Influence of Cutting Angle of Blade Trailing Edge on Unsteady Flow in a Centrifugal Pump Under Off-Design Conditions

Abstract

1. Introduction

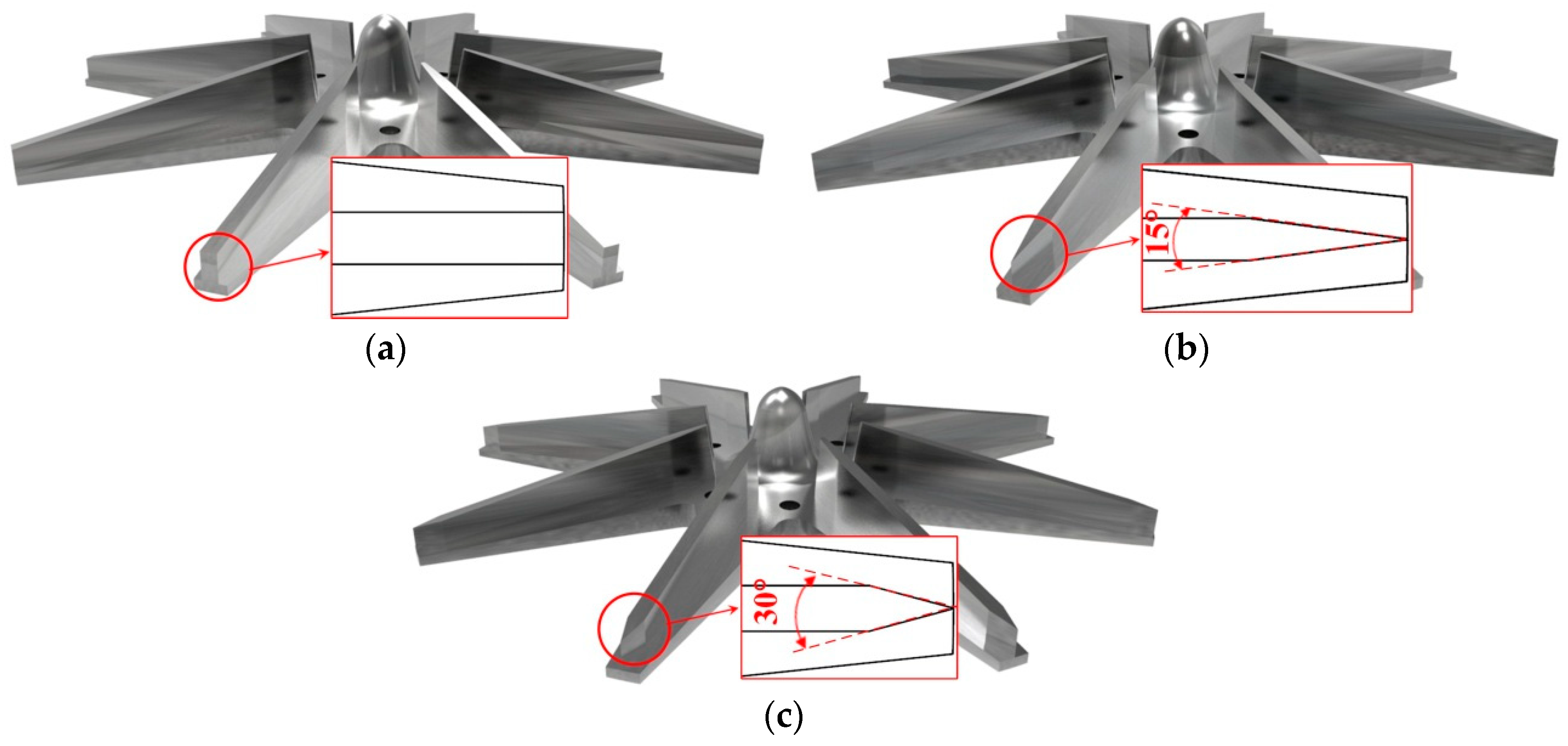

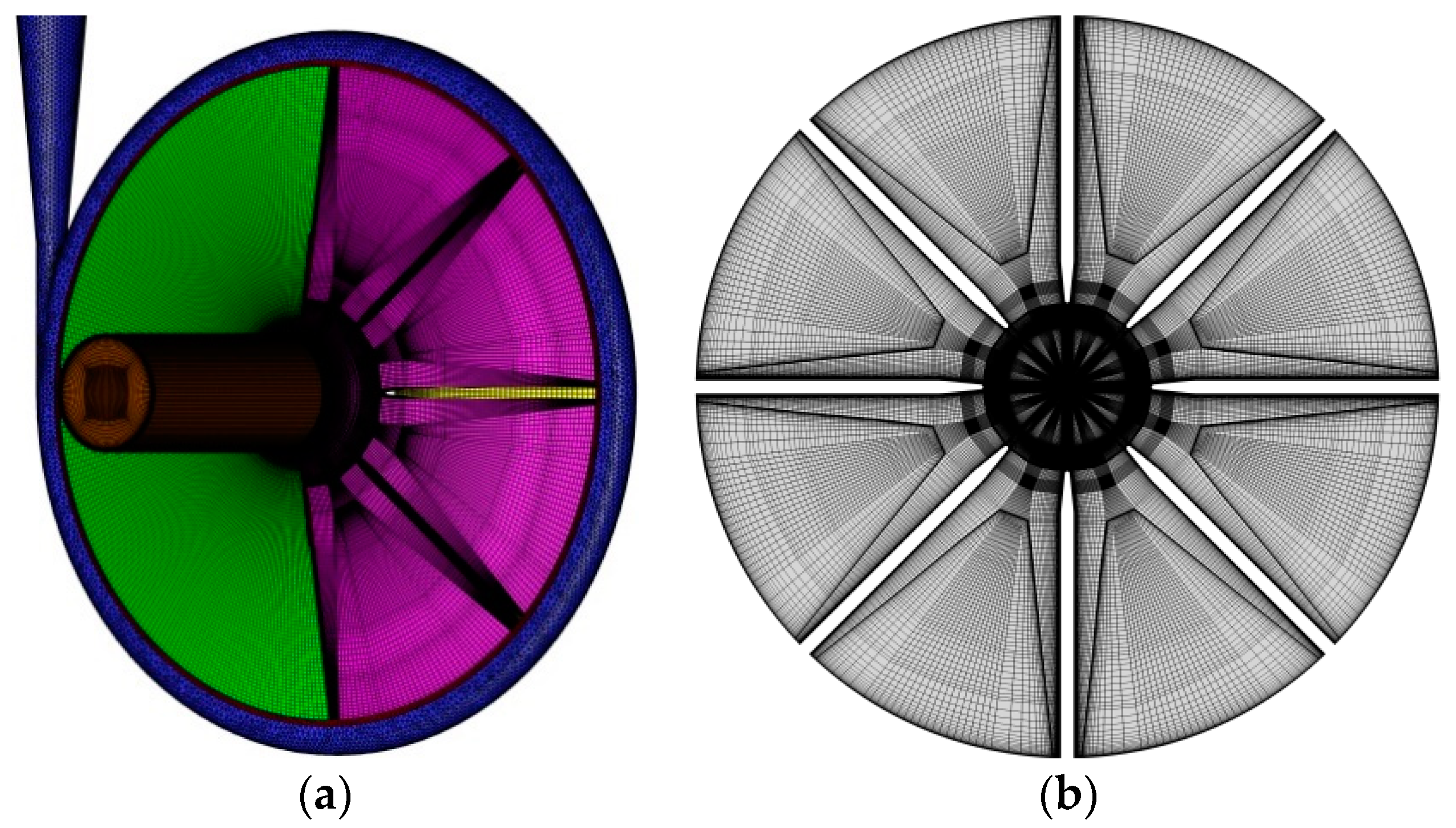

2. Geometric Models and Numerical Methods

2.1. Geometric Model and Meshing

2.2. Numerical Simulation Method

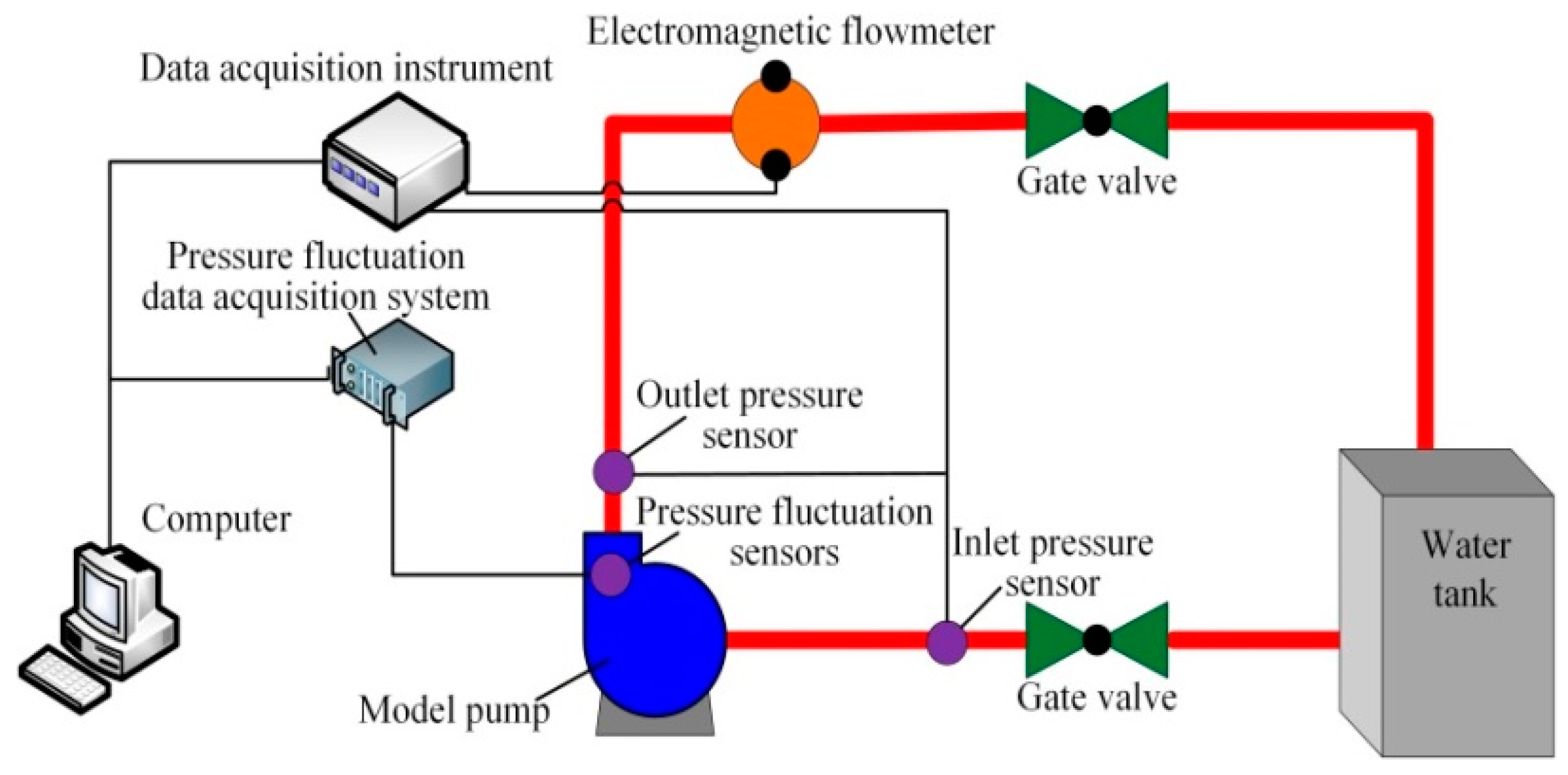

3. Experimental Setup and Method

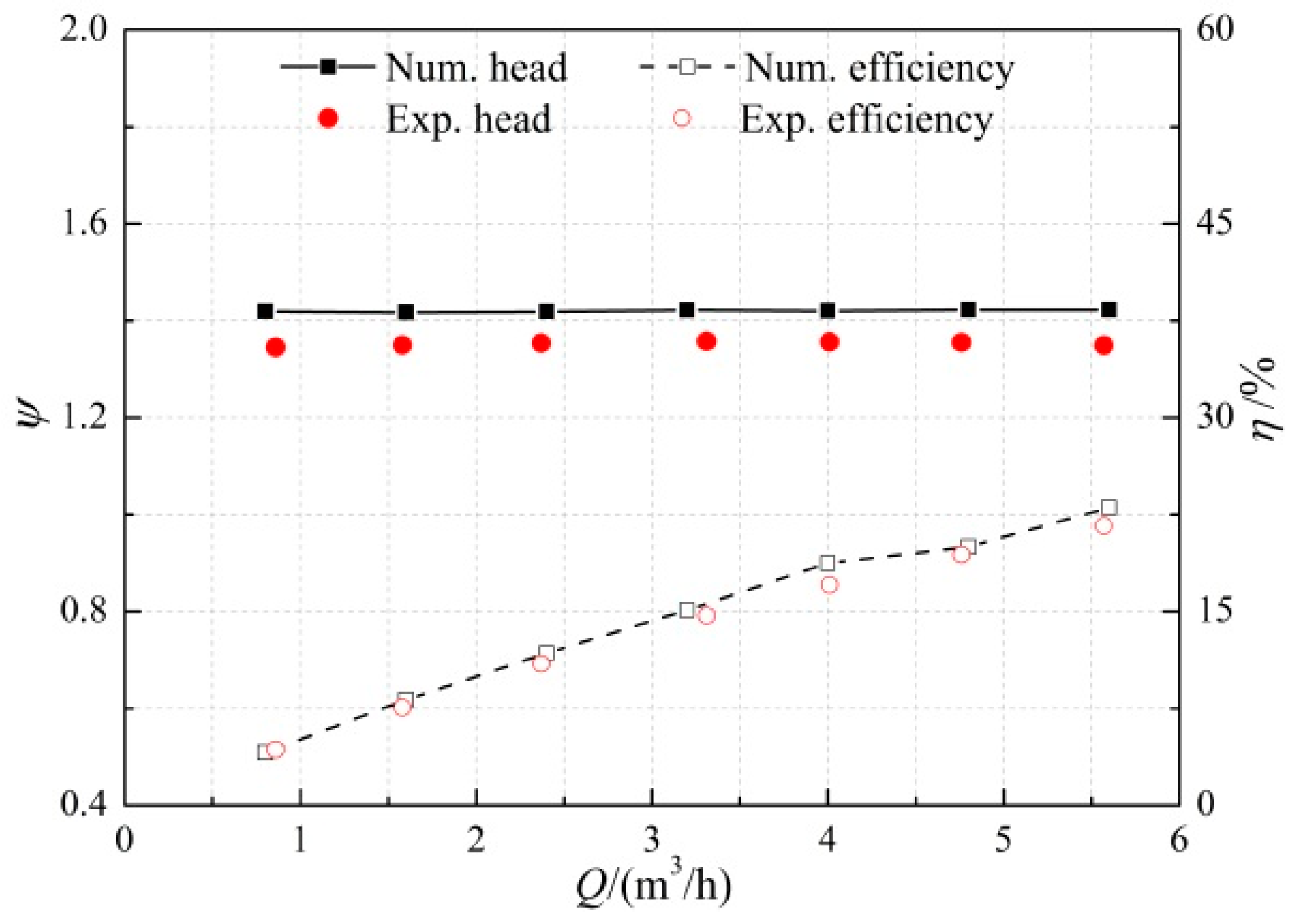

4. Results and Discussion

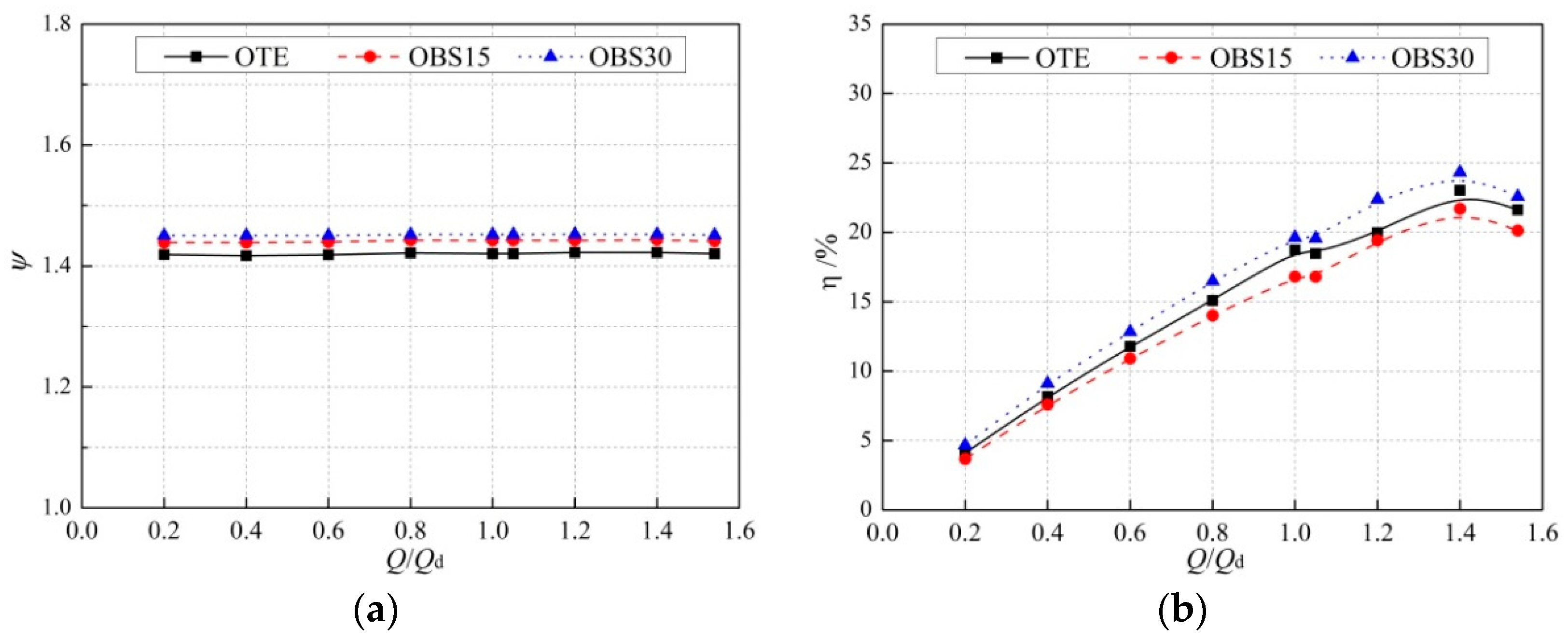

4.1. Performance Analysis

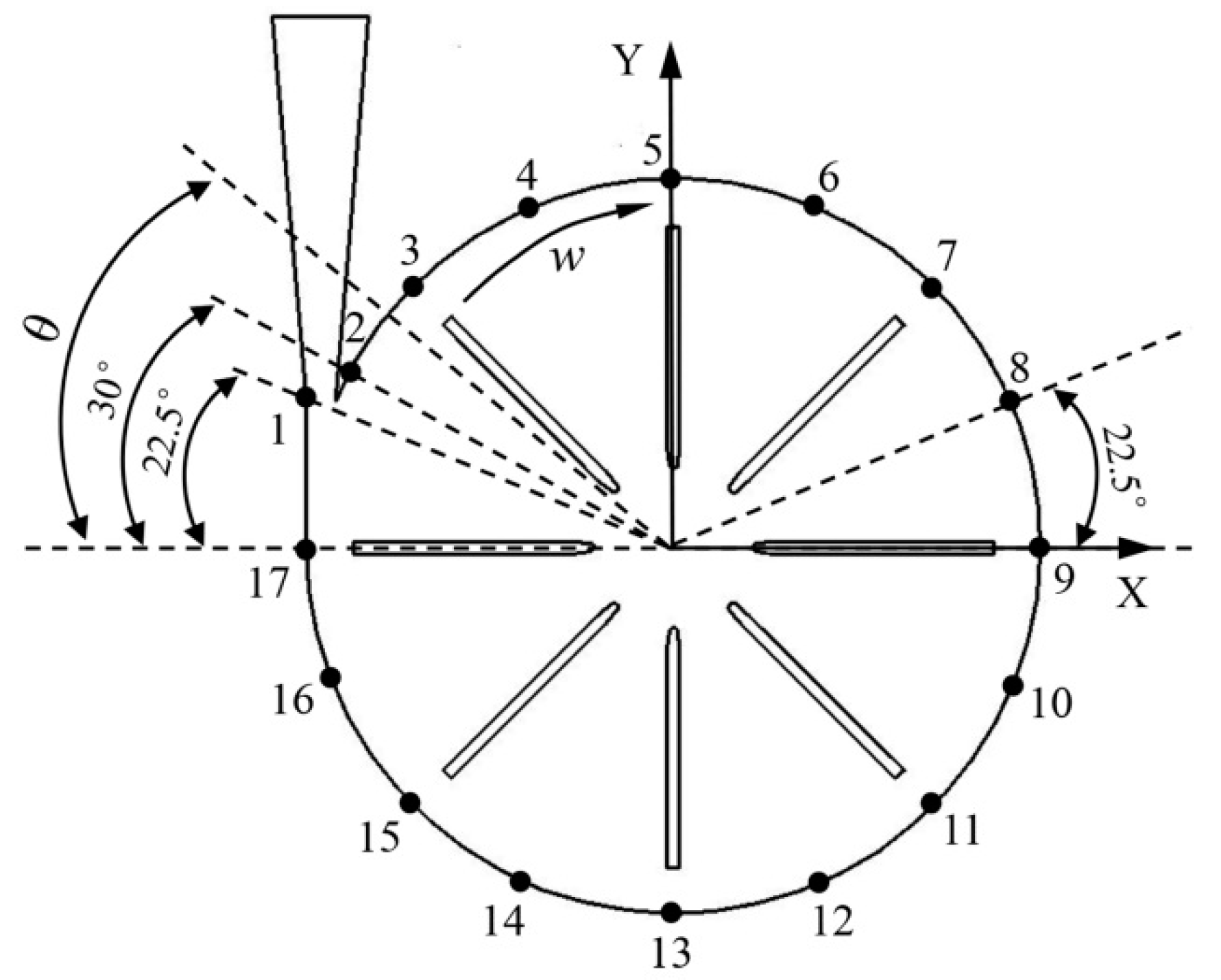

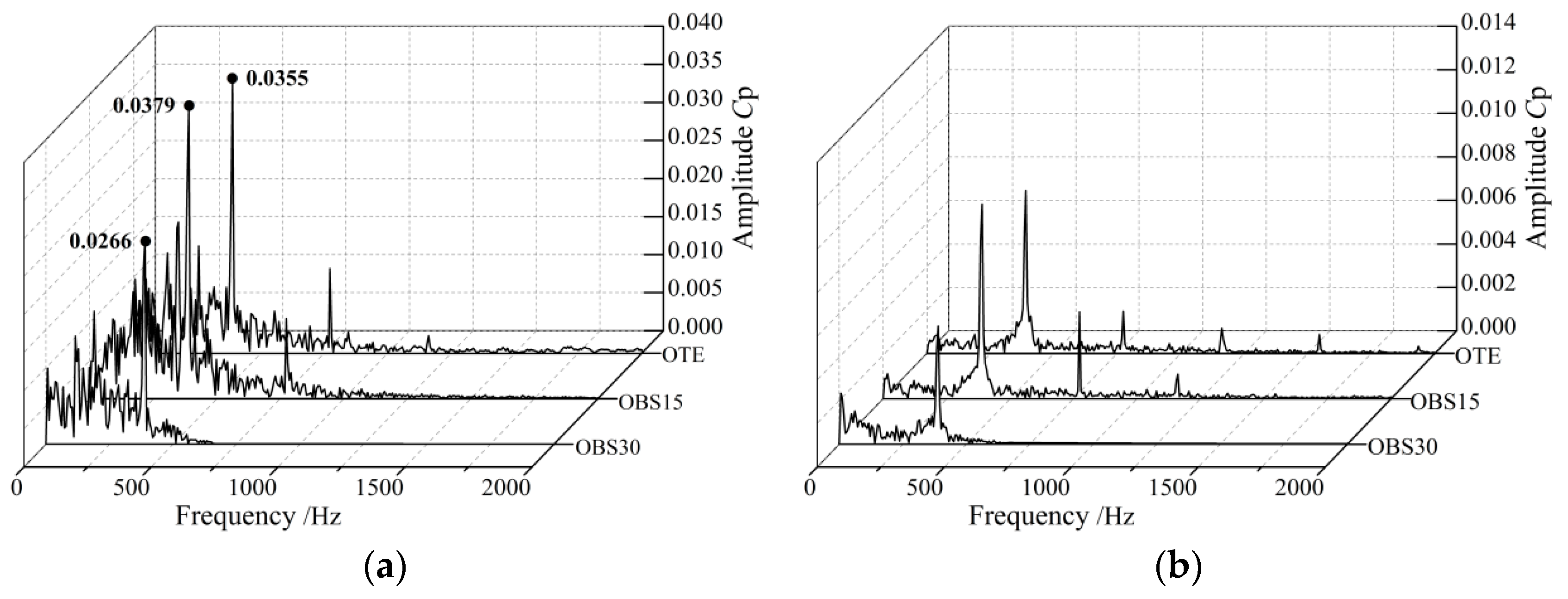

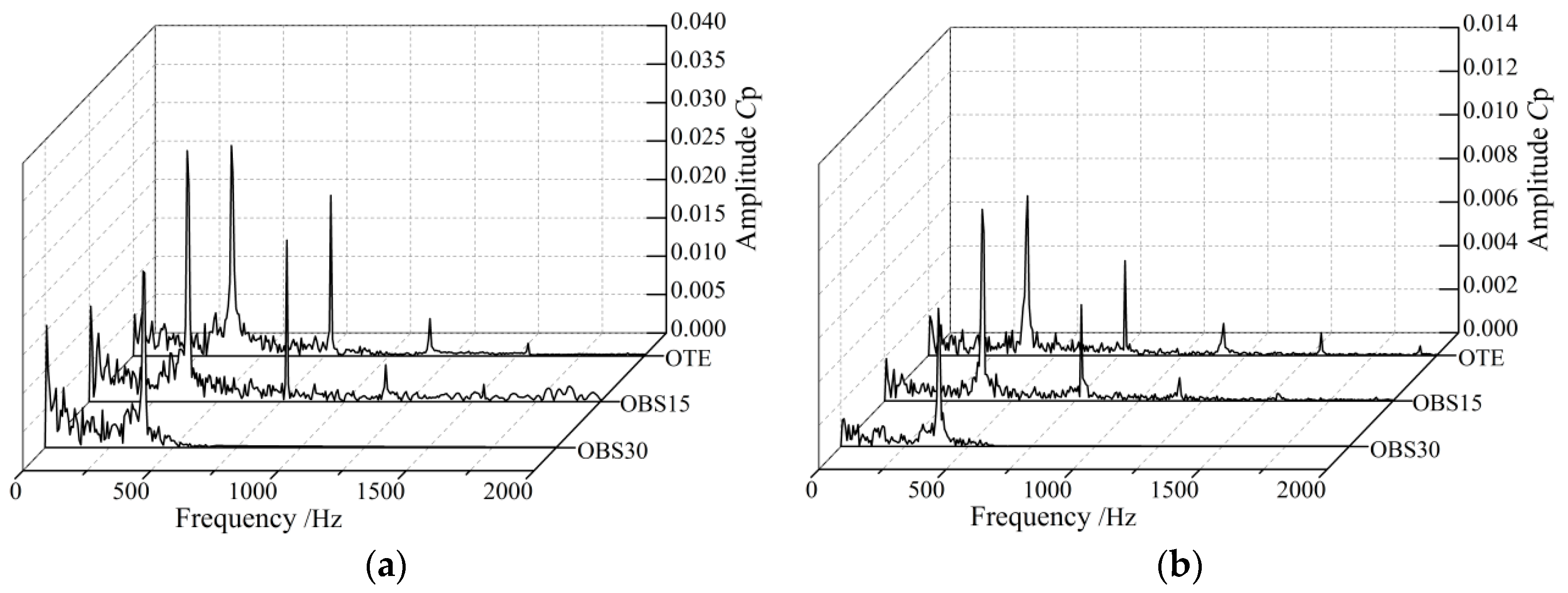

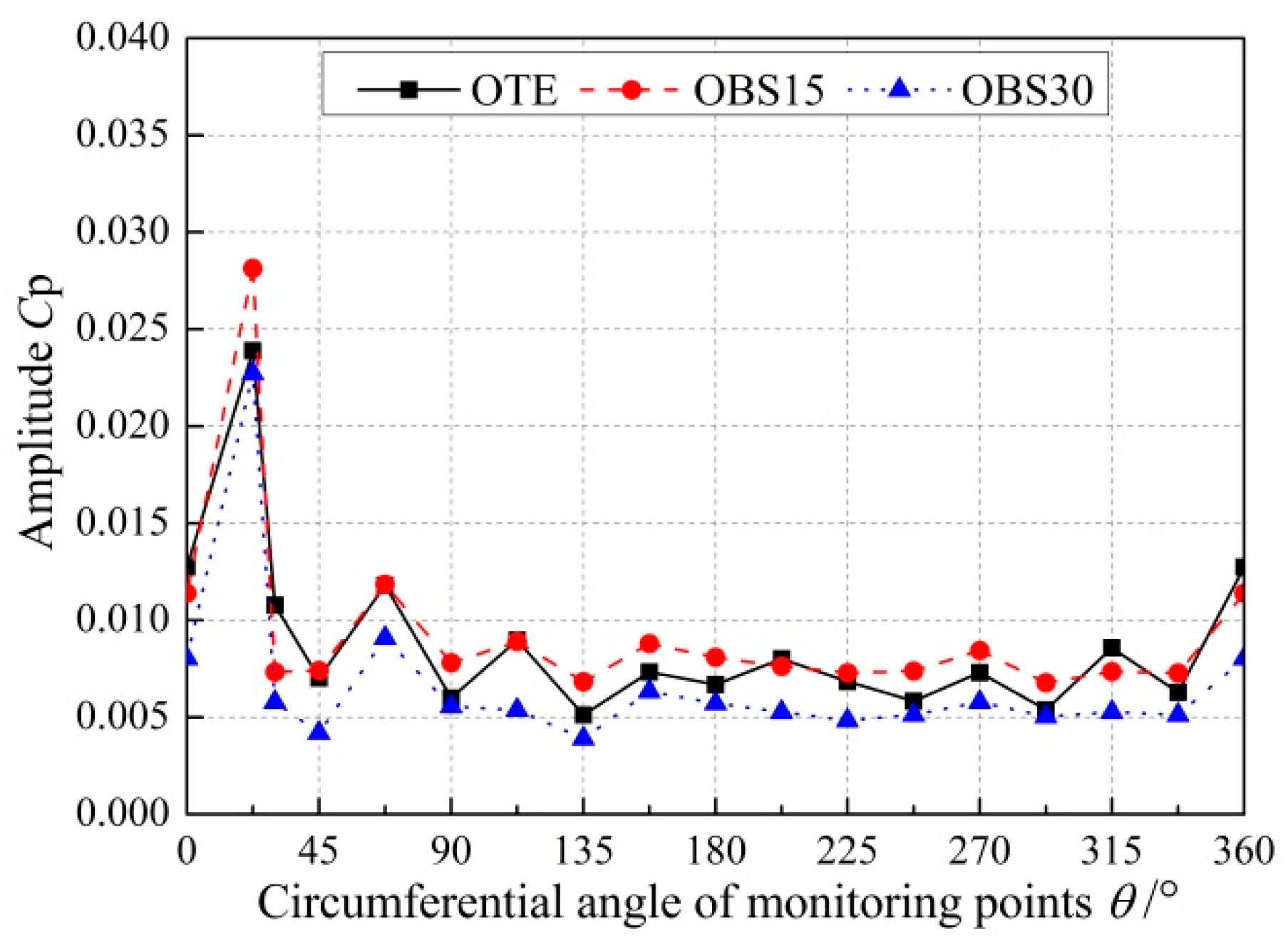

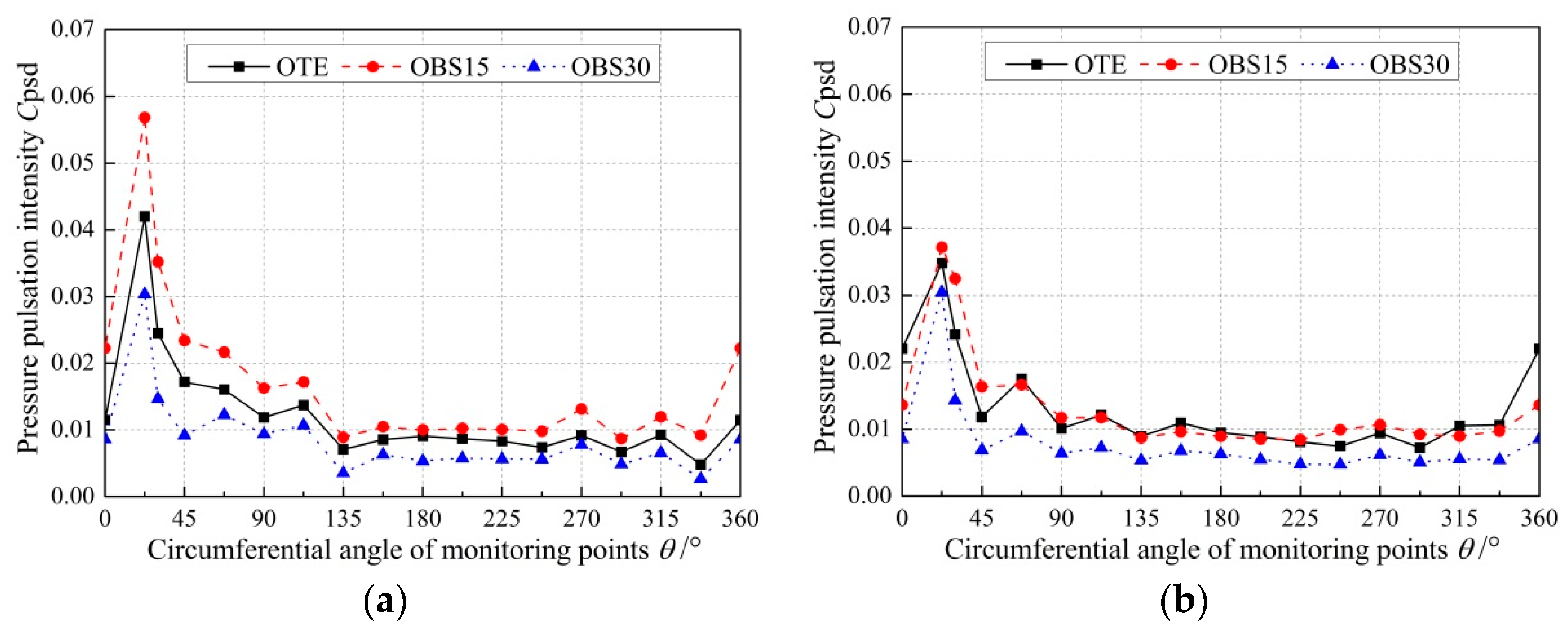

4.2. Analysis of Unstable Pressure Pulsations

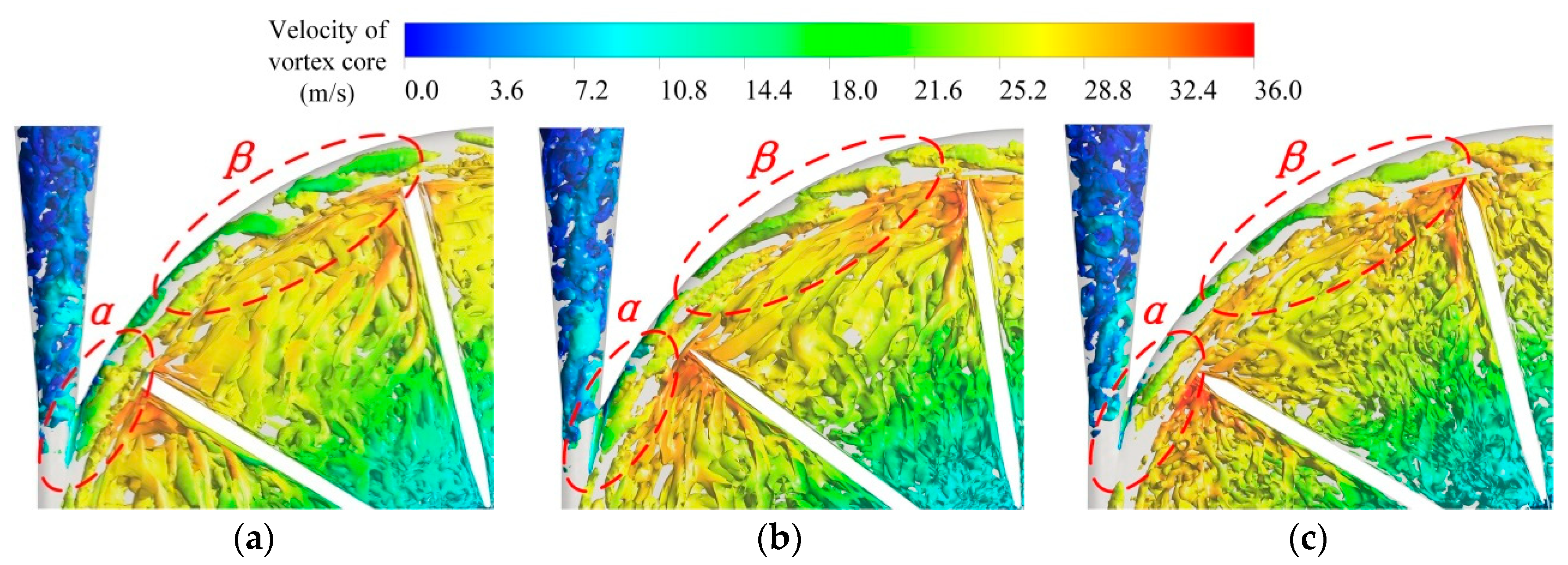

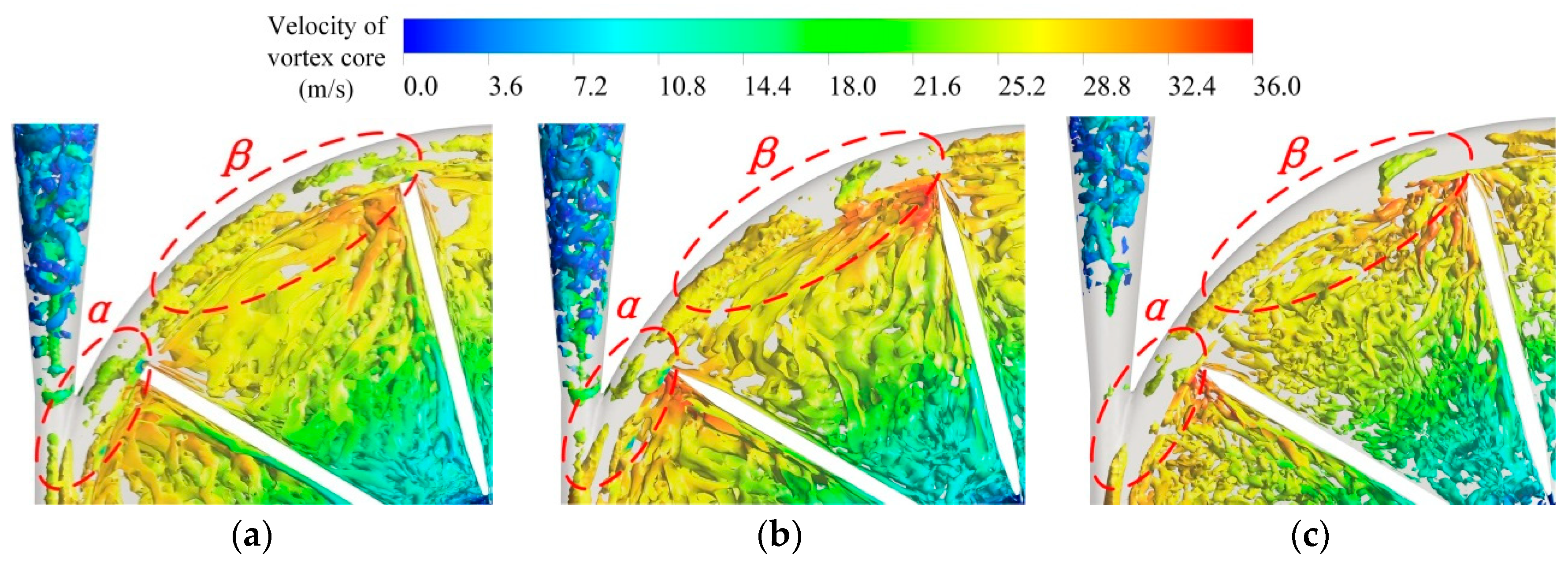

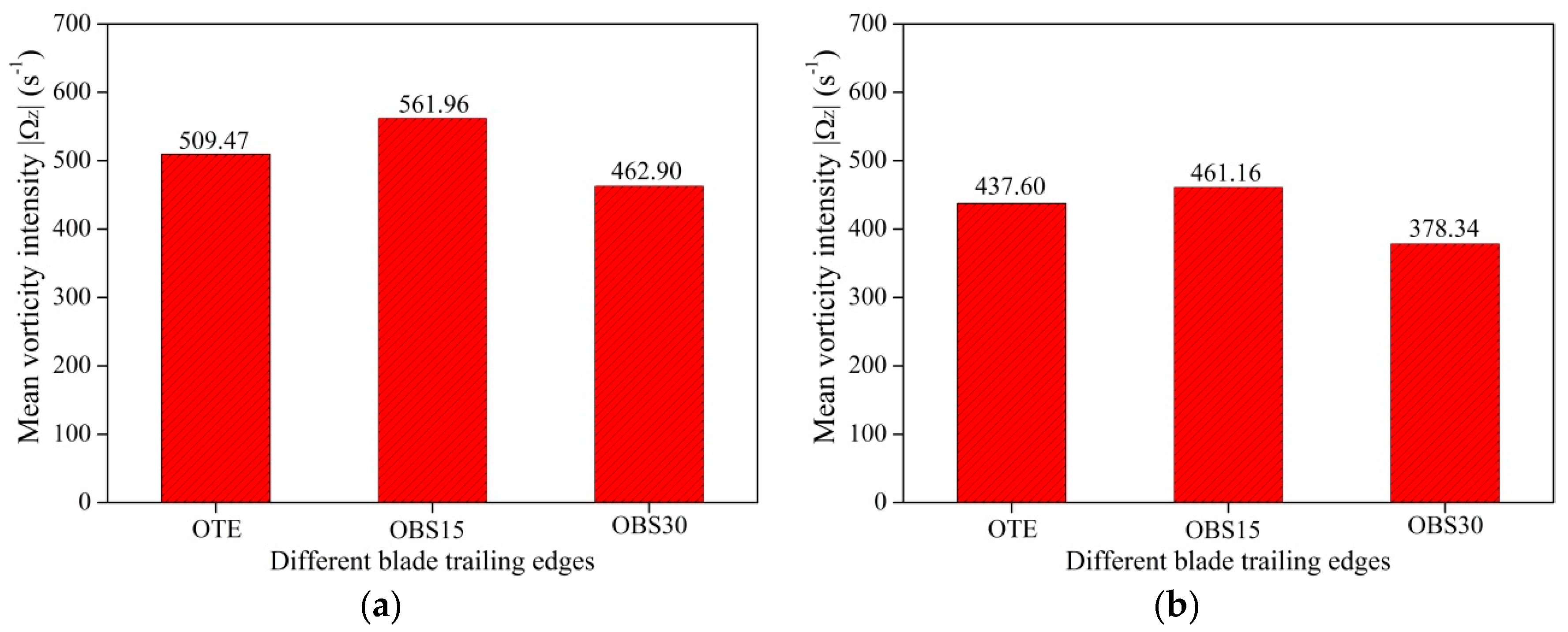

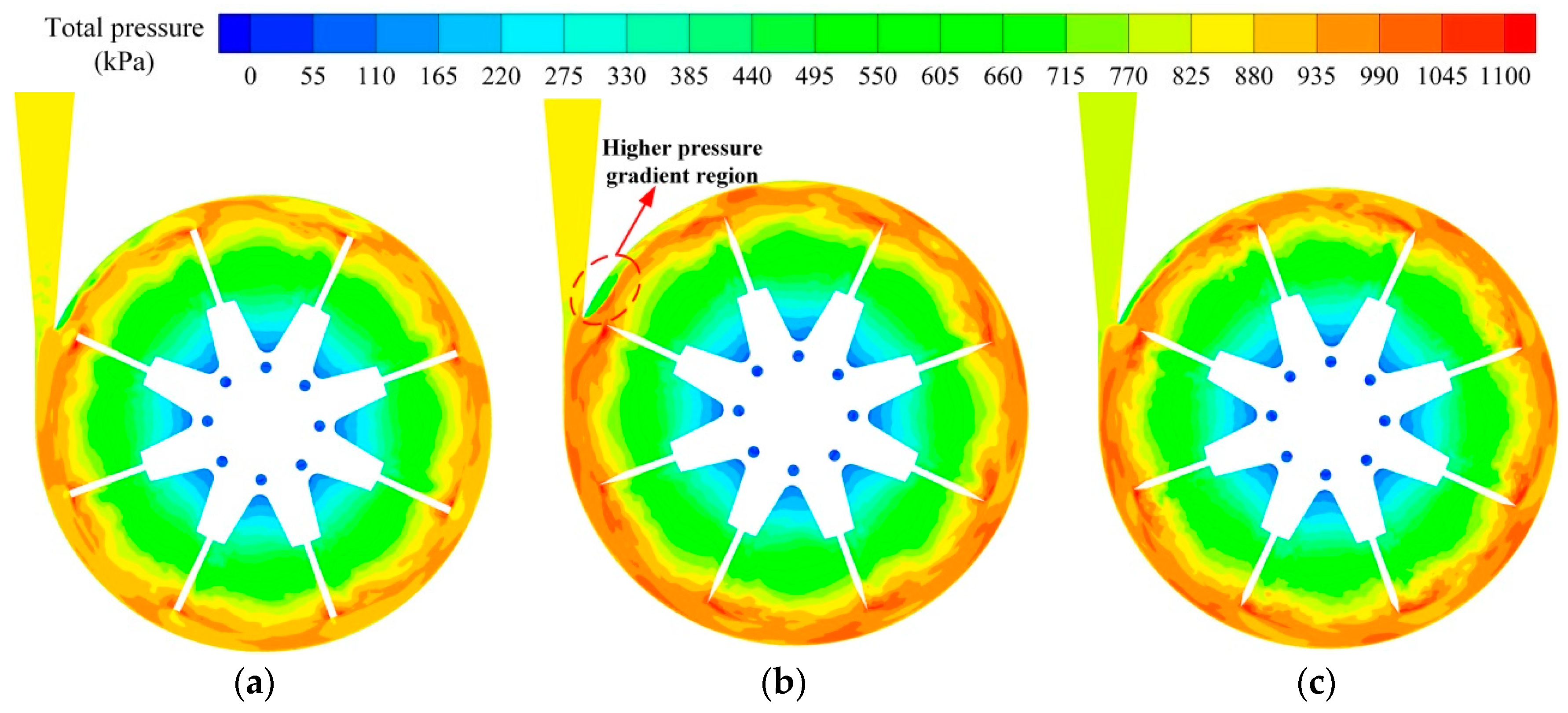

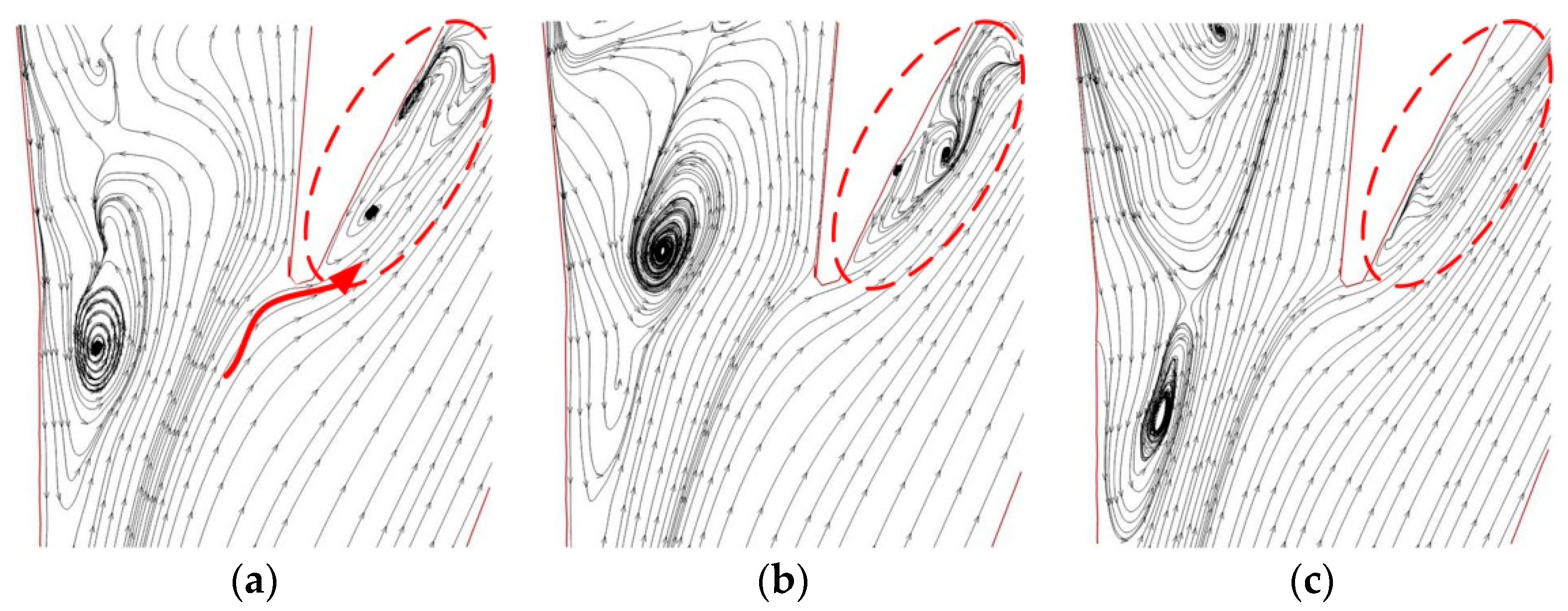

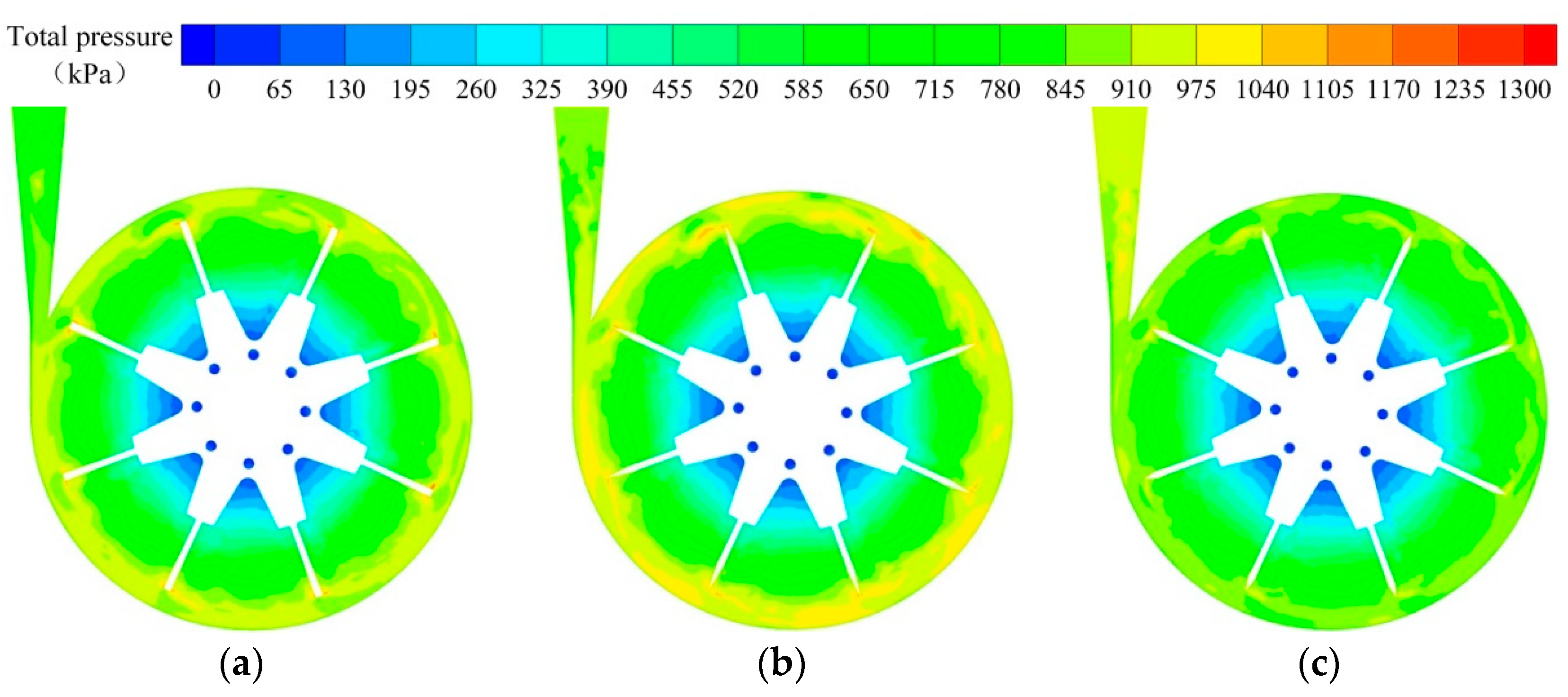

4.3. Analysis of Unstable Flow Structure

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Qd | design flow rate [m3/h] |

| H | head [m] |

| Hd | design head [m] |

| Z | blade number |

| Ds | pump inlet diameter [mm] |

| Do | pump outlet diameter [mm] |

| D1 | impeller inlet diameter [mm] |

| D2 | impeller outlet diameter [mm] |

| b1 | inlet width of blade [mm] |

| b2 | outlet width of blade [mm] |

| ψ | head coefficient [2Hg/u22] |

| ρ | fluid density [kg/m3] |

| μ | eddy viscosity [Pa s] |

| fBPF | blade-passing frequency [Hz] |

| Cp | non-dimensional static pressure coefficient |

| u2 | peripheral speed of the impeller outlet [m/s] |

| Ad | reduction rate of main frequency amplitude |

| Cpsd | non-dimensional coefficient of pressure pulsation intensity |

| R | vorticity |

| Ω | ratio of vorticity to total vorticity |

| Ωz | axial vorticity |

References

- Shankar, A.; Subramaniam, U.; Shanmugam, P.; Hanigovszki, N. A comprehensive review on energy efficiency enhancement initiatives in centrifugal pumping system. Appl. Energy 2016, 181, 495–513. [Google Scholar] [CrossRef]

- Posa, A.; Lippolis, A.; Balaras, E. Large-eddy simulation of a mixed-flow pump at off-design conditions. ASME J. Fluids Eng. 2015, 137, 101302. [Google Scholar] [CrossRef]

- Cheah, K.W.; Lee, T.S.; Winoto, S.H.; Zhao, Z.M. Numerical flow simulation in a centrifugal pump at design and off-design conditions. Int. J. Rotating Mach 2007, 2007, 83641. [Google Scholar] [CrossRef]

- Binama, M.; Su, W.; Cai, W.H. Blade trailing edge position influencing pump as turbine PAT pressure field under part-load conditions. Renew Energy 2019, 136, 33–47. [Google Scholar] [CrossRef]

- Si, Q.; Yuan, S.; Yuan, J.; Liang, Y. Investigation on flow-induced noise due to backflow in low specific speed centrifugal pumps. Adv. Mech. Eng. 2013, 2013, 109048. [Google Scholar] [CrossRef]

- Fu, Y.; Yuan, J.; Yuan, S.; Pace, G.; Agostino, L.; Huang, P.; Li, X. Numerical and experimental analysis of flow phenomena in a centrifugal pump operating under low flow rates. ASME J. Fluids Eng. 2015, 137, 011102. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, M.; Gao, B. Investigation of rotor-stator interaction and flow unsteadiness in a low specific speed centrifugal pump. Stroj. Vestn. J. Mech. Eng. 2015, 62, 21–31. [Google Scholar] [CrossRef]

- Jia, X.Q.; Zhu, Z.C.; Yu, X.L. Internal unsteady flow characteristics of centrifugal pump based on entropy generation rate and vibration energy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2018, 23, 456–473. [Google Scholar] [CrossRef]

- Tao, J.Y.; Lin, Z.; Ma, C.J. An experimental and numerical study of regulating performance and flow loss in a v-port ball valve. ASME J. Fluids Eng. 2020, 142. [Google Scholar] [CrossRef]

- Ji, B.; Long, Y.; Long, X. Large eddy simulation of turbulent attached cavitating flow with special emphasis on large scale structures of the hydrofoil wake and turbulence-cavitation interactions. J. Hydrodyn. 2017, 29, 27–39. [Google Scholar] [CrossRef]

- Furukawa, A.; Takahara, H.; Nakagawa, T. Pressure fluctuation in a vaned diffuser downstream from a centrifugal pump impeller. Int. J. Rotating Mach. 2003, 9, 285–292. [Google Scholar] [CrossRef]

- Gao, B.; Guo, P.; Zhang, N. Unsteady pressure pulsation measurements and analysis of a low specific speed centrifugal pump. ASME J. Fluids Eng. 2017, 139, 071101. [Google Scholar] [CrossRef]

- Yan, P.; Chu, N.; Wu, D. Computational fluid dynamics-based pump redesign to improve efficiency and decrease unsteady radial forces. ASME J. Fluids Eng. 2016, 139, 011101. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, M.; Gao, B. Experimental and numerical analysis of unsteady pressure pulsation in a centrifugal pump with slope volute. J. Mech. Sci. Technol. 2015, 29, 4231–4238. [Google Scholar] [CrossRef]

- Choi, J.S.; Mclaughlin, D.K.; Thompson, D.E. Experiments on the unsteady flow field and noise generation in a centrifugal pump impeller. J. Sound Vib. 2003, 263, 493–514. [Google Scholar] [CrossRef]

- Ding, H.; Li, Z.; Gong, X. The influence of blade outlet angle on the performance of centrifugal pump with high specific speed. Vacuum 2019, 159, 239–246. [Google Scholar] [CrossRef]

- Zhang, J.F.; Zhang, X.; Xie, L.H. Study on the influence of blade outlet angle on unsteady flow and structural dynamic characteristics for chemical process pump. IOP Conf. Ser. EES 2018, 163, 012047. [Google Scholar] [CrossRef]

- Zhang, J.F.; Li, G.D.; Mao, J.Y. Effects of the outlet position of splitter blade on the flow characteristics in low-specific-speed centrifugal pump. Adv. Mech. Eng. 2018, 10, 1–12. [Google Scholar] [CrossRef]

- Al-Qutub, A.M.; Khalifa, A.E.; Al-Sulaiman, F.A. Exploring the effect of V-shaped cut at blade outlet of a double volute centrifugal pump. J. Press. Vessel Technol. ASME 2012, 134, 021301–021309. [Google Scholar] [CrossRef]

- Wu, D.; Yan, P.; Chen, X. Effect of trailing-edge modification of a mixed-flow pump. ASME J. Fluids Eng. 2015, 137, 101205–101214. [Google Scholar] [CrossRef]

- Li, B.; Li, X.; Jia, X. The role of blade sinusoidal tubercle trailing edge in a centrifugal pump with low specific speed. Processes 2019, 7, 625. [Google Scholar] [CrossRef]

- Luo, Y.; Wen, F.; Wang, S.; Zhang, S.; Wang, S.; Wang, Z. Numerical investigation on the biomimetic trailing edge of a high-subsonic turbine blade. Aerosp. Sci. Technol. 2019, 89, 230–241. [Google Scholar] [CrossRef]

- Valipour, P.; Ghasemi, S.E.; Khosravani, M.R.; Ganji, D.D. Theoretical analysis on nonlinear vibration of fluid flow in single-walled carbon nanotube. J. Theor. Phys. 2016, 10, 211–218. [Google Scholar] [CrossRef]

- Zobeiri, A.; Ausoni, P.; Avellan, F. How oblique trailing edge of a hydrofoil reduces the vortex-induced vibration. J. Fluid Struct. 2012, 32, 78–89. [Google Scholar] [CrossRef]

- Heskestad, G.; Olberts, D.R. Influence of trailing-edge geometry on hydraulic-turbine-blade vibration resulting from vortex excitation. J. Eng. Gas Turbines Power 1960, 82, 103–109. [Google Scholar] [CrossRef]

- Gao, B.; Zhang, N.; Li, Z. Influence of the blade trailing edge profile on the performance and unsteady pressure pulsations in a low Specific speed centrifugal pump. ASME J. Fluids Eng. 2016, 138, 051106. [Google Scholar] [CrossRef]

- Pei, J.; Yuan, S.; Benra, F.K. Numerical prediction of unsteady pressure field within the whole flow passage of a radial single-blade pump. ASME J. Fluids Eng. 2012, 134, 101103. [Google Scholar] [CrossRef]

- Zhang, N.; Liu, X.; Gao, B. Effects of modifying the blade trailing edge profile on unsteady pressure pulsations and flow structures in a centrifugal pump. Int. J. Heat Fluid Flow 2019, 75, 227–238. [Google Scholar] [CrossRef]

- Ni, D.; Yang, M.; Gao, B. Numerical study on the effect of the diffuser blade trailing edge profile on flow instability in a nuclear reactor coolant pump. Nucl. Eng. Des. 2017, 322, 92–103. [Google Scholar] [CrossRef]

- Ni, D.; Yang, M.; Zhang, N. Unsteady flow structures and pressure pulsations in a nuclear reactor coolant pump with spherical casing. ASME J. Fluids Eng. 2017, 139, 051103. [Google Scholar] [CrossRef]

- Yang, B.; Li, B.; Chen, H. Numerical investigation of the clocking effect between inducer and impeller on pressure pulsations in a liquid rocket engine oxygen turbopump. ASME J. Fluids Eng. 2018, 141, 071109. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Y.; Yang, Y. New omega vortex identification method. Sci. China Phys. Mech. 2016, 59, 684711. [Google Scholar] [CrossRef]

| Blade Trailing Edge Profile | Frequency (Hz) | Reduction (%) | |

|---|---|---|---|

| OTE | 387.49 | 0.011172 | 0 |

| OBS15 | 386.33 | 0.012681 | −13.50 |

| OBS30 | 386.53 | 0.009715 | 13.04 |

| Blade Trailing Edge Profile | Frequency (Hz) | Reduction (%) | |

|---|---|---|---|

| OTE | 386.87 | 0.008737 | 0 |

| OBS15 | 387.58 | 0.009334 | −6.83 |

| OBS30 | 386.51 | 0.007552 | 13.56 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, B.; Zhang, C.; Zhang, Y.; Zhu, Z. Influence of Cutting Angle of Blade Trailing Edge on Unsteady Flow in a Centrifugal Pump Under Off-Design Conditions. Appl. Sci. 2020, 10, 580. https://doi.org/10.3390/app10020580

Cui B, Zhang C, Zhang Y, Zhu Z. Influence of Cutting Angle of Blade Trailing Edge on Unsteady Flow in a Centrifugal Pump Under Off-Design Conditions. Applied Sciences. 2020; 10(2):580. https://doi.org/10.3390/app10020580

Chicago/Turabian StyleCui, Baoling, Chenliang Zhang, Yuliang Zhang, and Zuchao Zhu. 2020. "Influence of Cutting Angle of Blade Trailing Edge on Unsteady Flow in a Centrifugal Pump Under Off-Design Conditions" Applied Sciences 10, no. 2: 580. https://doi.org/10.3390/app10020580

APA StyleCui, B., Zhang, C., Zhang, Y., & Zhu, Z. (2020). Influence of Cutting Angle of Blade Trailing Edge on Unsteady Flow in a Centrifugal Pump Under Off-Design Conditions. Applied Sciences, 10(2), 580. https://doi.org/10.3390/app10020580