An Experimental Study on Alkali Silica Reaction of Concrete Specimen Using Steel Slag as Aggregate

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

2.1.1. Binder

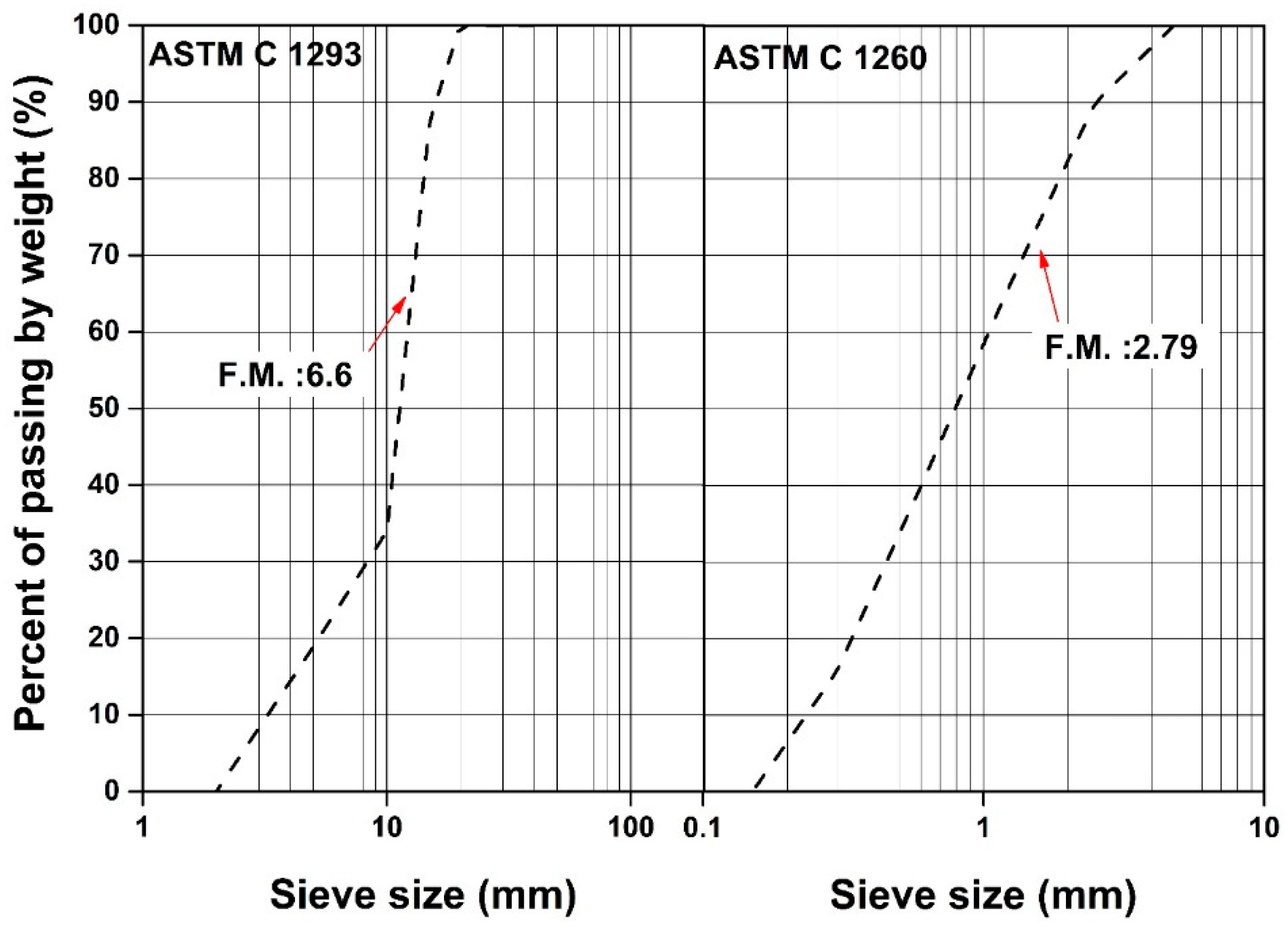

2.1.2. Natural Aggregates

2.1.3. Steel Slag

2.2. Evaluation of the Fundamental Properties of the Steel Slag

2.3. Evaluation of Expansion Properties of the Steel Slag

2.3.1. Immersion Expansion of the Steel Slag

2.3.2. Experimental Setup for the Alkali-Silica Reaction Expansion of Steel Slag

2.4. Evaluation of ASR Expansion of Concrete Specimen

3. Results and Discussion

3.1. Fundamental Properties of Steel Slag

3.2. Evaluation Expansion Properties of Steel Slag

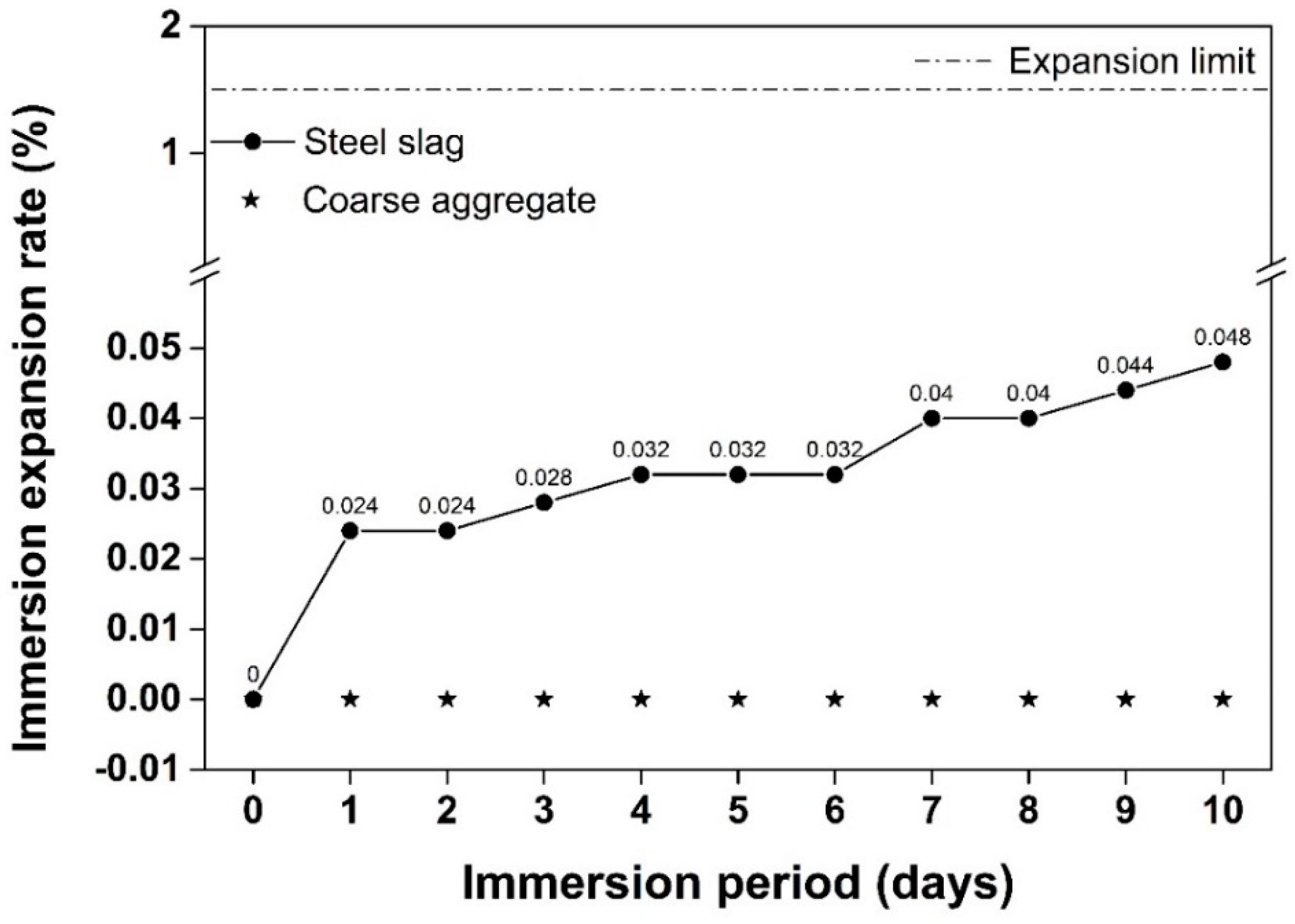

3.2.1. Immersion Expansion Properties

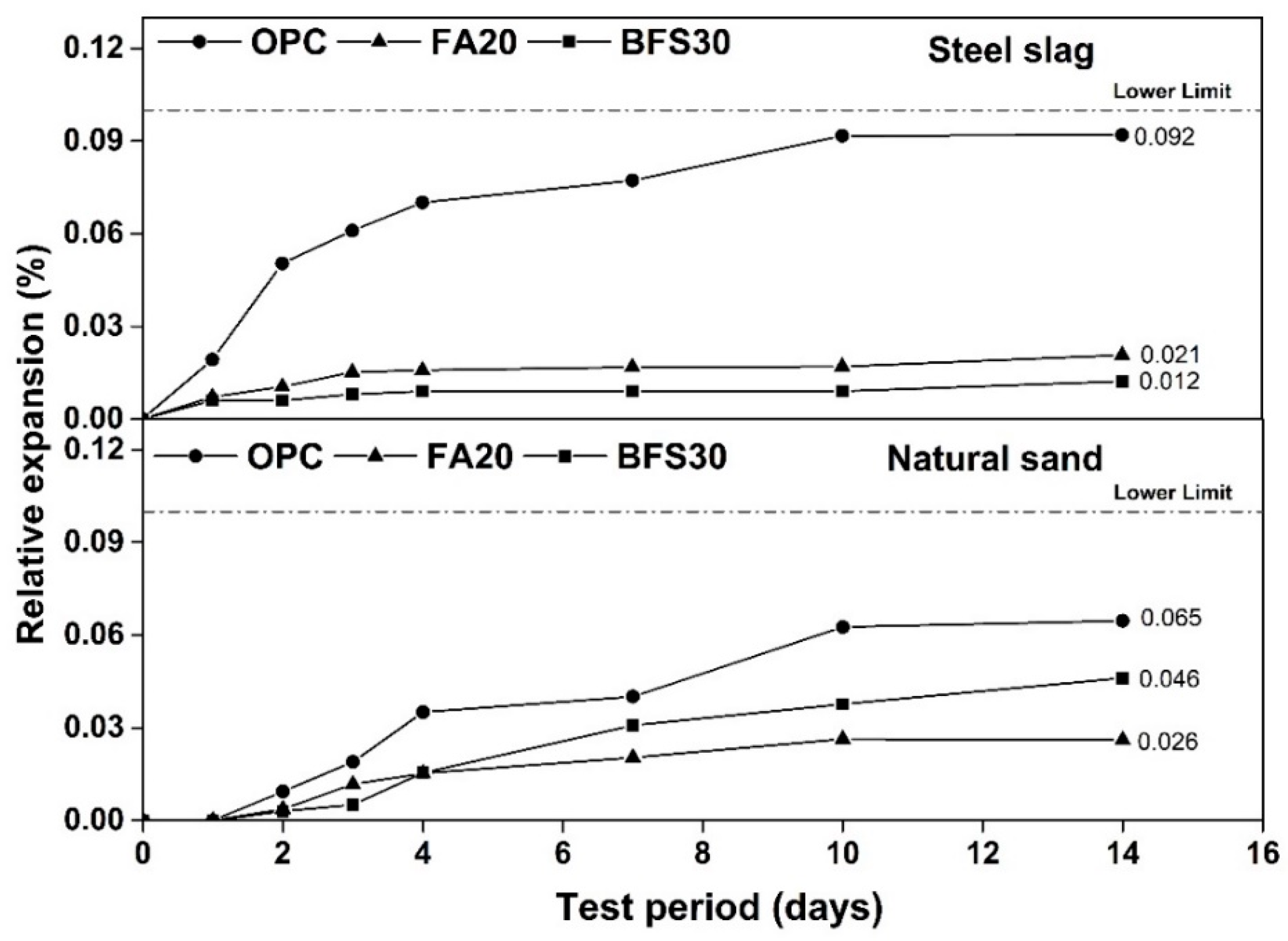

3.2.2. Change in Length of Mortar Bar with Steel Slag

3.3. Evaluation Expansion Properties of Concrete with Steel Slag

3.3.1. Evaluation Change in Length Concrete Specimen Due to ASR

3.3.2. Evaluation of Crack Propagation in Concrete Specimens Due to ASR

3.3.3. Evaluation of Crack Number and Crack Width in Concrete Specimens Due to ASR

4. Conclusions

- (1)

- To satisfy the JIS A 5015 standard of immersion expansibility of 1.5%, the steel slag should be aged in water for 1 month.

- (2)

- When steel slag used as fine aggregate in mortar bars, the ASR expansion increased with the increase in the duration of the test period. However, the ASR expansion was within the permitted limit of 0.1% after 14 days, as specified by the ASTM C 1260 standard.

- (3)

- When steel slag was used as coarse aggregate in concrete specimens, ASR expansion could not be maintained below the permitted limit of 0.04% specified by the ASTM C 1293 standard, regardless of the presence of mineral admixtures. In addition, although the expansion rate did not exceed the permitted limit after 7 days, cracks occurred in all specimens.

- (4)

- The evaluation of ASR expansion is affected by the mineral admixture type and the size of the steel slag. Furthermore, when mineral admixtures were used as the binder in the concrete specimens using steel slag aggregate, there were discrepancies in the results between the expansion rate and the crack properties, such as maximum length and total crack length. Thus, to accurately predict the deterioration due to ASR in concrete using steel slag as coarse aggregate, it is recommended to evaluate the expansion rate as well as to check crack patterns.

Author Contributions

Funding

Conflicts of Interest

References

- Rondi, L.; Bregoli, G.; Sorlini, S.; Cominoli, L.; Collivignarelli, C.; Plizzari, G. Concrete with EAF steel slag as aggregate: A comprehensive technical and environmental characterisation. Compos. Part B Eng. 2016, 90, 195–202. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, G.; Wang, B.; Wu, M. Mechanical strengths and durability properties of pervious concretes with blended steel slag and natural aggregate. J. Clean. Prod. 2020, 271, 122590. [Google Scholar] [CrossRef]

- Devi, V.S.; Kumar, M.M.; Iswarya, N.; Gnanavel, B. Durability of Steel Slag Concrete under Various Exposure Conditions. Mater. Today Proc. 2020, 22, 2764–2771. [Google Scholar] [CrossRef]

- Dhoble, Y.N.; Ahmed, S. Review on the innovative uses of steel slag for waste minimization. J. Mater. Cycles Waste Manag. 2018, 20, 1373–1382. [Google Scholar] [CrossRef]

- Kuo, W.-T.; Shu, C.-Y. Effect of particle size and curing temperature on expansion reaction in electric arc furnace oxidizing slag aggregate concrete. Constr. Build. Mater. 2015, 94, 488–493. [Google Scholar] [CrossRef]

- Hou, J.; Lv, Y.; Liu, J.; Wu, Q. Expansibility of cement paste with tri-component f-CaO in steel slag. Mater. Struct. 2018, 51, 113. [Google Scholar] [CrossRef]

- Lee, H.-S.; Lim, H.-S.; Ismail, M. Quantitative evaluation of free CaO in electric furnace slag using the ethylene glycol method. Constr. Build. Mater. 2017, 131, 676–681. [Google Scholar] [CrossRef]

- Siddique, R. Utilization of waste materials and by-products in producing controlled low-strength materials. Resour. Conserv. Recycl. 2009, 54, 1–8. [Google Scholar] [CrossRef]

- Moon, H.Y.; Yoo, J.H.; Kim, S.S. A Fundamental Study on the Steel Slag Aggregate for Concrete. Geosystem Eng. 2002, 5, 38–45. [Google Scholar] [CrossRef]

- Hamazaki, T.S.T. Development of Steam-aging Process for Steel Slag. Nippon Steel Sumitomo Met. 2015, 19, 23–26. [Google Scholar]

- Sasaki, M.; Niida, A.; Otsuki, T.; Tsuchiya, K.; Nagao, Y. Stabilization Mechanism of Steel Slag by Aging Treatment. Tetsu-to-Hagane 1982, 68, 641–648. [Google Scholar] [CrossRef]

- Soltangharaei, V.; Anay, R.; Hayes, N.W.; Assi, L.N.; Le Pape, Y.; Ma, Z.J.; Ziehl, P. Damage Mechanism Evaluation of Large-Scale Concrete Structures Affected by Alkali-Silica Reaction Using Acoustic Emission. Appl. Sci. 2018, 8, 2148. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monterio, P.J.M. Concrete: Microstructure, Properties, and Materials; MC Graw-Hill: New York, NY, USA, 2014. [Google Scholar]

- Stanton, T.E.; Porter, O.J.; Meder, L.C.; Nicol, A. California Experience with the Expansion of Concrete through Reaction between Cement and Aggregate. ACI J. Proc. 1942, 38, 209–236. [Google Scholar]

- Stanton, T.E. Expansion of Concrete through Reaction between Cement and Aggregate. Proc. Am. Soc. Civ. Eng. 1940, 66, 1781–1812. [Google Scholar]

- Multon, S.; Cyr, M.; Sellier, A.; Diederich, P.; Petit, L. Effects of aggregate size and alkali content on ASR expansion. Cem. Concr. Res. 2010, 40, 508–516. [Google Scholar] [CrossRef]

- Shon, C.-S.; Zollinger, D.G.; Sarkar, S.L. Evaluation of modified ASTM C 1260 accelerated mortar bar test for alkali–silica reactivity. Cem. Concr. Res. 2002, 32, 1981–1987. [Google Scholar] [CrossRef]

- Na, O.; Xi, Y.; Ou, E.; Saouma, V.E. The effects of alkali-silica reaction on the mechanical properties of concretes with three different types of reactive aggregate. Struct. Concr. 2016, 17, 74–83. [Google Scholar] [CrossRef]

- Japan Standards Association. 5015. Japan Industrial Standard–Iron and Steel Slag for Road Construction; Japan Standards Association: Tokyo, Japan, 2013. [Google Scholar]

- Lu, D.; Fournier, B.; Grattan-Bellew, P. Evaluation of accelerated test methods for determining alkali-silica reactivity of concrete aggregates. Cem. Concr. Compos. 2006, 28, 546–554. [Google Scholar] [CrossRef]

- Davies, G.; Oberholster, R. Use of the NBRI accelerated test to evaluate the effectiveness of mineral admixtures in preventing the alkali-silica reaction. Cem. Concr. Res. 1987, 17, 97–107. [Google Scholar] [CrossRef]

- Oberholster, R.; Davies, G. An accelerated method for testing the potential alkali reactivity of siliceous aggregates. Cem. Concr. Res. 1986, 16, 181–189. [Google Scholar] [CrossRef]

- ASTM. ASTM Standard C1260-14, Standard Test Method for Potential Alkali Reactivity of Aggregates (Mortar-Bar Method); ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM. ASTM Standard C1293-18, Standard Test Method for Determination of Length Change of Concrete Due to Alkali–Silica Reaction; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar]

- Korean Standards Association. 2527. Concrete Aggregate; Korean Standards Association: Seoul, Korea, 2018. (In Korean)

- Ramachandran, V. Alkali-aggregate expansion inhibiting admixtures. Cem. Concr. Compos. 1998, 20, 149–161. [Google Scholar] [CrossRef]

- Choi, S.Y.; Choi, Y.-S.; Yang, E.-I. Characteristics of volume change and heavy metal leaching in mortar specimens recycled heavyweight waste glass as fine aggregate. Constr. Build. Mater. 2018, 165, 424–433. [Google Scholar] [CrossRef]

- Shafaatian, S.M.; Akhavan, A.; Maraghechi, H.; Rajabipour, F. How does fly ash mitigate alkali–silica reaction (ASR) in accelerated mortar bar test (ASTM C1567)? Cem. Concr. Compos. 2013, 37, 143–153. [Google Scholar] [CrossRef]

- Klieger, P.; Lamond, J. STP169C Significance of Tests and Properties of Concrete and Concrete-Making Materials; ASTM International: West Conshohocken, PA, USA, 1994. [Google Scholar]

- Ayub, T.; Shafiq, N.; Khan, S.U.; Nuruddin, M. Durability of Concrete with Different Mineral Admixtures: A Review. Int. J. Civ. Sci. Eng. 2013, 7, 199–210. [Google Scholar]

- ASTM International. ASTM_C1778-14, Standard Guide for Reducing the Risk of Deleterious Alkali-Aggregate Reaction in Concrete; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Ian Sims, A.B.P. Alkali-Aggregate Reaction in Concrete: A World Review; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

| Binder | OPC | FA | BFS | ||

|---|---|---|---|---|---|

| Properties | |||||

| Physical | Specific gravity | 3.15 | 2.19 | 2.92 | |

| Blaine (cm2/g) | 3200 | 3400 | 6300 | ||

| Chemical (%) | SiO2 | 21.36 | 53.0 | 27.2 | |

| Al2O3 | 5.03 | 20.3 | 9.87 | ||

| Fe2O3 | 3.31 | 10.4 | 0.51 | ||

| CaO | 63.18 | 6.57 | 53.5 | ||

| MgO | 2.89 | 0.98 | 3.29 | ||

| SO3 | 2.30 | 1.08 | 3.17 | ||

| Equivalent alkalis (Na2O + 0.658K2O) | 0.85 | 2.58 | 0.58 | ||

| Loss on ignition (LOI) | 1.40 | 2.56 | 0.01 | ||

| Type | Density (g/cm3) | Absorption (%) | Fineness Modulus (F.M.) |

|---|---|---|---|

| Natural fine aggregate | 2.55 | 1.07 | 2.79 |

| Natural coarse aggregate | 2.68 | 1.35 | 6.6 |

| Contents | ASR Expansion of Mortar | ASR Expansion of Concrete |

|---|---|---|

| W/B ratio | 0.47 | 0.45 |

| Mineral admixture (replacement ratio) | FA (20%), BFS (30%) | FA (20%), BFS (30%) |

| Particle size distribution (mm) | Below 4.75 | 4.75 to 19 |

| Specimen size (mm) | 25 × 25 × 285 | 76 × 76 × 285 |

| Moisture condition | Immersion in solution | 100% humidity |

| Temperature (°C) | 80 | 38 |

| Period for testing (days) | 1, 3, 7, 10, 14 | Until the expansion limit is reached |

| Alkali condition | 1 N NaOH solution | Alkali content of 1.25% are added to the mixing water |

| Criteria | ASTM C 1260 | ASTM C 1293 |

|---|---|---|

| Non-reactive | 0.0% to 0.1% | Below 0.04% |

| Inconclusive | 0.1% to 0.2% | |

| Potentially reactive | Above 0.2% | 0.04% |

| Content | Specification | Criteria | Test Results | |

|---|---|---|---|---|

| Physical properties | Density (g/cm3) | KS F 2527 | 3.1 and above | 3.65 |

| Unit volume weight (kg/L) | KS F 2527 | 1.6 and above | 2.2 | |

| Absorption rate (%) | KS F 2527 | Below 2.0 | 2.05 | |

| Chemical composition | CaO (%) | KS F 2527 | Below 40 | 24.4 |

| MgO (%) | KS F 2527 | Below 10 | 0.5 | |

| FeO (%) | KS F 2527 | Below 50 | 51.5 | |

| Basicity (CaO/SiO2) | KS F 2527 | Below 2.0 | 2.97 | |

| Specimen ID | Test Period (days) | Number of Cracks | Crack Width (mm) | Maximum Crack Length (mm) | Total Crack Length (mm) |

|---|---|---|---|---|---|

| OPC | 2 | 7 | 0.2 | 11.59 | 63.95 |

| 7 | 21 | 0.25 | 96.18 | 699.23 | |

| 14 | 37 | 0.4 | 173.06 | 1444.75 | |

| FA20 | 3 | 19 | 0.05 | 15.57 | 158.12 |

| 7 | 12 | 0.2 | 47.75 | 333.30 | |

| 14 | 17 | 0.3 | 160.35 | 1031.31 | |

| BFS30 | 5 | 14 | 0.05 | 21.98 | 131.39 |

| 7 | 10 | 0.15 | 71.19 | 399.13 | |

| 14 | 17 | 0.3 | 104.16 | 694.78 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, S.Y.; Yang, E.I. An Experimental Study on Alkali Silica Reaction of Concrete Specimen Using Steel Slag as Aggregate. Appl. Sci. 2020, 10, 6699. https://doi.org/10.3390/app10196699

Choi SY, Yang EI. An Experimental Study on Alkali Silica Reaction of Concrete Specimen Using Steel Slag as Aggregate. Applied Sciences. 2020; 10(19):6699. https://doi.org/10.3390/app10196699

Chicago/Turabian StyleChoi, So Yeong, and Eun Ik Yang. 2020. "An Experimental Study on Alkali Silica Reaction of Concrete Specimen Using Steel Slag as Aggregate" Applied Sciences 10, no. 19: 6699. https://doi.org/10.3390/app10196699

APA StyleChoi, S. Y., & Yang, E. I. (2020). An Experimental Study on Alkali Silica Reaction of Concrete Specimen Using Steel Slag as Aggregate. Applied Sciences, 10(19), 6699. https://doi.org/10.3390/app10196699