3D and 4D Printing of Multistable Structures

Abstract

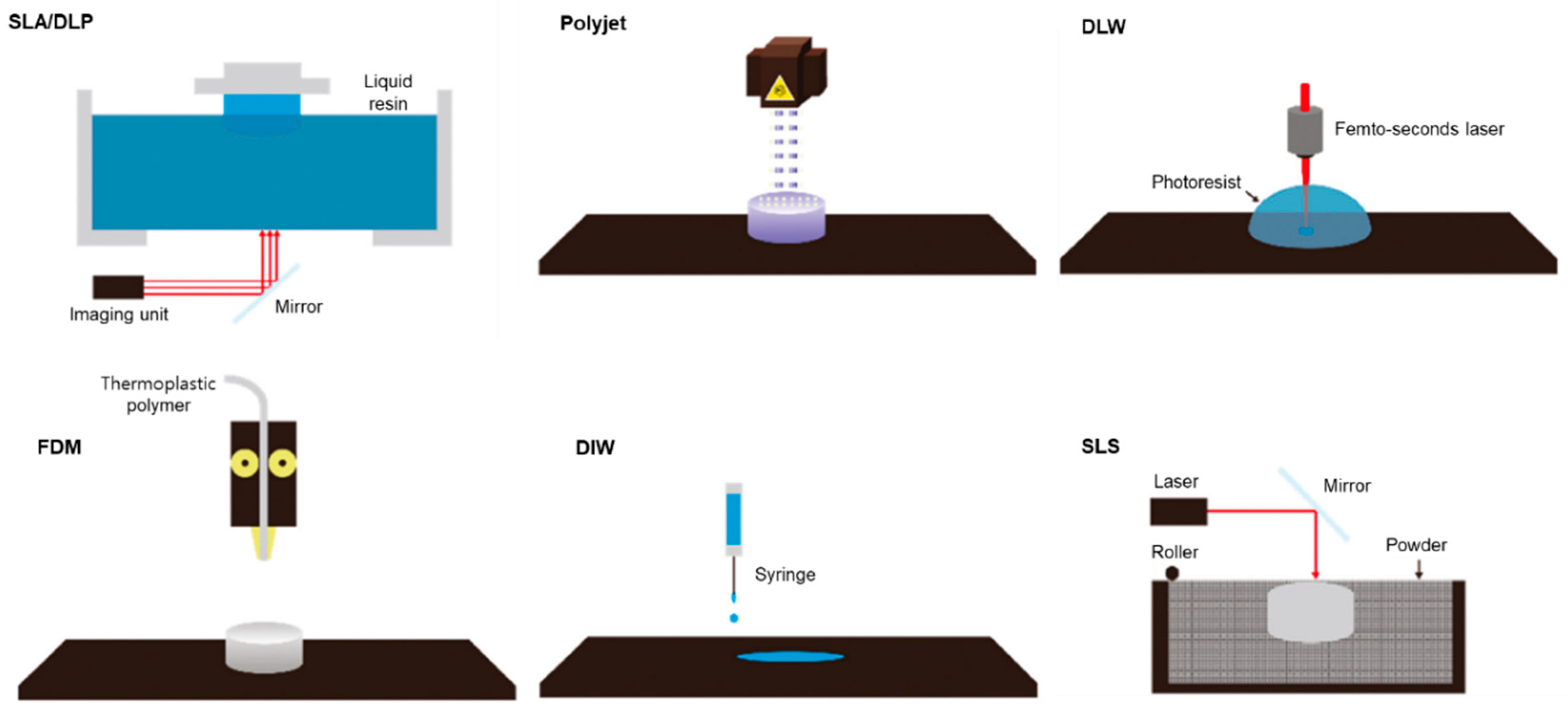

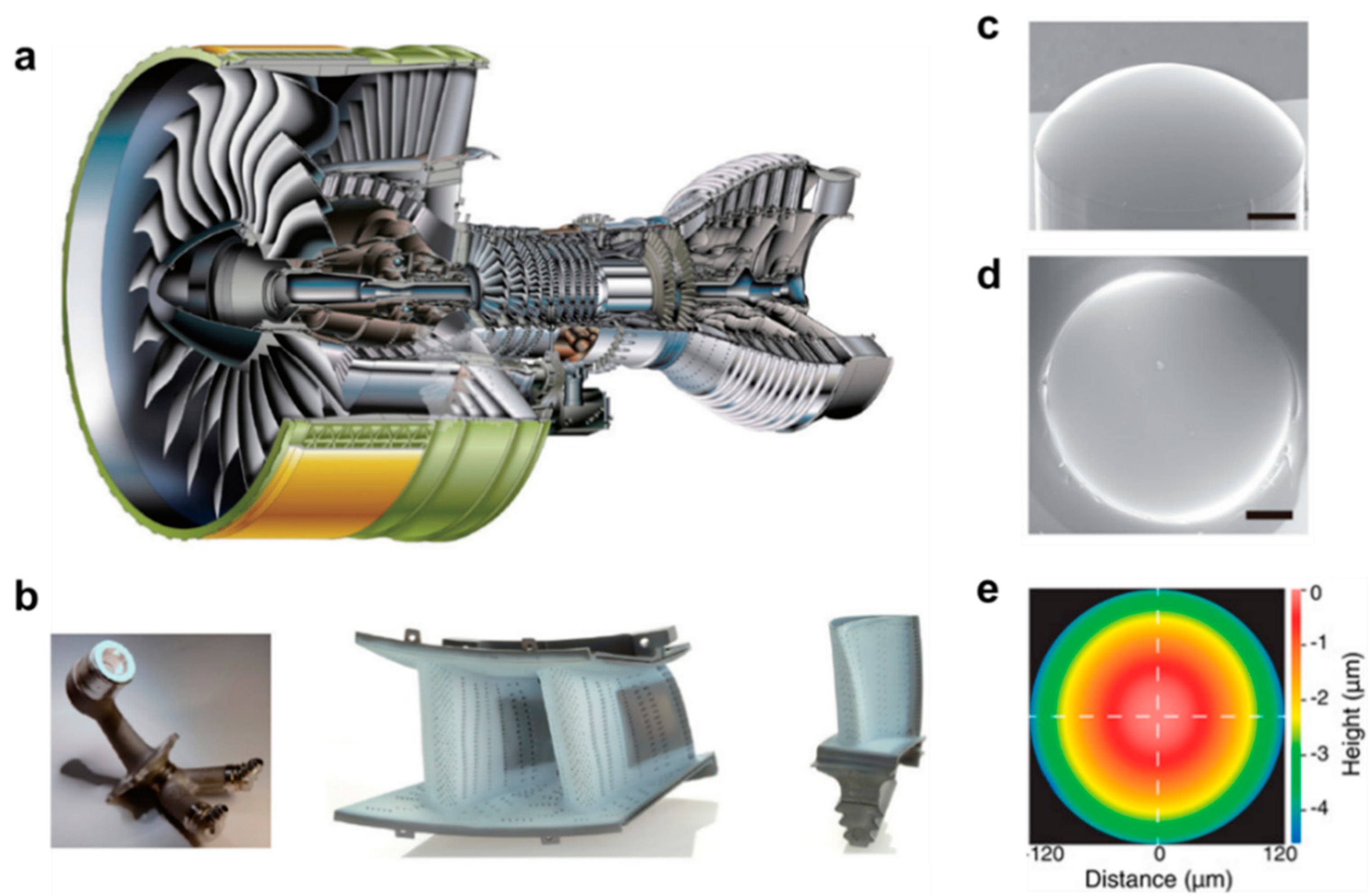

1. Introduction

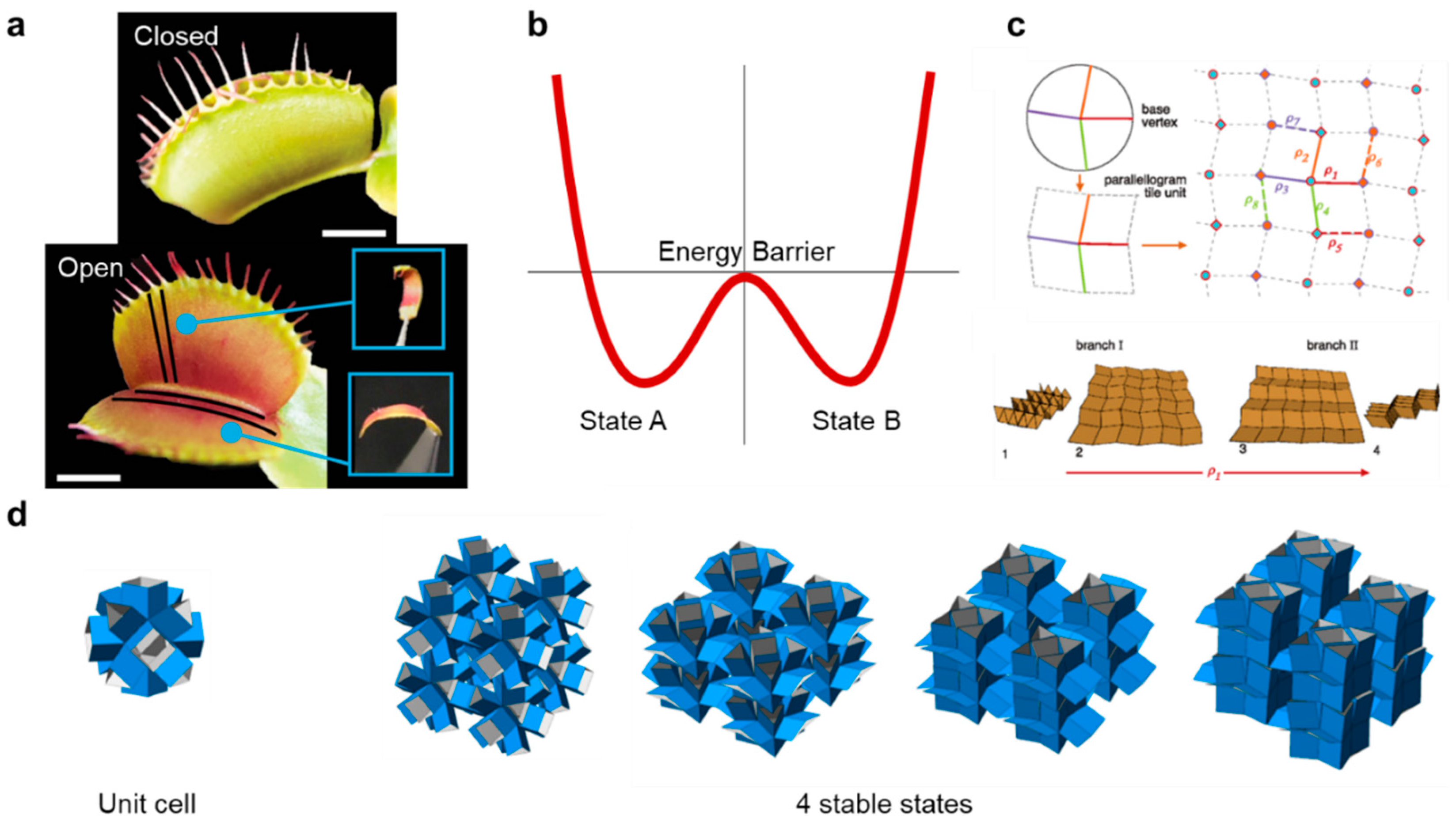

2. 3D Printing of Mechanical Multistable Structures

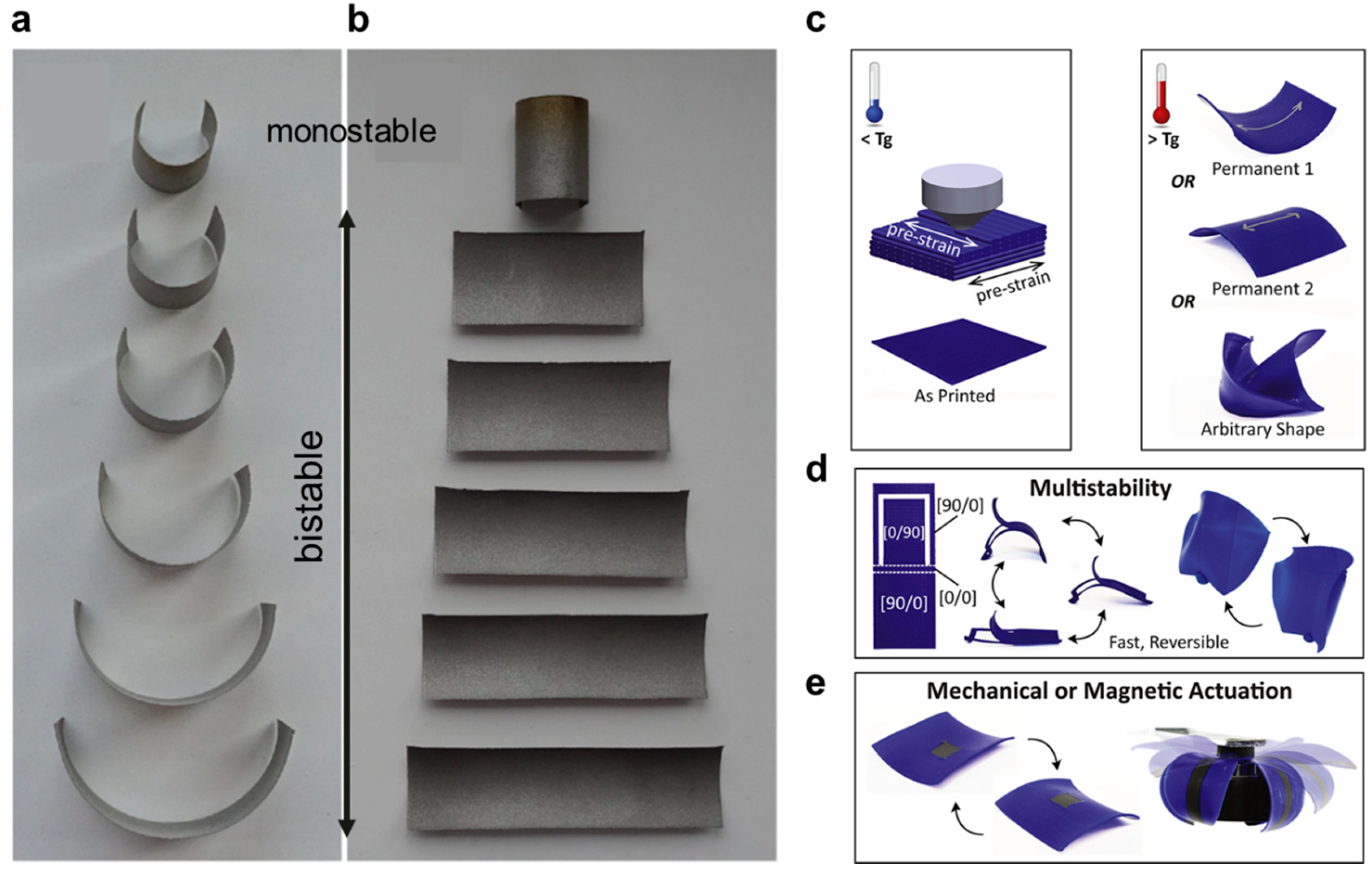

2.1. Strained Layer

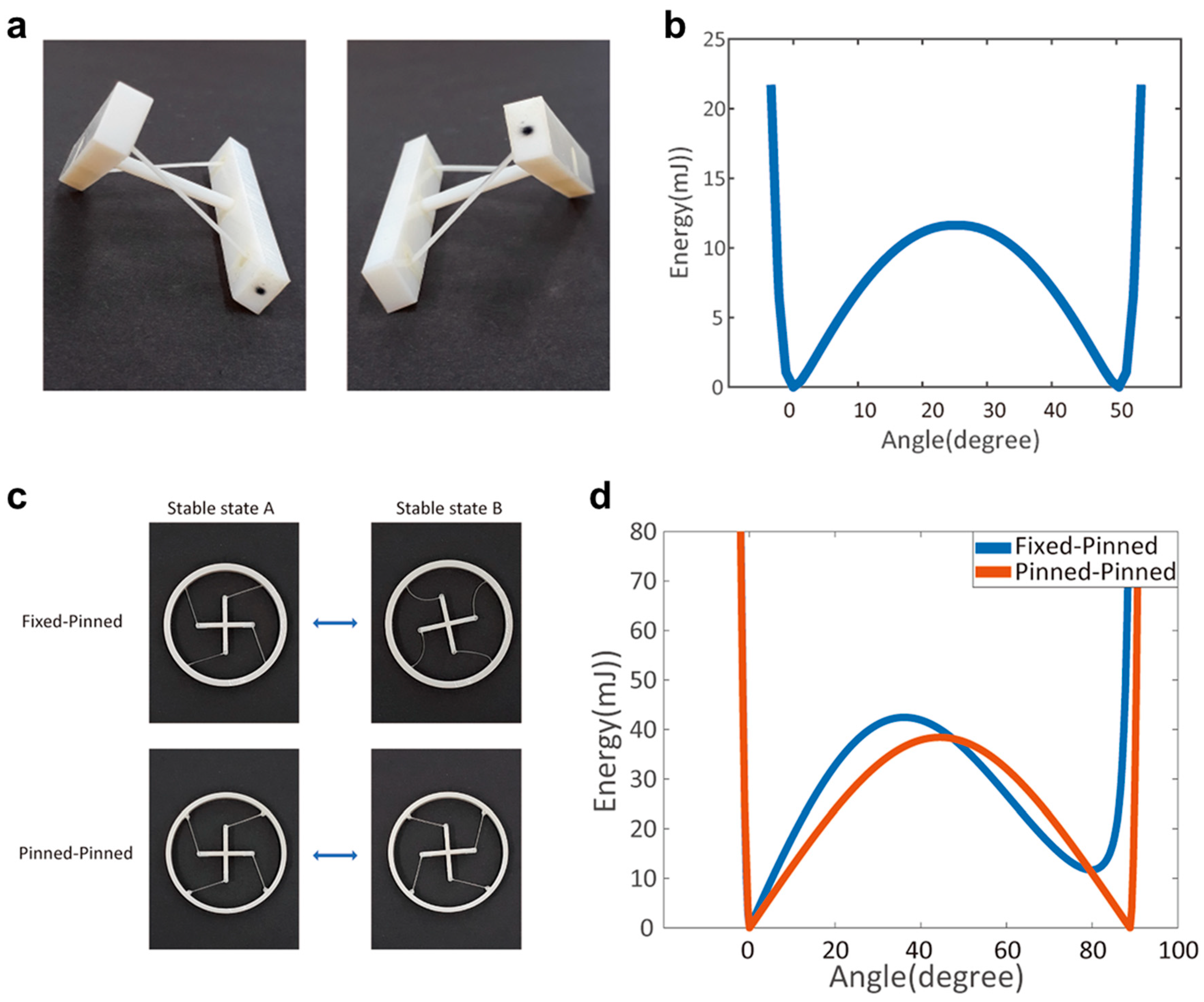

2.2. Compliant Mechanism

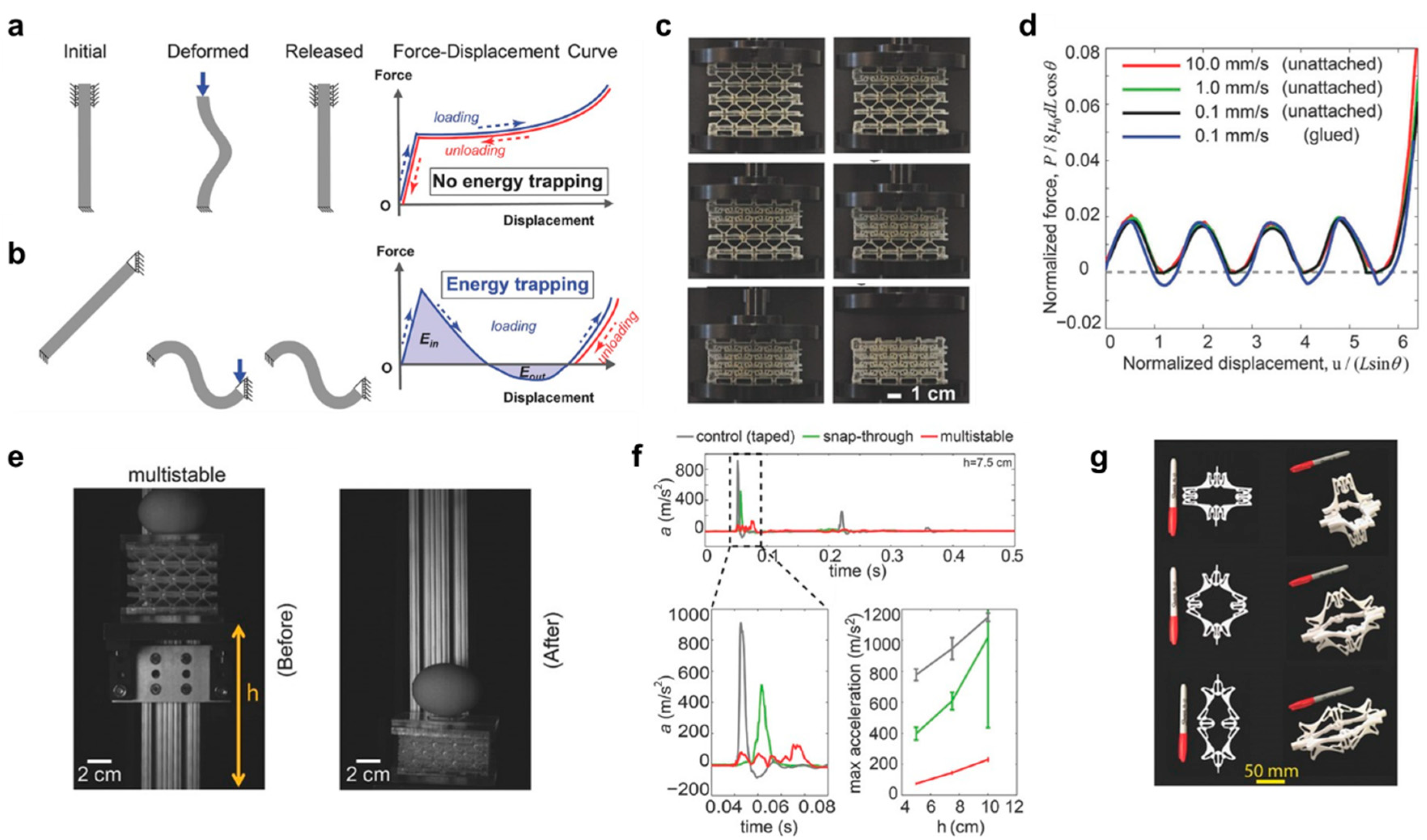

2.3. Mechanical Metamaterial

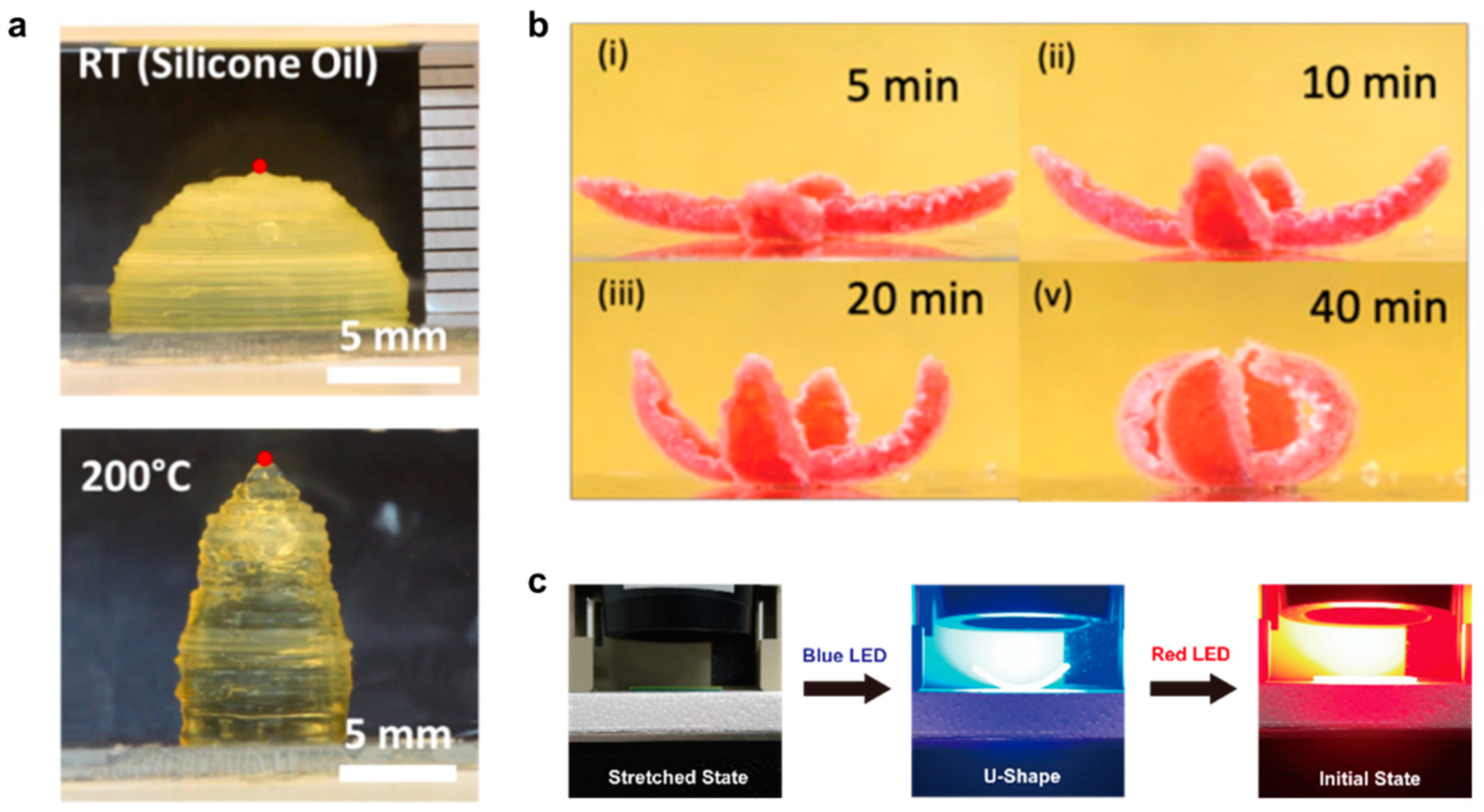

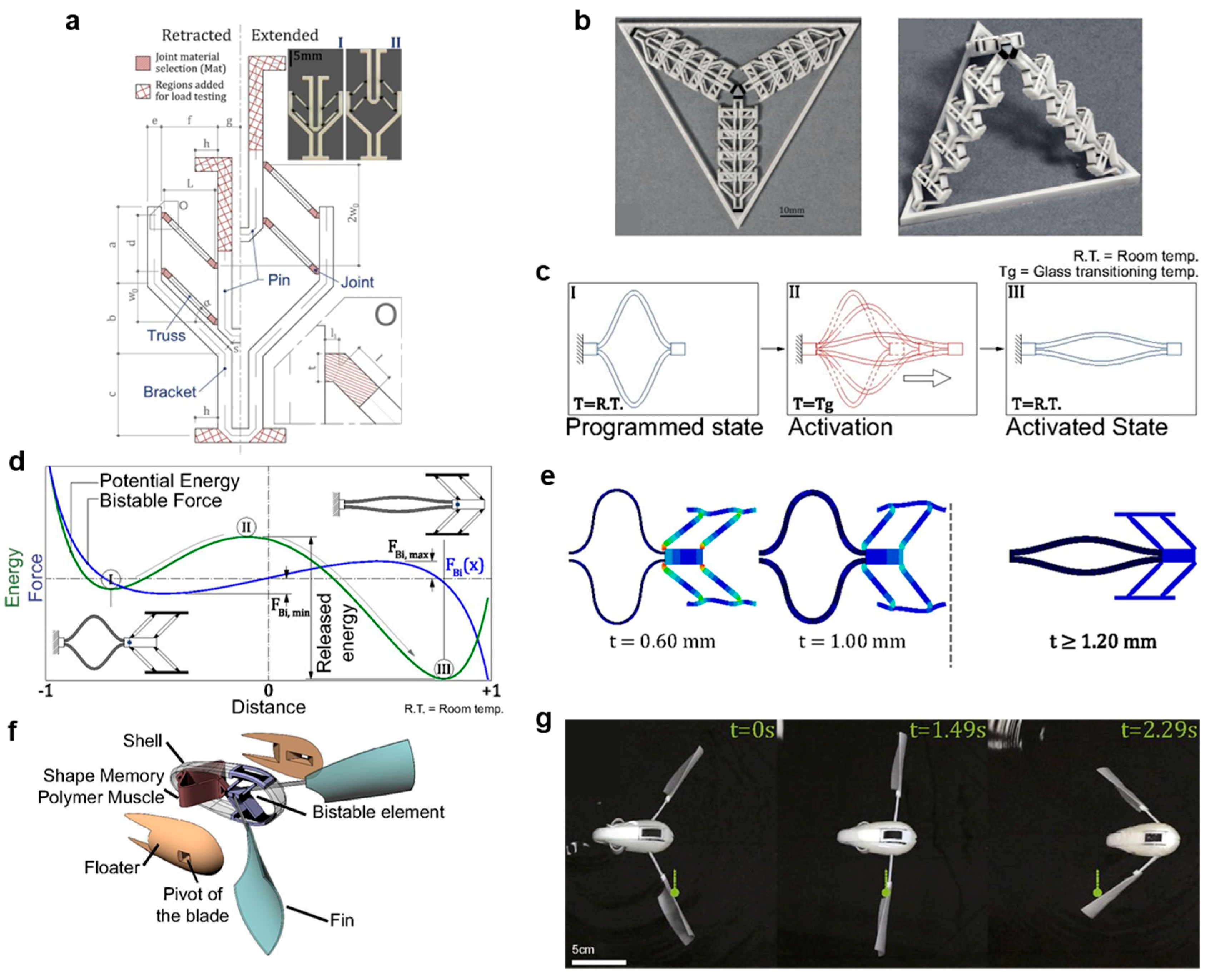

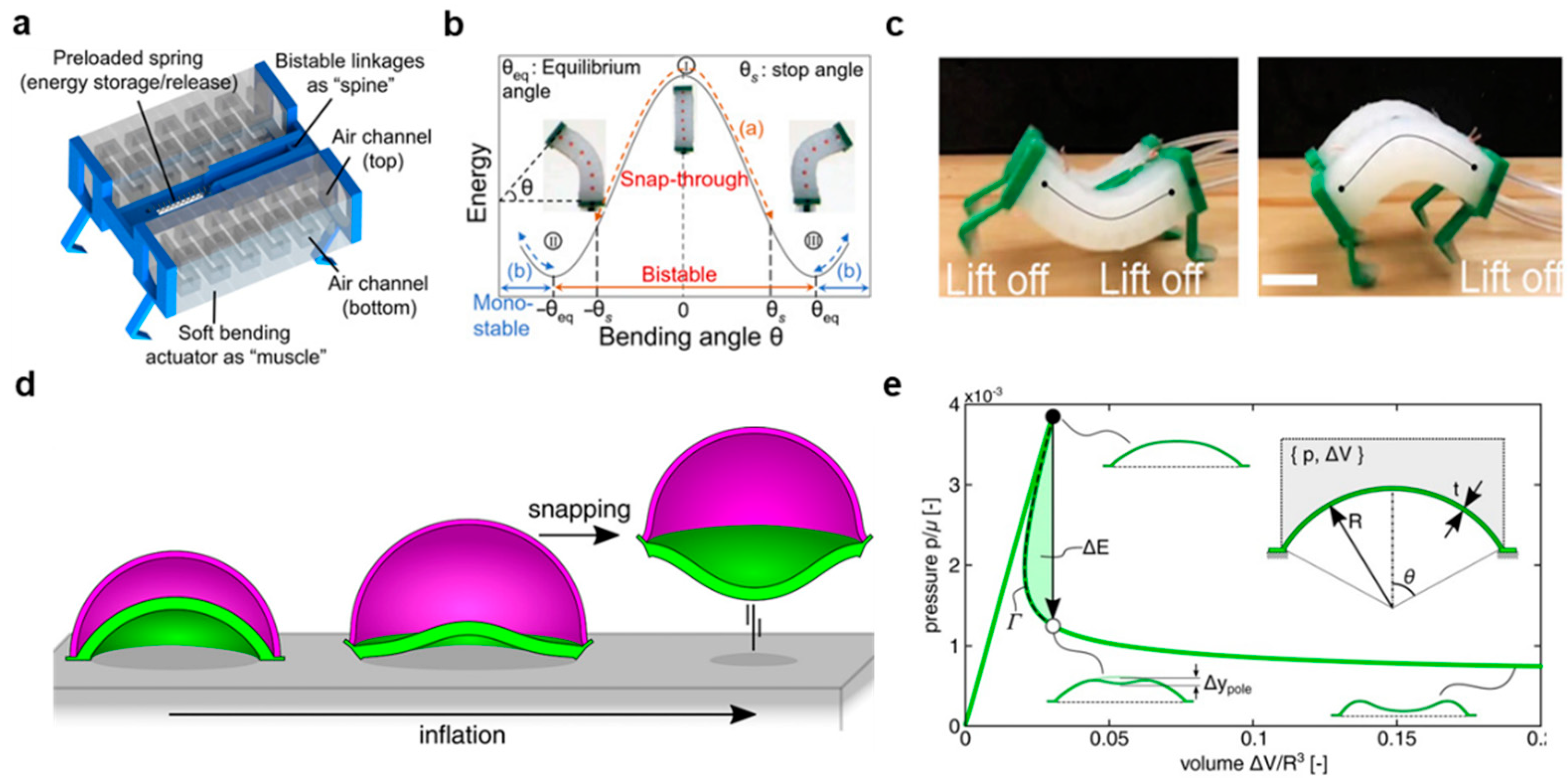

3. 4D Printing of Multistable Structures

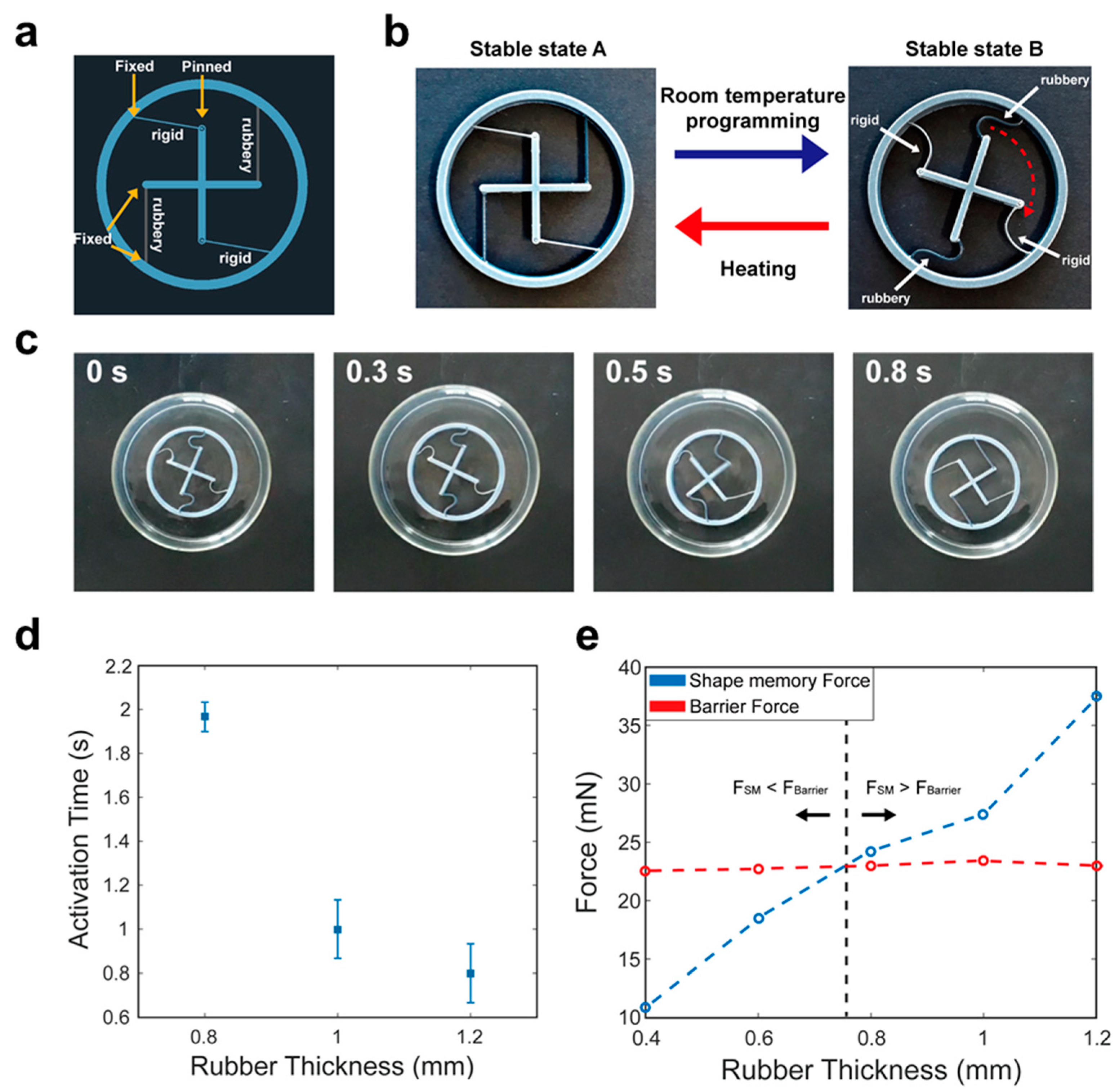

3.1. Heat-Responsive Structures

3.2. Solvent-Responsive Structures

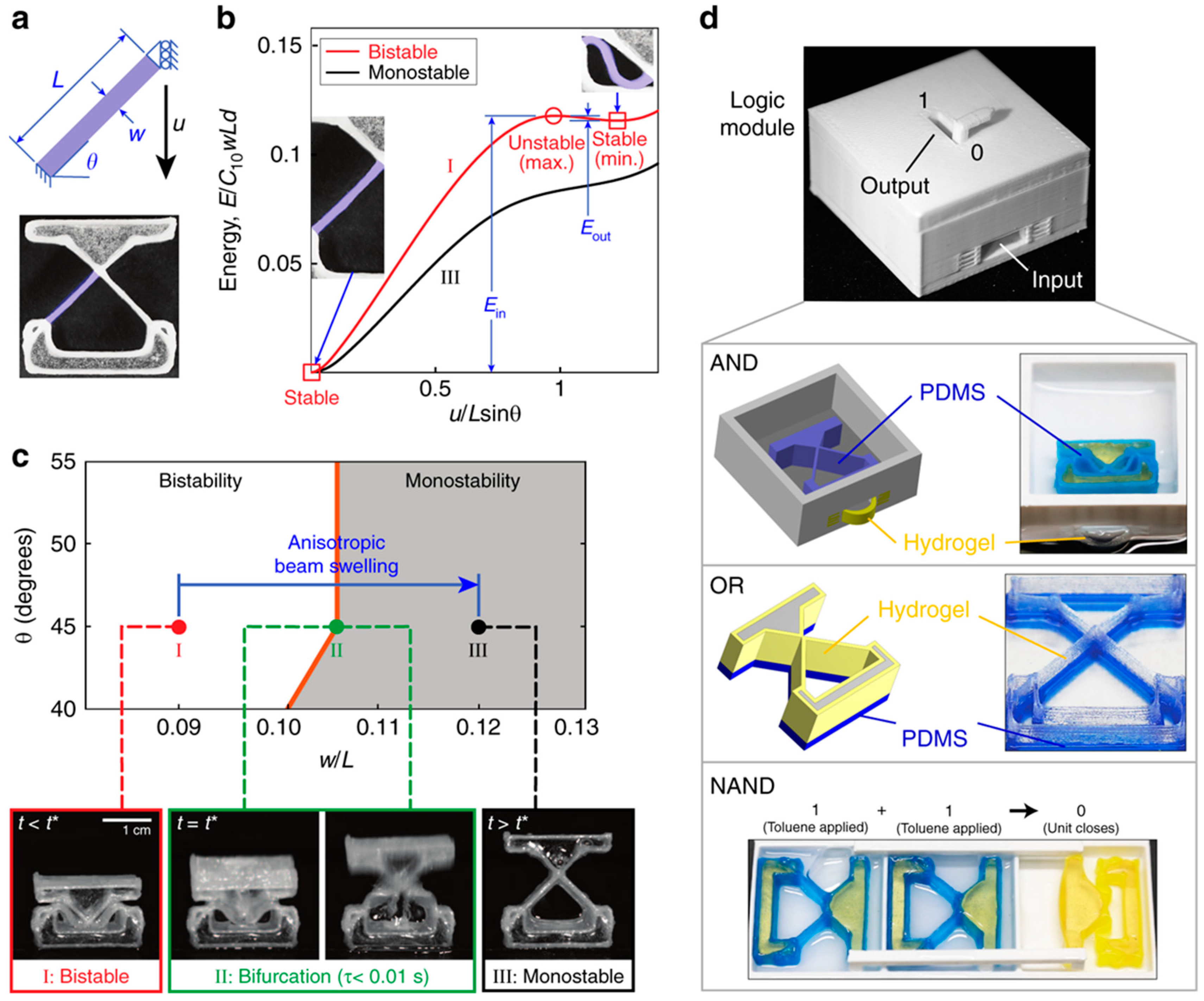

4. Conclusions and Future Prospects

Author Contributions

Funding

Conflicts of Interest

References

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The status, challenges, and future of additive manufacturing in engineering. Comput.-Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- Bose, S.; Vahabzadeh, S.; Bandyopadhyay, A. Bone tissue engineering using 3D printing. Mater. Today 2013, 16, 496–504. [Google Scholar] [CrossRef]

- Ma, H.; Feng, C.; Chang, J.; Wu, C. 3D-printed bioceramic scaffolds: From bone tissue engineering to tumor therapy. Acta Biomater. 2018, 79, 37–59. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yang, M.; Zhu, Y.; Wang, L.; Tomsia, A.P.; Mao, C. Phage nanofibers induce vascularized osteogenesis in 3D printed bone scaffolds. Adv. Mater. 2014, 26, 4961–4966. [Google Scholar] [CrossRef]

- Yan, Y.; Chen, H.; Zhang, H.; Guo, C.; Yang, K.; Chen, K.; Cheng, R.; Qian, N.; Sandler, N.; Zhang, Y.S. Vascularized 3D printed scaffolds for promoting bone regeneration. Biomaterials 2019, 190, 97–110. [Google Scholar] [CrossRef]

- Hull, C.W. Apparatus for Production of Three-Dimensional Objects by Stereolithography. U.S. Patent US4575330A, 8 August 1984. [Google Scholar]

- Han, P.L. Additive Design and Manufacturing of Jet Engine Parts. Engineering 2017, 3, 648–652. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Lee, E.; An, S.C.; Lim, Y.; Jun, Y.C. 3D and 4D printing for optics and metaphotonics. Nanophotonics 2020, 9, 1139–1160. [Google Scholar] [CrossRef]

- Suszek, J.; Siemion, A.; Bieda, M.S.; Błocki, N.; Coquillat, D.; Cywiński, G.; Czerwińska, E.; Doch, M.; Kowalczyk, A.; Palka, N. 3-D-printed flat optics for THz linear scanners. IEEE Trans. Terahertz Sci. Technol. 2015, 5, 314–316. [Google Scholar] [CrossRef]

- Udofia, E.N.; Zhou, W. 3D Printed optics with a soft and stretchable optical material. Addit. Manuf. 2020, 31, 100912. [Google Scholar]

- López-Valdeolivas, M.; Liu, D.; Broer, D.J.; Sánchez-Somolinos, C. 4D printed actuators with soft-robotic functions. Macromol. Rapid Commun. 2018, 39, 1700710. [Google Scholar] [CrossRef]

- Vaidya, N.; Solgaard, O. 3D printed optics with nanometer scale surface roughness. Microsyst. Nanoeng. 2018, 4, 18. [Google Scholar] [CrossRef]

- Shao, G.; Hai, R.; Sun, C. 3D Printing Customized Optical Lens in Minutes. Adv. Opt. Mater. 2020, 8, 1901646. [Google Scholar] [CrossRef]

- Tibbits, S. The emergence of “4D printing”. TED Conf. 2013. [Google Scholar]

- Tibbits, S. 4D printing: Multi-material shape change. Archit. Des. 2014, 84, 116–121. [Google Scholar] [CrossRef]

- Yuan, C.; Roach, D.J.; Dunn, C.K.; Mu, Q.; Kuang, X.; Yakacki, C.M.; Wang, T.; Yu, K.; Qi, H.J. 3D printed reversible shape changing soft actuators assisted by liquid crystal elastomers. Soft Matter 2017, 13, 5558–5568. [Google Scholar] [CrossRef]

- Saed, M.O.; Ambulo, C.P.; Kim, H.; De, R.; Raval, V.; Searles, K.; Siddiqui, D.A.; Cue, J.M.O.; Stefan, M.C.; Shankar, M.R. Molecularly-Engineered, 4D-Printed Liquid Crystal Elastomer Actuators. Adv. Funct. Mater. 2019, 29, 1806412. [Google Scholar] [CrossRef]

- Ahn, C.; Liang, X.; Cai, S. Bioinspired design of light-powered crawling, squeezing, and jumping untethered soft robot. Adv. Mater. Technol. 2019, 4, 1900185. [Google Scholar] [CrossRef]

- Bakarich, S.E.; Gorkin, R., III; Panhuis, M.I.H.; Spinks, G.M. 4D printing with mechanically robust, thermally actuating hydrogels. Macromol. Rapid Commun. 2015, 36, 1211–1217. [Google Scholar] [CrossRef]

- Gladman, A.S.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D printing. Nat. Mater. 2016, 15, 413–418. [Google Scholar] [CrossRef]

- Huang, L.; Jiang, R.; Wu, J.; Song, J.; Bai, H.; Li, B.; Zhao, Q.; Xie, T. Ultrafast digital printing toward 4D shape changing materials. Adv. Mater. 2017, 29, 1605390. [Google Scholar] [CrossRef]

- Ge, Q.; Qi, H.J.; Dunn, M.L. Active materials by four-dimension printing. Appl. Phys. Lett. 2013, 103, 131901. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, C.; Ding, Z.; Isakov, M.; Mao, Y.; Wang, T.; Dunn, M.L.; Qi, H.J. Multi-shape active composites by 3D printing of digital shape memory polymers. Sci. Rep. 2016, 6, 24224. [Google Scholar] [CrossRef]

- Ding, Z.; Yuan, C.; Peng, X.; Wang, T.; Qi, H.J.; Dunn, M.L. Direct 4D printing via active composite materials. Sci. Adv. 2017, 3, e1602890. [Google Scholar] [CrossRef]

- Zhang, Q.; Yan, D.; Zhang, K.; Hu, G. Pattern transformation of heat-shrinkable polymer by three-dimensional (3D) printing technique. Sci. Rep. 2015, 5, 8936. [Google Scholar] [CrossRef]

- Raviv, D.; Zhao, W.; McKnelly, C.; Papadopoulou, A.; Kadambi, A.; Shi, B.; Hirsch, S.; Dikovsky, D.; Zyracki, M.; Olguin, C. Active printed materials for complex self-evolving deformations. Sci. Rep. 2014, 4, 7422. [Google Scholar] [CrossRef] [PubMed]

- Kuksenok, O.; Balazs, A.C. Stimuli-responsive behavior of composites integrating thermo-responsive gels with photo-responsive fibers. Mater. Horiz. 2016, 3, 53–62. [Google Scholar] [CrossRef]

- Yang, H.; Leow, W.R.; Wang, T.; Wang, J.; Yu, J.; He, K.; Qi, D.; Wan, C.; Chen, X. 3D printed photoresponsive devices based on shape memory composites. Adv. Mater. 2017, 29, 1701627. [Google Scholar] [CrossRef] [PubMed]

- Nadgorny, M.; Xiao, Z.; Chen, C.; Connal, L.A. Three-dimensional printing of pH-responsive and functional polymers on an affordable desktop printer. ACS Appl. Mater. Interfaces 2016, 8, 28946–28954. [Google Scholar] [CrossRef] [PubMed]

- Ambulo, C.P.; Burroughs, J.J.; Boothby, J.M.; Kim, H.; Shankar, M.R.; Ware, T.H. Four-dimensional printing of liquid crystal elastomers. ACS Appl. Mater. Interfaces 2017, 9, 37332–37339. [Google Scholar] [CrossRef] [PubMed]

- Shiblee, M.N.I.; Ahmed, K.; Kawakami, M.; Furukawa, H. 4D Printing of Shape-Memory Hydrogels for Soft-Robotic Functions. Adv. Mater. Technol. 2019, 4, 1900071. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Woo, B.H.; Kim, N.; Jun, Y.C. Multicolor 4D printing of shape-memory polymers for light-induced selective heating and remote actuation. Sci. Rep. 2020, 10, 6258. [Google Scholar] [CrossRef]

- Yang, C.; Boorugu, M.; Dopp, A.; Ren, J.; Martin, R.; Han, D.; Choi, W.; Lee, H. 4D printing reconfigurable, deployable and mechanically tunable metamaterials. Mater. Horiz. 2019, 6, 1244–1250. [Google Scholar] [CrossRef]

- Akbari, S.; Sakhaei, A.H.; Kowsari, K.; Yang, B.; Serjouei, A.; Yuanfang, Z.; Ge, Q. Enhanced multimaterial 4D printing with active hinges. Smart Mater. Struct. 2018, 27, 065027. [Google Scholar] [CrossRef]

- Chen, T.; Mueller, J.; Shea, K. Integrated design and simulation of tunable, multi-state structures fabricated monolithically with multi-material 3D printing. Sci. Rep. 2017, 7, 45671. [Google Scholar] [CrossRef] [PubMed]

- Lunni, D.; Cianchetti, M.; Filippeschi, C.; Sinibaldi, E.; Mazzolai, B. Plant-Inspired Soft Bistable Structures Based on Hygroscopic Electrospun Nanofibers. Adv. Mater. Interfaces 2020, 7, 8. [Google Scholar] [CrossRef]

- Waitukaitis, S.; Menaut, R.; Chen, B.G.-g.; van Hecke, M. Origami multistability: From single vertices to metasheets. Phys. Rev. Lett. 2015, 114, 055503. [Google Scholar] [CrossRef]

- Dudte, L.H.; Vouga, E.; Tachi, T.; Mahadevan, L. Programming curvature using origami tessellations. Nat. Mater. 2016, 15, 583–588. [Google Scholar] [CrossRef]

- Iniguez-Rabago, A.; Li, Y.; Overvelde, J.T. Exploring multistability in prismatic metamaterials through local actuation. Nat. Commun. 2019, 10, 5577. [Google Scholar] [CrossRef]

- Kebadze, E.; Guest, S.; Pellegrino, S. Bistable prestressed shell structures. Int. J. Solids Struct. 2004, 41, 2801–2820. [Google Scholar] [CrossRef]

- Wang, B.; Ge, C.; Fancey, K.S. Snap-through behaviour of a bistable structure based on viscoelastically generated prestress. Compos. B Eng. 2017, 114, 23–33. [Google Scholar] [CrossRef]

- Jiang, X.; Pezzulla, M.; Shao, H.; Ghosh, T.K.; Holmes, D.P. Snapping of bistable, prestressed cylindrical shells. EPL 2018, 122, 64003. [Google Scholar] [CrossRef]

- Hu, N.; Han, X.; Huang, S.; Grover, H.; Yu, X.; Zhang, L.; Trase, I.; Zhang, J.; Zhang, L.; Dong, L. Edge effect of strained bilayer nanofilms for tunable multistability and actuation. Nanoscale 2017, 9, 2958–2962. [Google Scholar] [CrossRef]

- Loukaides, E.G.; Lewis, R.W.; Bowen, C.R. Additive manufacture of multistable structures. Smart Mater. Struct. 2019, 28, 02LT02. [Google Scholar] [CrossRef]

- Riley, K.S.; Ang, K.J.; Martin, K.A.; Chan, W.K.; Faber, J.A.; Arrieta, A.F. Encoding multiple permanent shapes in 3D printed structures. Mater. Des. 2020, 194, 108888. [Google Scholar] [CrossRef]

- An, S.C.; Lee, E.; Lee, C.H.; Jeong, H.Y.; Kwon, T.S.; Lee, J.H.; Jun, Y.C. Sharp Fano Resonance and Spectral Collapse in Stimuli-Responsive Photonic Structures. Adv. Opt. Mater. 2019, 7, 1801206. [Google Scholar] [CrossRef]

- Hussein, H.; Younis, M.I. Analytical study of the snap-through and bistability of beams with arbitrarily initial shape. J. Mech. Robot. 2020, 12, 041001. [Google Scholar] [CrossRef]

- Ma, F.; Chen, G.; Wang, H. Large-Stroke Constant-Force Mechanisms Utilizing Second Buckling Mode of Flexible Beams: Evaluation Metrics and Design Approach. J. Mech. Des. 2020, 142, 103303. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, X.; Zhang, H.; Zhu, B.; Chen, B. Topology optimization of bistable mechanisms with maximized differences between switching forces in forward and backward direction. Mech. Mach. Theory 2019, 139, 131–143. [Google Scholar] [CrossRef]

- Chen, G.; Ma, F.; Hao, G.; Zhu, W. Modeling large deflections of initially curved beams in compliant mechanisms using chained beam constraint model. J. Mech. Robot. 2019, 11, 011002. [Google Scholar] [CrossRef]

- Chen, G.; Han, Q.; Jin, K. A Fully Compliant Tristable Mechanism Employing Both Tensural and Compresural Segments. J. Mech. Robot. 2020, 12, 011003. [Google Scholar] [CrossRef]

- Chen, G.; Gou, Y.; Zhang, A. Synthesis of compliant multistable mechanisms through use of a single bistable mechanism. J. Mech. Des. 2011, 133, 081007. [Google Scholar] [CrossRef]

- Jeong, H.Y.; An, S.-C.; Seo, I.C.; Lee, E.; Ha, S.; Kim, N.; Jun, Y.C. 3D printing of twisting and rotational bistable structures with tuning elements. Sci. Rep. 2019, 9, 324. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L. Angle-Dependent Transitions Between Structural Bistability and Multistability. Adv. Eng. Mater. 2020, 22, 1900871. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L. Multi-stable mechanical metamaterials with shape-reconfiguration and zero Poisson’s ratio. Mater. Des. 2018, 152, 181–190. [Google Scholar] [CrossRef]

- Yang, H.; Ma, L. Multi-stable mechanical metamaterials by elastic buckling instability. J. Mater. Sci. 2019, 54, 3509–3526. [Google Scholar] [CrossRef]

- Shan, S.; Kang, S.H.; Raney, J.R.; Wang, P.; Fang, L.; Candido, F.; Lewis, J.A.; Bertoldi, K. Multistable architected materials for trapping elastic strain energy. Adv. Mater. 2015, 27, 4296–4301. [Google Scholar] [CrossRef]

- Che, K.; Yuan, C.; Wu, J.; Qi, H.J.; Meaud, J. Three-dimensional-printed multistable mechanical metamaterials with a deterministic deformation sequence. J. Appl. Mech. 2017, 84, 011004. [Google Scholar] [CrossRef]

- Che, K.; Yuan, C.; Qi, H.J.; Meaud, J. Viscoelastic multistable architected materials with temperature-dependent snapping sequence. Soft Matter 2018, 14, 2492–2499. [Google Scholar] [CrossRef]

- Haghpanah, B.; Salari-Sharif, L.; Pourrajab, P.; Hopkins, J.; Valdevit, L. Multistable shape-reconfigurable architected materials. Adv. Mater. 2016, 28, 7915–7920. [Google Scholar] [CrossRef]

- Chen, T.; Bilal, O.R.; Shea, K.; Daraio, C. Harnessing bistability for directional propulsion of soft, untethered robots. Proc. Natl. Acad. Sci. USA 2018, 115, 5698–5702. [Google Scholar] [CrossRef]

- Jeong, H.Y.; Lee, E.; Ha, S.; Kim, N.; Jun, Y.C. Multistable thermal actuators via multimaterial 4D printing. Adv. Mater. Technol. 2019, 4, 1800495. [Google Scholar] [CrossRef]

- Jiang, Y.; Korpas, L.M.; Raney, J.R. Bifurcation-based embodied logic and autonomous actuation. Nat. Commun. 2019, 10, 128. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Chi, Y.; Sun, J.; Huang, T.-H.; Maghsoudi, O.H.; Spence, A.; Zhao, J.; Su, H.; Yin, J. Leveraging elastic instabilities for amplified performance: Spine-inspired high-speed and high-force soft robots. Sci. Adv. 2020, 6, eaaz6912. [Google Scholar] [CrossRef]

- Gorissen, B.; Melancon, D.; Vasios, N.; Torbati, M.; Bertoldi, K. Inflatable soft jumper inspired by shell snapping. Sci. Robot. 2020, 5, eabb1967. [Google Scholar] [CrossRef]

- Fu, H.; Nan, K.; Bai, W.; Huang, W.; Bai, K.; Lu, L.; Zhou, C.; Liu, Y.; Liu, F.; Wang, J. Morphable 3D mesostructures and microelectronic devices by multistable buckling mechanics. Nat. Mater. 2018, 17, 268–276. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Tanaka, H. Rapid customization system for 3D-printed splint using programmable modeling technique—A practical approach. 3D Print. Med. 2018, 4, 5. [Google Scholar] [CrossRef]

- Guerra, A.J.; Cano, P.; Rabionet, M.; Puig, T.; Ciurana, J. 3D-Printed PCL/PLA Composite Stents: Towards a New Solution to Cardiovascular Problems. Materials 2018, 11, 1679. [Google Scholar] [CrossRef]

- Larush, L.; Kaner, I.; Fluksman, A.; Tamsut, A.; Pawar, A.A.; Lesnovski, P.; Benny, O.; Magdassi, S. 3D printing of responsive hydrogels for drug-delivery systems. J. 3D Print. Med. 2017, 1, 219–229. [Google Scholar] [CrossRef]

- Randall, C.L.; Gultepe, E.; Gracias, D.H. Self-folding devices and materials for biomedical applications. Trends Biotechnol. 2012, 30, 138–146. [Google Scholar] [CrossRef]

- Milazzo, M.; Negrini, N.C.; Scialla, S.; Marelli, B.; Farè, S.; Danti, S.; Buehler, M.J. Additive Manufacturing Approaches for Hydroxyapatite-Reinforced Composites. Adv. Funct. Mater. 2019, 29, 1903055. [Google Scholar] [CrossRef]

- Gao, B.; Yang, Q.; Zhao, X.; Jin, G.; Ma, Y.; Xu, F. 4D bioprinting for biomedical applications. Trends Biotechnol. 2016, 34, 746–756. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Li, Z.; Jiang, Z.; Yuan, D.; Huang, W.; Xia, A. Log-pile photonic crystal fabricated by two-photon photopolymerization. J. Opt. A Pure Appl. Opt. 2005, 7, 396–399. [Google Scholar] [CrossRef]

- Farsari, M.; Chichkov, B.N. Two-photon fabrication. Nat. Photonics 2009, 3, 450–452. [Google Scholar] [CrossRef]

- Ergin, T.; Stenger, N.; Brenner, P.; Pendry, J.B.; Wegener, M. Three-dimensional invisibility cloak at optical wavelengths. Science 2010, 328, 337–339. [Google Scholar] [CrossRef]

- Hahn, V.; Mayer, F.; Thiel, M.; Wegener, M. 3-D laser nanoprinting. Opt. Photonics News 2019, 30, 28–35. [Google Scholar] [CrossRef]

- Nocentini, S.; Riboli, F.; Burresi, M.; Martella, D.; Parmeggiani, C.; Wiersma, D.S. Three-dimensional photonic circuits in rigid and soft polymers tunable by light. ACS Photonics 2018, 5, 3222–3230. [Google Scholar] [CrossRef]

- Scarpa, E.; Lemma, E.D.; Fiammengo, R.; Cipolla, M.P.; Pisanello, F.; Rizzi, F.; De Vittorio, M. Microfabrication of pH-responsive 3D hydrogel structures via two-photon polymerization of high-molecular-weight poly (ethylene glycol) diacrylates. Sens. Actuators B Chem. 2019, 279, 418–426. [Google Scholar] [CrossRef]

- Tudor, A.; Delaney, C.; Zhang, H.; Thompson, A.J.; Curto, V.F.; Yang, G.-Z.; Higgins, M.J.; Diamond, D.; Florea, L. Fabrication of soft, stimulus-responsive structures with sub-micron resolution via two-photon polymerization of poly ionic liquids. Mater. Today 2018, 21, 807–816. [Google Scholar] [CrossRef]

- Lu, D.-X.; Zhang, Y.-L.; Han, D.-D.; Wang, H.; Xia, H.; Chen, Q.-D.; Ding, H.; Sun, H.-B. Solvent-tunable PDMS microlens fabricated by femtosecond laser direct writing. J. Mater. Chem. C 2015, 3, 1751–1756. [Google Scholar] [CrossRef]

| Name of the Scheme | Basic Cell and Principle | Key Feature | Printing Materials for Actuation | Actuation Stimulus | Ref. |

|---|---|---|---|---|---|

| Soft actuator | Bistable Von Mises truss (Figure 8a) | Sequential swimming in water | SMP | Heat | [61] |

| Rotational thermal actuator | Rotational compliant mechanism (Figure 6c and Figure 9a) | Room temperature programming | SMP | Heat | [62] |

| Logic operator | Constrained tilted elastic beam (Figure 7c and Figure 10a) | Logic operation with expandable bistable elements | PDMS, Hydrogel | Solvent (toluene, water) | [63] |

| Gripper | Strained bilayer (Figure 5e) | Gripping via thermomechanical and magnetic actuation | Iron/PLA | Magnetic field | [45] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, H.Y.; An, S.-C.; Lim, Y.; Jeong, M.J.; Kim, N.; Jun, Y.C. 3D and 4D Printing of Multistable Structures. Appl. Sci. 2020, 10, 7254. https://doi.org/10.3390/app10207254

Jeong HY, An S-C, Lim Y, Jeong MJ, Kim N, Jun YC. 3D and 4D Printing of Multistable Structures. Applied Sciences. 2020; 10(20):7254. https://doi.org/10.3390/app10207254

Chicago/Turabian StyleJeong, Hoon Yeub, Soo-Chan An, Yeonsoo Lim, Min Ji Jeong, Namhun Kim, and Young Chul Jun. 2020. "3D and 4D Printing of Multistable Structures" Applied Sciences 10, no. 20: 7254. https://doi.org/10.3390/app10207254

APA StyleJeong, H. Y., An, S.-C., Lim, Y., Jeong, M. J., Kim, N., & Jun, Y. C. (2020). 3D and 4D Printing of Multistable Structures. Applied Sciences, 10(20), 7254. https://doi.org/10.3390/app10207254