Hybrid Engineered Water–Polymer Flooding in Carbonates: A Review of Mechanisms and Case Studies

Abstract

1. Introduction

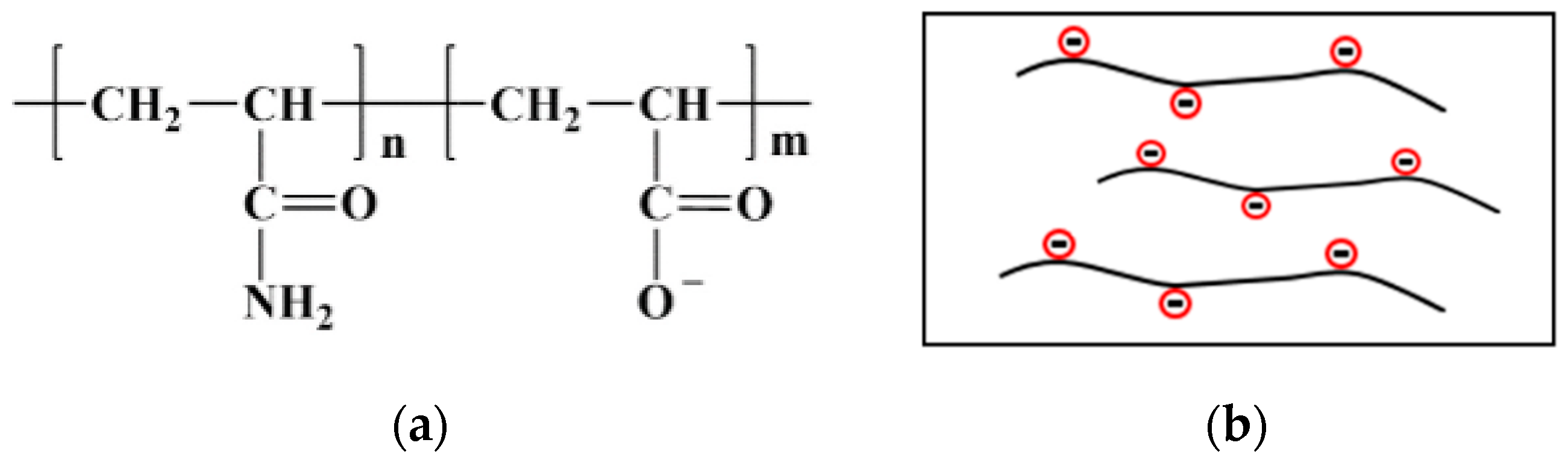

2. Polymer Flooding (PF)

2.1. Recovery Mechanism

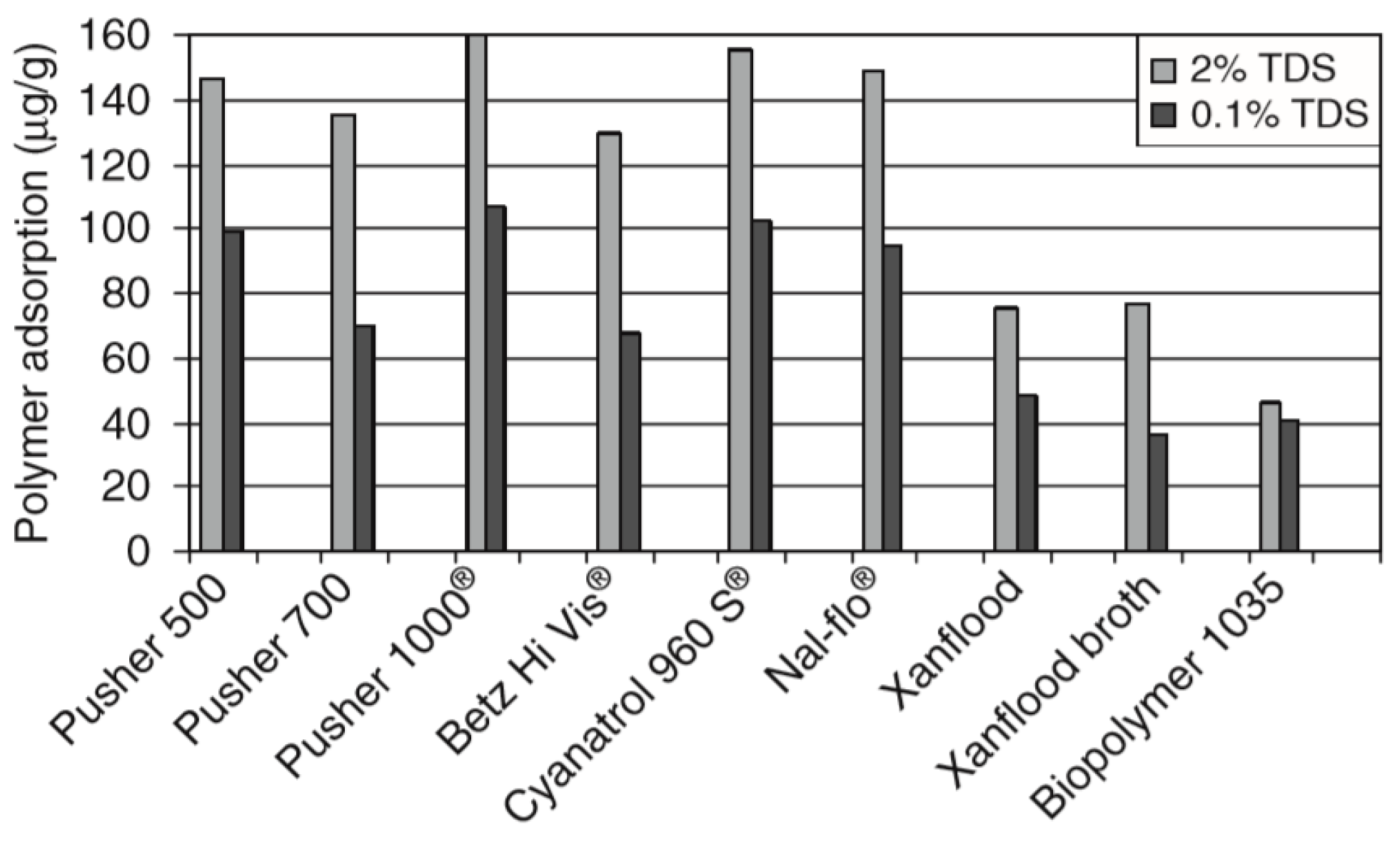

2.2. Challenges Associated with Polymer Flooding

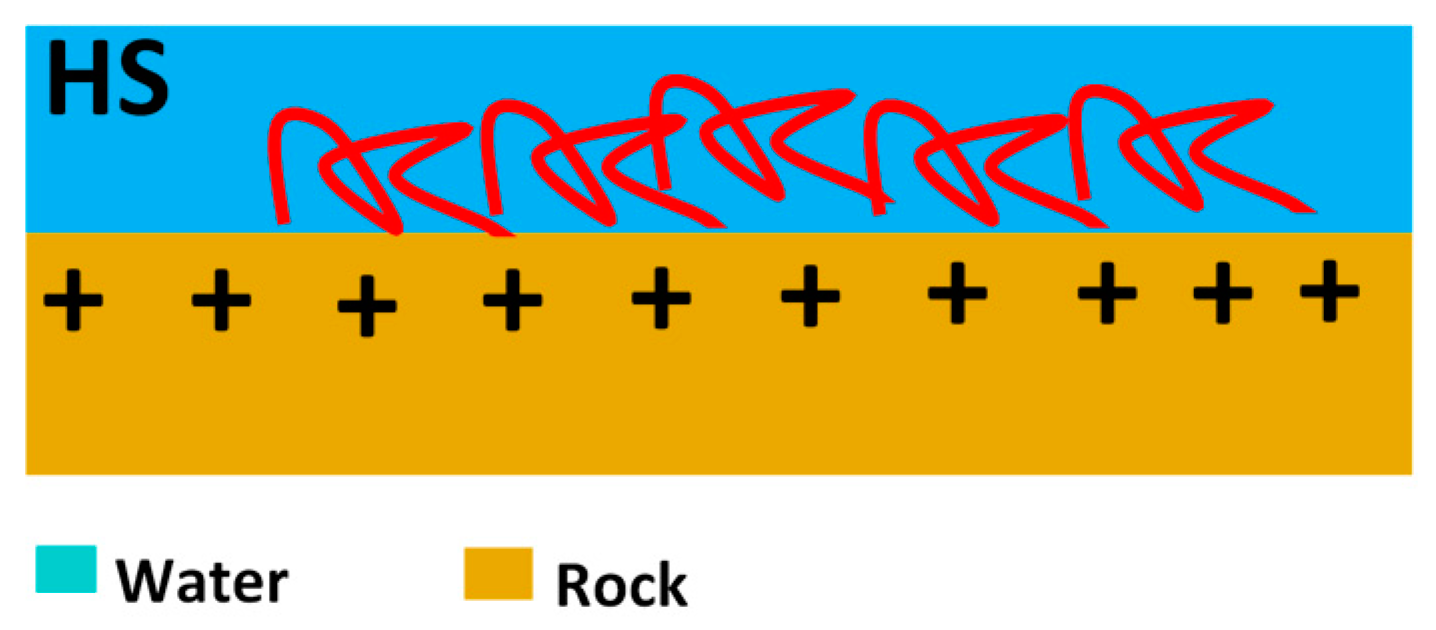

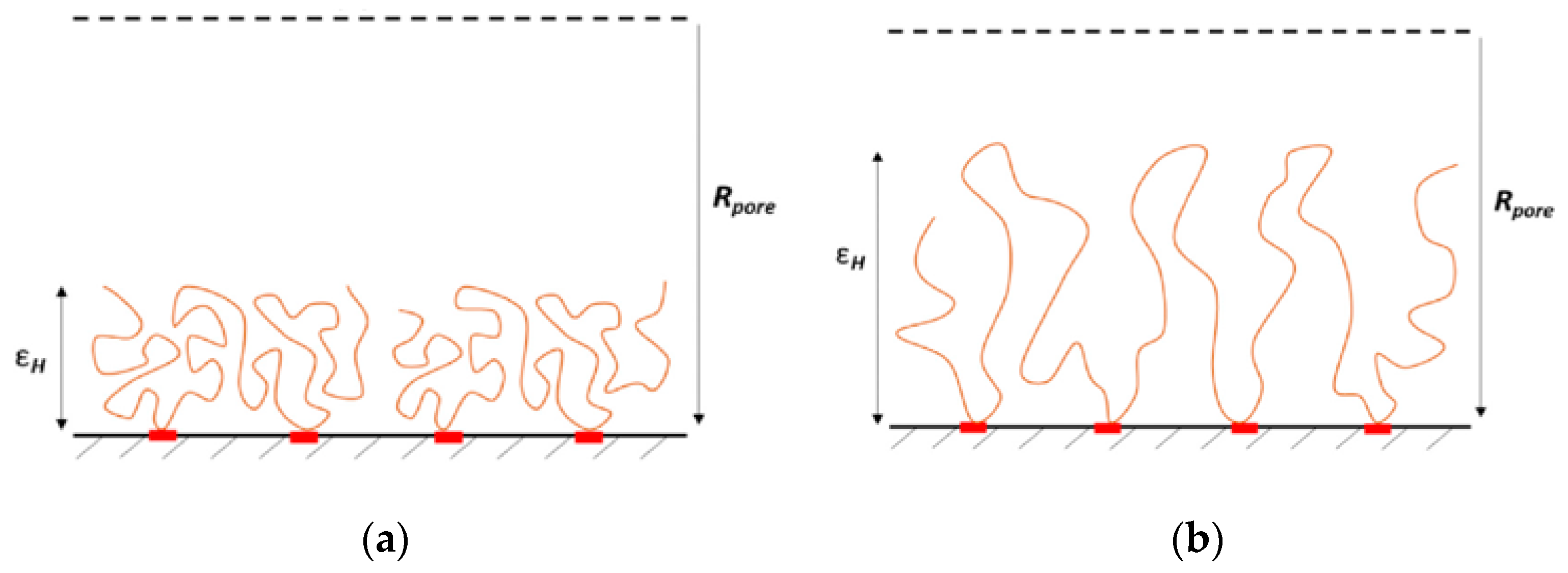

- The adsorption of HPAM in carbonate reservoirs is higher than for sandstones, possibly due to the strong attraction forces between the negatively charged carboxylates on the HPAM backbone and the positively charged calcite surface (Figure 2);

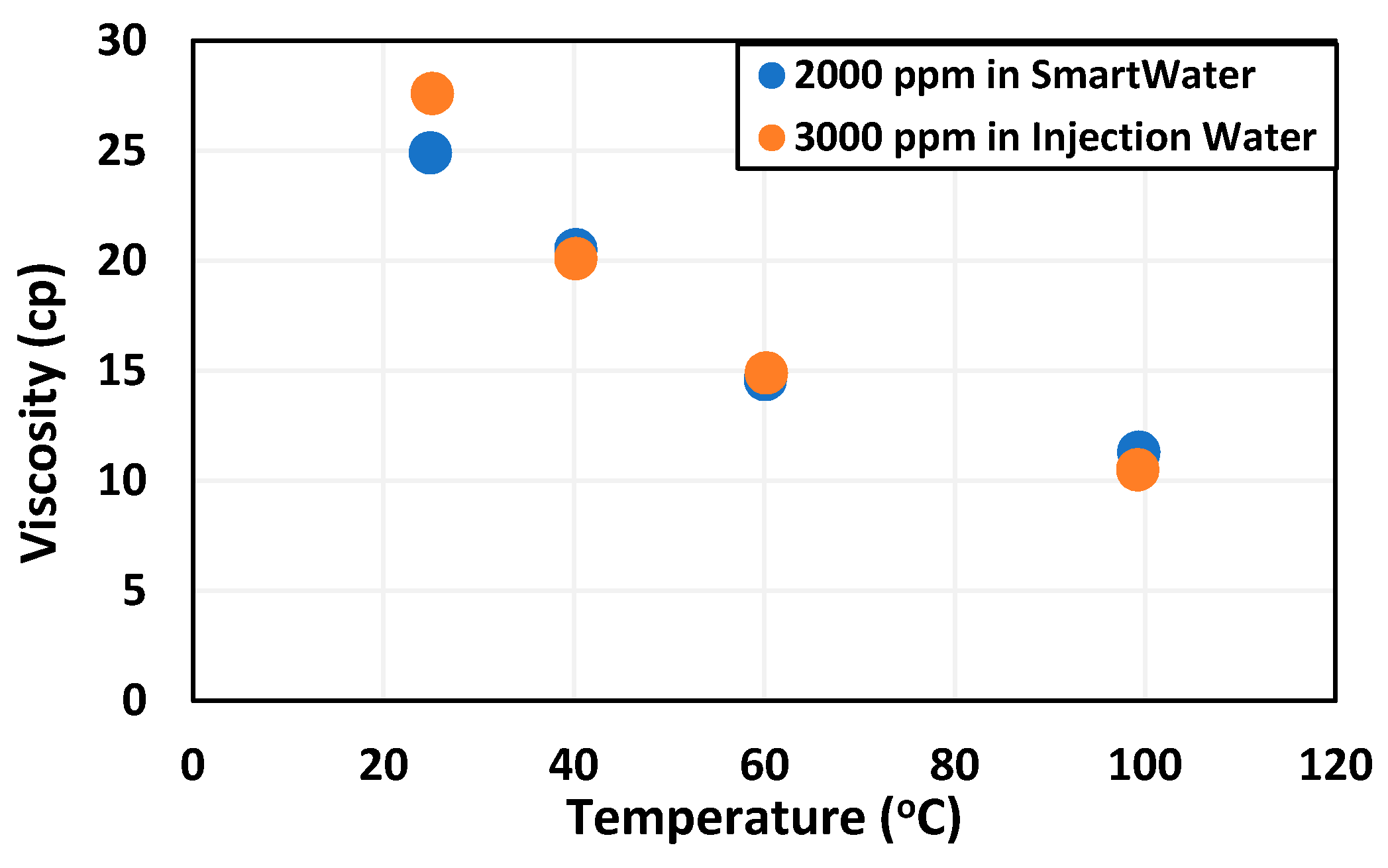

- High-salinity and high-temperature conditions are major challenges for conventional PF due to the instability and degradation of polymers under such conditions [49];

3. Engineered Water Flooding (EWF)

3.1. Recovery Mechanisms

3.2. Wettability Modification

3.2.1. Mineral Dissolution Reactions

3.2.2. Fluid–Fluid Interactions (Microdispersion)

3.2.3. Conditions for Engineered Water Flooding (EWF)

3.3. Limitations of EWF

4. Hybrid Engineered Water–Polymer Flooding (EWPF)

- The addition of a polymer to low-salinity water flooding enhances the volumetric sweep and can also mobilize the oil released due to wettability modification after LSWF, which otherwise would be trapped [117];

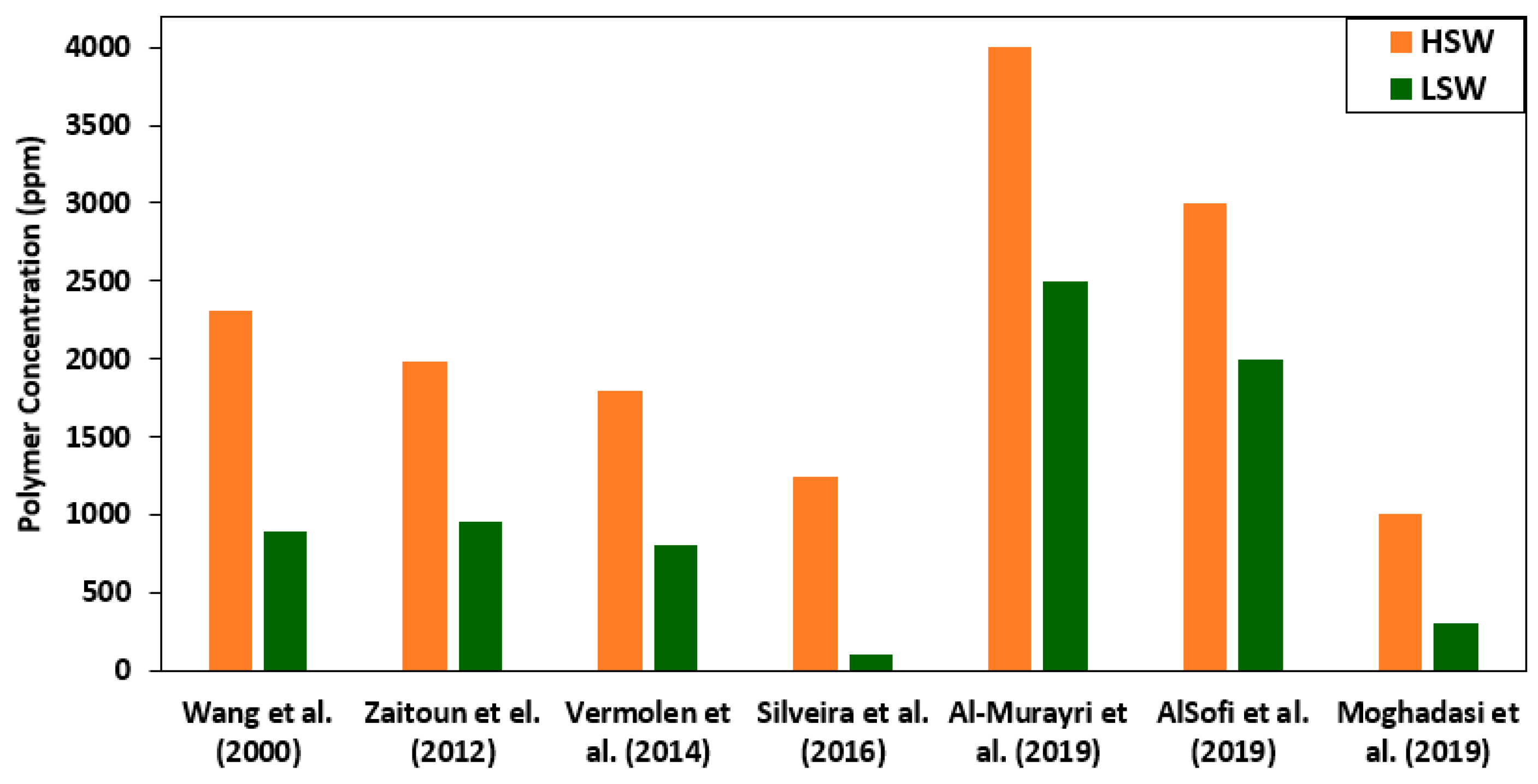

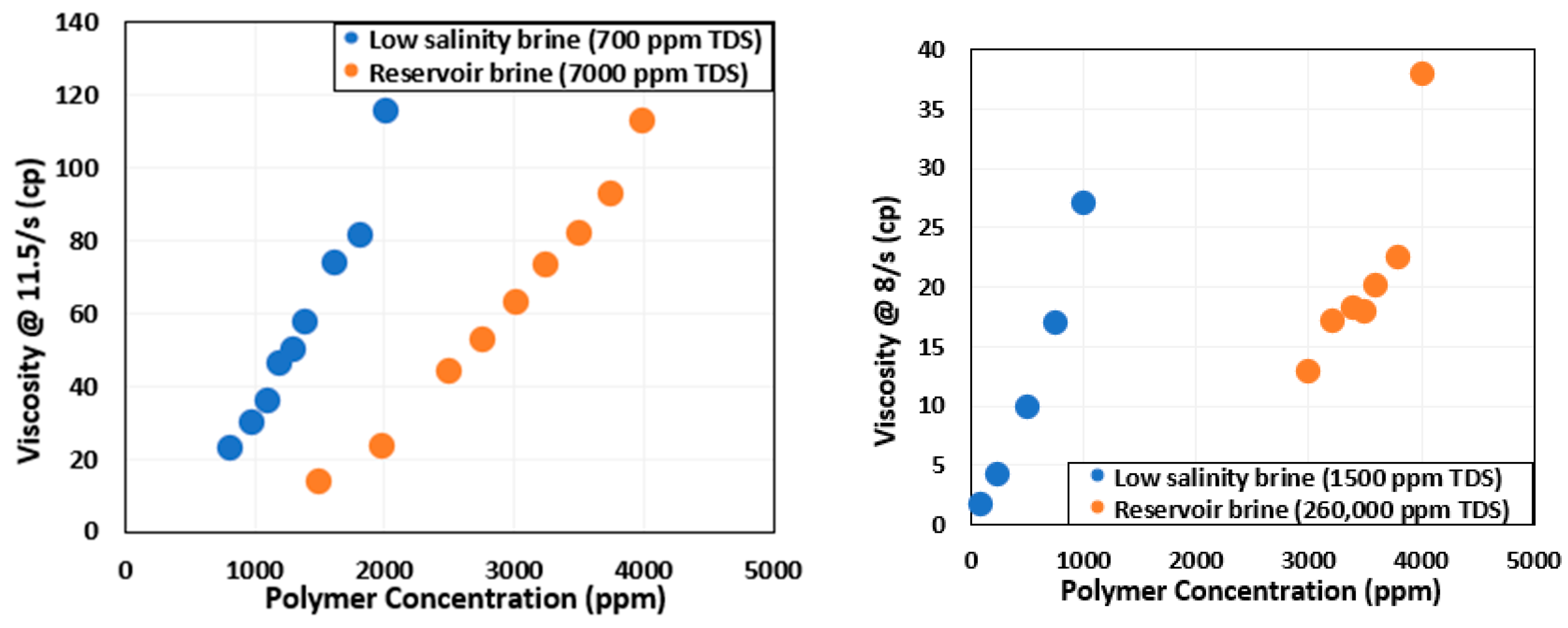

- Various studies have shown the added benefit of the reduced polymer concentration needed to attain the desired in situ viscosity by using low-salinity brine compared to high-salinity water [118]. This can result in a significant cost reduction;

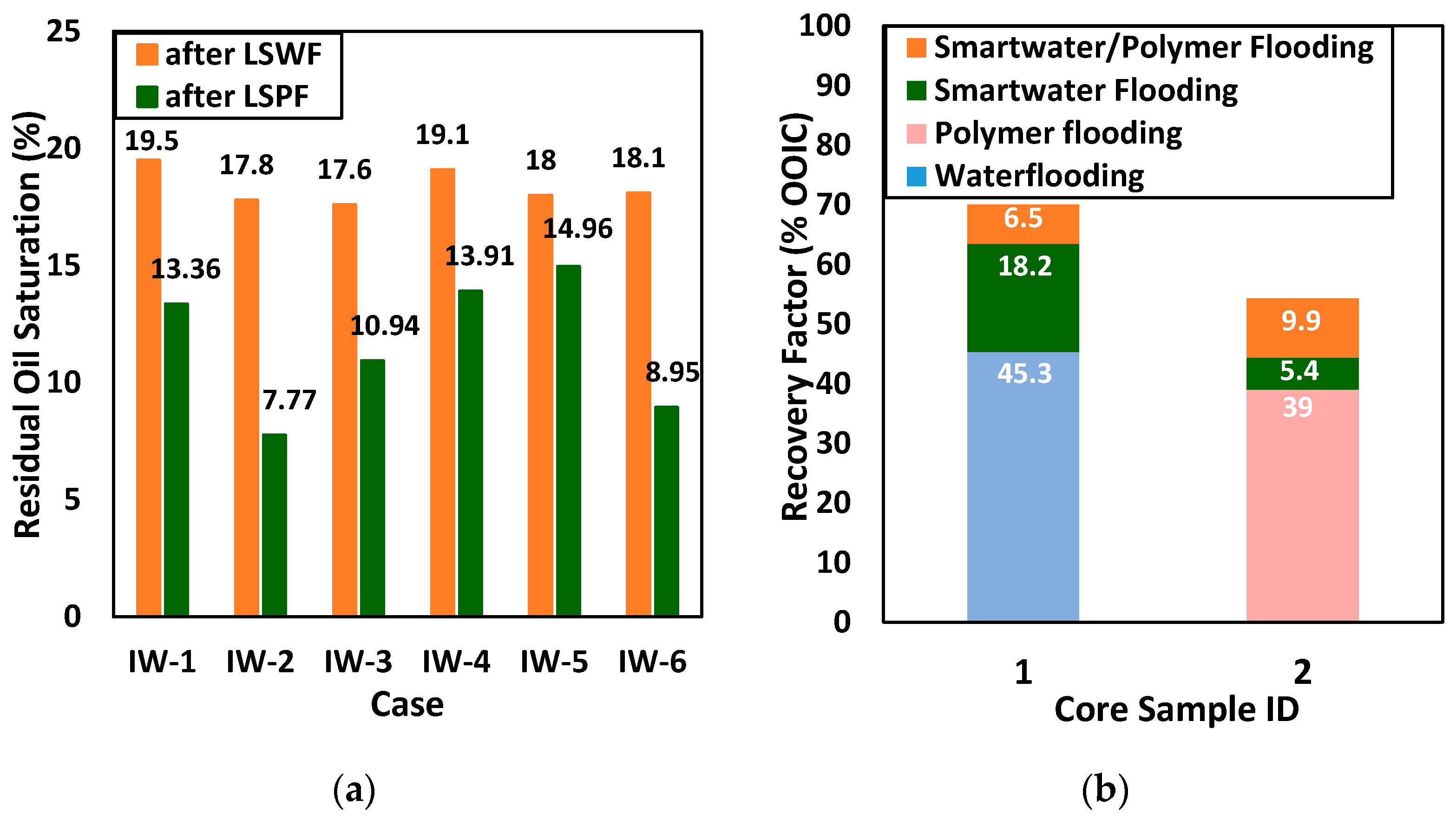

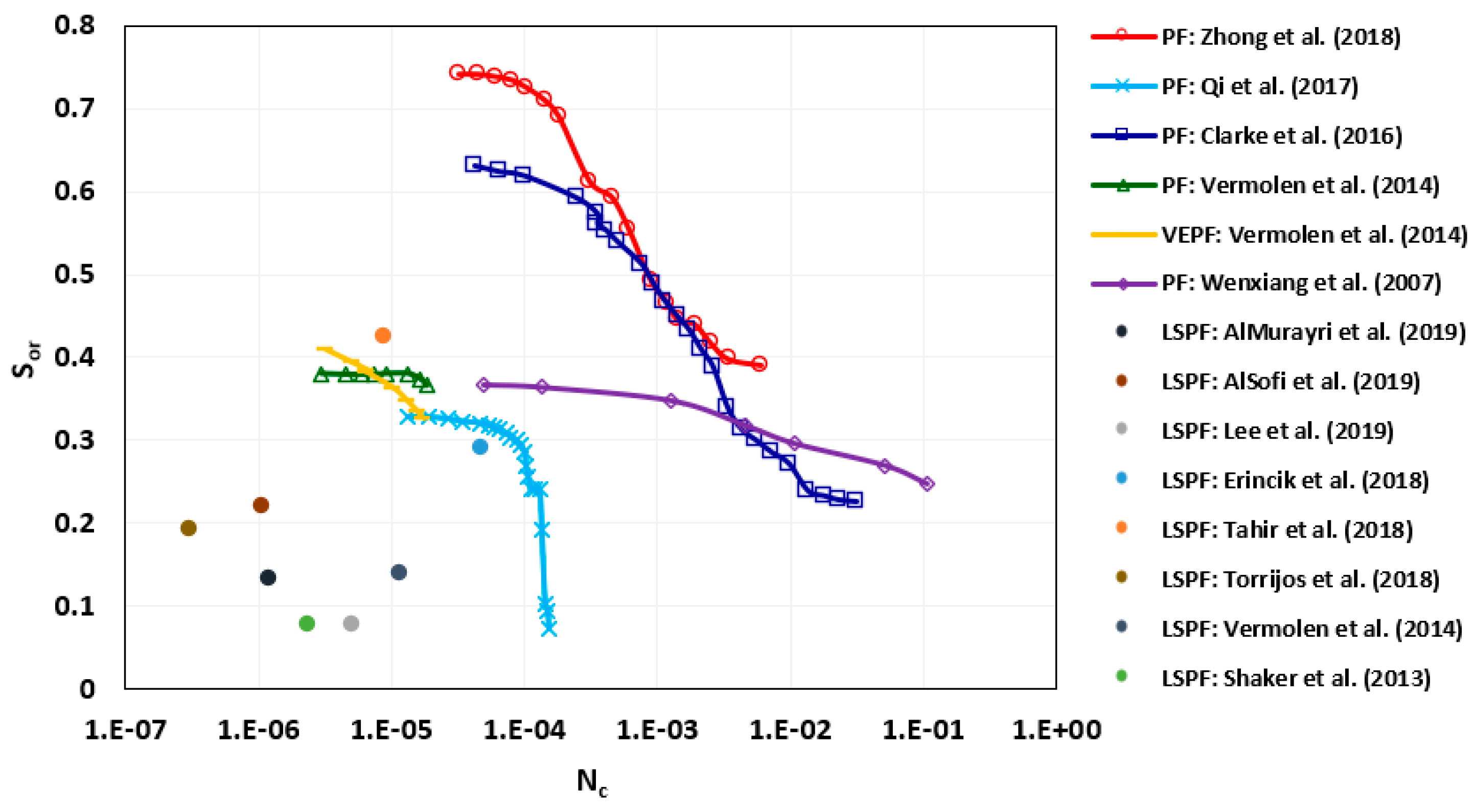

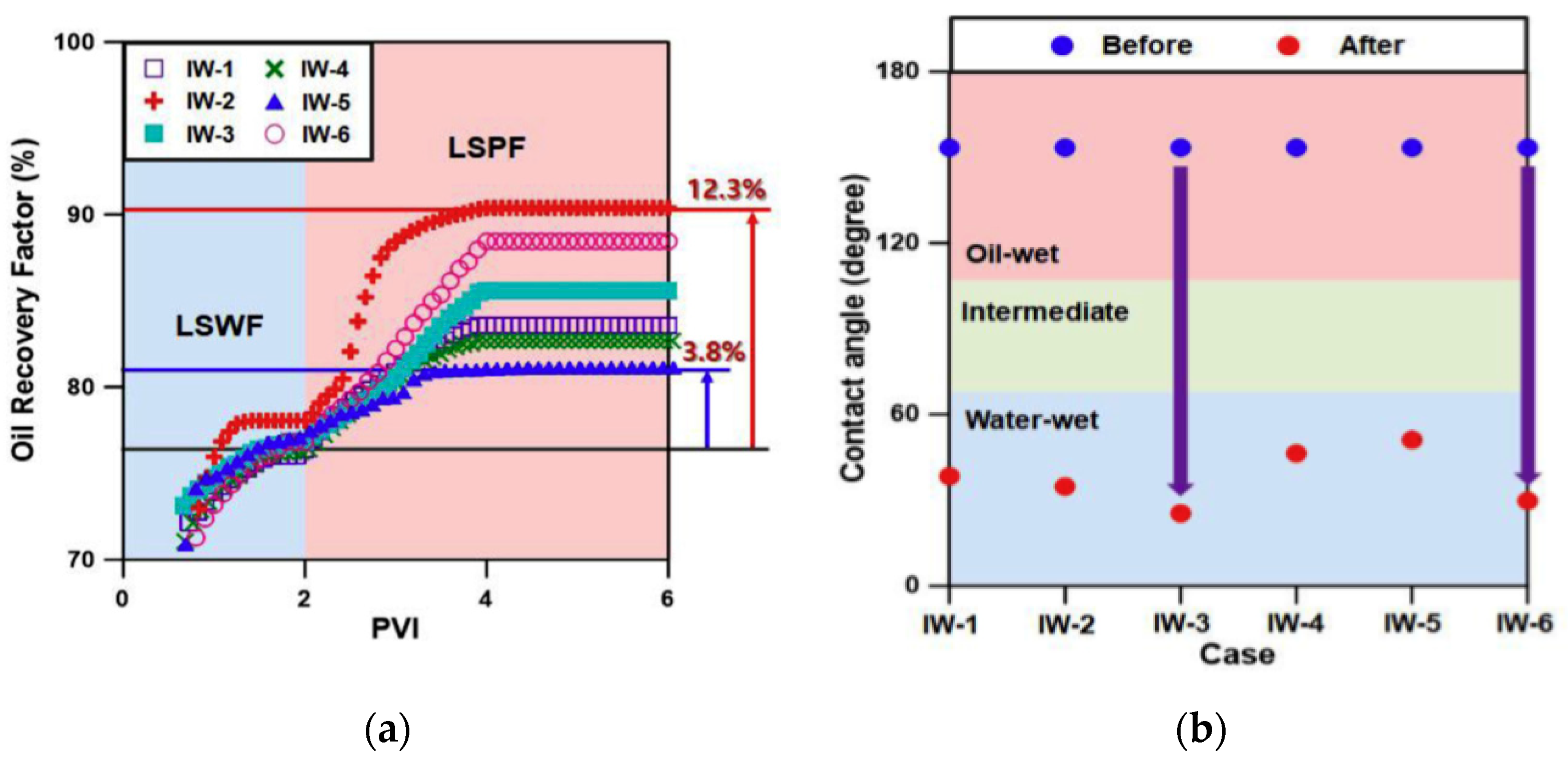

4.1. Effect of Hybrid EWPF on Residual Oil Saturation: Capillary Desaturation

4.2. Recovery Mechanisms

4.2.1. Wettability Modification Using Engineered Water

4.2.2. Role of Potential Determining Ions (PDIs)

4.2.3. Effect of Brine pH

4.2.4. Favorable Mobility Ratio from Polymer Flooding

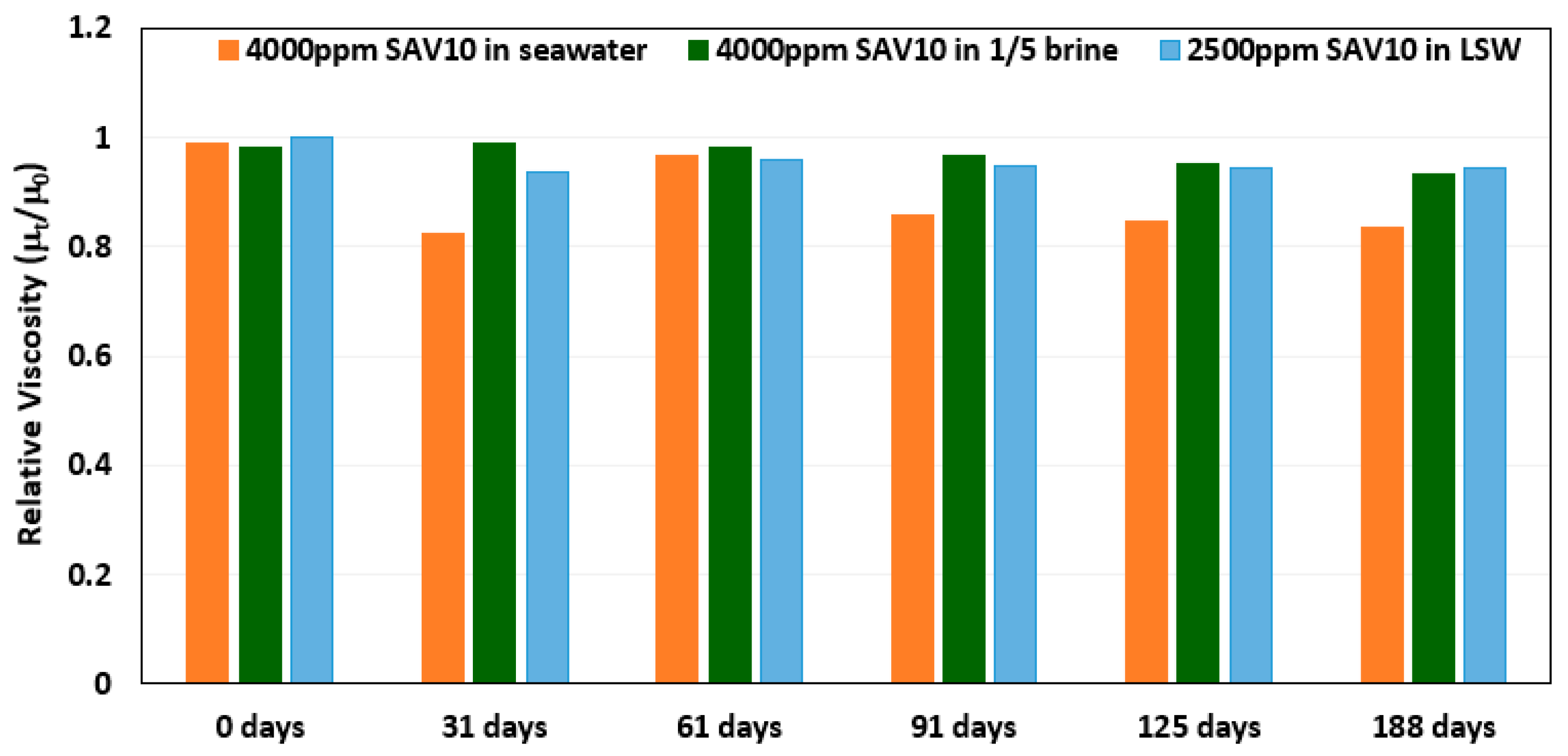

4.2.5. Enhanced Polymer Stability using EW

4.2.6. EW Effect on Polymer Retention

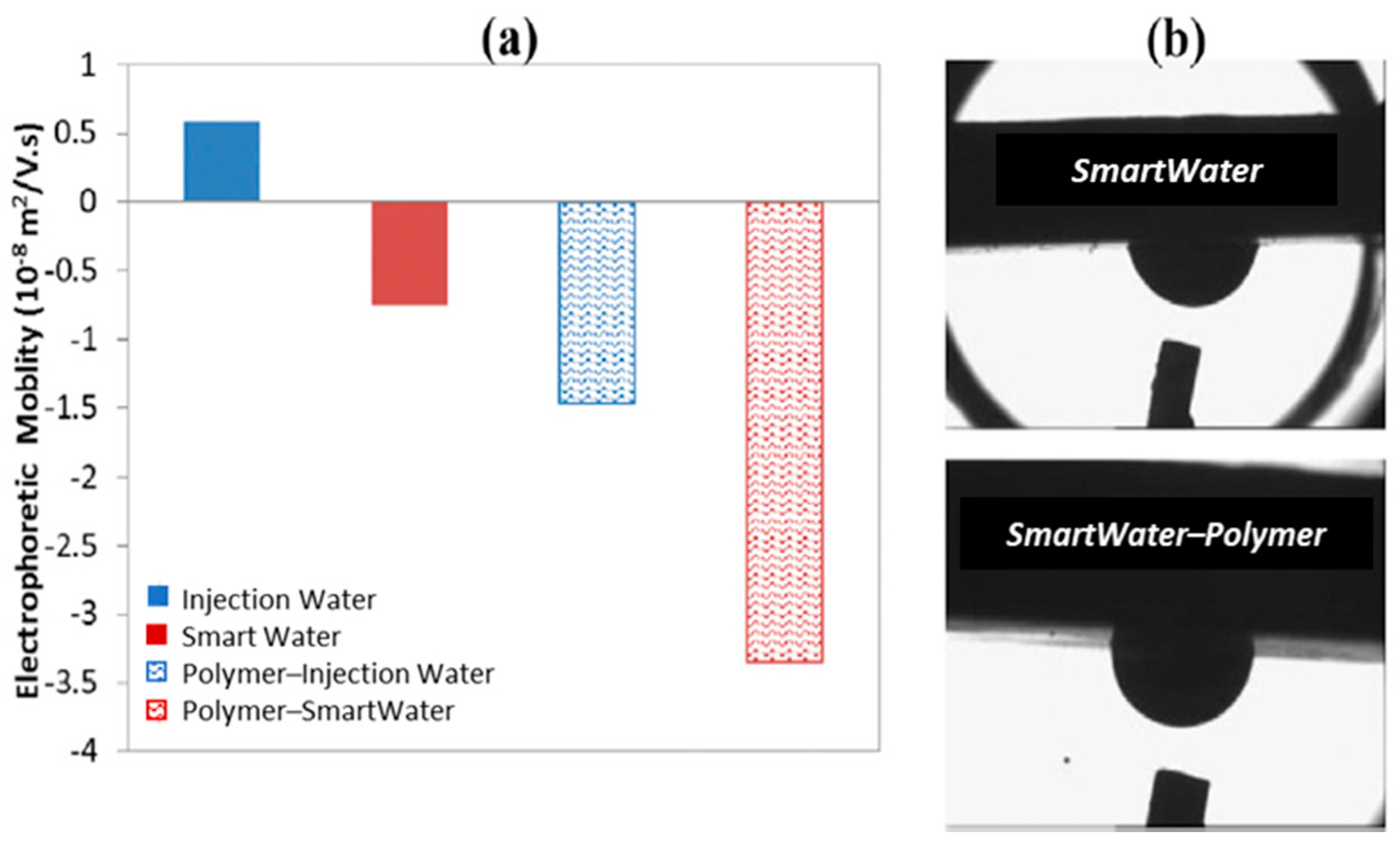

4.2.7. Impact of Polymer on EW Performance

4.3. Potential Risks Associated with EWPF

- The viscosity of a LSP solution is more sensitive to brine salinity compared to a solution containing high-salinity water (HSW). A slight increase in the brine salinity can reduce the polymer viscosity significantly, making it necessary to consider this factor while designing a LSPF project;

- The contamination of the LSP slug with already present high-salinity formation water also poses risks for polymer viscosity loss and increased adsorption;

- Another risk in this process is a delay of the incremental oil recovery due to the higher polymer slug needed to reach the required adsorption level as a result of a lower polymer concentration;

- The reduced injectivity levels of polymer and chase fluid in the presence of EW can also be a potential limitation involved in this hybrid method [180].

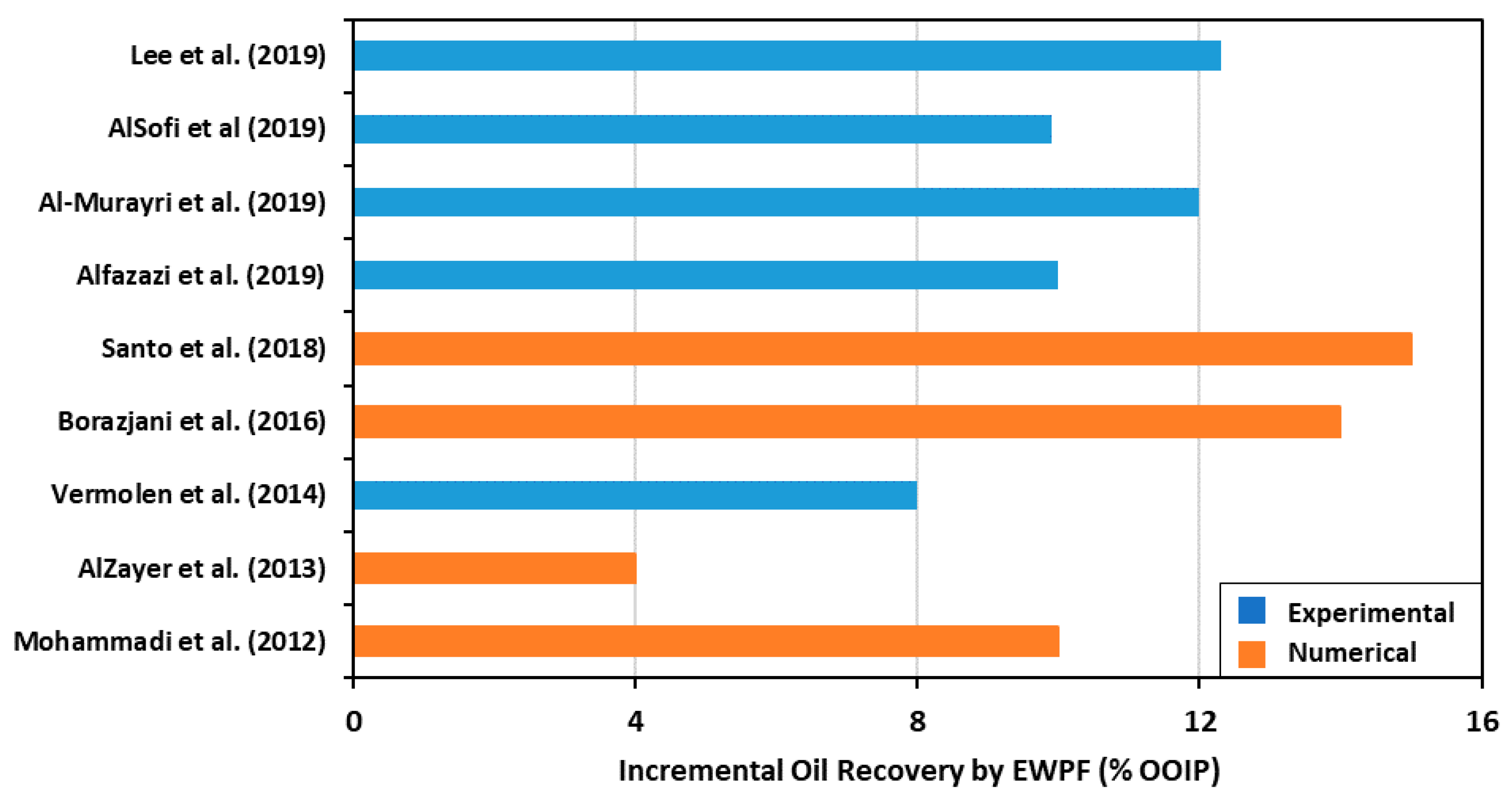

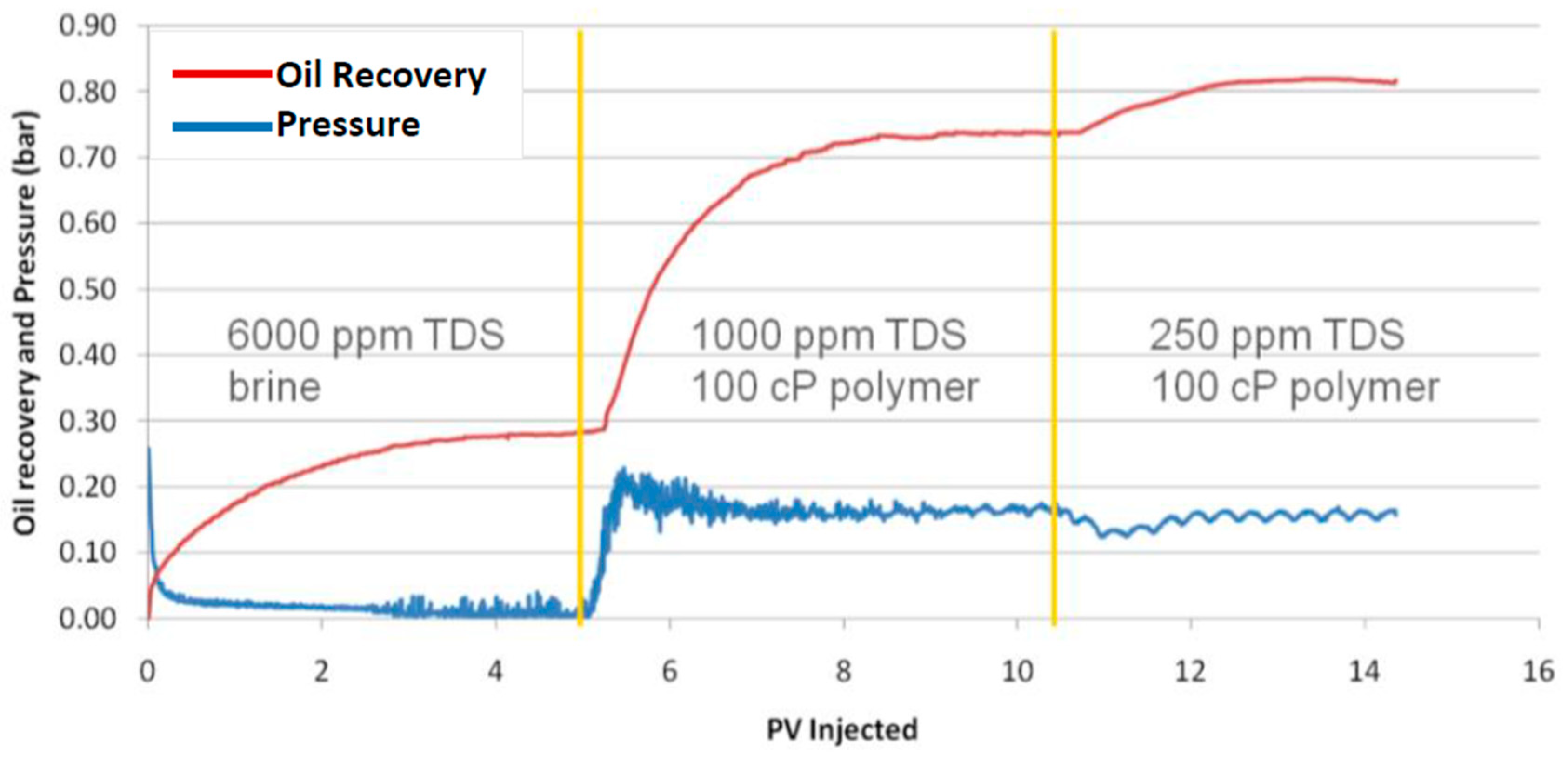

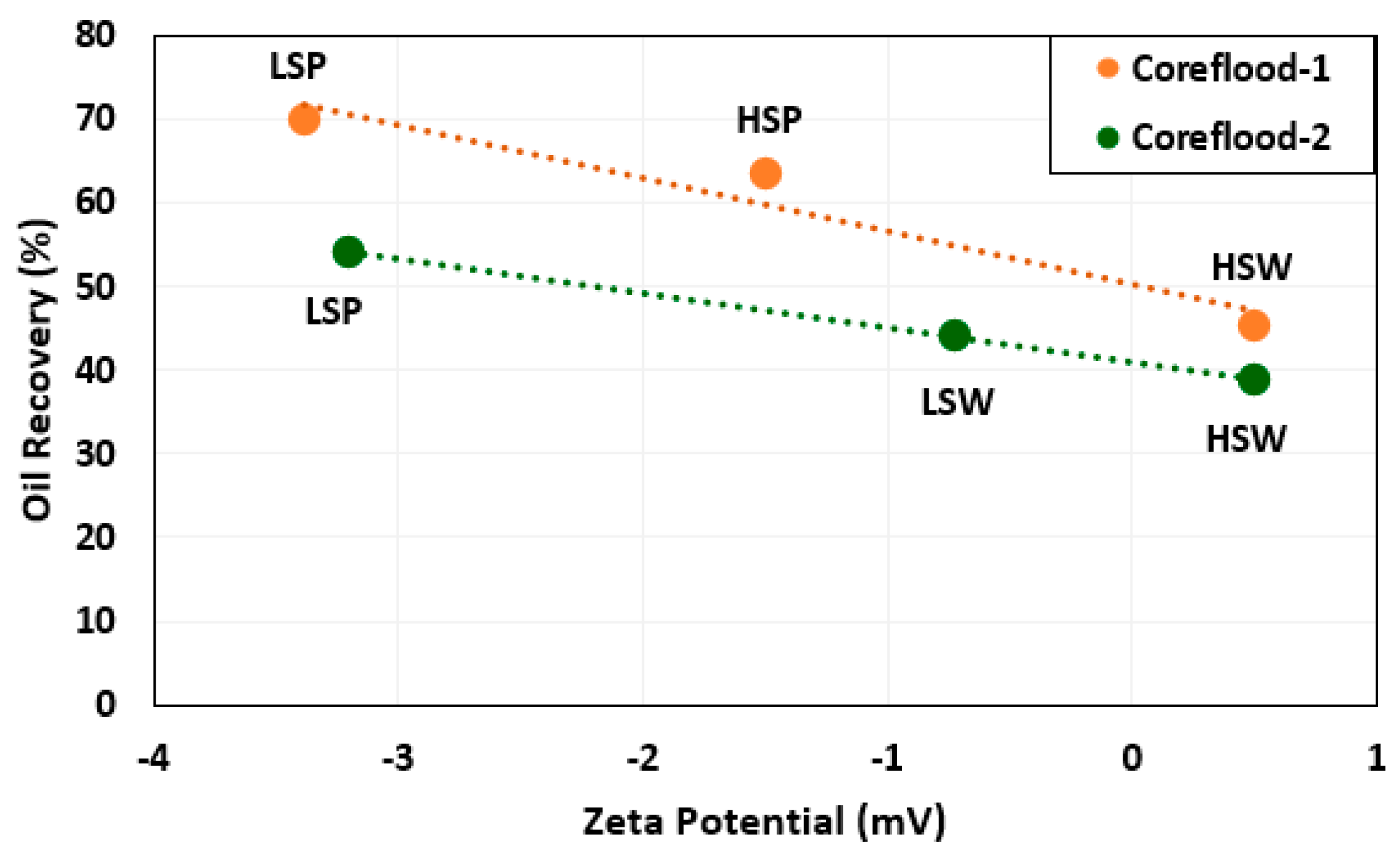

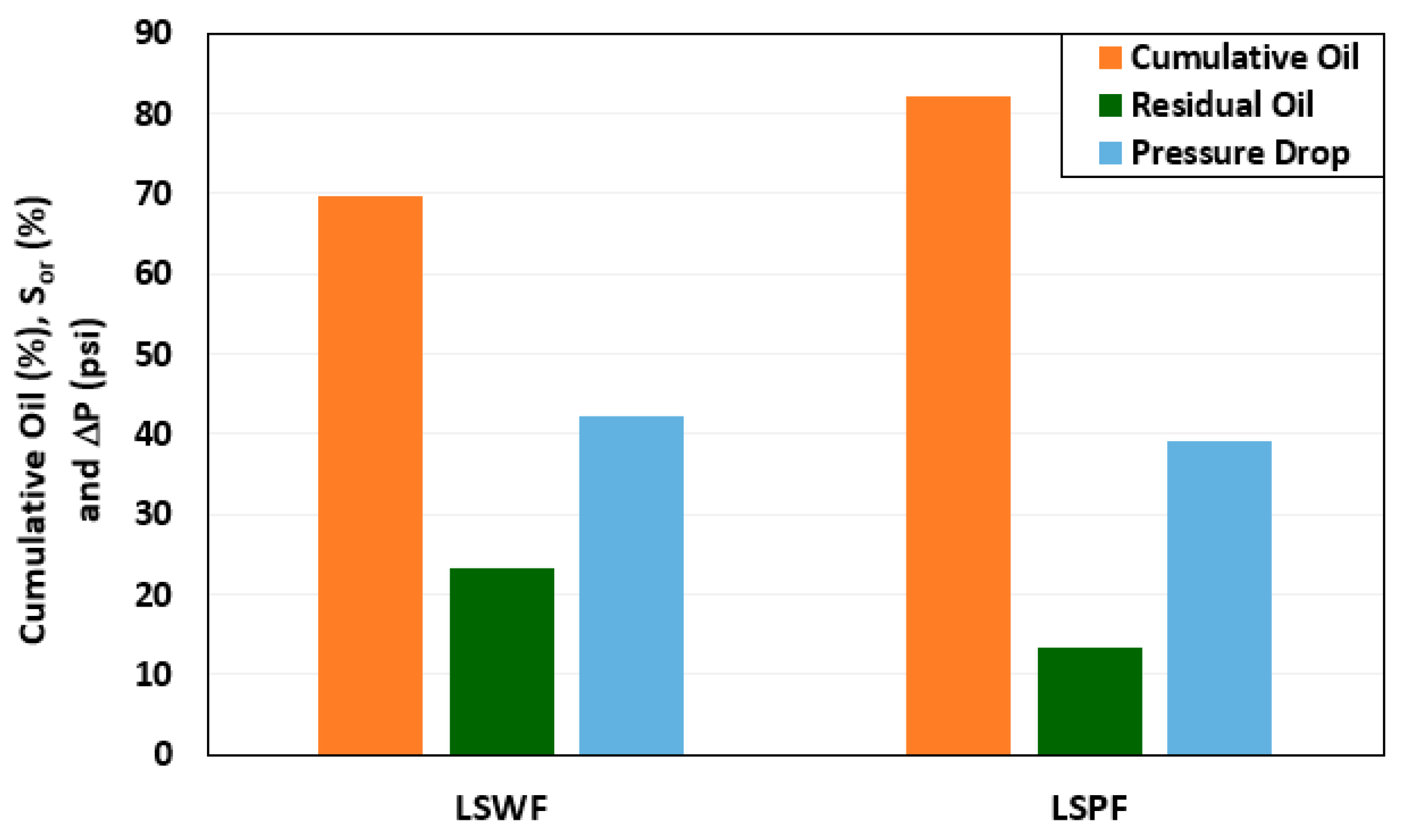

4.4. Lab-Scale Studies

4.5. Numerical Modeling Studies

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ahmadi, A.; Moosavi, M. Investigation of the effects of low-salinity waterflooding for improved oil recovery in carbonate reservoir cores. Energy Source Part A Recovery Util. Environ. Eff. 2018, 40, 1035–1043. [Google Scholar] [CrossRef]

- Mwangi, P.; Brady, P.V.; Radonjic, M.; Thyne, G. The effect of organic acids on wettability of sandstone and carbonate rocks. J. Pet. Sci. Eng. 2018, 165, 428–435. [Google Scholar] [CrossRef]

- Chilingar, G.V.; Yen, T. Some notes on wettability and relative permeabilities of carbonate reservoir rocks, II. Energy Sources 1983, 7, 67–75. [Google Scholar] [CrossRef]

- Treiber, L.; Owens, W. A laboratory evaluation of the wettability of fifty oil-producing reservoirs. Soc. Pet. Eng. J. 1972, 12, 531–540. [Google Scholar] [CrossRef]

- Lee, K.S.; Lee, J.H. Hybrid Enhanced Oil Recovery Using Smart Waterflooding; Gulf Professional Publishing: Cambridge, MA, USA, 2019. [Google Scholar]

- Bernard, G.G. Effect of floodwater salinity on recovery of oil from cores containing clays. In Proceedings of the SPE California Regional Meeting, Los Angeles, CA, USA, 26–27 October 1967. [Google Scholar]

- Hallenbeck, L.D.; Sylte, J.E.; Ebbs, D.J.; Thomas, L.K. Implementation of the Ekofisk field waterflood. SPE Form. Eval. 1991, 6, 284–290. [Google Scholar] [CrossRef]

- Sylte, J.; Hallenbeck, L.; Thomas, L. Ekofisk formation pilot waterflood. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 2–5 October 1988. [Google Scholar]

- Austad, T.; Shariatpanahi, S.F.; Strand, S.; Black, C.J.J.; Webb, K.J. Conditions for a low-salinity enhanced oil recovery (EOR) effect in carbonate oil reservoirs. Energy Fuels 2012, 26, 569–575. [Google Scholar] [CrossRef]

- Rivet, S.M. Coreflooding Oil Displacements with Low Salinity Brine. Ph.D. Thesis, University of Texas at Austin, Austin, TX, USA, 2009. [Google Scholar]

- Khaledialidusti, R.; Kleppe, J. Significance of geochemistry in single-well chemical-tracer tests by coupling a multiphase-flow simulator to the geochemical package. SPE J. 2018, 23, 1126–1144. [Google Scholar] [CrossRef]

- Mahani, H.; Keya, A.L.; Berg, S.; Nasralla, R. Electrokinetics of carbonate/brine interface in low-salinity waterflooding: Effect of brine salinity, composition, rock type, and pH on ζ-potential and a surface-complexation model. SPE J. 2017, 22, 53–68. [Google Scholar] [CrossRef]

- Khaledialidusti, R.; Kleppe, J. Surface-charge alteration at the carbonate/brine interface during single-well chemical-tracer tests: Surface-complexation model. SPE J. 2018, 23, 2302–2315. [Google Scholar] [CrossRef]

- Chang, H.L. Polymer flooding technology yesterday, today, and tomorrow. J. Pet. Technol. 1978, 30, 1113–1128. [Google Scholar] [CrossRef]

- Al-Murayri, M.T.; Kamal, D.S.; Al-Sabah, H.M.; AbdulSalam, T.; Al-Shamali, A.; Quttainah, R.; Glushko, D.; Britton, C.; Delshad, M.; Liyanage, J.; et al. Low-Salinity Polymer Flooding in a High-Temperature Low-Permeability Carbonate Reservoir in West Kuwait. In Proceedings of the SPE Kuwait Oil & Gas Show and Conference, Mishref, Kuwait, 13–16 October 2019. [Google Scholar]

- Pye, D.J. Improved secondary recovery by control of water mobility. J. Pet. Technol. 1964, 16, 911–916. [Google Scholar] [CrossRef]

- Sandiford, B. Laboratory and field studies of water floods using polymer solutions to increase oil recoveries. J. Pet. Technol. 1964, 16, 917–922. [Google Scholar] [CrossRef]

- Mungan, N. Rheology and adsorption of aqueous polymer solutions. J. Can. Pet. Technol. 1969, 8, 45–50. [Google Scholar] [CrossRef]

- Gogarty, W. Mobility control with polymer solutions. Soc. Pet. Eng. J. 1967, 7, 161–173. [Google Scholar] [CrossRef]

- Manrique, E.; Ahmadi, M.; Samani, S. Historical and recent observations in polymer floods: An update review. CtF-Cienc. Tecnol. Y Futuro 2017, 6, 17–48. [Google Scholar] [CrossRef]

- Gao, C.H. Scientific research and field applications of polymer flooding in heavy oil recovery. J. Pet. Explor. Prod. Technol. 2011, 1, 65–70. [Google Scholar] [CrossRef]

- Needham, R.B.; Doe, P.H. Polymer flooding review. J. Pet. Technol. 1987, 39, 1503–1507. [Google Scholar] [CrossRef]

- Zhang, Y. Survey and Data Analysis of Polymer Flooding Pilot and Field Applications in China. Master′s Thesis, Missouri University of Science and Techology, Rolla, MI, USA, 2015. [Google Scholar]

- Al-Saadi, F.S.; Al-amri, B.A.; Al Nofli, S.M.; Van Wunnik, J.N.M.; Jaspers, H.F.; Al Harthi, S.; Shuaili, K.; Cherukupalli, P.K.; Chakravarthi, R. Polymer Flooding in a large field in South Oman-initial results and future plans. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Saleh, L.D.; Wei, M.; Bai, B. Data analysis and updated screening criteria for polymer flooding based on oilfield data. Spe Reserv. Eval. Eng. 2014, 17, 15–25. [Google Scholar] [CrossRef]

- Sheng, J.J.; Leonhardt, B.; Azri, N. Status of polymer-flooding technology. J. Can. Pet. Technol. 2015, 54, 116–126. [Google Scholar] [CrossRef]

- Standnes, D.C.; Skjevrak, I. Literature review of implemented polymer field projects. J. Pet. Sci. Eng. 2014, 122, 761–775. [Google Scholar] [CrossRef]

- Campbell, T.; Bachman, R. Polymer-Augmented Waterflood in the Rapdan Upper Shaunavon Unit. J. Can. Pet. Technol. 1987, 26. [Google Scholar] [CrossRef]

- DeHekker, T.; Bowzer, J.L.; Coleman, R.V.; Bartos, W.B. A Progress Report on Polymer-Augmented Waterflooding in Wyoming′s North Oregon Basin and Byron Fields. In Proceedings of the SPE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 20–23 April 1986. [Google Scholar]

- Weiss, W.; Baldwin, R. Planning and implementing a large-scale polymer flood. J. Pet. Technol. 1985, 37, 720–730. [Google Scholar] [CrossRef]

- Moore, J.K. Reservoir Barrier and Polymer Waterflood, Northeast Hallsville Crane Unit. J. Pet. Technol. 1969, 21, 1130–1136. [Google Scholar] [CrossRef]

- Olajire, A.A. Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: Prospects and challenges. Energy 2014, 77, 963–982. [Google Scholar] [CrossRef]

- Sorbie, K. Polymer-Improved Oil Recovery; Blackie & Son: Glasgow, Scotland, 1991; pp. 126–163. [Google Scholar]

- Borthakur, A.; Rahman, M.; Sarmah, A.; Subrahmanyam, B. Partially Hydrolyzed Polyacrylamide for Enhanced Oil-Recovery. Res. Ind. 1995, 40, 90–94. [Google Scholar]

- Morgan, S.E.; McCormick, C.L. Water-soluble polymers in enhanced oil recovery. Prog. Polym. Sci. 1990, 15, 103–145. [Google Scholar] [CrossRef]

- Sun, Y.; Saleh, L.; Bai, B. Measurement and impact factors of polymer rheology in porous media. Rheol. Intech 2012, 187–188. [Google Scholar] [CrossRef]

- Wever, D.; Picchioni, F.; Broekhuis, A. Polymers for enhanced oil recovery: A paradigm for structure–property relationship in aqueous solution. Prog. Polym. Sci. 2011, 36, 1558–1628. [Google Scholar] [CrossRef]

- Liu, J.-F.; Feng, J.-Y.; Yang, S.-Z.; Gang, H.-Z.; Mu, B.-Z. The recovery of viscosity of HPAM solution in presence of high concentration sulfide ions. J. Pet. Sci. Eng. 2020, 107605. [Google Scholar] [CrossRef]

- Thomas, A. Polymer Flooding, Chemical Enhanced Oil Recovery (cEOR)-a Practical Overview, Dr. Laura Romero-Zerón. InTech 2016, 10, 64623. [Google Scholar]

- Saboorian-Jooybari, H.; Dejam, M.; Chen, Z. Heavy oil polymer flooding from laboratory core floods to pilot tests and field applications: Half-century studies. J. Pet. Sci. Eng. 2016, 142, 85–100. [Google Scholar] [CrossRef]

- Kaminsky, R.D.; Wattenbarger, R.C.; Szafranski, R.C.; Coutee, A. Guidelines for polymer flooding evaluation and development. In Proceedings of the International Petroleum Technology Conference, Dubai, UAE, 4–6 December 2007. [Google Scholar]

- Zhao, F.-L.; Wang, Y.-F.; Dai, C.-L.; Ren, S.; Jiao, C. Techniques of enhanced oil recovery after polymer flooding. Zhongguo Shi You Daxue Xuebao. J. China Univ. Pet. 2006, 30, 86–89. [Google Scholar]

- Sheng, J.J. Modern Chemical Enhanced Oil Recovery: Theory and Practice; Gulf Professional Publishing: Cambridge, MA, USA, 2010. [Google Scholar]

- Jung, J.C.; Zhang, K.; Chon, B.H.; Choi, H.J. Rheology and polymer flooding characteristics of partially hydrolyzed polyacrylamide for enhanced heavy oil recovery. J. Appl. Polym. Sci. 2013, 127, 4833–4839. [Google Scholar] [CrossRef]

- Kamal, M.S.; Sultan, A.S.; Al-Mubaiyedh, U.A.; Hussein, I.A. Review on Polymer Flooding: Rheology, Adsorption, Stability, and Field Applications of Various Polymer Systems. Polym. Rev. 2015, 55, 491–530. [Google Scholar] [CrossRef]

- Swiecinski, F.; Reed, P.; Andrews, W. The thermal stability of polyacrylamides in EOR applications. In Proceedings of the SPE Improved Oil Recovery Conference, Tulsa, OK, USA, 11–13 April 2016. [Google Scholar]

- Moradi-Araghi, A.; Doe, P.H. Hydrolysis and precipitation of polyacrylamides in hard brines at elevated temperatures. SPE Reserv. Eng. 1987, 2, 189–198. [Google Scholar] [CrossRef]

- Zaitoun, A.; Potie, B. Limiting conditions for the use of hydrolyzed polyacrylamides in brines containing divalent ions. In Proceedings of the SPE Oilfield and Geothermal Chemistry Symposium, Denver, Colorado, 1–3 June 1983. Society of Petroleum Engineers. [Google Scholar]

- Du, Y.; Guan, L. Field-scale polymer flooding: Lessons learnt and experiences gained during past 40 years. In Proceedings of the SPE International Petroleum Conference in Mexico, Puebla Pue, Mexico, 7–9 November 2004. Society of Petroleum Engineers. [Google Scholar]

- Li, M.; Guo, J.; Peng, B.; Lin, M.; Dong, Z.; Wu, Z. Formation of Crude Oil Emulsions in Chemical Flooding, in Emulsions and Emulsion Stability; CRC Press: Boca Raton, FL, USA, 2005; pp. 537–568. [Google Scholar]

- Nguyen, D.T.; Sadeghi, N. Stable emulsion and demulsification in chemical EOR flooding: Challenges and best practices. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Chen, D.; Li, F.; Gao, Y.; Yang, M. Pilot performance of chemical demulsifier on the demulsification of produced water from polymer/surfactant flooding in the Xinjiang oilfield. Water 2018, 10, 1874. [Google Scholar] [CrossRef]

- Thomas, S. Enhanced oil recovery-an overview. Oil Gas Sci. Technol. Rev. De L’ifp 2008, 63, 9–19. [Google Scholar] [CrossRef]

- Morel, D.C.; Jouenne, S.; Vert, M.; Nahas, E. Polymer injection in deep offshore field: The Dalia Angola case. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Andersen, P.Ø.; Evje, S.; Kleppe, H.; Skjaeveland, S.M. A model for wettability alteration in fractured reservoirs. SPE J. 2015, 20, 1261–1275. [Google Scholar] [CrossRef]

- AlGeer, M.A.; Gmira, A.; Al-Enezi, S.M.; Yousef, A.A. Impact of individual ions on oil/brine/rock interface: A macroscopic insight on wettability alteration. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 7–10 November 2016. [Google Scholar]

- Lashkarbolooki, M.; Riazi, M.; Hajibagheri, F.; Ayatollahi, S. Low salinity injection into asphaltenic-carbonate oil reservoir, mechanistical study. J. Mol. Liq. 2016, 216, 377–386. [Google Scholar] [CrossRef]

- Al-Shalabi, E.W.; Sepehrnoori, K. A comprehensive review of low salinity/engineered water injections and their applications in sandstone and carbonate rocks. J. Pet. Sci. Eng. 2016, 139, 137–161. [Google Scholar] [CrossRef]

- Elakneswaran, Y.; Takeya, M.; Ubaidah, A.; Shimokawara, M.; Okano, H.; Nawa, T. Integrated Geochemical Modelling of Low Salinity Waterflooding for Enhanced Oil Recovery in Carbonate Reservoir. In Proceedings of the Source International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. International Petroleum Technology Conference. [Google Scholar]

- Zahid, A.; Shapiro, A.; Skauge, A. Experimental Studies of Low Salinity Water Flooding in Carbonate Reservoirs: A New Promising Approach. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Fathi, S.J.; Austad, T.; Strand, S. Water-based enhanced oil recovery (EOR) by “smart water”: Optimal ionic composition for EOR in carbonates. Energy Fuels 2011, 25, 5173–5179. [Google Scholar] [CrossRef]

- Chandrasekhar, S.; Mohanty, K. Wettability Alteration with Brine Composition in High Temperature Carbonate. Paper SPE 166280. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–2 October 2013. [Google Scholar]

- Al-Attar, H.H.; Mahmoud, M.Y.; Zekri, A.Y.; Almehaideb, R.; Ghannam, M. Low-salinity flooding in a selected carbonate reservoir: Experimental approach. J. Pet. Explor. Prod. Technol. 2013, 3, 139–149. [Google Scholar] [CrossRef]

- Altahir, M.; Yu, M.; Hussain, F. Low salinity water flooding in carbonate rocks–dissolution effect. In Proceedings of the International Symposium of the Society of Core Analysts held in Vienna, Austria SCA2017-070, Vienna, Austria, 27 August–1 September 2017. [Google Scholar]

- Hiorth, A.; Cathles, L.; Madland, M. The impact of pore water chemistry on carbonate surface charge and oil wettability. Transp. Porous Media 2010, 85, 1–21. [Google Scholar] [CrossRef]

- Mahani, H.; Menezes, R.; Berg, S.; Fadili, A.; Nasralla, R.; Voskov, D.; Joekar-Niasar, V. Insights into the impact of temperature on the wettability alteration by low salinity in carbonate rocks. Energy Fuels 2017, 31, 7839–7853. [Google Scholar] [CrossRef]

- Mahani, H.; Keya, A.L.; Berg, S.; Bartels, W.B.; Nasralla, R.; Rossen, W.R. Insights into the mechanism of wettability alteration by low-salinity flooding (LSF) in carbonates. Energy Fuels 2015, 29, 1352–1367. [Google Scholar] [CrossRef]

- Ligthelm, D.J.; Gronsveld, J.; Hofman, J.; Brussee, N.; Marcelis, F.; van der Linde, H. Novel Waterflooding Strategy by Manipulation of Injection Brine Composition. In Proceedings of the EUROPEC/EAGE Conference and Exhibition, Amsterdam, The Netherlands, 8–11 June 2009. [Google Scholar]

- Lager, A.; Webb, K.J.; Black, C.J.J.; Singleton, M.; Sorbie, K.S. Low salinity oil recovery-an experimental investigation1. Petrophysics 2008, 49. [Google Scholar]

- RezaeiDoust, A.; Puntervold, T.; Strand, S.; Austad, T. Smart water as wettability modifier in carbonate and sandstone: A discussion of similarities/differences in the chemical mechanisms. Energy Fuels 2009, 23, 4479–4485. [Google Scholar] [CrossRef]

- Tang, G.-Q.; Morrow, N.R. Influence of brine composition and fines migration on crude oil/brine/rock interactions and oil recovery. J. Pet. Sci. Eng. 1999, 24, 99–111. [Google Scholar] [CrossRef]

- Bagci, S.; Kok, M.V.; Turksoy, U. Effect of brine composition on oil recovery by waterflooding. Pet. Sci. Technol. 2001, 19, 359–372. [Google Scholar] [CrossRef]

- Gupta, R.; Smith, P.G.J.; Hu, L.; Willingham, T.W.; Cascio, M.L.; Shyeh, J.J.; Harris, C.R. Enhanced waterflood for Middle East carbonate cores–Impact of injection water composition Paper SPE 142668. In Proceedings of the SPE Middle East oil and gas show and conference, Manama, Bahrain, 25-28 September 2011. [Google Scholar]

- Yousef, A.A.; Al-Saleh, S.H.; Al-Kaabi, A.; Al-Jawfi, M.S. Laboratory investigation of the impact of injection-water salinity and ionic content on oil recovery from carbonate reservoirs. SPE Reserv. Eval. Eng. 2011, 14, 578–593. [Google Scholar] [CrossRef]

- Awolayo, A.; Sarma, H.; AlSumaiti, A.M. A laboratory study of ionic effect of smart water for enhancing oil recovery in carbonate reservoirs. In Proceedings of the SPE EOR conference at oil and gas West Asia, Muscat, Oman, 31 March–2 April 2014. [Google Scholar]

- Alameri, W.; Teklu, T.W.; Graves, R.M.; Kazemi, H.; AlSumaiti, A.M. Experimental and numerical modeling of low-salinity waterflood in a low permeability carbonate reservoir. In Proceedings of the SPE Western Regional Meeting, Garden Grove, CA, USA 27–30 April 2015. [Google Scholar]

- Puntervold, T.; Strand, S.; Ellouz, R.; Austad, T. Modified seawater as a smart EOR fluid in chalk. J. Pet. Sci. Eng. 2015, 133, 440–443. [Google Scholar] [CrossRef]

- Qiao, C.; Li, L.; Johns, R.T.; Xu, J. A mechanistic model for wettability alteration by chemically tuned waterflooding in carbonate reservoirs. SPE J. 2015, 20, 767–783. [Google Scholar] [CrossRef]

- Fathi, S.J.; Austad, T.; Strand, S. “Smart water” as a wettability modifier in chalk: The effect of salinity and ionic composition. Energy Fuels 2010, 24, 2514–2519. [Google Scholar] [CrossRef]

- Mohsenzadeh, A.; Pourafshary, P.; Al-Wahaibi, Y. Oil recovery enhancement in carbonate reservoirs via low saline water flooding in presence of low concentration active ions; A case study. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 21–23 March 2016. [Google Scholar]

- Fani, M.; Al-Hadrami, H.; Pourafshary, P.; Vakili-Nezhaad, G.; Mosavat, N. Optimization of smart water flooding in carbonate reservoir. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 12–15 November 2018. [Google Scholar]

- Nasralla, R.A.; Mahani, H.; van der Linde, H.A.; Marcelis, F.H.; Masalmeh, S.K.; Sergienko, E.; Brussee, N.J.; Pieterse, S.G.; Basu, S. Low salinity waterflooding for a carbonate reservoir: Experimental evaluation and numerical interpretation. J. Pet. Sci. Eng. 2018, 164, 640–654. [Google Scholar] [CrossRef]

- Sarvestani, A.D.; Ayatollahi, S.; Moghaddam, M.B. Smart water flooding performance in carbonate reservoirs: An experimental approach for tertiary oil recovery. J. Pet. Explor. Prod. Technol. 2019, 9, 2643–2657. [Google Scholar] [CrossRef]

- Masalmeh, S.; Al-Hammadi, M.; Farzaneh, A.; Sohrabi, M. Low Salinity Water Flooding in Carbonate: Screening, Laboratory Quantification and Field Implementation. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, UAE, 11–14 November 2019. [Google Scholar]

- Strand, S.; Høgnesen, E.J.; Austad, T. Wettability alteration of carbonates—Effects of potential determining ions (Ca2+ and SO42−) and temperature. Colloids Surf. A Physicochem. Eng. Asp. 2006, 275, 1–10. [Google Scholar] [CrossRef]

- Thomas, M.M.; Clouse, J.A.; Longo, J.M. Adsorption of organic compounds on carbonate minerals: 1. Model compounds and their influence on mineral wettability. Chem. Geol. 1993, 109, 201–213. [Google Scholar] [CrossRef]

- Standnes, D.C.; Austad, T. Wettability alteration in carbonates: Interaction between cationic surfactant and carboxylates as a key factor in wettability alteration from oil-wet to water-wet conditions. Colloids Surf. A Physicochem. Eng. Asp. 2003, 216, 243–259. [Google Scholar] [CrossRef]

- Karoussi, O.; Hamouda, A.A. Imbibition of sulfate and magnesium ions into carbonate rocks at elevated temperatures and their influence on wettability alteration and oil recovery. Energy Fuels 2007, 21, 2138–2146. [Google Scholar] [CrossRef]

- Brady, P.V.; Thyne, G. Functional wettability in carbonate reservoirs. Energy Fuels 2016, 30, 9217–9225. [Google Scholar] [CrossRef]

- Xie, Q.; He, S.; Pu, W. The effects of temperature and acid number of crude oil on the wettability of acid volcanic reservoir rock from the Hailar Oilfield. Pet. Sci. 2010, 7, 93–99. [Google Scholar] [CrossRef]

- Mahani, H.; Keya, A.L.; Berg, S.; Bartels, W.B.; Nasralla, R.; Rossen, W. Driving mechanism of low salinity flooding in carbonate rocks. In Proceedings of the EUROPEC 2015, Madrid, Spain, 1–4 June 2015. [Google Scholar]

- Derkani, M.H.; Fletcher, A.J.; Abdallah, W.; Sauerer, B.; Anderson, J.; Zhang, Z.J. Low salinity waterflooding in carbonate reservoirs: Review of interfacial mechanisms. Colloids Interfaces 2018, 2, 20. [Google Scholar] [CrossRef]

- Awolayo, A.N.; Sarma, H.K.; Nghiem, L.X. Brine-dependent recovery processes in carbonate and sandstone petroleum reservoirs: Review of laboratory-field studies, interfacial mechanisms and modeling attempts. Energies 2018, 11, 3020. [Google Scholar] [CrossRef]

- Romanuka, J.; Hofman, J.; Ligthelm, D.J.; Suijkerbuijk, B.; Marcelis, F.; Oedai, S.; Brussee, N.; van der Linde, H.; Aksulu, H.; Austad, T. Low salinity EOR in carbonates. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Katende, A.; Sagala, F. A critical review of low salinity water flooding: Mechanism, laboratory and field application. J. Mol. Liq. 2019, 278, 627–649. [Google Scholar] [CrossRef]

- AlQuraishi, A.A.; AlHussinan, S.N.; AlYami, H.Q. Efficiency and recovery mechanisms of low salinity water flooding in sandstone and carbonate reservoirs. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 25–27 March 2015. [Google Scholar]

- Khisamov, V.; Akhmetgareev, V.; Shilova, T. Core Tests and Field Case Studies of Successful and Unsuccessful Low-Salinity Waterfloods from Four Oil Fields. In Proceedings of the 79th EAGE Conference and Exhibition 2017-Workshops, Paris, France, 12 June 2017. [Google Scholar]

- Mahani, H.; Sorop, T.; Ligthelm, D.J.; Brooks, D.; Vledder, P.; Mozahem, F.; Ali, Y. Analysis of field responses to low-salinity waterflooding in secondary and tertiary mode in Syria. In Proceedings of the SPE Europec/EAGE Annual Conference and Exhibition, Vienna, Austria, 23–26 May 2011. [Google Scholar]

- Yousef, A.A.; Al-Saleh, S.; Al-Kaabi, A.U.; Al-Jawfi, M.S. Laboratory investigation of novel oil recovery method for carbonate reservoirs. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AB, Canada, 19–21 October 2010. [Google Scholar]

- Hadi, Y.; Hussain, F.; Othman, F. Low salinity water flooding in carbonate reservoirs–dissolution effect. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Vienna, Austria, 10–11 April 2019. [Google Scholar]

- Den Ouden, L.; Nasralla, R.A.; Guo, H.; Bruining, H.; Van Kruijsdijk, C.P.J.W. Calcite dissolution behaviour during low salinity water flooding in carbonate rock. In Proceedings of the IOR 2015-18th European Symposium on Improved Oil Recovery: Dresden, Germany, 14–16 April 2015. [Google Scholar]

- Okasha, T.M.; Alshiwaish, A. Effect of brine salinity on interfacial tension in Arab-D carbonate reservoir, Saudi Arabia. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 15–18 March 2009. [Google Scholar]

- Mokhtari, R.; Ayatollahi, S.; Fatemi, M. Experimental investigation of the influence of fluid-fluid interactions on oil recovery during low salinity water flooding. J. Pet. Sci. Eng. 2019, 182, 106194. [Google Scholar] [CrossRef]

- Ayirala, S.C.; Al-Saleh, S.H.; Al-Yousef, A.A. Microscopic scale interactions of water ions at crude oil/water interface and their impact on oil mobilization in advanced water flooding. J. Pet. Sci. Eng. 2018, 163, 640–649. [Google Scholar] [CrossRef]

- Tetteh, J.T.; Rankey, E.; Barati, R. Low salinity waterflooding effect: Crude oil/brine interactions as a recovery mechanism in carbonate rocks. In Proceedings of the OTC Brasil, Rio de Janeiro, Brazil, 24–26 October 2017. [Google Scholar]

- Yi, Z.; Sarma, H.K. Improving waterflood recovery efficiency in carbonate reservoirs through salinity variations and ionic exchanges: A promising low-cost" Smart-Waterflood" approach. In Proceedings of the Abu Dhabi International Petroleum Conference and Exhibition, Abu Dhabi, UAE, 11–14 November 2012. [Google Scholar]

- Strand, S.; Austad, T.; Puntervold, T.; Høgnesen, E.J.; Olsen, M.; Barstad, S.M.F. “Smart water” for oil recovery from fractured limestone: A preliminary study. Energy Fuels 2008, 22, 3126–3133. [Google Scholar] [CrossRef]

- Ravari, R.; Strand, S.; Austad, T. Care must be taken to use outcrop limestone cores to mimic reservoir core material in SCAL linked to wettability alteration. In Proceedings of the 11th Intenational Symposium on Reservoir Wettability, Calgary, CA, USA, 6 September 2010. [Google Scholar]

- Yousef, A.A.; Al-Saleh, S.; Al-Jawfi, M.S. Improved/enhanced oil recovery from carbonate reservoirs by tuning injection water salinity and ionic content. In Proceedings of the SPE improved oil recovery symposium, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Skrettingland, K.; Holt, T.; Tweheyo, M.T.; Skjevrak, I. Snorre Low-Salinity-Water Injection--Coreflooding Experiments and Single-Well Field Pilot. SPE Reserv. Eval. Eng. 2011, 14, 182–192. [Google Scholar] [CrossRef]

- Ahmetgareev, V.; Zeinijahromi, A.; Badalyan, A.; Khisamov, R.; Bedrikovetsky, P. Analysis of low salinity waterflooding in Bastrykskoye field. Pet. Sci. Technol. 2015, 33, 561–570. [Google Scholar] [CrossRef]

- Bedrikovetsky, P.; Zeinijahromi, A.; Badalyan, A.; Ahmetgareev, V.; Khisamov, R. Fines-Migration-Assisted Low-Salinity Waterflooding: Field Case Analysis (Russian). In Proceedings of the SPE Russian petroleum technology conference, Moscow, Russia, 26–28 October 2015. Society of Petroleum Engineers. [Google Scholar]

- Reinholdtsen, A.J.; RezaeiDoust, A.R.; Strand, S.; Austad, T. Why Such a Small Low Salinity EOR–Potential from the Snorre Formation? In Proceedings of the IOR 2011-16th European Symposium on Improved Oil Recovery, Cambridge, UK, 12–14 April 2011. [Google Scholar]

- Al-Ibadi, H.; Stephen, K.; Mackay, E. Heterogeneity Effects on Low Salinity Water Flooding. In Proceedings of the SPE Europec featured at 82nd EAGE Conference and Exhibition, Amsterdam, The Netherlands, 8–11 December 2020. [Google Scholar]

- Chang, H.L.; Zhang, Z.Q.; Wang, Q.M.; Xu, Z.S.; Guo, Z.D.; Sun, H.Q.; Cao, X.L.; Qiao, Q. Advances in polymer flooding and alkaline/surfactant/polymer processes as developed and applied in the People’s Republic of China. J. Pet. Technol. 2006, 58, 84–89. [Google Scholar] [CrossRef]

- Feng, R.-S.; Guo, Y.J.; Zhang, X.M.; Hu, J.; Li, H.B. Alkali/surfactant/polymer flooding in the daqing oilfield Class II reservoirs using associating polymer. J. Chem. 2013, 2013, 275943. [Google Scholar] [CrossRef] [PubMed]

- Shaker Shiran, B.; Skauge, A. Enhanced oil recovery (EOR) by combined low salinity water/polymer flooding. Energy Fuels 2013, 27, 1223–1235. [Google Scholar] [CrossRef]

- Unsal, E.; Berge, A.T.; Wever, D. Low salinity polymer flooding: Lower polymer retention and improved injectivity. J. Pet. Sci. Eng. 2018, 163, 671–682. [Google Scholar] [CrossRef]

- Vermolen, E.C.; Pingo-Almada, M.; Wassing, B.M.; Ligthelm, D.J.; Masalmeh, S.K. Low-salinity polymer flooding: Improving polymer flooding technical feasibility and economics by using low-salinity make-up brine. In Proceedings of the IPTC 2014: International Petroleum Technology Conference, Doha, Qatar, 19–22 January 2014. [Google Scholar]

- Zaitoun, A. Makakou, P.; Blin, N.; Al-Maamari, R.S.; Al-Hashmi, A.A.R.; Abdel-Goad, M. Shear stability of EOR polymers. SPE J. 2012, 17, 335–339. [Google Scholar] [CrossRef]

- Kozaki, C. Efficiency of low salinity polymer flooding in sandstone cores. SPE J. 2012, 22, 179695. [Google Scholar]

- Torrijos, I.D.P.; Puntervold, T.; Strand, S.; Austad, T.; Bleivik, T.H.; Abdullah, H.I. An experimental study of the low salinity Smart Water-Polymer hybrid EOR effect in sandstone material. J. Pet. Sci. Eng. 2018, 164, 219–229. [Google Scholar] [CrossRef]

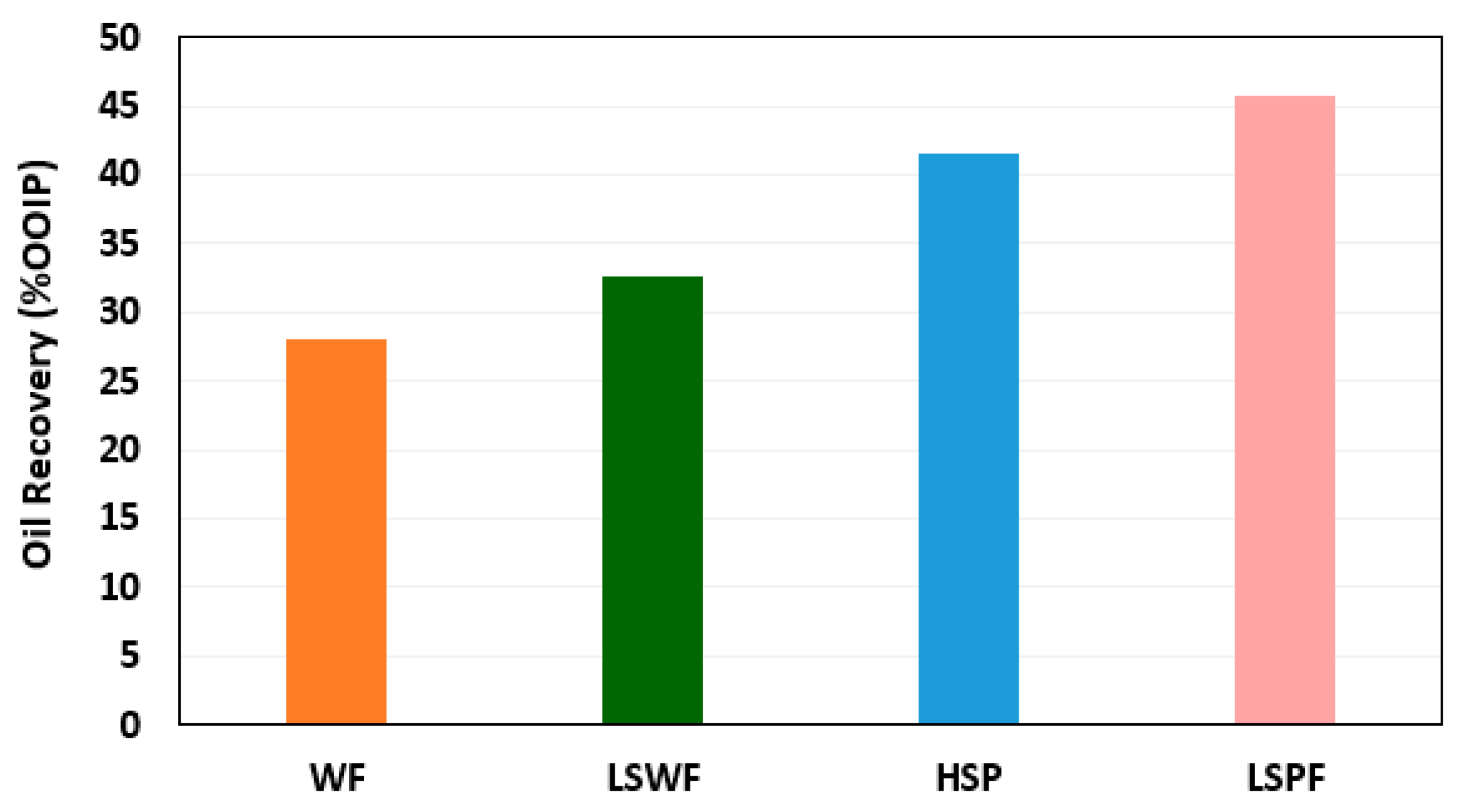

- Almansour, A.O.; AlQuraishi, A.A.; AlHussinan, S.N.; AlYami, H.Q. Efficiency of enhanced oil recovery using polymer-augmented low salinity flooding. J. Pet. Explor. Prod. Technol. 2017, 7, 1149–1158. [Google Scholar] [CrossRef]

- Tahir, M.; Hincapie, R.E.; Foedisch, H.; Abdullah, H.; Ganzer, L. Impact of Sulphates Presence During Application of Smart Water Flooding Combined with Polymer Flooding. In Proceedings of the SPE Europec featured at 80th EAGE Conference and Exhibition, Copenhagen, Denmark, 11–14 June 2018. [Google Scholar]

- Sandengen, K.; Kristoffersen, A.; Melhuus, K.; Jøsang, L.O. Osmosis as mechanism for low-salinity enhanced oil recovery. Spe J. 2016, 21, 1227–1235. [Google Scholar] [CrossRef]

- Buckley, J. Low Salinity Waterflooding-An Overview of Likely Mechanisms. Available online: https://www.uwyo.edu/eori/_files/eorctab_jan09/buckley_mechanisms.pdf (accessed on 15 January 2009).

- Callegaro, C.; Bartosek, M.; Masserano, F.; Nobili, M.; Parasiliti Parracello, V.P.; Pizzinelli, C.S.; Caschili, A. Opportunity of enhanced oil recovery low salinity water injection: From experimental work to simulation study up to field proposal. In Proceedings of the EAGE Annual Conference & Exhibition incorporating SPE Europec, London, UK, 10–13 June 2013. [Google Scholar]

- Fredriksen, S.B.; Rognmo, A.U.; Fernø, M.A. Pore-scale mechanisms during low salinity waterflooding: Oil mobilization by diffusion and osmosis. J. Pet. Sci. Eng. 2018, 163, 650–660. [Google Scholar] [CrossRef]

- Mohammadi, H.; Jerauld, G. Mechanistic modeling of the benefit of combining polymer with low salinity water for enhanced oil recovery. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2012. [Google Scholar]

- Alzayer, H.; Sohrabi, M. Numerical simulation of improved heavy oil recovery by low-salinity water injection and polymer flooding. In Proceedings of the SPE Saudi Arabia section technical symposium and exhibition, Al-Khobar, Saudi Arabia, 19–22 May 2013. Society of Petroleum Engineers. [Google Scholar]

- Borazjani, S.; Bedrikovetsky, P.; Farajzadeh, R. Analytical solutions of oil displacement by a polymer slug with varying salinity. J. Pet. Sci. Eng. 2016, 140, 28–40. [Google Scholar] [CrossRef]

- Santo, A.; Muggeridge, A. An Investigation into the Benefits of Combined Polymer-Low Salinity Waterflooding. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, An Investigation into the Benefits of Combined Polymer-Low Salinity Waterflooding, Brisbane, Australia, 23–25 October 2018. [Google Scholar]

- Alfazazi, U.; AlAmeri, W.; Hashmet, M.R. Experimental investigation of polymer flooding with low-salinity preconditioning of high temperature–high-salinity carbonate reservoir. J. Pet. Explor. Prod. Technol. 2019, 9, 1517–1530. [Google Scholar] [CrossRef]

- AlSofi, A.M.; Wang, J.; AlBoqmi, A.M.; AlOtaibi, M.B.; Ayirala, S.C.; AlYousef, A.A. Smartwater Synergy with Chemical Enhanced Oil Recovery: Polymer Effects on Smartwater. Spe Reserv. Eval. Eng. 2019, 22, 61–77. [Google Scholar] [CrossRef]

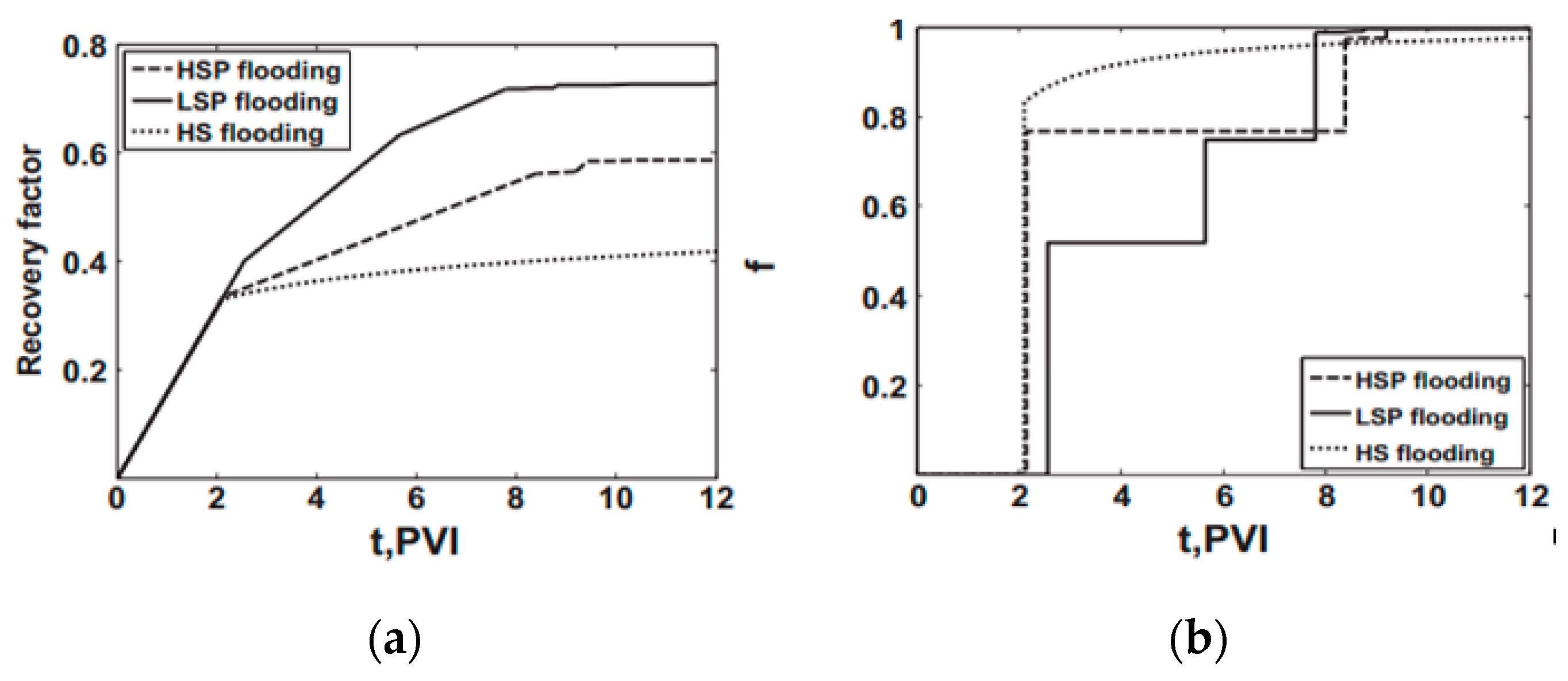

- Lee, Y.; Lee, W.; Jang, Y.; Sung, W. Oil recovery by low-salinity polymer flooding in carbonate oil reservoirs. J. Pet. Sci. Eng. 2019, 181, 106211. [Google Scholar] [CrossRef]

- Seright, R.S.; Campbell, A.; Mozley, P.; Han, P. Stability of partially hydrolyzed polyacrylamides at elevated temperatures in the absence of divalent cations. SPE J. 2010, 15, 341–348. [Google Scholar] [CrossRef]

- Ayirala, S.C.; Uehara-Nagamine, E.; Matzakos, A.N.; Chin, R.W.; Doe, P.H.; van den Hoek, P.J. A designer water process for offshore low salinity and polymer flooding applications. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. Society of Petroleum Engineers. [Google Scholar]

- Pourafshary, P.; Moradpour, N. Hybrid EOR Methods Utilizing Low-Salinity Water, in Enhanced Oil Recovery Processes-New Technologies. IntechOpen 2019. [Google Scholar] [CrossRef]

- AlSofi, A.M.; Wang, J.; AlBoqmi, A.M.; AlOtaibi, M.B.; Ayirala, S.C.; AlYousef, A.A. SmartWater Synergy with Chemical EOR for a Slightly Viscous Arabian Heavy Reservoir. In Proceedings of the SPE Heavy Oil Conference and Exhibition, Kuwait City, Kuwait, 6–8 December 2016. [Google Scholar]

- Morrow, N.; Chatzis, I.; Taber, J. Entrapment and mobilization of residual oil in bead packs. SPE Reserv. Eng. 1988, 3, 927–934. [Google Scholar] [CrossRef]

- Tang, J.S. Interwell Tracer Tests To Determine Residual Oil Saturation To Waterflood At Judy Creek Bhl′a′pool. J. Can. Pet. Technol. 1992, 31. [Google Scholar] [CrossRef]

- Abrams, A. The influence of fluid viscosity, interfacial tension, and flow velocity on residual oil saturation left by waterflood. Soc. Pet. Eng. J. 1975, 15, 437–447. [Google Scholar] [CrossRef]

- Chatzis, I.; Morrow, N.R. Correlation of capillary number relationships for sandstone. Soc. Pet. Eng. J. 1984, 24, 555–562. [Google Scholar] [CrossRef]

- Fulcher, R., Jr.; Ertekin, T.; Stahl, C. Effect of capillary number and its constituents on two-phase relative permeability curves. J. Pet. Technol. 1985, 37, 249–260. [Google Scholar] [CrossRef]

- Guo, H.; Dou, M.; Hanqing, W.; Wang, F.; Yuanyuan, G.; Yu, Z.; Yansheng, W.; Li, Y. Proper use of capillary number in chemical flooding. J. Chem. 2017, 2017, 4307368. [Google Scholar]

- Hilfer, R.; Armstrong, R.T.; Berg, S.; Georgiadis, A.; Ott, H. Capillary saturation and desaturation. Phys. Rev. E 2015, 92, 063023. [Google Scholar] [CrossRef] [PubMed]

- Morrow, N.R. Interplay of capillary, viscous and buoyancy forces in the mobilization of residual oil. J. Can. Pet. Technol. 1979, 18. [Google Scholar] [CrossRef]

- Garnes, J.M.; Mathisen, A.M.; Scheie, A.; Skauge, A. Capillary number relations for some North, Sea reservoir sandstones. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–25 April 1990. [Google Scholar]

- Moore, T.; Slobod, R. The effect of viscosity and capillarity on the displacement of oil by water. Prod. Mon. 1956, 20, 20–30. [Google Scholar]

- Donaldson, E.C.; Chilingarian, G.V.; Yen, T.F. Enhanced Oil Recovery, II: Processes and Operations; Elsevier: Amsterdam, The Netherlands, 1989. [Google Scholar]

- Lake, L.W. Enhanced oil Recovery; Prentice Hall: Upper Saddle River, NJ USA, 1989. [Google Scholar]

- Taber, J. Dynamic and static forces required to remove a discontinuous oil phase from porous media containing both oil and water. Soc. Pet. Eng. J. 1969, 9, 3–12. [Google Scholar] [CrossRef]

- Schneider, F.; Owens, W. Steady-state measurements of relative permeability for polymer/oil systems. Soc. Pet. Eng. J. 1982, 22, 79–86. [Google Scholar] [CrossRef]

- Pusch, G.; Lotsch, T.; Muller, T. Investigation of the Oil Displacing Efficiency of Suitable Polymer Products in Porous Media, Aspects of Recovery Mechanisms During Polymer Flooding. 16 Tab. DGMK-Report, 295-6. German Soc. Petrol. Sci. Coal Chem. 1987, 6, 295. [Google Scholar]

- Wenxiang, W.; Demin, W.; Haifeng, J. Effect of the visco-elasticity of displacing fluids on the relationship of capillary number and displacement efficiency in weak oil-wet cores. In Proceedings of the Asia Pacific Oil and Gas Conference and Exhibition, Jakarta, Indonesia, 30 October–1 November 2007. [Google Scholar]

- Vermolen, E.; van Haasterecht, M.; Masalmeh, S. A systematic study of the polymer visco-elastic effect on residual oil saturation by core flooding. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 31 March–2 April 2014. [Google Scholar]

- Qi, P.; Ehrenfried, D.H.; Koh, H.; Balhoff, M.T. Reduction of residual oil saturation in sandstone cores by use of viscoelastic polymers. SPE J. 2017, 22, 447–458. [Google Scholar] [CrossRef]

- Clarke, A.; Howe, A.M.; Mitchell, J.; Staniland, J.; Hawkes, L.A. How viscoelastic-polymer flooding enhances displacement efficiency. SPE J. 2016, 21, 675–687. [Google Scholar] [CrossRef]

- Zhong, H.; Zang, Q.; Yin, H.; Xia, H. Experimental study on medium viscosity oil displacement using viscoelastic polymer. Geofluids 2018, 2018, 4321380. [Google Scholar] [CrossRef]

- Erincik, M.Z.; Qi, P.; Balhoff, M.T.; Pope, G.A. New method to reduce residual oil saturation by polymer flooding. SPE J. 2018, 23, 1944–1956. [Google Scholar] [CrossRef]

- El-Hoshoudy, A.; Desouky, S.E.M.; Elkady, M.Y.; Al-Sabagh, A.M.; Betiha, M.A.; Mahmoud, S. Hydrophobically associated polymers for wettability alteration and enhanced oil recovery–Article review. Egypt. J. Pet. 2017, 26, 757–762. [Google Scholar] [CrossRef]

- Janiga, D.; Czarnota, R.; Stopa, J.; Wojnarowski, P.; Kosowski, P. Performance of nature inspired optimization algorithms for polymer enhanced oil recovery process. J. Pet. Sci. Eng. 2017, 154, 354–366. [Google Scholar] [CrossRef]

- Sandengen, K.; Melhuus, K.; Kristoffersen, A. Polymer “viscoelastic effect”; does it reduce residual oil saturation. J. Pet. Sci. Eng. 2017, 153, 355–363. [Google Scholar] [CrossRef]

- Wang, D.; Xia, H.; Liu, Z.; Yang, Q. Study of the mechanism of polymer solution with visco-elastic behavior increasing microscopic oil displacement efficiency and the forming of steady “Oil thread” flow channels. In Proceedings of the SPE Asia Pacific oil and gas conference and exhibition, Jakarta, Indonesia, 17–19 April 2001. [Google Scholar]

- Wang, J.; Dong, M. A laboratory study of polymer flooding for improving heavy oil recovery. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 12–14 June 2007. [Google Scholar]

- Xia, H.; Wang, D.; Wang, G.; Ma, W.G.; Deng, H.W.; Liu, J. Mechanism of the effect of micro-forces on residual oil in chemical flooding. In Proceedings of the SPE symposium on improved oil recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Urbissinova, T.; Trivedi, J.J.; Kuru, E. Effect of elasticity during viscoelastic polymer flooding-a possible mechanism of increasing the sweep efficiency. In Proceedings of the SPE western regional meeting, Anaheim, CA, USA, 27–29 May 2010. [Google Scholar]

- Al Shalabi, E.W.; Sepehrnoori, K.; Delshad, M. Mechanisms behind low salinity water injection in carbonate reservoirs. Fuel 2014, 121, 11–19. [Google Scholar] [CrossRef]

- Zhang, P.; Tweheyo, M.T.; Austad, T. Wettability alteration and improved oil recovery in chalk: The effect of calcium in the presence of sulfate. Energy Fuels 2006, 20, 2056–2062. [Google Scholar] [CrossRef]

- Bartels, W.-B.; Mahani, H.; Berg, S.; Hassanizadeh, S.M. Literature review of low salinity waterflooding from a length and time scale perspective. Fuel 2019, 236, 338–353. [Google Scholar] [CrossRef]

- Fathi, S.J.; Austad, T.; Strand, S. Water-based enhanced oil recovery (EOR) by ′′smart water′′ in carbonate reservoirs. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 16–18 April 2012. [Google Scholar]

- Zahid, A.; Stenby, E.H.; Shapiro, A.A. Smart waterflooding (high sal/low sal) in carbonate reservoirs. In Proceedings of the SPE Europec/EAGE Annual Conference, Copenhagen, Denmark, 4–7 June 2012. Society of Petroleum Engineers. [Google Scholar]

- Chandrasekhar, S.; Sharma, H.; Mohanty, K.K. Dependence of wettability on brine composition in high temperature carbonate rocks. Fuel 2018, 225, 573–587. [Google Scholar] [CrossRef]

- Jabbar, M.Y.; Al-Hashim, H.S.; Abdallah, W. Effect of brine composition on wettability alteration of carbonate rocks in the presence of polar compounds. In Proceedings of the SPE Saudi Arabia Section Technical Symposium and Exhibition, Al-Khobar, Saudi Arabia, 19–22 May 2013. [Google Scholar]

- Levitt, D.; Pope, G.A. Selection and screening of polymers for enhanced-oil recovery. In Proceedings of the SPE symposium on improved oil recovery, Tulsa, OK, USA, 20–23 April 2008. [Google Scholar]

- Wang, D.; Cheng, J.; Yang, Q.; Wenchao, G.; Qun, L.; Chen, F. Viscous-elastic polymer can increase microscale displacement efficiency in cores. In Proceedings of the SPE annual technical conference and exhibition, Dallas, TX, USA, 1–4 October 2000. [Google Scholar]

- Silveira, B.; Lopes, L.; Moreno, R. Rheological approach of HPAM solutions under harsh conditions for EOR applications. Int. J. Eng. Technol. 2016, 16, 1–8. [Google Scholar]

- Moghadasi, L.; Pisicchio, P.; Bartosek, M.; Braccalenti, E.; Albonico, P.; Moroni, I.; Veschi, R.; Masserano, F.; Scagliotti, S.; Del Gaudio, L.; et al. Laboratory Investigation on Synergy Effect of Low Salinity-Polymer Water Injection on Sandstone Porous Media. In Proceedings of the Offshore Mediterranean Conference and Exhibition, Ravenna, Italy, 27–29 March 2019. [Google Scholar]

- Lee, S.; Kim, D.H.; Huh, C.; Pope, G.A. Development of a comprehensive rheological property database for EOR polymers. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, Louisiana, 4–7 October 2009. [Google Scholar]

- AlSofi, A.M.; Wang, J.; Kaidar, Z.F. SmartWater synergy with chemical EOR: Effects on polymer injectivity, retention and acceleration. J. Pet. Sci. Eng. 2018, 166, 274–282. [Google Scholar] [CrossRef]

- Aluhwal, H.; Kalifa, O. Simulation Study of Improving oil Recovery by Polymer Flooding in a Malaysian Reservoir. Master’sThesis, Department of Petroleum Engineering, Universiti Teknologi Malaysia, Malaysia, 2008; p. 212. [Google Scholar]

- Guetni, I.; Marlière, C.; Rousseau, D.; Bihannic, I.; Pelletier, M.; Villieras, F. Transport of HPAM Solutions in low Permeability Porous Media: Impacts of Salinity and Clay Content. In Proceedings of the SPE Europec featured at 81st EAGE Conference and Exhibition, London, England, UK, 3–6 June 2019. [Google Scholar]

- Bennetzen, M.V.; Gilani, S.F.H.; Mogensen, K.; Ghozali, M.; Bounoua, N. Successful polymer flooding of low-permeability, oil-wet, carbonate reservoir cores. In Proceedings of the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, 10–13 November 2014. [Google Scholar]

- El-Khatib, M.F. Investigation of Low Salinity Polymer and Surfactant Flooding in Carbonate Reservoir at Reservoir Conditions. Master’sThesis, Department of Physics and Technology, The University of Bergen, Bergen, Norway, February 2018. [Google Scholar]

- Wang, J.; Ayirala, S.C.; AlSofi, A.M.; Al-Yousef, A.A.; Aramco, S. SmartWater Synergy with Surfactant Polymer Flooding for Efficient Oil Mobilization in Carbonates. In Proceedings of the SPE EOR Conference at Oil and Gas West Asia, Muscat, Oman, 26–28 March 2018. [Google Scholar]

- Pires, A.P.; Bedrikovetsky, P.G.; Shapiro, A.A. A splitting technique for analytical modelling of two-phase multicomponent flow in porous media. J. Pet. Sci. Eng. 2006, 51, 54–67. [Google Scholar] [CrossRef]

- Webb, K.; Lager, A.; Black, C. Comparison of high/low salinity water/oil relative permeability. In Proceedings of the International symposium of the society of core analysts, Abu Dhabi, UAE, 29 October–2 November 2008. [Google Scholar]

- Hirasaki, G. and G. Pope, Analysis of factors influencing mobility and adsorption in the flow of polymer solution through porous media. Soc. Pet. Eng. J. 1974, 14, 337–346. [Google Scholar] [CrossRef]

- Han, B.; Lee, J. Sensitivity analysis on the design parameters of enhanced oil recovery by polymer flooding with low salinity waterflooding. In Proceedings of the Twenty-fourth International Ocean and Polar Engineering Conference, Busan, Korea, 15–20 June 2014. [Google Scholar]

- Khamees, T.; Flori, R.E. Modeling the Combined Effects of Water Salinity and Polymer Rheology on the Performance of Polymer Flooding and In-Depth Gel Treatment. In Proceedings of the SPE Western Regional Meeting, Garden Grove, CA, USA, 22–26 April 2018. [Google Scholar]

- Xin, X.; Yu, G.; Chen, Z.; Wu, K.; Dong, X.; and Zhu, Z. Effect of polymer degradation on polymer flooding in heterogeneous reservoirs. Polymers 2018, 10, 857. [Google Scholar] [CrossRef] [PubMed]

- Dang, T.Q.C.; Chen, Z.; Nguyen, T.B.N.; Bae, W. Rheological modeling and numerical simulation of HPAM polymer viscosity in porous media. Energy SourcesPart A RecoveryUtil. Environ. Eff. 2015, 37, 2189–2197. [Google Scholar] [CrossRef]

- Gu, X.; Sang, H.; Pu, C.; Zhang, L.; Zhao, Q. Effect of pH on Gelling Performance and stability of HPAM/Cr3+ Weak Gel. In Proceedings of the 2015 International Forum on Energy, Environment Science and Materials, Shenzhen, China, 25–26 September 2015. [Google Scholar]

- Austad, T.; Strand, S.; Høgnesen, E.J.; Zhang, P. Seawater as IOR fluid in fractured chalk. In Proceedings of the SPE International Symposium on Oilfield Chemistry, The Woodlands, TX, USA, 2–4 February 2005. [Google Scholar]

- Alotaibi, M.B.; Azmy, R.; Nasr-El-Din, H.A. Wettability challenges in carbonate reservoirs. In Proceedings of the SPE Improved Oil Recovery Symposium, Tulsa, OK, USA, 24–28 April 2010. [Google Scholar]

- Zhang, P.; Austad, T. Wettability and oil recovery from carbonates: Effects of temperature and potential determining ions. Colloids Surf. A Physicochem. Eng. Asp. 2006, 279, 179–187. [Google Scholar] [CrossRef]

- Gomari, K.R.; Hamouda, A.; Denoyel, R. Influence of sulfate ions on the interaction between fatty acids and calcite surface. Colloids Surf. A Physicochem. Eng. Asp. 2006, 287, 29–35. [Google Scholar] [CrossRef]

- Al-Nofli, K.; Pourafshary, P.; Mosavat, N.; Shafiei, A. Effect of initial wettability on performance of smart water flooding in carbonate reservoirs—an experimental investigation with ior implications. Energies 2018, 11, 1394. [Google Scholar] [CrossRef]

| Study | Rock Type | Brine TDS (g/L) | Potential Determining Ions (PDIs) | Acid Number (AN) (mg KOH/g) | Temperature (°C) | Injection Mode | Incremental Recovery (%OOIP) | Remarks |

|---|---|---|---|---|---|---|---|---|

| Bagci, Kok [72] | Unconsolidated limestone | FW: Nil EW: 20 | KCI | - | 50 | Secondary | 18,4 | 2 wt% KCI case resulted in maximum recovery due to reduction in pH |

| Fathi, Austrad [61] | Outcrop chalk cores | FW: 62.80 EW: 16.79 | 4 times the amount of SO42− and 4 times the amount of Ca2+ | Oil A: 2.0 and Oil B: 0.5 | 70–120 | Secondary | 24 | The highest recoveries using EW were observed in 90–120 °C temperature range with SO42− ions. Effect of Ca 2+ was observed only at 120 °C. indicating that Ca2+ is less active at lower temperatures. |

| Gupta, Smith [73] | Limestone and dolomite | FW: 181 EW: 33 | 4 times the amount of SO42− | 0.11 | 70 °C for dolomite and 120 °C for limestone | Tertiary | 9% in dolomite and 5.1% in limestone | The lower recovery for the limestone core was attributed to anhydrite precipitation at higher temperatures. |

| Yousef, Al-Saleh [74] | Limestone | FW: 213 EW: 5.7 | SO42−, Ca2+, and Mg2+ present in sea water | 0.25 | 100 | Tertiary | 18 | The highest tertiary recovery by LSW is attributed to improved connectivity between pore systems due to mineral dissolution by salinity gradient. |

| Zahid, Shapiro [60] | Reservoir carbonate and outcrop chalk | FW: 213 EW: 57 | SO42−, Ca2+, and Mg2+ present in sea water | 0.96 | Ambient and 90 °C | Tertiary | LSW did not result in any incremental oil at ambient temperature because of negligible activity of potential ions. Higher recovery from carbonate at 90 °C was possibly due to dissolution reactions. Poor recovery from chalk was due to water wet nature of cores. | |

| Chandrasekhar and Mohanty [62] | Limestone | FW: 179 EW: 5.7 | SO42−, Ca2+, and Mg2+ | 2.45 | 120 | Secondary and tertiary | 32–36 | LSW with SO42– and Mg2+ gave best results in terms of oil recovery and wettability alteration. Ca2+ ions were not effective. Ion exchange and mineral dissolution were dominant mechanisms. Higher EW recovery can also be due to higher AN oil. |

| Al-Attar, Mahmoud [63] | Limestone | FW: 197 EW: 5 | SO42−, Ca2+ | - | 25 | Secondary | 24 | SO42– addition gave the highest recovery. However, addition of Ca2+ had a negative effect on recovery |

| Awolayo, Sarma [75] | Limestone | FW: 261 EW: 43.9 | 4 times the amount of SO42− | - | 110 | Tertiary | 10 | Increasing SO42– beyond 4 times the original amount did not give any incremental recovery possibly due to CaSO4 precipitation triggered at higher temperatures. |

| Alameri, Teklu [76] | Fractured limestone | FW: 100 EW: 12.8 | - | - | 90.6 | Tertiary | 7 | LSW can work for low permeability rocks, but the incremental recovery is high in less heterogeneous reservoirs |

| Puntervold, Strand [77] | Outcrop chalk cores | FW: 62.83 EW: 20.24 | 4 times the amount of SO42− | 0.5 | 90 | Secondary | 20 | LSW spiked with 4-fold amount of SO42– ions gave maximum incremental oil as compared to original seawater. |

| Qiao, Li [78] and Fathi, Austad [79] | Chalk | Molarity FW: 2.198 EW: 0.794 | 4 times the amount of SO42− and 4 times the amount of Ca2+ | 1.9 | 110 | Secondary | 14–22 | Effective LSW design should include higher amount of SO42– and small amount of divalent ions to increase water-wet fraction of rock. |

| Mohsenzadeh, Pourafshary [80] | Limestone | FW: 136 EW: 4.5 | - | - | 87 | Tertiary | 22.5 | IFT reduction was observed to be the main LSW recovery mechanism at low reservoir temperature and lower concentration of active ions. |

| Fani, Al-Hadrami [81] | Limestone | FW: 102.5 EW:7.7 | 4 times the amount of SO42− | - | 87 | Tertiary | 22.2 | Smaller tertiary EW slugs can provide comparable recovery to larger slugs if reasonable soaking time is given for EW to interact with the rock. |

| Nasralla, Mahani [82] | Limestone | FW: 239 EW: 4.4 | SO42– and Mg2+ present in seawater | - | 100 | Secondary and tertiary | 7 | LSW performance varies with rock properties and minerology. In low-permeability formations, LSW results in accelerated oil production at lower injection rates. |

| Sarvestani, Ayatollahi [83] | Limestone | FW:150 EW: 4 | SO42−, Ca2+, and Mg2+ | 0.14 | 90 | Secondary | 12 | Mg2+ affected the oil recovery more than Ca2+. The (SO42−)/(Mg2+) ratio is the controlling factor in the wettability modification. |

| Masalmeh, Al-Hammadi [84] | Limestone | FW:204 EW: 0.24 | - | 9.25 | 127 | Secondary and tertiary | 6.5–12.5 | Crude oils with high AN lead to extra oil recovery by LSW in both secondary and tertiary modes due to formation of microdispersions. |

| Parameter | Conditions |

|---|---|

| Polymer Flooding | |

| Porous Medium | Mostly sandstone. Limited application in carbonates mainly due to the high-salinity formation water associated with carbonates [25,26,27]. |

| Formation Water | Salinity should be < 100,000 ppm [43]. Chlorides should be < 20,000 ppm, Ca2+ and Mg2+ divalent ions must be < 500 ppm [47]. Low salinity (LS) is preferred to avoid polymer degradation [44]. |

| Permeability | Value range of 20 to 2300 md. Polymer adsorption can cause permeability reduction [14,45,191]. |

| Temperature | Should be < 93 °C. HPAM undergoes thermal degradation at high temperature [32,46,49]. |

| pH | High pH is favorable for HPAM due to increased electrostatic repulsion [192,193]. |

| Engineered Water Flooding | |

| Oil | Must have polar organic components in order to observe EW EOR effects [84,106,194]. |

| Injection Fluid | Salinity must be between 2000 and 5000 ppm [105,195], but can work up to 33,000 ppm [70,79]. Injection water must have PDIs, Mg2+, or Ca2+ and SO42− [74,85,196]. |

| Temperature | Should be > 70 °C [92,106,107,196]. |

| Initial Wettability | Oil-wet to mixed-wet [194,197,198]. |

| Engineered Water Polymer Flooding | |

| Formation Water | This method can be applied to reservoirs containing high-salinity and high-hardness formation water in the range of 167,000–239,000 ppm [15,133]. |

| Injection Water | Salinity should be low as compared to formation water. A value range of 300–9750 ppm has been reported in the literature [133,184]. |

| PDIs | Injection water spiked with 4 times the amount of SO42– ions gives the best results. Increase in Ca2+ concentration can cause polymer degradation [135]. |

| Temperature | Can be as high as 120 °C [133]. |

| Permeability | EWPF can also provide incremental recovery from low permeability formations (< 10md) [15,183]. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shakeel, M.; Pourafshary, P.; Rehan Hashmet, M. Hybrid Engineered Water–Polymer Flooding in Carbonates: A Review of Mechanisms and Case Studies. Appl. Sci. 2020, 10, 6087. https://doi.org/10.3390/app10176087

Shakeel M, Pourafshary P, Rehan Hashmet M. Hybrid Engineered Water–Polymer Flooding in Carbonates: A Review of Mechanisms and Case Studies. Applied Sciences. 2020; 10(17):6087. https://doi.org/10.3390/app10176087

Chicago/Turabian StyleShakeel, Mariam, Peyman Pourafshary, and Muhammad Rehan Hashmet. 2020. "Hybrid Engineered Water–Polymer Flooding in Carbonates: A Review of Mechanisms and Case Studies" Applied Sciences 10, no. 17: 6087. https://doi.org/10.3390/app10176087

APA StyleShakeel, M., Pourafshary, P., & Rehan Hashmet, M. (2020). Hybrid Engineered Water–Polymer Flooding in Carbonates: A Review of Mechanisms and Case Studies. Applied Sciences, 10(17), 6087. https://doi.org/10.3390/app10176087