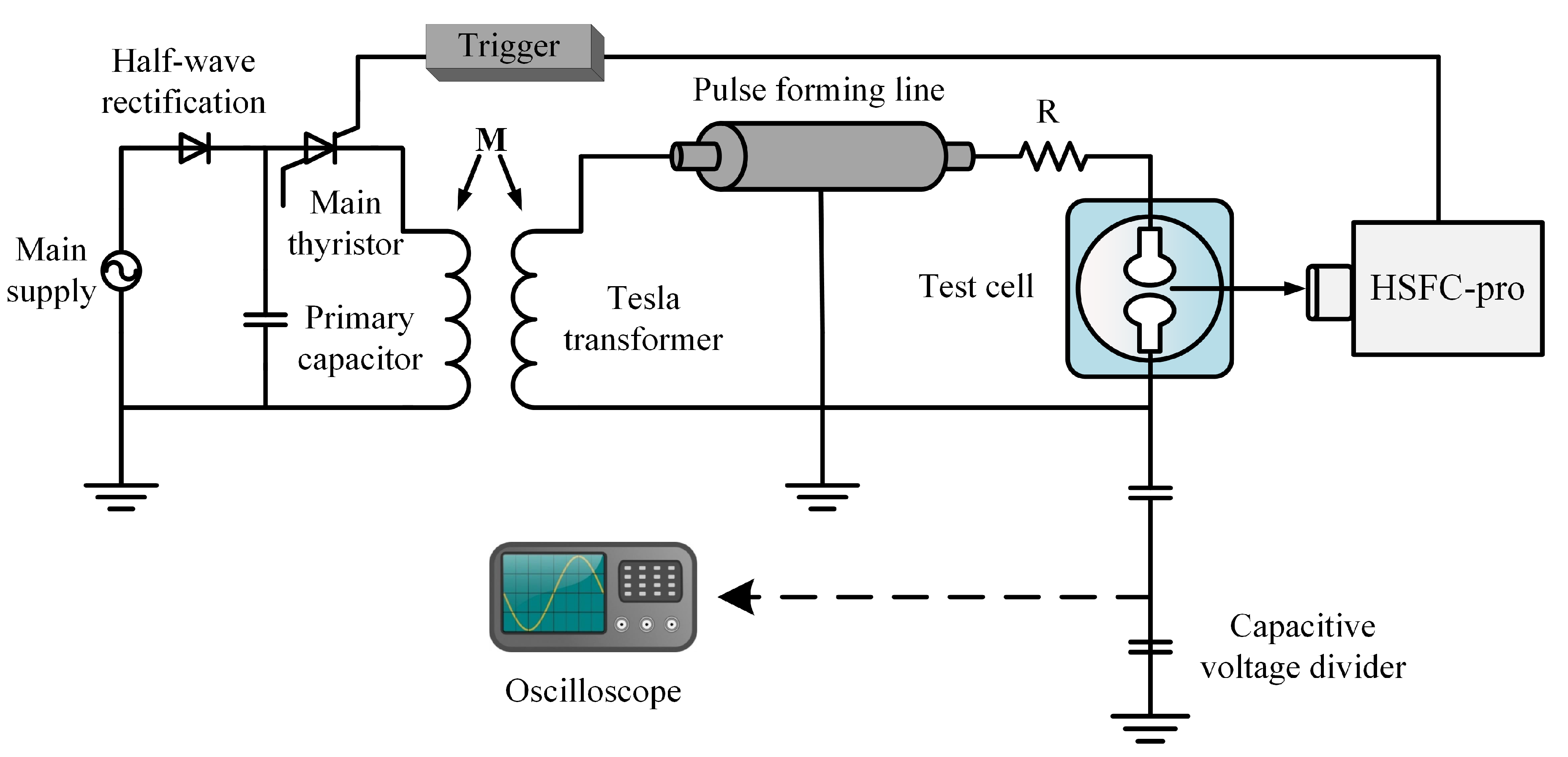

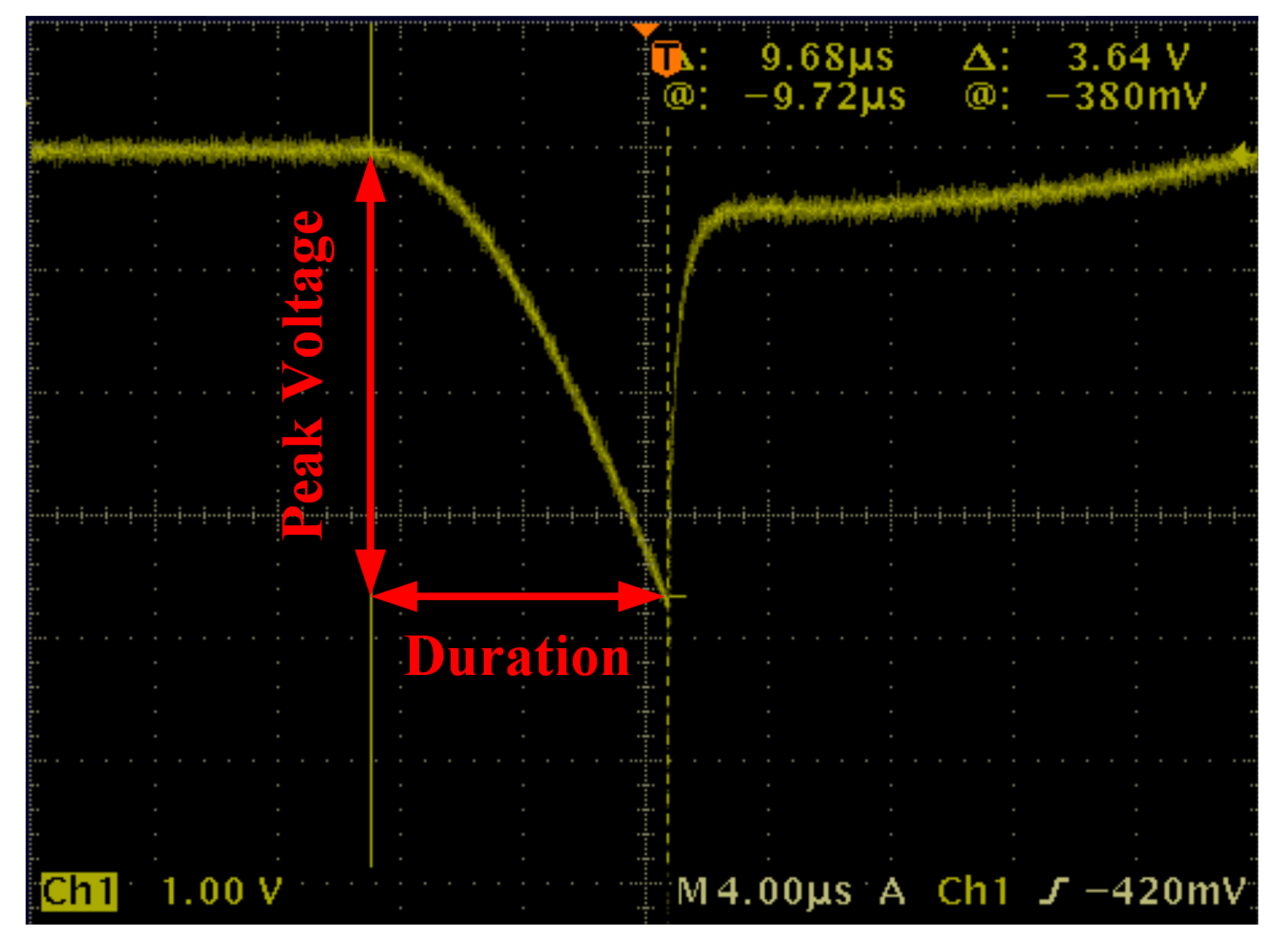

2. Set-Up and Experimental Method

3. Experimental Results and Analysis

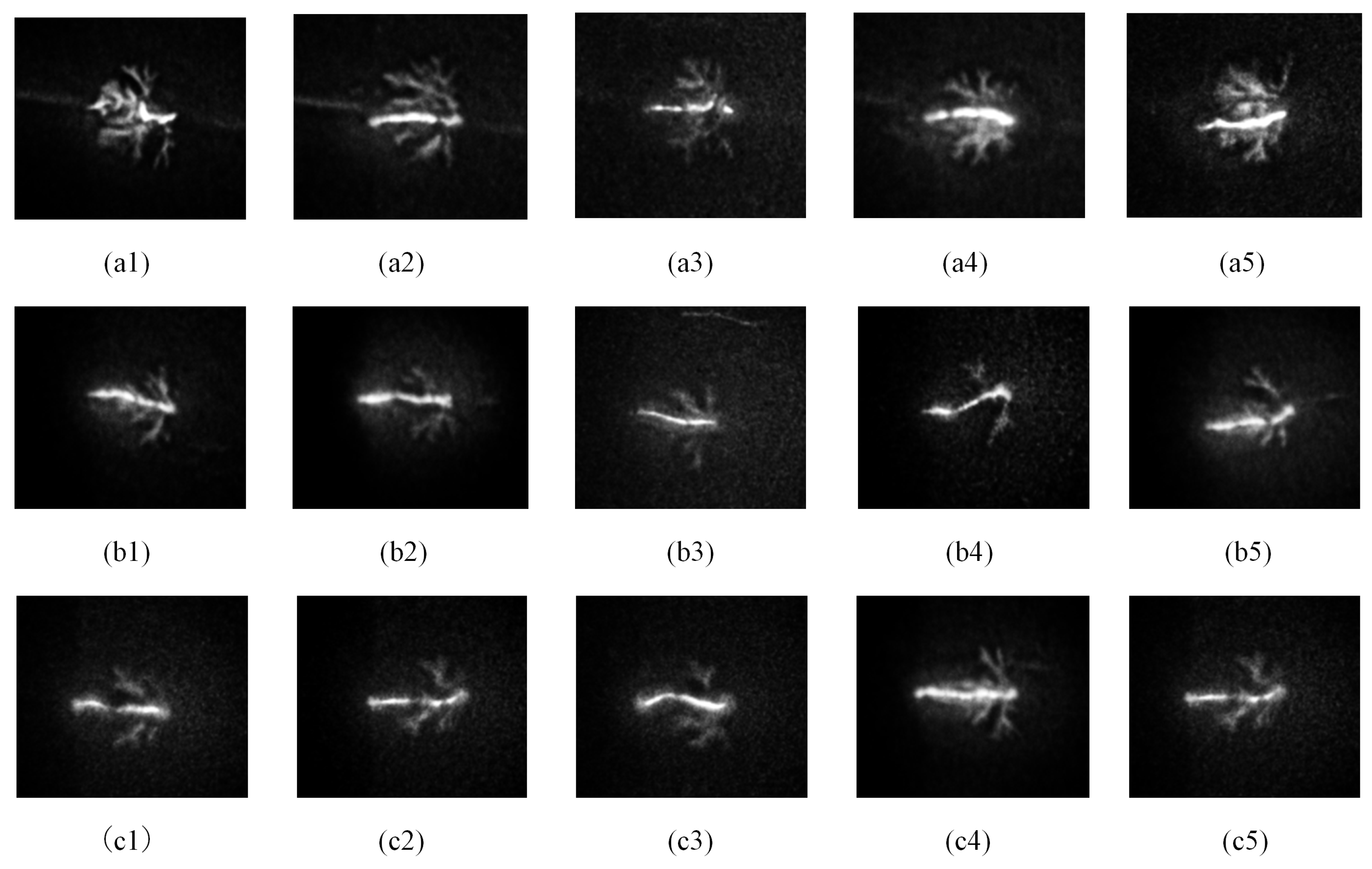

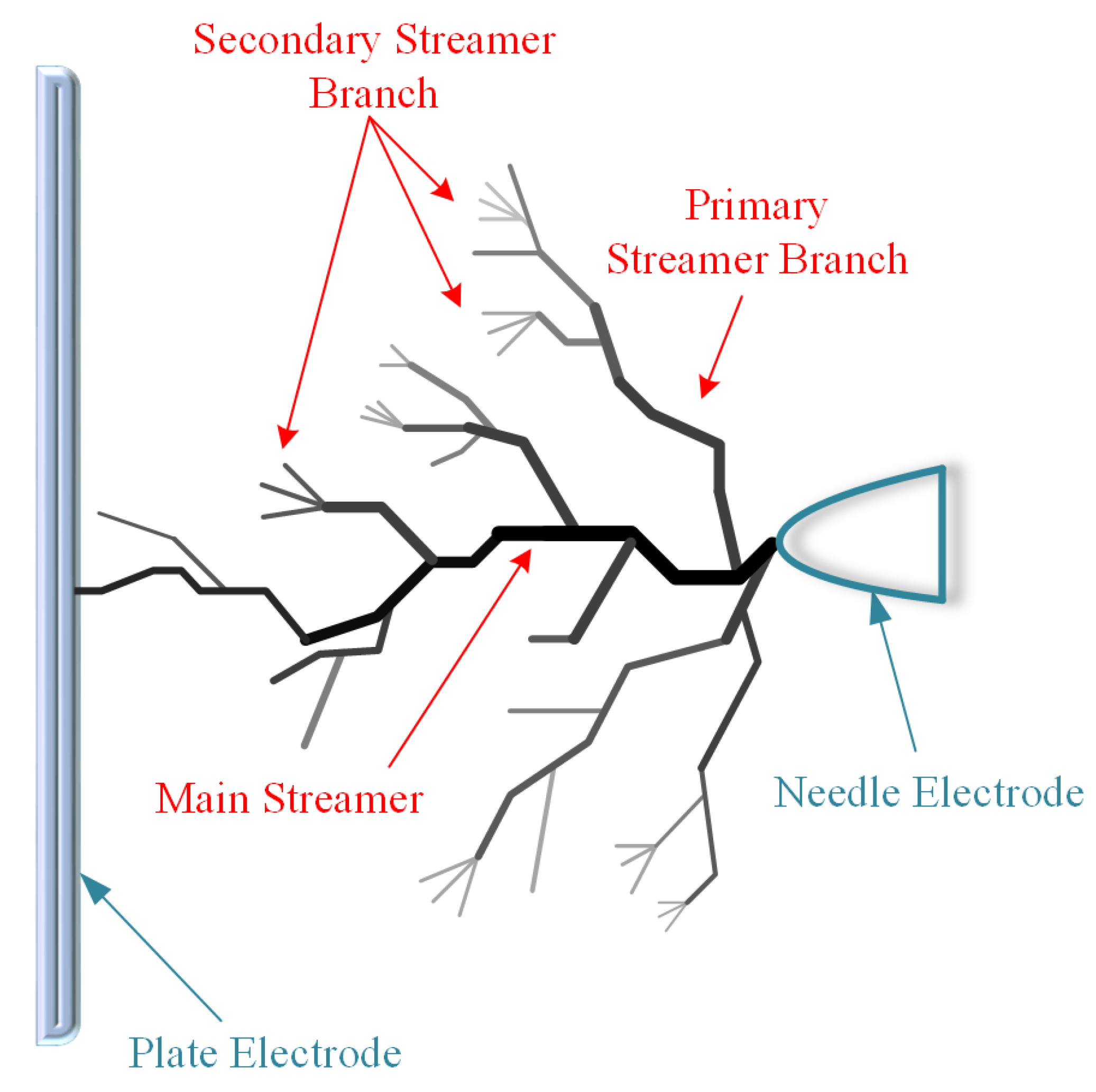

3.1. Streamer Analysis

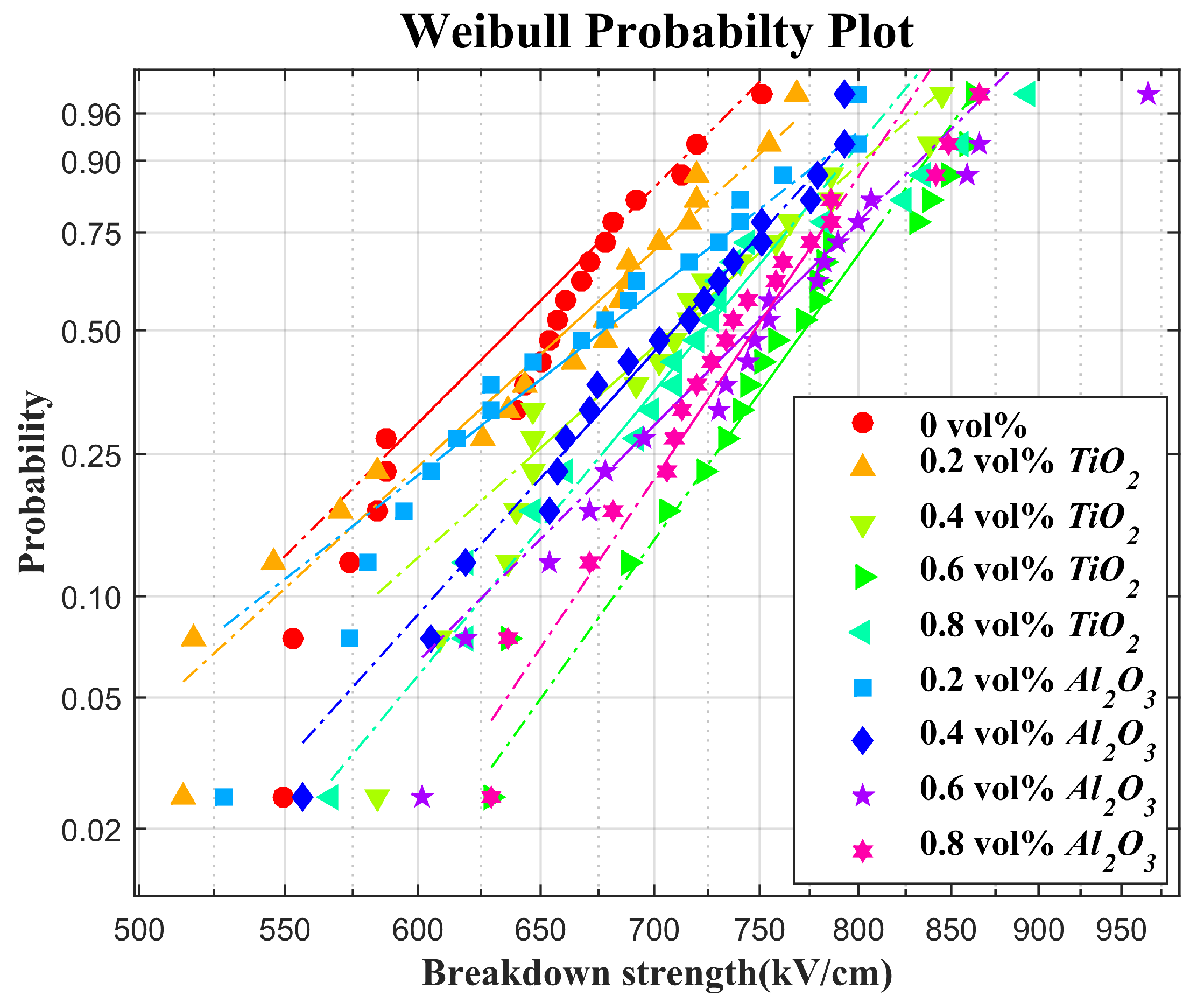

3.2. Breakdown Characteristics Analysis

4. Discussion

5. Conclusions

- The streamers in pure transformer oil exhibit thick bush-like qualities with many dispersed streamer branches, while in nano-liquids exhibit tree-like qualities with less sparse streamer branches;

- The addition of nano-particles can enhance the breakdown strength of transformer oil. With the increase in the volume fractions in nano-liquids, the negative influence on the modification effcet would counterbalance the positive influence on modification effect, and there would be a optimal volume fraction when maintaining a state of equilibrium between negative influence and positive influence.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.-C.; Zhang, J.-D.; Qian, B.-L.; Liu, C.B.; Xun, T.; Zhang, H.; Liang, B. Compact rep-rate GW pulsed generator based on forming line with built-in high-coupling transformer. IEEE Trans. Plasma Sci. 2014, 42, 241–248. [Google Scholar] [CrossRef]

- Levine, L.S.; Vitkovitsky, I.M. Pulsed power technology for controlled thermonuclear fusion. IEEE Trans. Nucl. Sci. 1971, 18, 255–264. [Google Scholar] [CrossRef]

- McNab, I.R. Developments in pulsed power technology. IEEE Trans. Magn. 2001, 37, 375–378. [Google Scholar] [CrossRef]

- Del Guercio, M. A 4.5-MJ pulsed power supply for railgun experiments. IEEE Trans. Magn. 2003, 39, 280–284. [Google Scholar] [CrossRef]

- Jin, Y.S.; Kim, Y.B.; Kim, J.S.; Cho, C.; Yang, K.S.; Kim, S.H.; Koo, I.S. A 4.8-MJ pulsed-power system for electromagnetic launcher experiment. IEEE Trans. Plasma Sci. 2015, 43, 3369–3373. [Google Scholar] [CrossRef]

- Le, D.V.; Go, B.S.; Song, M.G.; Park, M.; Yu, I.K. Development of a capacitor bank-based pulsed power supply module for electromagnetic induction coilguns. IEEE Trans. Plasma Sci. 2019, 47, 2458–2463. [Google Scholar] [CrossRef]

- Dong, S.; Yao, C.; Yang, N.; Luo, T.; Zhou, Y.; Wang, C. Solid-state nanosecond-pulse plasma jet apparatus based on Marx structure with crowbar switches. IEEE Trans. Plasma Sci. 2016, 44, 3353–3360. [Google Scholar] [CrossRef]

- Rao, J.; Lei, Y.; Jiang, S.; Li, Z.; Kolb, J.F. All solid-state rectangular sub-microsecond pulse generator for water treatment application. IEEE Trans. Plasma Sci. 2018, 46, 3359–3363. [Google Scholar] [CrossRef]

- Martin, J.C. Nanosecond pulse techniques. Proc. IEEE 1996, 80, 934–945. [Google Scholar] [CrossRef]

- Schamiloglu, E.; Barker, R.J.; Gundersen, M.; Neuber, A.A. Modern Pulsed Power: Charlie Martin and Beyond. Proc. IEEE 2004, 92, 1014–1020. [Google Scholar] [CrossRef]

- Li, S.; Gao, J.-M.; Shi, C.-Y.; Liu, X.; Yang, H.-W. Investigation on a fast rise time high voltage pulse transformer. Rev. Sci. Instrum. 2019, 90, 124707. [Google Scholar] [CrossRef] [PubMed]

- Pislaru-Danescu, L.; Morega, A.M.; Telipan, G.; Morega, M. Magnetic Nanofluid Applications in Electrical Engineering. IEEE Trans. Magn. 2013, 49, 5489–5497. [Google Scholar] [CrossRef]

- Sartoratto, P.P.C.; Neto, A.V.S.; Lima, E.C.D.; Rodrigues De Sa, A.L.C.; Morais, P.C. Preparation and electrical properties of oil-based magnetic fluids. J. Appl. Phys. 2005, 97, 10Q917. [Google Scholar] [CrossRef]

- Zahn, M.; Ohki, Y.; Fenneman, D.B. Dielectric properties of water and water/ethylene glycol mixtures for use in pulsed power system design. Proc. IEEE 1986, 74, 1182–1221. [Google Scholar] [CrossRef]

- Jin, H.-F.; Andritsch, T.; Tsekmes, I.A.; Kochetov, R.; Morshuis, P.H.F.; Smit, J.J. Properties of mineral oil based silica nanofluids. IEEE Trans. Dielectr. Electr. Insul. 2014, 21, 1100–1108. [Google Scholar]

- Joshi, R.P.; Thagard, S.M. Streamer-Like Electrical Discharges in Water: Part I. Fundamental Mechanisms. Plasma Chem. Plasma Process. 2013, 33, 1–15. [Google Scholar] [CrossRef]

- Joshi, R.P.; Kolb, J.F.; Xiao, S.; Schoenbach, K.H. Aspects of Plasma in Water: Streamer Physics and Applications. Plasma Process. Polym. 2009, 6, 763–777. [Google Scholar] [CrossRef]

- Stygar, W.A.; Savage, M.E.; Wagoner, T.C.; Bennett, L.F.; Corley, J.P.; Donovan, G.L.; Fehl, D.L.; Ives, H.C.; LeChien, K.R.; Leifeste, G.T.; et al. Dielectric-breakdown tests of water at 6MV. Phys. Rev. Accel. Beams 2009, 12, 308–312. [Google Scholar]

- Okabe, S. Evaluation of breakdown characteristics of oil-immersed transformers under non-standard lightning impulse insulation characteristics for non-standard lightning impulse waveforms with oscillations. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 679–688. [Google Scholar] [CrossRef]

- Okabe, S.; Takami, J. Evaluation of breakdown characteristics of oil-immersed transformers under non-standard lightning impulse waveforms-method for converting non-standard lightning impulse waveforms into standard lightning impulse waveforms. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1288–1296. [Google Scholar] [CrossRef]

- Wedin, P. Electrical breakdown in dielectric liquids—A short overview. IEEE Electr. Insul. Mag. 2014, 30, 20–25. [Google Scholar] [CrossRef]

- Pezeshkim, H.; Wolfsm, P.J.; Ledwich, G. Impact of High PV Penetration on Distribution Transformer Insulation Life. IEEE Trans. Power Deliv. 2014, 29, 1212–1220. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, L.; Li, J.; Li, Y. Study on Oscillating Switching Impulse Voltage Generation for Power Transformer Onsite Test. IEEE Trans. Power Deliv. 2014, 29, 2223–2230. [Google Scholar] [CrossRef]

- Hwang, J.G.; O’Sullivan, F.; Zahn, M.; Hjortstam, O.; Liu, R.S. Modeling of Streamer Propagation in Transformer Oil-Based Nanofluids. In Proceedings of the 2008 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Quebec, QC, Canada, 26–29 October 2008; pp. 361–366. [Google Scholar]

- Hwang, J.G.; Zahn, M.; O’Sullivan, F.M.; Pettersson, L.A.A.; Hjortstam, O.; Liu, R.S. Effects of nanoparticle charging on streamer development in transformer oil-based nanofluids. J. Appl. Phys. 2010, 107, 416–622. [Google Scholar] [CrossRef]

- Segal, V.; Hjortsberg, A.; Rabinovich, A.; Nattrass, D.; Raj, K. AC (60 Hz) and impulse breakdown strength of a colloidal fluid based on transformer oil and magnetite nanoparticles. Chem. Phys. Lett. 2016, 662, 192–195. [Google Scholar]

- Nadolny, Z.; Dombek, G. Electro-Insulating Nanofluids Based on Synthetic Ester and TiO2 or C60 Nanoparticles in Power Transformer. Energies 2018, 11, 1953. [Google Scholar] [CrossRef]

- Lue, Y.-F.; Hung, Y.-H.; Li, F.-S.; Teng, T.-P.; Chen, S.-Y.; Wu, C.-H.; Ou, Y.-C. Performance Assessment and Scooter Verification of Nano-Alumina Engine Oil. Appl. Sci. 2016, 6, 258. [Google Scholar] [CrossRef]

- Li, J.; Du, B.; Wang, F.; Yao, W.; Yao, S. The effect of nanoparticle surfactant polarization on trapping depth of vegetable insulating oil-based nanofluids. Phys. Lett. A 2015, 380, 604–608. [Google Scholar] [CrossRef]

- Abhishek, R.; Hamouda, A.A. Effect of Various Silica Nanofluids: Reduction of Fines Migrations and Surface Modification of Berea Sandstone. Appl. Sci. 2017, 7, 1216. [Google Scholar] [CrossRef]

- Lewis, T.J. A new model for the primary process of electrical breakdown in liquids. IEEE Trans. Dielectr. Electr. Insul. 1998, 5, 306–315. [Google Scholar] [CrossRef]

- Korobeynikov, S.M.; Melekhov, A.V. Nonelectrode Streamers in Deionized Water. IEEE Trans. Plasma Sci. 2011, 39, 2632–2633. [Google Scholar] [CrossRef]

- Korobeynikov, S.M.; Melekhov, A.V.; Posukh, V.G.; Ponomarenko, A.G.; Boyarintsev, E.L.; Antonov, V.M. Optical study of prebreakdown cathode processes in deionized water. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 504–508. [Google Scholar] [CrossRef]

- Linhjell, D.; Lundgaard, L.; Berg, G. Streamer propagation under impulse voltage in long point-plane oil gaps. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 447–458. [Google Scholar] [CrossRef]

- Du, Y.; Lv, Y.; Li, C.; Chen, M.; Zhong, Y.; Zhang, S.; Zhou, Y. Effect of nanoparticles on charge transport in nanofluid-impregnated pressboard. J. Appl. Phys. 2012, 111, 124322. [Google Scholar] [CrossRef]

- Ge, Y.; Lv, Y.Z.; Han, Q.B.; Sun, Q.; Yuan, J.S. Effects of TiO2 Nanoparticles on Streamer Propagation at the Surface of Oil-Impregnated Insulation Paper. IEEE Trans. Plasma Sci. 2018, 99, 1–6. [Google Scholar] [CrossRef]

- Sima, W.-X.; Cao, X.-F.; Yang, Q.; Song, H.; Shi, J. Preparation of Three Transformer Oil-Based Nanofluids and Comparison of Their Impulse Breakdown Characteristics. Nanosci. Nanotechnol. Lett. 2014, 6, 250–256. [Google Scholar] [CrossRef]

- Shi, J.; Yang, Q.; Sima, W.X.; Yu, F. Surface Modification of Nanoparticle and Its Charging Dynamics During Streamer Discharge in Transformer Oil. Nanosci. Nanotechnol. Lett. 2014, 6, 424–430. [Google Scholar]

- Gao, M.; Li, G.-F.; Li, J.-Z.; Zhao, Z.-G. The temperature dependence of insulation characteristics of transformer oil at low temperatures. In Proceedings of the IEEE Power Engineering and Automation Conference, Wuhan, China, 8–9 September 2011; Volume 2, pp. 27–30. [Google Scholar]

- Hou, Y.-P.; Zhang, Z.-C.; Zhang, J.-D. Significantly Enhanced Impulse Breakdown Performances of Propylene Carbonate Modified by TiO2 Nano-particles. Chem. Phys. Lett. 2016, 662, 192–195. [Google Scholar] [CrossRef]

- Hou, Y.-P.; Zhang, Z.-C.; Zhang, J.-D.; Liu, Z.-F.; Song, Z.-Y. Effect of BaTiO3 nano-particles on breakdown performance of propylene carbonate. Rev. Sci. Instrum. 2015, 86, 241–248. [Google Scholar] [CrossRef]

- Hou, Y.-P.; Zhang, Z.-C.; Zhang, J.-D.; Wang, Z.; Liu, H.-W. Experimental investigations into the enhanced dielectric breakdown performances of propylene carbonate modified by TiO2 nano-particles. IEEE Trans. Dielectr. Electr. Insul. 2016, 23, 2816–2821. [Google Scholar] [CrossRef]

- Hou, Y.-P.; Zhang, J.-D.; Zhang, Z.C.; Wang, Z.; Song, Z.-Y. Experimental study on breakdown characteristics of propylene carbonate-based nano-fluids under microsecond pulses. In Proceedings of the IEEE Pulsed Power Conference, Austin, TX, USA, 31 May–4 June 2015; Volume 133, pp. 1–5. [Google Scholar]

- Laurent, C.; Chauvet, C. The significance of the Weibull threshold in short-term breakdown statistics. IEEE Trans. Dielectr. Electr. Insul. 1994, 1, 160–162. [Google Scholar] [CrossRef]

- Wilson, M.P.; Given, M.J.; Timoshkin, I.V.; MacGregor, S.J.; Wang, T.; Sinclair, M.A.; Thomas, K.J.; Lehr, J.M. Impulse-driven surface breakdown data: A weibull statistical analysis. IEEE Trans. Plasma Sci. 2012, 40, 2449–2456. [Google Scholar] [CrossRef]

- Hashemi, R.; Nassar, N.N.; Almao, P.P. Nanoparticle technology for heavy oil in-situ upgrading and recovery enhancement: Opportunities and challenges. IEEE Trans. Dielectr. Electr. Insul. 2014, 133, 374–387. [Google Scholar] [CrossRef]

- Qian, J.; Joshi, R.P.; Schamiloglu, E.; Gaudet, J.; Woodworth, J.R.; Lehr, J. Analysis of polarity effects in the electrical breakdown of liquids. IEEE Trans. Plasma Sci. 2006, 39, 359. [Google Scholar] [CrossRef]

- Adamczyk, Z.; Weronski, P. Application of the DLVO theory for particle deposition problems. Adv. Colloid. Interfac. 1999, 83, 137–226. [Google Scholar] [CrossRef]

- Jadidian, J.; Zahn, M.; Lavesson, N.; Widlund, O.; Borg, K. Stochastic and deterministic causes of streamer branching in liquid dielectrics. J. Appl. Phys. 2013, 114, 6–17. [Google Scholar] [CrossRef]

- Luque, A.; Ebert, U. Electron density fluctuations accelerate the branching of positive streamer discharges in air. Phys. Rev. E 2011, 84, 046411. [Google Scholar] [CrossRef]

- Vega, F.; Pérez, A.T. Corona-induced electrohydrodynamic instabilities in low conducting liquids. Exp. Fluids 2003, 34, 726–735. [Google Scholar] [CrossRef]

| Volume Fractions | (kV/cm) | (kV/cm) | ||

|---|---|---|---|---|

| 0% | 670.6 | 670.6 | 0% | 0% |

| 0.2% | 686.2 | 704.6 | 2% | 5% |

| 0.4% | 741.9 | 729.9 | 11% | 9% |

| 0.6% | 791.5 | 790.3 | 18% | 18% |

| 0.8% | 761.7 | 770.7 | 14% | 15% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Zhang, Z.; Liu, S.; Li, S. The Modification Mechanism of Nano-Liquids on Streamer Morphology and Breakdown Strength under Microsecond Pulse. Appl. Sci. 2020, 10, 7376. https://doi.org/10.3390/app10207376

Li D, Zhang Z, Liu S, Li S. The Modification Mechanism of Nano-Liquids on Streamer Morphology and Breakdown Strength under Microsecond Pulse. Applied Sciences. 2020; 10(20):7376. https://doi.org/10.3390/app10207376

Chicago/Turabian StyleLi, Diangeng, Zicheng Zhang, Shifei Liu, and Song Li. 2020. "The Modification Mechanism of Nano-Liquids on Streamer Morphology and Breakdown Strength under Microsecond Pulse" Applied Sciences 10, no. 20: 7376. https://doi.org/10.3390/app10207376

APA StyleLi, D., Zhang, Z., Liu, S., & Li, S. (2020). The Modification Mechanism of Nano-Liquids on Streamer Morphology and Breakdown Strength under Microsecond Pulse. Applied Sciences, 10(20), 7376. https://doi.org/10.3390/app10207376