This section shows the eigenvalue analysis and the time response for the presented model. Starting from these plots, some physical relations will be derived and will help to understand the important phenomena influencing the behaviour of the wobble and weave eigenmodes as a function of vehicle speed.

4.1. Wobble

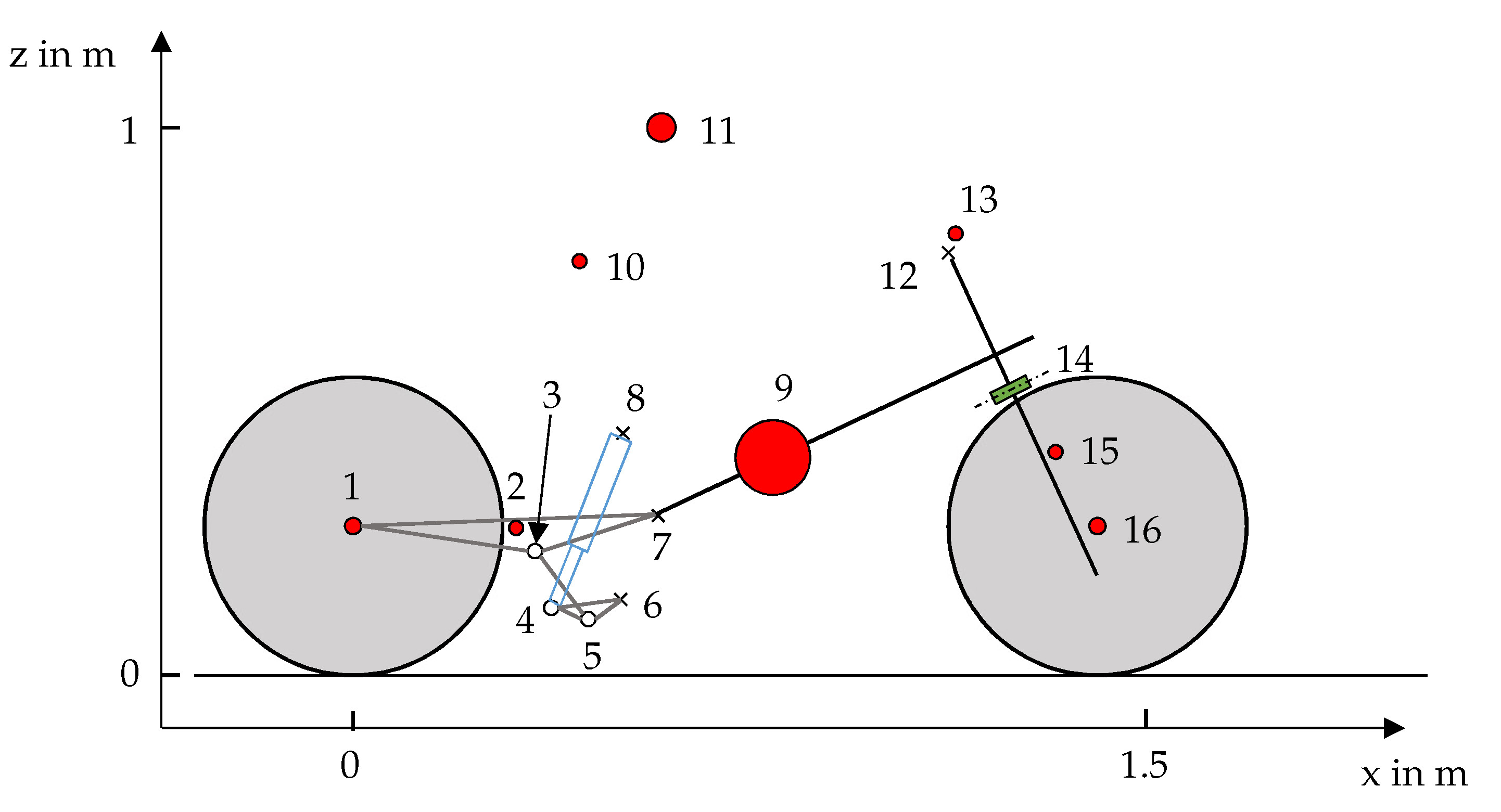

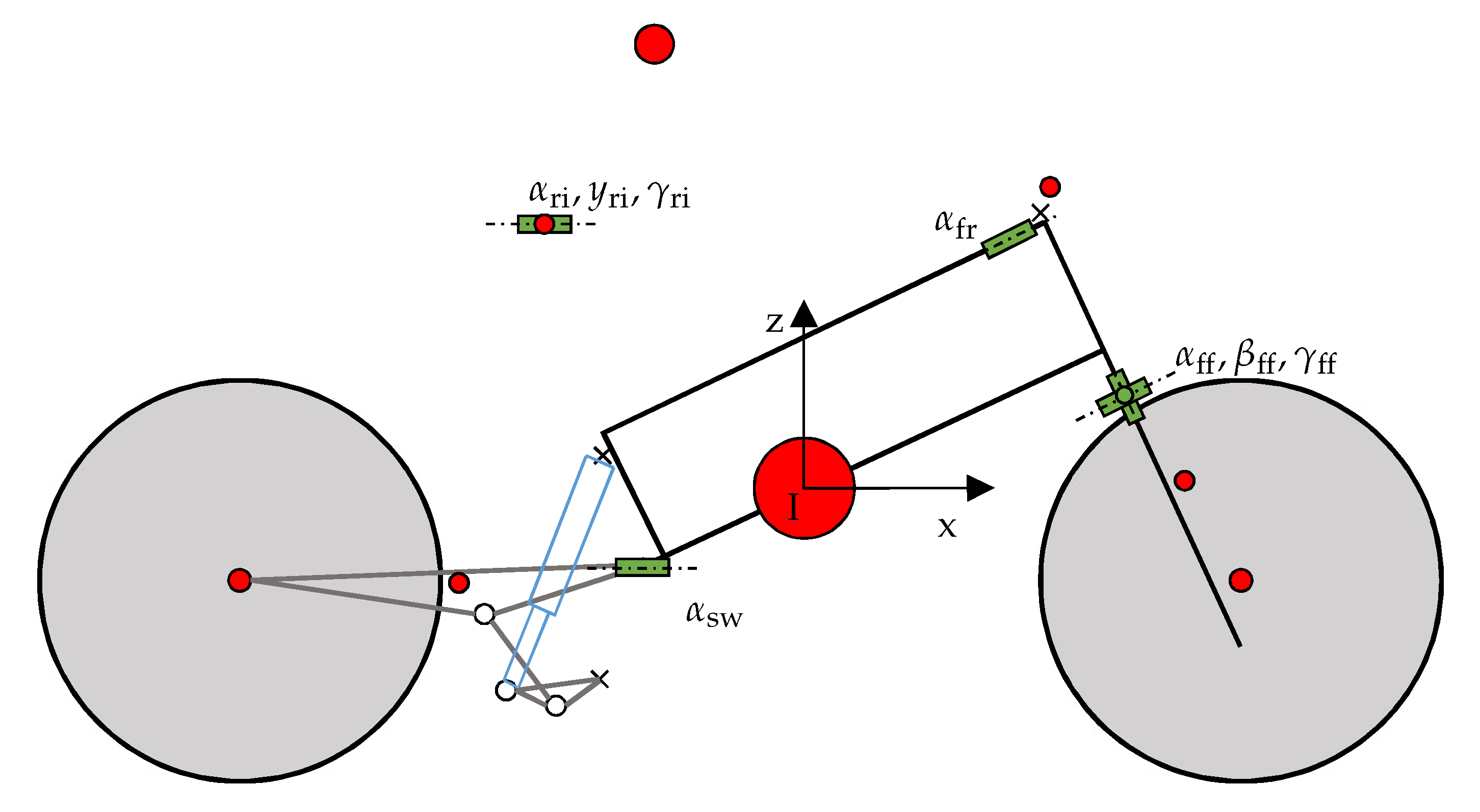

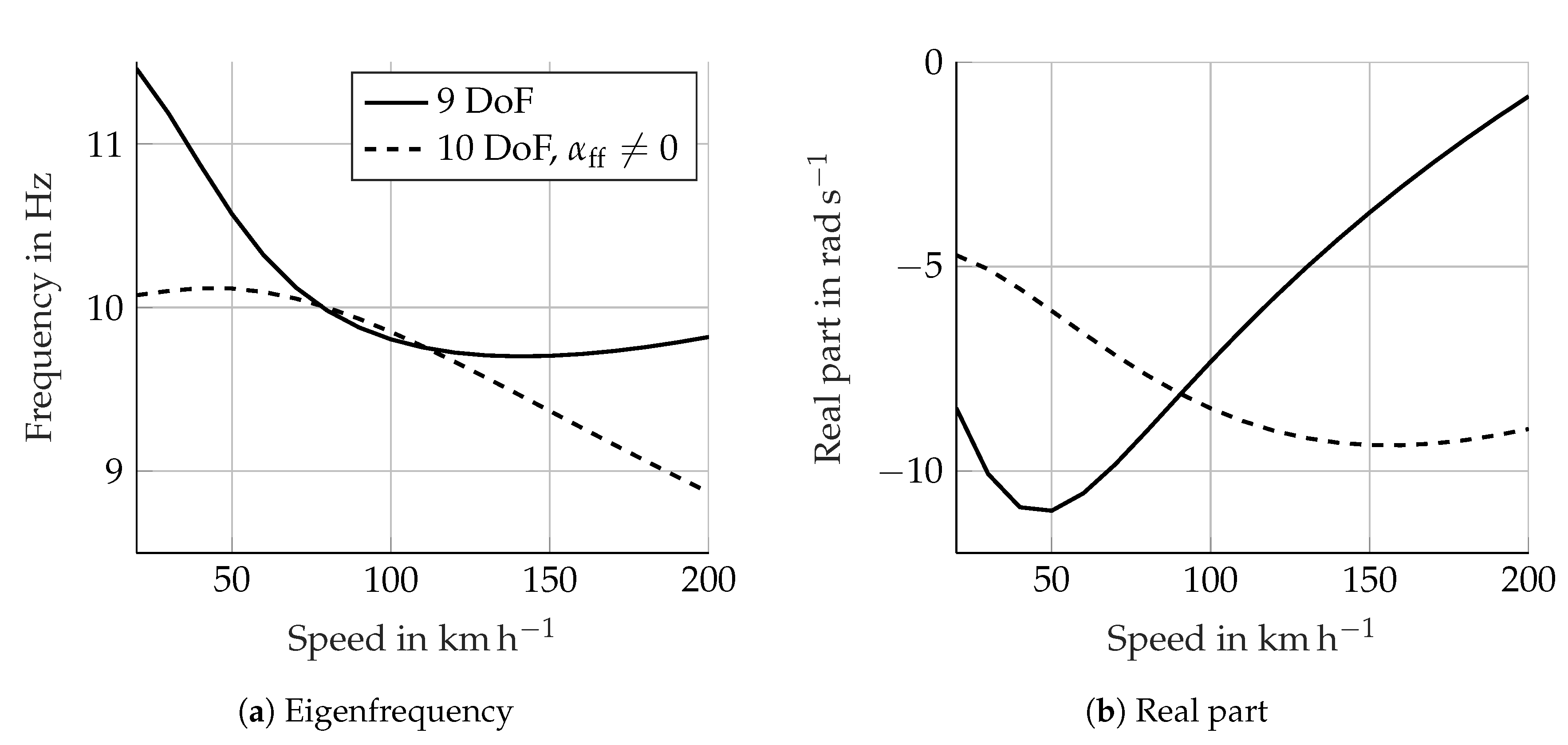

Section 2 describes how the front fork lateral flexibility (bending-compliance about the x axis) strongly influences the stability of wobble. This difference is shown in

Figure 4. In order to isolate the influence of the fork compliance, the curve relative to the rigid fork was obtained with a 9-DoF model, wherein the DoF used to represent the motorcycle’s stiffnesses, as described in

Section 3.1, have been eliminated. Moreover, the rider’s DoF are not present. In the curve relative to the flexible fork, only the DoF

has been added, so that the DoF are 10 in total. With the parameter set used in the present work and in the speed range considered, the wobble mode remains well damped. This is due to the relatively high value of the steering damper. In the following part of this section, the reason for such a drastic behaviour change between rigid and flexible fork is addressed. In particular, a possible cause is presented which partially differs from the explanation provided by Cossalter [

2] (p. 280) and Spierings [

6].

A key concept described in

Section 2 is the correlation between tyre properties and wobble. In particular, a tyre model with cornering stiffness is necessary to reproduce wobble [

3,

16,

17,

20]. Therefore, the tyre and specifically the lateral force due to the slip angle is a fundamental factor when considering wobble stability. However, what is the reason for the behaviour inversion in

Figure 4 and how can it be attributed to the tyre response? Equation (

2) shows how the slip angle depends on the lateral velocity of the wheel contact point

. The fork lateral flexibility allows some lateral motion of the wheel because of the rotation about the revolute joint axis (fork x axis), thereby influencing

.

This concept is shown schematically in

Figure 5. The variation of

due to the fork lateral flexibility can be expressed as:

To prove the effect of

, it is compensated by subtracting its value from

in Equation (

2).

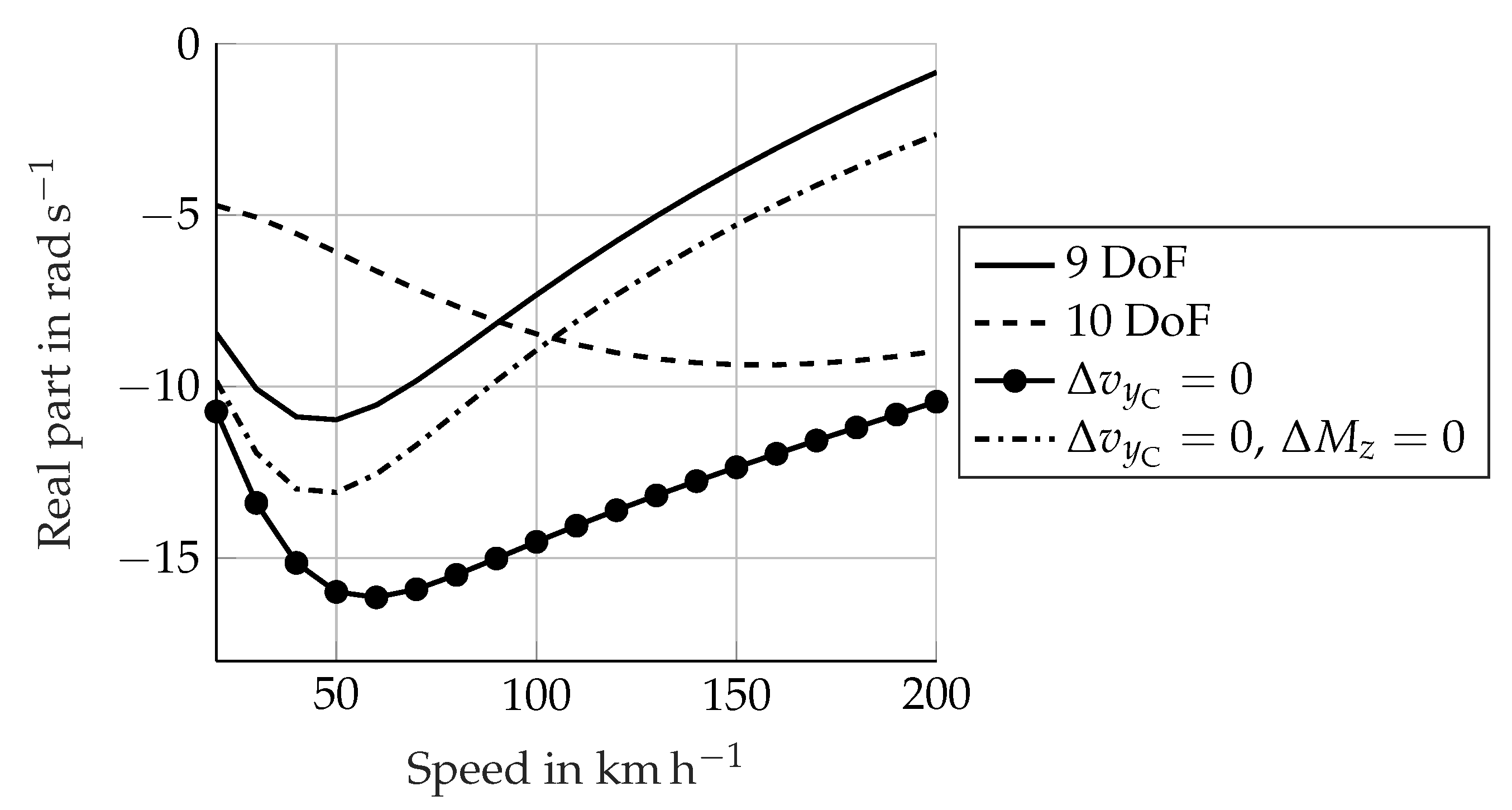

Figure 6 shows the corresponding eigenvalue analysis with the dots-marked curve. The compensation of

remarkably stabilises wobble. Moreover the curve shows the same behaviour for the 9-DoF model. At this point a conclusion can be drawn: the fork lateral flexibility influences the wobble stability through its effect on the lateral velocity

of the contact point.

In a subsequent step, it is of particular interest to observe whether

increases or reduces the value of

.

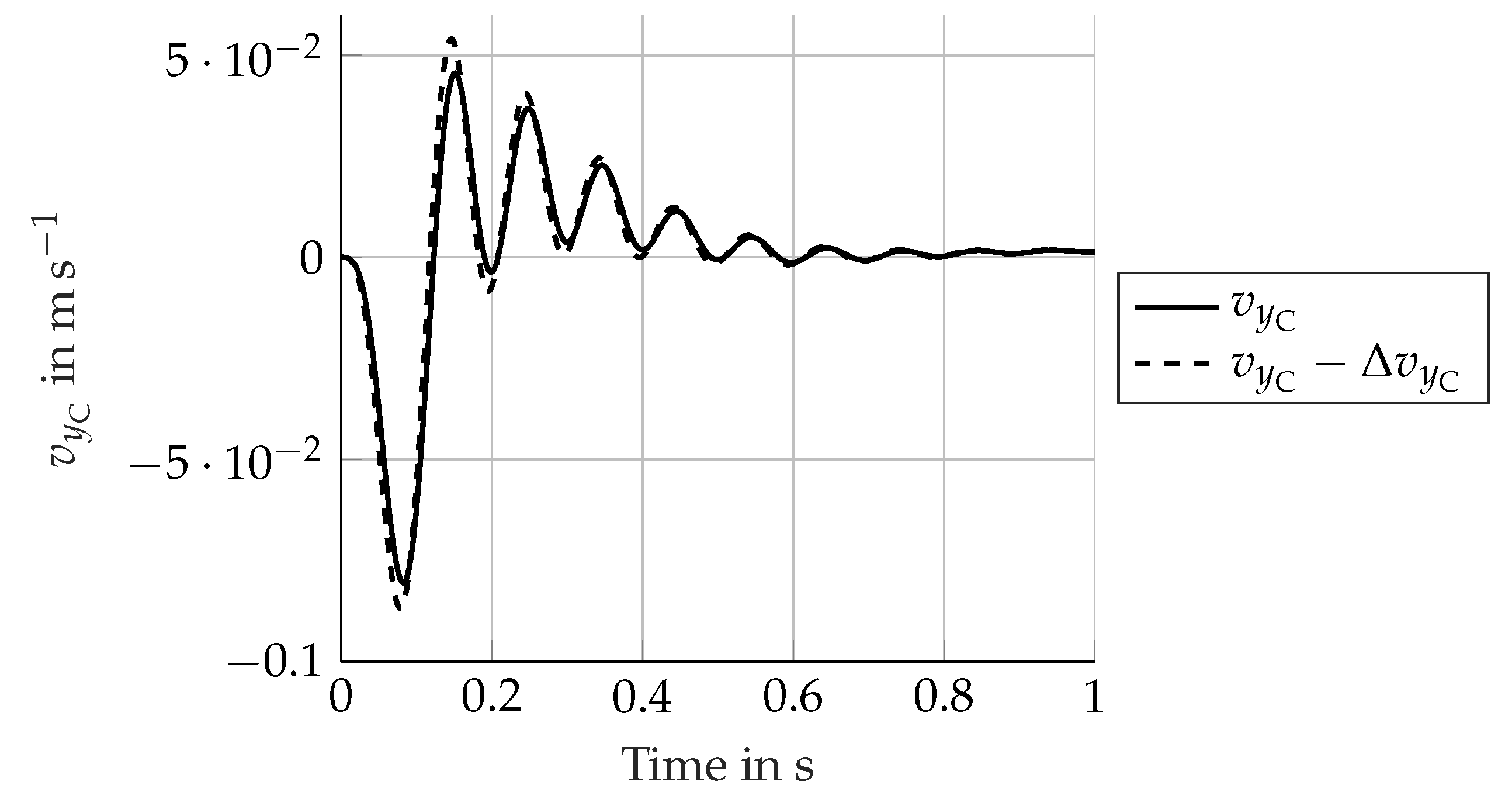

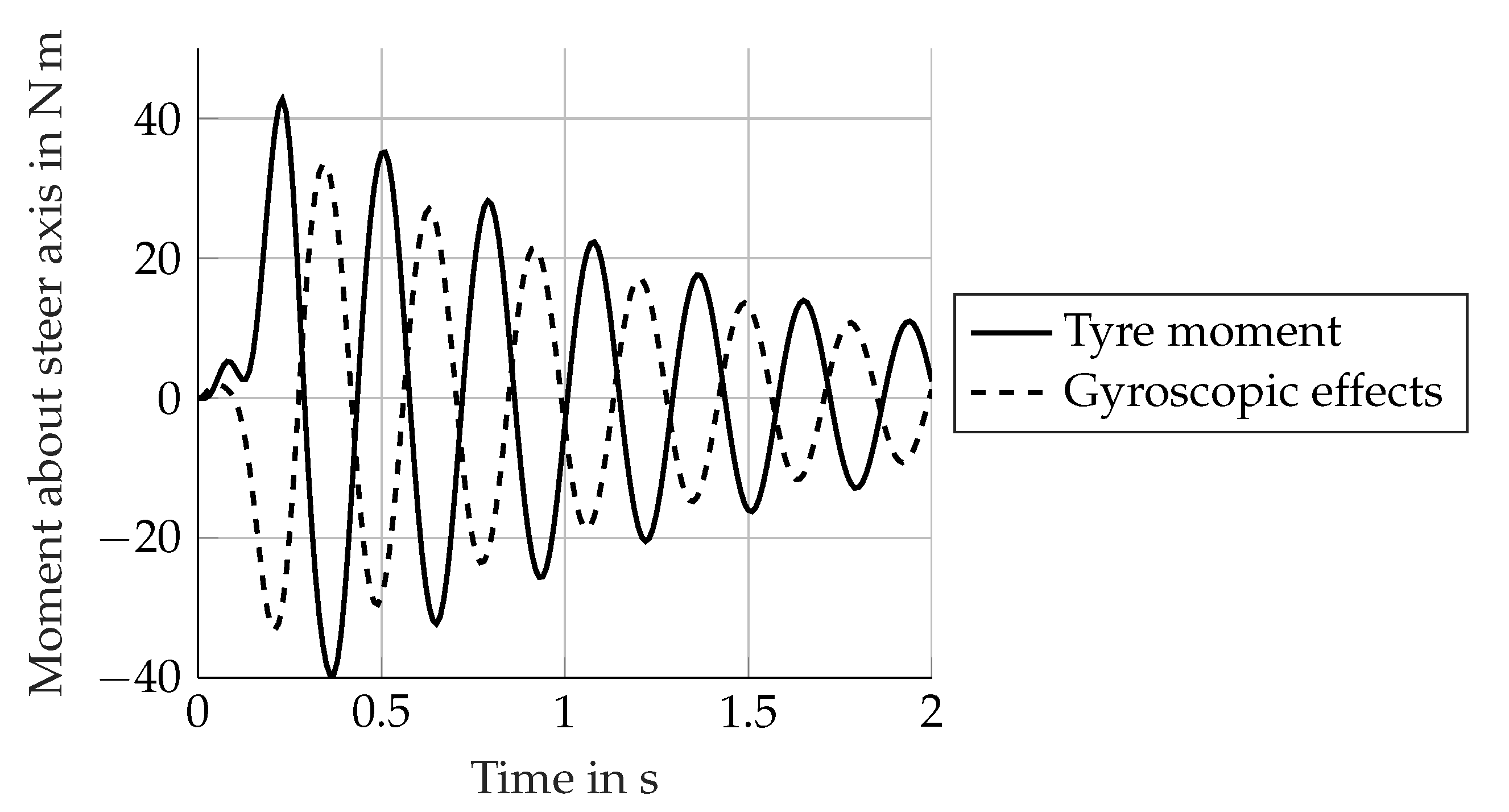

Figure 7 shows a time simulation at 50

−1 with a steer torque impulse as excitation. The full line represents

obtained from Equation (

5); the dashed line was obtained with

, whereby

was derived from Equation (

8). The subtraction of

increases the value of

:

, which is normally included in

, thereby reduces the amplitude of

. The tyre-lateral force is proportional to the slip angle, which is proportional to

(Equation (

2)). This force tends to oppose the wheel motion due to the wobble oscillation. Therefore, the fork flexibility introduces a

, which reduces the tyre-lateral force. This explains why the curve with

in

Figure 6 is significantly more stable than the 10-DoF case with

.

Even if the curve with compensated

in

Figure 6 assumes the same qualitative behaviour as the 9-DoF model, the damping values are still significantly different. In order to get a curve similar to that of the 9-DoF model, the gyroscopic moment introduced by fork bending must be compensated. The moment acts about the steering axis and can be calculated with Equation (

9) (this formula differs from the complete Euler equations (compare to Equation (

10)), whose left-hand side defines the whole gyroscopic effects. Equation (

9) is used here because its simple structure allows one to compensate the gyroscopic effects about the steering axis as external moments in the used multibody simulation software), as shown by Cossalter [

5]. This formula is also well-known in the literature, as it is present in the book on vehicle dynamics by Mitschke [

44]. The symbol

in Equation (

9) indicates that the formula only refers to the gyroscopic moment due to the fork lateral flexibility.

where

is the front wheel rotation speed and

is its polar moment of inertia. The dash-dotted curve in

Figure 6 shows the effect of compensating

. As expected, the damping curve gets very close to the 9-DoF model. The remaining offset can be attributed to other secondary phenomena, which have not yet been completely identified.

In summary, the influence of the fork bending compliance on wobble can be explained by considering two main phenomena:

Both of them originate through the rotation and its time derivatives.

When observing the curve of the 10-DoF case in

Figure 6, it is evident that it is less stable than the 9-DoF case only up to about 80

−1. Above this speed, the higher stability of the 10-DoF model compared to the 9-DoF model can be justified with the same consideration made by Cossalter [

5]: the gyroscopic moment

about the steering axis stabilises the wobble with increasing speed.

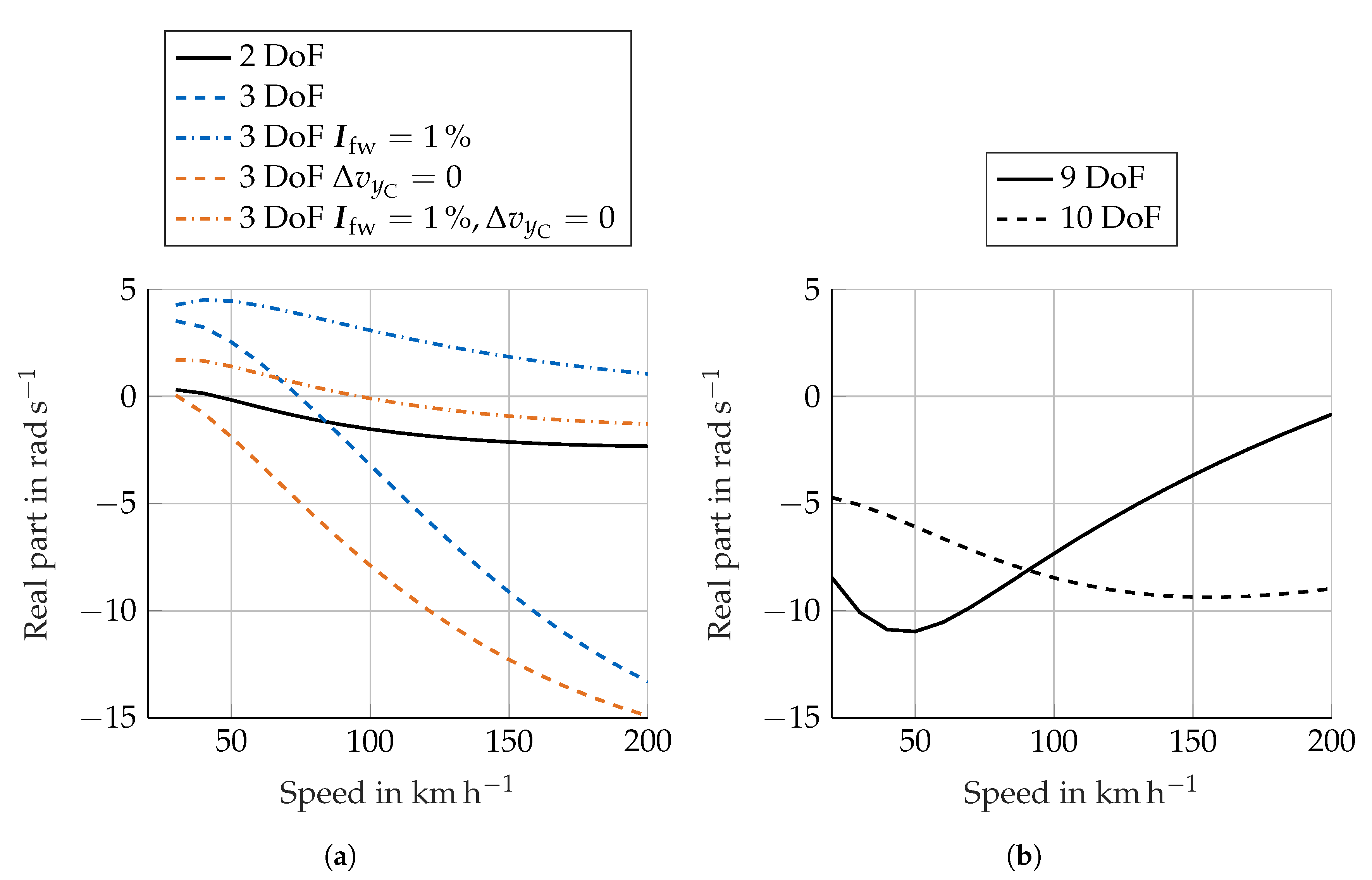

At this point another question may be raised: Which phenomenon is responsible for the decreasing wobble damping shown by the 9-DoF model and the model with compensated compared to the 10-DoF one? To answer this question, a model containing only the front fork and front wheel has been used. With this model two cases are studied: two DoF characterised by the rigid fork and three DoF with a flexible fork; the first model correlates with the 9-DoF model, and the second with the 10-DoF model.

Figure 8a shows the damping curves for these two models. Different variations were made: the wheel inertia tensor

was set to 1% of the original value (to eliminate the gyroscopic moments) and

has been compensated as in

Figure 6. Some important conclusions can be drawn:

The 2-DoF model did not show a decrease in damping with increasing speed, as did the 9-DoF model.

The damping of the 3-DoF model grew more rapidly than the one of the 10-DoF model.

The case

is very close to the curve of the 2-DoF model, as was expected by to theoretical observations. In fact, the 2-DoF model had no gyroscopic moments about the steering axis, as no rotation about the fork x axis was present. In

Figure 6 the curve with

shows a remarkable offset compared to the 9-DoF curve because of the gyroscopic moments. With

set to

they almost vanish, resulting in a smaller offset.

The difference in behaviour between the 2 and 9-DoF models can be justified by the additional roll motion of the 9-DoF case. This motion produces additional gyroscopic moments which apparently destabilise the wobble with increasing speed. These moments are also clearly present in the 10-DoF model. However, in this case they are compensated by the gyroscopic moment produced by the fork flexibility. The opposition of these two effects is underlined by the saturation shown in the 10-DoF model at about 150 −1, which is not present in the 3-DoF model.

In summary, the wobble damping behaviour of a real motorcycle is determined by three principal mechanisms. The front fork flexibility produces a lateral movement of the front wheel, which can be represented with a rotation . This reduces the tyre-lateral force and thus decreases the wobble damping at low speed compared to a rigid fork. When the speed increases, the gyroscopic moment caused by the rotation increases in magnitude and stabilises the wobble, thereby making the 10 DoF model more stable than the 9-DoF model. The third mechanism is related to the gyroscopic moments caused by the motorcycle’s roll motion. They destabilise the wobble with increasing speed, thereby explaining why the wobble damping in the 9-DoF model decreases with increasing speed. This does not happen in the 10-DoF model because the stabilising gyroscopic moment caused by outweighs the destabilising effect.

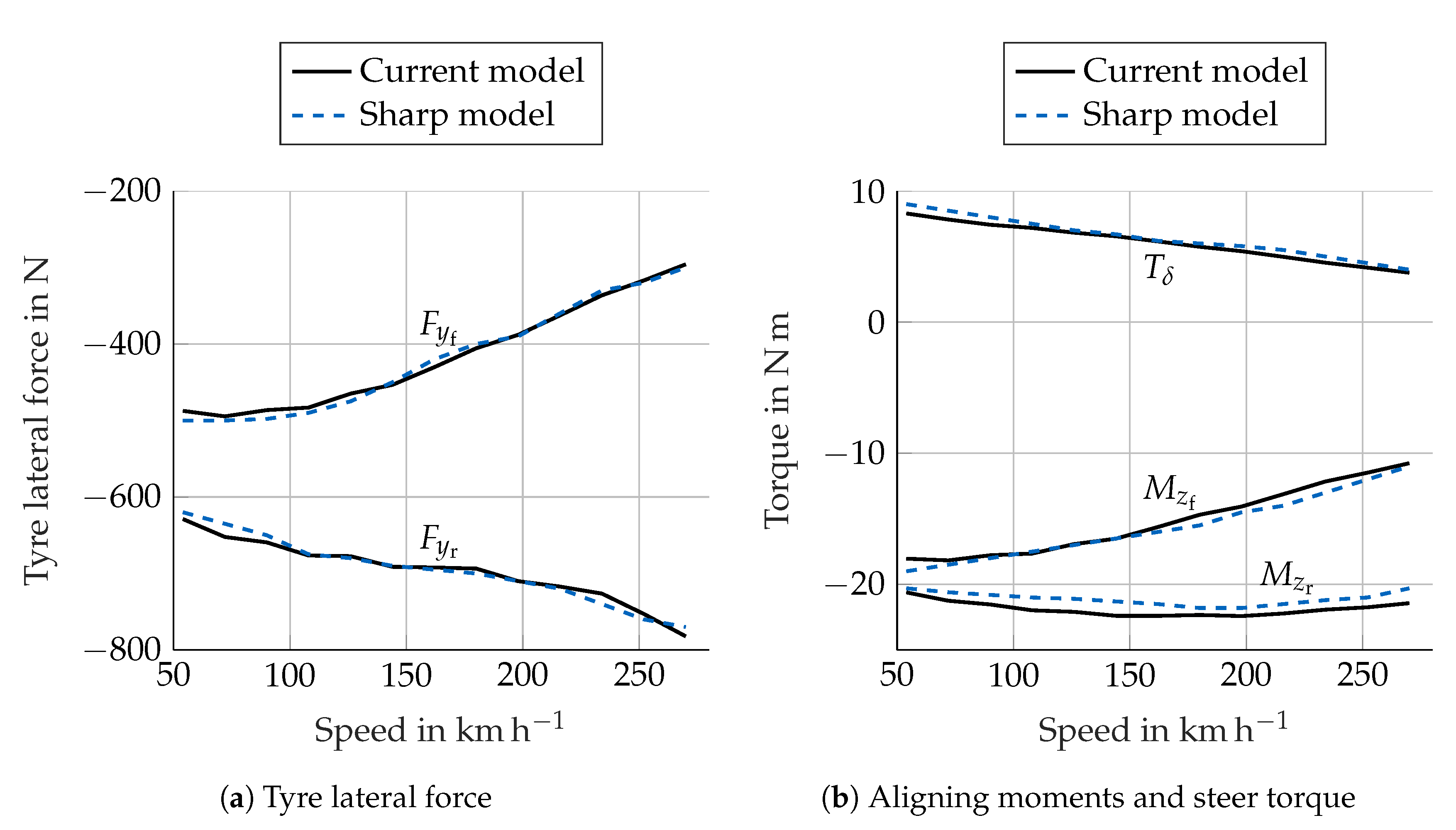

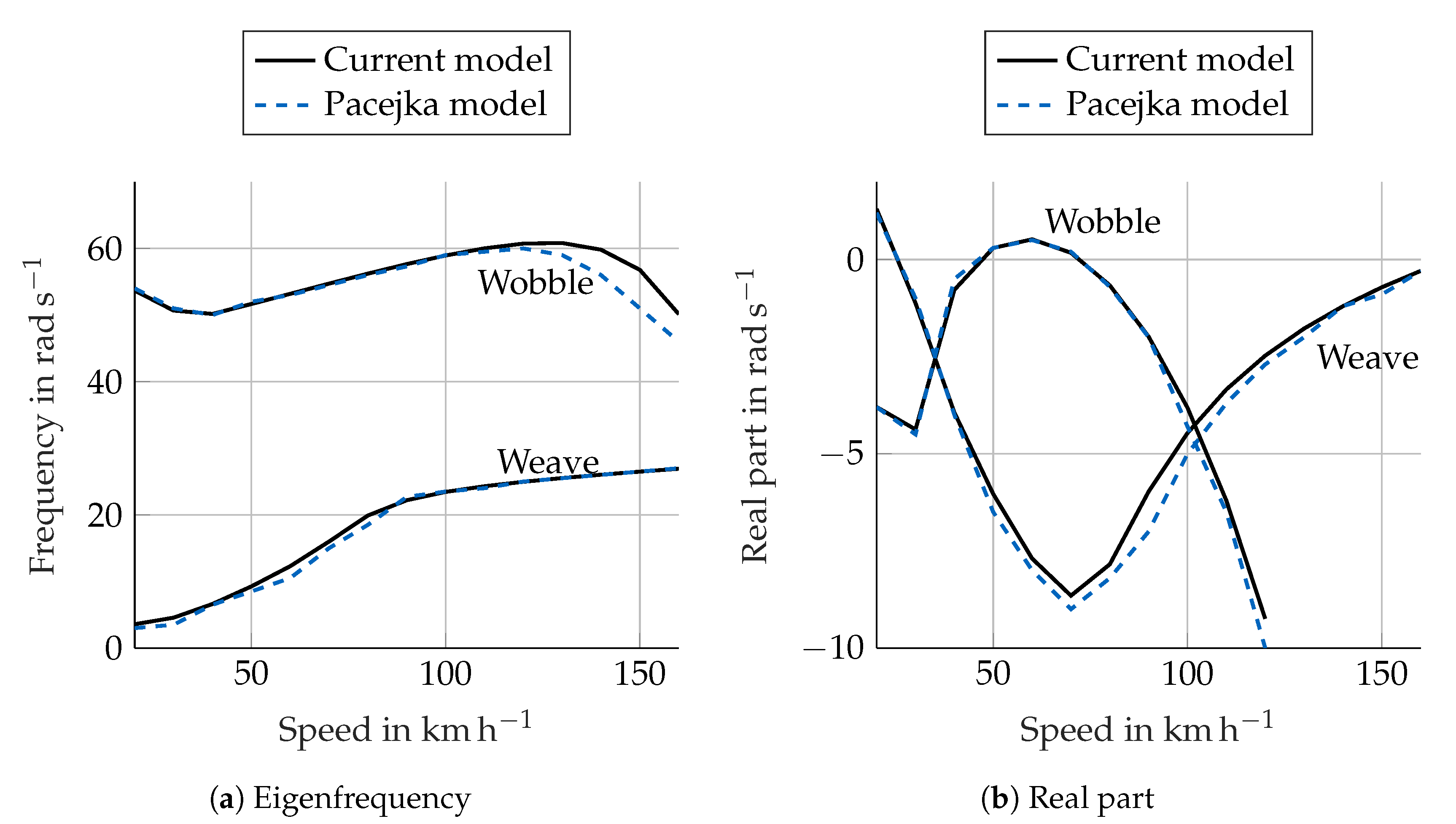

4.2. Weave

The weave mode was already captured in its essence by the very first motorcycle model by Whipple [

13] (p. 195). Moreover, there is no evidence of parameters which produce a behaviour inversion of the damping curve, as can be observed for the wobble mode. This already suggests that the weave mode reproduces in some way the "basic" motorcycle behaviour. This idea was also proposed by Schröter [

45] (p. 28), who describes the weave mode as a degenerated dynamic stabilisation process involving steering, roll and yaw oscillations. This can be shown with a simple time simulation where the upright riding motorcycle is excited with a lateral force impulse applied to the frame. Assuming that the wobble is well damped, the motorcycle reacts to this excitation with a weave oscillation, which may diverge or stabilise depending on the motorcycle’s speed and parameters.

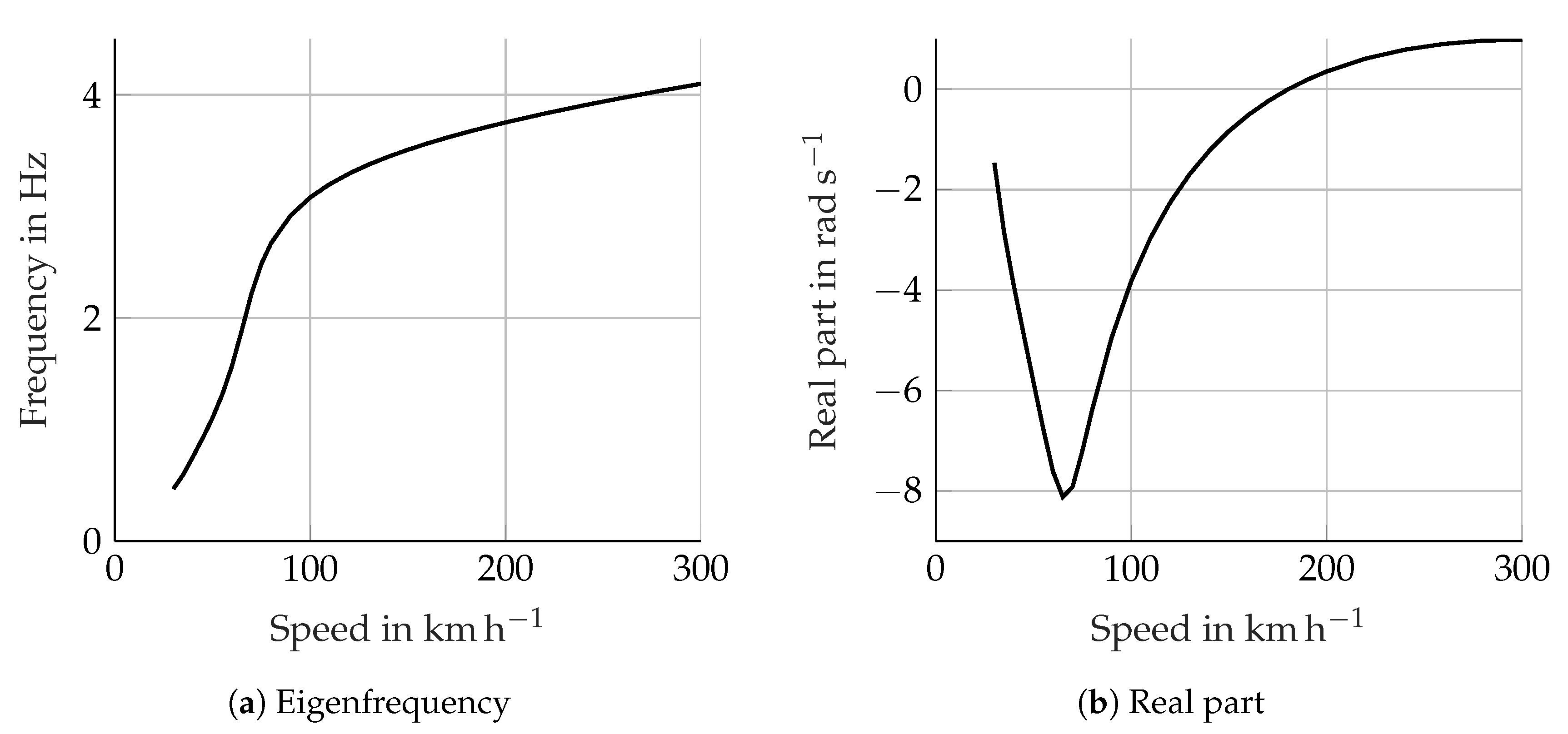

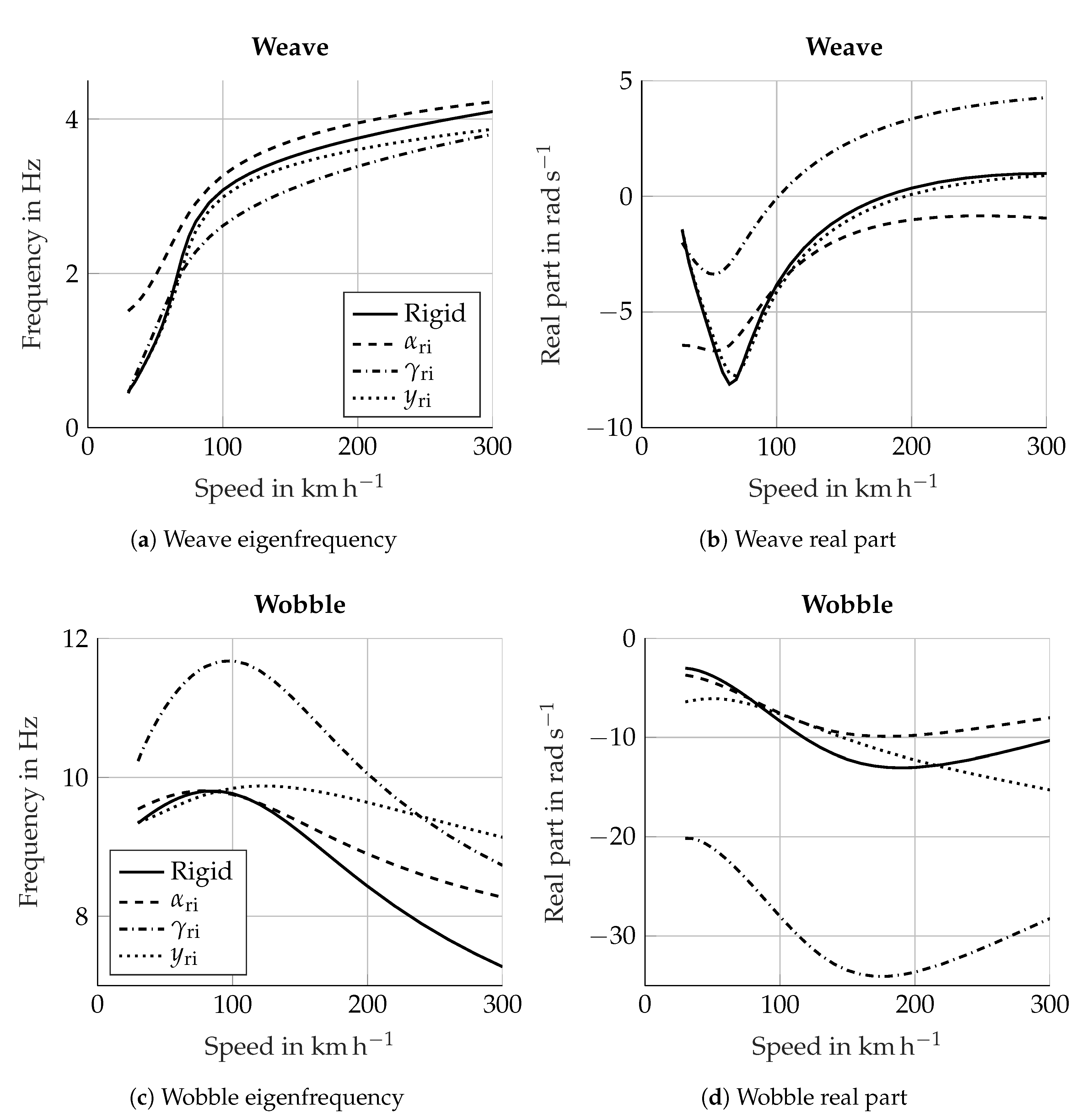

Figure 9 shows the frequency and damping of the weave mode as a function of the speed. The effect of the rider is analysed in

Section 4.3, so this figure refers to the case with a rigid rider; the other DoF are all present. In order to represent the saturation shown by the damping curve at high speed, the speed range differs from the one in

Figure 4. The behaviour of the weave damping shows some interesting characteristics: below 70

−1 weave is stabilised with increasing speed; above it is destabilised. However, above 220

−1 the weave damping shows a plateau. This particular behaviour suggests that the weave mode changes with speed. Moreover, the speed dependency could be explained by a certain influence of the gyroscopic effects, which are also speed dependent. The gyroscopic effects are obtained with the whole left-hand side of the Euler equations, which is shown in Equation (

10) for the front wheel.

where

is the rotational velocity vector of the front wheel and

is the front wheel inertia tensor.

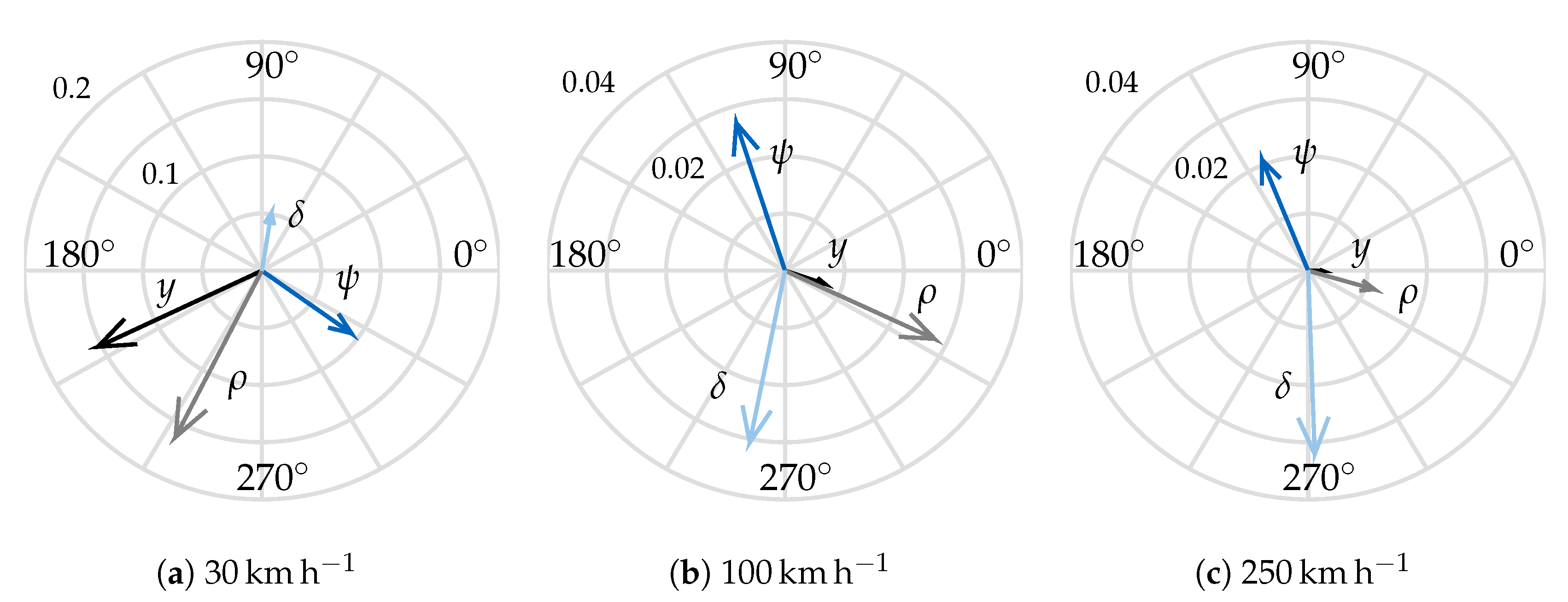

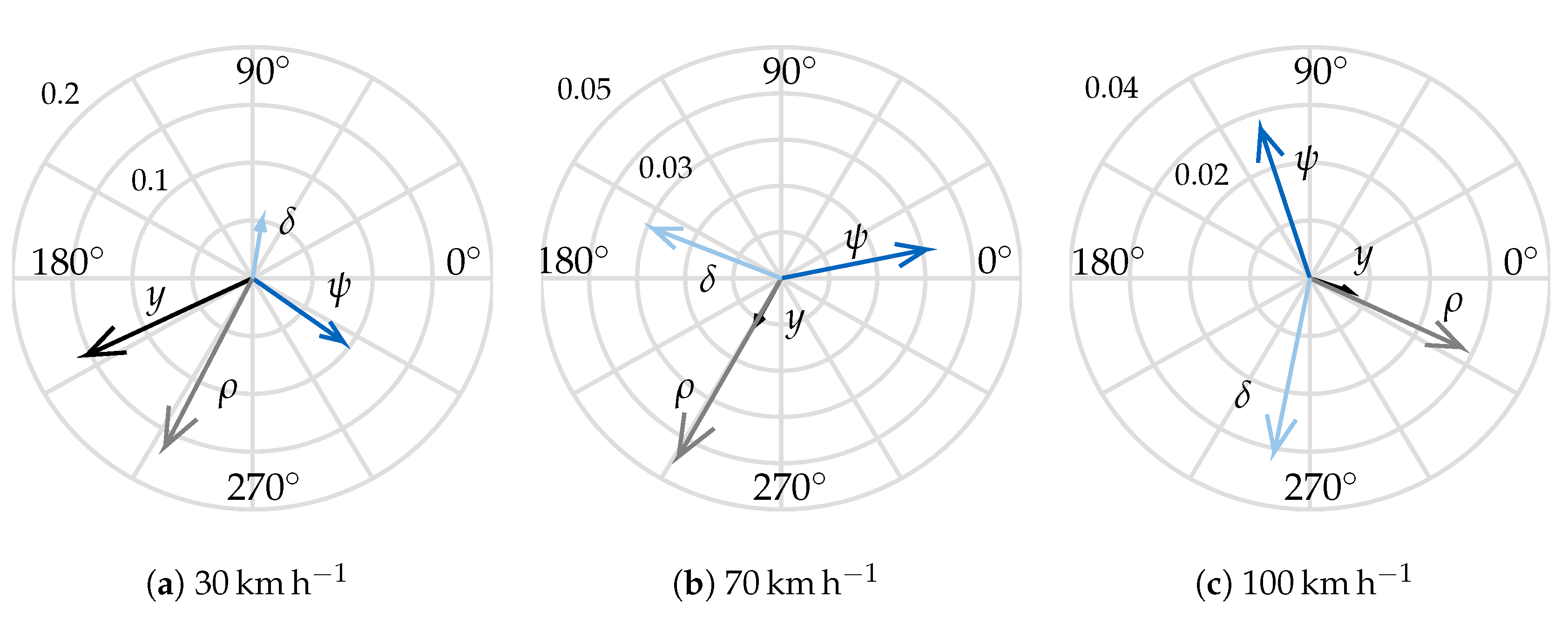

Figure 10 further illustrates this concept. In this figure, the weave eigenvector is shown with the so-called compass plot. The arrows are named phasors and represent how the motorcycle’s DoF are involved in the weave oscillation. An arrow’s length is the magnitude of the motion of the related DoF. In order to maintain the information about the absolute amplitude of the phasors, no normalisation is present. The phasor’s angle shows the phase. In the following paragraphs the relative angle between the phasors is called relative phase.

At low speed, (

Figure 10a) the roll (

) and lateral displacement (

y) show big amplitudes. The latter is due to the small gyroscopic effects, so that if weave is excited (for example, with a lateral impulse), the motorcycle describes a “slalom” at low frequency (see

Figure 9) involving a significant lateral displacement. This can be described as a low-frequency “self-stabilising” motion, which the literature already considers as weave.

As the speed increases (

Figure 10b), the relative phase between the motions significantly changes, whereby the lateral displacement is no longer important. The other DoF show a similar amplitude. Finally, when the speed increases further (

Figure 10c), the relative phase does not change remarkably. The most important observation, however, is the reduction of the roll (

) amplitude with increasing speed, which can be seen when comparing the related phasor in

Figure 10b,c. This can also be observed in the time simulation. If the motorcycle is excited by a lateral impulse at high speed, the resulting weave oscillation does not show a significant roll motion, while the front wheel and the frame rotate around the steering and vertical axis almost in opposition of phase, as shown by the vectors

in

Figure 10c. The reduction in roll motion with increasing speed is also shown by a free rolling wheel. This phenomenon can be explained considering the gyroscopic effects which increase with speed, thereby preventing the wheel (or the motorcycle) capsizing.

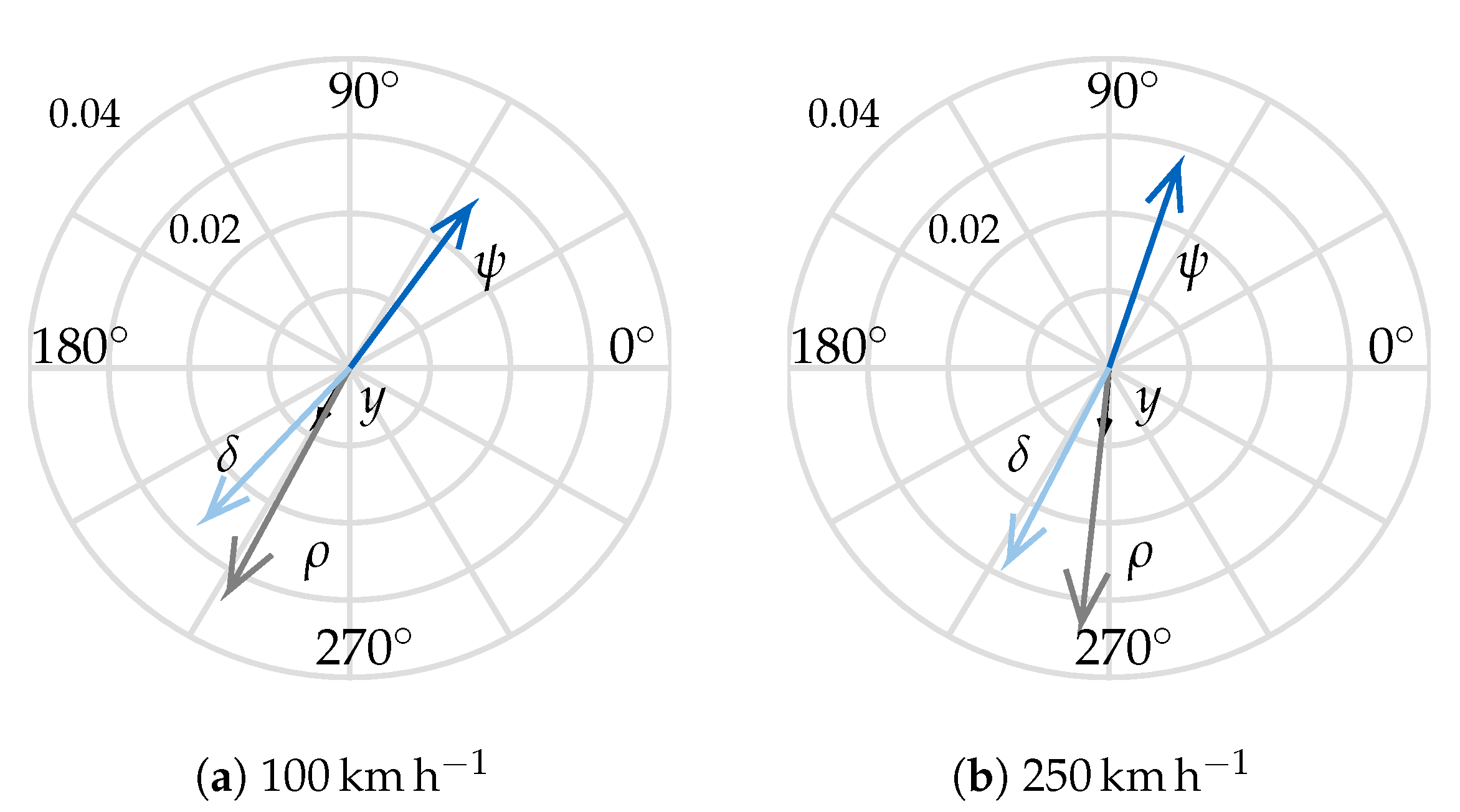

Which are the possible causes of the peculiar damping behaviour shown in

Figure 9b? Some useful knowledge can be derived by an eigenvalue analysis with reduced wheel inertia. The correlation to

Figure 10 is shown in

Figure 11, for which the total wheel inertia tensors

was set to 10% of the original tensors. The first consideration resulting from the comparison is that in

Figure 11 the relative phase between the phasors no longer changes with speed, as it happens in

Figure 10. The plot at 30

−1 is not present, as the weave mode is no longer available at this speed. It is important to point out that, because of this massive inertia reduction, the gyroscopic effects almost disappear. Two main observations can be made:

The missing weave mode at low speed can be attributed to the (almost) missing gyroscopic effects. The time simulation at 30 −1 with a lateral force impulse shows that the motorcycle does not react to the excitation with a weave oscillation, but it capsizes. With the original inertia values the gyroscopic effects are present, despite the low speed. They prevent the motorcycle from capsizing immediately after the excitation and producing the low-frequency “self-stabilising” motion.

The gyroscopic effects are also the main cause for the change in the weave eigenvector shown in

Figure 10. In fact, when they are very small, as in

Figure 11, the relative phase between the eigenvector components is no longer speed dependent.

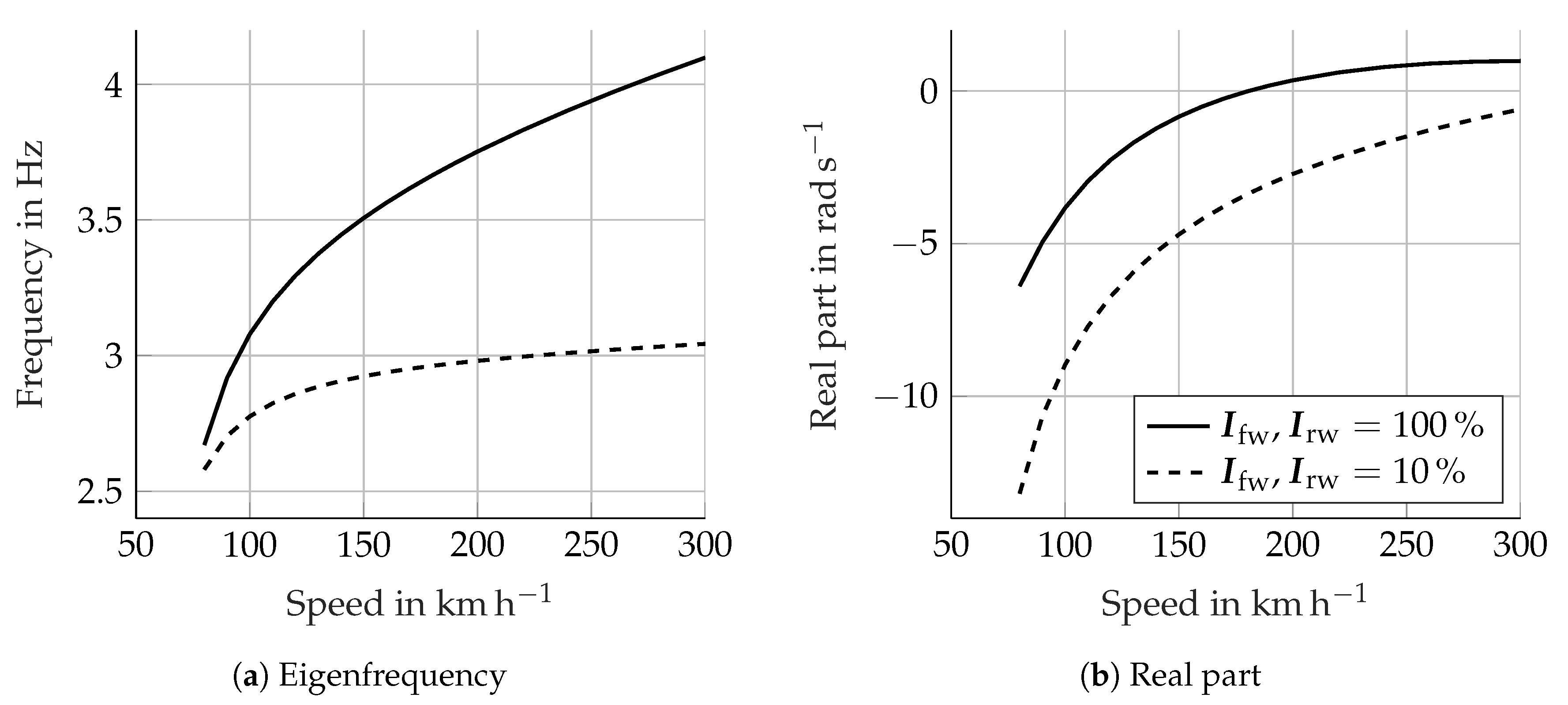

The correlation with

Figure 9 is shown in

Figure 12. The speed range starts now from 80

−1, as for the following reasoning only this range is necessary. Moreover, the weave with reduced wheel inertia is not present up to about 50

−1 and in the range 50

−1 it is extremely well damped (real part > 25

−1). Similarly to the full inertia case, the damping continues to decrease with increasing speed in the small inertia case shown in

Figure 12b. As the gyroscopic effects are almost missing, the reason for this behaviour can be determined by investigating in the tyre response. The tyre-lateral force is proportional to the slip angle which is in turn proportional to the ratio between

and

(Equation (

2)). The authors verified that

mainly depends on the kinematic steering angle (see [

2] for its definition), which is proportional to the steering angle.

Figure 11 shows that above a certain speed (100

−1) the amplitude of steering motion in the weave eigenvector remains fairly constant. The numerator of

in Equation (

2) is therefore almost constant with speed. The denominator of

is given by

, which clearly increases with speed. As a result,

decreases with increasing speed and so does the tyre-lateral force. The tyre-lateral forces tend to bring the motorcycle back to the equilibrium position, thereby stabilising the weave. The decreasing tyre force is therefore responsible for the decreasing weave damping and the hyperbolic behaviour of the dashed curve in

Figure 12b.

Considering again the curve with the original wheel inertia in

Figure 12, the first observation is the smaller weave damping. This can be explained by taking into account the additional impact of the gyroscopic effects. The gyroscopic effects of the front wheel about the steering axis are in counterphase with respect to the tyre moments, as

Figure 13 shows, therefore they work against them. For this reason, the weave damping is lower compared to the reduced inertia case. The gyroscopic effects also justify the slower damping decrease in the case with original wheel inertia (see

Figure 12). In fact, due to the progressively changing eigenvector (

Figure 10), i.e., the decreasing roll motion amplitude, the gyroscopic effects increase underproportionally with the speed. For example, in a time simulation with lateral force excitation, the first peak of the front wheel gyroscopic effects about the

z axis increase from 100 to 150

−1 by 37.5%, while they only increase by 14.5% from 250 to 300

−1. As a consequence, they also underproportionally reduce the tyre forces with increasing speed. This, combined with the decreasing tyre forces, leads to the mentioned saturation above 220

−1, which is not present in the reduced inertia case.

The last characteristic to be observed is the increase in damping shown below 80

−1 in

Figure 9b. The authors’ belief is that in this lower speed range the weave mode can still be seen as the already mentioned low-speed “self-stabilising” motion. When increasing the speed, this motion progressively changes to the “real” weave, thereby producing the observed increase in damping.

Figure 14 illustrates this fact. Following the three compass plots with increasing speed, one can see that the phase and amplitude of the phasors progressively change; i.e., the weave changes from the “self-stabilising” motion to the classical weave. In fact, above 100

−1 the relative angle between the phasors no longer changes significantly, as the comparison of

Figure 10b,c shows.