A Low-Autogenous-Shrinkage Alkali-Activated Slag and Fly Ash Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mixtures

2.3. Experimental Methods

2.3.1. Autogenous Shrinkage of Paste

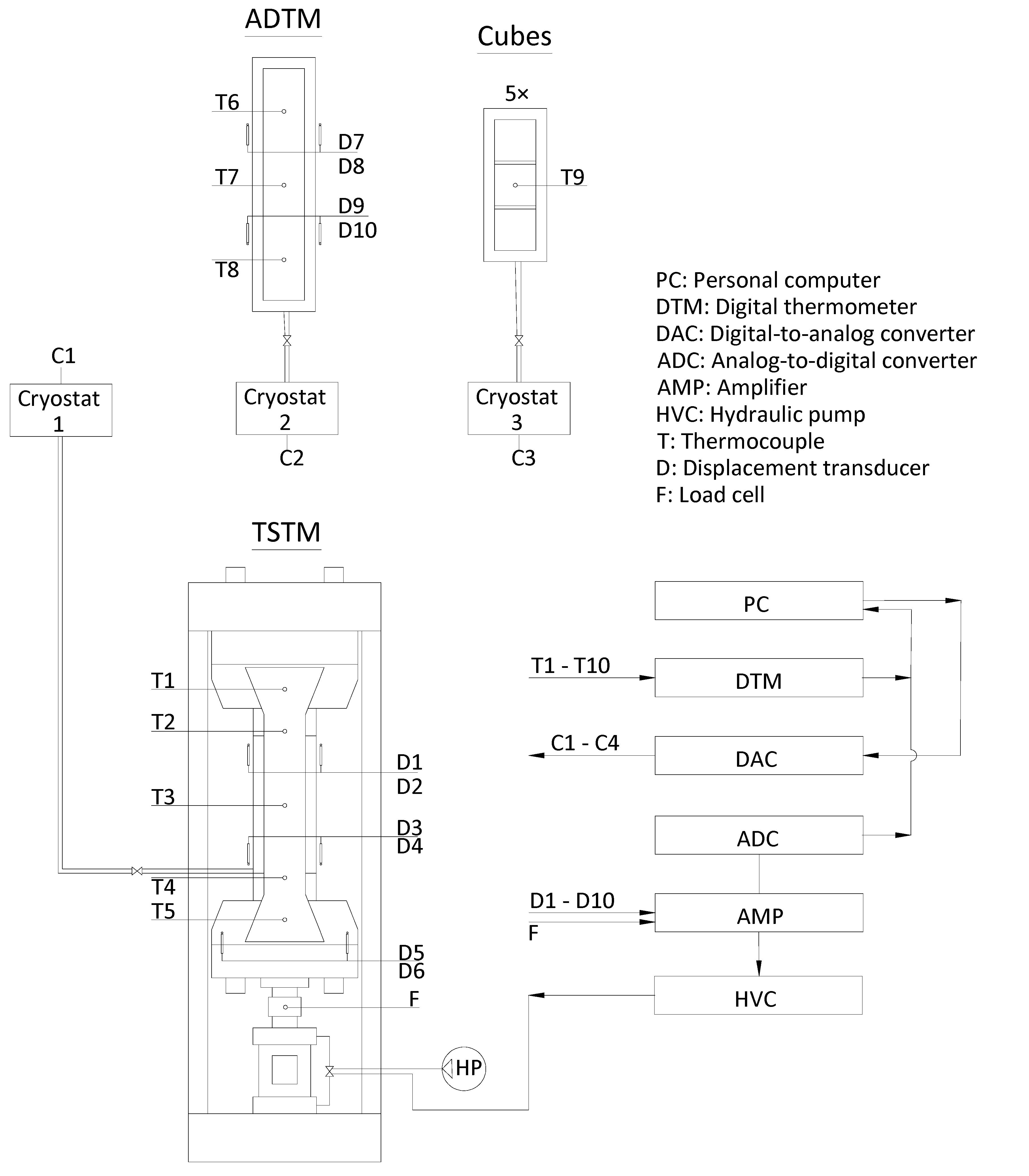

2.3.2. Cracking Potential of Paste

2.3.3. Workability of Concrete

2.3.4. Autogenous Shrinkage of Concrete

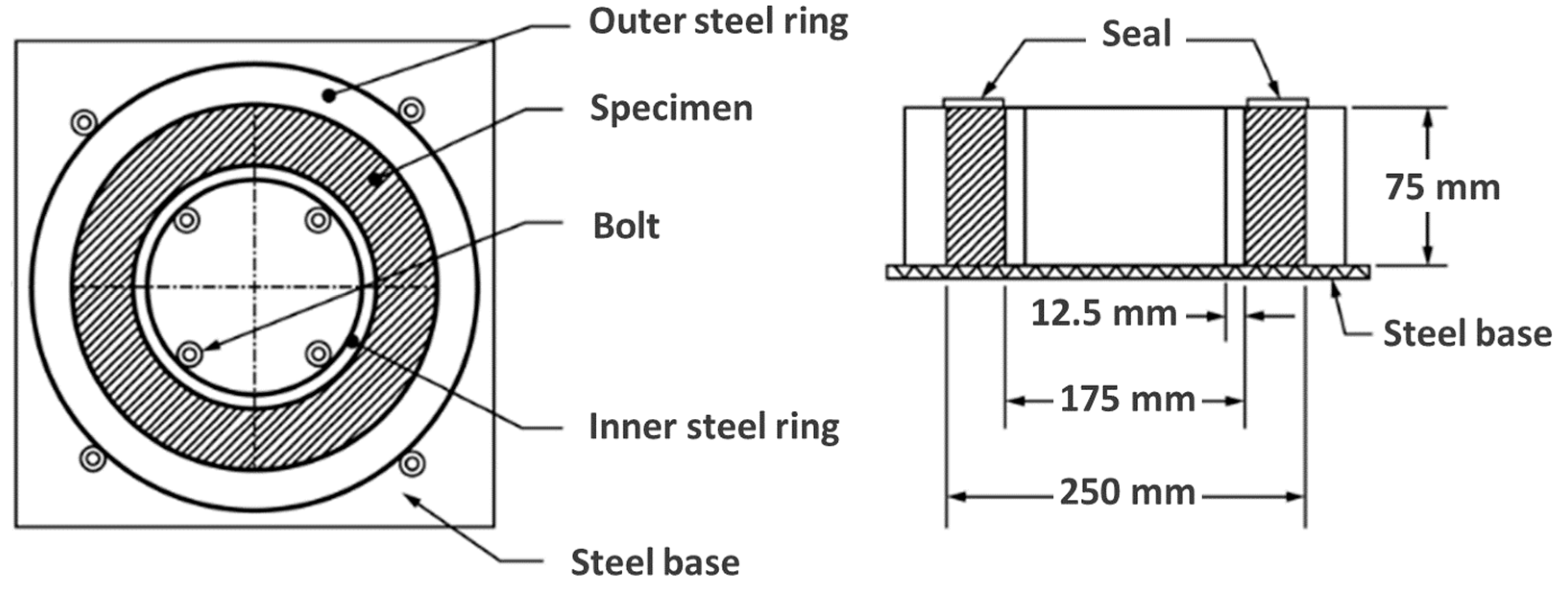

2.3.5. Cracking Potential of Concrete

2.3.6. Strength of Concrete

3. Results and Discussion

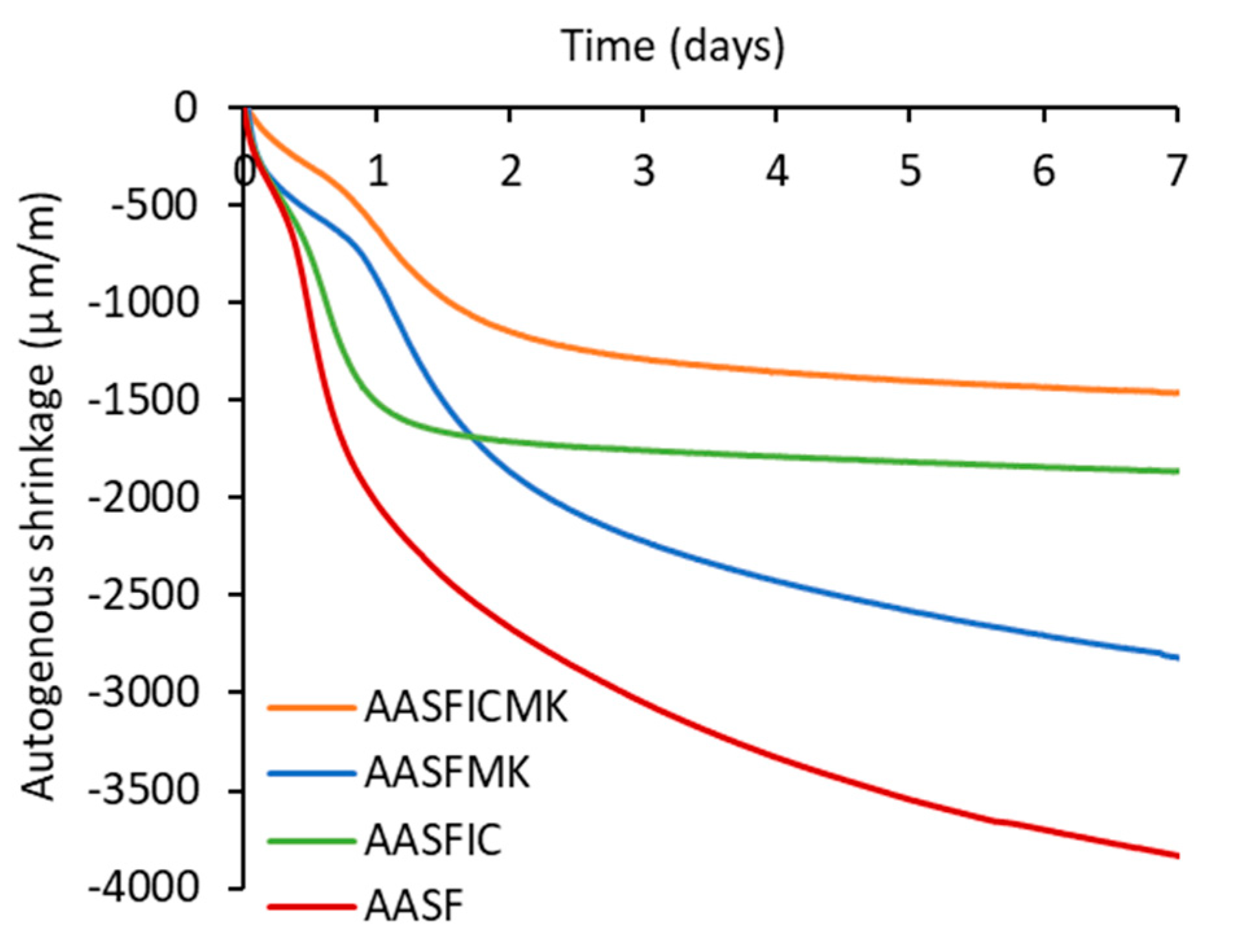

3.1. Autogenous Shrinkage of Paste

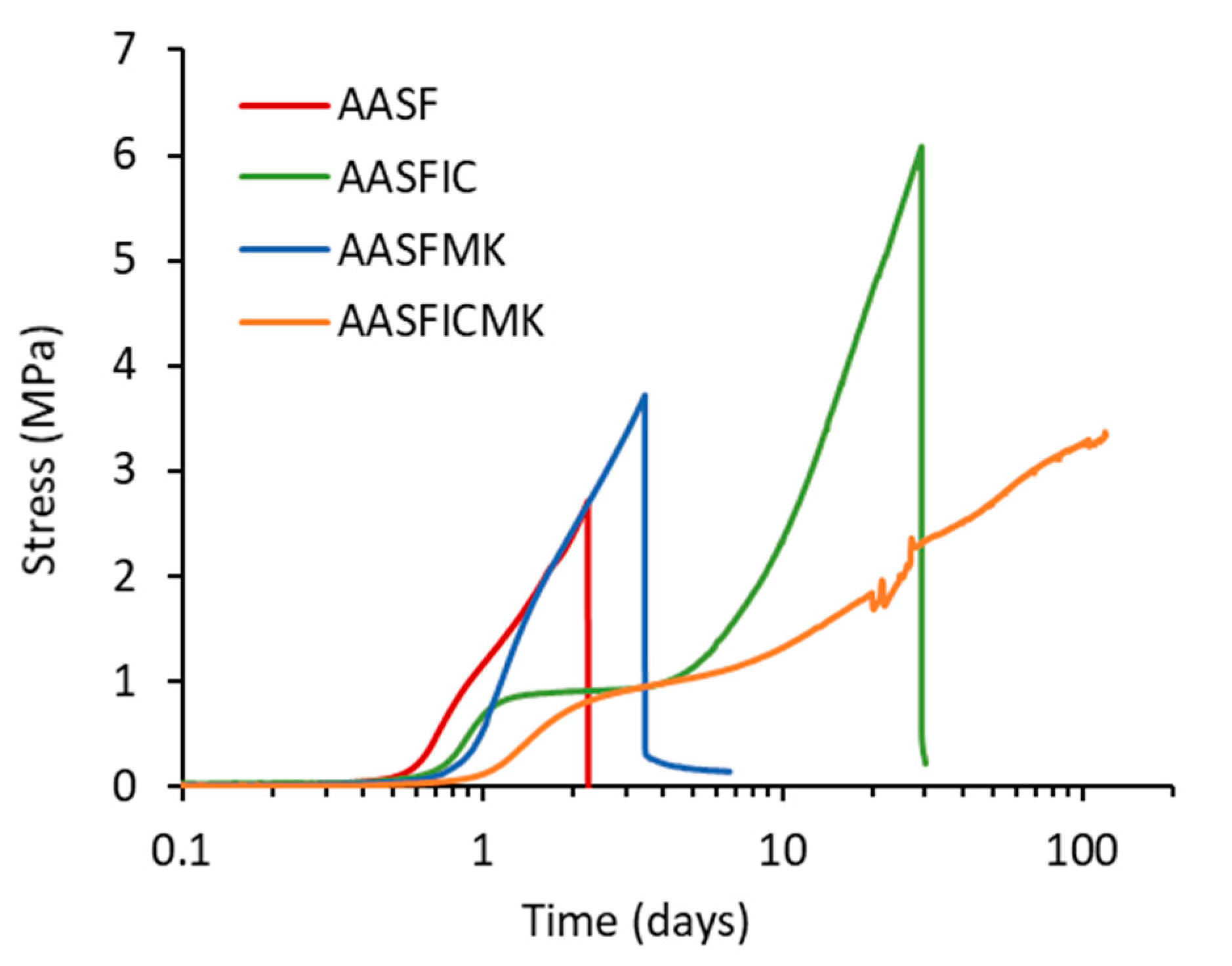

3.2. Cracking Potential of Paste

3.3. Workability and Consistence of Fresh Concrete

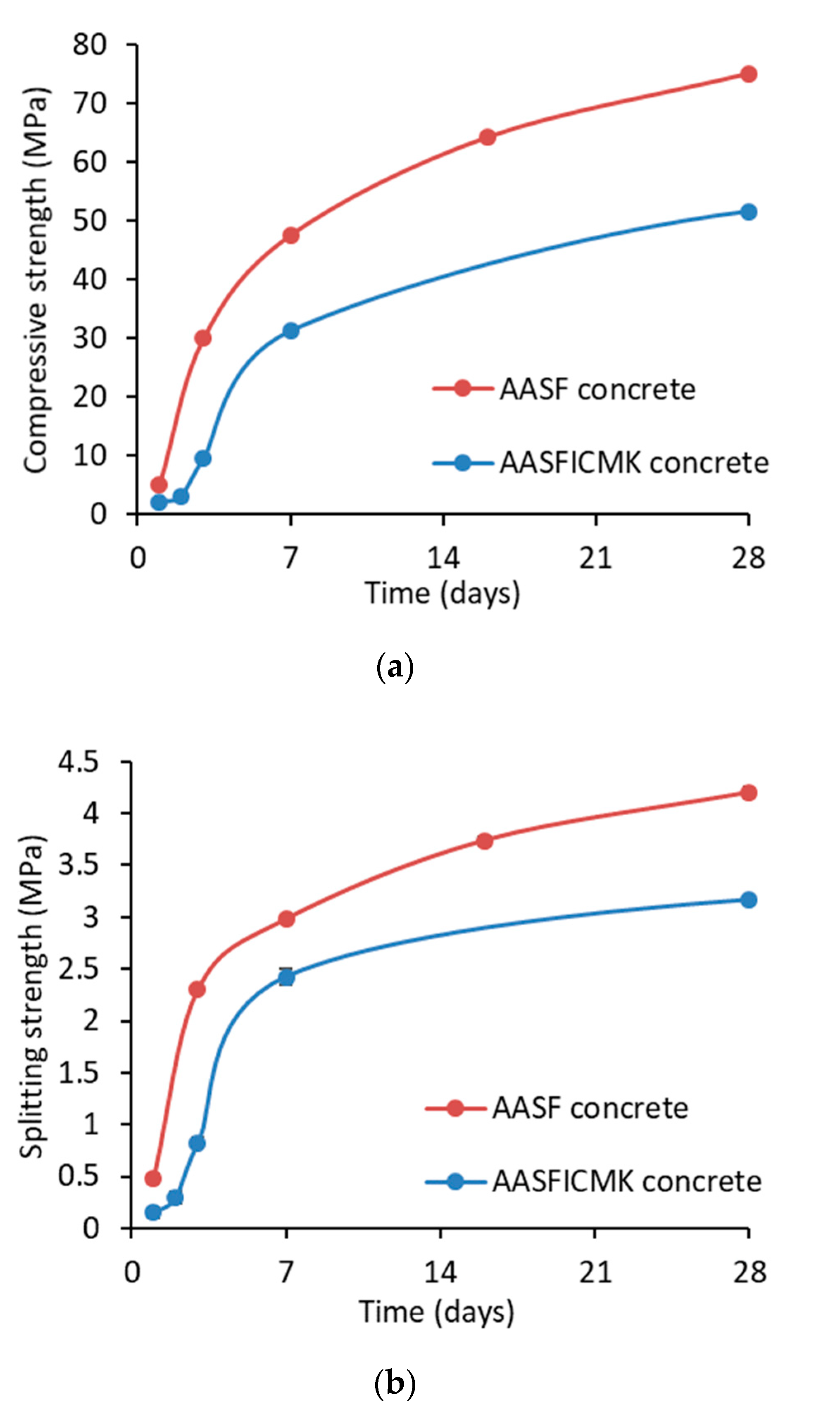

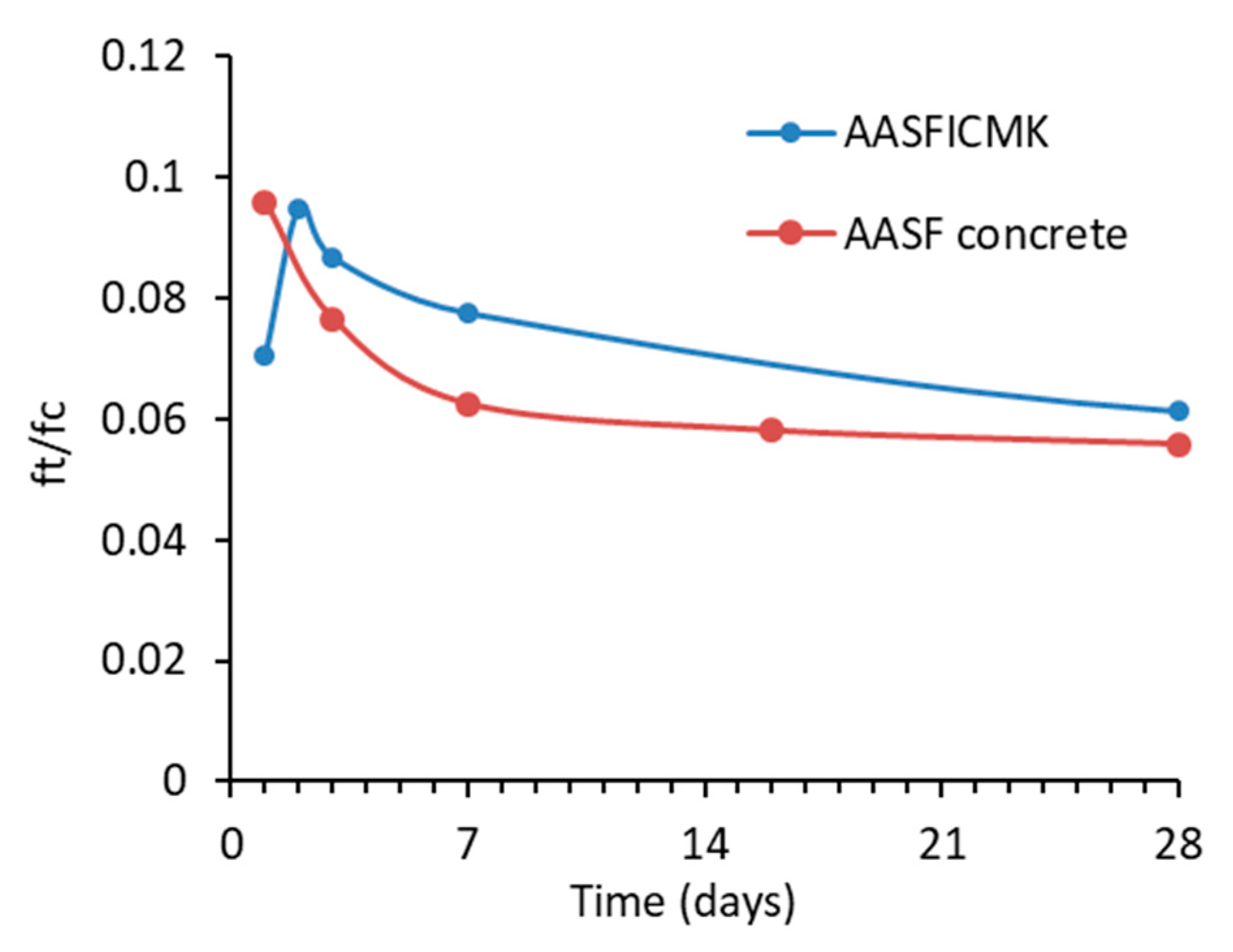

3.4. Strength of Concrete

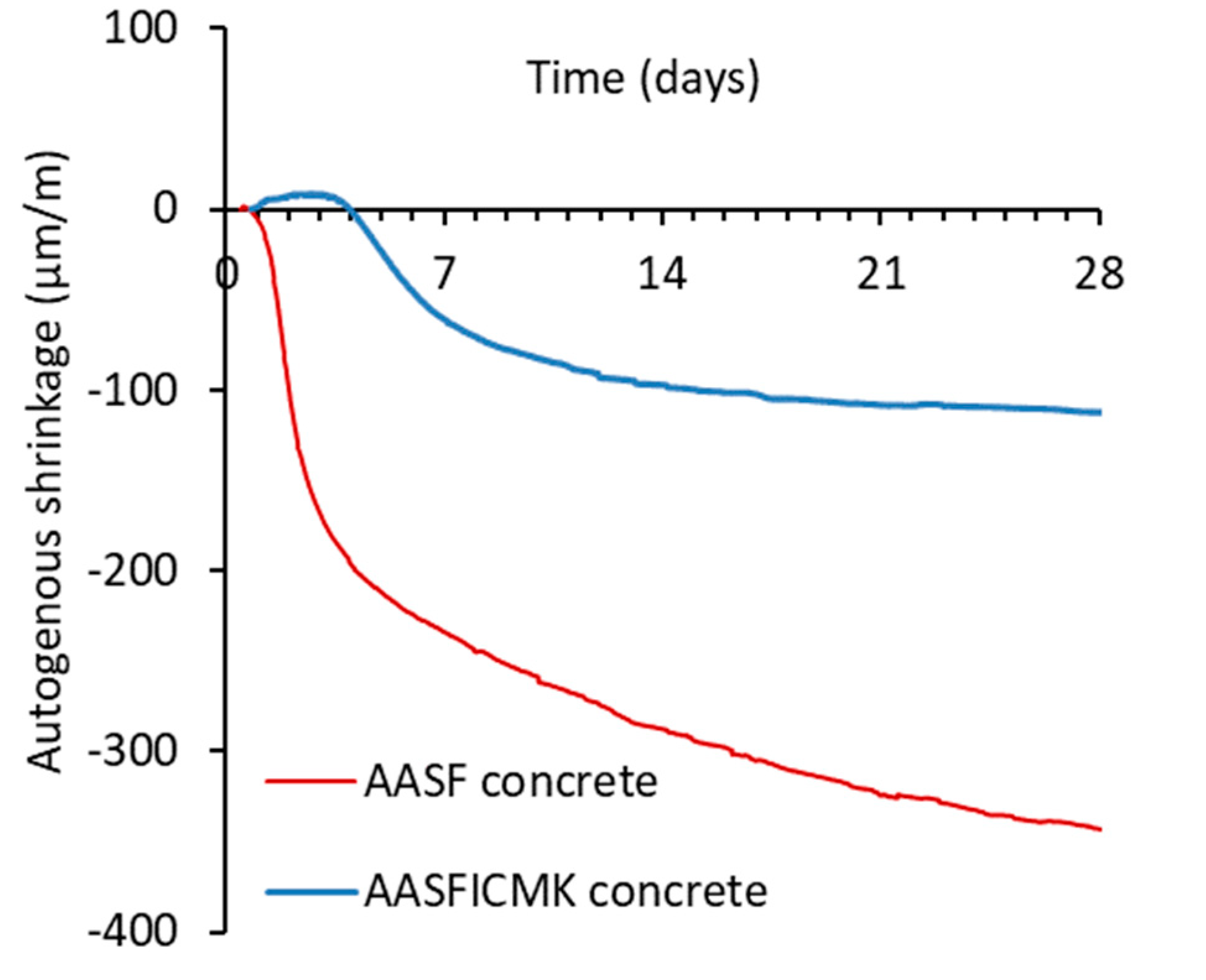

3.5. Autogenous Shrinkage of Concrete

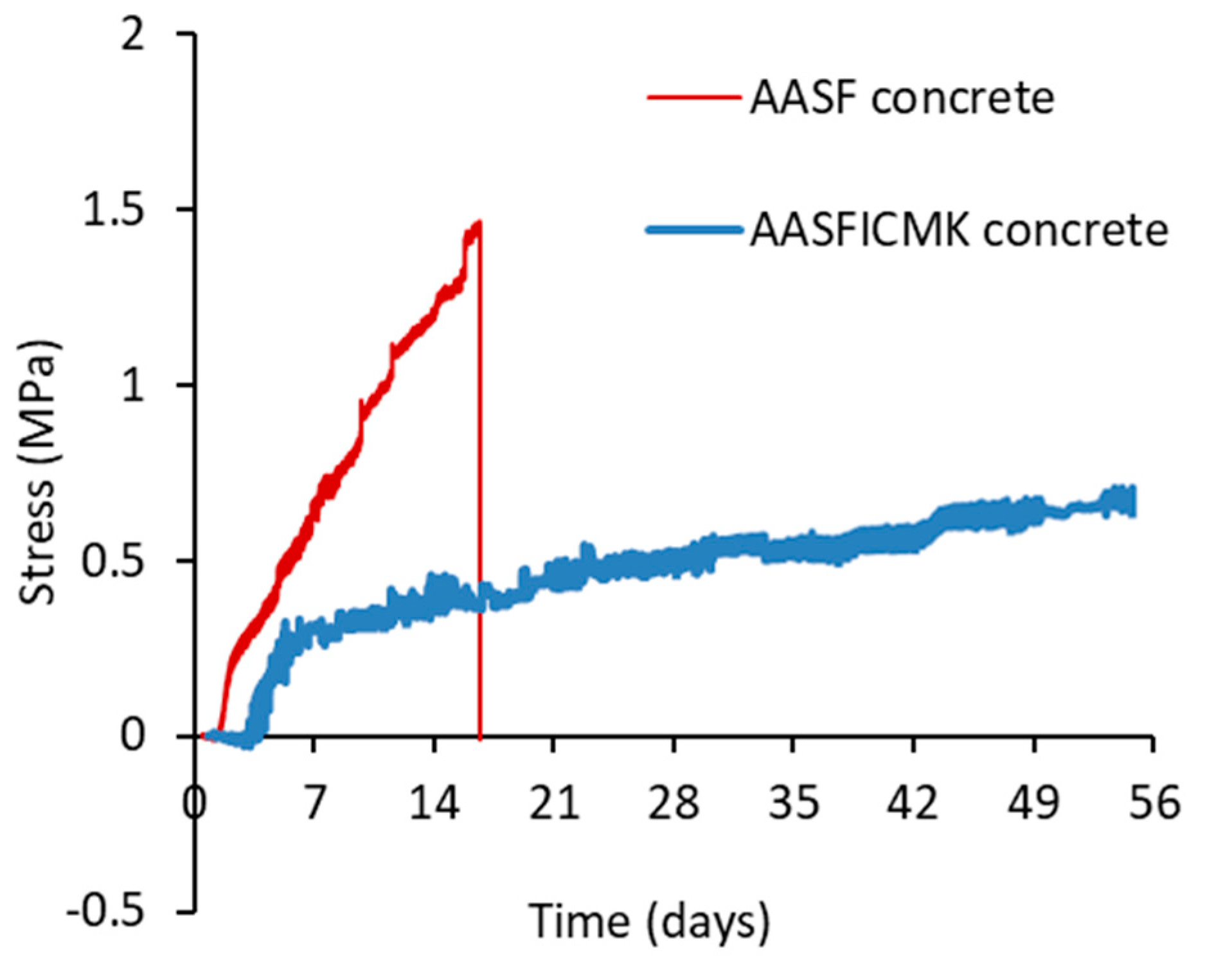

3.6. Cracking Potential of Concrete

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S.J. The role of inorganic polymer technology in the development of ‘green concrete’. Cem. Concr. Res. 2007, 37, 1590–1597. [Google Scholar] [CrossRef]

- Provis, J.L.; Van Deventer, J.S.J. Geopolymers: Structures, Processing, Properties and Industrial Applications; Woodhead: Cambridge, UK, 2009. [Google Scholar]

- Arbi, K.; Nedeljković, M.; Zuo, Y.; Ye, G. A Review on the Durability of Alkali-Activated Fly Ash/Slag Systems: Advances, Issues, and Perspectives. Ind. Eng. Chem. Res. 2016, 55, 5439–5453. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Constr. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Cartwright, C.; Rajabipour, F.; Radli, A. Shrinkage Characteristics of Alkali-Activated Slag Cements. J. Mater. Civ. Eng. 2014, 27, 1–9. [Google Scholar] [CrossRef]

- Nedeljković, M.; Li, Z.; Ye, G. Setting, Strength, and Autogenous Shrinkage of Alkali-Activated Fly Ash and Slag Pastes: Effect of Slag Content. Materials 2018, 11, 2121. [Google Scholar] [CrossRef]

- Bilek, V., Jr.; Kalina, L.; Fojtík, O. Shrinkage-Reducing Admixture Efficiency in Alkali-Activated Slag across the Different Doses of Activator. In Key Engineering Materials; Trans Tech Publications Ltd.: Zurich, Switzerland, 2018; Volume 761, pp. 19–22. [Google Scholar]

- Ye, H.; Radlińska, A. Shrinkage mitigation strategies in alkali-activated slag. Cem. Concr. Res. 2017, 101, 131–143. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.G.; Cheng, Y. Effect of elevated temperature curing on properties of alkali-activated slag concrete. Cem. Concr. Res. 1999, 29, 1619–1625. [Google Scholar] [CrossRef]

- Li, Z.; Nedeljković, M.; Chen, B.; Ye, G. Mitigating the autogenous shrinkage of alkali-activated slag by metakaolin. Cem. Concr. Res. 2019, 122, 30–41. [Google Scholar] [CrossRef]

- Li, Z.; Wyrzykowski, M.; Dong, H.; Granja, J.; Azenha, M.; Lura, P.; Ye, G. Internal curing by superabsorbent polymers in alkali-activated slag. Cem. Concr. Res. 2020, 135, 106123. [Google Scholar] [CrossRef]

- Tu, W.; Zhu, Y.; Fang, G.; Wang, X.; Zhang, M. Internal curing of alkali-activated fly ash-slag pastes using superabsorbent polymer. Cem. Concr. Res. 2019, 116, 179–190. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Liang, X.; Ye, G. Internal curing of alkali-activated slag-fly ash paste with superabsorbent polymers. Constr. Build. Mater. 2020. under peer review. [Google Scholar]

- Li, Z.; Ye, G. Experimental study of the chemical deformation of metakaolin based geopolymer. In Proceedings of the SynerCrete’18 International Conference on Interdisciplinary Approaches for Cement-based Materials and Structural Concrete, Funchal, Portugal, 24–26 October 2018; pp. 443–448. [Google Scholar]

- ASTM C1608. Standard Test Method for Chemical Shrinkage of Hydraulic Cement Paste; ASTM: West Conshohocken, PA, USA, 2007; pp. 667–670. [Google Scholar]

- Li, Z.; Zhang, S.; Zuo, Y.; Chen, W.; Ye, G. Chemical deformation of metakaolin based geopolymer. Cem. Concr. Res. 2019, 120, 108–118. [Google Scholar] [CrossRef]

- Li, Z.; Liang, X.; Chen, Y.; Ye, G. Effect of metakaolin on the autogenous shrinkage of alkali-activated slag-fly ash paste. Constr. Build. Mater. 2020. under peer review. [Google Scholar]

- ASTM C1968. Standard Test Method for Autogenous Strain of Cement Paste and Mortar; ASTM: West Conshohocken, PA, USA, 2013; pp. 1–8. [Google Scholar] [CrossRef]

- Li, Z.; Lu, T.; Liang, X.; Dong, H.; Ye, G. Mechanisms of autogenous shrinkage of alkali-activated slag and fly ash pastes. Cem. Concr. Res. 2020, 135, 106107. [Google Scholar] [CrossRef]

- Eren, Ö.; Abdalkader, A.H.M. Plastic shrinkage cracking of fiber reinforced concrete. In Proceedings of the 10th East Asia-Pacific Conference on Structural Engineering and Construction (EASEC), Bankok, Thailand, 3–5 August 2006; pp. 473–480. [Google Scholar] [CrossRef]

- Hossain, A.B.; Weiss, J. Assessing residual stress development and stress relaxation in restrained concrete ring specimens. Cem. Concr. Compos. 2004, 26, 531–540. [Google Scholar] [CrossRef]

- ASTM C1581. Standard Test Method for Determining Age at Cracking and Induced Tensile Stress Characteristics of Mortar and Concrete under Restrained Shrinkage; ASTM: West Conshohocken, PA, USA, 2009; pp. 1–7. [Google Scholar] [CrossRef]

- Schlitter, J.L.; Senter, A.H.; Bentz, D.P.; Nantung, T.; Weiss, W.J. A dual concentric ring test for evaluating residual stress development due to restrained volume change. J. ASTM Int. 2010, 7, 1–13. [Google Scholar]

- NEN-EN 12350-2. Testing Fresh Concrete—Part 2: Slump-Test; BSI: London, UK, 2009. [Google Scholar]

- ASTM C191. Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle BT—Standard Test Methods for Time of Setting of Hydraulic Cement by Vicat Needle; ASTM: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Lokhorst, S.J. Deformational Behaviour of Concrete Influenced by Hydration Related Changes of the Microstructure; Delft University of Technology: Delft, The Netherlands, 2001. [Google Scholar]

- NEN-EN 12390-3. Testing hardened concrete—Part 3: Compressive Strength of Test Specimens; BSI: London, UK, 2009. [Google Scholar]

- Sule, M.S. Effect of Reinforcement on Early-Age Cracking in High Strength Concrete; Delft University of Technology: Delft, The Netherlands, 2003. [Google Scholar]

- Lura, P. Autogenous Deformation and Internal Curing of Concrete; Delft University of Technology: Delft, The Netherlands, 2003. [Google Scholar]

- Lu, T.; Li, Z.; Huang, H. Effect of Supplementary Materials on the Autogenous Shrinkage of Cement Paste. Materials 2020, 13, 3367. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, S.; Liang, X.; Ye, G. Cracking potential of alkali-activated slag and fly ash concrete subjected to restrained autogenous shrinkage. Cem. Concr. Compos. 2020, 103767. [Google Scholar] [CrossRef]

- NEN-EN 12350-8. Testing Fresh Concrete—Part 8: Self-Compacting Concrete—Slump-Flow Test; BSI: London, UK, 2019. [Google Scholar]

- ACI (American Concrete Institute). Building Code Requirements for Structural Concrete and Commentary; ACI: Brussels, Belgium, 2011. [Google Scholar]

- Arioglu, N.; Canan Girgin, Z.; Arioglu, E. Evaluation of ratio between splitting tensile strength and compressive strength for concretes up to 120 MPa and its application in strength criterion. ACI Mater. J. 2006, 103, 18–24. [Google Scholar]

- Li, Z.; Lu, T.; Chen, Y.; Wu, B.; Ye, G. Prediction of the autogenous shrinkage of alkali-activated slag and fly ash concrete. Mater. Struct. 2020. under peer review. [Google Scholar]

- Darquennes, A.; Staquet, S.; Delplancke-Ogletree, M.P.; Espion, B. Effect of autogenous deformation on the cracking risk of slag cement concretes. Cem. Concr. Compos. 2011, 33, 368–379. [Google Scholar] [CrossRef]

| Oxide (wt. %) | SiO2 | Al2O3 | CaO | MgO | Fe2O3 | SO3 | K2O | TiO2 | Other |

|---|---|---|---|---|---|---|---|---|---|

| Slag | 31.8 | 13.3 | 40.5 | 9.3 | 0.5 | 1.5 | 0.3 | 1.0 | 1.9 |

| Fly ash | 56.8 | 23.8 | 4.8 | 1.5 | 7.2 | 0.3 | 1.6 | 1.2 | 2.8 |

| MK | 55.1 | 38.4 | 0.6 | - | 2.6 | - | 0.2 | 1.1 | 2.1 |

| Particle Size (µm) | Density (g/cm3) | |||

|---|---|---|---|---|

| D10 | D50 | D90 | ||

| Slag | 4.6 | 18.3 | 33.2 | 2.9 |

| Fly ash | 10.6 | 48.1 | 83.4 | 2.4 |

| MK | 27.0 | 69.4 | 113.5 | 2.7 |

| Composition (wt. %) | AASF Paste | AASFIC | AASFMK | AASFICMK |

|---|---|---|---|---|

| Slag | 1 | 1 | 0.9 | 0.9 |

| Fly ash | 1 | 1 | 1 | 1 |

| Activator | 1 | 1 | 1 | 1 |

| SAPs | - | 0.0032 | - | 0.0032 |

| Extra activator for internal curing | - | 0.064 | - | 0.064 |

| MK | - | - | 0.1 | 0.1 |

| Composition (kg/m3 of Concrete) | AASF Concrete | AASFICMK Concrete |

|---|---|---|

| Slag | 200 | 180 |

| Fly ash | 200 | 200 |

| Activator | 200 | 200 |

| SAPs | - | 0.64 |

| Extra activator for internal curing | - | 12.8 |

| MK | - | 20 |

| Aggregate (0–4 mm) | 789 | 789 |

| Aggregate (4–8 mm) | 440 | 440 |

| Aggregate (8–16 mm) | 525 | 525 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yao, X.; Chen, Y.; Lu, T.; Ye, G. A Low-Autogenous-Shrinkage Alkali-Activated Slag and Fly Ash Concrete. Appl. Sci. 2020, 10, 6092. https://doi.org/10.3390/app10176092

Li Z, Yao X, Chen Y, Lu T, Ye G. A Low-Autogenous-Shrinkage Alkali-Activated Slag and Fly Ash Concrete. Applied Sciences. 2020; 10(17):6092. https://doi.org/10.3390/app10176092

Chicago/Turabian StyleLi, Zhenming, Xingliang Yao, Yun Chen, Tianshi Lu, and Guang Ye. 2020. "A Low-Autogenous-Shrinkage Alkali-Activated Slag and Fly Ash Concrete" Applied Sciences 10, no. 17: 6092. https://doi.org/10.3390/app10176092

APA StyleLi, Z., Yao, X., Chen, Y., Lu, T., & Ye, G. (2020). A Low-Autogenous-Shrinkage Alkali-Activated Slag and Fly Ash Concrete. Applied Sciences, 10(17), 6092. https://doi.org/10.3390/app10176092