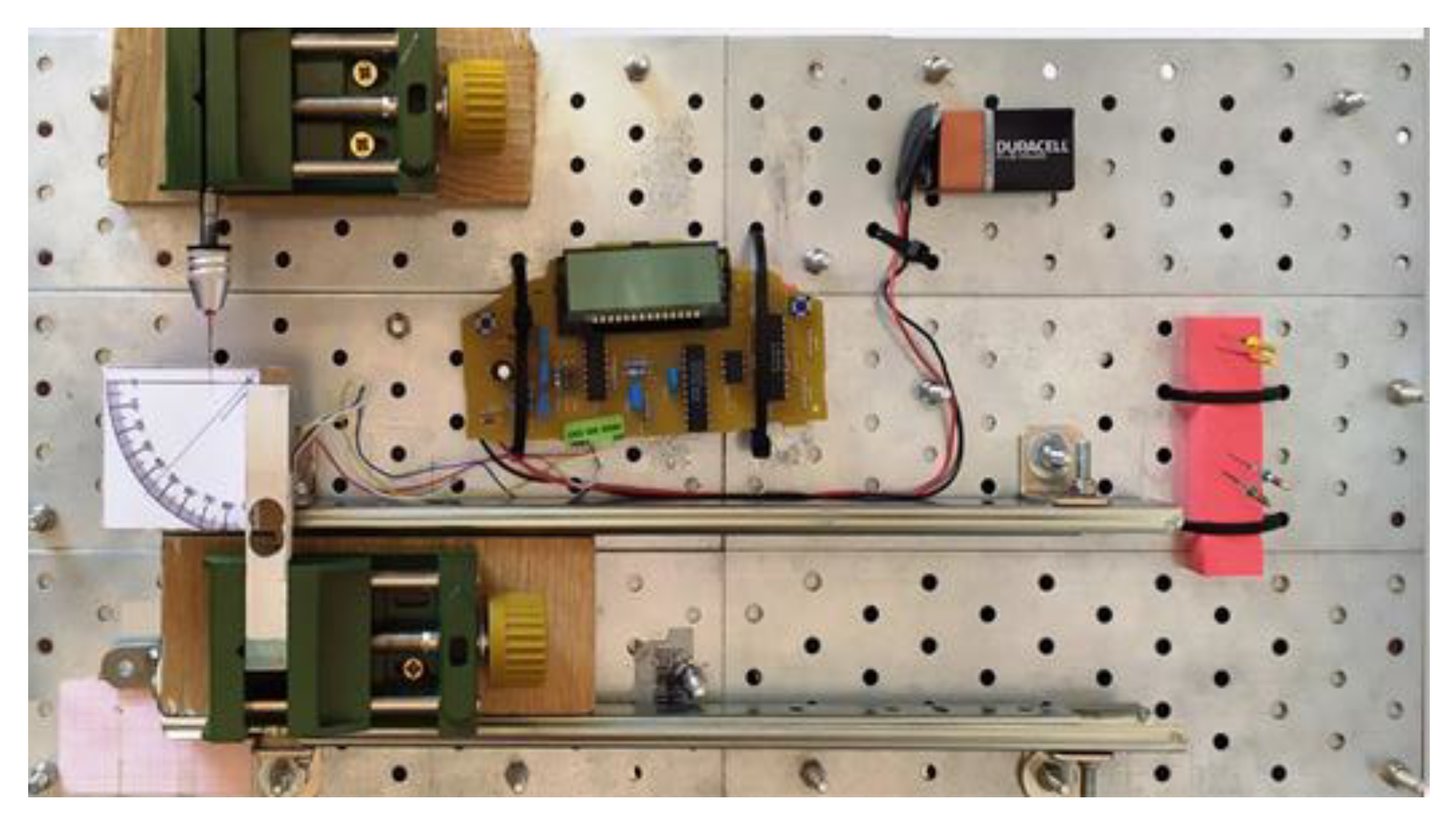

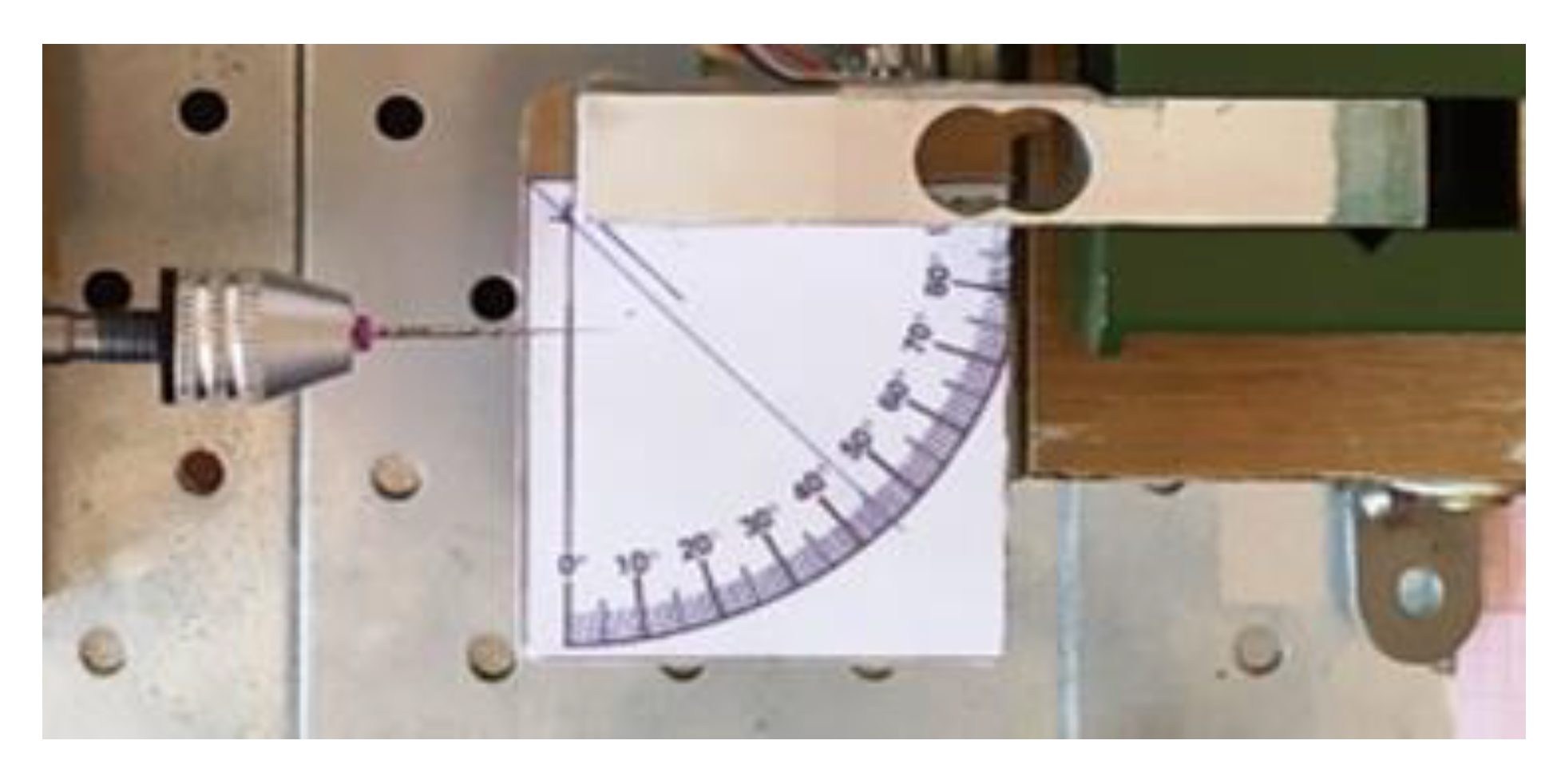

A New Device to Test the Bending Resistance of Mechanical Endodontic Instruments

Abstract

1. Introduction

2. Materials and Methods

3. Results

- Each instrument alone (S1, S2, F1, F2) at each specific point (3, 6, and 9 mm);

- Each instrument of the series (S1, S2, F1, F2) comparing ET with PTU;

- Each instrument of the series (S1, S2, F1, F2) comparing ETP with PTG.

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tabassum, S.; Zafar, K.; Umer, F. Nickel-Titanium Rotary File Systems: What’s New? Eur. Endod. J. 2019, 4, 111–117. [Google Scholar] [CrossRef] [PubMed]

- Htun, P.H.; Ebihara, A.; Maki, K.; Kimura, S.; Nishijo, M.; Tokita, D.; Okiji, T. Comparison of torque, force generation and canal shaping ability between manual and nickel-titanium glide path instruments in rotary and optimum glide path motion. Odontology 2020, 108, 188–193. [Google Scholar] [CrossRef] [PubMed]

- McGuigan, M.B.; Louca, C.; Duncan, H.F. Endodontic instrument fracture: Causes and prevention. Br. Dent. J. 2013, 214, 341–348. [Google Scholar] [CrossRef] [PubMed]

- Miccoli, G.; Seracchiani, M.; Del Giudice, A.; Mazzoni, A.; D’Angelo, M.; Bhandi, S.; Gambarini, G.; Testarelli, L. Fatigue resistance of two nickel-titanium rotary instruments before and after ex vivo root canal treatment. J. Cont. Dent. Pract. 2020, 21, 728–732. [Google Scholar] [CrossRef]

- Di Nardo, D.; Seracchiani, M.; Mazzoni, A.; Del Giudice, A.; Gambarini, G.; Testarelli, L. Torque range, a new parameter to evaluate new and used instrument safety. Appl. Sci. 2020, 10, 3418. [Google Scholar] [CrossRef]

- Mazzoni, A.; Pacifici, A.; Zanza, A.; Del Giudice, A.; Reda, R.; Testarelli, L.; Gambarini, G.; Pacifici, L. Assessment of Real-Time Operative Torque during Nickel–Titanium Instrumentation with Different Lubricants. Appl. Sci. 2020, 10, 6201. [Google Scholar] [CrossRef]

- Gambarini, G.; Miccoli, G.; Di Nardo, D.; Del Giudice, A.; Mazzoni, A.; Seracchiani, M.; Testarelli, L. Torsional Resistance of Two New Heat Treated Nickel Titanium Rotary Instruments: An in Vitro Evaluation. Pesqui. Bras. Odontopediatria Clín. Integr. 2020, 20, 0053. [Google Scholar] [CrossRef]

- Di Nardo, D.; Miccoli, G.; Mazzoni, A.; Seracchiani, M.; Gambarini, G.; Testarelli, L. Centering ability of a new nickel-titanium rotary instruments with a peculiar flat-side design: An in vitro study. J. Contemp. Dent. Pract. 2020, 21, 539–542. [Google Scholar]

- Gambarini, G.; Galli, M.; Di Nardo, D.; Seracchiani, M.; Donfrancesco, O.; Testarelli, L. Differences in cyclic fatigue lifespan between two different heat treated NiTi endodontic rotary instruments: WaveOne Gold vs EdgeOne Fire. J. Clin. Exp. Dent. 2019, 11, 609–613. [Google Scholar] [CrossRef]

- Gambarini, G.; Miccoli, G.; Seracchiani, M.; Khrenova, T.; Donfrancesco, O.; D’Angelo, M.; Galli, M.; Di Nardo, D.; Testarelli, L. Role of the Flat-Designed Surface in Improving the Cyclic Fatigue Resistance of Endodontic NiTi Rotary Instruments. Materials 2019, 12, 2523. [Google Scholar] [CrossRef]

- Pedullà, E.; Lo Savio, F.; La Rosa, G.R.M.; Miccoli, G.; Bruno, E.; Rapisarda, S.; Chang, S.W.; Rapisarda, E.; La Rosa, G.; Gambarini, G.; et al. Cyclic fatigue resistance, torsional resistance, and metallurgical characteristics of M3 Rotary and M3 Pro Gold NiTi files. Restor. Dent. Endod. 2018, 23, 43. [Google Scholar] [CrossRef] [PubMed]

- Hartmann, R.C.; Fensterseifer, M.; Peters, O.A.; de Figueiredo, J.A.P.; Gomes, M.S.; Rossi-Fedele, G. Methods for measurement of root canal curvature: A systematic and critical review. Int. Endod. J. 2019, 52, 169–180. [Google Scholar] [CrossRef] [PubMed]

- Martins, J.N.R.; Ordinola-Zapata, R.; Marques, D.; Francisco, H.; Caramês, J. Differences in root canal system configuration in human permanent teeth within different age groups. Int. Endod. J. 2018, 51, 931–941. [Google Scholar] [CrossRef]

- Ozcan, G.; Sekerci, A.E.; Cantekin, K.; Aydinbelge, M.; Dogan, S. Evaluation of root canal morphology of human primary molars by using CBCT and comprehensive review of the literature. Acta Odontol. Scand. 2016, 74, 250–258. [Google Scholar] [CrossRef]

- Fu, Y.; Deng, Q.; Xie, Z.; Sun, J.; Song, D.; Gao, Y.; Huang, D. Coronal root canal morphology of permanent two-rooted mandibular first molars with novel 3D measurements. Int. Endod. J. 2020, 53, 167–175. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Mazza, C.; Petrovic, R.; Testarelli, L.; Gambarini, G. Influence of size and taper of artificial canals on the trajectory of NiTi rotary instruments in cyclic fatigue studies. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2010, 109, 60–66. [Google Scholar] [CrossRef]

- Testarelli, L.; Plotino, G.; Al-Sudani, D.; Vincenzi, V.; Giansiracusa, A.; Grande, N.M.; Gambarini, G. Bending properties of a new nickel-titanium alloy with a lower percent by weight of nickel. J. Endod. 2011, 37, 1293–1295. [Google Scholar] [CrossRef]

- Di Nardo, D.; Gambarini, G.; Seracchiani, M.; Mazzoni, A.; Zanza, A.; Del Giudice, A.; D’Angelo, M.; Testarelli, L. Influence of different cross-section on cyclic fatigue resistance of two nickel–titanium rotary instruments with same heat treatment: An in vitro study. Saudi Endod. J. 2020, 10, 221–225. [Google Scholar] [CrossRef]

- Jamleh, A.; Alghaihab, A.; Alfadley, A.; Alfawaz, H.; Alqedairi, A.; Alfouzan, K. Cyclic Fatigue and Torsional Failure of EdgeTaper Platinum Endodontic Files at Simulated Body Temperature. J. Endod. 2019, 45, 611–614. [Google Scholar] [CrossRef]

- Gambarini, G.; Cicconetti, A.; Di Nardo, D.; Miccoli, G.; Zanza, A.; Testarelli, L.; Seracchiani, M. Influence of Different Heat Treatments on Torsional and Cyclic Fatigue Resistance of Nickel–Titanium Rotary Files: A Comparative Study. Appl. Sci. 2020, 10, 5604. [Google Scholar] [CrossRef]

- Gambarini, G.; Seracchiani, M.; Piasecki, L.; Valenti Obino, F.; Galli, M.; Di Nardo, D.; Testarelli, L. Measurement of torque generated during intracanal instrumentation in vivo. Int. Endod. J. 2019, 52, 737–745. [Google Scholar] [CrossRef] [PubMed]

- Plotino, G.; Grande, N.M.; Isufi, A.; Ioppolo, P.; Pedullà, E.; Bedini, R.; Gambarini, G.; Testarelli, L. Fracture Strength of Endodontically Treated Teeth with Different Access Cavity Designs. J. Endod. 2017, 43, 995–1000. [Google Scholar] [CrossRef]

| PTU | ET | |||||||

|---|---|---|---|---|---|---|---|---|

| S1 | S2 | F1 | F2 | S1 | S2 | F1 | F2 | |

| 3 mm | 101.33 ± 3.80 | 151.33 ± 5.79 | 226.17 ± 6.84 | 256.33 ± 5.24 | 125.00 ± 5.7 | 228.83 ± 7.3 | 317.50 ± 4.0 | 329.17 ± 3.9 |

| 6 mm | 249.00 ± 10.28 | 381.50 ± 7.15 | 432.50 ± 9.98 | 434.17 ± 8,35 | 528.67 ± 8.0 | 554.33 ± 9.1 | 556.17 ± 5.8 | 566.33 ± 7.8 |

| 9 mm | 764.33 ± 24.48 | 764.33 ± 15.94 | 820.33 ± 13.30 | 825.67 ± 21.92 | 1048.00 ± 23.3 | 980.00 ± 4.1 | 967.17 ± 12.1 | 974.67 ± 12.8 |

| PTG | ETP | |||||||

|---|---|---|---|---|---|---|---|---|

| S1 | S2 | F1 | F2 | S1 | S2 | F1 | F2 | |

| 3 mm | 54,33 ± 2.94 | 103.67 ± 2.40 | 116.17 ± 2.33 | 154.50 ± 6.21 | 42.83 ± 2.56 | 86.33 ± 3.50 | 113.67 ± 3.52 | 116.83 ± 5.49 |

| 6 mm | 230.00 ± 9.16 | 294.00 ± 9.20 | 269.00 ± 9.12 | 281.67 ± 5.39 | 209.17 ± 4.60 | 233.00 ± 5.46 | 218.33 ± 4.24 | 205.67 ± 4.55 |

| 9 mm | 556.67 ± 7.77 | 558.00 ± 11.49 | 562.17 ± 8.56 | 564.33 ± 8.85 | 472.00 ± 8.77 | 445.33 ± 4.98 | 443.00 ± 7.06 | 457.00 ± 3.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miccoli, G.; Cicconetti, A.; Gambarini, G.; Del Giudice, A.; Ripanti, F.; Di Nardo, D.; Testarelli, L.; Seracchiani, M. A New Device to Test the Bending Resistance of Mechanical Endodontic Instruments. Appl. Sci. 2020, 10, 7215. https://doi.org/10.3390/app10207215

Miccoli G, Cicconetti A, Gambarini G, Del Giudice A, Ripanti F, Di Nardo D, Testarelli L, Seracchiani M. A New Device to Test the Bending Resistance of Mechanical Endodontic Instruments. Applied Sciences. 2020; 10(20):7215. https://doi.org/10.3390/app10207215

Chicago/Turabian StyleMiccoli, Gabriele, Andrea Cicconetti, Gianluca Gambarini, Andrea Del Giudice, Federico Ripanti, Dario Di Nardo, Luca Testarelli, and Marco Seracchiani. 2020. "A New Device to Test the Bending Resistance of Mechanical Endodontic Instruments" Applied Sciences 10, no. 20: 7215. https://doi.org/10.3390/app10207215

APA StyleMiccoli, G., Cicconetti, A., Gambarini, G., Del Giudice, A., Ripanti, F., Di Nardo, D., Testarelli, L., & Seracchiani, M. (2020). A New Device to Test the Bending Resistance of Mechanical Endodontic Instruments. Applied Sciences, 10(20), 7215. https://doi.org/10.3390/app10207215