Investigation of Microcrystalline Silicon Thin Film Fabricated by Magnetron Sputtering and Copper-Induced Crystallization for Photovoltaic Applications †

Abstract

1. Introduction

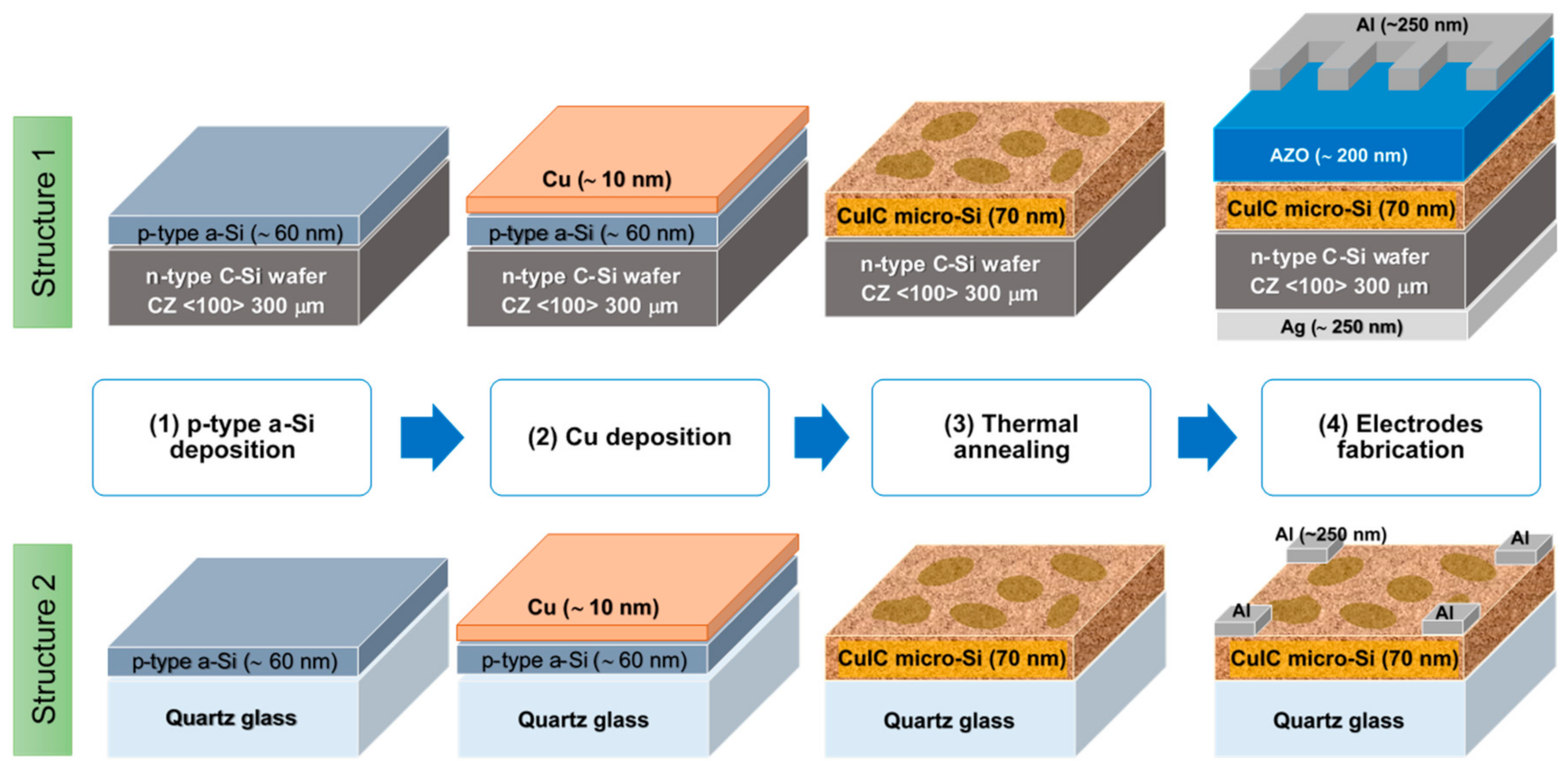

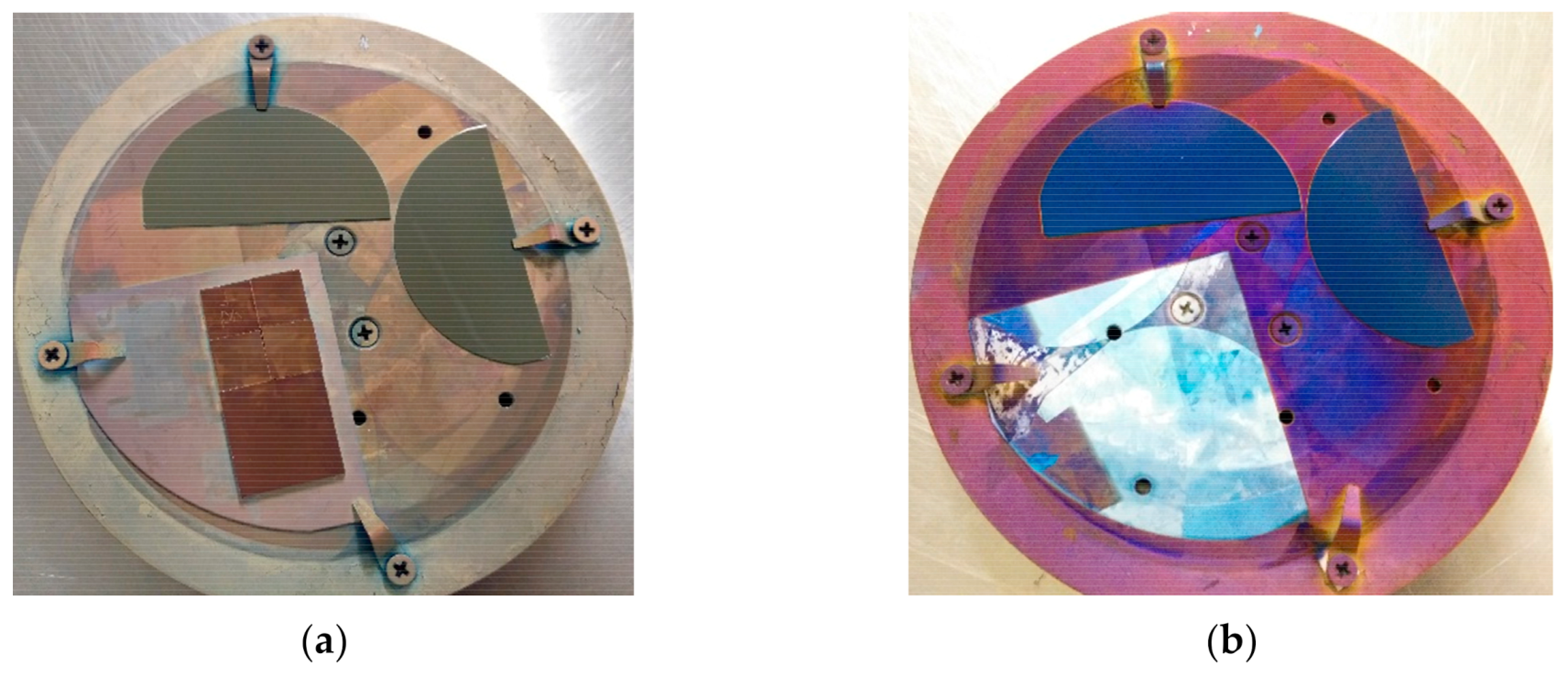

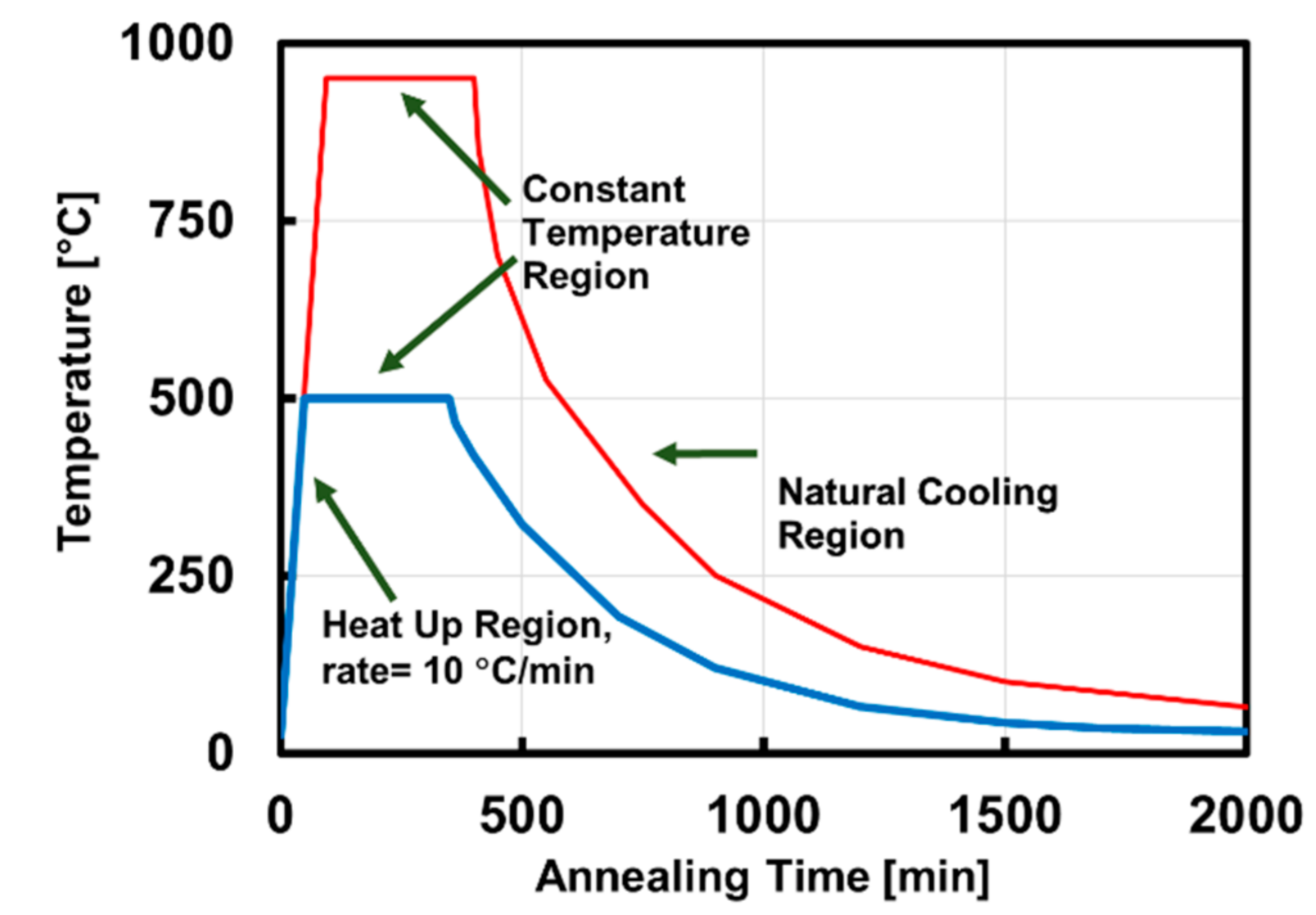

2. Micro-Si Thin Film Fabrication Process

3. Thin Film Characterizations

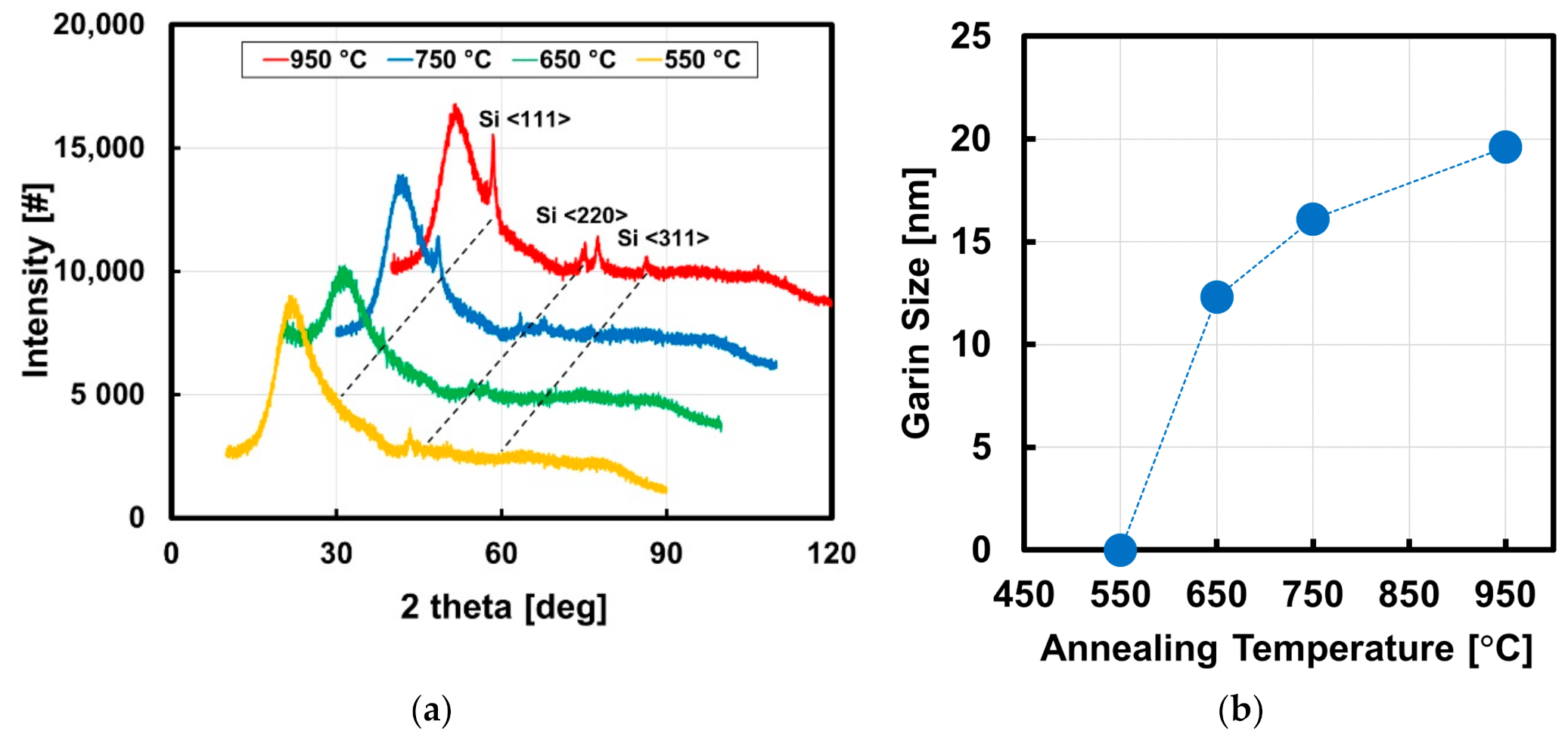

4. Results and Discussions

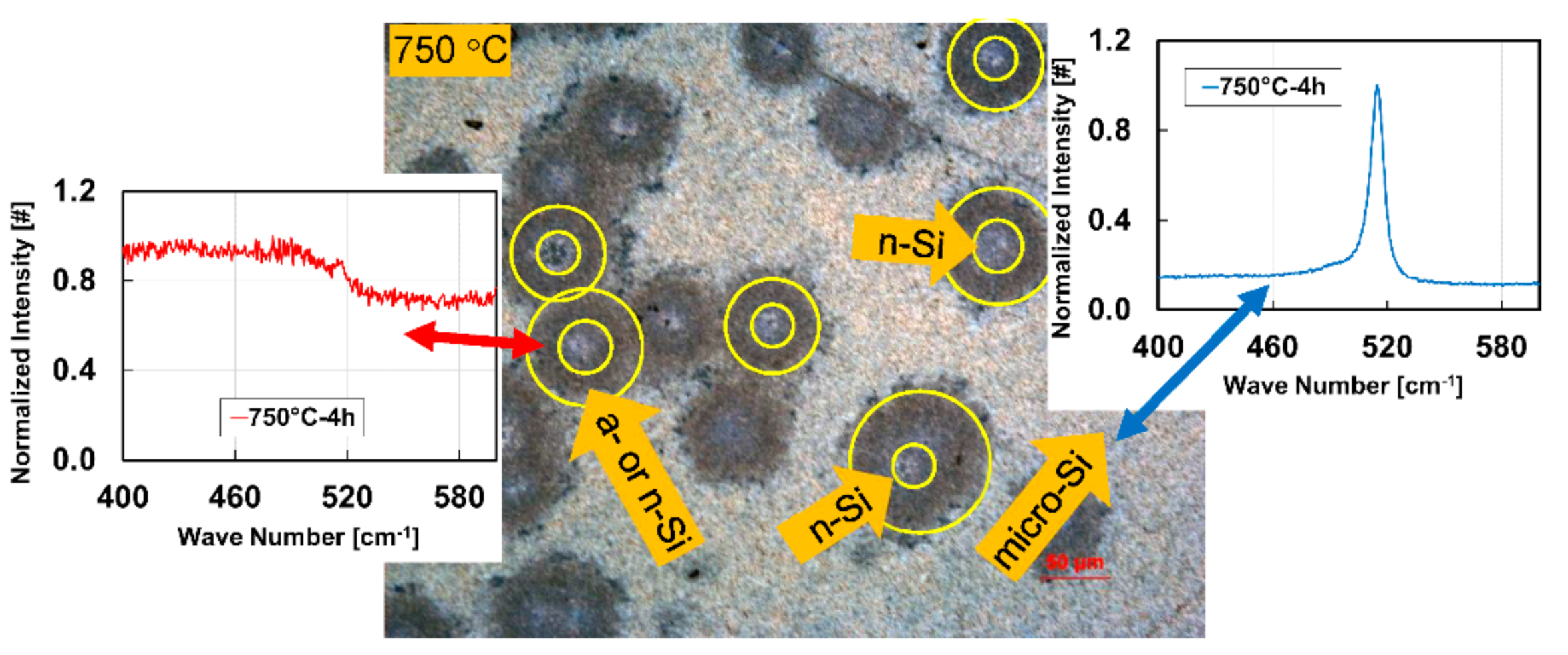

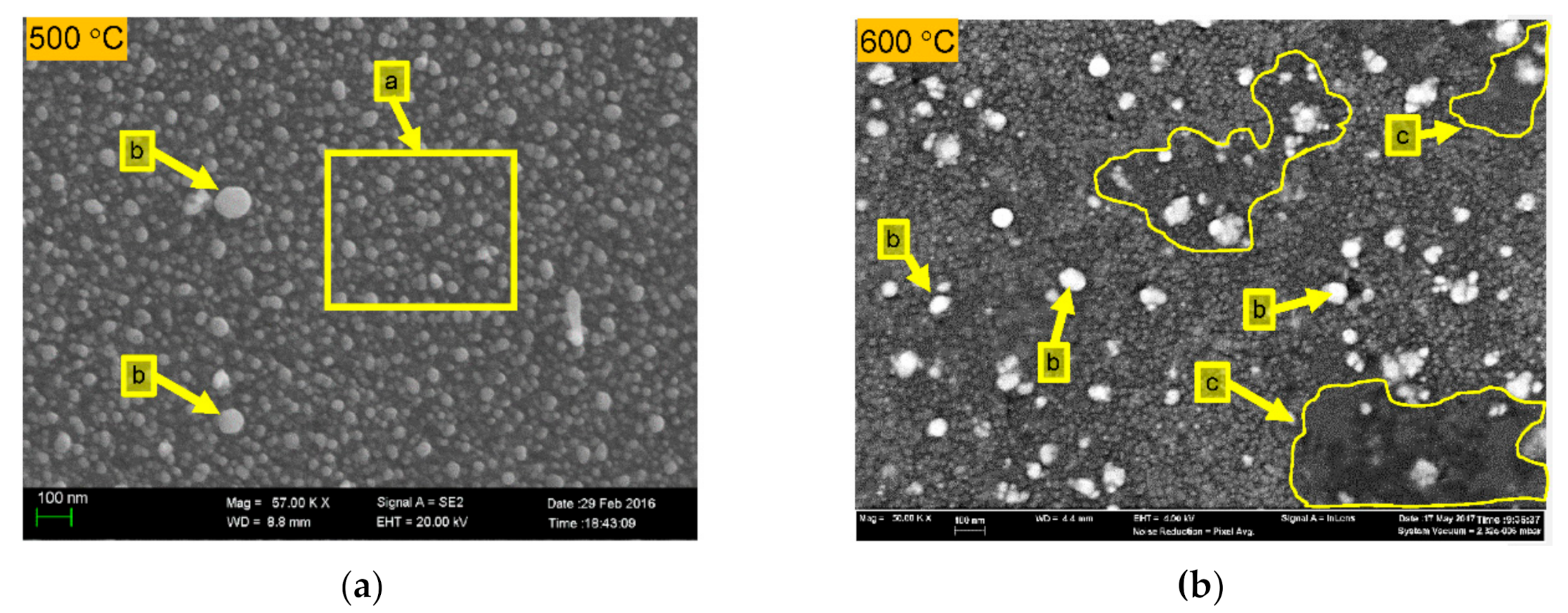

4.1. Material and Crystal Properties

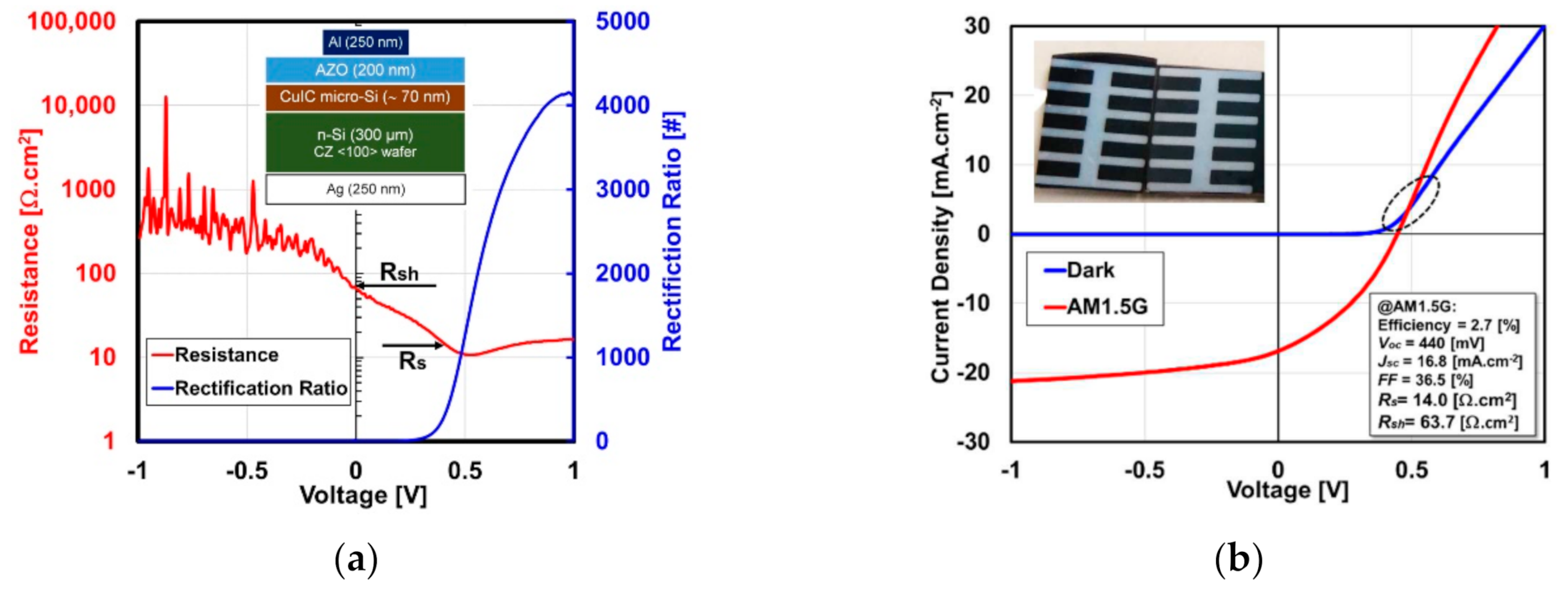

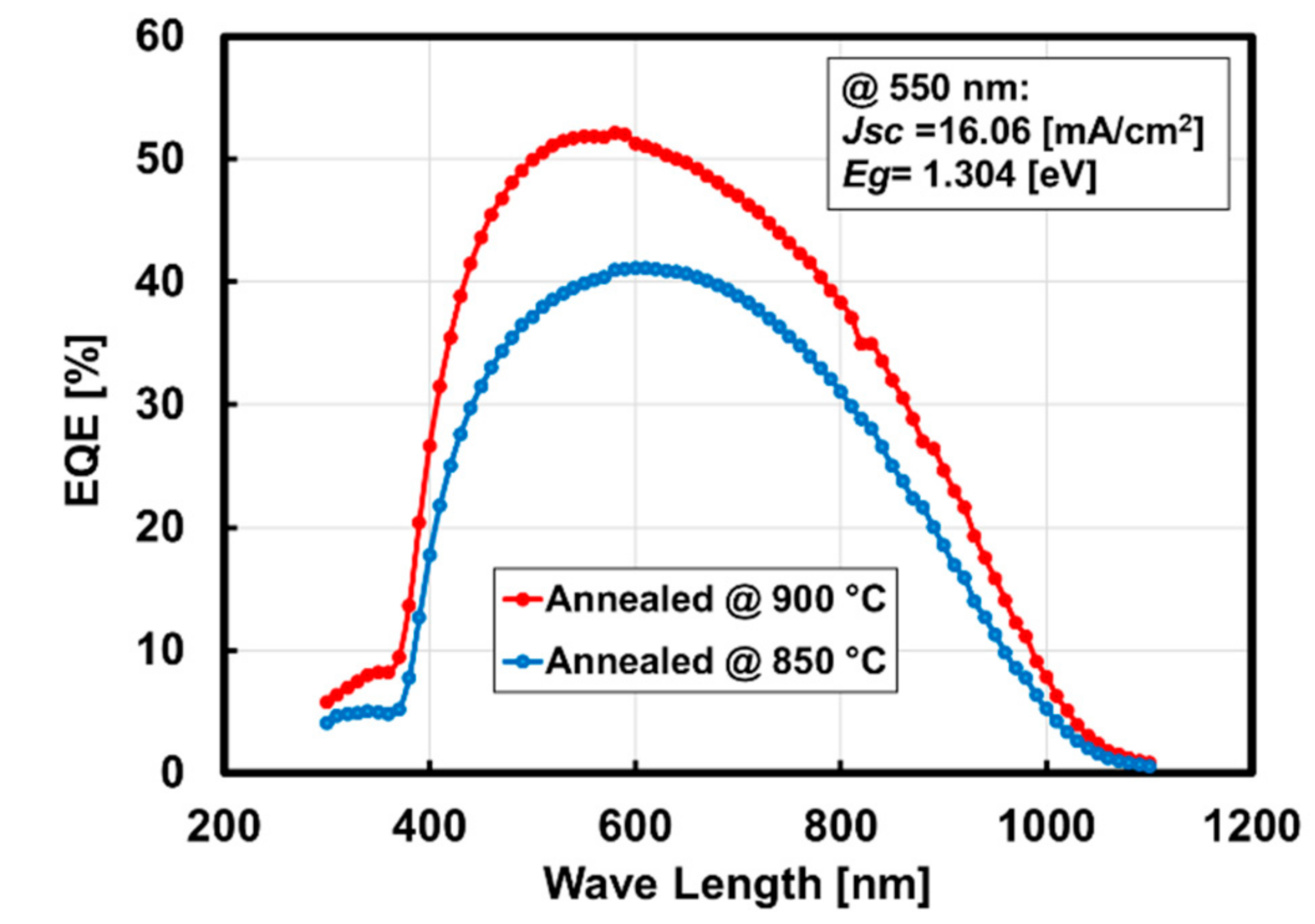

4.2. Electrical and Photovoltaic Properties

5. Principle and Mechanism of CuIC

6. Conclusions

- P-type, micro-Si, thin film preparation by MS and CuIC techniques, as a simple, low-cost, scalable and eco-friendly method for the fabrication of polycrystalline silicon.

- Demonstration of p+-n junction thin film solar cell fabrication in only three steps, with an emitter layer made by MS and CuIC without any chemical process.

- Measuring a photovoltaic conversion efficiency of η = 2.7%, an open circuit voltage of Voc = 440 mV and a short circuit current density of Jsc = 16.7 mA/cm2.

- Presenting a simple model for the CuIC principle, and illustrating the mechanism of micro-Si thin film growth during thermal annealing.

Author Contributions

Funding

Conflicts of Interest

References

- Gall, S.; Becker, C.; Conrad, E.; Dogan, P.; Fenske, F.; Gorka, B.; Lee, K.Y.; Rau, B.; Ruske, F.; Rech, B. Polycrystalline silicon thin-film solar cells on glass. Sol. Energy Mater. Sol. Cells 2009, 93, 1004–1008. [Google Scholar] [CrossRef]

- Gall, S.; Becker, C.; Lee, K.Y.; Sontheimer, T.; Rech, B. Growth of polycrystalline silicon on glass for thin-film solar cells. J. Cryst. Growth 2010, 312, 1277–1281. [Google Scholar] [CrossRef]

- Fortunato, G. Polycrystalline silicon thin-film transistors: A continuous evolving technology. Thin Solid Films 1997, 296, 82–90. [Google Scholar] [CrossRef]

- Her, Y.C.; Chen, J.H.; Tsai, M.H.; Tu, W.T. Nickel-induced crystallization of amorphous Ge film for blue-ray recording under thermal annealing and pulsed laser irradiation. J. Appl. Phys. 2009, 106, 023530. [Google Scholar] [CrossRef]

- Matsuda, A. Microcrystalline silicon. Growth and device application. J. Non-Cryst. Solids 2004, 338, 1–12. [Google Scholar] [CrossRef]

- Lucovsky, G.; Wang, C.; Nemanich, R.J.; Williams, M.J. Deposition of μc-Si and μc-SiC thin films by remote plasma-enhanced chemical-vapor deposition. Sol. Cells 1991, 30, 419–434. [Google Scholar] [CrossRef]

- Meier, J.; Flückiger, R.; Keppner, H.; Shah, A. Complete microcrystalline p-i-n solar cell—Crystalline or amorphous cell behavior. Appl. Phys. Lett. 1994, 65, 860–862. [Google Scholar] [CrossRef]

- Aberle, A.G. Thin-film solar cells. Thin Solid Films 2009, 517, 4706–4710. [Google Scholar] [CrossRef]

- Ishibashi, K. Development of the Cat-CVD apparatus and its feasibility for mass production. Thin Solid Films 2001, 395, 55–60. [Google Scholar] [CrossRef]

- Schropp, R.E.I. Present status of micro- and polycrystalline silicon solar cells made by hot-wire chemical vapor deposition. Thin Solid Films 2004, 451, 455–465. [Google Scholar] [CrossRef][Green Version]

- Becker, C.; Amkreutz, D.; Sontheimer, T.; Preidel, V.; Lockau, D.; Haschke, J.; Jogschies, L.; Klimm, C.; Merkel, J.J.; Plocica, P.; et al. Polycrystalline silicon thin-film solar cells: Status and perspectives. Sol. Energy Mater. Sol. Cells 2013, 119, 112–123. [Google Scholar] [CrossRef]

- Safi, I. Recent aspects concerning DC reactive magnetron sputtering of thin films: A review. Surf. Coatings Technol. 2000, 127, 203–218. [Google Scholar] [CrossRef]

- Tan, X.Q.; Liu, J.Y.; Niu, J.R.; Liu, J.Y.; Tian, J.Y. Recent progress in magnetron sputtering technology used on fabrics. Materials 2018, 11, 1953. [Google Scholar] [CrossRef] [PubMed]

- Delachat, F.; Antoni, F.; Prathap, P.; Slaoui, A.; Cayron, C.; Ducros, C. Thin film pc-Si by aluminium induced crystallization on metallic substrate. EPJ Photovolt. 2013, 4, 45102. [Google Scholar] [CrossRef]

- van Gestel, D.; Gordon, I.; Poortmans, J. Aluminum-induced crystallization for thin-film polycrystalline silicon solar cells: Achievements and perspective. Sol. Energy Mater. Sol. Cells 2013, 119, 261–270. [Google Scholar] [CrossRef]

- Nast, O.; Wenham, S.R. Elucidation of the layer exchange mechanism in the formation of polycrystalline silicon by aluminum-induced crystallization. J. Appl. Phys. 2000, 88, 124–132. [Google Scholar] [CrossRef]

- Wang, Z.; Gu, L.; Phillipp, F.; Wang, J.Y.; Jeurgens, L.P.H.; Mittemeijer, E.J. Metal-catalyzed growth of semiconductor nanostructures without solubility and diffusivity constraints. Adv. Mater. 2011, 23, 854–859. [Google Scholar] [CrossRef]

- Wang, Z.; Jeurgens, L.P.H.; Mittemeijer, E.J. Metal-Induced Crystallization; Pan Stanford Publishing: Singapore, 2015. [Google Scholar]

- Nast, O.; Brehme, S.; Neuhaus, D.H.; Wenham, S.R. Polycrystalline silicon thin films on glass by aluminum-induced crystallization. IEEE Trans. Electron Devices 1999, 46, 2062–2068. [Google Scholar] [CrossRef]

- Nast, O.; Brehme, S.; Pritchard, S.; Aberle, A.G.; Wenham, S.R. Aluminium-induced crystallisation of silicon on glass for thin-film solar cells. Sol. Energy Mater. Sol. Cells 2001, 65, 385–392. [Google Scholar] [CrossRef]

- Chu, H.Y.; Weng, M.H.; Yang, R.Y.; Huang, C.W.; Li, C.H. Effect of Al thickness on the Al induced low temperature poly-si film crystallization process. In Proceedings of the 2009 4th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Shenzhen, China, 5–8 January 2009; pp. 641–644. [Google Scholar]

- Kuraseko, H.; Orita, N.; Koaizawa, H.; Kondo, M. Inverted Aluminum-Induced Layer Exchange Method for Thin Film Polycrystalline Silicon Solar Cells on Insulating Substrates. Appl. Phys. Express 2009, 2, 015501. [Google Scholar] [CrossRef]

- Sakic, A.; Qi, L.; Scholtes, T.L.M.; van der Cingel, J.; Nanver, L.K. Aluminum-induced iso-epitaxy of silicon for low-temperature fabrication of centimeter-large p+n junctions. Solid. State. Electron. 2013, 84, 65–73. [Google Scholar] [CrossRef]

- Shekoofa, O.; Wang, J.; Li, D.; Luo, Y.; Sun, C.; Hao, Z.; Han, Y.; Xiong, B.; Wang, L.; Li, H. P-silicon thin film fabricated by magnetron sputtering and aluminium induced crystallization for Schottky silicon solar cells. Mater. Sci. Semicond. Process. 2017, 71, 366–373. [Google Scholar] [CrossRef]

- Mereu, R.A.; Marchionna, S.; le Donne, A.; Ciontea, L.; Binetti, S.; Acciarri, M. Optical and electrical studies of transparent conductive AZO and ITO sputtered thin films for CIGS photovoltaics. Phys. Status Solidi Curr. Top. Solid State Phys. 2014, 11, 1464–1467. [Google Scholar] [CrossRef]

- Hu, Q.; Wang, J.; Zhao, Y.; Li, D. Highly crystallized sputtered silicon with textured morphology for thin-film solar cells. Appl. Surf. Sci. 2011, 257, 4978–4981. [Google Scholar] [CrossRef]

- Yong, Z. Copper-induced Polycrystalline Silicon Via Sputtering and Its Application in Solar Cells. Ph.D. Dissertation, Department of Electronic Engineering, Tsinghua University, Beijing, China, 2012. [Google Scholar]

- Hsueh, W.C.; Lee, S.C. The fabrication of polysilicon thin film transistors by copper-induced lateral crystallization. IEEE Trans. Electron Devices 2003, 50, 816–821. [Google Scholar] [CrossRef]

- Chen, I.; Lin, P.-Y.; Li, T.T.; Chang, J.-Y. Kinetic study of the thermal crystallization behavior of hydrogenated amorphous silicon prepared by ECRCVD. ECS J. Solid State Sci. Technol. 2014, 3, N75–N82. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, J.; Hu, Q.; Li, D. Crystallization of sputtered amorphous silicon induced by silvercopper alloy with high crystalline volumeratio. J. Cryst. Growth 2010, 312, 3599–3602. [Google Scholar] [CrossRef]

- Lee, S.B.; Choi, D.-K.; Lee, D.N. Transmission electron microscopy observations of Cu-induced directional crystallization of amorphous silicon. J. Appl. Phys. 2005, 98, 114911. [Google Scholar] [CrossRef]

- Neuhaus, D.H.; Bardos, R.; Feitknecht, L.; Puzzer, T.; Keevers, M.J.; Aberle, A.G. Minority carrier properties of single- and polycrystalline silicon films formed by aluminium-induced crystallisation [solar cells]. In Proceedings of the Conference Record of the Twenty-Eighth IEEE Photovoltaic Specialists Conference—2000 (Cat. No.00CH37036), Anchorage, AK, USA, 15–22 September 2000; pp. 65–68. [Google Scholar]

- Ito, T.; Fukushima, H.; Yamaguchi, M. Fabrication of thin-film polycrystalline silicon solar cells by silane-gas-free process using aluminum-induced crystallization. Jpn. J. Appl. Phys. 2003, 42, 1526–1532. [Google Scholar] [CrossRef]

- Shekoofa, O.; Wang, J. Fabrication of P-Type Microcrystalline Silicon Thin Film by Magnetron Sputtering and Copper Induced Crystallization. In Proceedings of the Electrical Engineering (ICEE), Mashhad, Iran, 8–10 May 2018; pp. 289–293. [Google Scholar]

- Shekoofa, O.; Wang, J.; Li, D.; Luo, Y.; Sun, C.; Hao, Z.; Han, Y.; Xiong, B.; Wang, L.; Li, H. Nano-crystalline thin films fabricated by Si-Al co-sputtering and metal induced crystallization for photovoltaic applications. Sol. Energy 2018, 173, 539–550. [Google Scholar] [CrossRef]

| MS Parameters | Cu | p-Type Si | AZO |

|---|---|---|---|

| Base Pressure [Pa] | < 5 × 10−4 | < 5 × 10−4 | < 5 × 10−4 |

| Sputtering Pressure [Pa] | 2 | 1.2 | 2 |

| Sputtering DC Power [W] | 200 | 250 | 250 |

| Duration [sec] | 30 | 180 | 250 |

| Deposition Rate [nm/sec] | 0.33 | 0.33 | 0.8 |

| Thickness [nm] | 10 | 60 | 200 |

| Ar Flow Rate [sccm] | 40 | 40 | 40 |

| Substrates Temperature [°C] | 170 | 170 | 170 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shekoofa, O.; Wang, J.; Li, D.; Luo, Y. Investigation of Microcrystalline Silicon Thin Film Fabricated by Magnetron Sputtering and Copper-Induced Crystallization for Photovoltaic Applications. Appl. Sci. 2020, 10, 6320. https://doi.org/10.3390/app10186320

Shekoofa O, Wang J, Li D, Luo Y. Investigation of Microcrystalline Silicon Thin Film Fabricated by Magnetron Sputtering and Copper-Induced Crystallization for Photovoltaic Applications. Applied Sciences. 2020; 10(18):6320. https://doi.org/10.3390/app10186320

Chicago/Turabian StyleShekoofa, Omid, Jian Wang, Dejie Li, and Yi Luo. 2020. "Investigation of Microcrystalline Silicon Thin Film Fabricated by Magnetron Sputtering and Copper-Induced Crystallization for Photovoltaic Applications" Applied Sciences 10, no. 18: 6320. https://doi.org/10.3390/app10186320

APA StyleShekoofa, O., Wang, J., Li, D., & Luo, Y. (2020). Investigation of Microcrystalline Silicon Thin Film Fabricated by Magnetron Sputtering and Copper-Induced Crystallization for Photovoltaic Applications. Applied Sciences, 10(18), 6320. https://doi.org/10.3390/app10186320