Ultra-Strong Knits for Personal Protective Equipment

Abstract

1. Introduction

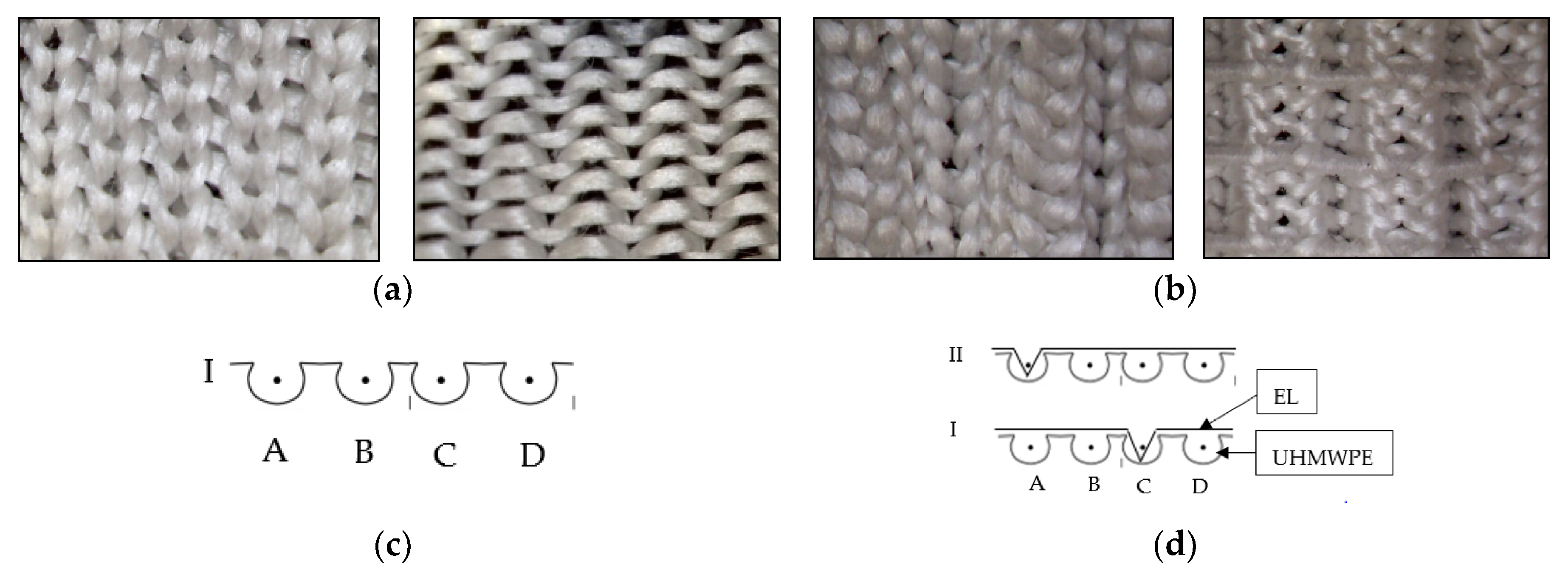

2. Materials and Methods

3. Results and Discussion

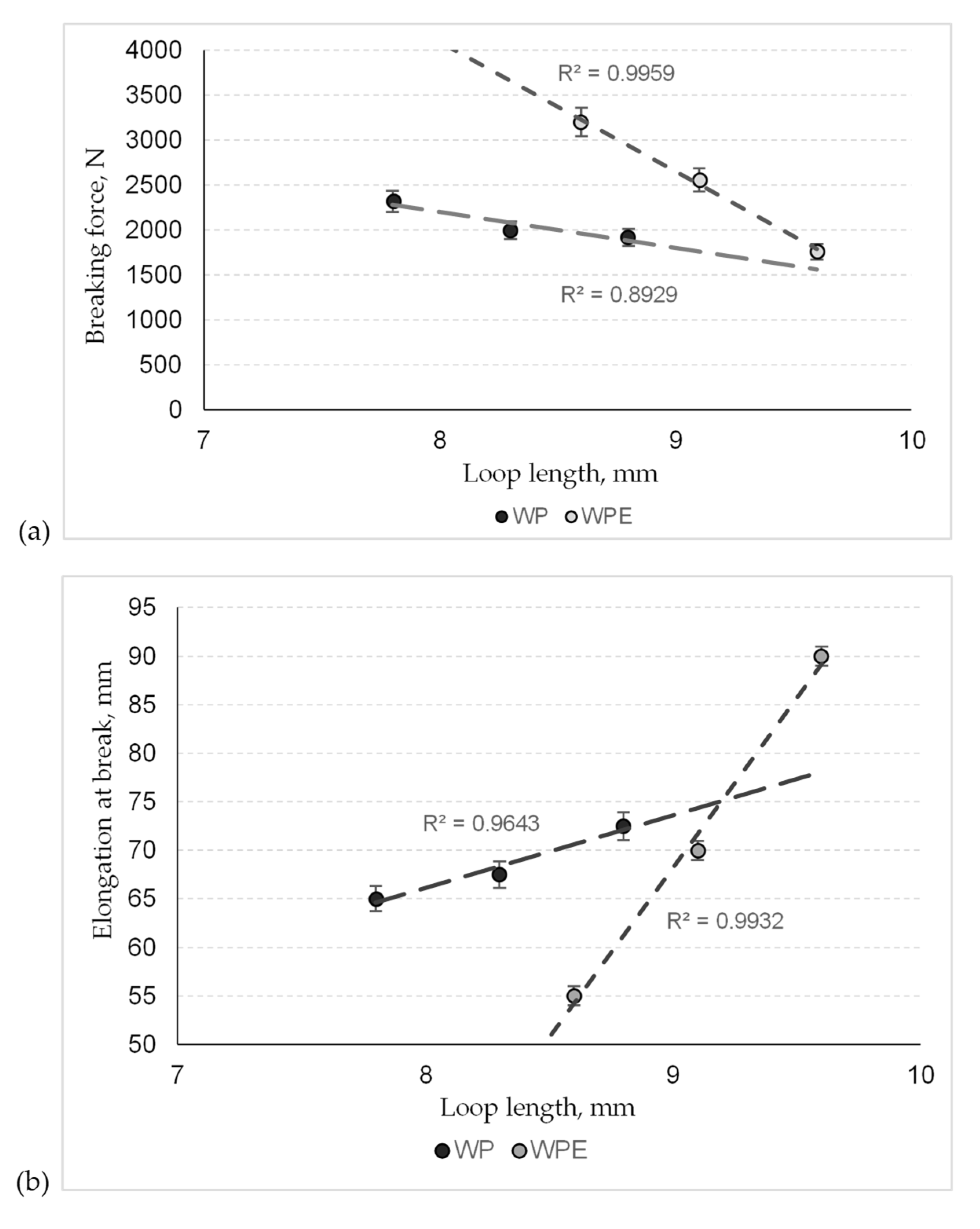

3.1. Tensile Strength

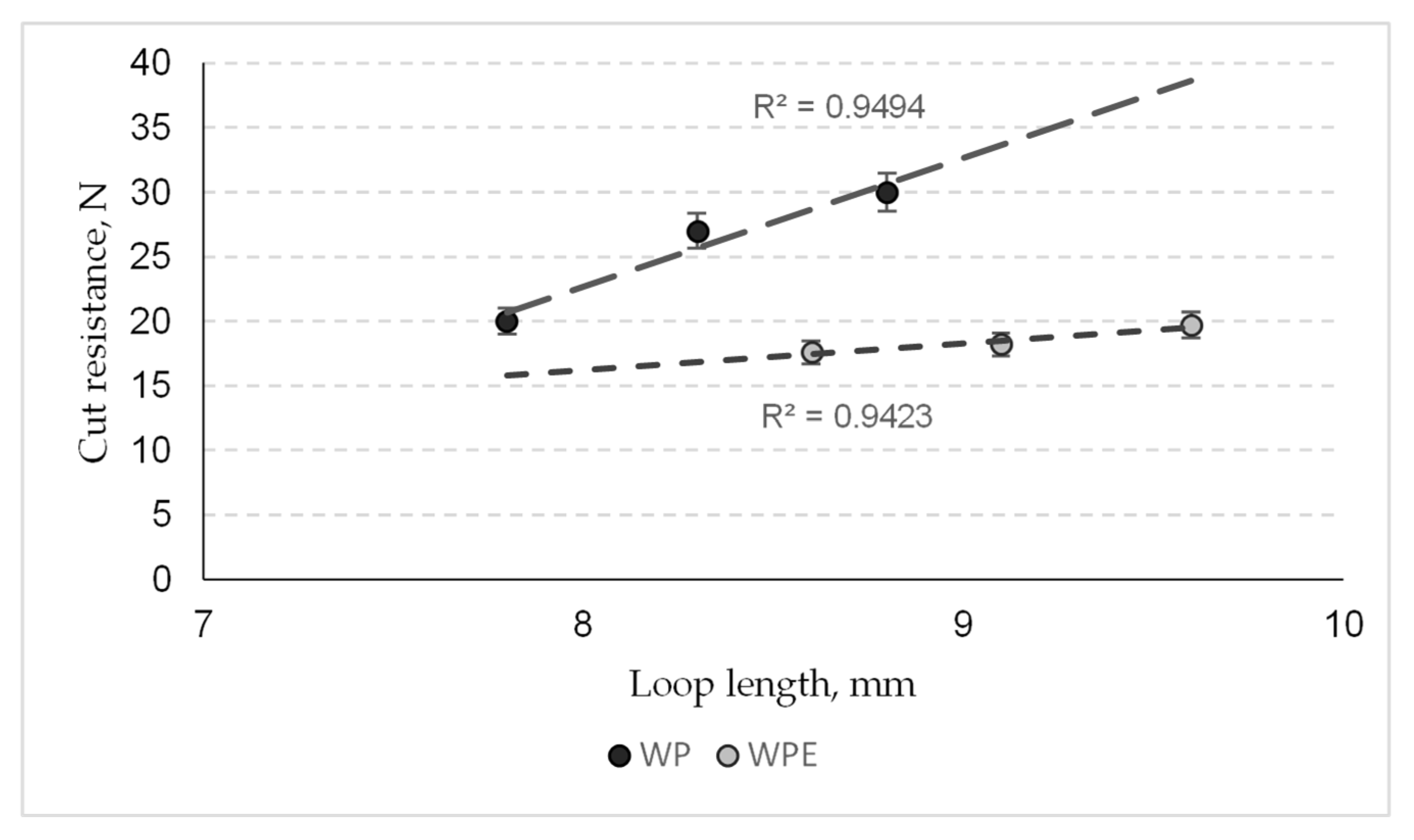

3.2. Cut Resistance

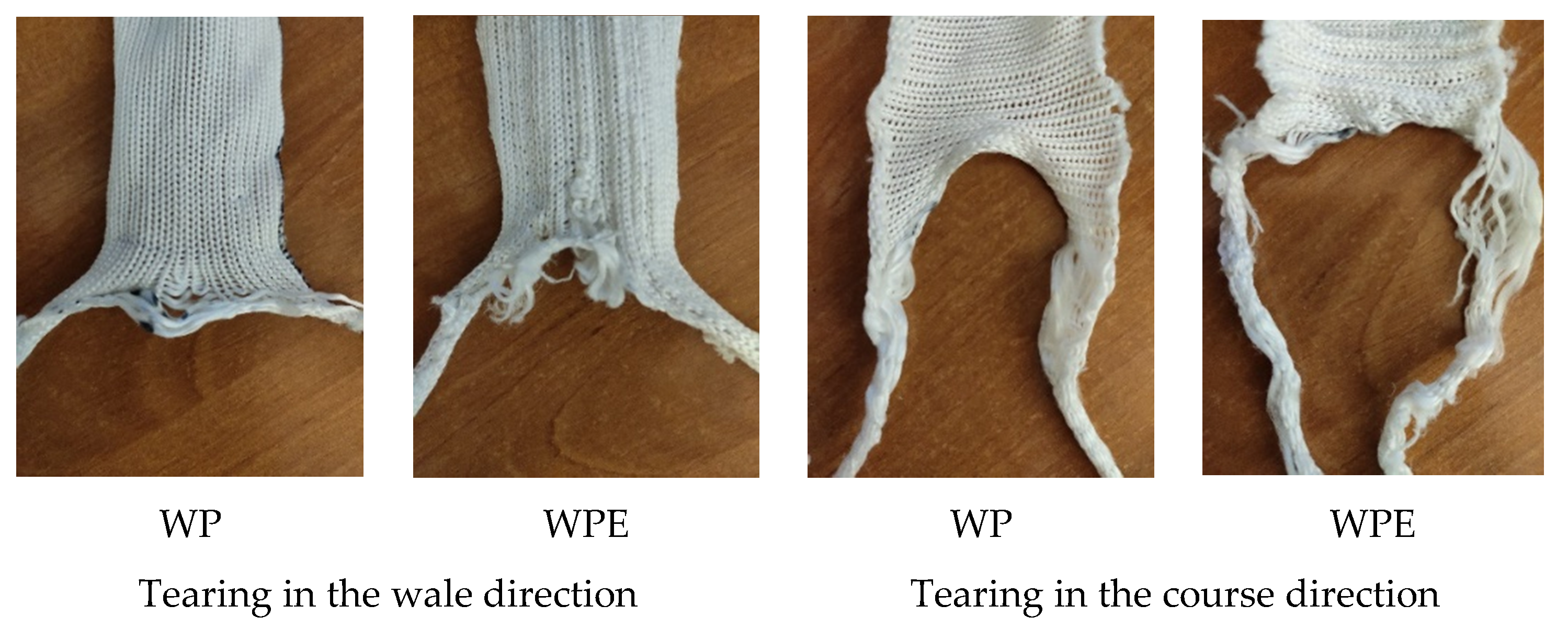

3.3. Tearing Resistance

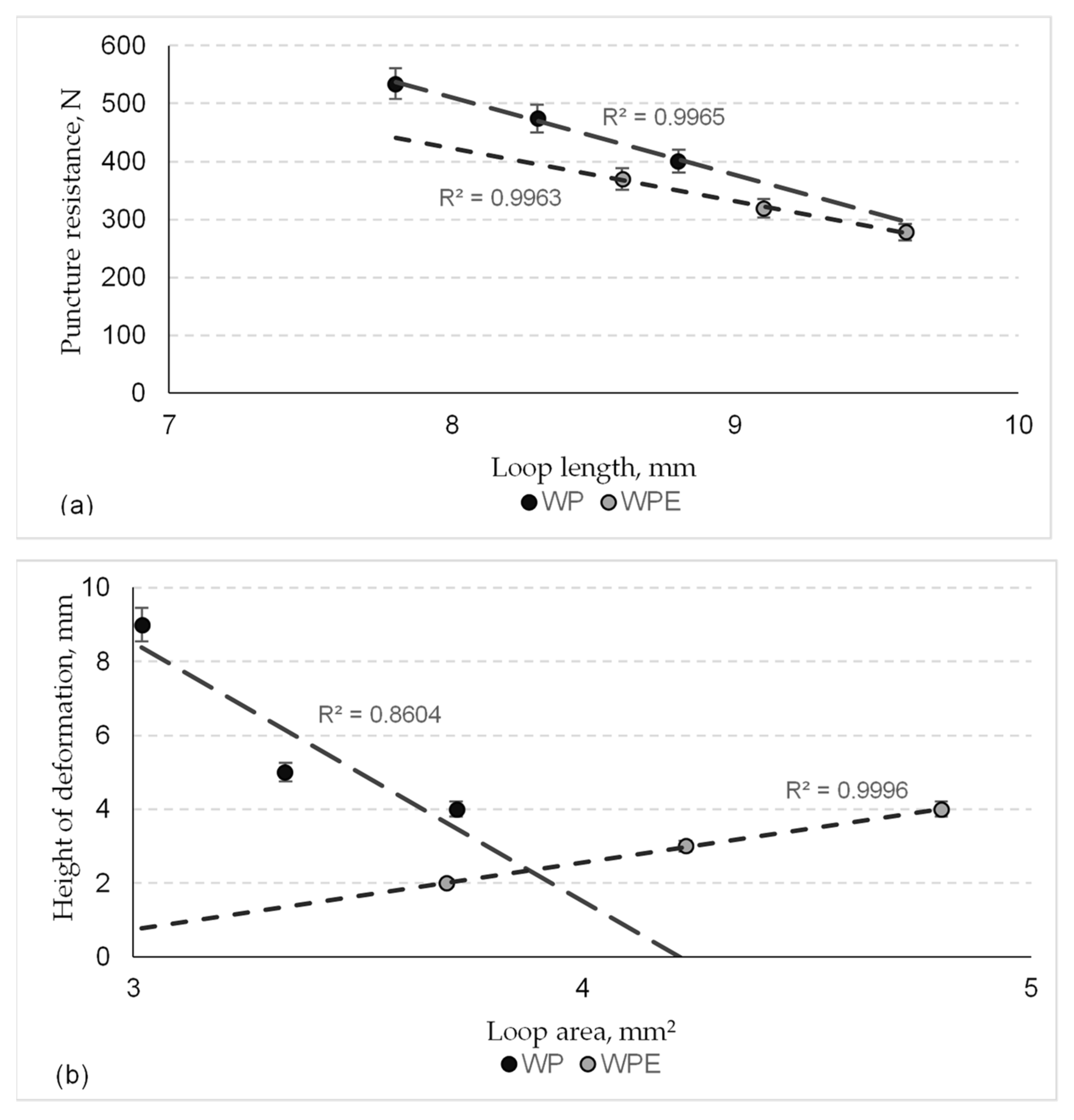

3.4. Puncture Resistance

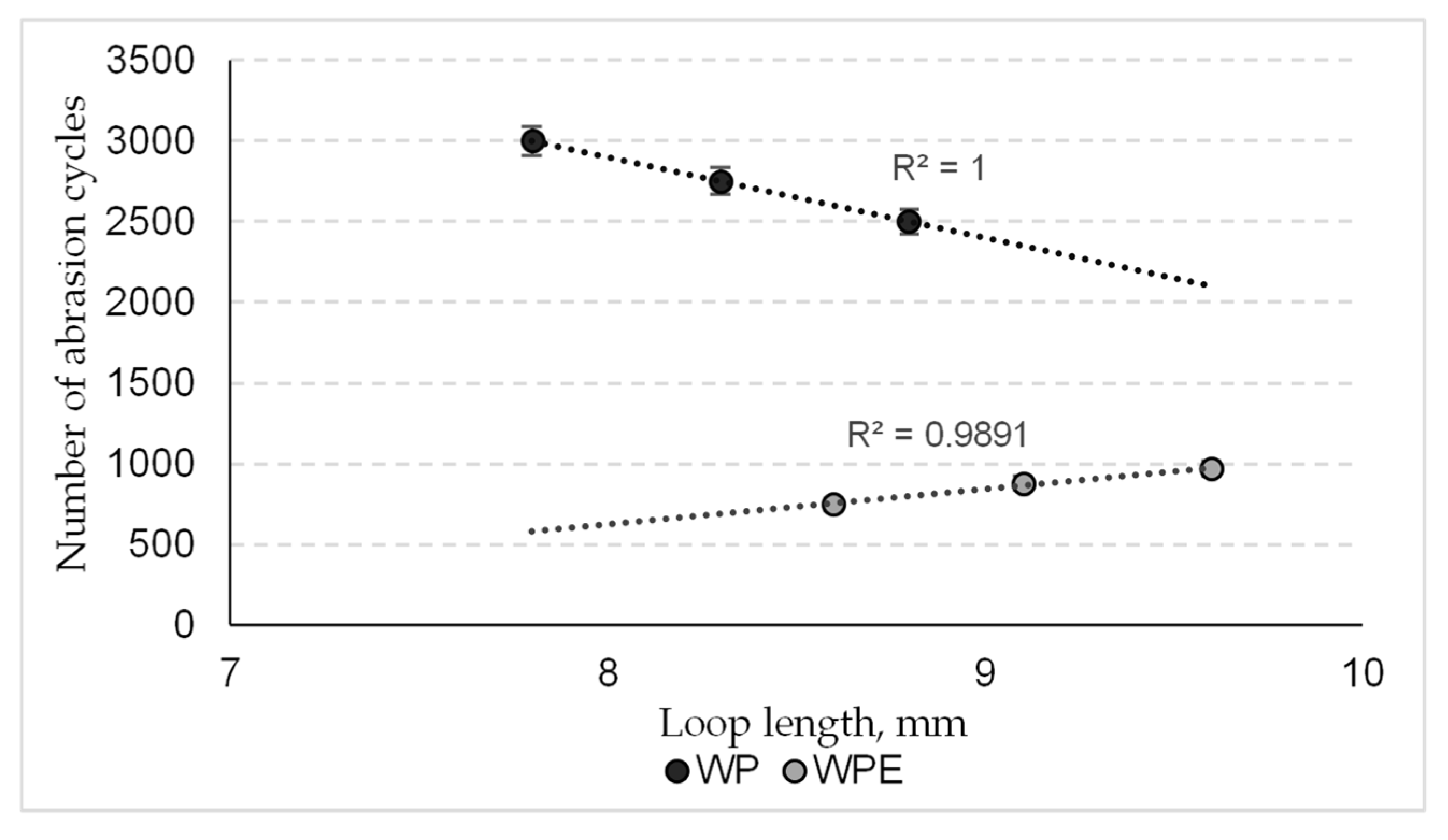

3.5. Abrasion Resitance

4. Conclusions

- An increase in the loop length of the weft plain knits with elastomeric tuck-miss laid yarn has approx. four times higher influence on the decrease of the breaking force and increases the elongation at the break when compared to weft plain knits without elastomeric yarn.

- The increase of the loop length influenced higher cut resistance. However, this influence for plain knits with elastomeric yarn is approx. three times lower than for knits without the elastomeric yarn.

- Tearing force of all investigated fabrics varied in the ranges of 217–227 N irrespectively of the tearing direction, knitting structure and differences in loop length. Moreover, samples break in the area of sample parts clamped into the top and bottom clamps while the main part of the sample remains not damaged.

- A decrease of a loop length in 1 mm can determine approx. 33% higher resistance to puncture of both plain knit variants, with and without the elastomeric yarn in the structure. However, plain knitted fabrics without the elastomeric yarn are more puncture resistant than fleece fabrics with elastomeric yarn because of different deformation abilities during the puncture.

- Abrasion resistance of the plain structure knits decreases with increases in the loop length, as the looser structure of a knit is less resistant to abrasion. However, the increase of the loop length of plain knits with elastomeric tuck-miss laid yarn leads to the increase in the abrasion resistance as the elastomeric yarn results formation of the relief surface, the convex part of which is first subjected to abrasion upon contact with the abrasive surface.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Fangueiro, R.; Carvalho, R.; Silveira, D.; Ferreira, N.; Ferreira, C.; Monteiro, F.; Sampaio, S. Development of high-performance single layer weft knitted structures for cut and puncture protection. J. Textile. Sci. Eng. 2015, 5, 225–230. [Google Scholar]

- Deniz, M.A.; Gamze, G.B. Sewability (Based on Needle Penetration Force) of 1×1 Rib Knitted Fabrics Produced with Separate Ends of Yarns. AUTEX Res. J. 2019, 19, 340–346. [Google Scholar]

- Ma, J.; Elmaaty, T.; Okubayashi, S. Effect of Supercritical Carbon Dioxide on Dyeability and Physical Properties of Ultra-High-Molecular-Weight Polyethylene Fiber. Autex Res. J. 2019, 19, 228–235. [Google Scholar] [CrossRef]

- Guo, Z.; Martinez-Morales, S.; Chen, W. Projectile strength effects on the ballistic impact response of soft armor targets. Text. Res. J. 2020, 90, 282–293. [Google Scholar] [CrossRef]

- Naveen, J.; Jawaid, M.; Zainudin, E.S.; Sultan, M.T.H.; Yahaya, R. Effect of graphene nanoplatelets on the ballistic performance of hybrid Kevlar/Cocos nucifera sheath-reinforced epoxy composites. Text. Res. J. 2019, 89, 4349–4362. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Wang, Y.L.; Huang, Y.; Wan, Y.Z. Preparation and properties of three-dimensional braided UHMWPE fiber reinforced PMMA composites. J. Reinf. Plast. Compos. 2006, 25, 1601–1609. [Google Scholar] [CrossRef]

- Roylance, D.; Wilde, A.; Tocci, G. Ballistic impact of textile structures. Text. Res. J. 1973, 43, 34–41. [Google Scholar] [CrossRef]

- Mikucioniene, D.; Arbataitis, E. Comparative Analysis of the Influence of Bamboo and Other Cellulose Fibres on Selected Structural Parameters and Physical Properties of Knitted Fabrics. Fib. Text. East. Eur. 2013, 21, 76–80. [Google Scholar]

- Guo, N.; Sun, M.; Cheng, L.; Jiang, C.; Chen, W.; Jing, L. Strength characteristic and failure criterion of flexible multi-axial warp-knitted fabrics coated with polyurethane on single side. J. Indust. Text. 2019, 49, 318–327. [Google Scholar] [CrossRef]

- Mikucioniene, D.; Ciukas, R.; Mickeviciene, A. The Influence of Knitting Structure on Mechanical Properties of Weft Knitted Fabrics. Mat. Scien.-Medzg. 2010, 16, 221–225. [Google Scholar]

- Mikucioniene, D.; Milasiute, L.; Milasius, R. Influence of Knits Structure on Flammability and Comfortability. Autex Res. J. 2014, 14, 226–232. [Google Scholar] [CrossRef]

- Krauledaite, J.; Ancutiene, K.; Urbelis, V.; Krauledas, S.; Sacevičiene, V. Development and evaluation of 3D knitted fabrics to protect against mechanical risk. J. Indust. Text. 2019, 49, 383–401. [Google Scholar] [CrossRef]

- Hussainn, S.; Glombikova, V.; Akhtar, N.; Mazari, A.; Mansoor, T.; Khan, K. Liquid Moisture Transportation Properties of Functional Underwears: Part 1. Autex Res. J. 2019, 19, 97–103. [Google Scholar] [CrossRef]

- Bivainyte, A.; Mikucioniene, D. Influence of Shrinkage on Air and Water Vapour Permeability of Double-Layered Weft Knitted Fabrics. Mat. Sci.-Medzg. 2012, 18, 271–274. [Google Scholar] [CrossRef]

- Kiekens, P.; Jayaraman, S. Intelligent Textiles and Clothing for Balistic and NBC Protection. Technology at the Cutting Edge (NATO Science for Peace and Security Series B: Physics and Biophysics); Springer: Dordrecht, The Netherlands; Berlin/Heidelberg, Germany, 2012; pp. 1–29. [Google Scholar]

- Li, M.; Wang, P.; Boussu, F.; Soulat, D. Effect of Fabric Architecture on Tensile Behaviour of the High-Molecular-Weight Polyethylene 3-Dimensional Interlock Composite Reinforcements. Polymers 2020, 12, 1045. [Google Scholar] [CrossRef] [PubMed]

- Abtewa, M.A.; Boussu, F.; Bruniauxa, P.; Loghinc, C.; Cristian, I. Ballistic impact mechanisms—A review on textiles and fibre-reinforced composites impact responses. Comp. Struct. 2019, 223, 110966. [Google Scholar] [CrossRef]

| Sample Code | Loop Length, mm | Wale Density, cm−1 | Course Density, cm−1 | Loop Area, mm2 | Area Density, g/m2 | Thickness, mm |

|---|---|---|---|---|---|---|

| WP1 | 7.8 | 4.6 | 7.2 | 3.02 | 343 | 1.41 |

| WP2 | 8.3 | 4.4 | 6.8 | 3.34 | 337 | 1.31 |

| WP3 | 8.8 | 4.2 | 6.4 | 3.72 | 323 | 1.22 |

| WPE1 | 8.6 | 6.4 | 7.0 | 2.23 | 715 | 1.80 |

| WPE2 | 9.1 | 6.0 | 6.4 | 2.60 | 569 | 1.65 |

| WPE3 | 9.6 | 5.0 | 6.0 | 3.34 | 433 | 1.50 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikucioniene, D.; Halavska, L.; Bobrova, S.; Ielina, T.; Milasius, R. Ultra-Strong Knits for Personal Protective Equipment. Appl. Sci. 2020, 10, 6197. https://doi.org/10.3390/app10186197

Mikucioniene D, Halavska L, Bobrova S, Ielina T, Milasius R. Ultra-Strong Knits for Personal Protective Equipment. Applied Sciences. 2020; 10(18):6197. https://doi.org/10.3390/app10186197

Chicago/Turabian StyleMikucioniene, Daiva, Liudmyla Halavska, Svitlana Bobrova, Tetiana Ielina, and Rimvydas Milasius. 2020. "Ultra-Strong Knits for Personal Protective Equipment" Applied Sciences 10, no. 18: 6197. https://doi.org/10.3390/app10186197

APA StyleMikucioniene, D., Halavska, L., Bobrova, S., Ielina, T., & Milasius, R. (2020). Ultra-Strong Knits for Personal Protective Equipment. Applied Sciences, 10(18), 6197. https://doi.org/10.3390/app10186197