Accurate Bearing Fault Diagnosis under Variable Shaft Speed using Convolutional Neural Networks and Vibration Spectrogram

Abstract

1. Introduction

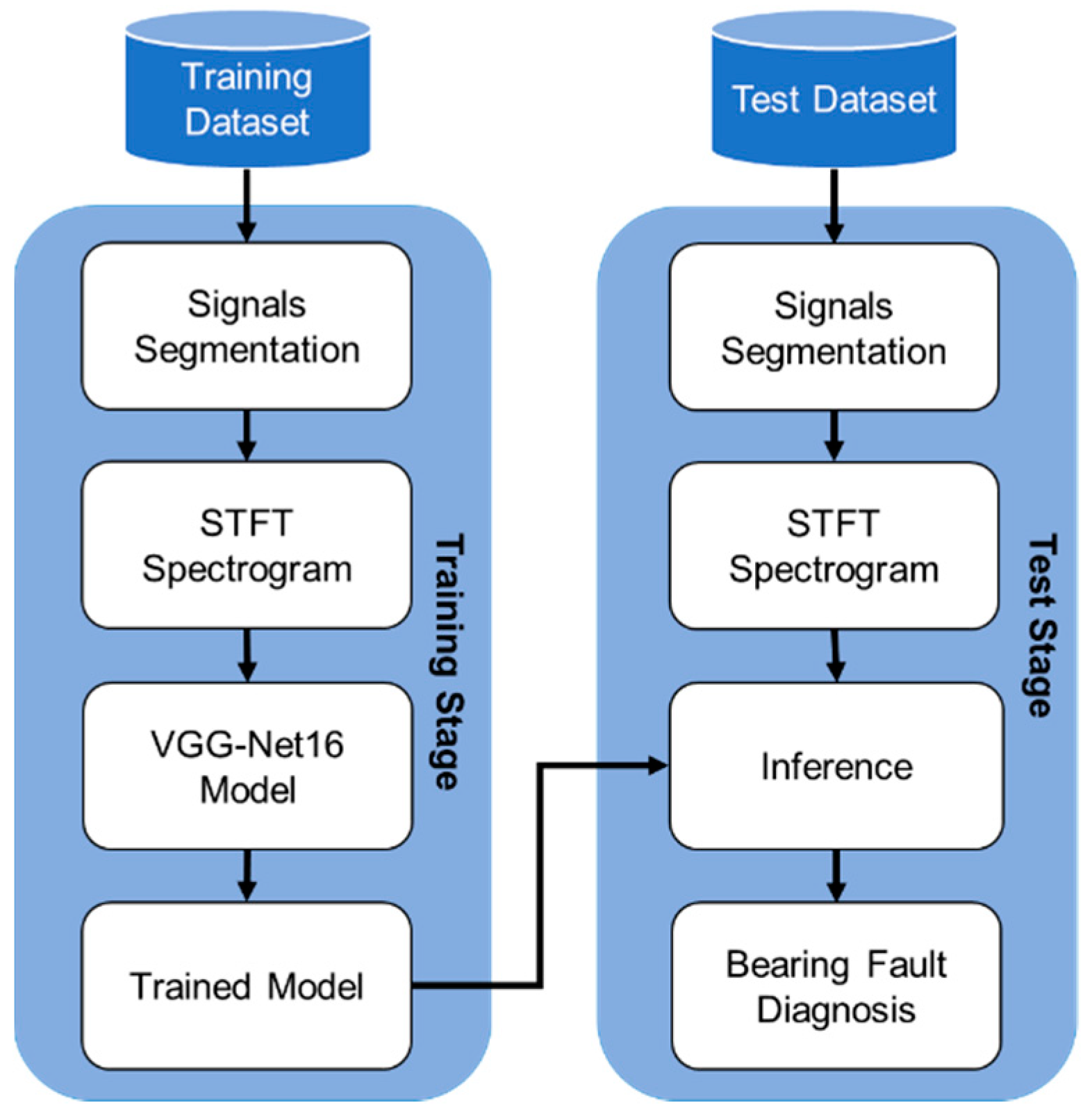

2. Proposed Bearing Fault Diagnosis Method

2.1. Signal Preprocessing

2.1.1. Short-Time Fourier Transform

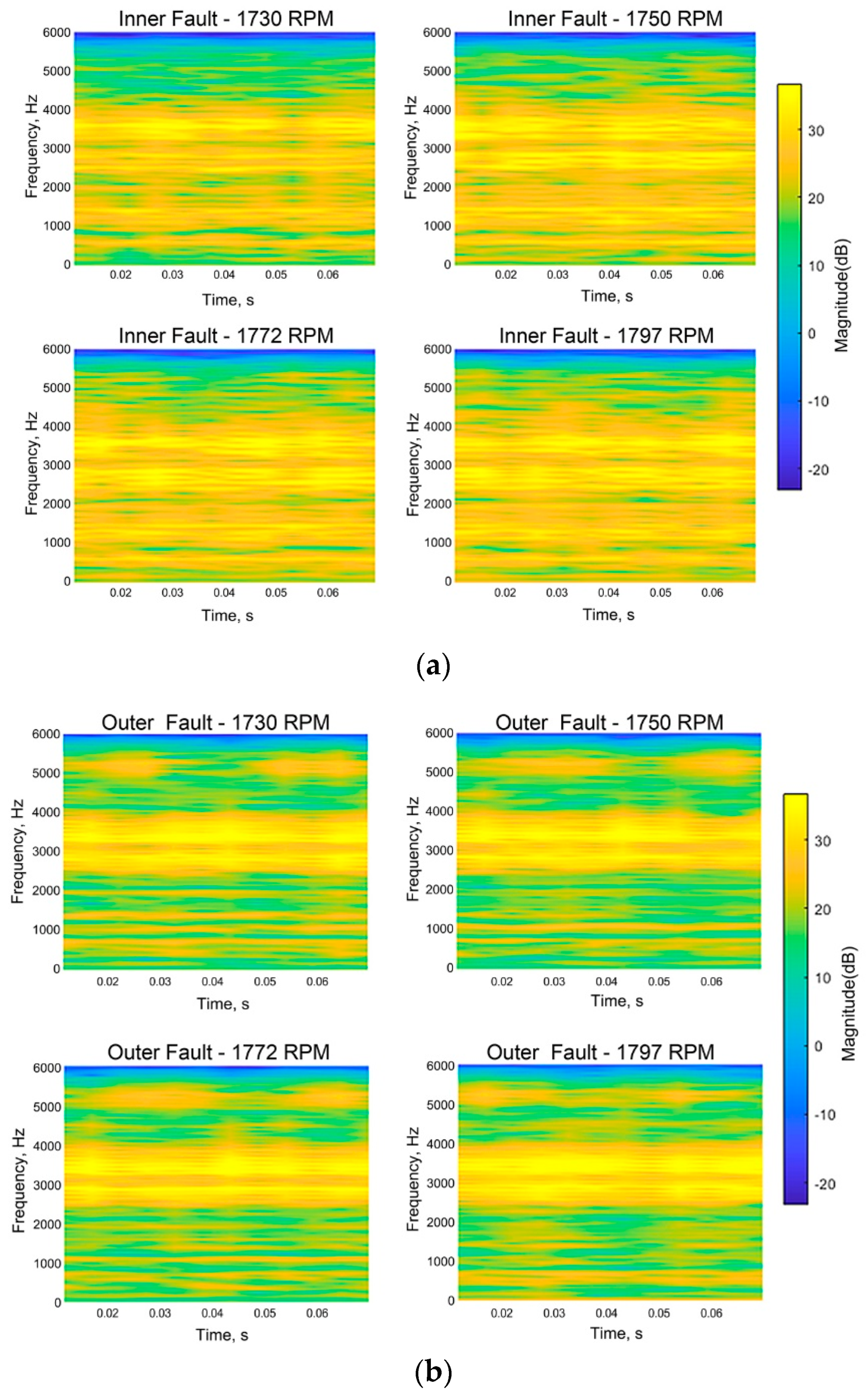

2.1.2. Implementing STFT Analysis for Spectrograms

2.2. CNN-VGG16 Model for Bearing Fault Classification

3. Experimental Implementation

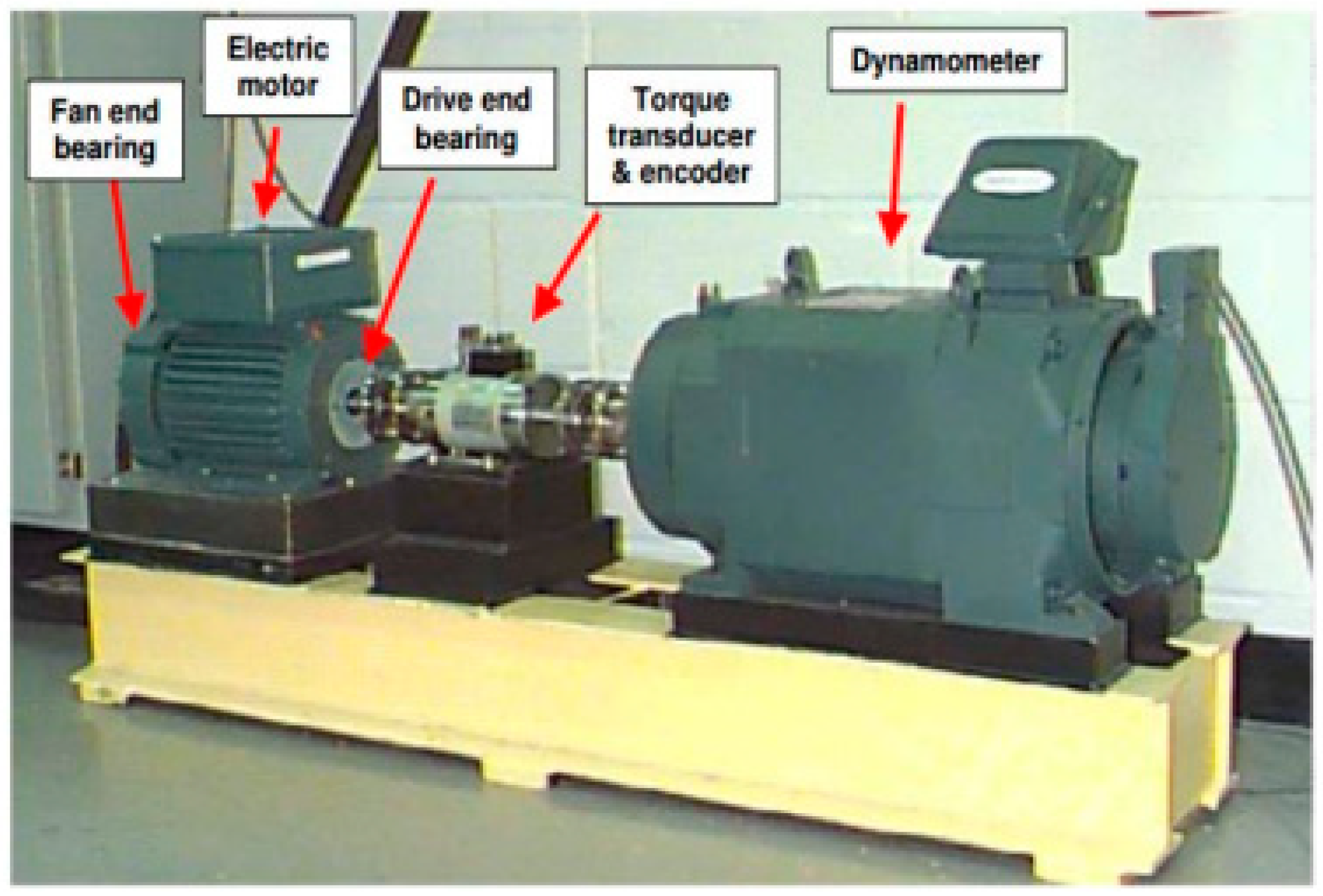

3.1. Single Faults Dataset

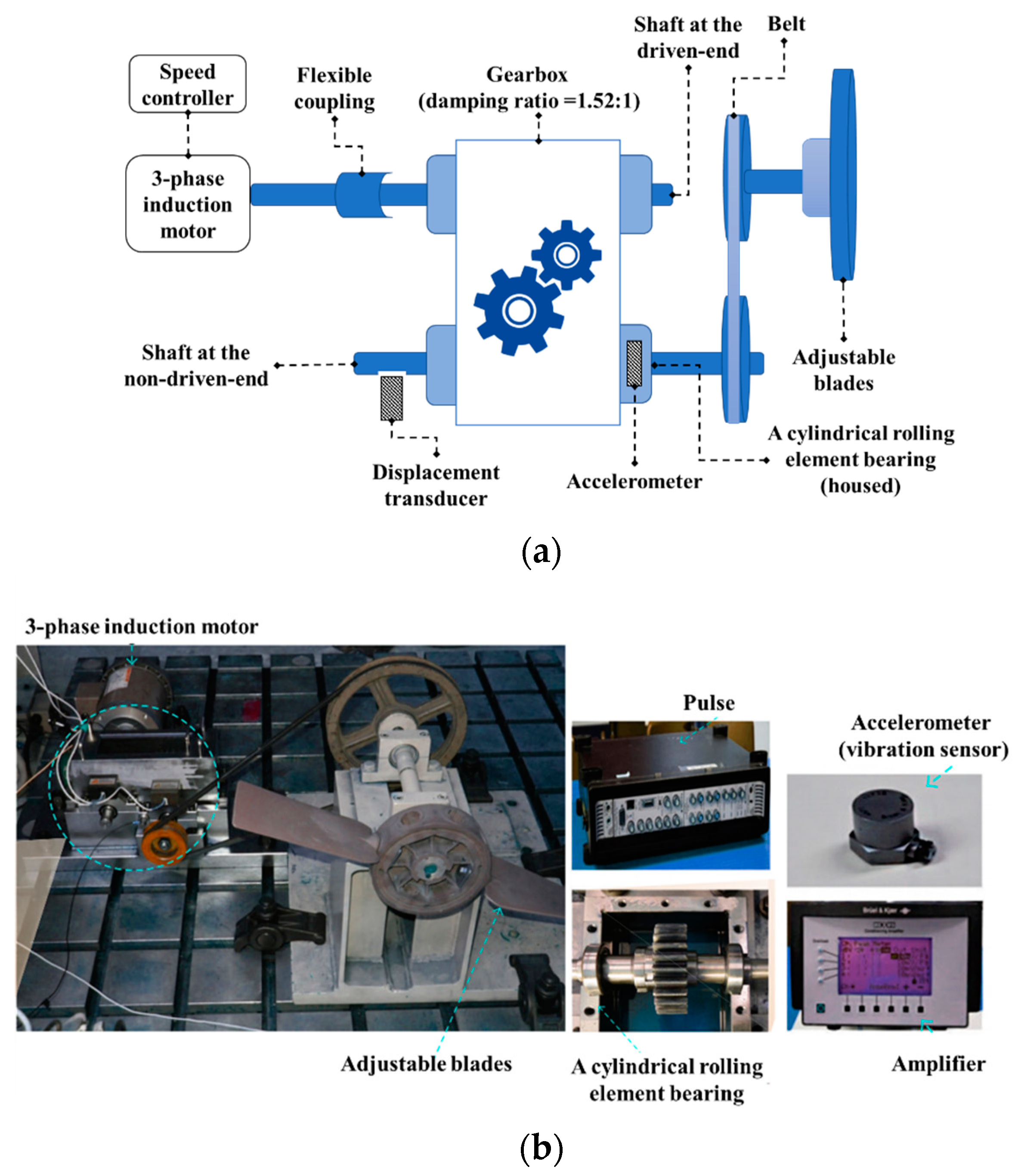

3.2. Compound Faults Dataset

4. Experimental Results

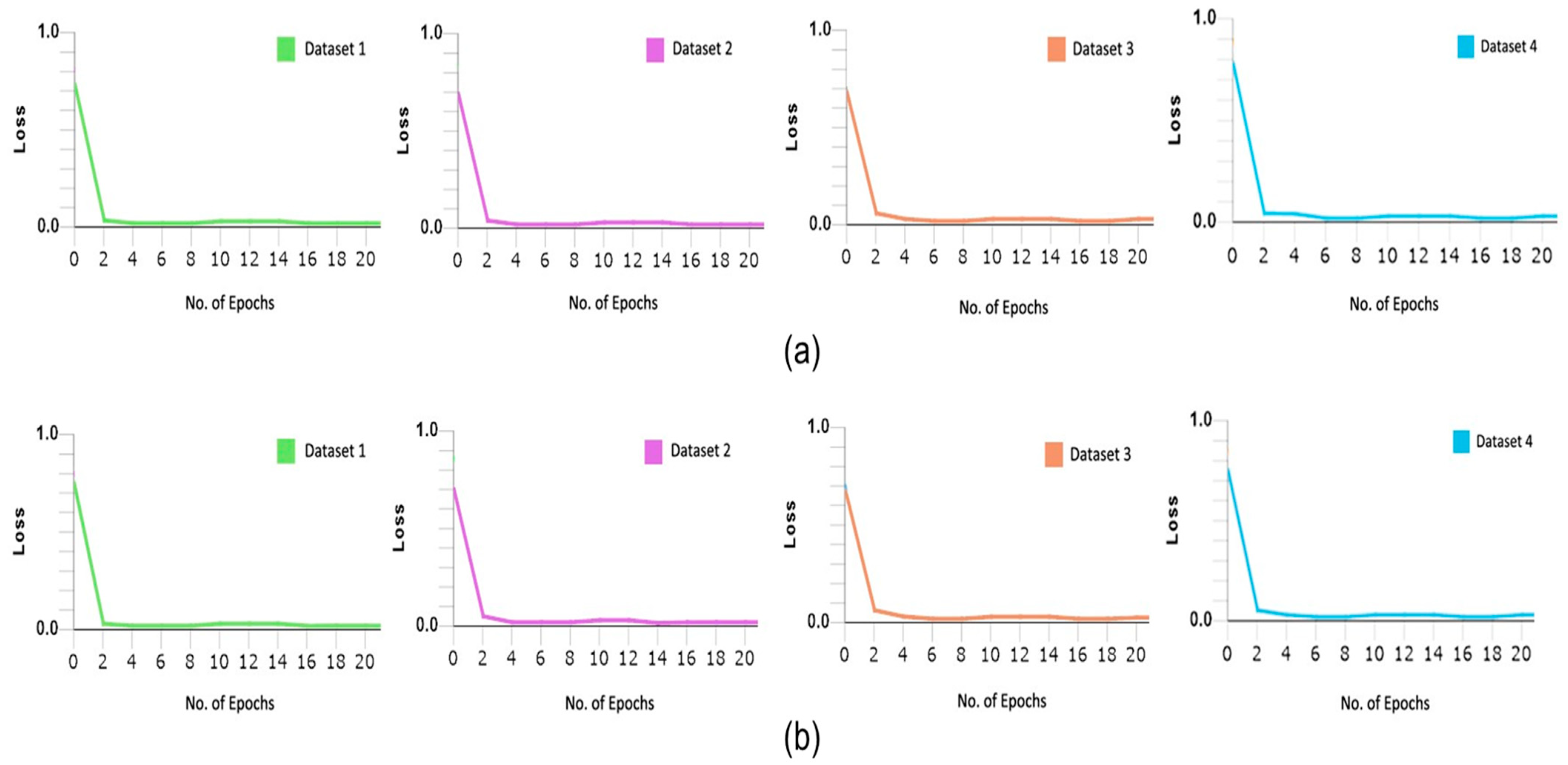

4.1. Fault Diagnosis Accuracy for Single Bearing Faults

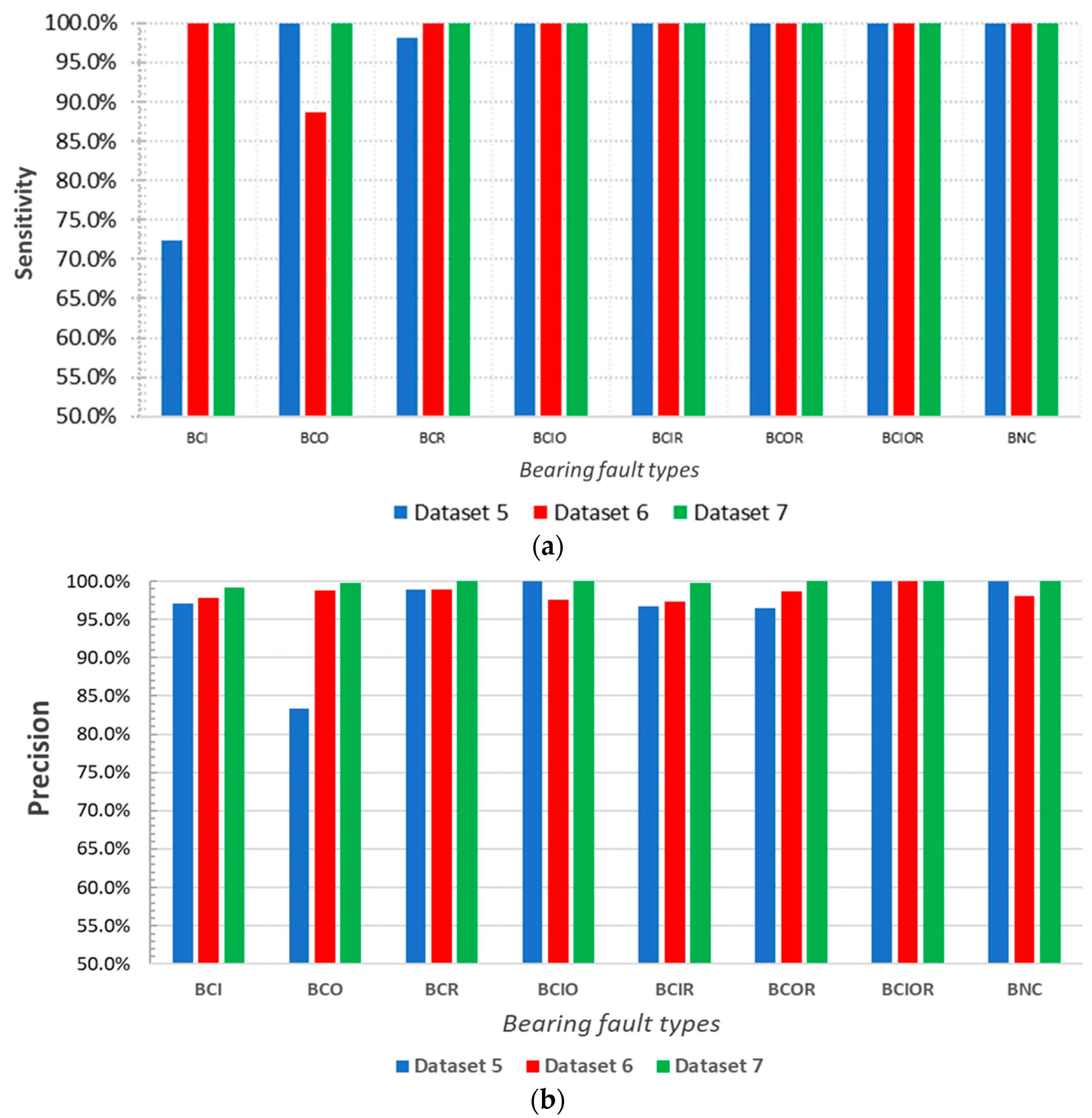

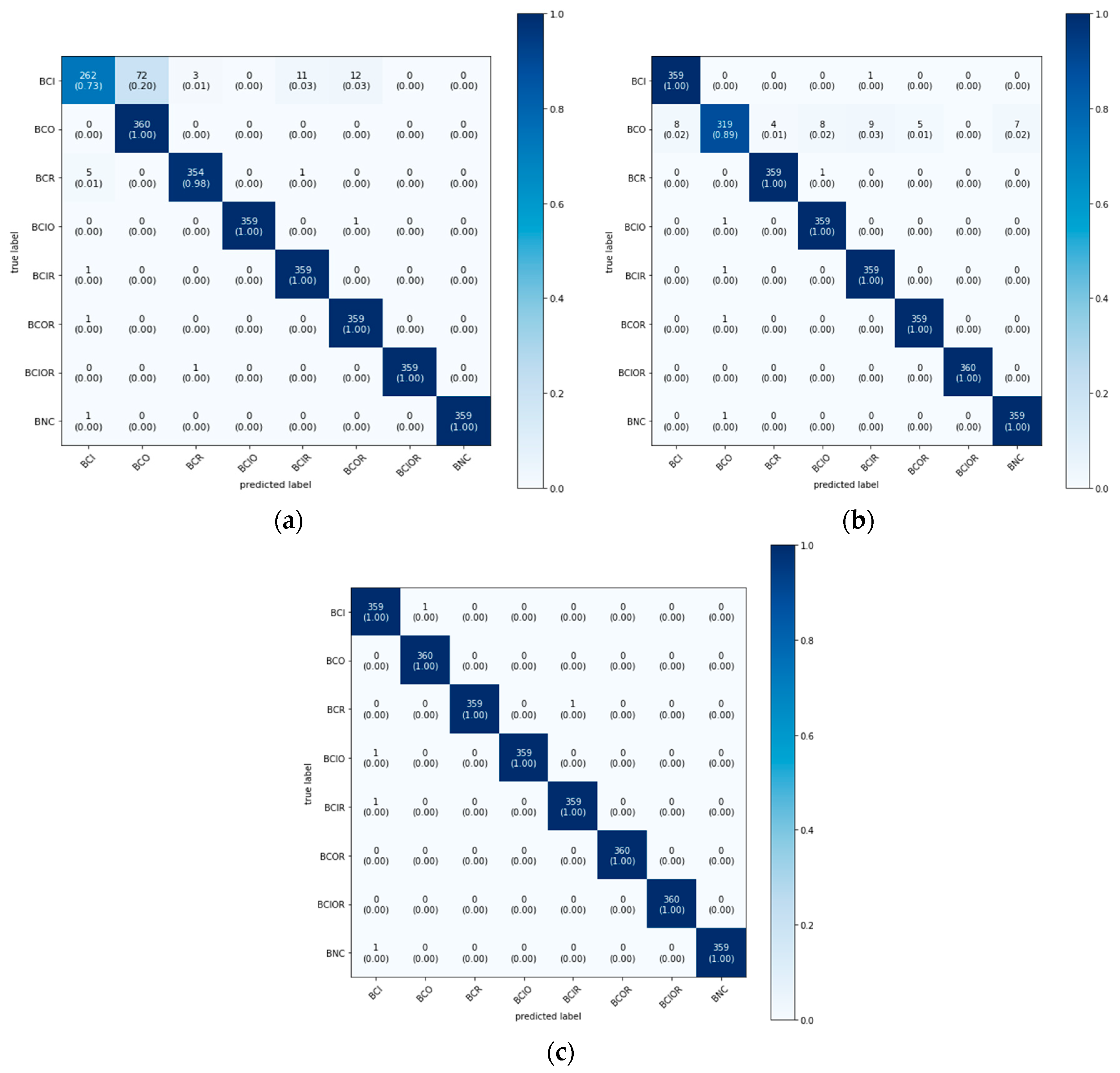

4.2. Fault Diagnosis Accuracy for Compound Bearing Faults

4.3. Bearing Fault Diagnosis Accuracy in Noise Environments

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Albrecht, P.F.; Appiarius, J.C.; McCoy, R.M.; Owen, E.L.; Sharma, D.K. Assessment of the Reliability of Motors in Utility Applications-Updated. IEEE Trans. Energy Convers. 1986, EC-1, 39–46. [Google Scholar] [CrossRef]

- McInerny, S.A.; Dai, Y. Basic vibration signal processing for bearing fault detection. IEEE Trans. Educ. 2003, 46, 149–156. [Google Scholar]

- Peng, Z.K.; Tse, P.W.; Chu, F.L. A comparison study of improved Hilbert-Huang transform and wavelet transform: Application to fault diagnosis for rolling bearing. Mech. Syst. Signal Process. 2005, 19, 974–988. [Google Scholar] [CrossRef]

- Saidi, L.; Ben Ali, J.; Fnaiech, F.; Morello, B. Bi-spectrum based-EMD applied to the non-stationary vibration signals for bearing faults diagnosis. ISA Trans. 2014, 53, 1650–1660. [Google Scholar] [CrossRef] [PubMed]

- Tyagi, S. A DWT and SVM based method for rolling element bearing fault diagnosis and its comparison with Artificial Neural Networks. J. Appl. Comput. Mech. 2017, 3, 80–91. [Google Scholar]

- Bhadane, M.; Ramachandran, K.I. Bearing fault identification and classification with convolutional neural network. In Proceedings of the 2017 International Conference on Circuit, Kollam, India, 20–21 April 2017; pp. 1–5. [Google Scholar]

- Hoang, D.T.; Kang, H.J. Rolling element bearing fault diagnosis using convolutional neural network and vibration image. Cogn. Syst. Res. 2019, 53, 42–50. [Google Scholar]

- Sohaib, M.; Kim, J.M. Fault Diagnosis of Rotary Machine Bearings under Inconsistent Working Conditions. IEEE Trans. Instrum. Meas. 2020, 69, 3334–3347. [Google Scholar] [CrossRef]

- Yuan, Z.; Zhang, L.; Duan, L.; Li, T. Intelligent Fault Diagnosis of Rolling Element Bearings Based on HHT and CNN. In Proceedings of the 2018 Prognostics and System Health Management, Chong Qing, China, 26–28 October 2018; pp. 292–296. [Google Scholar]

- Verstraete, D.; Ferrada, A.; Droguett, E.L.; Meruane, V.; Modarres, M. Deep learning enabled fault diagnosis using time-frequency image analysis of rolling element bearings. Shock Vib. 2017, 2017. [Google Scholar] [CrossRef]

- Benesty, J.; Sondhi, M.M.; Huang, Y. Springer Handbook of Speech Processing, 1; Springer: Berlin, Germany, 2008. [Google Scholar]

- Zhivomirov, H. On the development of STFT-analysis and ISTFT-synthesis routines and their practical implementation. TEM J. 2019, 8, 56–64. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning; MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Tra, V.; Kim, J.; Kim, J.-M. Fault Diagnosis of Bearings with Variable Rotational Speeds Using Convolutional Neural Networks. In Advances in Computer Communication and Computational Sciences; Bhatia, S.K., Tiwari, S., Mishra, K.K., Trivedi, M.C., Eds.; Springer: Singapore, 2019; Volume 759, pp. 71–81. [Google Scholar]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Ha, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. ImageNet classification with deep convolutional neural networks. Commun. ACM 2017, 60, 84–90. [Google Scholar] [CrossRef]

- B. D. C. Case Western Reserve University. Seeded Fault Test Data. Available online: http://csegroups.case.edu/bearingdatacenter/home/ (accessed on 1 May 2020).

| Training Sample Speed (RPM) | Test Sample Speed (RPM) | |

|---|---|---|

| Dataset 1 | 1796 | (1772, 1748, 1722) |

| Dataset 2 | 1772 | (1796, 1748, 1722) |

| Dataset 3 | 1748 | (1772, 1796, 1722) |

| Dataset 4 | 1722 | (1772, 1748, 1796) |

| NEXUS conditioning amplifier (type 2692-C) | (1) Frequency range: 0.1 Hz–100 kHz (2) Sensitivity: 10 mV/ms−2 |

| Piezoelectric charge accelerometer (type 4371) | (1) Frequency range: 0.1 Hz–12.6 kHz (2) Sensitivity: 9.8pC/g |

| Portable data acquisition device (PULSE type 3560-C) | Maximum sampling frequency: 25.6 kHz |

| Rotational Speed (RPM) | Crack Size | ||||

|---|---|---|---|---|---|

| Length (mm) | Width (mm) | Depth (mm) | |||

| Dataset 5 | Training dataset | 300, 400, 500 | 3 | 0.60 | 0.30 |

| Test dataset | 250, 350, 450 | ||||

| Dataset 6 | Training dataset | 300, 400, 500 | 6 | 0.60 | 0.50 |

| Test dataset | 250, 350, 450 | ||||

| Dataset 7 | Training dataset | 300, 400, 500 | 12 | 0.60 | 0.50 |

| Test dataset | 250, 350, 450 | ||||

| Fault Diagnosis Method | Diagnosis Accuracy (Sensitivity, %) | Average Accuracy (%) | ||||

|---|---|---|---|---|---|---|

| Inner | Outer | Roller | Normal | |||

| Dataset 1 | [8] | 81.5 | 81.4 | 79.2 | 82.9 | 81.2 |

| Proposed method | 98.1 | 99.1 | 98.2 | 100.0 | 98.8 | |

| Dataset 2 | [8] | 83.9 | 79.1 | 78.6 | 83.9 | 81.4 |

| Proposed method | 97.6 | 100.0 | 100.0 | 100.0 | 99.4 | |

| Dataset 3 | [8] | 80.1 | 78.2 | 80.9 | 82.5 | 80.4 |

| Proposed method | 96.3 | 99.6 | 100.0 | 99.6 | 98.9 | |

| Dataset 4 | [8] | 78.4 | 77.7 | 77.3 | 80.8 | 78.6 |

| Proposed method | 98.1 | 100.0 | 100.0 | 99.2 | 99.3 | |

| Algorithm | Computational Cost |

|---|---|

| STFT | 218,000 (MAC) |

| VGG16 | 15.52 (GMAC) |

| SNR (dB) | Diagnosis Accuracy in Noisy Environments (%) | Average Accuracy (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| BCI | BCO | BCR | BCIO | BCIR | BCOR | BCIOR | BNC | |||

| Dataset 5 | 10 | 73.9 | 100.0 | 100.0 | 97.8 | 63.0 | 100. | 100.00 | 95.7 | 91.3 |

| 5 | 72.7 | 100.0 | 100.0 | 75.6 | 62.8 | 100.0 | 100.0 | 97.6 | 88.6 | |

| 0 | 73.9 | 97.8 | 95.6 | 73.9 | 52.2 | 100.0 | 100.0 | 89.1 | 85.3 | |

| Dataset 6 | 10 | 100.0 | 73.9 | 100 | 73.9 | 100.0 | 97.8 | 100.0 | 100 | 96.5 |

| 5 | 100.0 | 78.3 | 100.0 | 97.8 | 100.0 | 95.7 | 100.0 | 97.8 | 96.2 | |

| 0 | 100.0 | 73.9 | 95.7 | 100.0 | 100.0 | 100.0 | 100.0 | 97.8 | 95.9 | |

| Dataset 7 | 10 | 97.7 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 100.0 | 99.7 |

| 5 | 97.6 | 100.0 | 100.0 | 100.0 | 97.7 | 100.0 | 100.0 | 97.7 | 99.1 | |

| 0 | 97.6 | 100.0 | 100.0 | 100.0 | 97.6 | 100.0 | 100.0 | 93.2 | 98.6 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pham, M.T.; Kim, J.-M.; Kim, C.H. Accurate Bearing Fault Diagnosis under Variable Shaft Speed using Convolutional Neural Networks and Vibration Spectrogram. Appl. Sci. 2020, 10, 6385. https://doi.org/10.3390/app10186385

Pham MT, Kim J-M, Kim CH. Accurate Bearing Fault Diagnosis under Variable Shaft Speed using Convolutional Neural Networks and Vibration Spectrogram. Applied Sciences. 2020; 10(18):6385. https://doi.org/10.3390/app10186385

Chicago/Turabian StylePham, Minh Tuan, Jong-Myon Kim, and Cheol Hong Kim. 2020. "Accurate Bearing Fault Diagnosis under Variable Shaft Speed using Convolutional Neural Networks and Vibration Spectrogram" Applied Sciences 10, no. 18: 6385. https://doi.org/10.3390/app10186385

APA StylePham, M. T., Kim, J.-M., & Kim, C. H. (2020). Accurate Bearing Fault Diagnosis under Variable Shaft Speed using Convolutional Neural Networks and Vibration Spectrogram. Applied Sciences, 10(18), 6385. https://doi.org/10.3390/app10186385