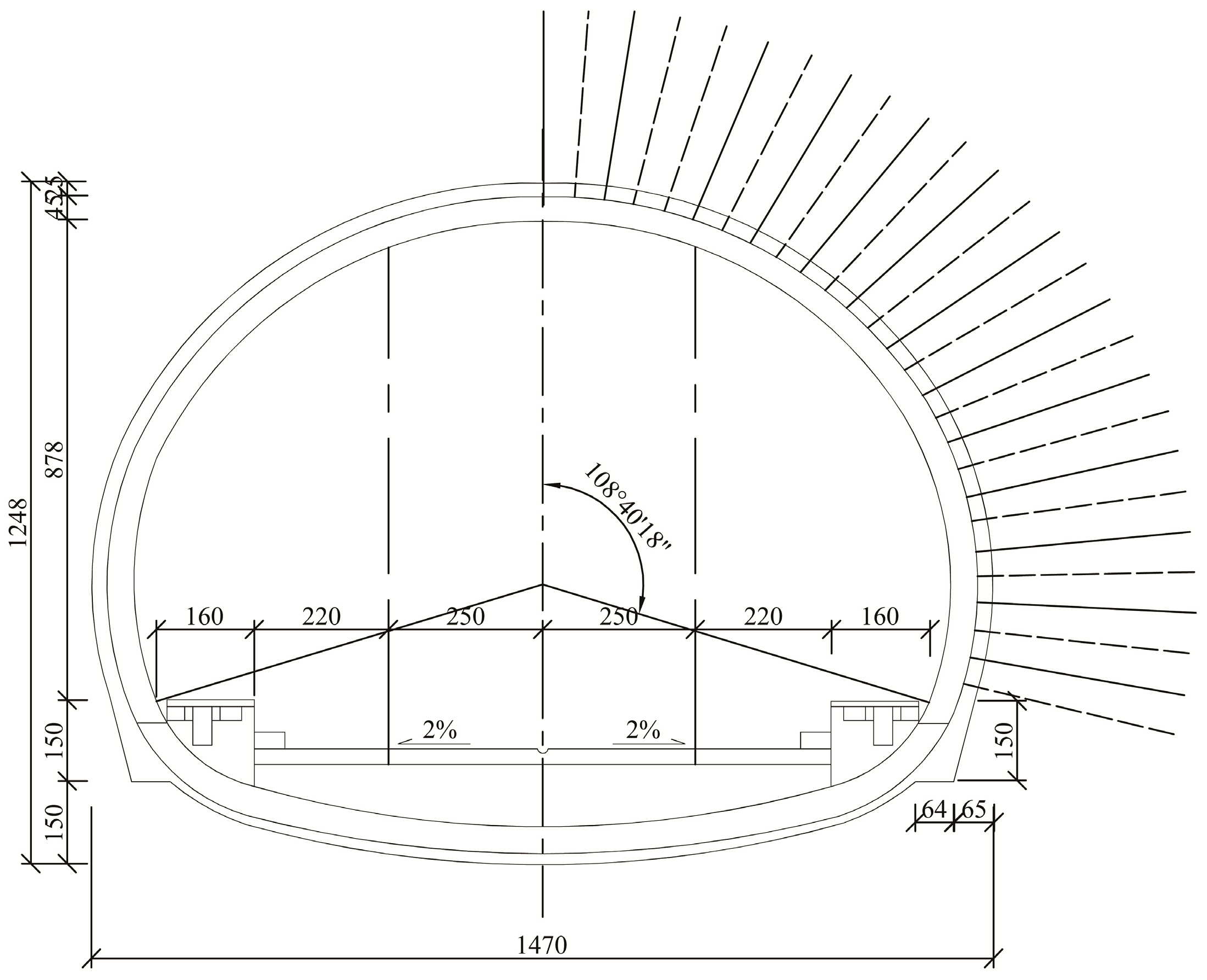

Figure 1.

Layout of tunnel section (unit: cm).

Figure 1.

Layout of tunnel section (unit: cm).

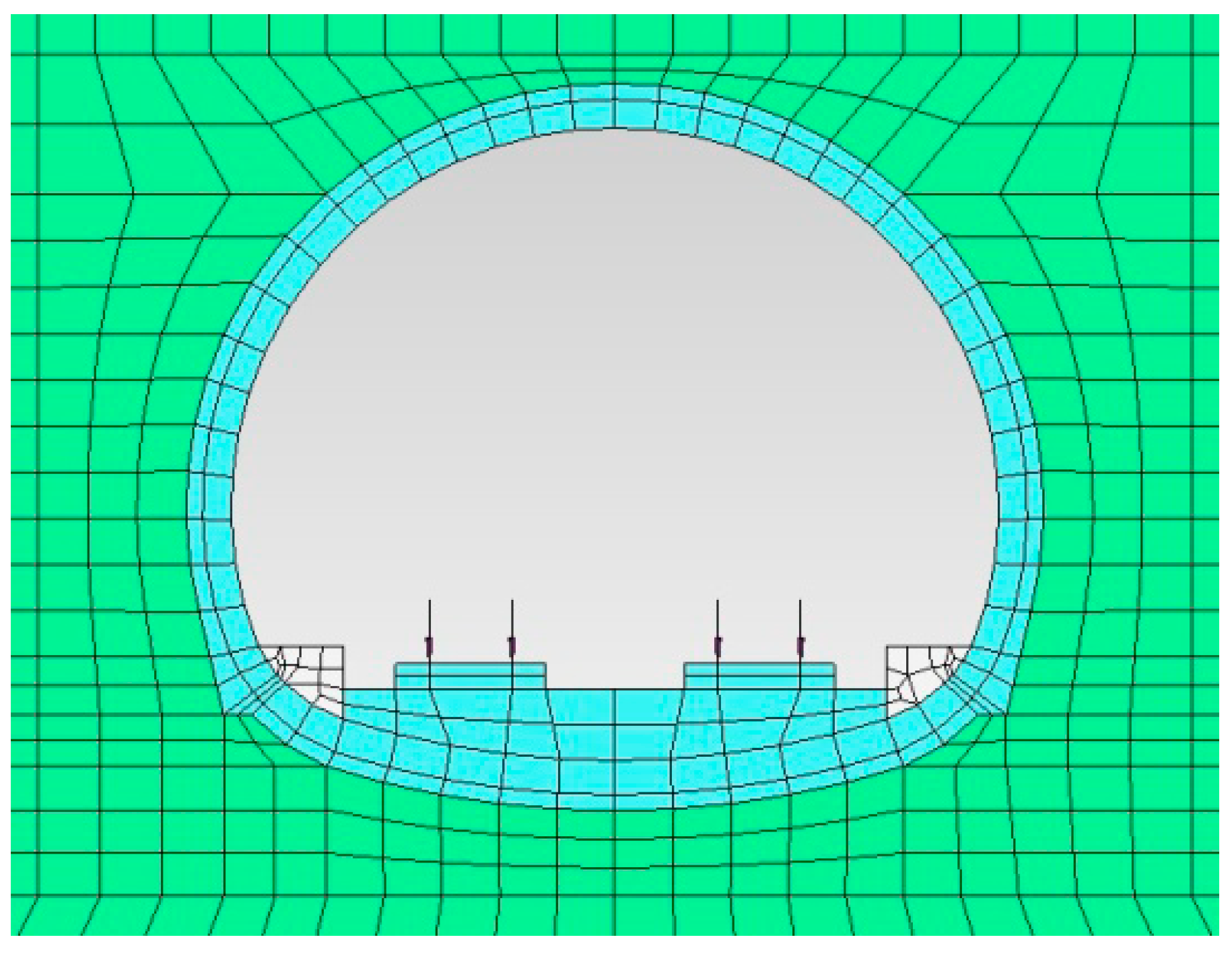

Figure 2.

Numerical simulation model: the cross angle of two tunnels for (a), (b), (c), and (d) are 0°, 30°, 60°, and 90°, respectively.

Figure 2.

Numerical simulation model: the cross angle of two tunnels for (a), (b), (c), and (d) are 0°, 30°, 60°, and 90°, respectively.

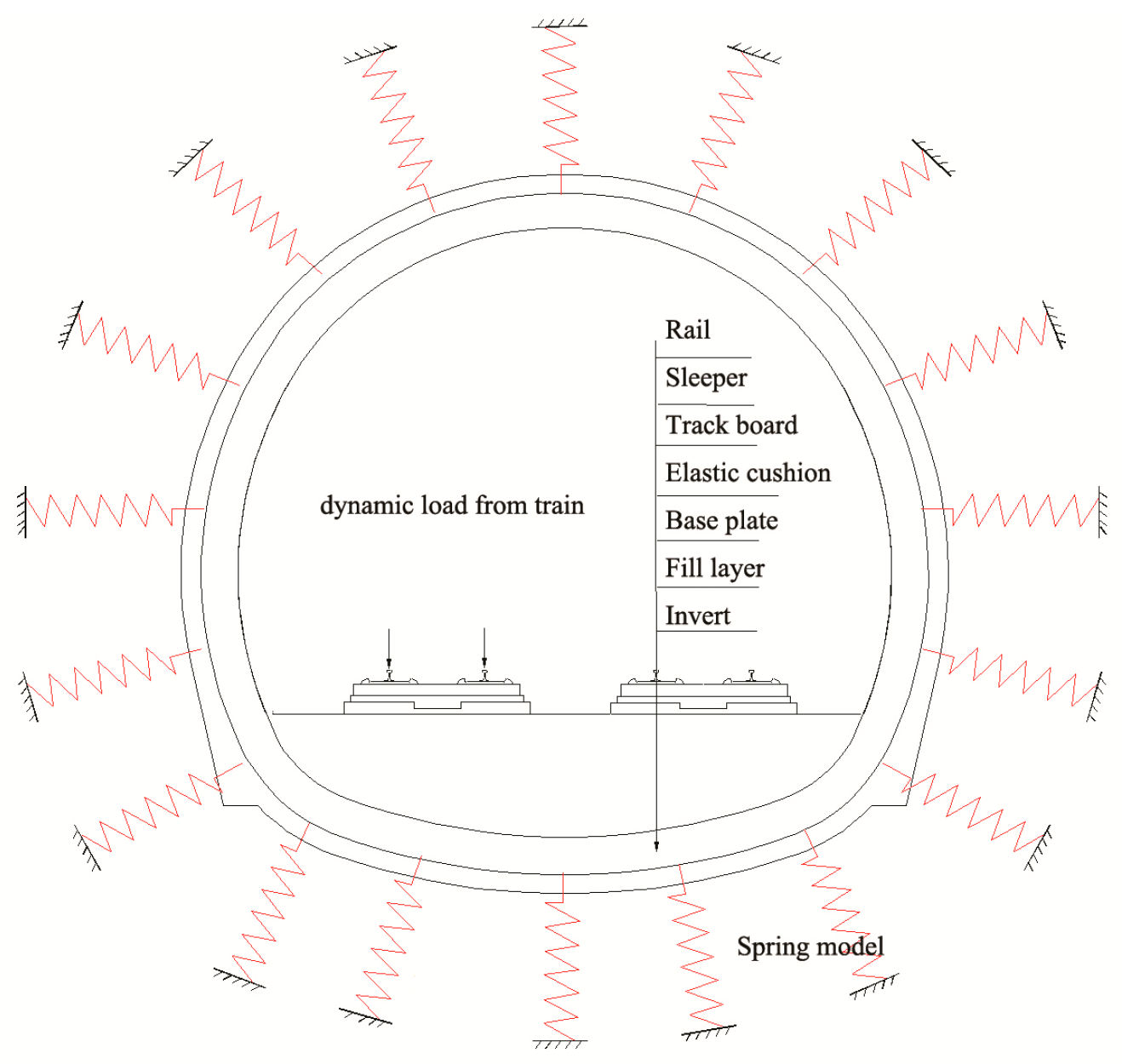

Figure 4.

Boundary condition.

Figure 4.

Boundary condition.

Figure 5.

Time-history curve of the train load.

Figure 5.

Time-history curve of the train load.

Figure 6.

Schematic of the fatigue test.

Figure 6.

Schematic of the fatigue test.

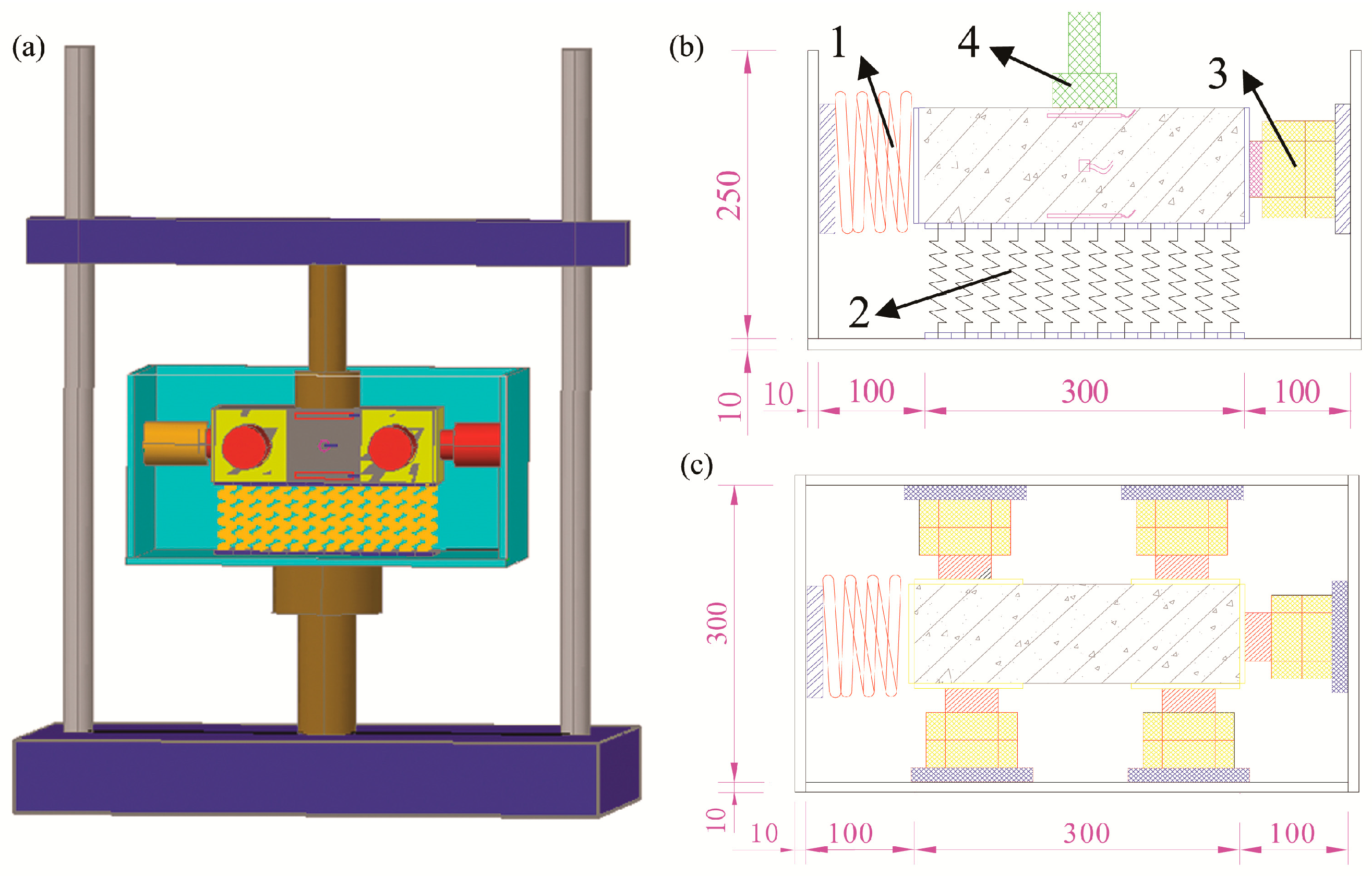

Figure 7.

Structure of the fatigue test system: (a) three-dimensional (3D) model, (b) lateral view, and (c) top view; 1 and 2 refer to the lateral spring, 3 refers to the hydraulic jacks, and 4 refers to the MTS (American brand of electro-hydraulic, servo-material testing machine).

Figure 7.

Structure of the fatigue test system: (a) three-dimensional (3D) model, (b) lateral view, and (c) top view; 1 and 2 refer to the lateral spring, 3 refers to the hydraulic jacks, and 4 refers to the MTS (American brand of electro-hydraulic, servo-material testing machine).

Figure 8.

Test instrument and its components: (a) device box and MTS, (b) bottom spring plate, and (c) hydraulic jacks.

Figure 8.

Test instrument and its components: (a) device box and MTS, (b) bottom spring plate, and (c) hydraulic jacks.

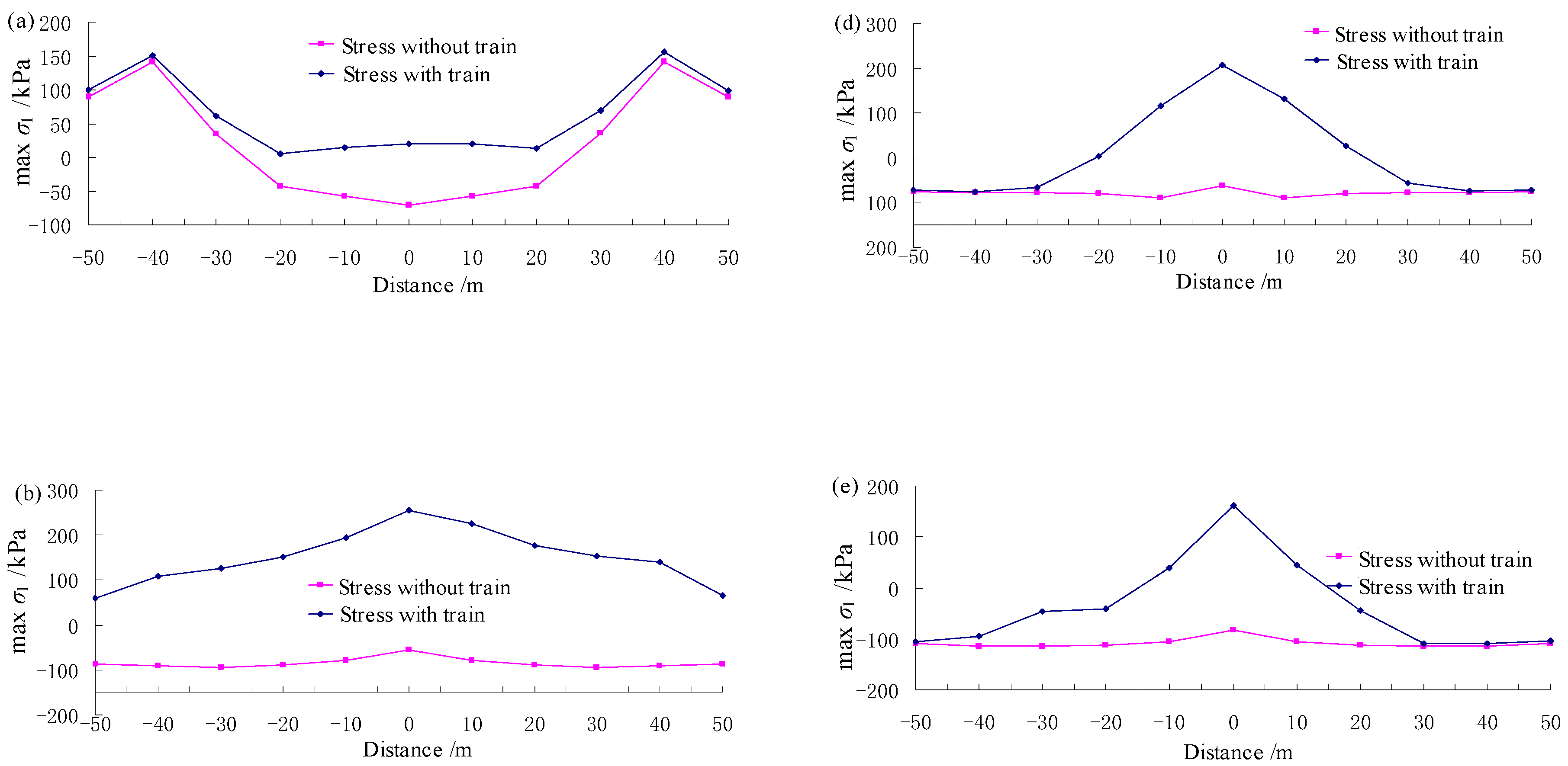

Figure 9.

Distribution of secondary lining along the longitudinal direction of the tunnel: (a) arch of upper tunnel, (b) side wall of upper tunnel, (c) inversion of upper tunnel, (d) arch of lower tunnel, (e) side wall of lower tunnel, and (f) inversion of lower tunnel.

Figure 9.

Distribution of secondary lining along the longitudinal direction of the tunnel: (a) arch of upper tunnel, (b) side wall of upper tunnel, (c) inversion of upper tunnel, (d) arch of lower tunnel, (e) side wall of lower tunnel, and (f) inversion of lower tunnel.

Figure 10.

Distribution of secondary lining along the longitudinal direction of the tunnel: (a) arch of the upper tunnel, (b) side wall of the upper tunnel, (c) invert of the upper tunnel, (d) arch of the lower tunnel, (e) side wall of the lower tunnel, and (f) invert of the lower tunnel.

Figure 10.

Distribution of secondary lining along the longitudinal direction of the tunnel: (a) arch of the upper tunnel, (b) side wall of the upper tunnel, (c) invert of the upper tunnel, (d) arch of the lower tunnel, (e) side wall of the lower tunnel, and (f) invert of the lower tunnel.

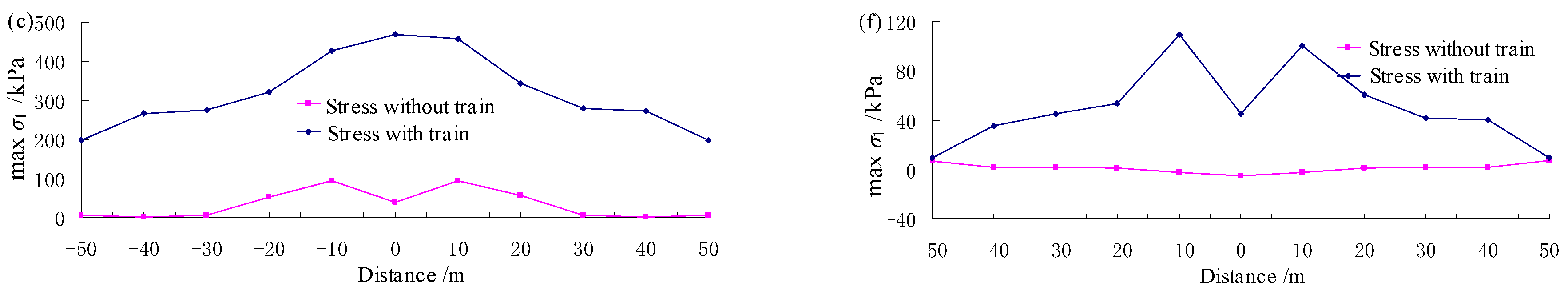

Figure 11.

Stress increment comparison due to the train loading: (a) and (b) show the major principal stress of the upper and lower tunnels, respectively; (c) and (d) illustrate the third principal stress of the upper and lower tunnels, respectively.

Figure 11.

Stress increment comparison due to the train loading: (a) and (b) show the major principal stress of the upper and lower tunnels, respectively; (c) and (d) illustrate the third principal stress of the upper and lower tunnels, respectively.

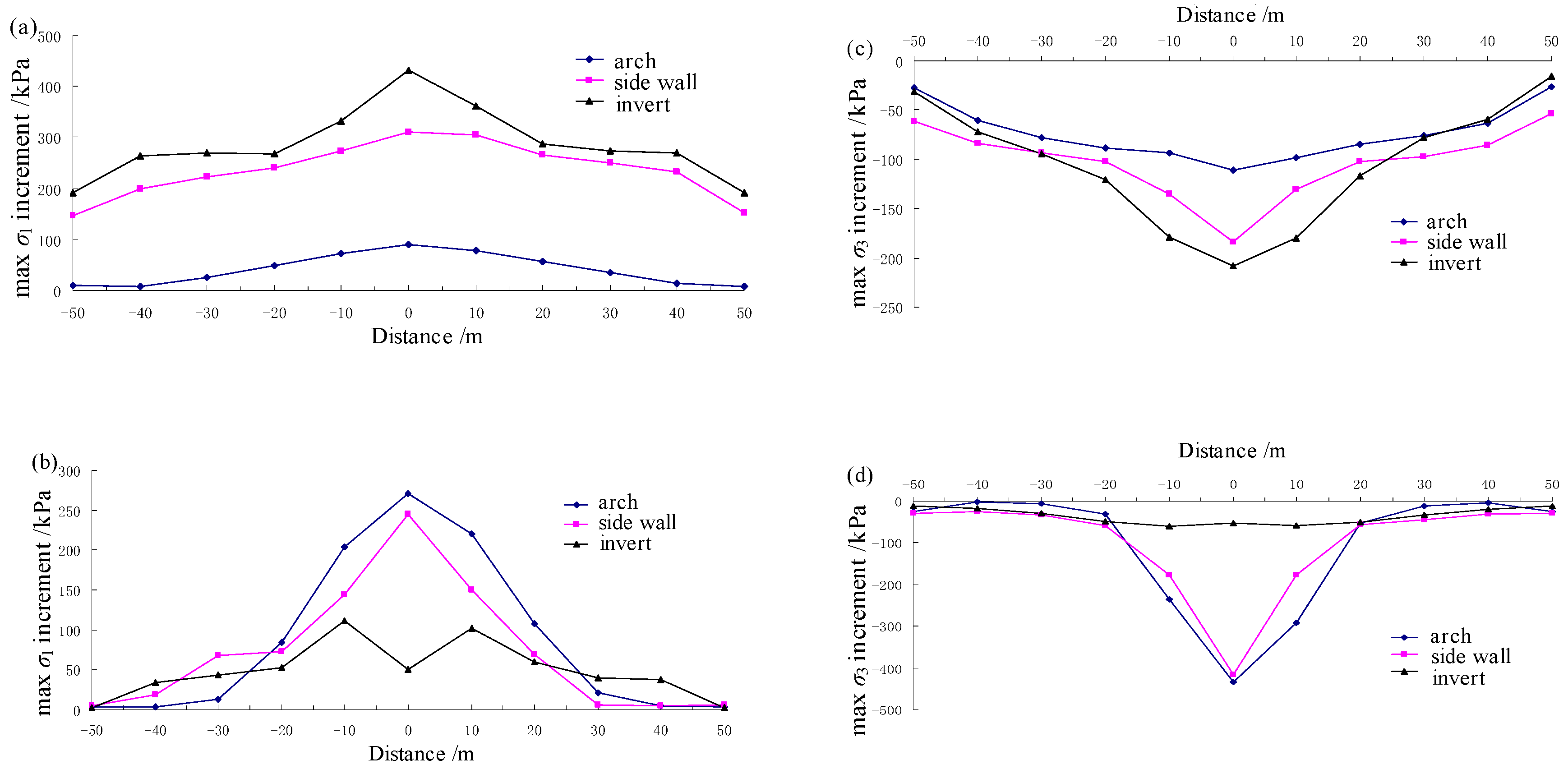

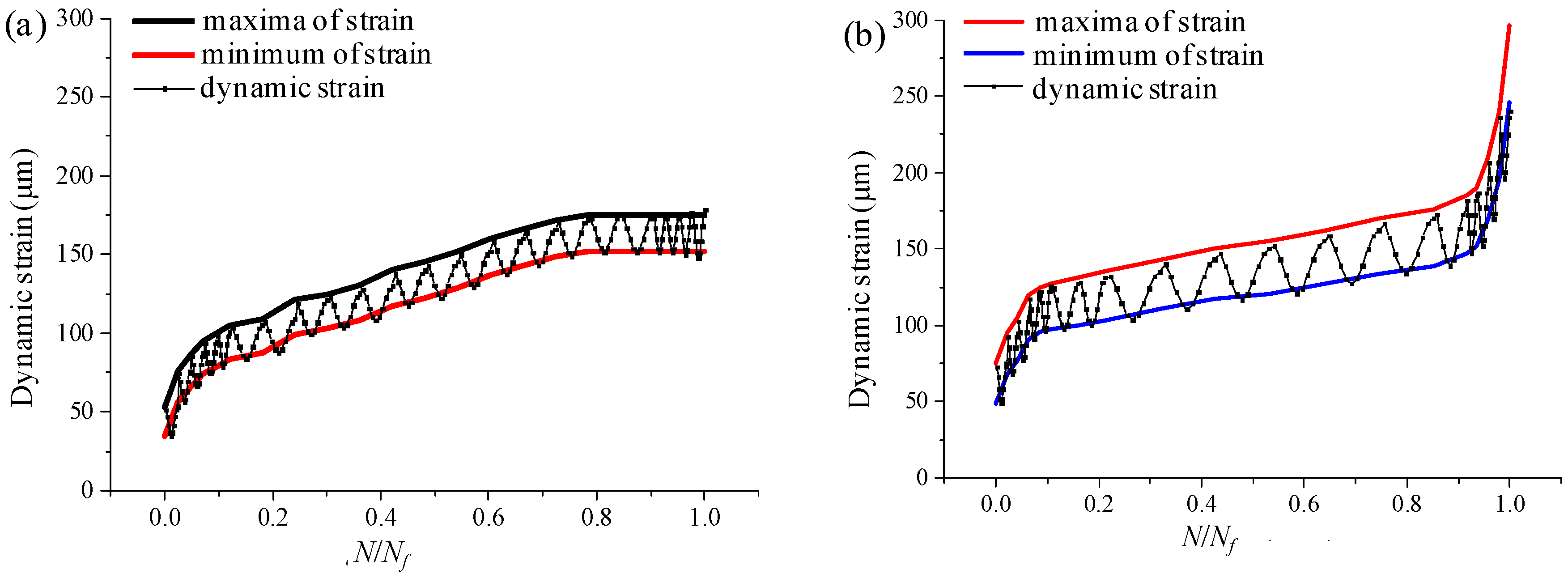

Figure 12.

Dynamic strain curve: (a) static load = 25 kN, (b) static load = 27 kN, (c) static load = 29 kN, and (d) static load = 31 kN.

Figure 12.

Dynamic strain curve: (a) static load = 25 kN, (b) static load = 27 kN, (c) static load = 29 kN, and (d) static load = 31 kN.

Figure 13.

Damage state of the inverted arch structure at different stages: (a) initial stage, (b) intermediate stage, (c) failure stage, and (d) cracking position.

Figure 13.

Damage state of the inverted arch structure at different stages: (a) initial stage, (b) intermediate stage, (c) failure stage, and (d) cracking position.

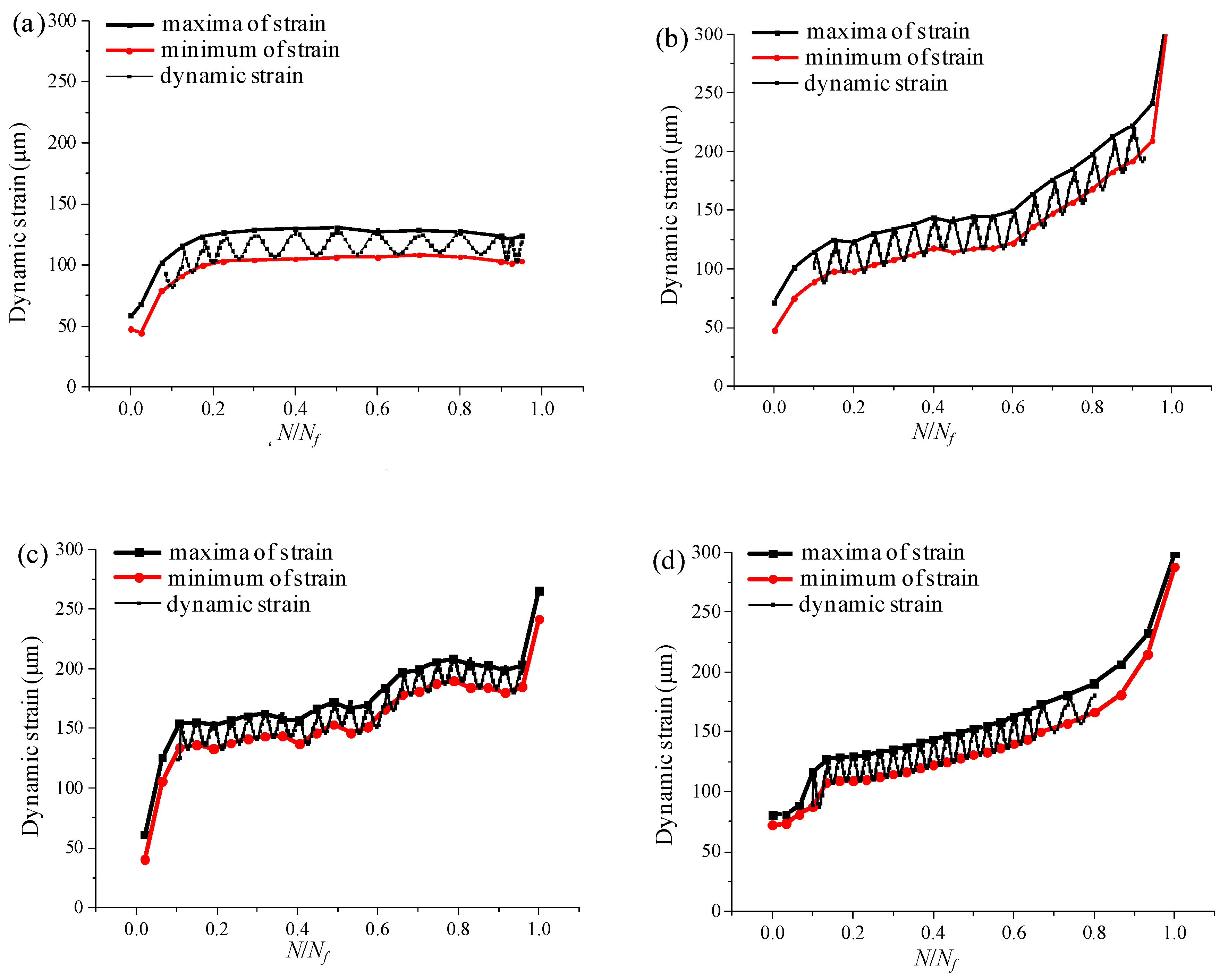

Figure 14.

Dynamic strain curve: (a) dynamic load = 1.6 kN, (b) dynamic load = 2.4 kN, (c) dynamic load = 3.6 kN, and (d) dynamic load = 4.5 kN.

Figure 14.

Dynamic strain curve: (a) dynamic load = 1.6 kN, (b) dynamic load = 2.4 kN, (c) dynamic load = 3.6 kN, and (d) dynamic load = 4.5 kN.

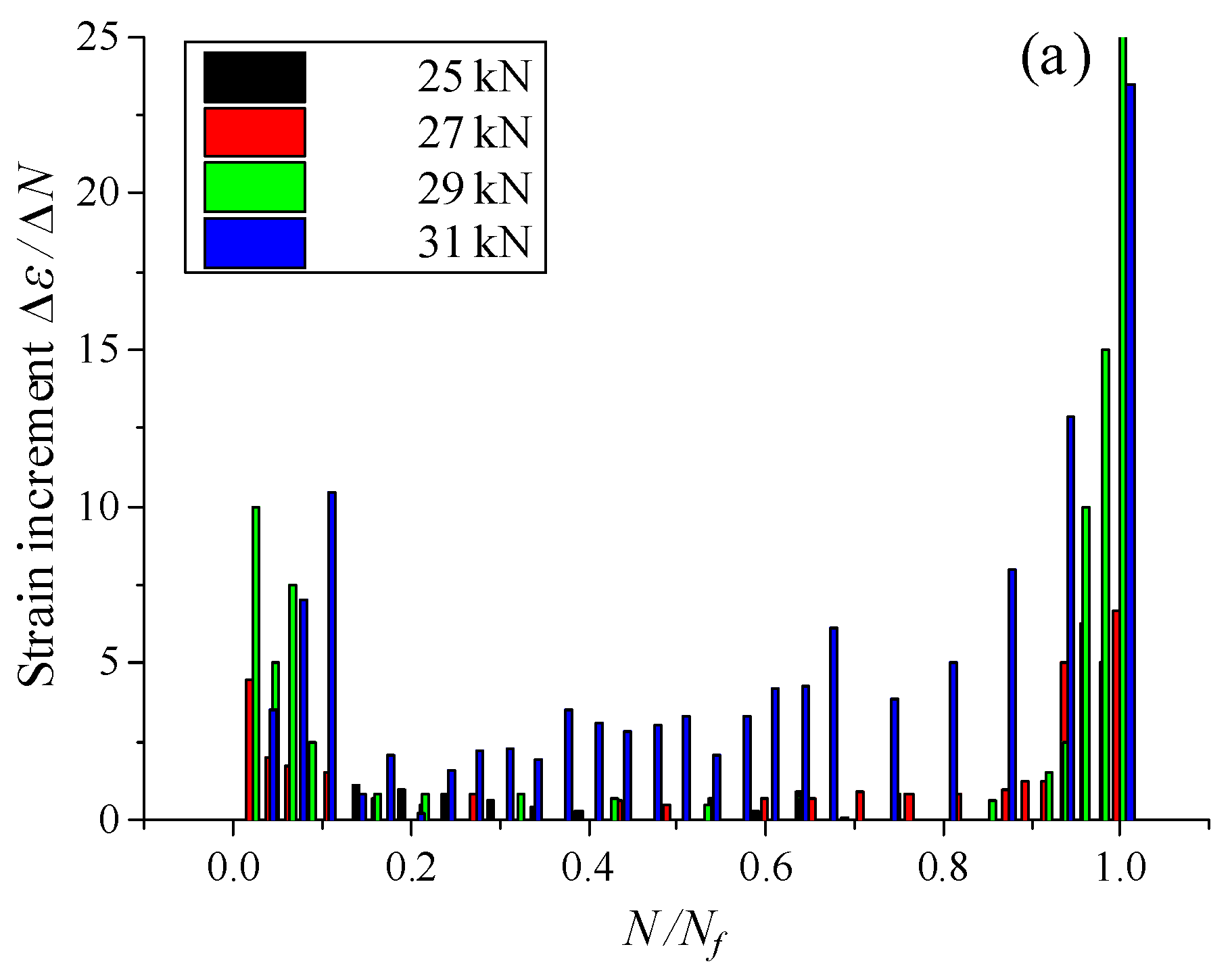

Figure 15.

Evolution of strain characteristics for different static stress levels: (a) strain increment and (b) εn/ε0.

Figure 15.

Evolution of strain characteristics for different static stress levels: (a) strain increment and (b) εn/ε0.

Figure 16.

Evolution of strain characteristics for different dynamic stress: (a) strain increment, (b) εn/ε0.

Figure 16.

Evolution of strain characteristics for different dynamic stress: (a) strain increment, (b) εn/ε0.

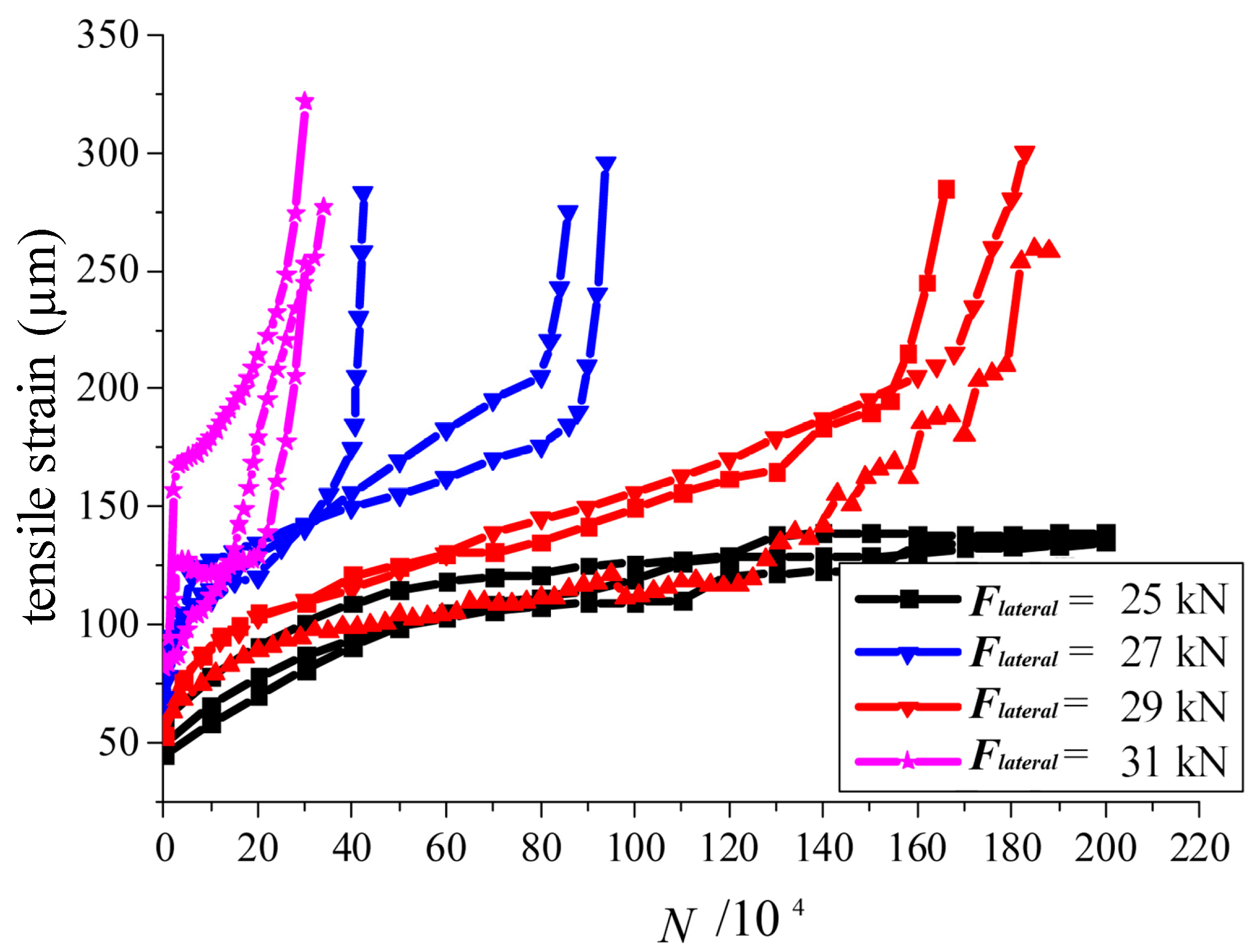

Figure 17.

Process of strain evolution.

Figure 17.

Process of strain evolution.

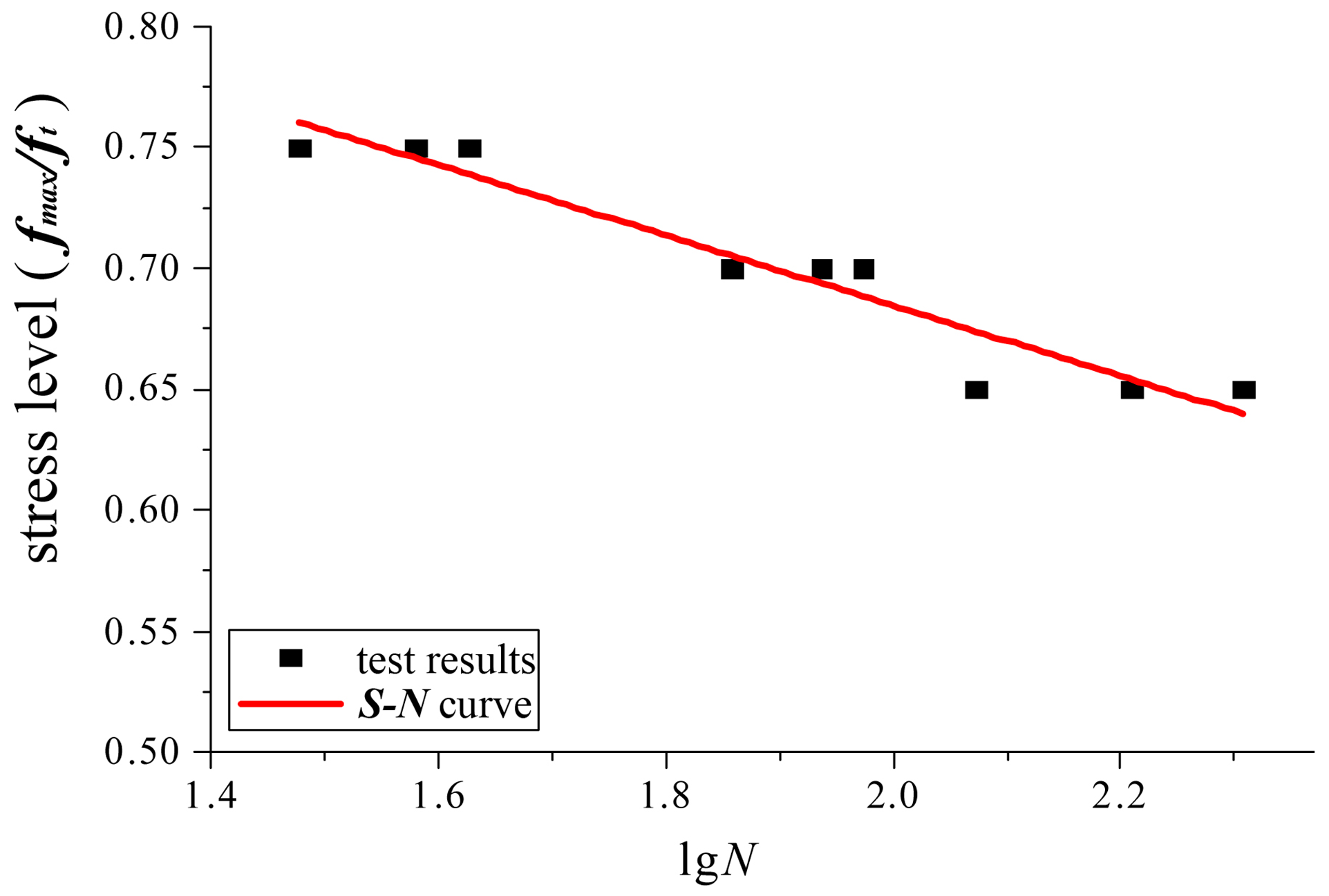

Figure 18.

Least squares fitting of S–N curve fitting.

Figure 18.

Least squares fitting of S–N curve fitting.

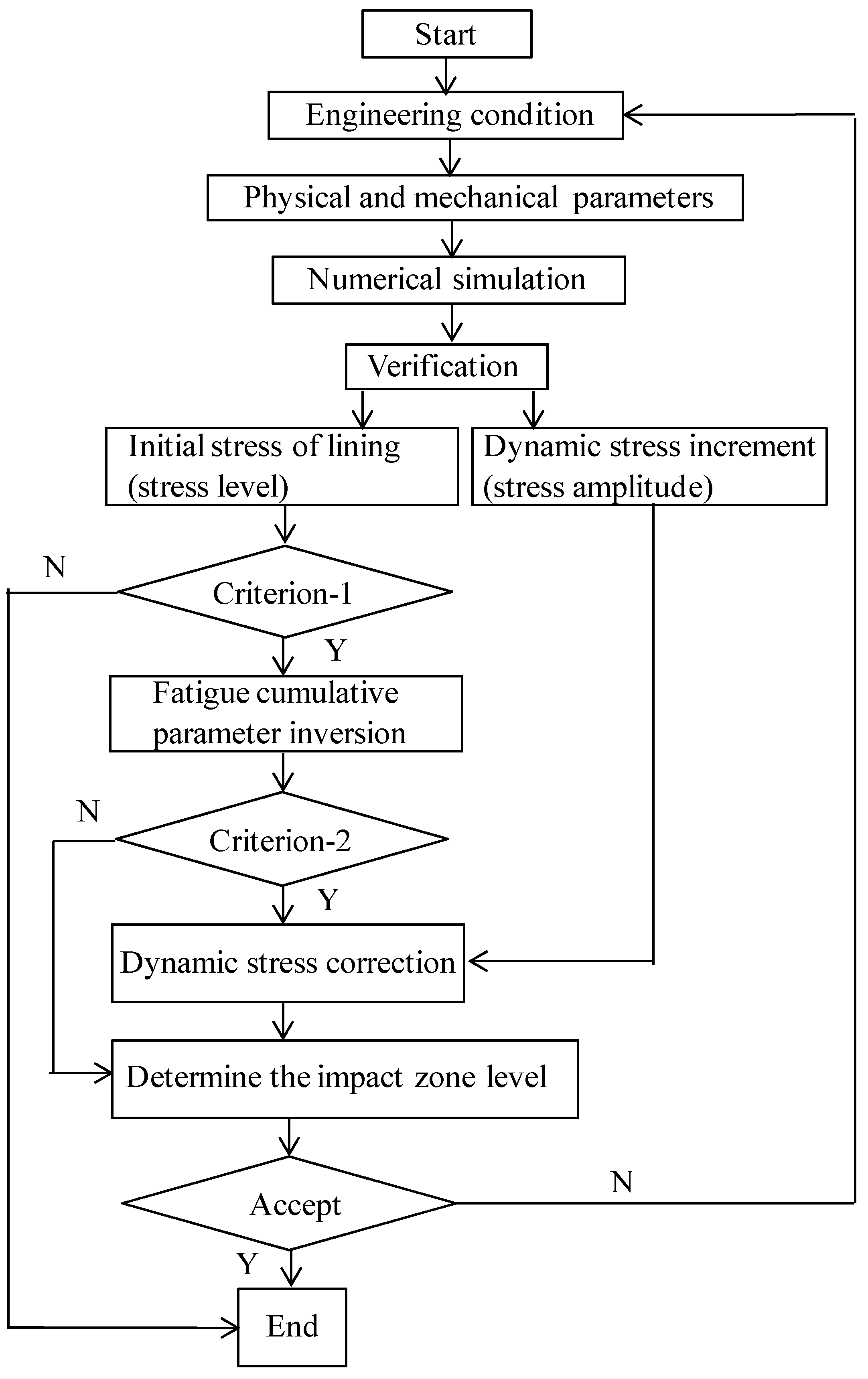

Figure 19.

Influential zoning procedure of cross tunnel.

Figure 19.

Influential zoning procedure of cross tunnel.

Table 1.

Stratum mechanical parameters.

Table 1.

Stratum mechanical parameters.

| Rock Level | | E/GPa | μ | C/kPa | Φ/° |

|---|

| III | 25 | 13.5 | 0.30 | 763.4 | 39 |

| IV | 22 | 3.1 | 0.35 | 153.4 | 30 |

| V | 19.5 | 0.9 | 0.35 | 93.8 | 25 |

Table 2.

Structural mechanical parameters (e.g., lining and track plates).

Table 2.

Structural mechanical parameters (e.g., lining and track plates).

| Structural Component | | E/GPa | μ | | |

|---|

| Secondary lining (C35) | 26.3 | 31.5 | 0.2 | 1.65 | 17.5 |

| Concrete foundation (C30) | 25 | 30 | 0.2 | 1.5 | 11.0 |

| Filling layer (C25) | 23 | 28 | 0.2 | 1.3 | 12.5 |

| Primary lining (C25) | 25 | 33.4 | 0.2 | 1.3 | 12.5 |

| Track plate (C45) | 27 | 33.5 | 0.2 | 1.9 | 21.5 |

Table 3.

Load-sharing ratio during tunnel construction.

Table 3.

Load-sharing ratio during tunnel construction.

| Rock Level | Primary Lining | Secondary Lining |

|---|

| III | 100 | 0 |

| IV | 60 | 40 |

| V | 30 | 70 |

Table 4.

Dynamic and static mechanical parameters.

Table 4.

Dynamic and static mechanical parameters.

| Dynamic | Static |

|---|

| Size | E (GPa) | G (GPa) | | Size | E (GPa) | C (MPa) | |

| 100 × 100 × 300 mm | 41.8 | 16.9 | 0.23 | 100 × 100 × 100 mm | 31.7 | 42.3 | 0.23 |

Table 5.

Case for different levels of static load (stress level).

Table 5.

Case for different levels of static load (stress level).

| Parameters | Cases | S-1 | S-2 | S-3 | S-4 |

|---|

| Lateral load(kN) | Dynamic load amplitude

(kN) | Loading frequency

(Hz) | Static load force | 25 kN | 27 kN | 29 kN | 31 kN |

| 1.5 | 2.4 | 12 | Stress level | 0.65 | 0.7 | 0.75 | 0.80 |

Table 6.

Case for different levels of dynamic load (dynamic stress amplitude).

Table 6.

Case for different levels of dynamic load (dynamic stress amplitude).

| Parameters | Cases | D-1 | D-2 | D-3 | D-4 |

|---|

| Lateral load(kN) | Vertical static load

(kN) | Loading frequency

(Hz) | Dynamic load amplitude | 1.6 kN | 2.4 kN | 3.6 kN | 4.5 kN |

| 1.5 | 27 | 12 | Stress level | 0.6 | 0.7 | 0.75 | 0.85 |

Table 7.

Maximum dynamic tensile stress increment for different design parameters of the cross tunnel.

Table 7.

Maximum dynamic tensile stress increment for different design parameters of the cross tunnel.

| Condition | Dynamic Tensile Stress Increment (MPa) | Location |

|---|

| Rock level | III | 0.357 | Side wall of upper tunnel |

| IV | 0.404 | Invert of upper tunnel |

| V | 0.513 | Invert of upper tunnel |

| The way the train passes | Upper tunnel | 0.513 | Invert of lower tunnel |

| Lower tunnel | 0.386 | Side wall of upper tunnel |

| Both tunnels simultaneously | 0.789 | Invert of lower tunnel |

| Train speed | 250 km/h | 0.221 | Invert of upper tunnel |

| 300 km/h | 0.343 | Invert of upper tunnel |

| 350 km/h | 0.513 | Invert of upper tunnel |

| Cross-angle | 0° | 0.378 | Invert of upper tunnel |

| 30° | 0.385 | Invert of upper tunnel |

| 60° | 0.398 | Invert of upper tunnel |

| 90° | 0.513 | Invert of upper tunnel |

| Rock pillar thickness between two tunnels | 1 m | 0.513 | Invert of upper tunnel |

| 3 m | 0.461 | Invert of upper tunnel |

| 5 m | 0.432 | Invert of upper tunnel |

| 10 m | 0.348 | Invert of upper tunnel |

Table 8.

Strain evolution equation fitting parameters.

Table 8.

Strain evolution equation fitting parameters.

| Fitting Equation | Fitting Parameters | ε1/ε0 | α | β | ρ |

|---|

| Dynamic load = 2.4 kN | 0.7 | 1.6 | 1.01 | 5.5 |

| Dynamic load = 3.6 kN | 0.7 | 1.8 | 1.01 | 5.0 |

| Dynamic load = 4.5 kN | 0.7 | 1.0 | 1.00 | 4.0 |

| Static load = 27 kN | 0.7 | 2.0 | 1.00 | 6.0 |

| Static load = 29 kN | 0.6 | 1.4 | 1.01 | 6.5 |

| Static load = 31 kN | 0.5 | 1.0 | 1.00 | 5.0 |

Table 9.

Relationship between the maximum tensile stress under dynamic load (fmax)/ft and fatigue life (Nf) from the fatigue test.

Table 9.

Relationship between the maximum tensile stress under dynamic load (fmax)/ft and fatigue life (Nf) from the fatigue test.

| fmax/ft | fmin/fmax | Nf (106) |

|---|

| 0.6 | 0.68 | >2 |

| 0.65 | 0.63 | 2.03, 1.62, 1.18 |

| 0.7 | 0.58 | 0.94, 0.863, 0.72 |

| 0.75 | 0.56 | 0.423, 0.301, 0.38 |

Table 10.

Influence zoning of high-speed railway (HSR) cross tunnels for train speed = 250 km/h.

Table 10.

Influence zoning of high-speed railway (HSR) cross tunnels for train speed = 250 km/h.

| Rock Level | Angle/° | Rock Thickness |

|---|

| Strong | Weak | None |

|---|

| III | 0–60 | - | H 0.2D | H > 0.2D |

| 60–90 | - | H 0.5D | H > 0.5D |

| IV | 0–60 | - | H 0.4D | H > 0.4D |

| 60–90 | - | H 0.7D | H > 0.7D |

| V | 0–60 | - | H 0.8D | H > 0.8D |

| 60–90 | - | H 1.1D | H > 1.1D |

Table 11.

Influence zoning of HSR cross tunnels for train speed = 300 km/h.

Table 11.

Influence zoning of HSR cross tunnels for train speed = 300 km/h.

| Rock Level | Angle/° | Thickness of Rock Pillar |

|---|

| Strong | Weak | None |

|---|

| III | 0–60 | - | H 0.8D | H > 0.8D |

| 60–90 | - | H 1.1D | H > 1.1D |

| IV | 0–60 | - | H 1D | H > 1D |

| 60–90 | H 0.2D | 0.2D < H 1.3D | H > 1.3D |

| V | 0–60 | H 0.4D | 0.4D < H 1.5D | H > 1.5D |

| 60–90 | H 0.7D | 0.7D < H 1.7D | H > 1.7D |

Table 12.

Influence zoning of HSR cross tunnels for train speed = 350 km/h.

Table 12.

Influence zoning of HSR cross tunnels for train speed = 350 km/h.

| Rock Level | Angle/° | Rock Thickness |

|---|

| Strong | Weak | None |

|---|

| III | 0–60 | H 0.5D | 0.5D < H 1.6D | H > 1.6D |

| 60–90 | H 0.7D | 0.7D < H 1.8D | H > 1.8D |

| IV | 0–60 | H 0.7D | 0.7D < H 1.8D | H > 1.8D |

| 60–90 | H 1D | 1D < H 2D | H > 2D |

| V | 0–60 | H 1.1D | 1.1D < H 2.2D | H > 2.2D |

| 60–90 | H 1.4D | 1.4D < H 2.4D | H > 2.4D |