Agro-Pellets from Oil Palm Residues/Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Biomass Sources and Sampling

2.2. Agro-Pellets Production

2.3. Biomass Mixtures and Agro-Pellets Characterization

2.4. Statistical Analysis

3. Results

3.1. Chemical Characteristics, Proximate Analysis, and Bulk Density of Biomass Mixtures

3.2. Proximate Analysis, Physical, Mechanical, and Energy Characteristics of Agro-Pellets

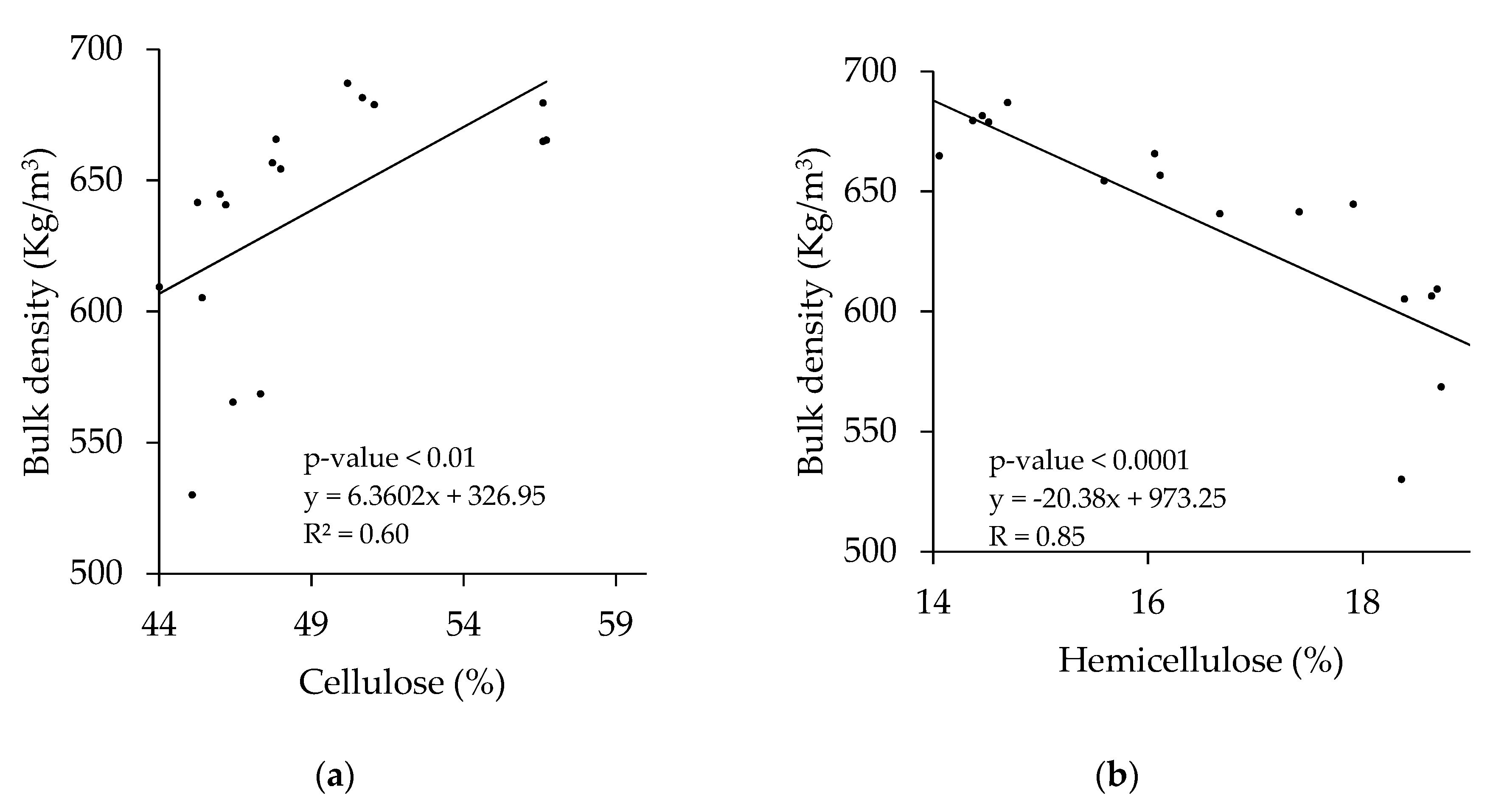

3.3. Relationship of Agro-Pellet Properties with Chemical Characteristics of Oil Palm Residues:Pine Sawdust Mixtures

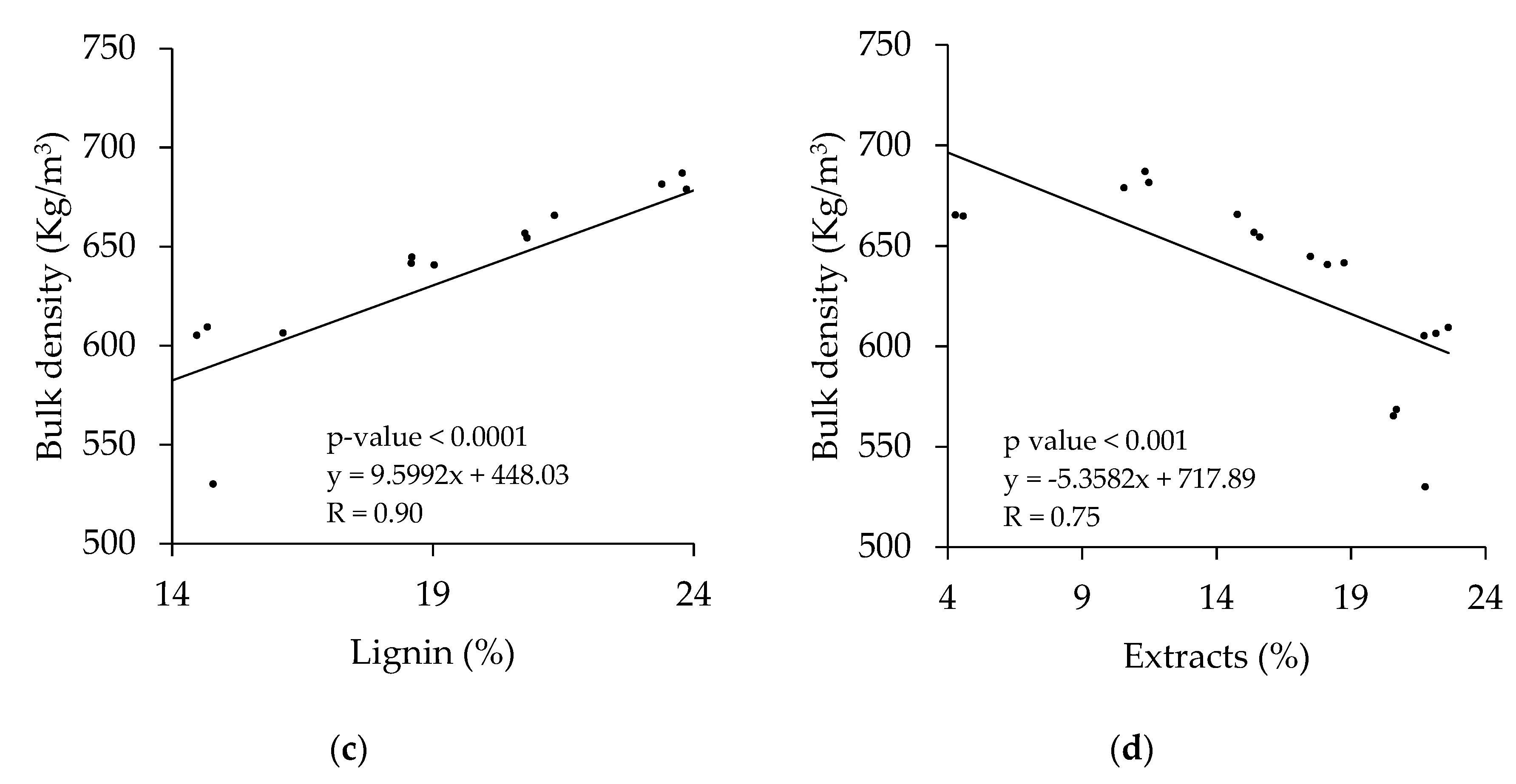

3.4. Relationship of Agro-Pellets Energy with Mixtures and Proximate Elements

4. Discussion

4.1. Agro-Pellets Characterization

4.2. Relationships of Agro-Pellets Characteristics and Raw Material Properties

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Malico, I.; Carrajola, J.; Gomes, C.P.; Lima, J. Biomass residues for energy production and habitat preservation. Case study in a montado area in Southwestern Europe. J. Clean. Prod. 2016, 112, 3676–3683. [Google Scholar] [CrossRef]

- Rios, M.; Kaltschmitt, M. Bioenergy potential in Mexico—Status and perspectives on a high spatial distribution. Biomass Convers. Biorefin. 2013, 3, 239–254. [Google Scholar] [CrossRef]

- Mani, S.; Sokhansanj, S.; Bi, X.; Turhollow, A. Economics of producing fuel pellets from biomass. Appl. Eng. Agric. 2006, 22, 421–426. [Google Scholar] [CrossRef]

- Zheng, A.; Zhao, Z.; Chang, S.; Huang, Z.; Wang, X.; He, F.; Li, H. Effect of torrefaction on structure and fast pyrolysis behavior of corncobs. Bioresour. Technol. 2013, 128, 370–377. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. A study of bonding and failure mechanisms in fuel pellets from different biomass resources. Biomass Bioenergy 2011, 35, 910–918. [Google Scholar] [CrossRef]

- Nielsen, N.P.K.; Gardner, D.J.; Poulsen, T.; Felby, C. Importance of temperature, moisture content, and species for the conversion process of wood residues into fuel pellets. Wood Fiber Sci. 2009, 41, 414–425. [Google Scholar]

- Kiss, I.; Alexa, V.; Sárosi, J. About the wood sawdust-one of the most important renewable energy sources. Ann. Fac. Eng. Hunedoara 2016, 14, 215. [Google Scholar]

- Owoyemi, J.M.; Zakariya, H.O.; Elegbede, I. Sustainable wood waste management in Nigeria. Environ. Socio Econ. Stud. 2016, 4, 1–9. [Google Scholar] [CrossRef]

- Cocchi, M.; Nikolaisen, L.; Junginger, M.; Goh, C.S.; Heinimö, J.; Bradley, D.; Thrän, D. Global wood pellet industry market and trade study. In IEA Bioenergy Task; IEA Bioenergy: Dutch, The Netherlands, 2011; Volume 40, p. 190. [Google Scholar]

- Šafran, B.; Jug, M.; Radmanović, K.; Đukić, I.; Kramar, D.; Beljo-Lučić, R.; Risović, S. Analysis of the Raw Material Properties in the Agro-wood Pellets Production. In Proceedings of the 28th International Conference on Wood Science and Technology, Zagreb, Croatia, 7–8 December 2017. [Google Scholar]

- Pastre, O. Analysis of the Technical Obstacles Related to the Production and Utilisation of Fuel Pellets Made from Agricultural Residues. Available online: http://www.Pelletcentre.Info/Resources/1093.Pdf (accessed on 9 November 2019).

- Forero-Nuñez, C.A.; Jochum, J.; Sierra-Vargas, F.E. Characterization and feasibility of biomass fuel pellets made of Colombian timber, coconut and oil palm residues regarding European standards. Environ. Biotechnol. 2012, 8, 67–76. [Google Scholar]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Serrano, C.; Monedero, E.; Lapuerta, M.; Portero, H.; Villalba, M.E.M. Effect of moisture content, particle size and pine addition on quality parameters of barley straw pellets. Fuel Process. Technol. 2011, 92, 699–706. [Google Scholar] [CrossRef]

- Kuokkanen, M.J.; Vilppo, T.; Kuokkanen, T.; Stoor, T.; Niinimäki, J. Additives in wood pellet production—A pilot-scale study of binding agent usage. Bioresources 2011, 6, 4331–4355. [Google Scholar] [CrossRef]

- Atuesta-Boada, L.E.; Sierra-Vargas, F.E. Caracterización físico-química de pellets producidos a partir de mezclas 50/50 carbón bituminoso/madera residual. Inf. Técnico 2015, 79, 18–25. [Google Scholar] [CrossRef][Green Version]

- Vijay, V.; Pimm, S.L.; Jenkins, C.N.; Smith, S.J. The Impacts of Oil Palm on Recent Deforestation and Biodiversity Loss. PLoS ONE 2016, 11, e0159668. [Google Scholar] [CrossRef] [PubMed]

- Forero-Núñez, C.A.; Jochum, J.; Sierra-Vargas, F.E. Effect of particle size and addition of cocoa pod husk on the properties of sawdust and coal pellets. Ing. Investig. 2015, 35, 17–23. [Google Scholar] [CrossRef]

- Munawar, S.S.; Subiyanto, B. Characterization of Biomass Pellet Made from Solid Waste Oil Palm Industry. Procedia Environ. Sci. 2014, 20, 336–341. [Google Scholar] [CrossRef]

- Trangkaprasith, K.; Chavalparit, O. Heating value enhancement of fuel pellets from frond of oil palm. In International Conference on Biology, Environment and Chemistry; IACSIT Press: Singapore, 2011. [Google Scholar]

- Goering, H.K.; Van Soest, P.J. Forage Fiber Analysis. Apparatus, Reagents, Procedures and Some Applications; Agricultural Research Service, US Department of Agriculture: Washington, DC, USA, 1970; Volume 379, p. 20. [Google Scholar]

- UNE-EN-14774. Biocombustibles Sólidos. Determinación del Contenido de Humedad. Método de Secado en Estufa; Parte H; Asociación Española de Normalización y Certificación: Madrid, Spain, 2010. [Google Scholar]

- UNE-EN 15148. Biocombustibles Sólidos. Determinación del Contenido en Materias Volátiles; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2010. [Google Scholar]

- UNE-EN-14775. Biocombustibles Sólidos. Método Para la Determinación del Contenido en Cenizas; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2010. [Google Scholar]

- UNE-EN 14918. Determinación del Poder Calorífico; UNE-EN 14918:2011; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2011. [Google Scholar]

- UNE-ENISO 17828. Biocombustibles Sólidos Determinación de la Densidad a Granel; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2016. [Google Scholar]

- Acda, M.N.; Devera, E.E. Physico-chemical properties of wood pellets from forest residues. J. Trop. For. Sci. 2014, 26, 589–595. [Google Scholar]

- Richards, S. Physical testing of fuel briquettes. Fuel Process. Technol. 1990, 25, 89–100. [Google Scholar] [CrossRef]

- Steel, R.G.D.; Torrie, J.H. Principles and Procedures of Statistics. Biometrika 1961, 48, 234. [Google Scholar] [CrossRef]

- ISO 17225. Solid Biofuels—Fuel Specifications and Classes—Part 1: General Requirements; International Organization for Standardization: Geneva, Switzerland, 2014. [Google Scholar]

- Tenorio, C.; Moya, R.; Tomazello-Filho, M.; Valaert, J. Quality of Pellets Made from Agricultural and Forestry Crops in Costa Rican Tropical Climates. Bioresources 2014, 10, 482–498. [Google Scholar] [CrossRef]

- Onochie, U.P.; Obanor, A.I.; Aliu, S.A.; Igbodaro, O.O. Proximate and ultimate analysis of fuel pellets from oil palm residues. Niger. J. Technol. 2017, 36, 987–990. [Google Scholar]

- CEN/TS EN 14961-2. Solid Biofuels—Fuel Specification and Classes—Wood Pellets for Non-Industrial Use; Asociación Española de Normalización y Certificación (AENOR): Madrid, Spain, 2012. [Google Scholar]

- Correa-Méndez, F.; Carrillo-Parra, A.; Rutiaga-Quiñones, J.G.; Márquez-Montesino, F.; González-Rodríguez, H.; Jurado-Ybarra, E.; Garza-Ocañas, F. Moisture and Inorganic Substance Content in Pine Timber Products for Use in Pellets and Briquettes. Rev. Chapingo Ser. Cienc. For. Ambient. 2014, 20, 77–88. [Google Scholar] [CrossRef]

- Thek, G.; Obernberger, I. The Pellet Handbook: The Production and Thermal Utilization of Biomass Pellets; Routledge: London, UK, 2012. [Google Scholar]

- Tenorio, C. Characterisation of pellets made from oil palm residues in costa rica. J. Oil Palm Res. 2016, 28, 198–210. [Google Scholar] [CrossRef][Green Version]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. Effects of compressive force, particle size and moisture content on mechanical properties of biomass pellets from grasses. Biomass Bioenergy 2006, 30, 648–654. [Google Scholar] [CrossRef]

- Hosseinizand, H.; Sokhansanj, S.; Lim, C.J. Co-pelletization of microalgae Chlorella vulgaris and pine sawdust to produce solid fuels. Fuel Process. Technol. 2018, 177, 129–139. [Google Scholar] [CrossRef]

- Zvicevičius, E.; Raila, A.; Čiplienė, A.; Černiauskienė, Ž.; Kadziuliene, Z.; Tilvikienė, V. Effects of moisture and pressure on densification process of raw material from Artemisia dubia Wall. Renew. Energy 2018, 119, 185–192. [Google Scholar] [CrossRef]

- Riaza, J.; Khatami, R.; Levendis, Y.A.; Álvarez, L.; Gil, M.V.; Pevida, C.; Rubiera, F.; Pis, J.J.; Pevida, C. Combustion of single biomass particles in air and in oxy-fuel conditions. Biomass Bioenergy 2014, 64, 162–174. [Google Scholar] [CrossRef]

- Obernberger, I.; Thek, G. Physical characterisation and chemical composition of densified biomass fuels with regard to their combustion behaviour. Biomass Bioenergy 2004, 27, 653–669. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef]

- Van Dam, J.E.; VandenOever, M.; Teunissen, W.; Keijsers, E.; Peralta, A. Process for production of high density/high performance binderless boards from whole coconut huskPart 1: Lignin as intrinsic thermosetting binder resin. Ind. Crop. Prod. 2004, 19, 207–216. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent developments in biomass pelletization—A review. Bioresources 2012, 7, 4451–4490. [Google Scholar]

- Li, Y.; Liu, H. High-pressure densification of wood residues to form an upgraded fuel. Biomass Bioenergy 2000, 19, 177–186. [Google Scholar] [CrossRef]

- Sirrajudin, M.S.; Rasat, M.S.M.; Wahab, R.; Amini, M.H.M.; Mohamed, M.; Ahmad, M.I.; Moktar, J.; Ibrahim, M.A. Enhancing the energy properties of fuel pellets from oil palm fronds of agricultural residues by mixing with glycerin. ARPN J. Eng. Appl. Sci. 2016, 11, 6122–6127. [Google Scholar]

- Kataki, R.; Konwer, D. Fuelwood characteristics of indigenous tree species of north-east India. Biomass Bioenergy 2002, 22, 433–437. [Google Scholar] [CrossRef]

| Biomass Mixtures Characteristics | Oil Palm Residues:Pine Sawdust Mixtures | |||||

|---|---|---|---|---|---|---|

| 100:0 | 80:20 | 60:40 | 40:60 | 20:80 | 0:100 | |

| Structural compounds and extracts | ||||||

| Cellulose (%) | 46.28 (1.13) | 44.16 (1.18) | 45.82 (0.49) | 47.85 (0.14) | 50.64 (0.44) | 56.64 (0.06) |

| Hemicellulose (%) | 18.81 (0.49) | 18.58 (0.16) | 17.33 (0.63) | 15.92 (0.29) | 14.56 (0.12) | 14.14 (0.20) |

| Lignin (%) | 13.90 (0.80) | 15.09 (0.90) | 18.73 (0.25) | 20.97 (0.32) | 23.68 (0.25) | 25.02 (0.27) |

| Extracts (%) | 21.01 (0.65) | 22.17 (0.45) | 18.12 (0.63) | 15.26 (0.44) | 11.12 (0.50) | 4.20 (0.43) |

| Proximate analysis | ||||||

| Moisture content (%) | 7.58 (0.03) * | 9.84 (0.047) | 9.28 (0.11) | 8.88 (0.18) | 7.66 (0.32) | 10.14 (0.09) |

| Volatile material (%) | 83.95 (1.98) | 88.75 (1.70) | 87.01 (1.26) | 88.91 (1.99) | 91.86 (1.27) | 88.83 (1.64) |

| Ash (%) | 0.51 (0.57) | 0.38 (0.05) | 0.36 (0.33) | 0.35 (0.03) | 0.31 (0.03) | 0.36 (0.05) |

| Fixed carbon (%) | 15.54 (1.92) | 10.86 (1.72) | 12.63 (1.29) | 10.73 (1.97) | 7.83 (1.30) | 10.81 (1.66) |

| Physical properties | ||||||

| Bulk density (g/cm3) | 0.12 (0.01) | 0.15 (0.01) | 0.17 (0.01) | 0.20 (0.01) | 0.21 (0.01) | 0.20 (0.01) |

| Pellets Characteristics | Oil Palm Residues:Pine Sawdust Mixtures | |||||

|---|---|---|---|---|---|---|

| 100:0 | 80:20 | 60:40 | 40:00 | 20:80 | 0:100 | |

| Proximate analysis | ||||||

| Moisture content (%) | 6.45 (0.26) | 5.83 (0.17) | 6.77 (0.07) | 6.76 (0.89) | 5.84 (9.19) | 5.58 (0.42) |

| Material volatile (%) | 79.40 (1.90) | 80.04 (1.47) | 80.41 (1.02) | 87.32 (1.92) | 85.68 (1.63) | 89.31 (3.68) |

| Ash (%) | 0.54 (0.07) | 0.54 (0.05) | 0.58 (0.04) | 0.44 (0.11) | 0.53 (0.07) | 0.44 (0.08) |

| Fixed carbon (%) | 20.05 (1.83) | 19.42 (1.42) | 19.01 (0.98) | 12.23 (1.81) | 13.79 (1.57) | 10.25 (3.60) |

| Physical and mechanical properties | ||||||

| Bulk density (Kg m3) | 540 (170) | 610 (10) | 640 (10) | 660 (10) | 680 (10) | 670 (10) |

| Particle density (Kg m3) | 1180 (230) | 1240 (220) | 1190 (270) | 1250 (370) | 1090 (240) | 1340 (520) |

| Compression ratio | 4.74 | 4.13 | 3.74b | 3.29 | 3.28 | 3.29 |

| Impact resistance index | 158 (65.44) | 155 (78.89) | 144 (72.75) | 114 (28.65) | 126 (50.31) | 108 (27.02) |

| Energy properties | ||||||

| Gross calorific value (MJ/Kg) | 21.89 (0.16) | 22.31 (0.02) | 21.19 (0.47) | 20.75 (0.06) | 19.70 (0.13) | 18.84 (0.48) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrillo-Parra, A.; Contreras-Trejo, J.C.; Pompa-García, M.; Pulgarín-Gámiz, M.Á.; Rutiaga-Quiñones, J.G.; Pámanes-Carrasco, G.; Ngangyo-Heya, M. Agro-Pellets from Oil Palm Residues/Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure. Appl. Sci. 2020, 10, 6383. https://doi.org/10.3390/app10186383

Carrillo-Parra A, Contreras-Trejo JC, Pompa-García M, Pulgarín-Gámiz MÁ, Rutiaga-Quiñones JG, Pámanes-Carrasco G, Ngangyo-Heya M. Agro-Pellets from Oil Palm Residues/Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure. Applied Sciences. 2020; 10(18):6383. https://doi.org/10.3390/app10186383

Chicago/Turabian StyleCarrillo-Parra, Artemio, Juan Carlos Contreras-Trejo, Marín Pompa-García, Miguel Ángel Pulgarín-Gámiz, José Guadalupe Rutiaga-Quiñones, Gerardo Pámanes-Carrasco, and Maginot Ngangyo-Heya. 2020. "Agro-Pellets from Oil Palm Residues/Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure" Applied Sciences 10, no. 18: 6383. https://doi.org/10.3390/app10186383

APA StyleCarrillo-Parra, A., Contreras-Trejo, J. C., Pompa-García, M., Pulgarín-Gámiz, M. Á., Rutiaga-Quiñones, J. G., Pámanes-Carrasco, G., & Ngangyo-Heya, M. (2020). Agro-Pellets from Oil Palm Residues/Pine Sawdust Mixtures: Relationships of Their Physical, Mechanical and Energetic Properties, with the Raw Material Chemical Structure. Applied Sciences, 10(18), 6383. https://doi.org/10.3390/app10186383