The Effect of Shape on Chloride Penetration of Circular Reinforcement Concrete Columns and Its Durability Design

Abstract

1. Introduction

2. Circular Diffusion Model for a Cross-Section of an RC Circular Column

2.1. Theoretical Derivation

2.2. Statistical Properties of Model Parameters

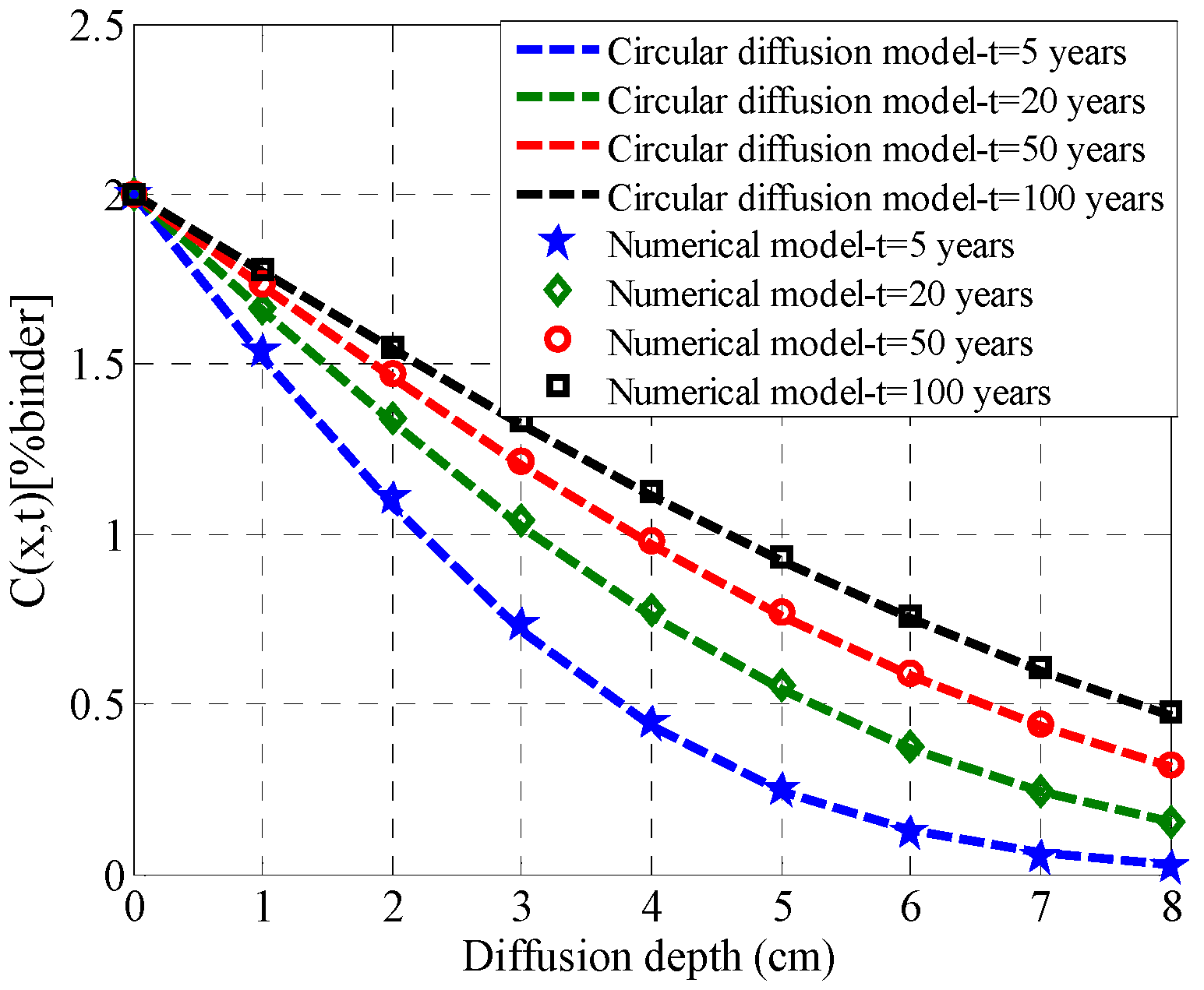

2.3. Validation Using a Numerical Model

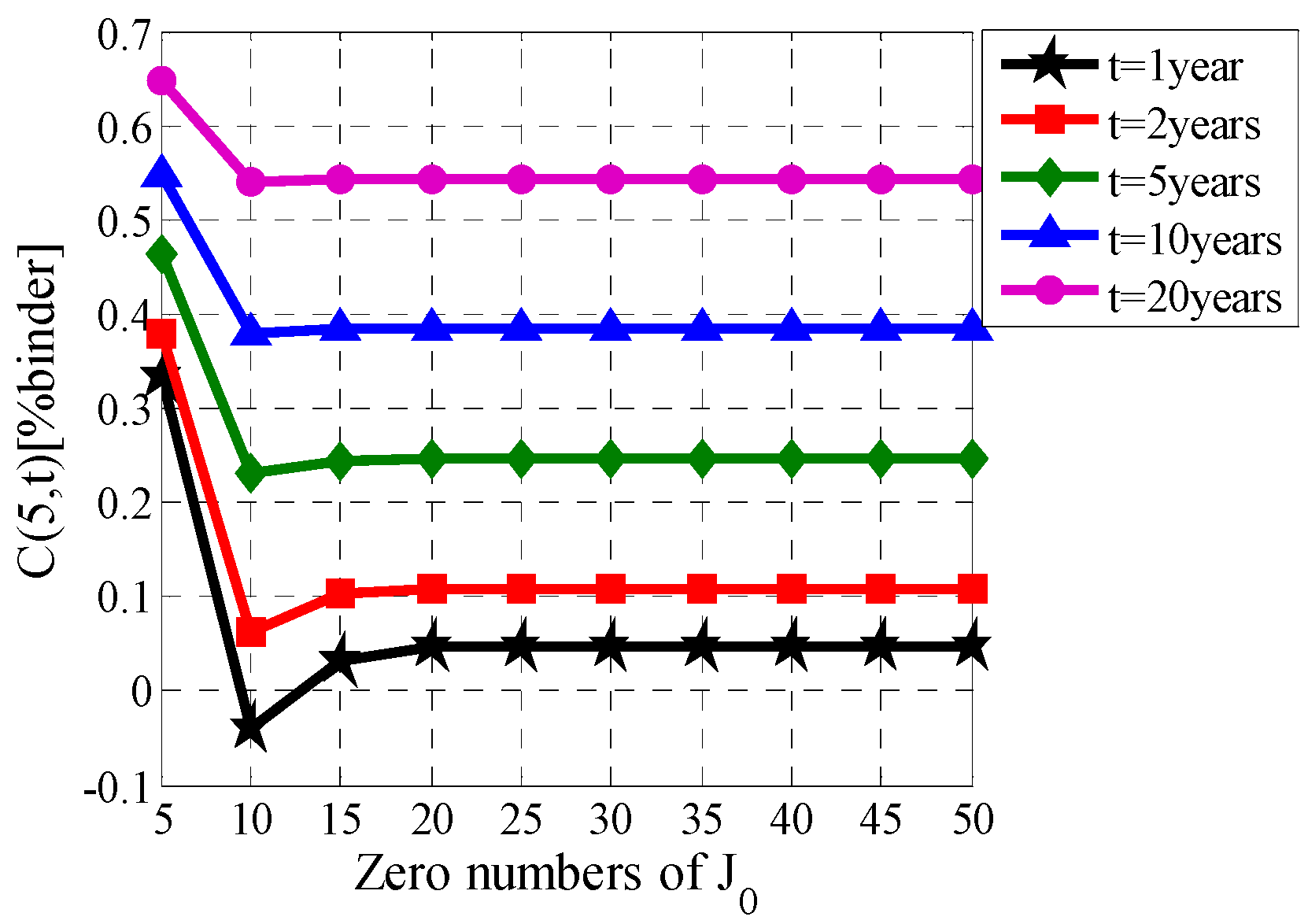

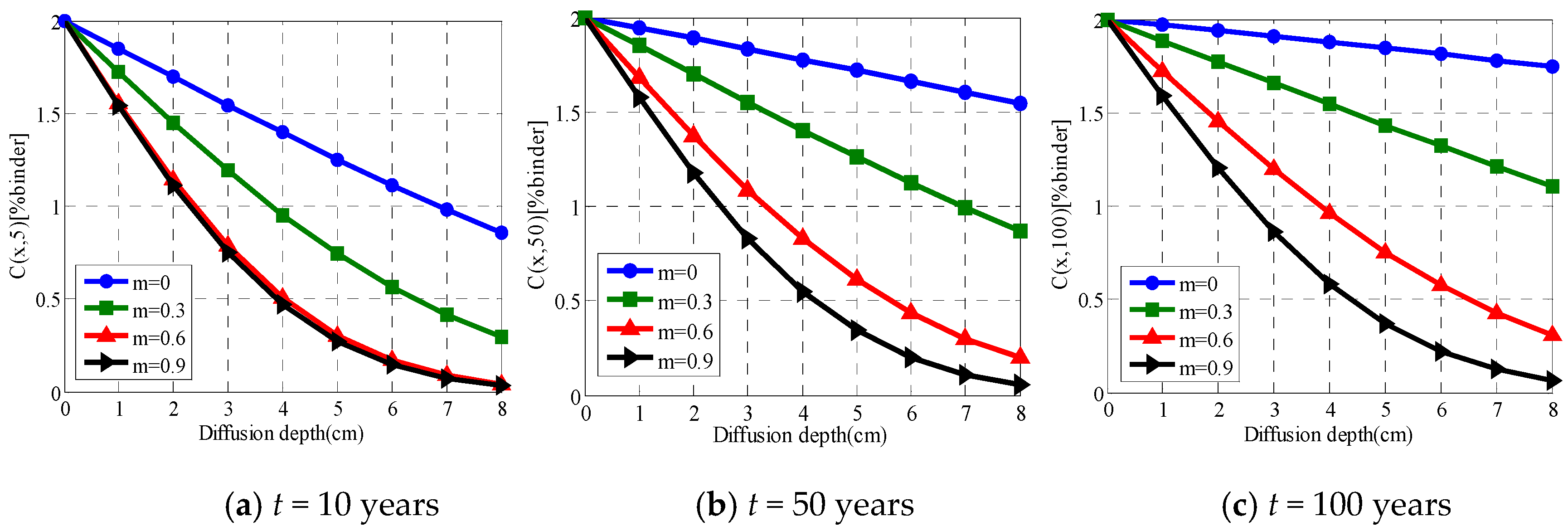

2.4. The Effect of a Time-Variant Diffusion Coefficient on Chloride Diffusion

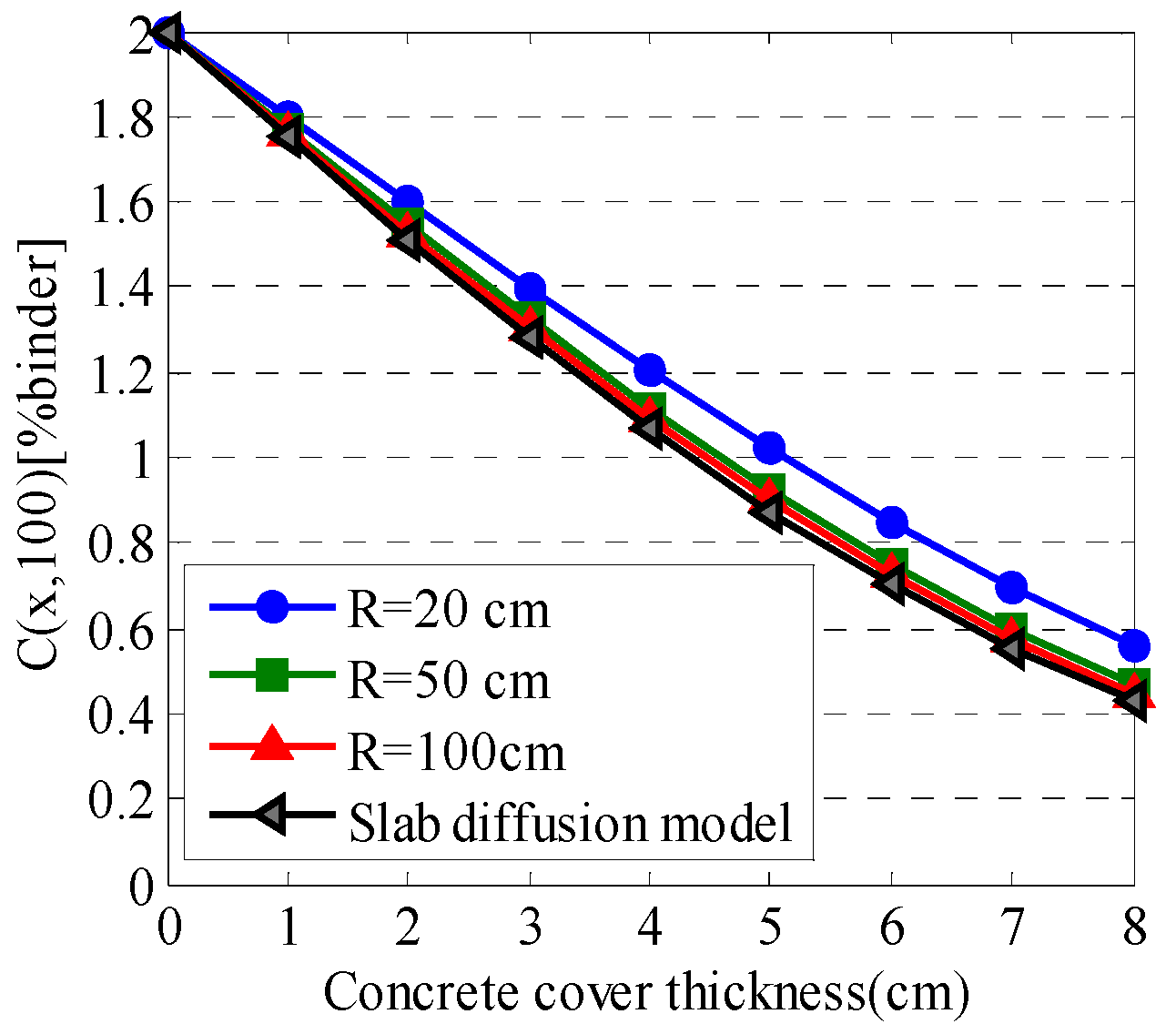

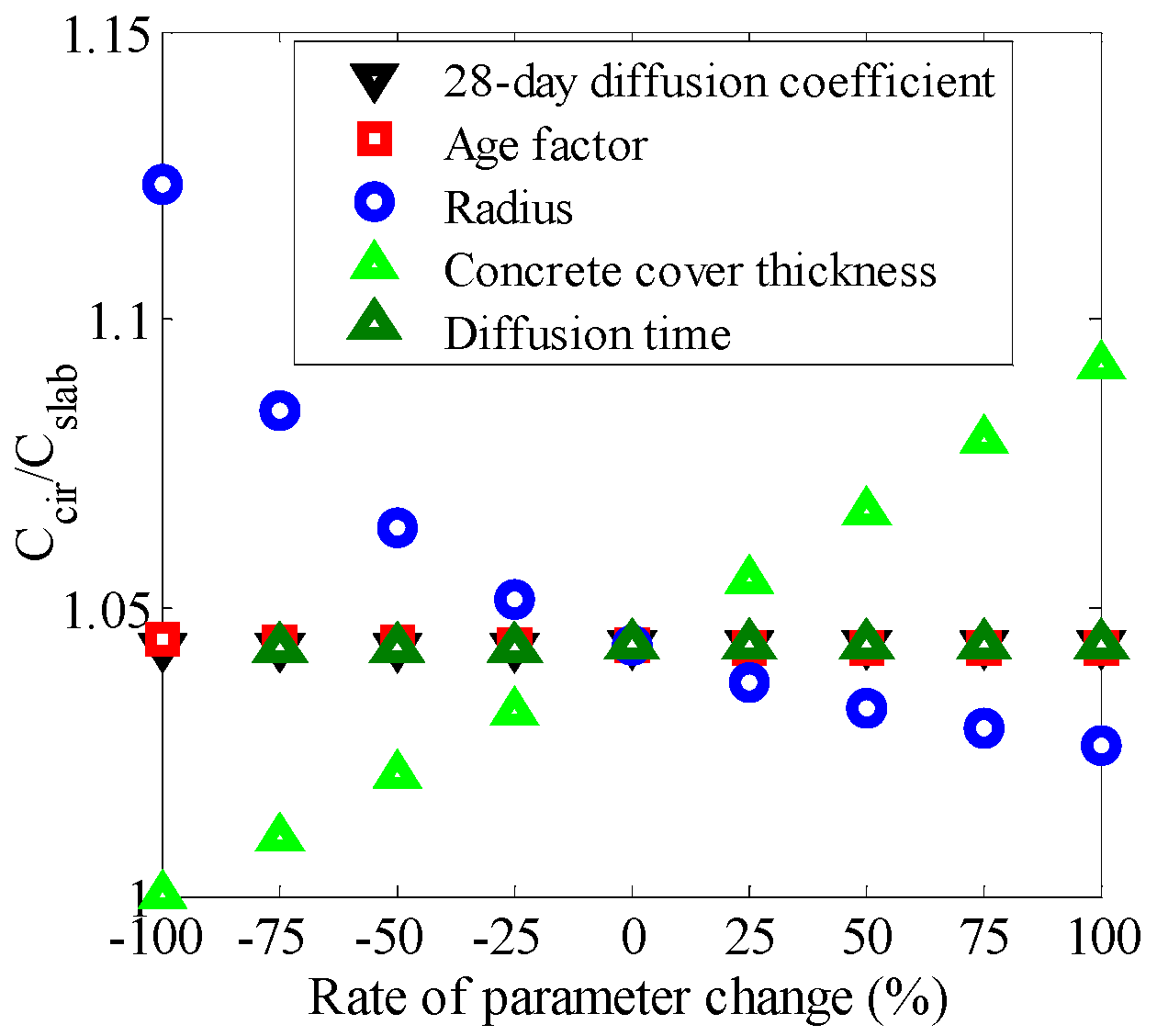

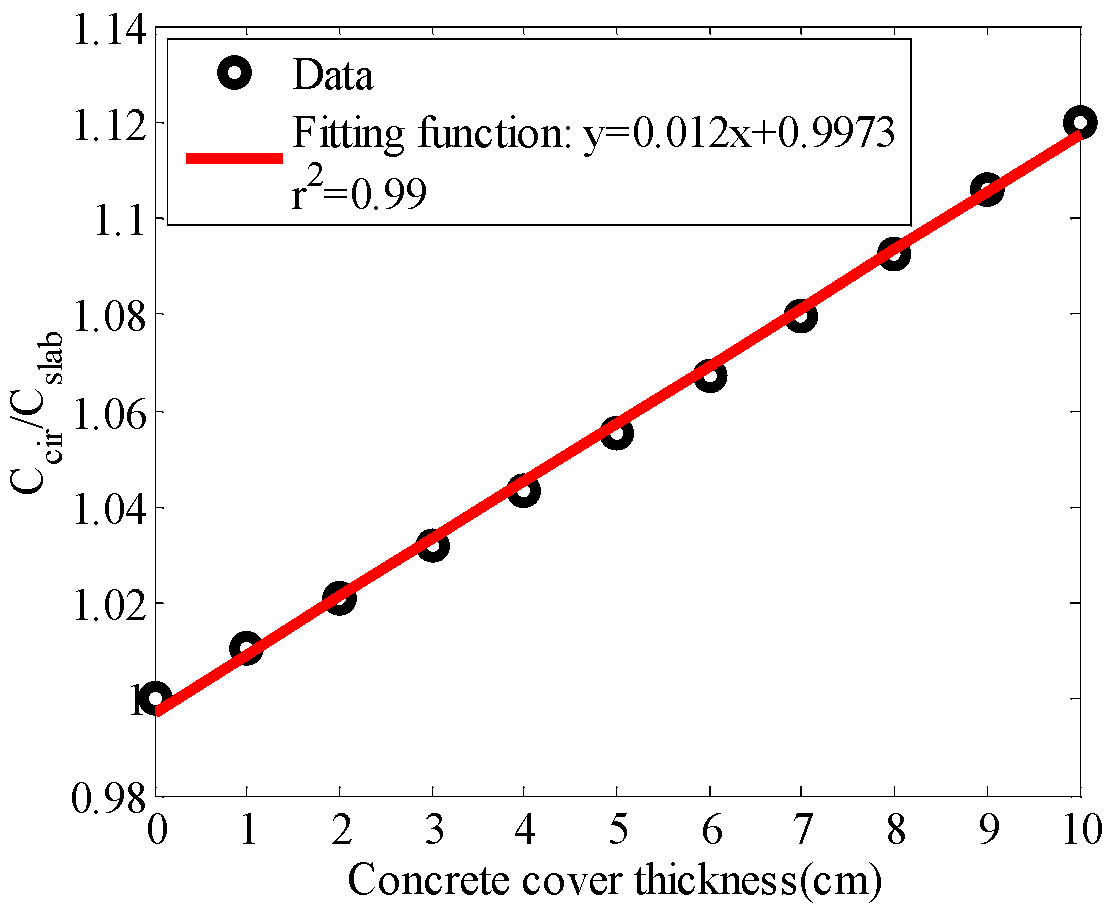

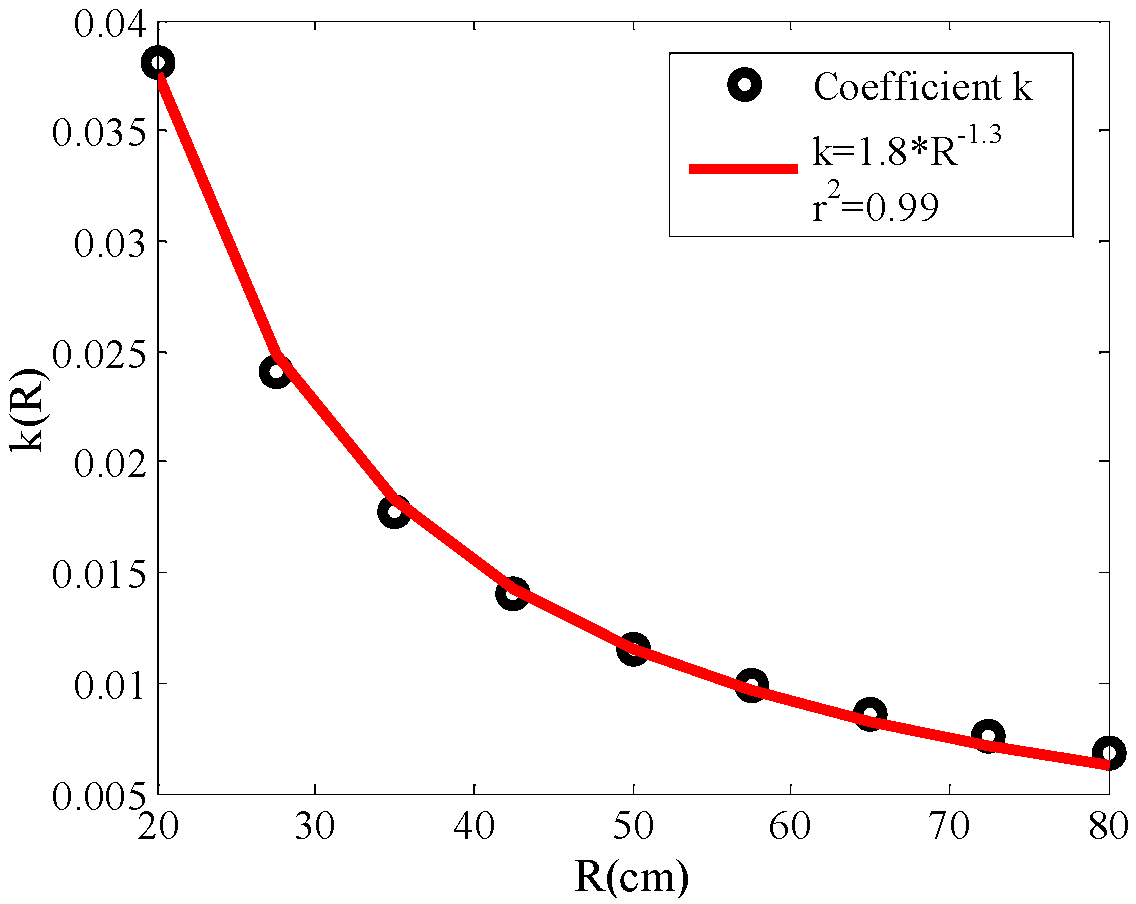

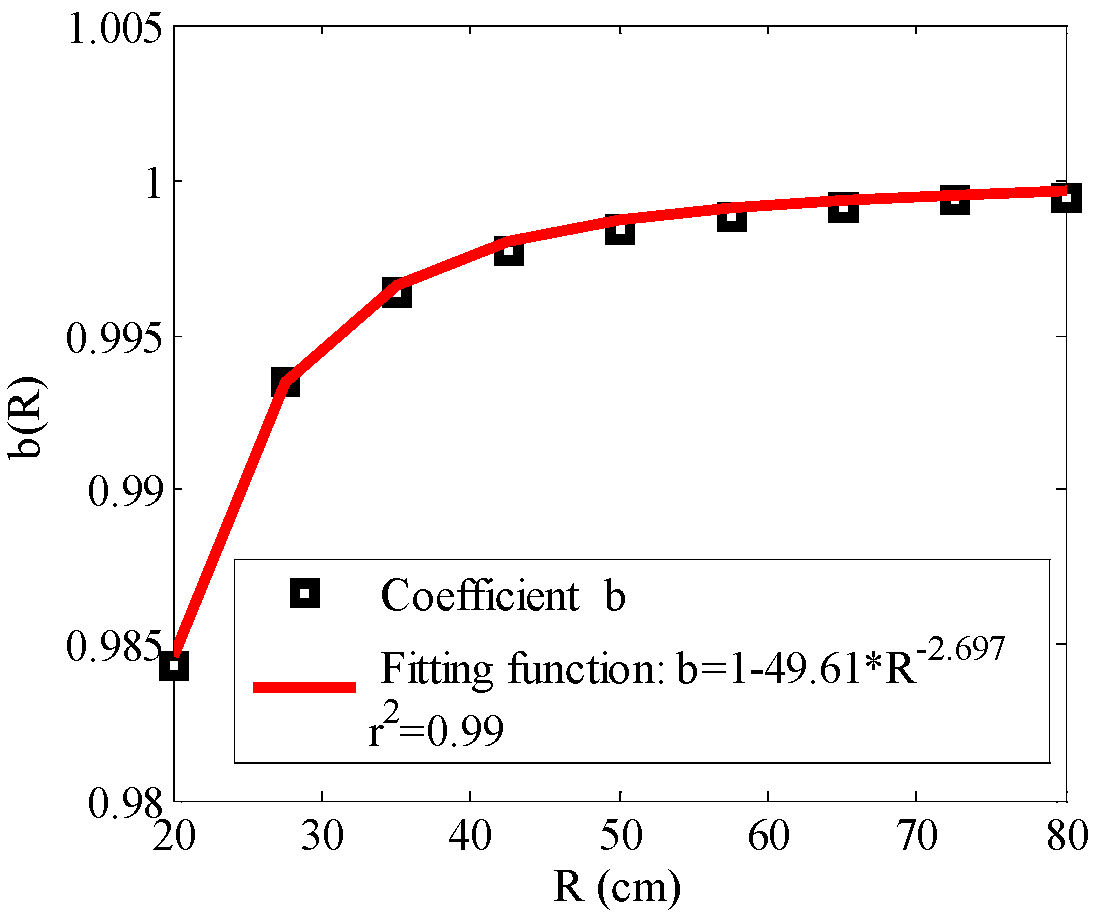

3. Comparison between Circular and Slab Diffusion Models

3.1. Chloride Concentration Estimation

3.2. The Pre-Corrosion Initiation Time for the RC Circular Column

3.3. Durability Design of the RC Circular Column against Chloride Degradation

3.3.1. Basic Model

3.3.2. The Effect of RC Circular Section Shape on the Estimation of Reliability Index

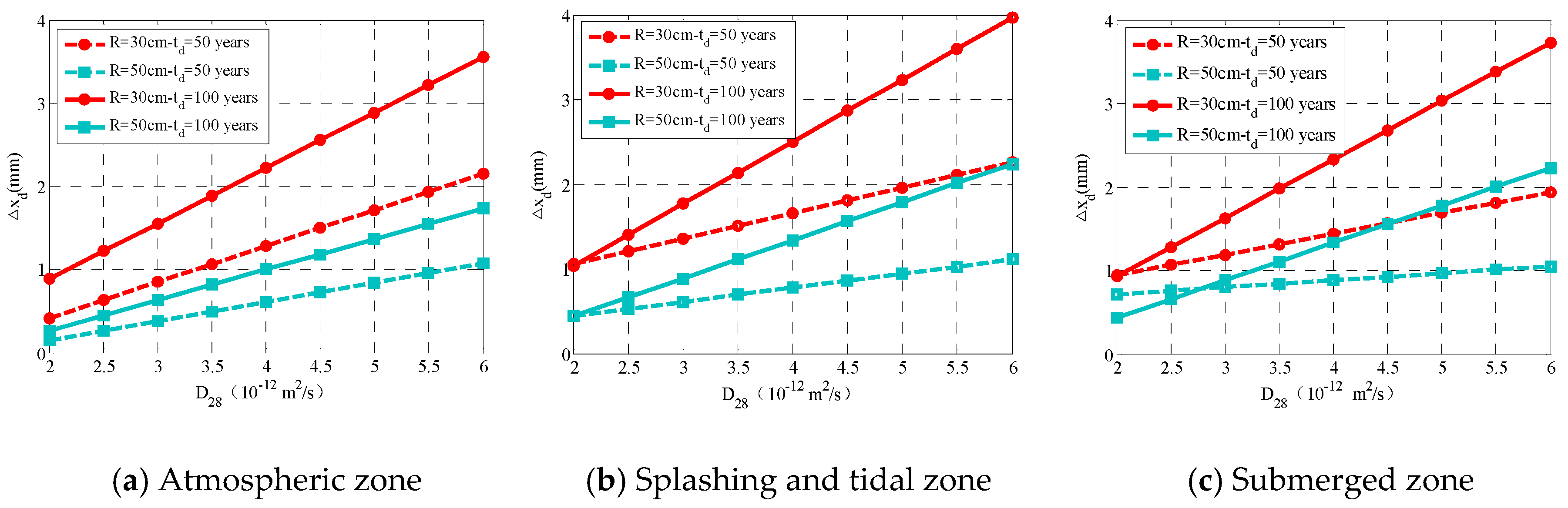

3.3.3. Chloride Diffusion Coefficient D28 and Concrete Cover Thickness xd

4. Conclusions

- (a)

- The use of a constant diffusion coefficient causes the overestimation of the chloride concentration distribution, shortening the service life of the structure.

- (b)

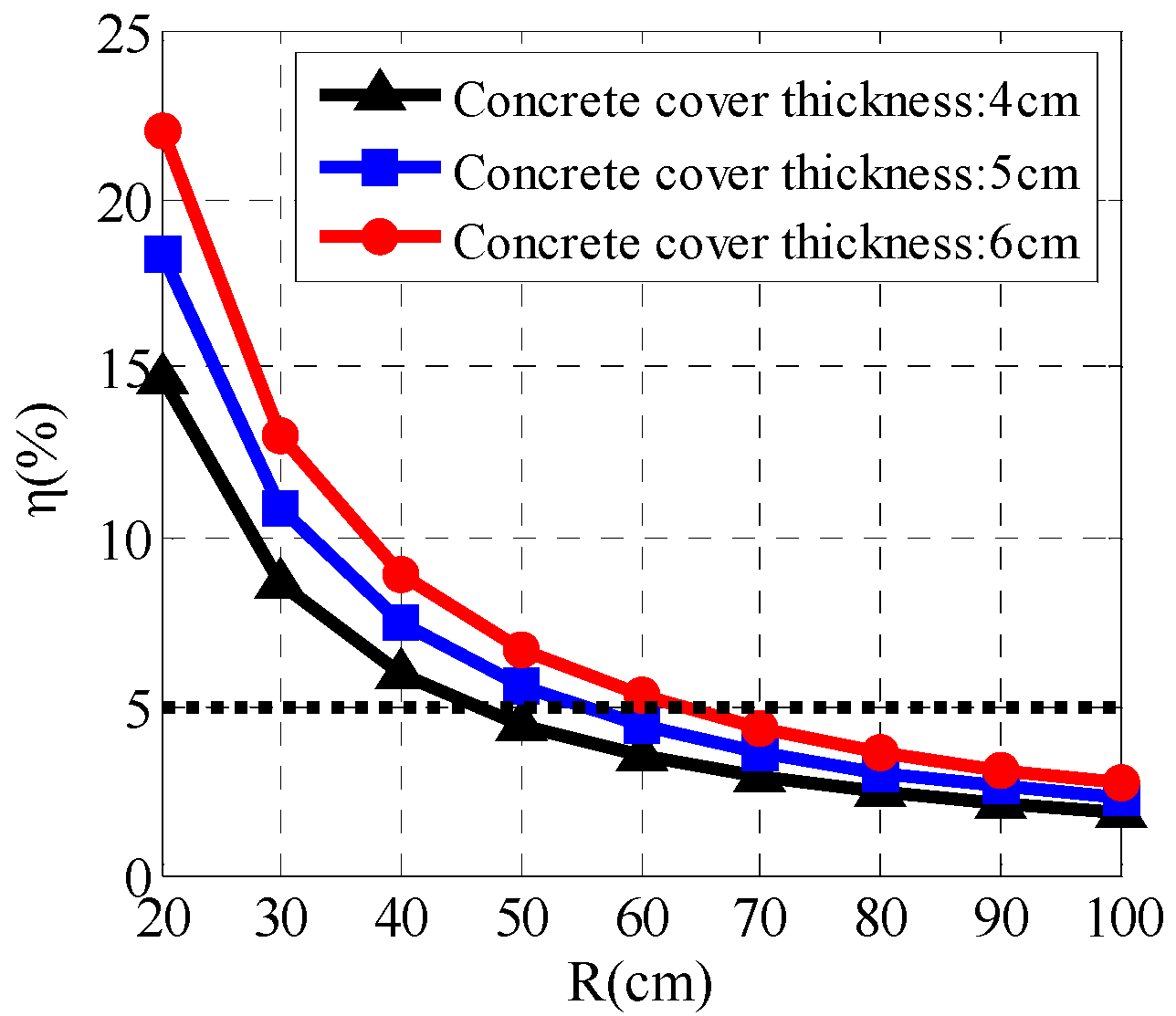

- The shape of the circular section element accelerates chloride diffusion compared with the slab element. The error caused by adopting the slab diffusion model shows close relationships with the radius and the diffusion depth. The decrease of the radius of column and the increase of the diffusion depth enlarge this error. In general, the modified slab diffusion model is preferable for a radius below 60 cm.

- (c)

- The pre-corrosion initiation time of the RC circular column is underestimated with the slab diffusion model. Each model parameter shows sensitivity for the difference value between the time estimated with slab diffusion model and that estimated for the modified slab one. The shape of the circular section affects minimally the estimation of the time to corrosion initiation compared with other model parameters.

- (d)

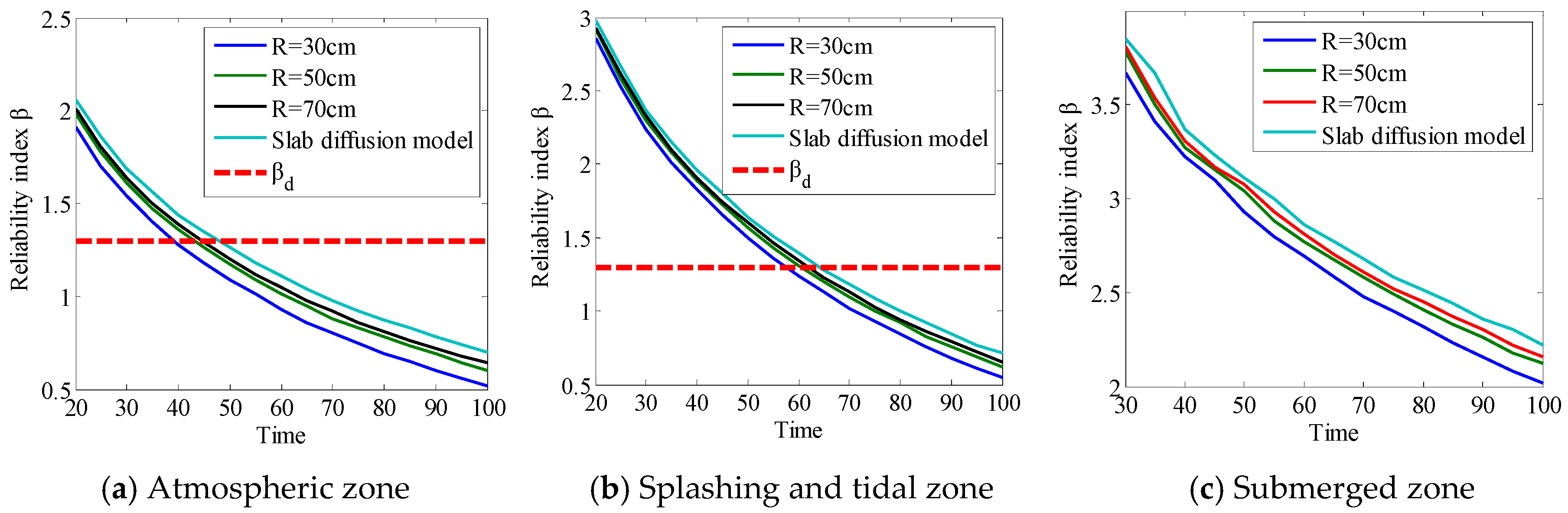

- The service life of RC circular column is overestimated when the circular section is viewed as a slab element. The modified slab diffusion model should be used when the radius of the column below 50 cm.

- (e)

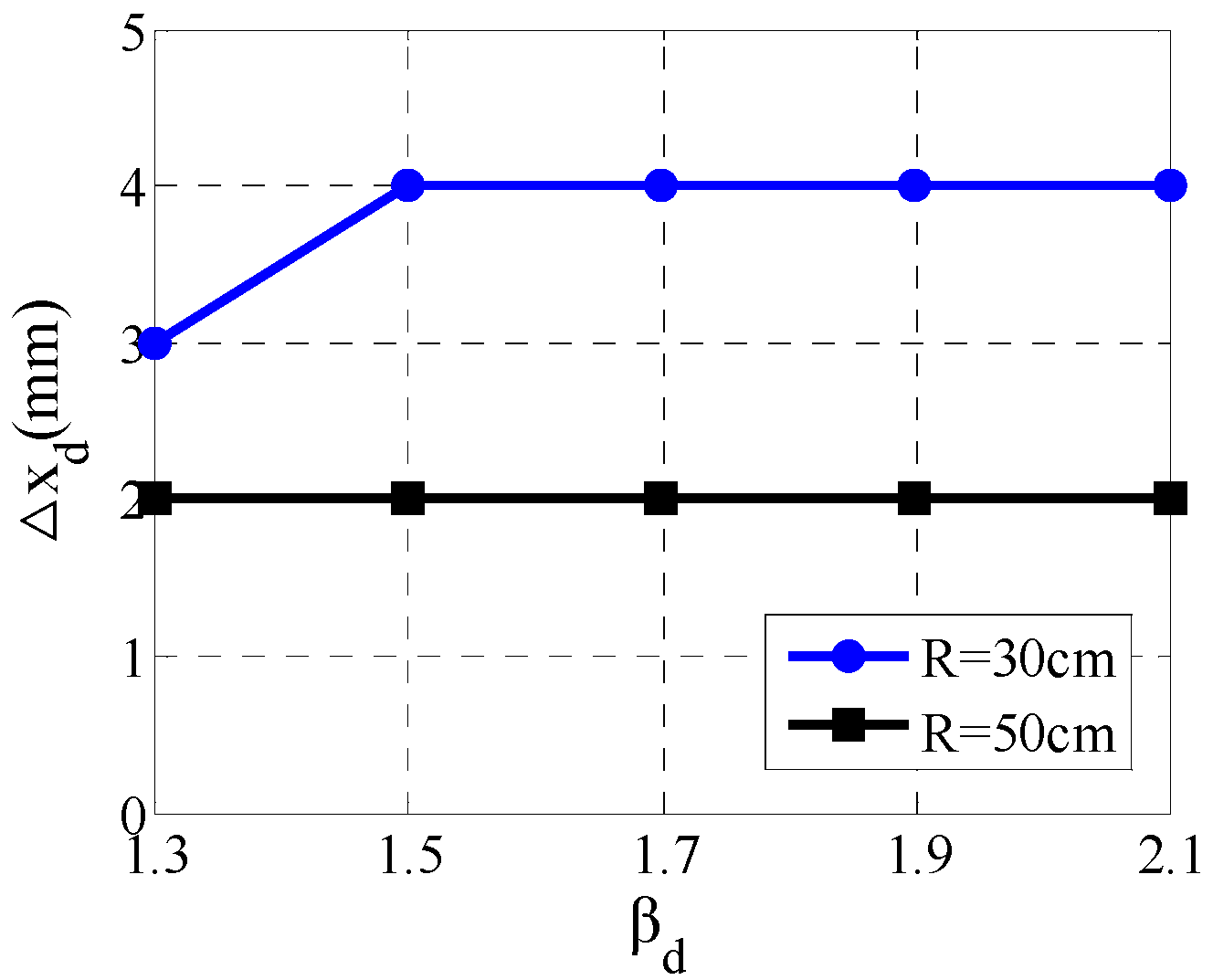

- The RC circular section simplified as a slab element slightly affects the durability design against chloride corrosion. The minimum concrete cover thickness increases by 5 mm for the RC circular column based on the design result of the slab element.

Author Contributions

Funding

Conflicts of Interest

References

- Tuutti, K. Corrosion of Steel in Concrete; No. CBI Research FO 4:82; Swedish Cement and Concrete Research Institute: Stockholm, Sweden, 1982. [Google Scholar]

- Transportation Research Board. National Cooperative Highway Research Program, and Strategic Highway Research Program. Strategic Highway Research Program: Research Plans; Federal Highway Administration: Washington, DC, USA, 1986.

- Collepardi, C.M.; Marcialis, A.; Turriziani, R. Penetration of chloride ions into cement pastes and concrete. J. Am. Ceram. Soc. 1972, 55, 534–535. [Google Scholar] [CrossRef]

- Mangat, P.S.; Molloy, B.T. Prediction of long-term chloride concentration in concrete. Mater. Struct. 1994, 27, 338–346. [Google Scholar] [CrossRef]

- Engelund, S.; Edvardsen, C.; Mohr, L. General Guidelines for Durability Design and Redesign; DuraCrete Project Document BE95-1347/R17; CUR: Lyngby, Denmark, 2000. [Google Scholar]

- Cui, F.; Zhang, H.; Ghosn, M.; Xu, Y. Seismic fragility analysis of deteriorating RC bridge substructures subject to marine chloride-induced corrosion. Eng. Struct. 2018, 155, 61–72. [Google Scholar] [CrossRef]

- Shivang, S.; Jayadipta GJamie, E.P. Seismic life-cycle cost analysis of ageing highway bridges under chloride exposure conditions: Modelling and recommendations. Struct. Infrastruct. Eng. 2018, 14, 941–966. [Google Scholar]

- Costa, A.; Appleton, J. Chloride penetration into concrete in marine environment—Part I: Main parameters affecting chloride penetration. Mater. Struct. 1999, 32, 354–359. [Google Scholar] [CrossRef]

- Andrade, C.; Diez, L.M.; Alonso, C. Mathematical modeling of a concrete surface “skin effect” on diffusion in chloride contaminated media. Adv. Cem. Based Mater. 1997, 6, 39–44. [Google Scholar] [CrossRef]

- Val, D.V.; Trapper, P.A. Probabilistic evaluation of initiation time of chloride-induced corrosion. Reliab. Eng. Syst. Saf. 2008, 93, 364–372. [Google Scholar] [CrossRef]

- Muthulingam, S.; Rao, B.N. Non-uniform corrosion states of rebar in concrete under chloride environment. Corros. Sci. 2015, 93, 267–282. [Google Scholar] [CrossRef]

- Shafei, B.; Alipour, A. Estimation of corrosion initiation time in reinforced concrete bridge columns: How to incorporate spatial and temporal uncertainties. J. Eng. Mech. 2015, 141, 04015037. [Google Scholar] [CrossRef]

- Hu, S.; Peng, J.; Zhang, J. Numerical simulation method of the chloride ion diffusion in concrete and its application in bridge. China J. Railw. Sci. Eng. 2017, 14, 2570–2578. [Google Scholar]

- Morga, M.; Marano, G.C. Chloride penetration in circular concrete columns. Int. J. Concr. Struct. Mater. 2015, 9, 173–183. [Google Scholar] [CrossRef]

- Luping, T.; Nilsson, L.O. Chloride diffusivity in high strength concrete at different ages. Nord. Concr. Res. 1992, 1, 162–171. [Google Scholar]

- Nilsson, L.O.; Poulsen, E.; Sandberg, P.; Sørensen, H.E.; Klinghoffer, O. Chloride Penetration into Concrete, State-of-the-Art. Transport Processes, Corrosion Initiation, Test Methods and Prediction Models; Danish Road Directorate: Copenhagen, Denmark, 1996. [Google Scholar]

- Song, H.W.; Lee, C.H.; Ann, K.Y. Factors influencing chloride transport in concrete structures exposed to marine environments. Cem. Concr. Compos. 2008, 30, 113–121. [Google Scholar] [CrossRef]

- Pack, S.M.; Jung, M.S.; Song, H.W.; Kim, S.H. Prediction of time dependent chloride transport in concrete structures exposed to a marine environment. Cem. Concr. Res. 2012, 40, 302–312. [Google Scholar] [CrossRef]

- Wu, L.J.; Li, W.; Yu, X.N. Time-dependent chloride penetration in concrete in marine environments. Constr. Build. Mater. 2017, 152, 406–413. [Google Scholar] [CrossRef]

- ACI318-05; ACI318R-05. Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2005. [Google Scholar]

- CCES01-2004. Guide for Durability Design and Construction of Concrete Structures, 2nd ed.; China Building Industry Press: Beijing, China, 2005. (In Chinese) [Google Scholar]

- CEN. Design of Concrete Structures (pr EN 1992-1-1); Eurocode 2; CEN: Brussels, Belgium, 2002. [Google Scholar]

- Marano, G.C.; Greco, R. Axial-bending interaction diagrams of reinforced concrete columns exposed to chloride attack. Appl. Mech. Mater. 2016, 847, 415–422. [Google Scholar] [CrossRef]

- Stewart, M.G.; Rosowsky, D.V. Structural safety and service ability of concrete bridges subject to corrosion. J. Infrastruct. Syst. 1998, 4, 146–155. [Google Scholar] [CrossRef]

- Li, Q.W.; Li, K.F.; Zhou, X.G. Model-based durability design of concrete structures in Hong Kong–Zhuhai–Macau sea link project. Struct. Saf. 2015, 53, 1–12. [Google Scholar] [CrossRef]

- Bentz, E.C.; Thomas, M.D.A. Life-365 Service Life Prediction Model and Computer Program for Predicting the Service Life and Life-Cycle Costs of Reinforced Concrete Exposed to Chlorides. User Manual, Version 2.0; Life-365 Consortium II, USA. 2008. Available online: https://www.nrmca.org/research/Life365v2UsersManual.pdf (accessed on 31 December 2019).

- JSCE. Standard Specifications for Concrete Structures; Japan Society of Civil Engineering: Tokyo, Japan, 2007. [Google Scholar]

- Li, Z.; Jin, Z.; Zhao, T. Service life prediction of reinforced concrete in a sea-crossing railway bridge in Jiaozhou Bay: A case study. Appl. Sci. 2019, 9, 3570. [Google Scholar] [CrossRef]

- Li, K.F.; Li, Q.W.; Zhou, X.G. Durability design of the Hong Kong–Zhuhai–Macau sea-link project: Principle and Procedure. J. Bridge Eng. 2015, 20, 04015001. [Google Scholar] [CrossRef]

| Parameters | Exposure Condition | Distribution Type | Mean Value | Standard Deviation |

|---|---|---|---|---|

| C0 (%binder) | Atmospheric zone | Lognormal distribution | 2 | 0.31 |

| Splashing and tidal zone | 5.4 | 0.82 | ||

| Submerged zone | 4.5 | 0.68 | ||

| m | Atmospheric zone | Normal distribution | 0.53 | 0.08 |

| Splashing and tidal zone | 0.47 | 0.028 | ||

| Submerged zone | 0.44 | 0.028 |

| Parameters | Mean Value | Lower Limitation | Upper Limitation |

|---|---|---|---|

| D28 | 3.435 cm2/a | 2.51 cm2/a | 4.36 cm2/a |

| m | 0.53 | 0.37 | 0.69 |

| R | 50 cm | 20 cm | 80 cm |

| x | 4 cm | 0 cm | 8 cm |

| t | 50a | 0a | 100a |

| Exposure Class | Distribution Type | Mean Value (%Binder) | STANDARD Deviation (%Binder) |

|---|---|---|---|

| Atmospheric zone | Lognormal distribution | 0.85 | 0.13 |

| Splashing and tidal zone | Beta distribution (L = 0.45%, U = 1.25%) | 0.75 | 0.23 |

| Submerged zone | Beta distribution (L = 1%, U = 3.5%) | 2 | 0.72 |

| Parameters | Mean Value | Lower Limitation | Upper Limitation |

|---|---|---|---|

| C0 (%binder) | 2 | 1.38 | 2.62 |

| Ccr (%binder) | 0.85 | 0.59 | 1.11 |

| Time (Years) | R = 30 cm | R = 50 cm | R = 70 cm | Slab Diffusion Model |

|---|---|---|---|---|

| Atmospheric zone | 39 | 42 | 45 | 46 |

| Splashing and tidal zone | 57 | 60 | 61 | 64 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, G.; Pan, L. The Effect of Shape on Chloride Penetration of Circular Reinforcement Concrete Columns and Its Durability Design. Appl. Sci. 2020, 10, 459. https://doi.org/10.3390/app10020459

Yin G, Pan L. The Effect of Shape on Chloride Penetration of Circular Reinforcement Concrete Columns and Its Durability Design. Applied Sciences. 2020; 10(2):459. https://doi.org/10.3390/app10020459

Chicago/Turabian StyleYin, Gu, and Li Pan. 2020. "The Effect of Shape on Chloride Penetration of Circular Reinforcement Concrete Columns and Its Durability Design" Applied Sciences 10, no. 2: 459. https://doi.org/10.3390/app10020459

APA StyleYin, G., & Pan, L. (2020). The Effect of Shape on Chloride Penetration of Circular Reinforcement Concrete Columns and Its Durability Design. Applied Sciences, 10(2), 459. https://doi.org/10.3390/app10020459