Determination of Permissible Load in Selected Parts of the Human Musculoskeletal System While Feeding Cows with Maize Silage

Abstract

1. Introduction

2. Materials and Methods

2.1. Participants

2.2. Survey

- Which of the farm activities places the greatest load on your musculoskeletal system?

- Which parts of the body are most notably stressed when you perform the activity in question 1?

- Do you feel any pain or discomfort when you perform the activities you gave in question 1?

- How many times a day do you perform the activity that you gave in question 1?

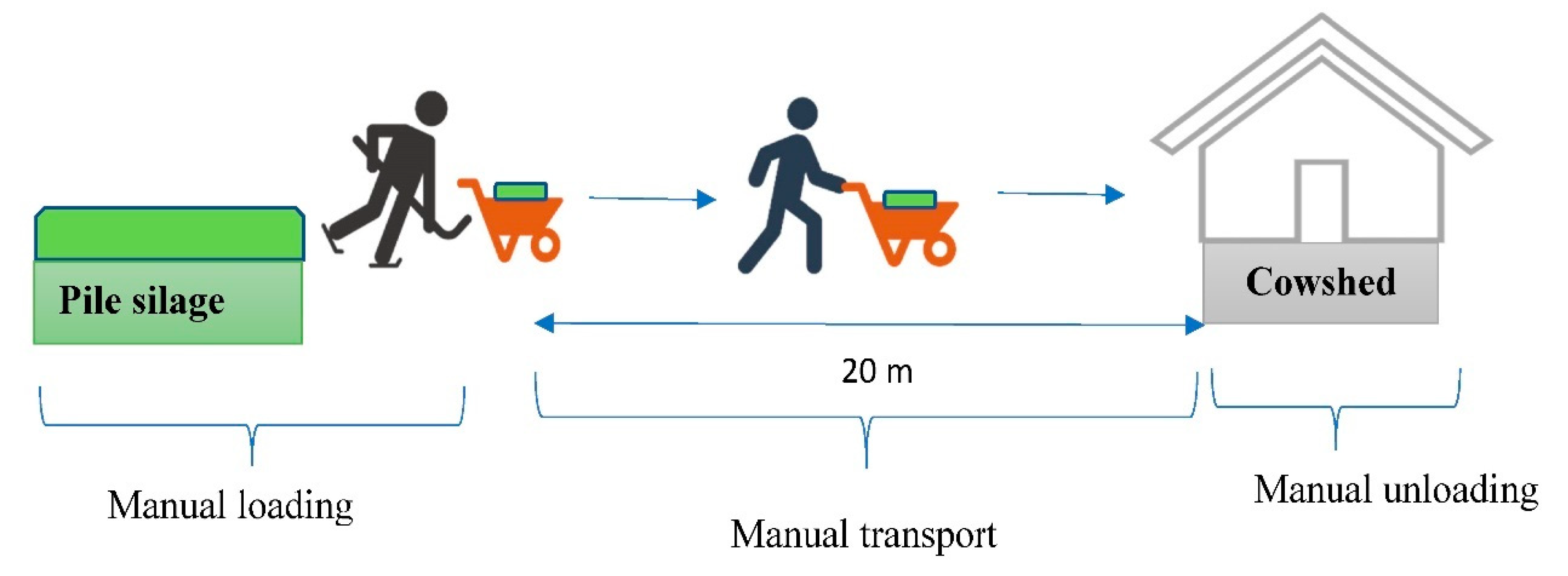

2.3. Task Performance

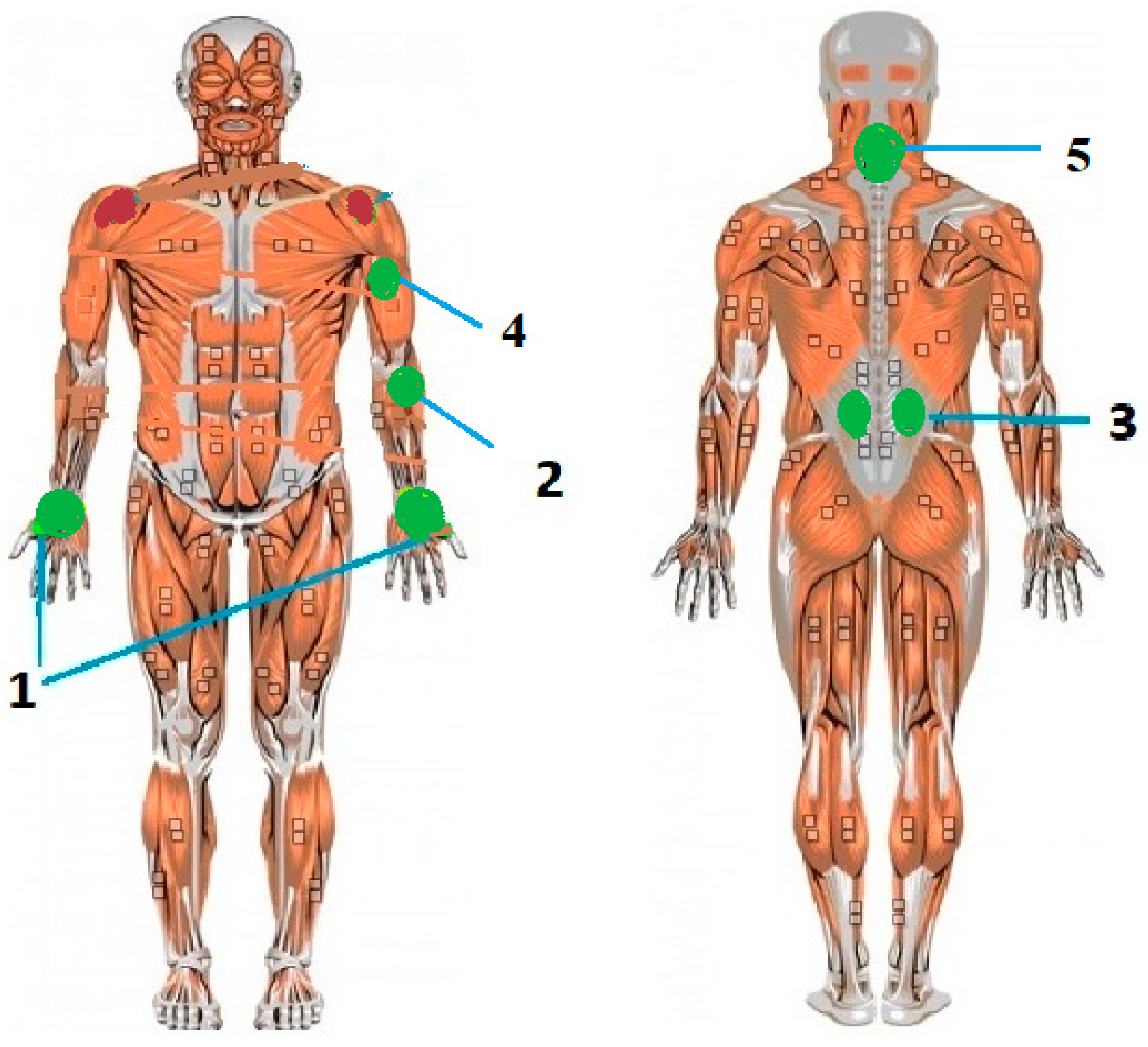

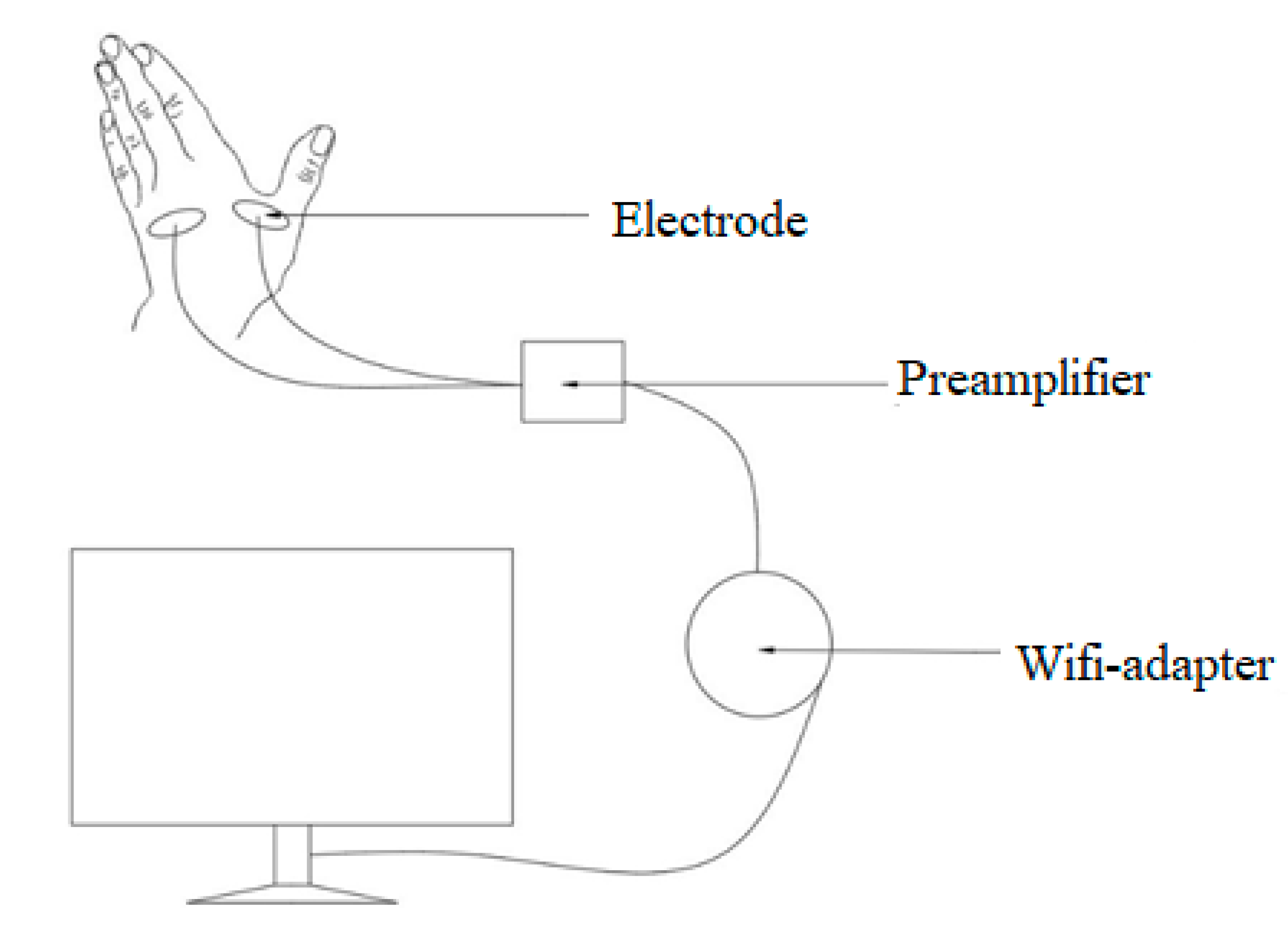

2.4. Muscle Load Measurement

2.5. Statistics

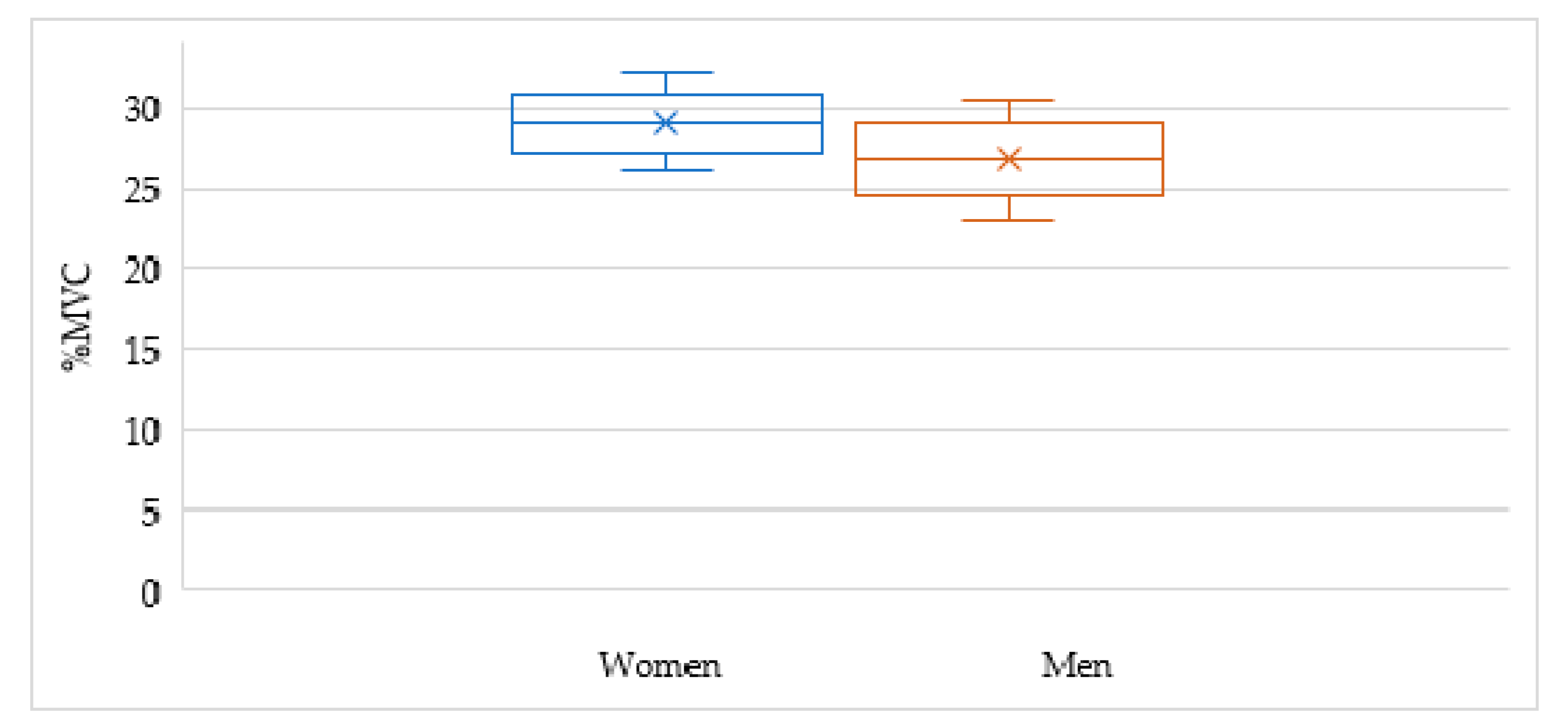

3. Results

3.1. Survey

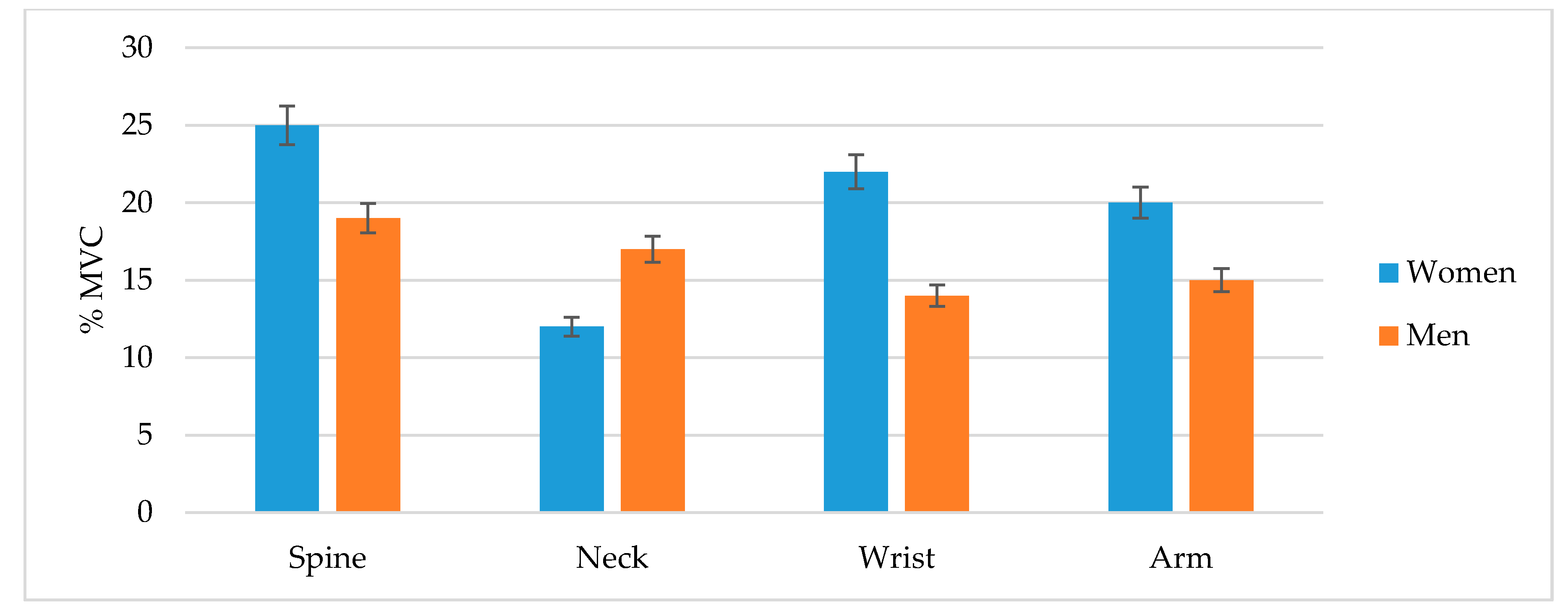

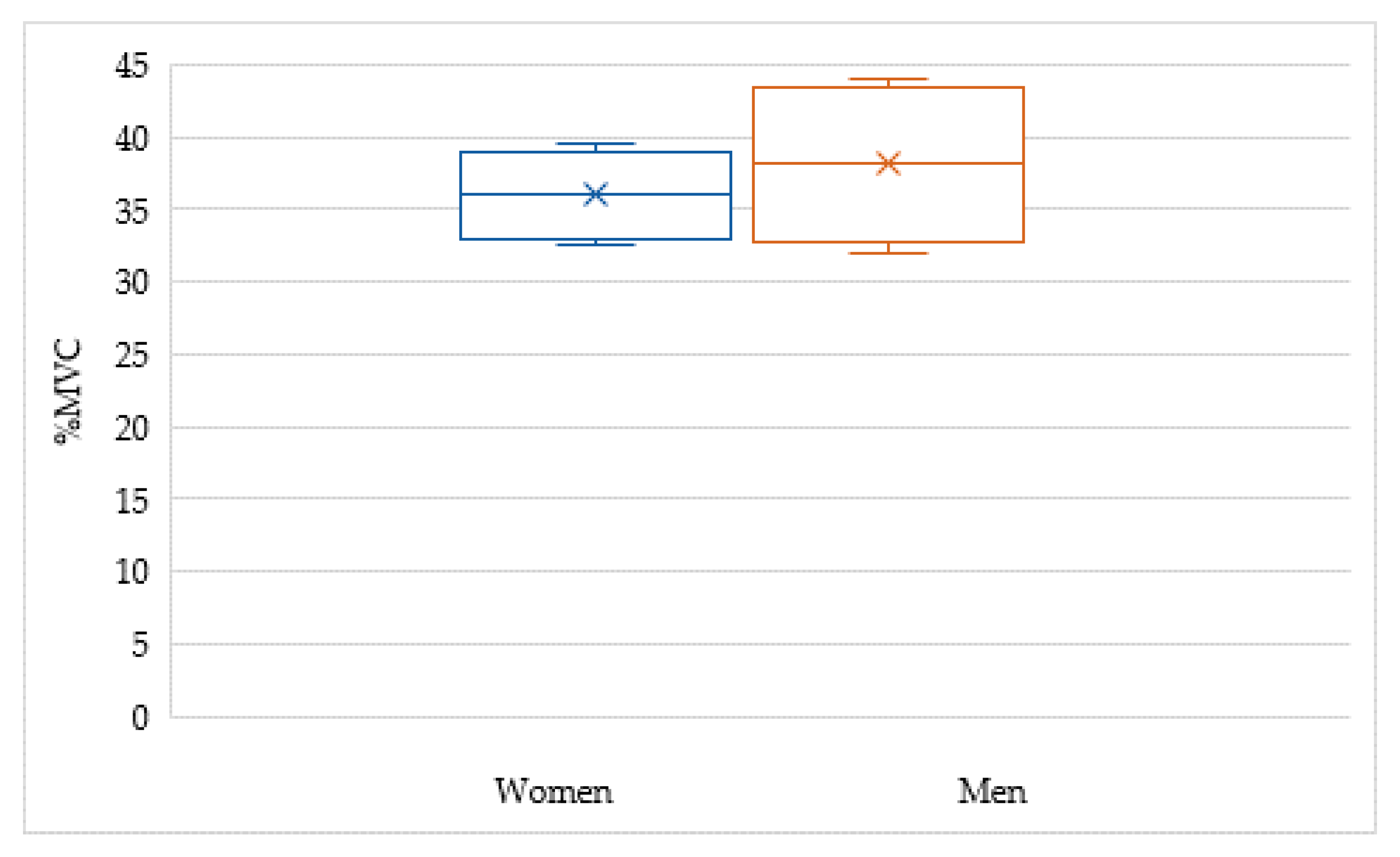

3.2. Manual Silage Loading

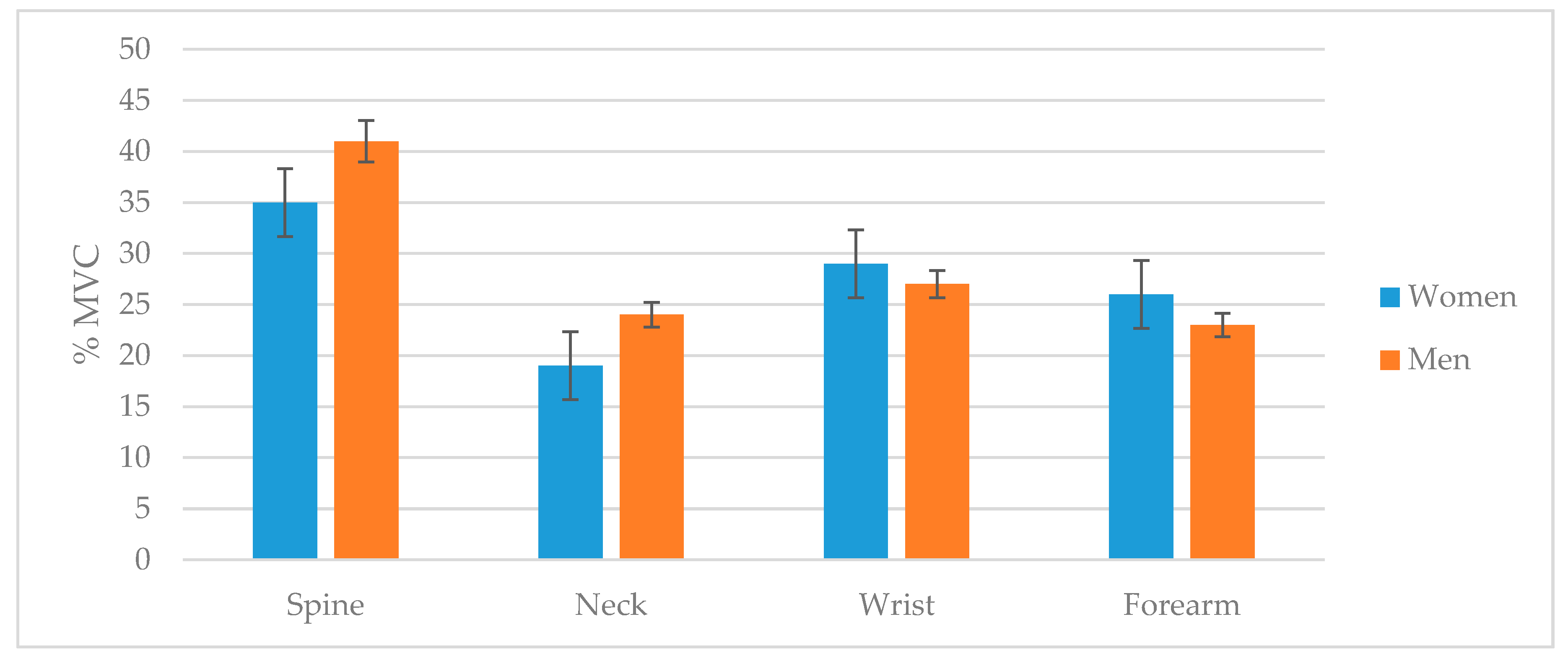

3.3. Manual Transport and Unloading

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lötters, F.; Burdorf, A.; Kuiper, J.; Miedema, H. Model for the work-relatedness of low-back pain. Scand. J. Work. Environ. Health 2003, 29, 431–440. [Google Scholar] [CrossRef] [PubMed]

- Marras, W.S.; Allread, W.G.; Burr, D.L.; Fathallah, F.A. Prospective validation of a low-back disorder risk model and assessment of ergonomic interventions associated with manual materials handling tasks. Ergonomics 2000, 43, 1866–1886. [Google Scholar] [CrossRef] [PubMed]

- Compare, A. La sicurezza sul laroro in agricultura. In Tesi di Laurea; Universita degli Studi di Torino: Torino, Italy, 2000. [Google Scholar]

- Colémont, A.; Broucke, S.V.D. Measuring determinants of occupational health related behavior in flemish farmers: An application of the Theory of Planned Behavior. J. Saf. Res. 2008, 39, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Holmberg, S.; Thelin, A.; Stiernstrom, E.; Svardsudd, K. The impact of physical work exposure on musculoskeletal symptoms among farmers and rural non-farmers. Ann. Agric. Environ. Med. 2003, 10, 179–184. [Google Scholar]

- Douphrate, D.I.; Nonnenmann, M.; Rosecrance, J. Ergonomics in Industrialized Dairy Operations. J. Agromed. 2009, 14, 406–412. [Google Scholar] [CrossRef]

- Norton, T.; Berckmans, D. Engineering advances in Precision Livestock Farming. Biosyst. Eng. 2018, 173, 1–3. [Google Scholar] [CrossRef]

- Cross, A.J.; A Rohrer, G.; Brown-Brandl, T.M.; Cassady, J.P.; Keel, B.N. Feed-forward and generalised regression neural networks in modelling feeding behaviour of pigs in the grow-finish phase. Biosyst. Eng. 2018, 173, 124–133. [Google Scholar] [CrossRef]

- Ekholm, J.; Nisell, R.; Arborelius, U.P.; Svensson, O.; Nemeth, G. Load on the knee muscular activity during machine milking. Ergonomics 1985, 28, 665–682. [Google Scholar] [CrossRef]

- Grujicic, M.; Pandurangan, B.; Xie, X.; Gramopadhye, A.; Wagner, D.W.; Ozen, M. Musculoskeletal computational analysis of the influence of car-seat design/adjustments on long-distance driving fatigue. Int. J. Ind. Ergon. 2010, 40, 345–355. [Google Scholar] [CrossRef]

- Sartorio, F.; Franchignoni, F.; Ferriero, G.; Vercelli, S.; Odescalchi, L.; Augusti, D.; Migliano, M. Work reloaded musculoskeletal disorders in dentistry professionals. 2. Prevention, ergonomic strategies and therapatic programs. G. Ital. Med. Lav. Ergon. 2005, 27, 442–448. [Google Scholar]

- Hansson, G.Å.; Asterland, P.; Kellerman, M. Modular data logger system for physical workload measurements. Ergonomics 2003, 46, 407–415. [Google Scholar] [CrossRef] [PubMed]

- Mehta, C.; Gite, L.; Pharade, S.; Majumder, J.; Pandey, M. Review of anthropometric considerations for tractor seat design. Int. J. Ind. Ergon. 2008, 38, 546–554. [Google Scholar] [CrossRef]

- Stål, M.; Hansson, G.Å.; Moritz, U. Wrist positions and movements as possible risk factors during machine milking. Appl. Ergon. 1999, 30, 527–533. [Google Scholar] [CrossRef]

- Na, S.; Lim, S.; Choi, H.-S.; Chung, M.K. Evaluation of driver’s discomfort and postural change using dynamic body pressure distribution. Int. J. Ind. Ergon. 2005, 35, 1085–1096. [Google Scholar] [CrossRef]

- Rasmussen, J.; Tørholm, S.; De Zee, M. Computational analysis of the influence of seat pan inclination and friction on muscle activity and spinal joint forces. Int. J. Ind. Ergon. 2009, 39, 52–57. [Google Scholar] [CrossRef]

- Blüthner, R.; Seidel, H.; Hinz, B. Laboratory study as basis of the development for a seat testing procedure in horizontal directions. Int. J. Ind. Ergon. 2008, 38, 447–456. [Google Scholar] [CrossRef]

- Occhipinti, E.; Colombini, D. Updating reference values and predictive models of the OCRA method in the risk assessment of work-related musculoskeletal disorders of the upper limbs. Ergonomics 2007, 50, 1727–1739. [Google Scholar] [CrossRef]

- Waters, T.R.; Lu, M.-L.; Occhipinti, E. New procedure for assessing sequential manual lifting jobs using the revised NIOSH lifting equation. Ergonomics 2007, 50, 1761–1770. [Google Scholar] [CrossRef]

- Denis, D.; Lortie, M.; Bruxelles, M. Impact of observers’ experience and training on reliability of observations for a manual handling task. Ergonomics 2002, 45, 441–454. [Google Scholar] [CrossRef]

- Grujicic, M.; Pandurangan, B.; Arakere, G.; Bell, W.; He, T.; Xie, X. Seat-cushion and soft-tissue material modeling and a finite element investigation of the seating comfort for passenger-vehicle occupants. Mater. Des. 2009, 30, 4273–4285. [Google Scholar] [CrossRef]

- Jaworski, H. Preventive and rehabilitation activities carried out by KRUS to reduce damage to the musculoskeletal system. In Diagnosis and Ways to Reduce the Risk of Diseases of the Musculoskeletal System Associated with Work in Agriculture; Institute of Rural Medicine: Lublin, Poland, 2009; pp. 69–79. [Google Scholar]

- Lach, J. Prevention of diseases of the musculoskeletal system resulting from overloading while working in the Agricultural Combine—Kietrz. In Diagnosis and Ways to Reduce the Risk of Diseases of the Musculoskeletal System Associated with Work in Agriculture; Institute of Rural Medicine: Lublin, Poland, 2000; pp. 180–190. [Google Scholar]

- Fabunmi, A.A.; Aba, S.O.; Odunaiya, N.A. Prevalence of low back pain among peasant farmers in a rural community in South West Nigeria. Afr. J. Med. Sci. 2005, 34, 259–262. [Google Scholar]

- Molen, H.F.V.; Grouwstra, R.; Kuijer, P.P.F.; Sluiter, J.K.; Frings-Dresen, M.H. Efficacy of adjusting working height and mechanizing of transport on physical work demands and local discomfort in construction work. Ergonomics 2004, 47, 772–783. [Google Scholar] [CrossRef] [PubMed]

- Solecki, L. Preliminary assessment of musculoskeletal pain reported by individual farmers. Occup. Med. 2012, 63, 281–293. [Google Scholar]

- Barrero, L.H.; Hsu, Y.-H.; Terwedow, H.; Perry, M.J.; Dennerlein, J.T.; Brain, J.D.; Xu, X. Prevalence and Physical Determinants of Low Back Pain in a Rural Chinese Population. Spine 2006, 31, 2728–2734. [Google Scholar] [CrossRef]

- Xiang, H.; Stallones, L.; Keefe, T.J. Back pain and agricultural work among farmers: Analysis of the Colorado Farm Family Health and Hazard Surveillance Survey. Am. J. Med. 1999, 35, 310–316. [Google Scholar] [CrossRef]

- Hodges, P.W.; Eriksson, A.M.; Shirley, D.; Gandevia, S.C. Intra-abdominal pressure increases stiffness of the lumbar spine. J. Biomech. 2005, 38, 1873–1880. [Google Scholar] [CrossRef] [PubMed]

- Merletti, R.; Parker, P. Electromiography: Physiology, Engineering and Non-Invasive Applications; Wiley-IEEE Press: Piscataway, NJ, USA, 2004; pp. 10–30. [Google Scholar]

- Zhang, Q.; Wang, L.; Zheng, W. Surface electromiography of pelvic floor muscles in stress urinary incontience. Int. J. Gynecol. Obstet. 2006, 95, 177–178. [Google Scholar] [CrossRef]

- Chaitow, L.; Jones, R. Chronic Pelvic Pain and Dysfunction; Churchill Livingstone: London, UK, 2011. [Google Scholar]

- Jantos, M. Vulvodynia: A Psychophysiological Profile Based on Electromyographic Assessment. Appl. Psychophysiol. Biofeedback 2008, 33, 29–38. [Google Scholar] [CrossRef]

- Jakob, M.C.; Liebers, F. Potential of a Quarter Individual Milking System to Reduce the Workload in Large-Herd Dairy Operations. J. Agromed. 2011, 16, 280–291. [Google Scholar] [CrossRef]

- Nishijima, Y.; Kato, T.; Yoshizawa, M.; Miyashita, M.; Iida, H. Application of the segment weight dynamic movement method to the normalization of gait EMG amplitude. J. Electromyogr. Kinesiol. 2010, 20, 550–557. [Google Scholar] [CrossRef]

- Buchanan, T.S.; Lloyd, D.G.; Manal, K.; Besier, T.F. Neuromusculoskeletal Modeling: Estimation of Muscle Forces and Joint Moments and Movements from Measurements of Neural Command. J. Appl. Biomech. 2004, 20, 367–395. [Google Scholar] [CrossRef] [PubMed]

- Pick, A.J.; Cole, D.J. Measurement of Driver Steering Torque Using Electromyography. J. Dyn. Syst. Meas. Control. 2006, 128, 960–968. [Google Scholar] [CrossRef]

- Rajvordhan, R.P.; Shoukapal, S.R.; Vijaykumar, S.M. Effect of wheel geometry parameters on vehicle steering. SASTECH J. 2010, 9, 11–18. [Google Scholar]

- Komarnicki, P.; Stopa, R.; Kuta, Ł.; Szyjewicz, D. Determination of apple bruise resistance based on the surface pressure and contact area measurements under impact loads. Comput. Electron. Agric. 2017, 142, 155–164. [Google Scholar] [CrossRef]

- Pinzke, S.; Stal, M.; Hansson, G.A. Physical workload on upper extremities in various operations during machine milking. Ann. Agric. Environ. Med. 2001, 8, 63–70. [Google Scholar] [PubMed]

- Stål, M.; Pinzke, S.; Hansson, G.Å. The effect on workload by using a support arm in parlour milking. Int. J. Ind. Ergon. 2003, 32, 121–132. [Google Scholar] [CrossRef]

- Zaniewska, R.; Okurowska-Zawada, B.; Kułak, W.; Domian, K. Analysis of the quality of life of patients with lower back pain syndrome after transcutaneous electrical nerve stimulation—TENS. Inst. Occup. Med. Nofer’s Name Łódź 2012, 63, 295–302. [Google Scholar]

- Ganah, A.; John, G.A. Integrating Building Information Modeling and Health and Safety for Onsite Construction. Saf. Health Work 2015, 6, 39–45. [Google Scholar] [CrossRef]

- Mahmoudi, S.; Ghasemi, F.; Mohammadfam, I.; Soleimani, E. Framework for continuous assessment and improvement of occupational health and safety issues in construction companies. Saf. Health Work 2014, 5, 125–130. [Google Scholar] [CrossRef]

- Boschman, J.S.; Frings-Dresen, M.H.; Van Der Molen, H.F. Use of Ergonomic Measures Related to Musculoskeletal Complaints among Construction Workers: A 2-year Follow-up Study. Saf. Health Work 2015, 6, 90–96. [Google Scholar] [CrossRef]

- Occhipinti, E. OCRA: A concise index forthe assessment of exposure to repetitive movements of the upper limbs. Ergonomics 1998, 41, 1290–1311. [Google Scholar] [CrossRef] [PubMed]

- Moore, J.S.; Garg, A. The strain index: A proposed method to analyze jobs for risk of distal upper extrem-ity disorders. Am. Ind. Hyg. Assoc. J. 1995, 56, 443–458. [Google Scholar] [CrossRef]

- Miedema, M.C.; Douwes, M.; Dul, J. Recommended maximum holding times for prevention of discomfort of static standing postures. Int. J. Ind. Ergon. 1997, 19, 9–18. [Google Scholar] [CrossRef]

- Yates, J.; Karwowski, W. Maximum acceptable lifting loads during seated and standing work positions. Appl. Ergon. 1987, 18, 239–243. [Google Scholar] [CrossRef]

- Frontera, W.R.; Ochala, J. Skeletal Muscle: A Brief Review of Structure and Function. Calcif. Tissue Int. 2014, 96, 183–195. [Google Scholar] [CrossRef] [PubMed]

| Anthropometric Features | Men (n = 32) | Women (n = 18) | ||

|---|---|---|---|---|

| Average | Standard Deviation | Average | Standard Deviation | |

| Age [years] | 45 | 3.6 | 37 | 4.3 |

| Height [cm] | 177 | 6.1 | 168 | 10.0 |

| Body mass [kg] | 82 | 2.9 | 80 | 4.8 |

| Body Part | Level of Physical Load | Load Level |

|---|---|---|

| Neck | 5.1 | Medium |

| Arm | 7.6 | Medium |

| Forearm | 8.2 | High |

| Lumbar spine | 8.4 | High |

| Wrist | 5.0 | Medium |

| Body Part | Men | Female |

|---|---|---|

| MVC [%] | ||

| Forearm | 28 | 30 |

| Wrist | 22 | 24 |

| Neck | 17 | 21 |

| Spine | 41 | 44 |

| Arm | 31 | 34 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuta, Ł.; Stopa, R.; Komarnicki, P.; Słupska, M.; Górecki, K. Determination of Permissible Load in Selected Parts of the Human Musculoskeletal System While Feeding Cows with Maize Silage. Appl. Sci. 2020, 10, 7125. https://doi.org/10.3390/app10207125

Kuta Ł, Stopa R, Komarnicki P, Słupska M, Górecki K. Determination of Permissible Load in Selected Parts of the Human Musculoskeletal System While Feeding Cows with Maize Silage. Applied Sciences. 2020; 10(20):7125. https://doi.org/10.3390/app10207125

Chicago/Turabian StyleKuta, Łukasz, Roman Stopa, Piotr Komarnicki, Monika Słupska, and Kamil Górecki. 2020. "Determination of Permissible Load in Selected Parts of the Human Musculoskeletal System While Feeding Cows with Maize Silage" Applied Sciences 10, no. 20: 7125. https://doi.org/10.3390/app10207125

APA StyleKuta, Ł., Stopa, R., Komarnicki, P., Słupska, M., & Górecki, K. (2020). Determination of Permissible Load in Selected Parts of the Human Musculoskeletal System While Feeding Cows with Maize Silage. Applied Sciences, 10(20), 7125. https://doi.org/10.3390/app10207125