1. Introduction

Fatigue of the wires in an overhead conductor occurs within the couplings that restrict the conductor vibration from incurring a vortex-induced oscillation [

1,

2,

3]. At present, most of the overhead conductors are made of steel-cored aluminum strands (ACSRs), and ACSR is widely used in power delivery systems around the world [

4,

5]. An aeolian vibration is one of the causes of a fretting fatigue failure of a conductor. Such failures invariably occur in suspension clamps, dampers, and spacers [

6,

7].

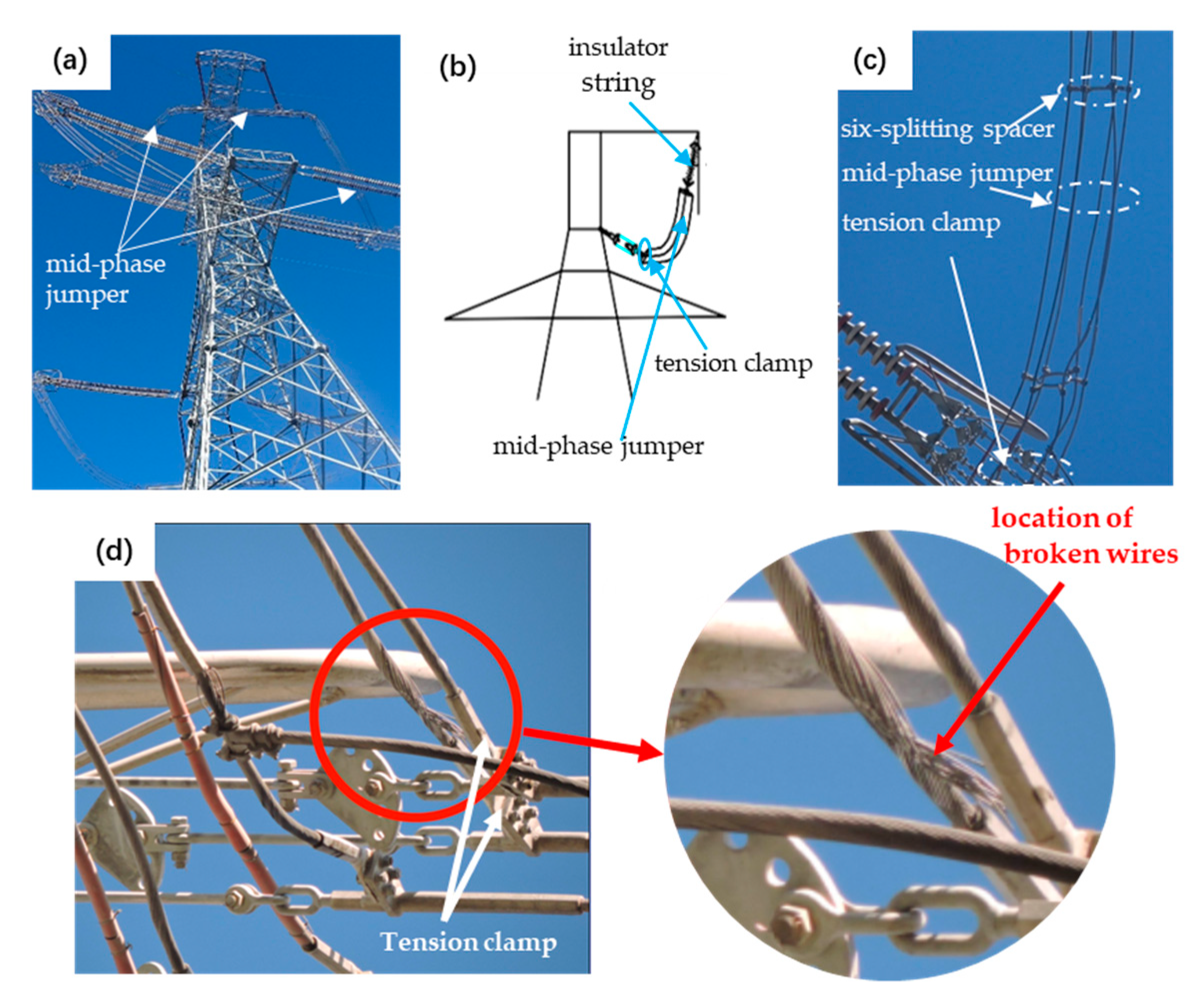

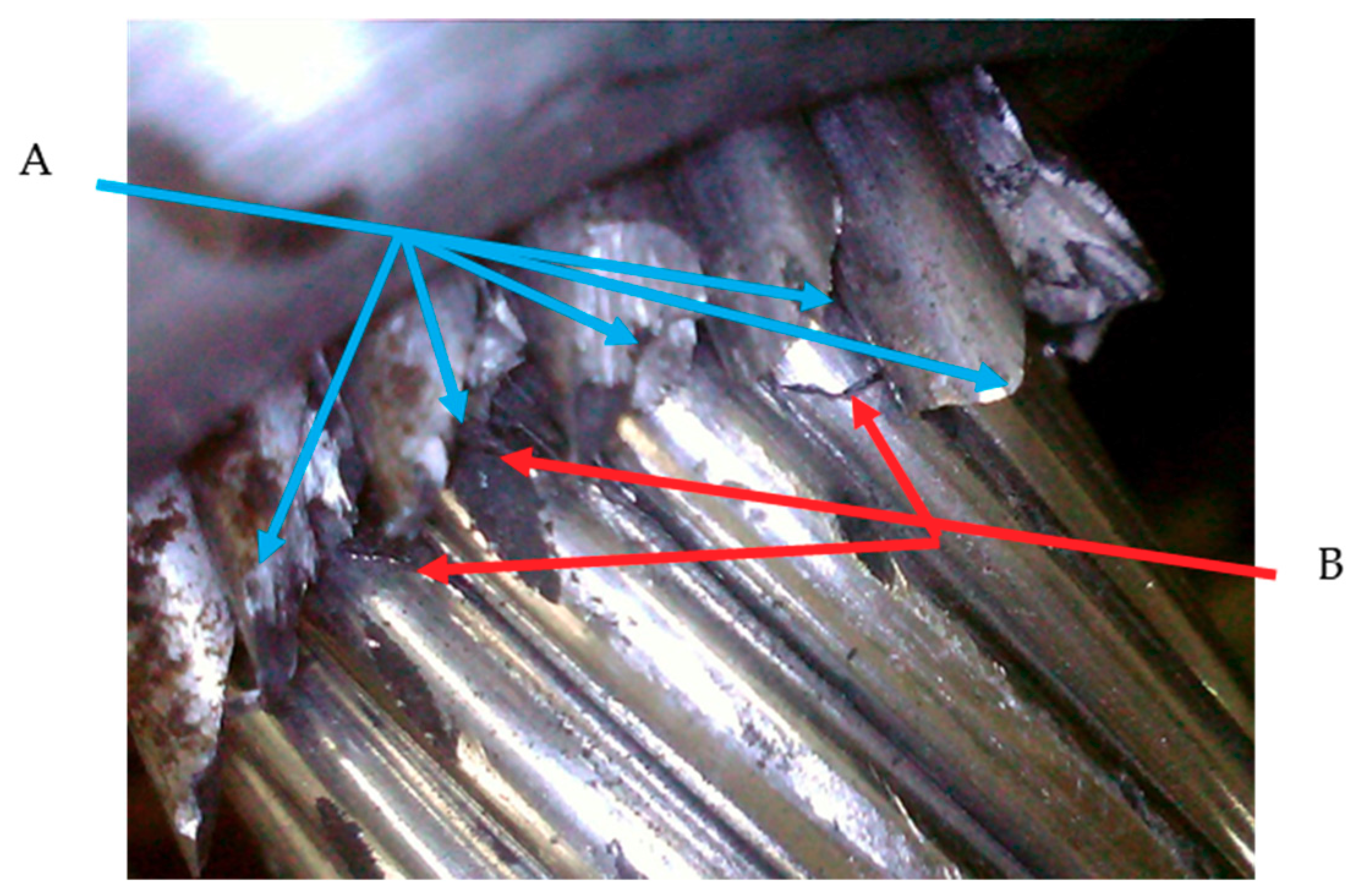

The northwest part of China has several areas with a strong wind, which significantly impacts the operation of transmission and transformation lines. According to statistics, from July 2015 to September 2016, 750 kV ultra-high voltage (UHV) transmission lines undertaking the task of power transmission from the west to the east in a strong wind areas suffered three strand breaks of the mid-phase jumper in succession, resulting in significant economic losses. Therefore, it is very important to study the stress and deformation distribution of the mid-phase jumper in terms of the movement under strong winds to provide guidance for the treatment measures.

Rizzo et al. [

8] described a method based on outlier analysis and the wavelet transform for structural damage detection based on guided ultrasonic waves. Furthermore, this method was applied to the detection of notch-like defects in a seven-wire strand by using built-in magnetostrictive devices for ultrasound transduction. Castellano et al. [

9] presented an innovative non-destructive experimental technique based on ultrasonic waves for a quantitative determination of the damage level in structural components. Neslušan et al. [

10] presented a systematic study using a magnetic non-destructive evaluation of corrosion attack in rope wires via Barkhausen noise emission. Because of the complexity of the scene, it is difficult to detect the damage of a six-splitting mid-phase jumper directly. Through the establishment of the finite element model six-splitting of a mid-phase jumper, the damage under wind load can be calculated. This paper presents an effective finite element modeling method for a large steel-cored aluminum strand when a main bending deformation occurs.

Because of the interaction between strands, multi-layer strands have a variable bending stiffness. With the bending of the strands, they begin to gradually slide with respect to each other, resulting in a decrease in the bending stiffness. However, the structural model of the conductor studied here is larger and has a spatial bending form. Therefore, it is extremely difficult to establish a finite element model of a mid-phase jumper with equal proportions.

Some scholars have proposed different modeling methods to study the mechanical response of steel strands during a bending deformation. Raoof and Hobbs [

11] idealized a strand as a series of concentric orthotropic cylinders, each of which is associated with a specific layer and its corresponding mechanical properties. The bending process of the wire was also considered. In addition, Lanteigne [

12] studied the mechanical behavior of cables under an arbitrary combination of tension, torsion, and bending. The force model of the cables is universal.

Leclair and Costello [

13] applied the love crank balance equation to each conductor and deduced a mechanical conductor model that can predict the stress of single twisted strands under axial, bending, and torsion loads. Hong et al. [

14] established a mechanical model of the conductor bending behavior under tension, although the model was significantly simplified. For example, the contact between adjacent cables of the same layer is neglected in the established model, and the contact line is used instead of the contact point of the superimposed layer. In addition, the cross-section of the twisted strand after bending is still planar.

Judge et al. [

15] used LS-DYNA to establish a full three-dimensional, elastic–plastic finite element model of multi-layer helical cables under a quasi-static axial load. The model uses three-dimensional solid elements to discretize each strand and simulates the contact types between all strands. The model also uses the law of non-linear hardening to explain the plastic deformation. Zhang et al. [

16] succeeded in analyzing the flexural stiffness of the strands using a solid three-dimensional finite element model, although their research was limited to single-pitch, single-layer cables. To summarize, the method of full three-dimensional solid modeling considers the contact between wires, among other factors, which results in a large number of computations, and thus the length of a fully three-dimensional solid element finite element model is usually very short. To reduce the computational complexity of the model, some scholars have used a beam element instead of solid element to establish a finite element model of a strand. Zhou et al. [

17] used a beam element to model a single-layer conductor and managed the contact interaction between the lines using a coupling equation between the corresponding nodes, and thus the slip between the lines was not considered. The model was applied to the analysis of strands under bending loads, which is still limited to single-layer strands with a small deflection. Beleznai et al. [

18] also modeled a conductor. Each line contact was simulated using a spring element. The stiffness of the spring element was based on the Hertzian contact theory. Although the correctness of this method has been proved, its application was still limited to single or double layers with a small displacement. Lalonde et al. [

19,

20] proposed a finite element modeling method for multi-layer steel strands under multi-axial loads. This method utilizes a beam element and a three-dimensional line contact, which greatly reduce the computational complexity of the model under the premise of ensuring a high level of accuracy.

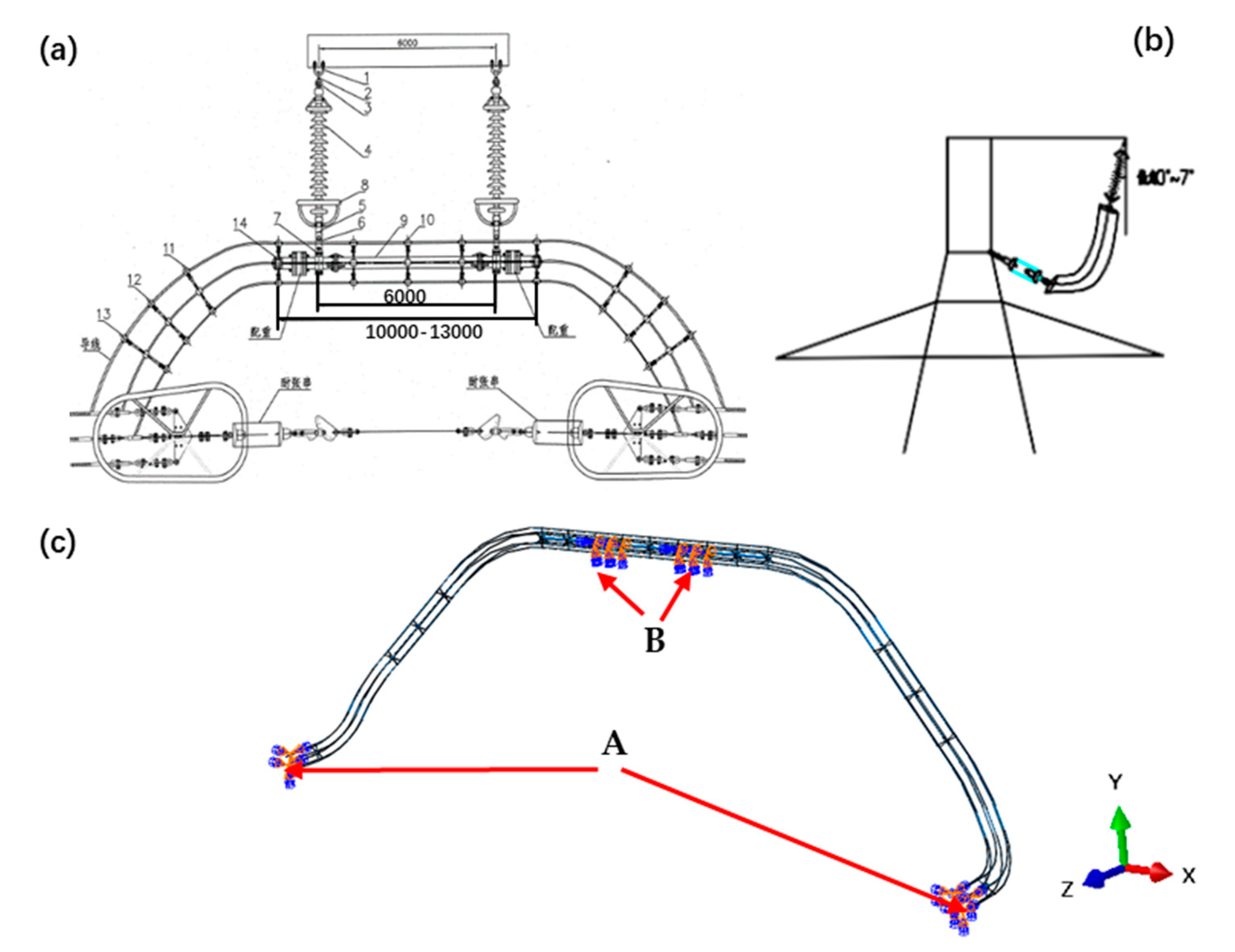

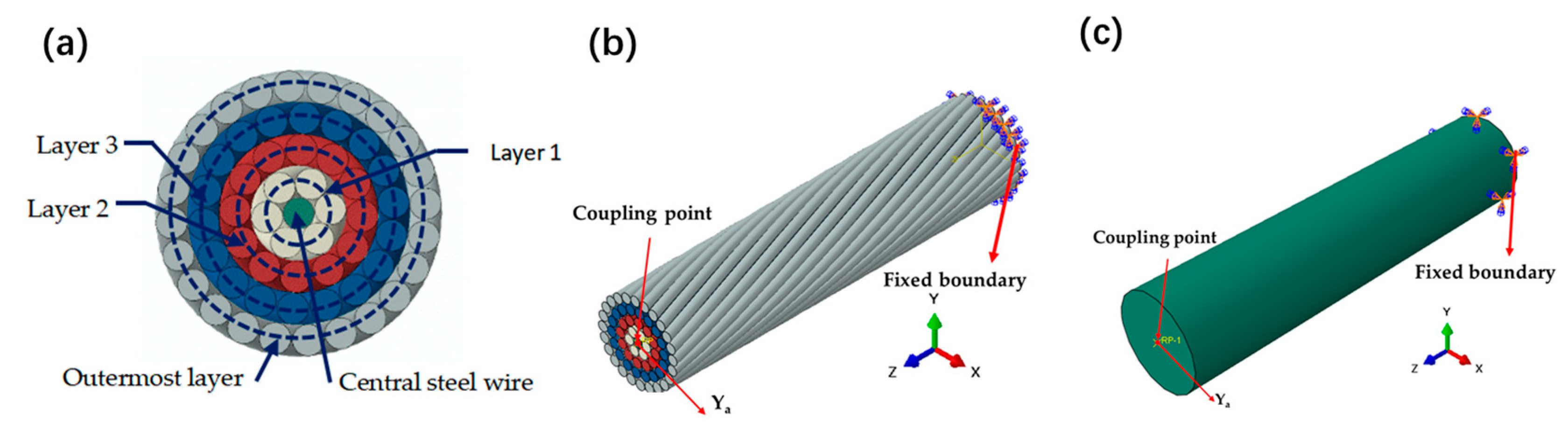

In this study, a finite element, fully three-dimensional solid modeling method was used to study the mechanical response of a steel-cored aluminum strand with a mid-phase jumper under a bending deformation. A whole model (simplifying an ACSR into a solid cylinder) and a local model (modeling according to the actual structure of an ACSR) of the mid-phase jumper were established. First, the movement of the mid-phase jumper of the tension tower under wind load was studied based on the whole finite element model, and the equivalent Young’s modulus of the whole model was adjusted based on the local model. The results of the whole model were then imported into the local model, and the stress distribution of each strand of the ACSR was analyzed in detail under a bending deformation to provide guidance for the treatment measures. Therefore, the whole model and the local model complemented each other, which could reduce the number of model operations and ensure the accuracy of the results. The feasibility of this method was verified through a comparison with the results of subsequent experiments. Although this modeling method was applied to the stress and deformation analysis of a mid-phase jumper in this study, it can be used to study the bending deformation of rope structures with a complex geometry and the main bending deformation. The finite element modeling method of a mid-phase jumper presented in this paper can be implemented in any general finite element software. Abaqus (2018, Dassault Systemes Simulia Corp, Johnston, RI, USA) was also used in this study.

3. Matching Adjustment of Whole Model and Local Model

On the one hand, in order to accurately simulate the deformation of a six-splitting mid-phase jumper under wind load, it is necessary to adjust the equivalent Young’s modulus of the whole model to make it have the same bending resistance as the local model. On the other hand, in order to more accurately simulate the stress of each strand of a conductor at the outlet of the tension clamp, it is necessary to ensure the accuracy of the deformation of the whole model introduced into the local model, that is, to ensure that the whole model has the same bending resistance as the local model. Therefore, it is very important for the accuracy of the simulation results to adjust the Young’s modulus of the whole model and obtain the equivalent Young’s modulus of the whole model based on the local model.

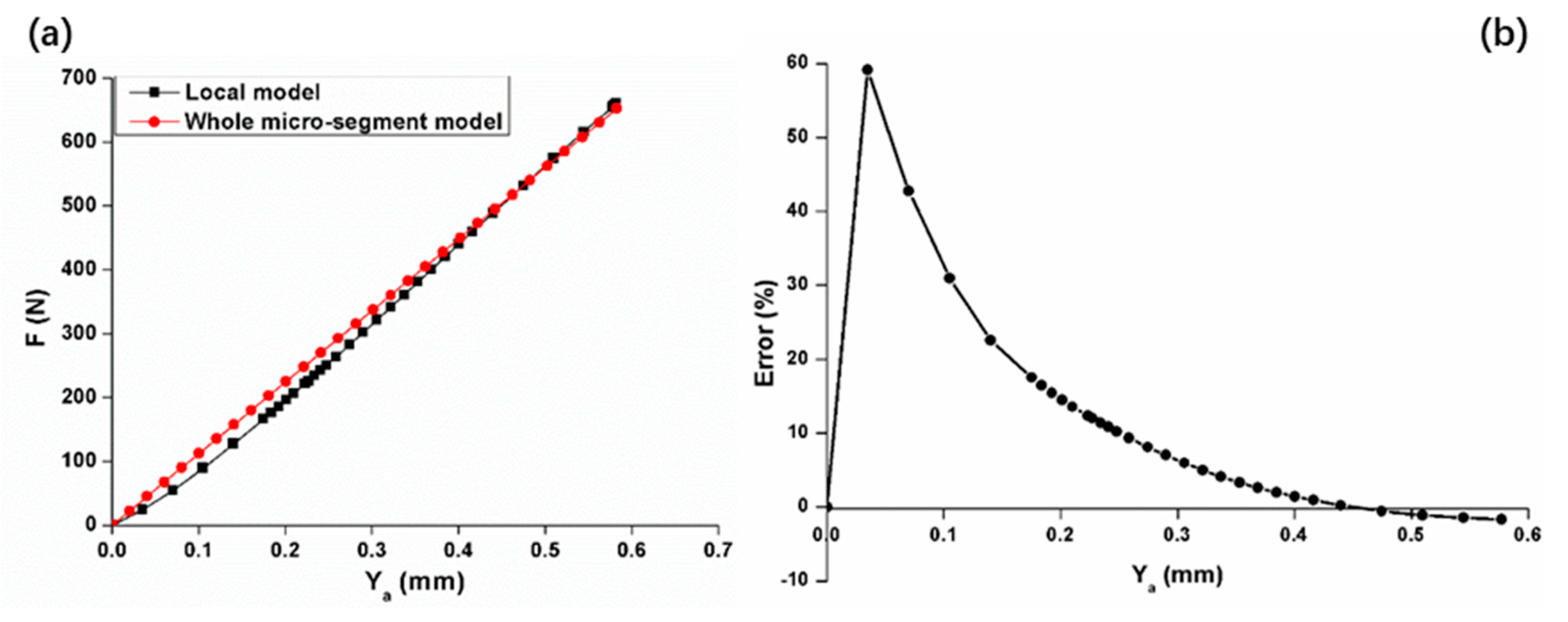

The Young’s modulus of the whole model is really the key of this paper, which was determined using the following method. In order to determine the Young’s modulus of the whole model, as shown in

Figure 3c, the whole microsegment model with a length of 120 mm was established, which was consistent with the cross section of the whole model (27.63 mm). By adjusting the Young’s modulus of the whole microsegment model, the whole microsegment model and the local model had the same bending stiffness, and then the adjusted Young’s modulus was input into the whole model such that the whole model had the same bending stiffness as the local model. A hexahedral incompatible element (C3D8I) was used in the whole microsegment model. The number of elements and nodes were approximately 2.4 × 10

4 and 2.6 × 10

4, respectively. One end of the whole microsegment model was completely fixed, while the other end was coupled with the central point, and the displacement boundary condition (Y

a) was applied to the coupling point. The boundary conditions of the microsegment whole model were in good agreement with those of the local model.

The Y

a of the coupling point and the force (F) needed to achieve the Y

a were obtained by changing Y

a. As shown in

Figure 5a, for the local model, the relationship of F − Y

a was approximately linear. By continuously adjusting the Young’s modulus of the whole microsegment model, the relationship of F − Y

a under different Young’s moduli can be obtained, and the relationship of F − Y

a was approximately linear. As shown in

Figure 5a, when the Young’s modulus of the whole microsegment model was 6.25 GPa, the F − Y

a lines of the whole microsegment model and the local model almost coincided. Therefore, when the Young’s modulus of the whole microsegment model was 6.25 GPa, the whole microsegment model and the local model had a similar bending stiffness. Then, 6.25 GPa was input into the whole model, which had the same bending stiffness as the local model.

As shown in

Figure 5b, for the same Y

a, the difference in F between the whole microsegment model and the local model was defined as ΔF. Based on an F corresponding to a Y

a of the local model, the ratio of ΔF to F corresponding to Y

a of this model was the error when applying this method. As shown in

Figure 5b, Y

a had a larger error of 0–0.25 mm and a smaller error of 0.25–0.6 mm. According to the simulation results in the fourth section, Y

a corresponding to a strong wind was between 0.25–0.60; therefore, this study mainly considered the part of Y

a between 0.25 and 0.60 mm. The absolute error of this part was less than 10%, which is within a reasonable range.

4. Results and Discussion

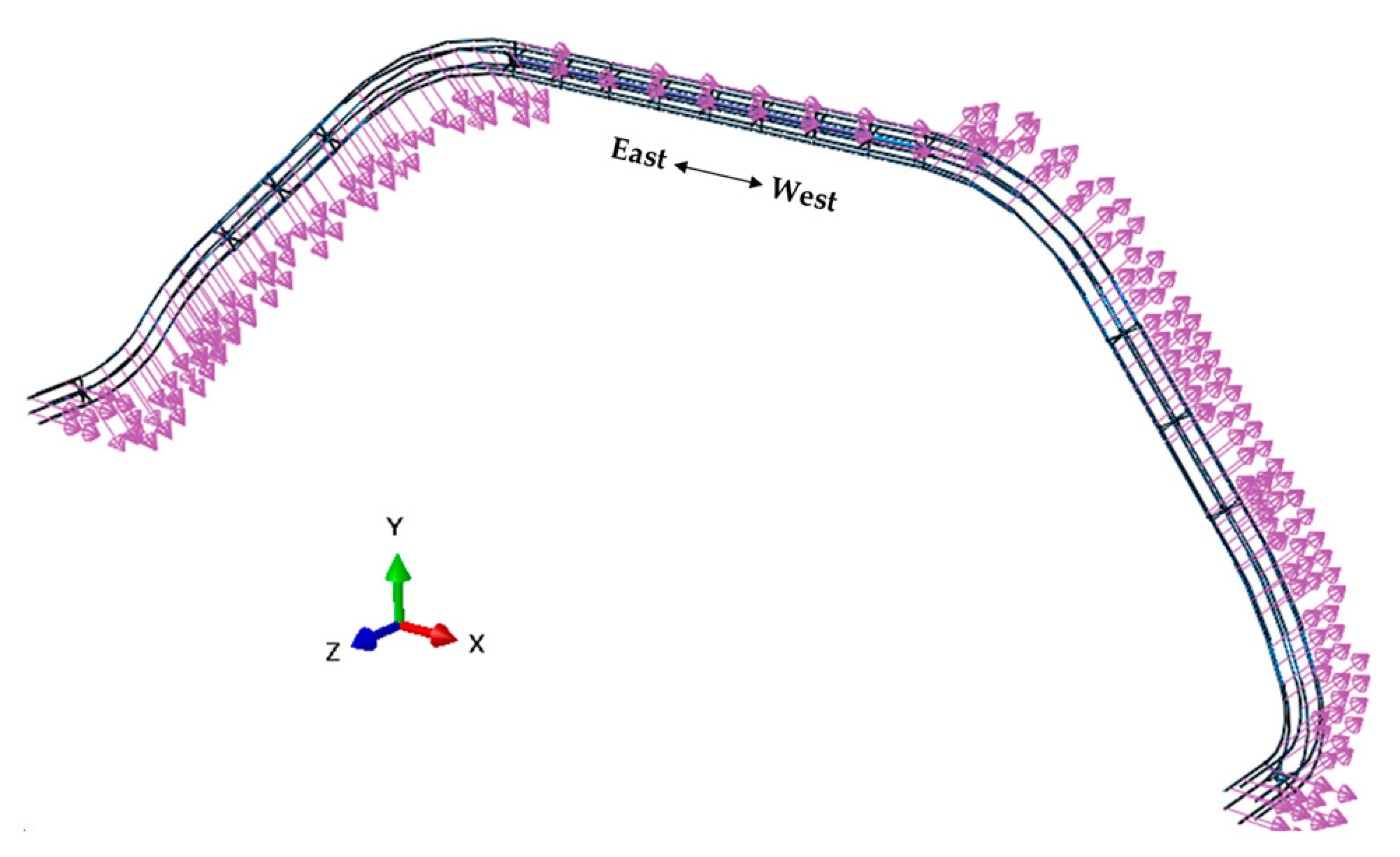

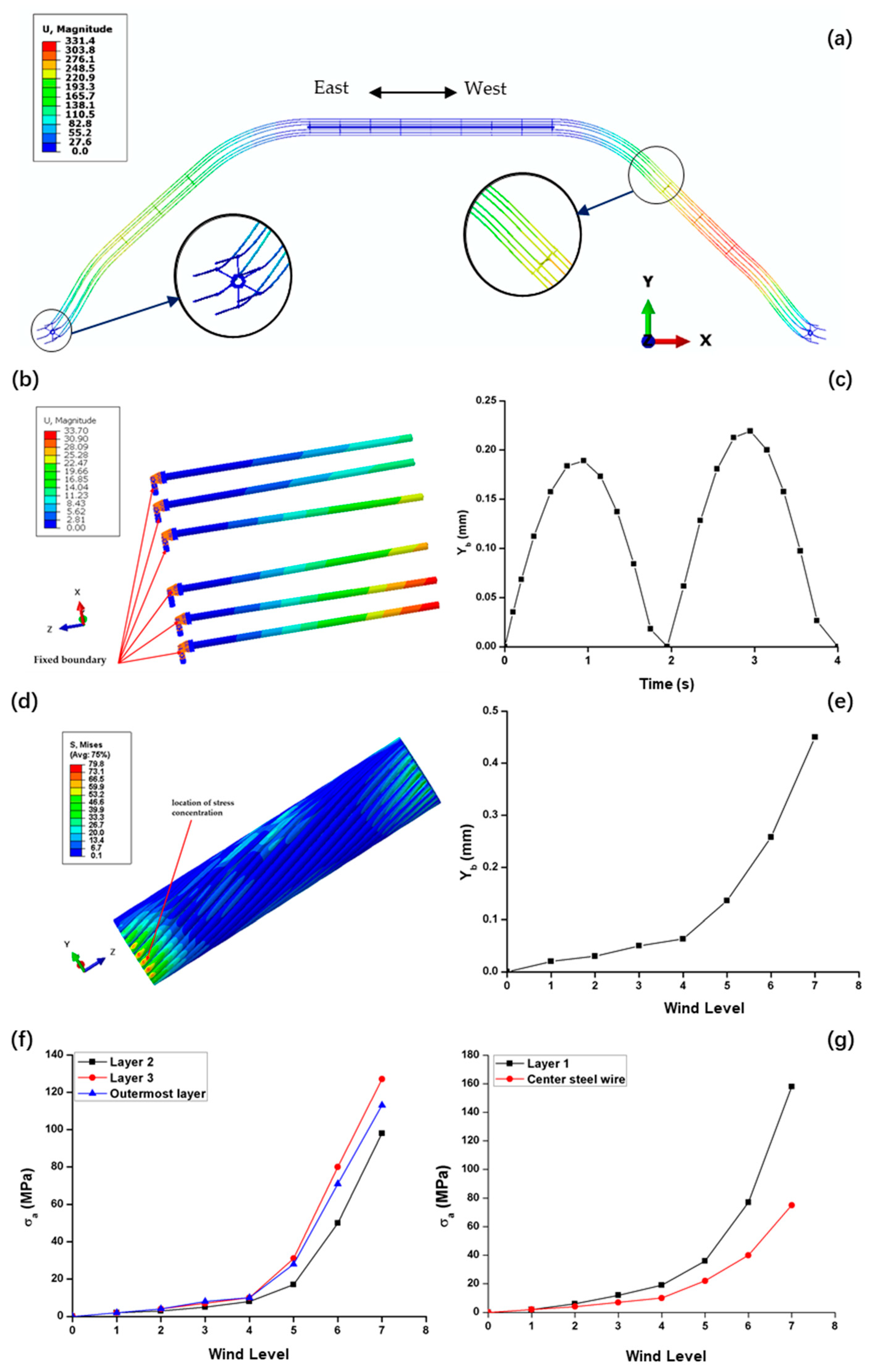

Figure 6a shows a displacement nephogram of the whole model under a westerly, level-6 wind.

Figure 6b shows the displacement nephogram of the whole model with a length of 1000 mm at the outlet of the tension clamp. The middle section of the mid-phase jumper swung back and forth along the east–west direction. The swing of the mid-phase jumper in this direction caused a greater bending moment at the lower area of the mid-phase jumper.

It was assumed that the deflection of the conductor with the maximum displacement at the lower area of the whole model under wind load was Y

b at 89 mm away from the outlet of the tension clamp. When Y

b corresponding to different wind loads was imported into the local model, the maximum equivalent stress (σ

a) corresponding to the outlet position of the tension clamp of the local model under different wind loads could be obtained. As shown in

Figure 6c, Y

b changed with the swing of the whole model. When the displacement of the middle part of the mid-phase jumper along the negative X direction reached the maximum, Y

b also reached the maximum (

t = 3 s). This maximum value of Y

b (0.258 mm) was imported into the local model to obtain the stress distribution at the outlet of the tension clamp under the level-6 wind, as shown in

Figure 6d. It is seen that the stress concentration appeared near the fixed end of the local model, that is, the stress concentration appeared near the outlet of the tension clamp and the maximum stress appeared here. This explains why the actual mid-phase jumper breakage occurred at the outlet of the tension clamp.

As shown in

Figure 6e, with an increase in the wind load, Y

b increased, accelerating rapidly after a level-4 wind, which was due to the rapid increase in the wind load applied to the whole model. As shown in

Figure 6f, with an increase in the wind load, the value of σ

a of the outermost, third, and second layers of the aluminum conductor increased, where the σ

a of the third layer was the largest. The σ

a of the outermost and third layers were higher than the yield strength of the conductor under the level-6 wind. The difference between σ

a of the outermost layer and σ

a of the third layer increased gradually with the wind load increases, and the difference was approximately 10 MPa under the level-6 wind load. As shown in

Figure 6g, the steel layers had not reached their yield strength (275 MPa) when all three aluminum layers yielded under the level-7 wind load, although σ

a on the first layer was the largest at this time. This was because the Young’s modulus of the first layer was much larger than that of the aluminum because of its steel material, which resulted in a larger stress on the first layer of the steel core.

6. Effect of the Friction Coefficient

Because the friction coefficient is affected by the metal type, chemical composition, surface state, deformation temperature, and contact pressure, the friction coefficient between aluminum strands is not easy to determine. This paper mainly studied the bending deformation of a conductor, and the contact between each strand of a conductor is extremely complex during the process of the bending deformation. Coulomb’s law was introduced to study this problem. The tangential contact of each strand in the aluminum strand follows this law. The Coulomb friction model was used in Abaqus.

Papailiou et al. [

25] proposed a conductor model that can withstand both the tension and bending loads, and considered the interlayer friction and slip during the process of wire bending. It was found that the bending analysis of the conductor was extremely sensitive to the selection of the friction coefficients between two adjacent layers of the conductors. The range of friction coefficients between cables was found to be between 0.55 and 0.9. Wharton et al. [

26] measured the fretting fatigue strength of A1-4Mg-0.7Mn in contact with aluminum and copper. It was found that the friction coefficient of A1-4Mg-0.7Mn in contact with aluminum and copper was extremely low, but with an increase in the number of fatigue cycles, the friction coefficient increased to approximately 1.0 and remained unchanged at this value. Clearly, a conductor bending analysis is extremely sensitive to the choice of friction coefficient between two adjacent conductors. In the process of long-term service, the friction coefficient between strands of a conductor will change due to the wear between strands. In order to accurately evaluate the change of the friction coefficient in the service process of the mid-phase jumper, this section discusses the influence of the friction coefficient on the stress of the mid-phase jumper when other conditions remain unchanged. Thus, the friction coefficients between the steel-cored aluminum strands were set to 0.3, 0.5, and 0.7. At this time, the equivalent Young’s modulus of the whole finite element model was 6.78, 6.68, and 7.67 GPa, respectively, and the other conditions remained unchanged. The influence of the friction coefficient is discussed next.

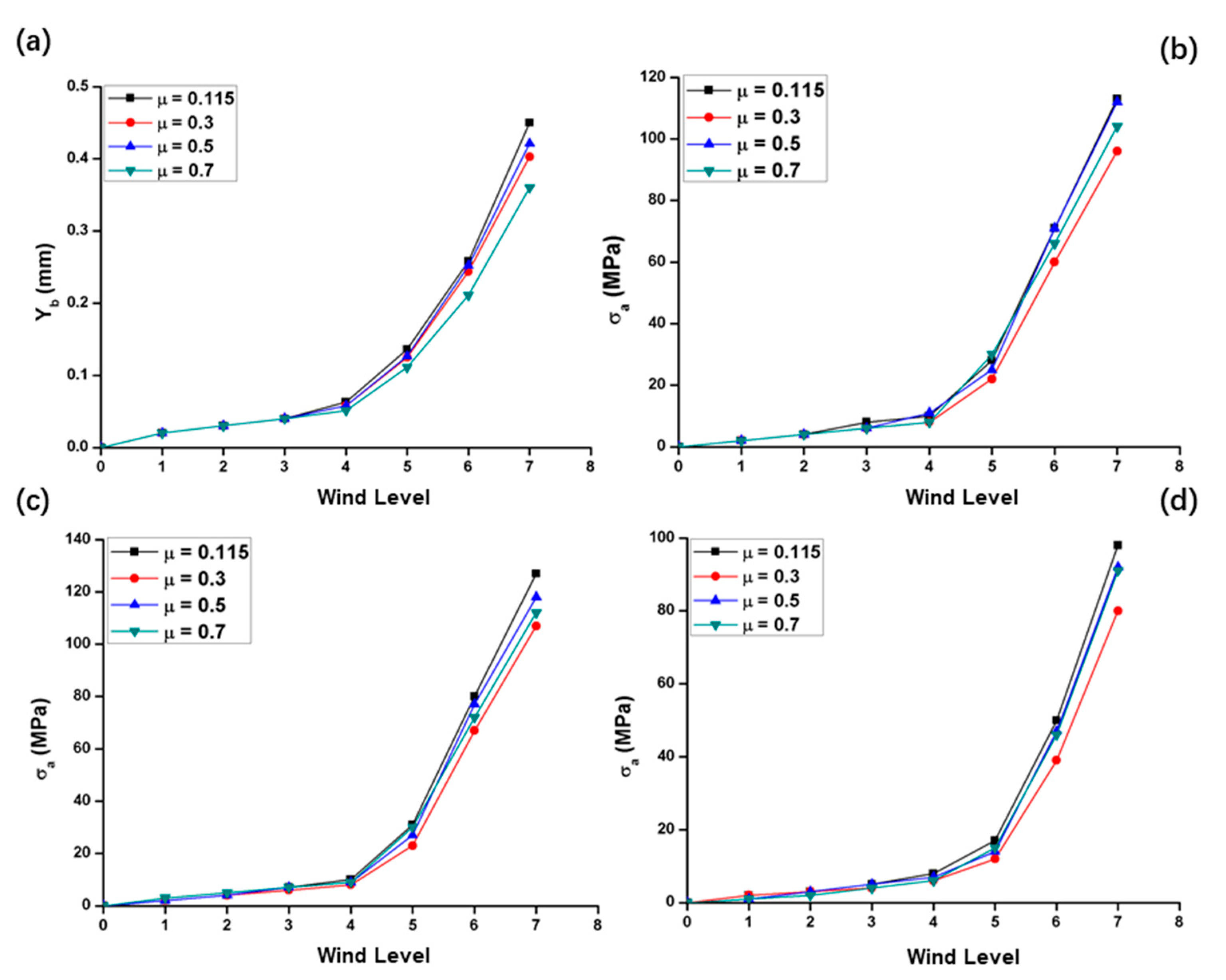

As shown in

Figure 14, between level-1 and level-3 wind loads, the wind load was small, and thus σ

a and Y

b were extremely small; therefore, the friction coefficient had little effect on the corresponding σ

a and Y

b. Between level-4 and level-7 wind loads, when the friction coefficient was 0.115 to 0.50, σ

a and Y

b first decreased and then increased with an increase of the friction coefficient under the same wind load; when the friction coefficient was 0.50 to 0.70, σ

a and Y

b decreased again with an increase of the friction coefficient under the same wind load. Therefore, the friction coefficient had a great effect on the corresponding σ

a and Y

b between level-4 and level-7 wind loads. The difference in σ

a between the outermost layer and the third layer reached the maximum under a level-7 wind load when the friction coefficient took the above four parameters, and the maximum difference did not exceed 20 MPa. In conclusion, the friction coefficient influenced the bending of the mid-phase jumper, but the effect was not great.

7. Conclusions

In this paper, a finite element, fully three-dimensional solid modeling method was used to study the mechanical response of a steel-cored aluminum strand (ACSR) with a mid-phase jumper under a wind load. The whole model (simplifying an ACSR into a solid cylinder) and a local model (modeling according to the actual structure of an ACSR) of the mid-phase jumper were established. First, the movement of the mid-phase jumper of the tension tower under a wind load was studied based on a whole finite element model, and the equivalent Young’s modulus of the whole model was adjusted based on the local model. The results of the whole model were then imported into the local model, and the stress distribution of each strand of the ACSR was analyzed in detail to provide guidance for the treatment measures. Therefore, the whole model and the local model complemented each other, which could reduce the number of model operations and ensure the accuracy of the results. Although this method was applied to the stress and deformation analysis of a mid-phase jumper in this paper, it can be used to study the bending deformation of rope structures with a complex geometry and a main bending deformation.

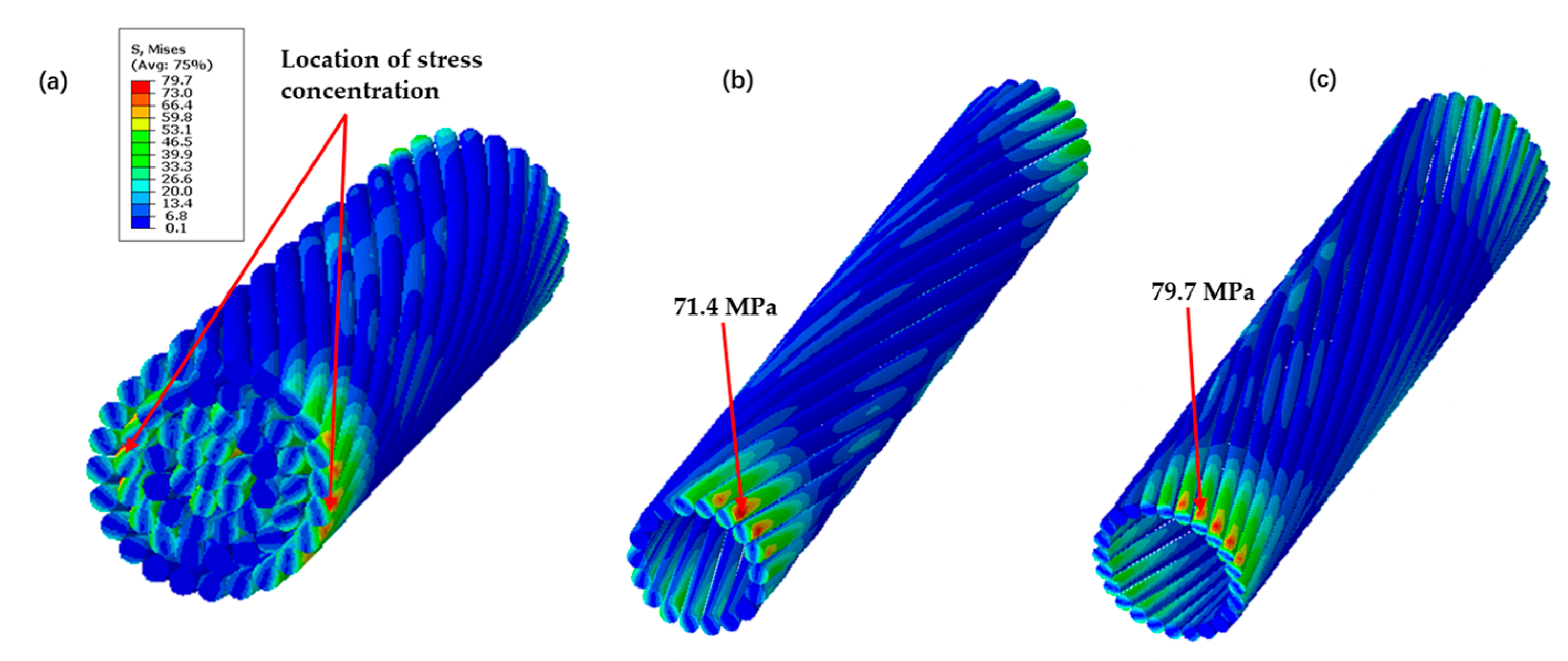

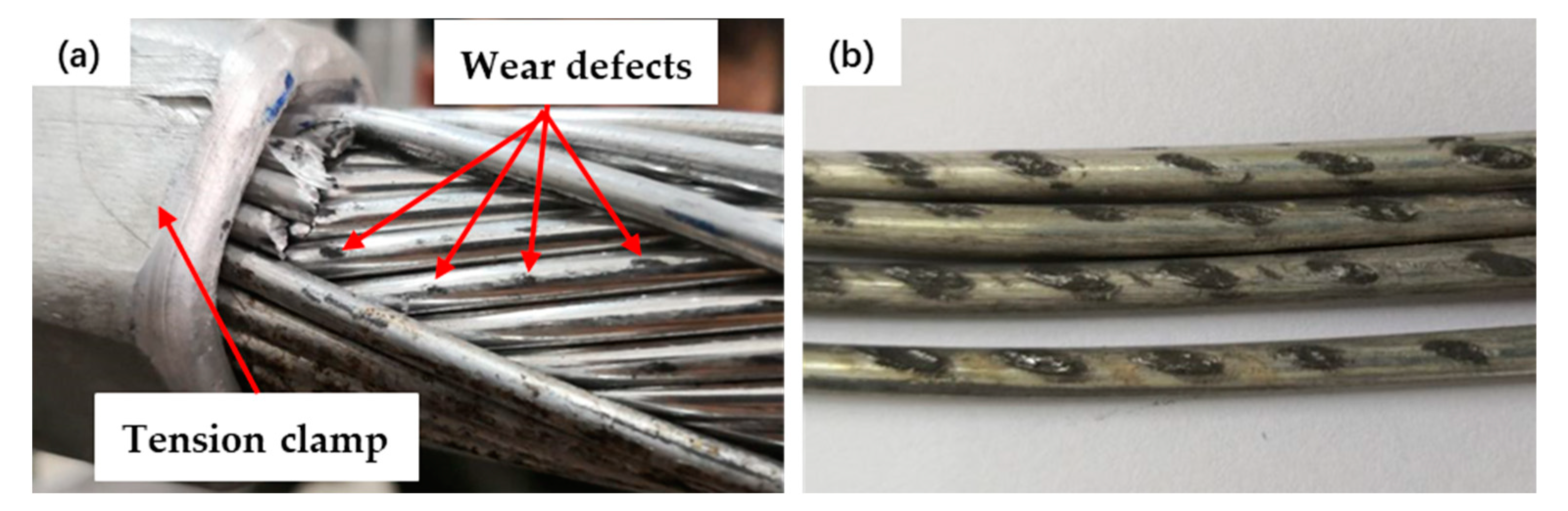

The analysis showed that the swing of the mid-phase jumper in the east–west direction caused a greater bending moment at the lower area of the mid-phase jumper, which led to the stress concentration appearing near the outlet of the tension clamp. This explained why the actual mid-phase jumper breakage occurred at the outlet of the tension clamp. The maximum stresses of the outermost and third layers were higher than the yield strength under a level-6 wind. The difference in σa between the outermost and third layers increased gradually when the wind load increased, and the difference was approximately 10 MPa under a level-6 wind load.

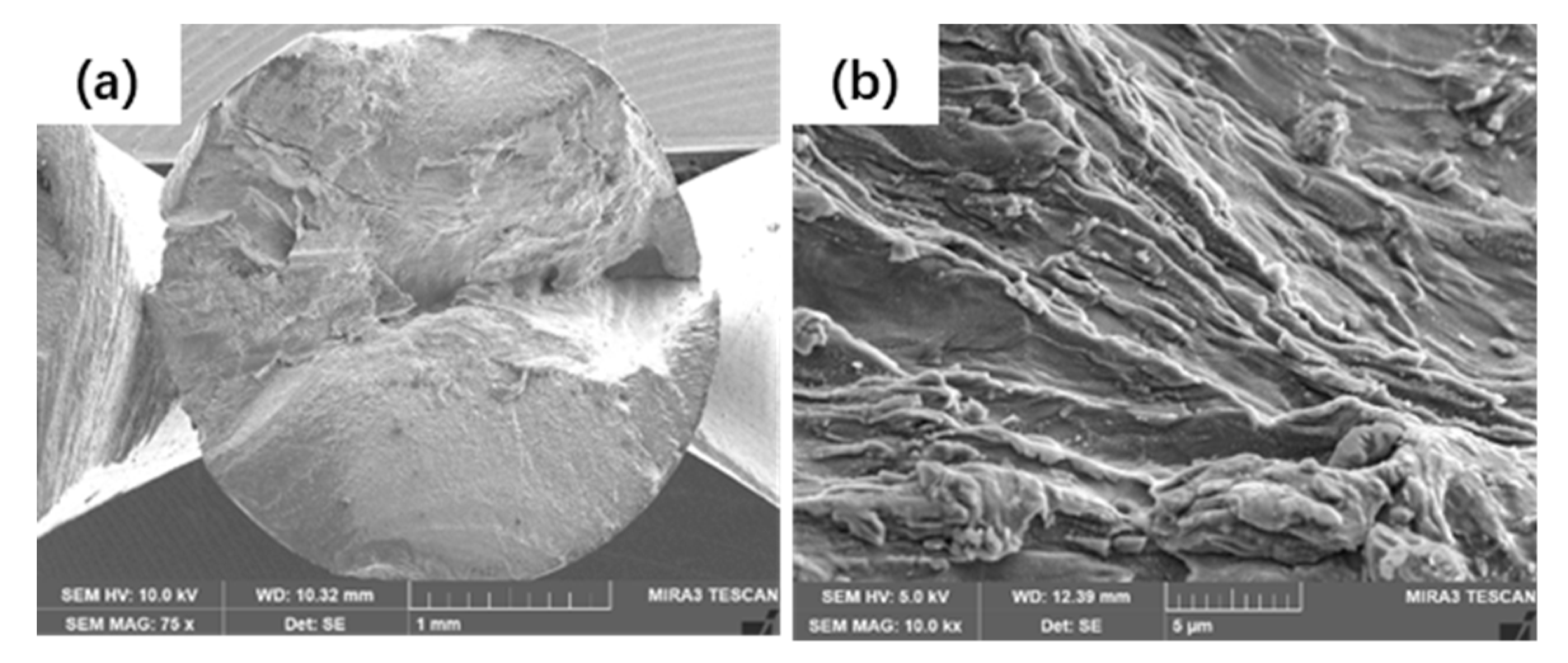

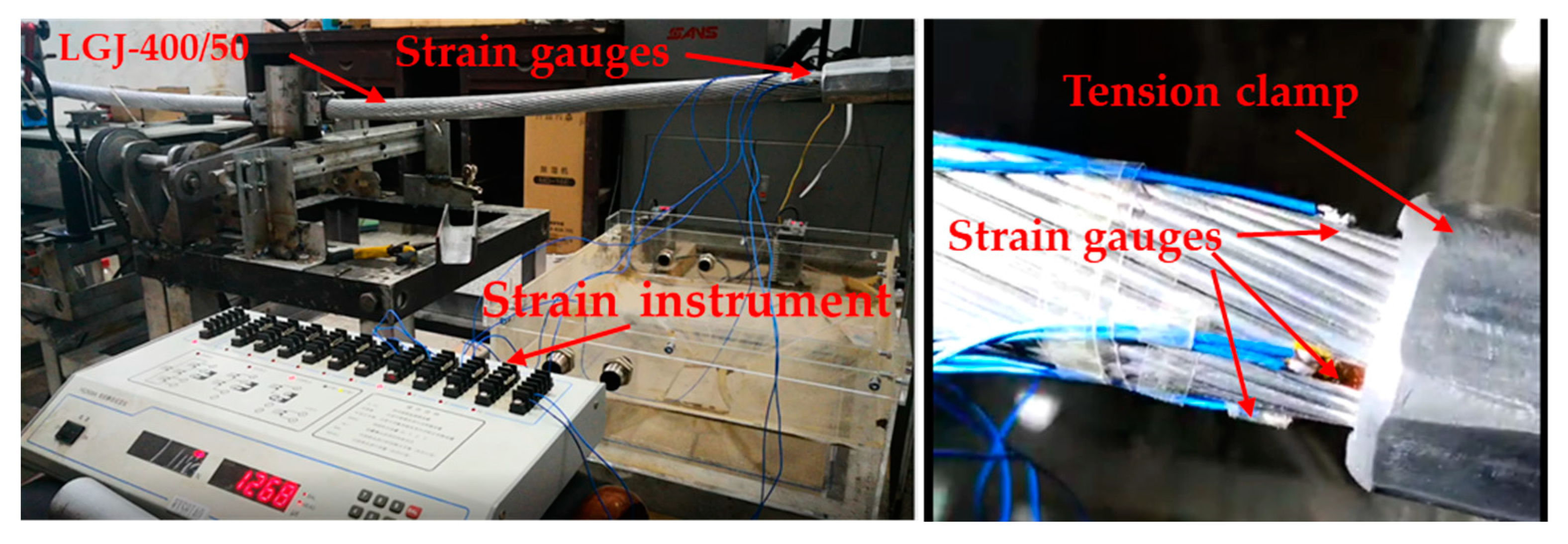

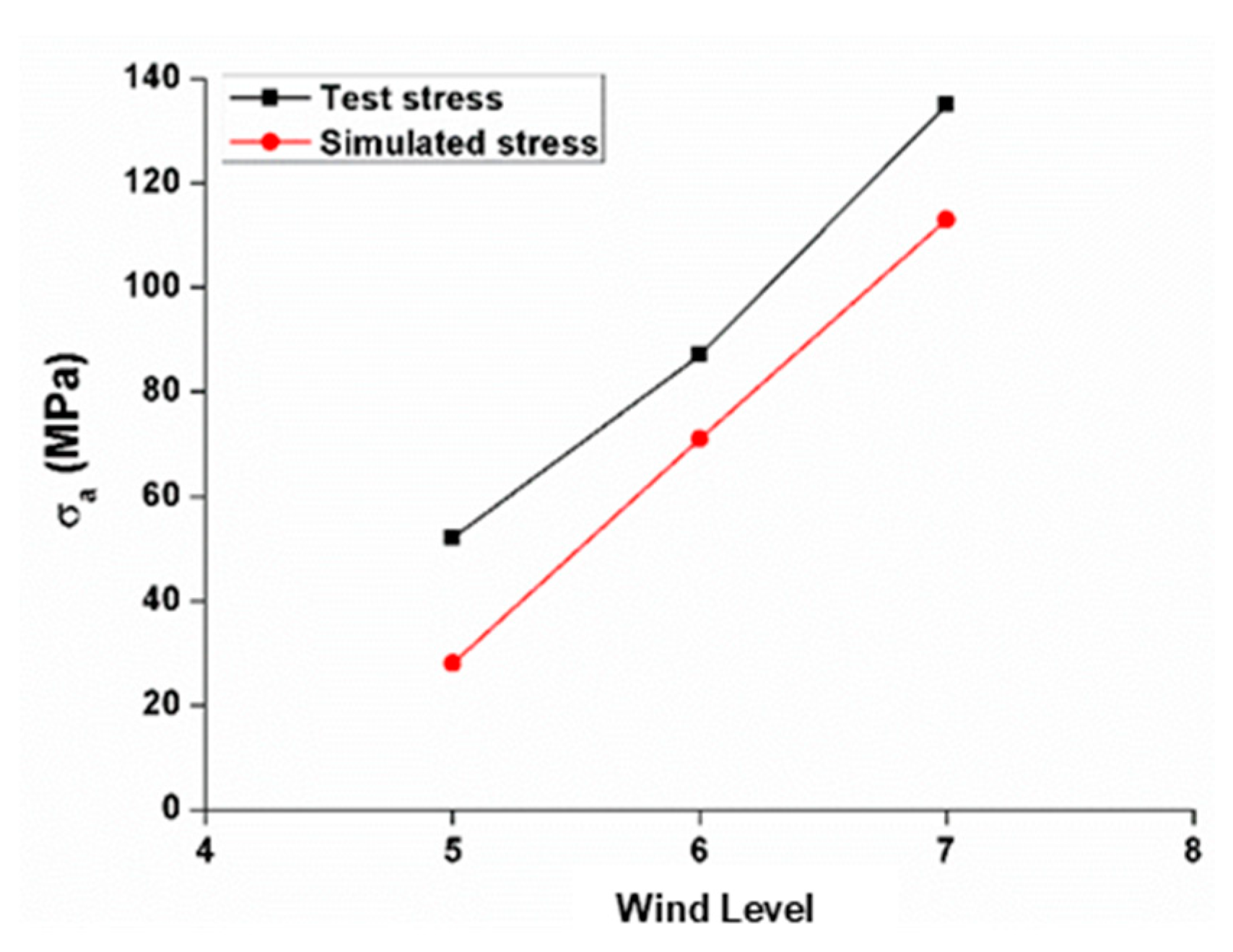

Interestingly, σa of the third layer of the conductor (79.7 MPa) was greater than σa of the outermost conductor (71.4 MPa), which was verified by the results of the fatigue tests. Based on the analysis of the surface wear of the third layer of the conductor, the reason for the fracture of the third layer of conductor was explained. The feasibility of the element modeling method was verified through a comparison with the results of a subsequent series of experiments.

In addition, the effects of the friction coefficient on the bending of a mid-phase jumper were studied. It was found that the friction coefficient influenced the bending of the mid-phase jumper, but the effect was not great.