Improved SP-MCTS-Based Scheduling for Multi-Constraint Hybrid Flow Shop

Abstract

1. Introduction

2. Hybrid Flow Shop Scheduling Problem

2.1. Assumption

- At the beginning, each job release time is 0.

- Job j can only be processed once in each stage.

- Each process of job j can only be processed in one machine, and each machine can only process one job at a time.

- There are infinite buffers in the adjacent two stages. Job setup time and the travel time between consecutive stages are included in the processing time Pjs or are ignored.

2.2. Symbol Definition

- Pjk is the processing time of job j at stage k.

- Djk is the start processing time of job j at stage k.

- BM denotes a very large number, the traditional “Big M”.

- xjik if job j is assigned to machine i at stage k, then xjik = 1, otherwise xjik = 0.

- yjj’k if job j is processed earlier than j’ at stage k, then yjj’k = 1, otherwise yjj’k = 0.

2.3. Mathematical Model

3. ISP-MCTS Algorithm Design

3.1. HFSSP Model

- Step 1:

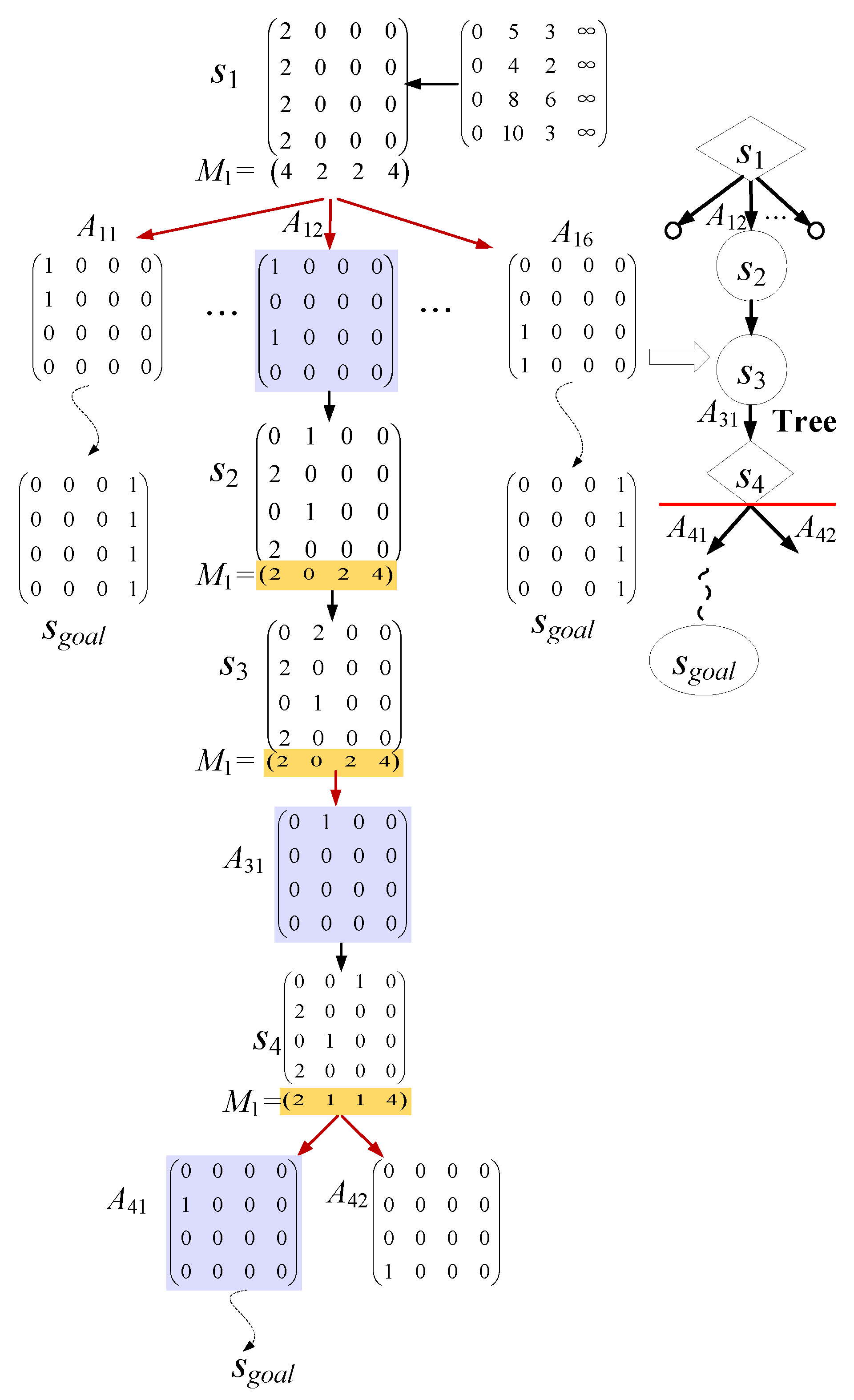

- Construct the n × m matrix of the initial state s1 and the completion state sgoal. In Figure 1, M is the number of parallel machines in each stage, M1 is the number of idle machines in each stage during the process, and the matrix evolves from s1 to sgoal.

- Step 2:

- According to the state of the job and the occupancy of the machine, the available scheduling policy set has ak = (Akγ, Akβ,…, Akδ) during searching for the k-floor shop state node sk. Meanwhile, the search method is selected on the basis of the traversal times N(sk) of the state node sk. Details are shown as follows: ① when N(sk) ≤ P (P is the critical value of the simulation times), heuristic rules are applied to select the scheduling policy for searching to the sgoal state; ② as shown in Figure 1, when N(k) > P, the selection policy of the SP-MCTS algorithm is used to evaluate the policy set ak and select the scheduling policy Ak. After executing strategy Ak, it will search from state sk to sk+1.

- Step 3:

- If sk+1 ≠ sgoal, step 2 is repeated for state evolution until the sgoal.

3.2. ISP-MCTS Algorithm Optimization Process

3.2.1. Selection

3.2.2. Expansion

3.2.3. Simulation

3.2.4. Backpropagation

3.2.5. Evaluation and Policy Set

3.3. The Complete Process of ISP-MCTS

| Algorithm 1 The main procedure of ISP-MCTS | ||

| 1: | Initialize: C, D, T1, s1, P, N = 0, sgoal, s = s1. | |

| 2: | While the halting criterion is not satisfied do | |

| 3: | Step 1: Selection and expansion | |

| 4: | if N(s) ≤ P then | |

| 5: | go to step 2 | |

| 6: | else The improved UCT in Section 3.2.1 is applied to select the scheduling policy a | |

| 7: | Update state s→s’ | |

| 8: | if the state s’ is a node in the tree then | |

| 9: | s = s1, return Step 1 | |

| 10: | else s’ is expanded to a leaf node in the tree | |

| 11: | end if | |

| 12: | if The new expanded leaf node s has one optional policy or no one | |

| 13: | N(s) = P + 1, return Step 1 | |

| 14: | else go to step 2 | |

| 15: | end if | |

| 16: | end if | |

| 17: | Step 2: Simulation | |

| 18: | The node s’ is taken as the simulation start state. | |

| 19: | Selecting the simulation policy | |

| 20: | Simulation to sgoal, the completion time Tn is obtained, go to Step 3 | |

| 21: | Step 3: Update simulation policy | |

| 22: | if Tn < Tmin then | |

| 23: | The policy set (A1γ, A2β,…, Avδ) from s1→sgoal is recorded, Tmin = Tn | |

| 24: | go to step 4 | |

| 25: | else go to step 4 | |

| 26: | end if | |

| 27: | Step 4: Backpropagation | |

| 28: | The information from the leaf node s to the root node s1 branch path node is updated according to Equation (11)→(14) | |

| 29: | ||

| 30: | if The halting criterion is not satisfied | |

| 31: | Output the optimal policy set, Tmin | |

| 32: | else s = s1, return Step 1 | |

| 33: | end if | |

| 34: | end while | |

4. Calibration of the Proposed Algorithms

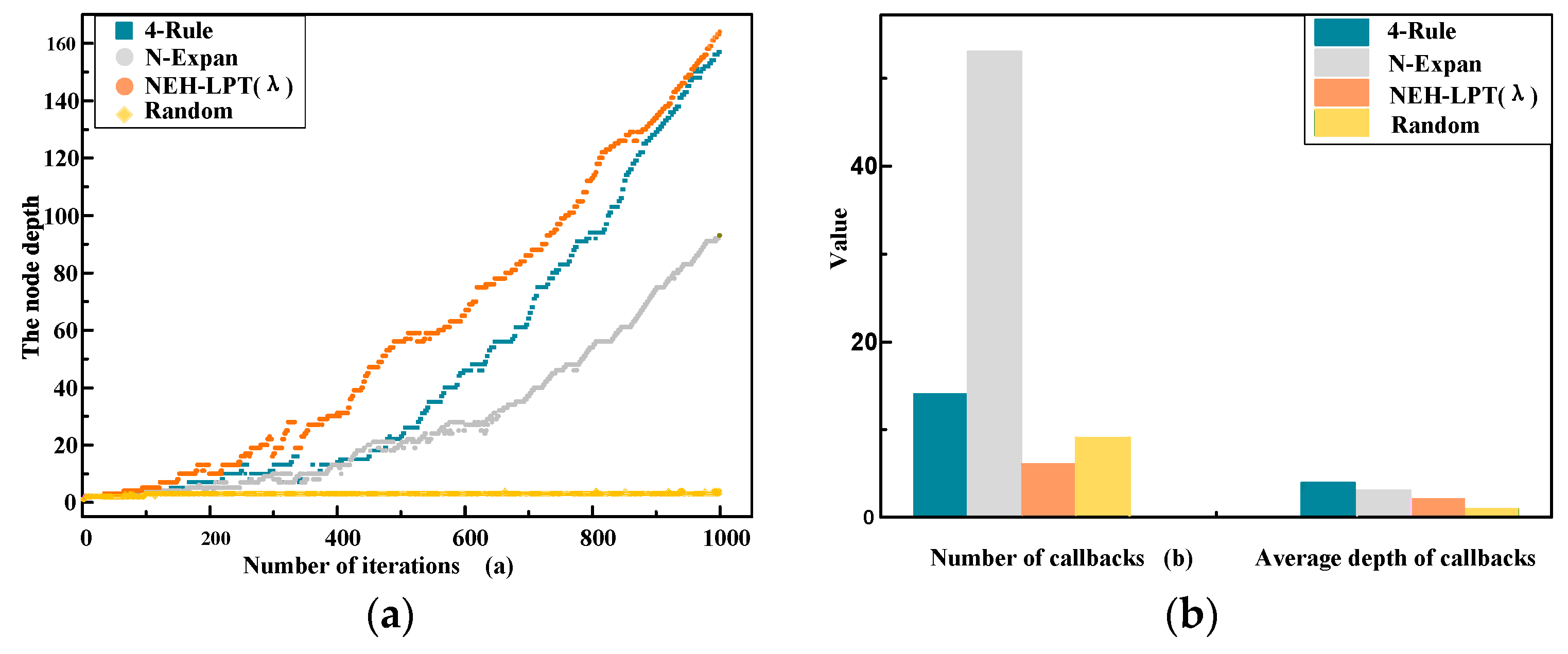

4.1. Simulation Policy Verificationᾱ

4.2. Parameter Setting

5. Calculation Results and Analysis

5.1. Comparison of Carlier and Neron’s Benchmarks

5.2. Comparison of Liao’s Benchmarks

6. Conclusions

- This paper analyzed the HFSSP operation mechanism, and proposed a tree search algorithm based on SP-MCTS to solve HFSSP. In order to solve the problem of HFSSP by SP-MCTS algorithm, the three steps of selection, expansion and simulation were improved respectively. The improvement of the algorithm included the selection blending standard deviation, the single-branch expansion strategy and the 4-Rule policy simulation. The results show that these improvements can quickly and accurately locate high-potential branches, and obtain the optimal solution.

- The 4-Rule simulation policy was selected based on a comparative analysis of the problems, and the 4-Rule can give an accurate evaluation of the leaf nodes during the search process, thus improving the search efficiency of the algorithm. According to the magnitude of the search, the combination of the parameters C and D was determined to ensure the convergence speed of the algorithm.

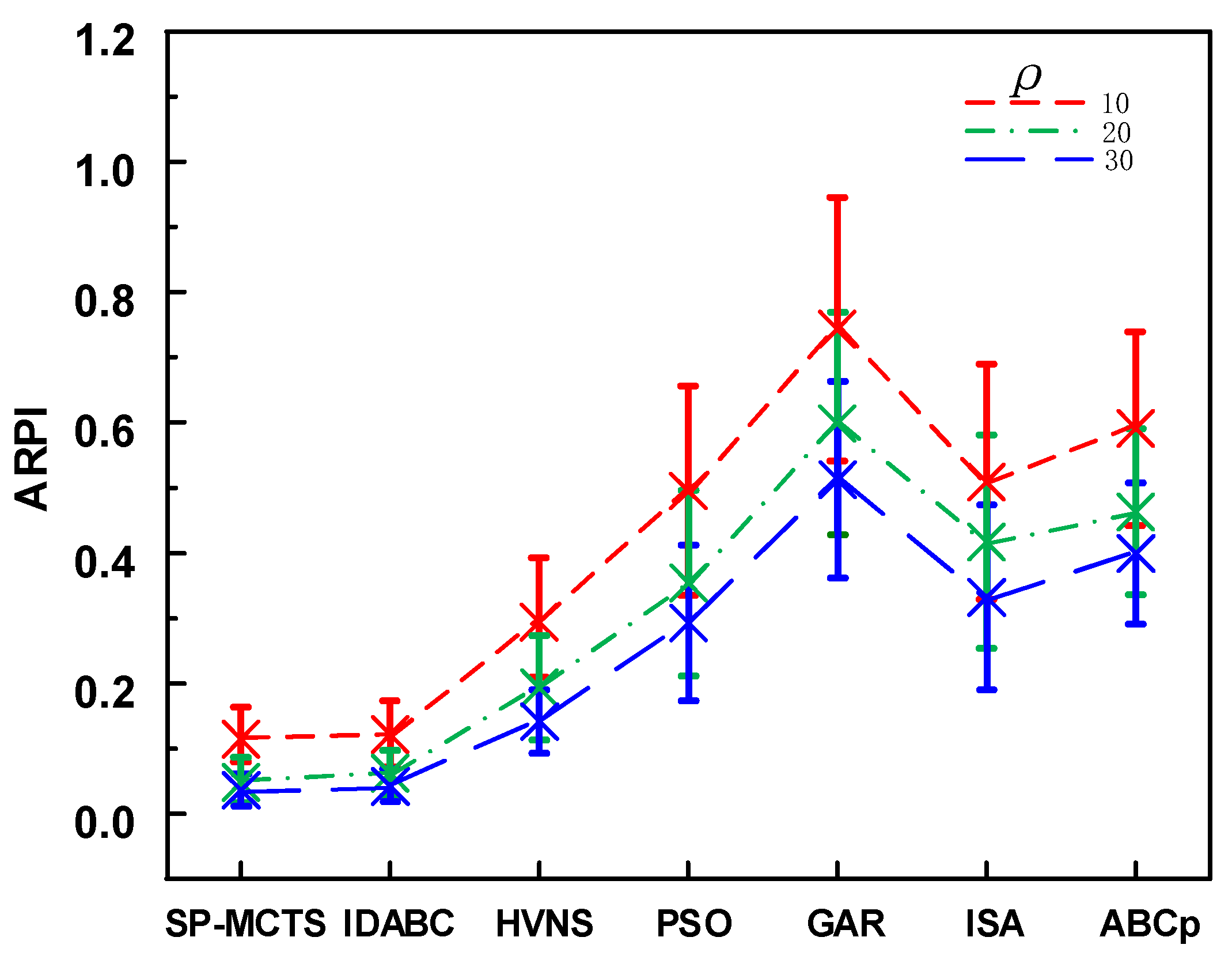

- The experimental results of the standard problems show that the ISP-MCTS algorithm is effective, and the optimal solutions of 47 class a and class b problems can be obtained at 100%. The ISP-MCTS algorithm solved the optimal solution of 18 problems in the c and d problems, and the average deviation was 3.4%, which was lower than the other five comparison algorithms. This proves that the ISP-MCTS algorithm has certain advantages in solving the HFSSP problems. According to the statistical analysis results of each algorithm to solve the Liao problems, the ISP-MCTS performance is obviously better than the HVNS and PSO algorithms, and it has a certain superiority in solution quality and stability compared with the IDABC algorithm.

- Through the comparison of large-scale random problems, it shows that the ISP-MCTS algorithm is superior to the comparison algorithms in terms of CPU time, solution quality and stability.

Author Contributions

Funding

Conflicts of Interest

References

- Johnson, S.M. Optimal two- and three-stage production schedules with setup times included. Nav. Res. Logist. Q. 1954, 1, 61–68. [Google Scholar] [CrossRef]

- Ruiz, R.; Maroto, C. A genetic algorithm for hybrid flowshops with sequence dependent setup times and machine eligibility. Eur. J. Oper. Res. 2006, 169, 781–800. [Google Scholar] [CrossRef]

- Gupta, J.N.D. Two-Stage, Hybrid Flowshop Scheduling Problem. J. Oper. Res. Soc. 1988, 39, 359–364. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Liu, Y.; Wu, N. Multi-agent and Bargaining-game-based Real-time Scheduling for Internet of Things-enabled Flexible Job Shop. IEEE IoT J. 2018, 6, 1. [Google Scholar]

- Ribas, I.; Leisten, R.; Framinan, J.M. Review and classification of hybrid flow shop scheduling problems from a production system and a solutions procedure perspective. Comput. Oper. Res. 2010, 37, 1439–1454. [Google Scholar] [CrossRef]

- Arthanary, T.S.; Ramaswamy, K.G. An extension of two machine sequencing problems. Oper. Res. 1971, 8, 10–22. [Google Scholar]

- Portmann, M.-C.; Vignier, A.; Dardilhac, D.; Dezalay, D. Branch and bound crossed with GA to solve hybrid flowshops. Eur. J. Oper. Res. 1998, 107, 389–400. [Google Scholar] [CrossRef]

- Néron, E.; Baptiste, P.; Gupta, J.N. Solving hybrid flow shop problem using energetic reasoning and global operations. Omega 2001, 29, 501–511. [Google Scholar] [CrossRef]

- Gupta, J.N.D.; Tunc, E.A. Minimizing tardy jobs in a two-stage hybrid flow shop. Int. J. Prod. Res. 1998, 36, 2397–2417. [Google Scholar] [CrossRef]

- Kahraman, C.; Engin, O.; Kaya, I.; Öztürk, R.E. Multiprocessor task scheduling in multistage hybrid flow-shops: A parallel greedy algorithm approach. Appl. Soft Comput. 2010, 10, 1293–1300. [Google Scholar] [CrossRef]

- Lin, H.-T.; Liao, C.-J. A case study in a two-stage hybrid flow shop with setup time and dedicated machines. Int. J. Prod. Econ. 2003, 86, 133–143. [Google Scholar] [CrossRef]

- Fakhrzad, M.; Heydari, M. A Heuristic Algorithm for Hybrid Flow-Shop Production Scheduling to Minimize the Sum of the Earliness and Tardiness Costs. J. Chin. Inst. Ind. Eng. 2008, 25, 105–115. [Google Scholar] [CrossRef]

- Paternina-Arboleda, C.D.; Montoya-Torres, J.R.; Acero-Dominguez, M.J.; Herrera-Hernandez, M.C. Scheduling jobs on a k-stage flexible flow-shop. Ann. Oper. Res. 2007, 164, 29–40. [Google Scholar] [CrossRef]

- Nowicki, E.; Smutnicki, C. The flow shop with parallel machines: A tabu search approach. Eur. J. Oper. Res. 1998, 106, 226–253. [Google Scholar] [CrossRef]

- Alaykýran, K.; Engin, O.; Döyen, A. Using ant colony optimization to solve hybrid flow shop scheduling problems. Int. J. Adv. Manuf. Technol. 2007, 35, 541–550. [Google Scholar] [CrossRef]

- Kahraman, C.; Engin, O.; Kaya, I.; Yilmaz, M.K. An application of effective genetic algorithms for solving hybrid flow shop scheduling problems. Int. J. Intell. Syst. 2008, 1, 134–147. [Google Scholar] [CrossRef]

- Liao, C.J.; Tjandradjaj, E.; Chung, T.P. An approach using particle swarm optimization and bottleneck heuristic to solve flowshop scheduling problem. Appl. Soft Comput. 2012, 12, 1755–1764. [Google Scholar] [CrossRef]

- Marichelvam, M.K.; Prabaharan, T.; Yang, X.-S. Improved cuckoo search algorithm for hybrid flow shop scheduling problems to minimize makespan. Appl. Soft Comput. 2014, 19, 93–101. [Google Scholar] [CrossRef]

- Pan, Q.-K.; Wang, L.; Li, J.-Q.; Duan, J.-H. A novel discrete artificial bee colony algorithm for the hybrid flowshop scheduling problem with makespan minimisation. Omega 2014, 45, 42–56. [Google Scholar] [CrossRef]

- Li, J.-Q.; Pan, Q.-K.; Wang, F.-T. A hybrid variable neighborhood search for solving the hybrid flow shop scheduling problem. Appl. Soft Comput. 2014, 24, 63–77. [Google Scholar] [CrossRef]

- Cui, Z.; Gu, X. An improved discrete artificial bee colony algorithm to minimize the makespan on hybrid flow shop problems. Neurocomputing 2015, 148, 248–259. [Google Scholar] [CrossRef]

- Komaki, G.; Teymourian, E.; Kayvanfar, V. Minimising makespan in the two-stage assembly hybrid flow shop scheduling problem using artificial immune systems. Int. J. Prod. Res. 2015, 54, 1–21. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Chen, L. A re-entrant hybrid flow shop scheduling problem with machine eligibility constraints. Int. J. Prod. Res. 2017, 56, 1–13. [Google Scholar] [CrossRef]

- Niu, Q.; Zhou, T.; Ma, S. A quantum-inspired immune algorithm for hybrid flowshop with makespan criterion. J. Univ. Comput. Sci. 2009, 15, 765–785. [Google Scholar]

- Engin, O.; Döyen, A. A new approach to solve hybrid flow shop scheduling problems by artificial immune system. Futur. Gener. Comput. Syst. 2004, 20, 1083–1095. [Google Scholar] [CrossRef]

- Ramanan, T.R.; Sridharan, R.; Shashikant, K.S.; Haq, A.N. An artificial neural network based heuristic for flow shop scheduling problems. J. Intell. Manuf. 2009, 22, 279–288. [Google Scholar] [CrossRef]

- Izonin, I.; Tkachenko, R.; Kryvinska, N.; Tkachenko, P.; Greguš ml., M. Multiple Linear Regression Based on Coefficients Identification Using Non-iterative SGTM Neural-like Structure. In Advances in Computational Intelligence; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Tkachenko, R.; Izonin, I. Model and Principles for the Implementation of Neural-Like Structures Based on Geometric Data Transformations; Springer Science and Business Media LLC: Heidelberg, Germany, 2018; pp. 578–587. [Google Scholar]

- Gupta, J.N.D.; Majumder, A.; Laha, D. Flowshop scheduling with artificial neural networks. J. Oper. Res. Soc. 2019, 1–19. [Google Scholar] [CrossRef]

- Zhao, F.; Qin, S.; Zhang, Y.; Ma, W.; Zhang, C.; Song, H. A hybrid biogeography-based optimization with variable neighborhood search mechanism for no-wait flow shop scheduling problem. Expert Syst. Appl. 2019, 126, 321–339. [Google Scholar] [CrossRef]

- Powley, E.J.; Cowling, P.I.; Whitehouse, D. Information capture and reuse strategies in Monte Carlo Tree Search, with applications to games of hidden information. Artif. Intell. 2014, 217, 92–116. [Google Scholar] [CrossRef]

- Chaslot, G.; De, J.S.; Saito, J.T. Monte-Carlo tree search in production management problems. In Proceedings of the 18th Belgium-Netherlands Conference on Artificial Intelligence, Namur, Belgium, 5–6 October 2006; Volume 2, pp. 91–98. [Google Scholar]

- Wu, T.-Y.; Wu, I.-C.; Liang, C.-C. Multi-objective Flexible Job Shop Scheduling Problem Based on Monte-Carlo Tree Search. In Proceedings of the 2013 Conference on Technologies and Applications of Artificial Intelligence, Taipei, Taiwan, 6–8 December 2013; pp. 73–78. [Google Scholar] [CrossRef]

- Chou, J.-J.; Liang, C.-C.; Wu, H.-C.; Wu, I.-C.; Wu, T.-Y.; Jen-Jai, C.; Chao-Chin, L.; Hung-Chun, W.; I-Chen, W.; Tung-Ying, W. A new MCTS-based algorithm for multi-objective flexible job shop scheduling problem. In Proceedings of the 2015 Conference on Technologies and Applications of Artificial Intelligence (TAAI), Tainan, Taiwan, 20–22 November 2015; Institute of Electrical and Electronics Engineers (IEEE): Piscataway, NJ, USA, 2015; pp. 136–141. [Google Scholar]

- Furuoka, R.; Matsumoto, S. Worker’s knowledge evaluation with single-player Monte Carlo tree search for a practical reentrant scheduling problem. Artif. Life Robot. 2016, 22, 130–138. [Google Scholar] [CrossRef]

- Schadd, M.P.D.; Winands, M.H.M.; Herik, J.V.D.; Chaslot, G.; Uiterwijk, J.W.H.M. Single-Player Monte-Carlo Tree Search. Computers and Games; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Schadd, M.P.; Winands, M.H.M.; Tak, M.J.; Uiterwijk, J.W.H.M. Single-player Monte-Carlo tree search for SameGame. Knowl. Based Syst. 2012, 34, 3–11. [Google Scholar] [CrossRef]

- Shimpei, M.; Noriaki, H.; Kyohei, I. Evaluation of Simulation Strategy on Single-Player Monte-Carlo Tree Search and its Discussion for a Practical Scheduling Problem. Lect. Notes Eng. Comput. Sci. 2010, 1, 2182. [Google Scholar]

- Sylvain, G.; David, S. Monte- Carlo tree search and rapid action value estimation in computer Go. Artific. Intell. 2011, 175, 1856–1875. [Google Scholar]

- Hazeghi, K.; Puterman, M.L. Markov Decision Processes: Discrete Stochastic Dynamic Programming. J. Am. Stat. Assoc. 1995, 90, 392. [Google Scholar] [CrossRef]

- Boutilier, C. Knowledge Representation for Stochastic Decision Processes: Artificial Intelligence Today; Springer Science and Business Media LLC: Heidelberg, Germany, 1999; Volume 1600, pp. 111–152. [Google Scholar]

- Carlier, J.; Néron, E. An Exact Method for Solving the Multi-Processor Flow-Shop. RAIRO Oper. Res. 2000, 34, 1–25. [Google Scholar] [CrossRef]

- Naderi, B.; Zandieh, M.; Balagh, A.K.G.; Roshanaei, V. An improved simulated annealing for hybrid flowshops with sequence-dependent setup and transportation times to minimize total completion time and total tardiness. Expert Syst. Appl. 2009, 36, 9625–9633. [Google Scholar] [CrossRef]

| Problem | 4-Rule | N-Expan | NEH-LPT(λ) | Random |

|---|---|---|---|---|

| 20 × 4 | 0.01 | 0.02 | 4.92 | 12.23 |

| 20 × 6 | 0.03 | 0.04 | 4.37 | 13.11 |

| 20 × 8 | 0.15 | 0.29 | 5.76 | 14.45 |

| 40 × 4 | 0.08 | 0.12 | 4.11 | 10.17 |

| 40 × 6 | 0.14 | 0.37 | 4.77 | 13.67 |

| 40 × 8 | 0.11 | 0.28 | 5.67 | 15.42 |

| 60 × 4 | 0.04 | 0.16 | 4.52 | 12.83 |

| 60 × 6 | 0.07 | 0.52 | 4.87 | 14.17 |

| 60 × 8 | 0.13 | 0.31 | 5.12 | 17.85 |

| 80 × 4 | 0.02 | 0.47 | 2.31 | 11.77 |

| 80 × 6 | 0.03 | 0.17 | 7.57 | 13.46 |

| 80 × 8 | 0.06 | 0.24 | 6.86 | 15.52 |

| 100 × 4 | 0.03 | 0.23 | 3.18 | 12.83 |

| 100 × 6 | 0.08 | 0.29 | 3.57 | 17.51 |

| 100 × 8 | 0.07 | 0.61 | 6.85 | 21.84 |

| Ave. | 0.07 | 0.275 | 4.963 | 14.455 |

| N-Expan and 4-Rule | NEH-LPT(λ) and 4-Rule | Random and 4-Rule | |

|---|---|---|---|

| p-Value | 0.00 | 0.00 | 0.00 |

| Significant? (p < 0.05) | Yes | Yes | Yes |

| (C,D) | (0.1, 32) | (0.5, 10,000) | (1, 20,000) |

|---|---|---|---|

| 0–105(j15c5d2) (~10 s) | |||

| Average completion time | 84.83 | 85.14 | 88.27 |

| Standard deviation | 0.53 | 1.27 | 2.50 |

| Average depth | 57 | 19 | 11 |

| 105–106(j30c5e4) (~100 s) | |||

| Average completion time | 570.9 | 567.3 | 581.1 |

| Standard deviation | 3.51 | 2.77 | 4.73 |

| Average depth | 207 | 73 | 14 |

| 106–5 × 106(j30c5e1) (~200 s) | |||

| Average completion time | 482.7 | 465.3 | 480.5 |

| Standard deviation | 3.56 | 2.72 | 3.21 |

| Average depth | 289 | 98 | 27 |

| Problem | LB | ISP-MCTS | IDABC | HVNS | PSO | GA | AIS | B&B | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | ||

| j10c5a2 | 88 | 88 | 0.003 | 88 | 0.002 | 88 | 0.004 | 88 | 0.002 | 88 | 0.000 | 88 | 1 | 88 | 13 |

| j10c5a3 | 117 | 117 | 0.003 | 117 | 0.003 | 117 | 0.004 | 117 | 0.002 | 117 | 0.000 | 117 | 1 | 117 | 7 |

| j10c5a4 | 121 | 121 | 0.002 | 121 | 0.003 | 121 | 0.002 | 121 | 0.003 | 121 | 0.015 | 121 | 1 | 121 | 6 |

| j10c5a5 | 122 | 122 | 0.004 | 122 | 0.005 | 122 | 0.003 | 122 | 0.013 | 122 | 0.000 | 122 | 1 | 122 | 11 |

| j10c5a6 | 110 | 110 | 0.022 | 110 | 0.009 | 110 | 0.024 | 110 | 0.174 | 110 | 0.015 | 110 | 4 | 110 | 6 |

| j10c5b1 | 130 | 130 | 0.003 | 130 | 0.003 | 130 | 0.003 | 130 | 0.003 | 130 | 0.000 | 130 | 1 | 130 | 13 |

| j10c5b2 | 107 | 107 | 0.003 | 107 | 0.004 | 107 | 0.003 | 107 | 0.003 | 107 | 0.000 | 107 | 1 | 107 | 6 |

| j10c5b3 | 109 | 109 | 0.003 | 109 | 0.003 | 109 | 0.003 | 109 | 0.012 | 109 | 0.000 | 109 | 1 | 109 | 9 |

| j10c5b4 | 122 | 122 | 0.003 | 122 | 0.003 | 122 | 0.004 | 122 | 0.025 | 122 | 0.000 | 122 | 2 | 122 | 6 |

| j10c5b5 | 153 | 153 | 0.003 | 153 | 0.003 | 153 | 0.003 | 153 | 0.001 | 153 | 0.000 | 153 | 1 | 153 | 6 |

| j10c5b6 | 115 | 115 | 0.003 | 115 | 0.004 | 115 | 0.002 | 115 | 0.001 | 115 | 0.000 | 115 | 1 | 115 | 11 |

| j10c10a1 | 139 | 139 | 0.031 | 139 | 0.009 | 139 | 0.227 | 139 | 0.055 | 139 | 0.015 | 139 | 1 | 139 | 41 |

| j10c10a2 | 158 | 158 | 0.337 | 158 | 0.009 | 158 | 0.354 | 158 | 0.87 | 158 | 0.125 | 158 | 18 | 158 | 21 |

| j10c10a3 | 148 | 148 | 0.036 | 148 | 0.008 | 148 | 0.225 | 148 | 0.017 | 148 | 0.047 | 148 | 1 | 148 | 58 |

| j10c10a4 | 149 | 149 | 0.010 | 149 | 0.007 | 149 | 0.007 | 149 | 0.085 | 149 | 0.141 | 149 | 2 | 149 | 21 |

| j10c10a5 | 148 | 148 | 0.006 | 148 | 0.006 | 148 | 0.006 | 148 | 0.102 | 148 | 0.000 | 148 | 1 | 148 | 36 |

| j10c10a6 | 146 | 146 | 0.282 | 146 | 0.008 | 146 | 0.264 | 146 | 0.239 | 146 | 0.156 | 146 | 4 | 146 | 20 |

| j10c10b1 | 163 | 163 | 0.006 | 163 | 0.007 | 163 | 0.006 | 163 | 0.013 | 163 | 0.000 | 163 | 1 | 163 | 36 |

| j10c10b2 | 157 | 157 | 0.114 | 157 | 0.009 | 157 | 0.104 | 157 | 0.221 | 157 | 0.131 | 157 | 1 | 157 | 66 |

| j10c10b3 | 169 | 169 | 0.007 | 169 | 0.007 | 169 | 0.006 | 169 | 0.014 | 169 | 0.000 | 169 | 1 | 169 | 19 |

| j10c10b4 | 159 | 159 | 0.012 | 159 | 0.005 | 159 | 0.068 | 159 | 0.021 | 159 | 0.015 | 159 | 1 | 159 | 20 |

| j10c10b5 | 165 | 165 | 0.007 | 165 | 0.007 | 165 | 0.005 | 165 | 0.037 | 165 | 0.016 | 165 | 1 | 165 | 33 |

| j10c10b6 | 165 | 165 | 0.008 | 165 | 0.006 | 165 | 0.005 | 165 | 0.056 | 165 | 0.016 | 165 | 1 | 165 | 34 |

| j15c5a1 | 178 | 178 | 0.007 | 178 | 0.016 | 178 | 0.006 | 178 | 0.060 | 178 | 0.031 | 178 | 1 | 178 | 18 |

| j15c5a2 | 165 | 165 | 0.005 | 165 | 0.018 | 165 | 0.005 | 165 | 0.005 | 165 | 0.015 | 165 | 1 | 165 | 35 |

| j15c5a3 | 130 | 130 | 0.008 | 130 | 0.017 | 130 | 0.005 | 130 | 0.006 | 130 | 0.015 | 130 | 1 | 130 | 34 |

| j15c5a4 | 156 | 156 | 0.010 | 156 | 0.019 | 156 | 0.005 | 156 | 0.013 | 156 | 0.015 | 156 | 2 | 156 | 21 |

| j15c5a5 | 164 | 164 | 0.005 | 164 | 0.016 | 164 | 0.003 | 164 | 0.004 | 164 | 0.046 | 164 | 1 | 164 | 34 |

| j15c5a6 | 178 | 178 | 0.007 | 178 | 0.016 | 178 | 0.005 | 178 | 0.006 | 178 | 0.032 | 178 | 1 | 178 | 38 |

| j15c5b1 | 170 | 170 | 0.007 | 170 | 0.012 | 170 | 0.005 | 170 | 0.003 | 170 | 0.015 | 170 | 1 | 170 | 16 |

| j15c5b2 | 152 | 152 | 0.005 | 152 | 0.015 | 152 | 0.003 | 152 | 0.005 | 152 | 0.015 | 152 | 1 | 152 | 25 |

| j15c5b3 | 157 | 157 | 0.006 | 157 | 0.014 | 157 | 0.006 | 157 | 0.030 | 157 | 0.015 | 157 | 1 | 157 | 15 |

| j15c5b4 | 147 | 147 | 0.010 | 147 | 0.017 | 147 | 0.007 | 147 | 0.000 | 147 | 0.015 | 147 | 1 | 147 | 37 |

| j15c5b5 | 166 | 166 | 0.100 | 166 | 0.020 | 166 | 0.088 | 166 | 0.086 | 166 | 0.016 | 166 | 2 | 166 | 20 |

| j15c5b6 | 175 | 175 | 0.007 | 175 | 0.018 | 175 | 0.004 | 175 | 0.016 | 175 | 0.015 | 175 | 1 | 175 | 23 |

| j15c10a1 | 236 | 236 | 0.011 | 236 | 0.033 | 236 | 0.008 | 236 | 0.018 | 236 | 0.015 | 236 | 1 | 236 | 40 |

| j15c10a2 | 200 | 200 | 0.120 | 200 | 0.048 | 200 | 0.339 | 200 | 0.214 | 200 | 0.015 | 200 | 30 | 200 | 154 |

| j15c10a3 | 198 | 198 | 0.130 | 198 | 0.032 | 198 | 0.313 | 198 | 0.171 | 198 | 0.063 | 198 | 4 | 198 | 45 |

| j15c10a4 | 225 | 225 | 0.070 | 225 | 0.034 | 225 | 0.212 | 225 | 0.072 | 225 | 0.031 | 225 | 12 | 225 | 78 |

| j15c10a5 | 182 | 182 | 0.011 | 182 | 0.036 | 182 | 0.008 | 182 | 0.509 | 182 | 0.016 | 182 | 2 | 183 | c |

| j15c10a6 | 200 | 200 | 0.052 | 200 | 0.033 | 200 | 0.024 | 200 | 0.468 | 200 | 0.031 | 200 | 2 | 200 | 44 |

| j15c10b1 | 222 | 222 | 0.026 | 222 | 0.048 | 222 | 0.009 | 222 | 0.017 | 222 | 0.031 | 222 | 3 | 222 | 70 |

| j15c10b2 | 187 | 187 | 0.009 | 187 | 0.044 | 187 | 0.008 | 187 | 0.012 | 187 | 0.047 | 187 | 1 | 187 | 80 |

| j15c10b3 | 222 | 222 | 0.009 | 222 | 0.039 | 222 | 0.008 | 222 | 0.007 | 222 | 0.015 | 222 | 1 | 222 | 80 |

| j15c10b4 | 221 | 221 | 0.009 | 221 | 0.037 | 221 | 0.008 | 221 | 0.007 | 221 | 0.016 | 221 | 1 | 221 | 84 |

| j15c10b5 | 200 | 200 | 0.109 | 200 | 0.048 | 200 | 0.045 | 200 | 0.135 | 200 | 0.094 | 200 | 1 | 200 | 84 |

| j15c10b6 | 219 | 219 | 0.010 | 219 | 0.037 | 219 | 0.009 | 219 | 0.006 | 219 | 0.031 | 219 | 1 | 219 | 67 |

| AVE | 0.035 | 0.017 | 0.052 | 0.082 | 0.028 | 2.574 | 35.674 | ||||||||

| Problem | LB | ISP-MCTS | IDABC | HVNS | PSO | GA | AIS | B&B | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | Cmax | CPU | ||

| j10c5c1 | 68 | 68 | 0.275 | 68 | 0.017 | 68 | 0.792 | 68 | 0.332 | 68 | 0.031 | 68 | 32 | 68 | 28 |

| j10c5c2 | 74 | 74 | 0.633 | 74 | 0.055 | 74 | 0.752 | 74 | 0.535 | 74 | 0.016 | 74 | 4 | 74 | 19 |

| j10c5c3 | 71 | 71 | 0.752 | 72 | a | 72 | 0.141(a) | 71 | 36.997 | 71 | 0.016 | 72 | a | 71 | 240 |

| j10c5c4 | 66 | 66 | 0.161 | 66 | 0.005 | 66 | 0.631 | 66 | 0.215 | 66 | 0.031 | 66 | 3 | 66 | 1017 |

| j10c5c5 | 78 | 78 | 0.382 | 78 | 0.004 | 78 | 0.129 | 78 | 0.122 | 78 | 0.094 | 78 | 14 | 78 | 42 |

| j10c5c6 | 69 | 69 | 0.527 | 69 | 0.004 | 69 | 0.226 | 69 | 0.405 | 69 | 0.000 | 69 | 12 | 69 | 4865 |

| j10c5d1 | 66 | 66 | 0.268 | 66 | 0.005 | 66 | 0.148 | 66 | 0.185 | 66 | 0.046 | 66 | 5 | 66 | 6490 |

| j10c5d2 | 73 | 73 | 0.271 | 73 | 0.069 | 73 | 0.142 | 73 | 1.158 | 73 | 0.110 | 73 | 31 | 73 | 2617 |

| j10c5d3 | 64 | 64 | 0.277 | 64 | 0.007 | 64 | 0.157 | 64 | 0.098 | 64 | 0.015 | 64 | 15 | 64 | 481 |

| j10c5d4 | 70 | 70 | 0.895 | 70 | 0.003 | 70 | 0.675 | 70 | 0.337 | 70 | 0.000 | 70 | 5 | 70 | 393 |

| j10c5d5 | 66 | 66 | 1.576 | 66 | 0.009 | 66 | 1.382 | 66 | 0.515 | 66 | 0.031 | 66 | 1446 | 66 | 1627 |

| j10c5d6 | 62 | 62 | 0.276 | 62 | 0.009 | 62 | 0.135 | 62 | 0.383 | 62 | 0.062 | 62 | 8 | 62 | 6861 |

| j10c10c1 | 113 | 114 | 2.822(a) | 115 | a | 115 | 0.571(a) | 115 | a | 115 | a | 115 | a | 127 | c |

| j10c10c2 | 116 | 117 | 0.414(a) | 119 | a | 117 | 0.448(a) | 117 | a | 117 | a | 119 | a | 116 | 1100 |

| j10c10c3 | 98 | 108 | 2.706(a) | 116 | a | 116 | 0.698(a) | 116 | a | 116 | a | 116 | a | 133 | c |

| j10c10c4 | 103 | 112 | 2.315(a) | 120 | a | 120 | 0.461(a) | 120 | a | 120 | a | 120 | a | 135 | c |

| j10c10c5 | 121 | 125 | 2.831(a) | 125 | a | 125 | 2.125(a) | 125 | a | 125 | a | 126 | a | 145 | c |

| j10c10c6 | 97 | 105 | 2.663(a) | 106 | a | 106 | 0.343(a) | 106 | a | 106 | a | 106 | a | 112 | c |

| j15c5c1 | 85 | 85 | 1.179 | 85 | 0.127 | 85 | 1.128 | 85 | 4.205 | 85 | 0.031 | 85 | 774 | 85 | 2131 |

| j15c5c2 | 90 | 90 | 0.785 | 90 | 27 | 90 | 0.491 | 90 | 1198 | 91 | a | 91 | a | 90 | 184 |

| j15c5c3 | 87 | 87 | 0.511 | 87 | 0.048 | 87 | 0.502 | 87 | 2.398 | 87 | 0.109 | 87 | 16 | 87 | 202 |

| j15c5c4 | 89 | 89 | 0.653 | 89 | 0.038 | 89 | 0.569 | 89 | 2.208 | 89 | 0.000 | 89 | 317 | 90 | c |

| j15c5c5 | 73 | 74 | 2.197(a) | 74 | a | 74 | 1.968(a) | 74 | a | 75 | a | 74 | a | 84 | c |

| j15c5c6 | 91 | 91 | 0.370 | 91 | 0.027 | 91 | 0.180 | 91 | 0.191 | 91 | 0.047 | 91 | 19 | 91 | 57 |

| j15c5d1 | 167 | 167 | 0.005 | 167 | 0.020 | 167 | 0.004 | 167 | 0 | 167 | 0.015 | 167 | 1 | 167 | 24 |

| j15c5d2 | 82 | 84 | 1.133(a) | 84 | a | 84 | 0.915(a) | 84 | a | 84 | a | 84 | a | 85 | c |

| j15c5d3 | 77 | 82 | 2.171(a) | 82 | a | 82 | 1.356(a) | 82 | a | 83 | a | 83 | a | 96 | c |

| j15c5d4 | 61 | 84 | 0.672(a) | 84 | a | 84 | 1.325(a) | 84 | a | 84 | a | 84 | a | 101 | c |

| j15c5d5 | 67 | 79 | 1.559(a) | 79 | a | 79 | 0.585(a) | 79 | a | 80 | a | 80 | a | 97 | c |

| j15c5d6 | 79 | 81 | 1.683(a) | 81 | a | 81 | 1.123(a) | 81 | a | 82 | a | 82 | a | 87 | c |

| AVE | 0.544 | 1.615 | 0.473 | 73.43 | 0.038 | 168.88 | 455.23 | ||||||||

| Algorithm | a and b Problems | c and d Problems | ||

|---|---|---|---|---|

| Solved | Deviation | Solved | Deviation | |

| ISP-MCTS | 47 | 0 | 18 | 3.40% |

| IDABC | 47 | 0 | 17 | 4.00% |

| HVNS | 47 | 0 | 17 | 4.00% |

| PSO | 47 | 0 | 18 | 3.95% |

| GA | 47 | 0 | 17 | 4.17% |

| AIS | 47 | 0 | 16 | 4.26% |

| B&B | 46 | 0.12% | 18 | 9.32% |

| Problem | ISP-MCTS | IDABC | HVNS | PSO | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ave. | Min. | Std. | CPU | Ave. | Min. | Std. | CPU | Ave. | Min. | Std. | CPU | Ave. | Min. | Std. | CPU | |

| j30c5e1 | 463.2 | 462 | 0.81 | 14.52 | 465.2 | 463 | 1.80 | 57 | 465.41 | 464 | 1.34 | 29.16 | 474.70 | 471 | 1.42 | 96.16 |

| j30c5e2 | 616.0 | 616 | 0 | 10.32 | 616.0 | 616 | 0 | 2 | 616.22 | 616 | 0.32 | 11.69 | 616.25 | 616 | 0.44 | 55.28 |

| j30c5e3 | 594.7 | 593 | 0.97 | 20.37 | 596.4 | 593 | 1.70 | 49 | 598.51 | 595 | 3.32 | 27.33 | 610.25 | 602 | 4.70 | 64.56 |

| j30c5e4 | 565.3 | 563 | 1.23 | 18.53 | 566.2 | 565 | 1.60 | 39 | 568.32 | 566 | 1.44 | 37.00 | 577.10 | 575 | 1.52 | 86.98 |

| j30c5e5 | 600.9 | 600 | 0.77 | 17.23 | 602.0 | 600 | 1.60 | 58 | 603.75 | 601 | 1.26 | 21.32 | 606.80 | 605 | 1.11 | 79.84 |

| j30c5e6 | 602.8 | 600 | 1.44 | 17.06 | 603.1 | 601 | 1.80 | 55 | 607.01 | 603 | 3.32 | 33.39 | 612.50 | 605 | 3.49 | 67.99 |

| j30c5e7 | 626.4 | 626 | 0.31 | 18.23 | 626.0 | 626 | 0 | 19 | 627.34 | 626 | 0.83 | 27.37 | 630.60 | 629 | 0.75 | 87.18 |

| j30c5e8 | 674.4 | 674 | 0.69 | 22.69 | 674.7 | 674 | 0.90 | 55 | 676.40 | 674 | 2.23 | 31.40 | 684.20 | 678 | 2.50 | 97.67 |

| j30c5e9 | 643.1 | 642 | 0.76 | 21.37 | 643.7 | 642 | 1.00 | 67 | 645.28 | 643 | 1.66 | 33.81 | 654.65 | 651 | 1.87 | 83.80 |

| j30c5e10 | 574.2 | 573 | 1.09 | 23.81 | 576.3 | 573 | 1.50 | 76 | 581.33 | 577 | 3.97 | 29.72 | 599.75 | 594 | 5.28 | 77.46 |

| Ave. | 596.1 | 594.9 | 0.83 | 18.41 | 596.9 | 595.3 | 1.19 | 47.7 | 598.96 | 596.5 | 1.97 | 28.22 | 606.68 | 602.6 | 2.31 | 79.69 |

| ISP-MCTS and IDABC | ISP-MCTS and HVNS | ISP-MCTS and PSO | |

|---|---|---|---|

| p-Value | 0.12 | 0.018 | 0 |

| Significant? (p < 0.05) | NO | Yes | Yes |

| Problem | ISP-MCTS | IDABC | HVNS | PSO | GAR | ISA | ABCp |

|---|---|---|---|---|---|---|---|

| 20 × 4 | 0.03 | 0.03 | 0.31 | 0.71 | 1.01 | 0.68 | 0.38 |

| 20 × 6 | 0.12 | 0.11 | 0.24 | 0.77 | 1.27 | 0.78 | 0.69 |

| 20 × 8 | 0.33 | 0.34 | 0.61 | 1.03 | 1.21 | 1.18 | 0.82 |

| 40 × 4 | 0.03 | 0.03 | 0.22 | 0.31 | 0.52 | 0.34 | 0.49 |

| 40 × 6 | 0.04 | 0.03 | 0.15 | 0.22 | 0.71 | 0.29 | 0.77 |

| 40 × 8 | 0.17 | 0.18 | 0.66 | 0.98 | 1.39 | 1.12 | 1.13 |

| 60 × 4 | 0.11 | 0.13 | 0.11 | 0.33 | 0.51 | 0.35 | 0.48 |

| 60 × 6 | 0.16 | 0.16 | 0.23 | 0.41 | 0.61 | 0.47 | 0.55 |

| 60 × 8 | 0.21 | 0.25 | 0.42 | 0.67 | 1.10 | 0.71 | 1.04 |

| 80 × 4 | 0.06 | 0.06 | 0.11 | 0.20 | 0.35 | 0.21 | 0.33 |

| 80 × 6 | 0.20 | 0.21 | 0.24 | 0.46 | 0.65 | 0.52 | 0.60 |

| 80 × 8 | 0.12 | 0.12 | 0.33 | 0.55 | 0.61 | 0.32 | 0.52 |

| 100 × 4 | 0.00 | 0.01 | 0.03 | 0.05 | 0.18 | 0.05 | 0.11 |

| 100 × 6 | 0.05 | 0.05 | 0.10 | 0.23 | 0.41 | 0.27 | 0.38 |

| 100 × 8 | 0.09 | 0.11 | 0.18 | 0.51 | 0.62 | 0.35 | 0.57 |

| Ave. | 0.115 | 0.121 | 0.263 | 0.495 | 0.743 | 0.509 | 0.591 |

| Problem | ISP-MCTS | IDABC | HVNS | PSO | GAR | ISA | ABCp |

|---|---|---|---|---|---|---|---|

| 20 × 4 | 0.02 | 0.01 | 0.27 | 0.62 | 0.88 | 0.57 | 0.29 |

| 20 × 6 | 0.04 | 0.06 | 0.16 | 0.68 | 1.03 | 0.66 | 0.57 |

| 20 × 8 | 0.21 | 0.23 | 0.47 | 0.89 | 0.96 | 1.01 | 0.44 |

| 40 × 4 | 0.02 | 0.03 | 0.15 | 0.24 | 0.41 | 0.29 | 0.36 |

| 40 × 6 | 0.01 | 0.02 | 0.11 | 0.15 | 0.56 | 0.17 | 0.51 |

| 40 × 8 | 0.10 | 0.13 | 0.53 | 0.73 | 1.15 | 1.01 | 0.99 |

| 60 × 4 | 0.05 | 0.07 | 0.09 | 0.21 | 0.47 | 0.31 | 0.42 |

| 60 × 6 | 0.06 | 0.10 | 0.17 | 0.33 | 0.48 | 0.36 | 0.51 |

| 60 × 8 | 0.12 | 0.13 | 0.31 | 0.42 | 0.92 | 0.62 | 0.93 |

| 80 × 4 | 0.02 | 0.02 | 0.08 | 0.11 | 0.29 | 0.18 | 0.31 |

| 80 × 6 | 0.09 | 0.13 | 0.17 | 0.23 | 0.65 | 0.46 | 0.48 |

| 80 × 8 | 0.05 | 0.09 | 0.25 | 0.33 | 0.47 | 0.28 | 0.42 |

| 100 × 4 | 0.00 | 0.00 | 0.02 | 0.03 | 0.13 | 0.03 | 0.09 |

| 100 × 6 | 0.02 | 0.02 | 0.07 | 0.11 | 0.28 | 0.16 | 0.31 |

| 100 × 8 | 0.06 | 0.06 | 0.21 | 0.39 | 0.46 | 0.31 | 0.48 |

| Ave. | 0.058 | 0.073 | 0.204 | 0.365 | 0.609 | 0.428 | 0.474 |

| Problem | ISP-MCTS | IDABC | HVNS | PSO | GAR | ISA | ABCp |

|---|---|---|---|---|---|---|---|

| 20 × 4 | 0.00 | 0.00 | 0.15 | 0.43 | 0.76 | 0.49 | 0.22 |

| 20 × 6 | 0.03 | 0.03 | 0.12 | 0.51 | 0.97 | 0.58 | 0.52 |

| 20 × 8 | 0.17 | 0.21 | 0.29 | 0.77 | 0.82 | 0.91 | 0.41 |

| 40 × 4 | 0.00 | 0.01 | 0.11 | 0.12 | 0.33 | 0.21 | 0.27 |

| 40 × 6 | 0.01 | 0.01 | 0.09 | 0.11 | 0.41 | 0.14 | 0.42 |

| 40 × 8 | 0.06 | 0.09 | 0.35 | 0.62 | 0.95 | 0.75 | 0.86 |

| 60 × 4 | 0.02 | 0.02 | 0.06 | 0.17 | 0.36 | 0.26 | 0.36 |

| 60 × 6 | 0.04 | 0.05 | 0.13 | 0.31 | 0.41 | 0.27 | 0.44 |

| 60 × 8 | 0.05 | 0.06 | 0.18 | 0.37 | 0.75 | 0.45 | 0.74 |

| 80 × 4 | 0.00 | 0.00 | 0.07 | 0.09 | 0.24 | 0.11 | 0.26 |

| 80 × 6 | 0.03 | 0.05 | 0.14 | 0.18 | 0.55 | 0.32 | 0.37 |

| 80 × 8 | 0.05 | 0.05 | 0.16 | 0.27 | 0.43 | 0.19 | 0.34 |

| 100 × 4 | 0.00 | 0.00 | 0.02 | 0.03 | 0.09 | 0.01 | 0.08 |

| 100 × 6 | 0.01 | 0.01 | 0.06 | 0.09 | 0.26 | 0.11 | 0.28 |

| 100 × 8 | 0.04 | 0.04 | 0.19 | 0.32 | 0.35 | 0.18 | 0.41 |

| Ave. | 0.034 | 0.042 | 0.141 | 0.293 | 0.512 | 0.332 | 0.399 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Shi, Y.; Chen, Z.; Yu, T.; Shirinzadeh, B.; Zhao, P. Improved SP-MCTS-Based Scheduling for Multi-Constraint Hybrid Flow Shop. Appl. Sci. 2020, 10, 6220. https://doi.org/10.3390/app10186220

Guo J, Shi Y, Chen Z, Yu T, Shirinzadeh B, Zhao P. Improved SP-MCTS-Based Scheduling for Multi-Constraint Hybrid Flow Shop. Applied Sciences. 2020; 10(18):6220. https://doi.org/10.3390/app10186220

Chicago/Turabian StyleGuo, Jian, Yaoyao Shi, Zhen Chen, Tao Yu, Bijan Shirinzadeh, and Pan Zhao. 2020. "Improved SP-MCTS-Based Scheduling for Multi-Constraint Hybrid Flow Shop" Applied Sciences 10, no. 18: 6220. https://doi.org/10.3390/app10186220

APA StyleGuo, J., Shi, Y., Chen, Z., Yu, T., Shirinzadeh, B., & Zhao, P. (2020). Improved SP-MCTS-Based Scheduling for Multi-Constraint Hybrid Flow Shop. Applied Sciences, 10(18), 6220. https://doi.org/10.3390/app10186220