Enhancing the Ballistic Performances of 3D Warp Interlock Fabric Through Internal Structure as New Material for Seamless Female Soft Body Armor Development

Abstract

Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

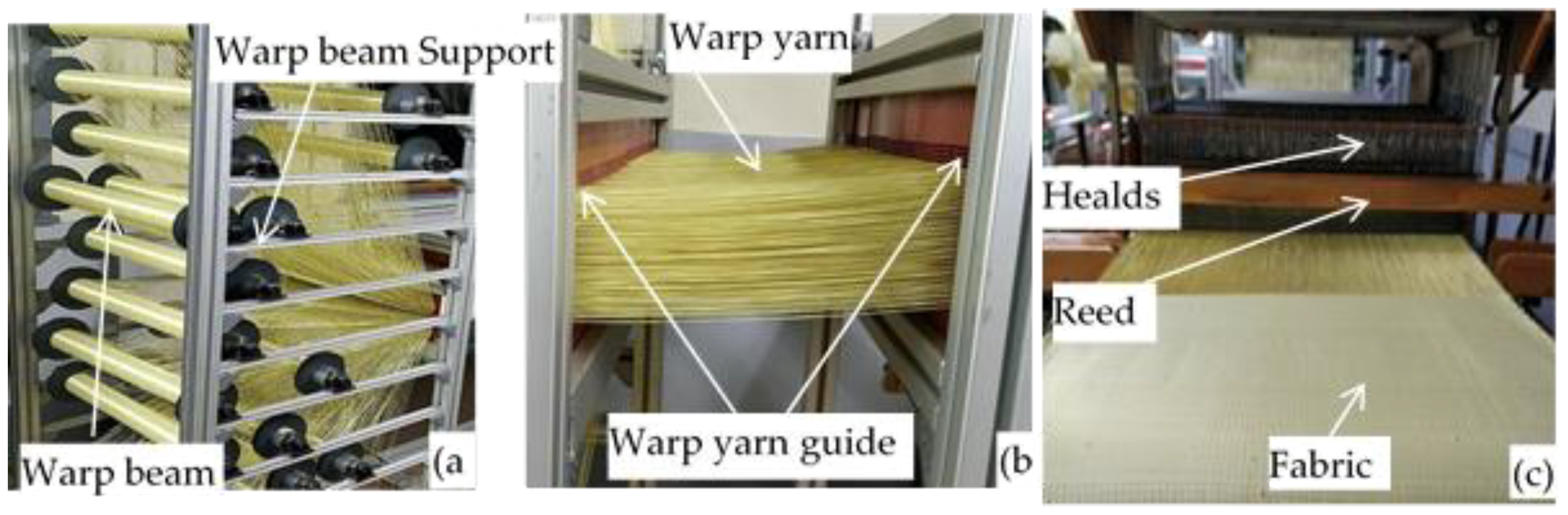

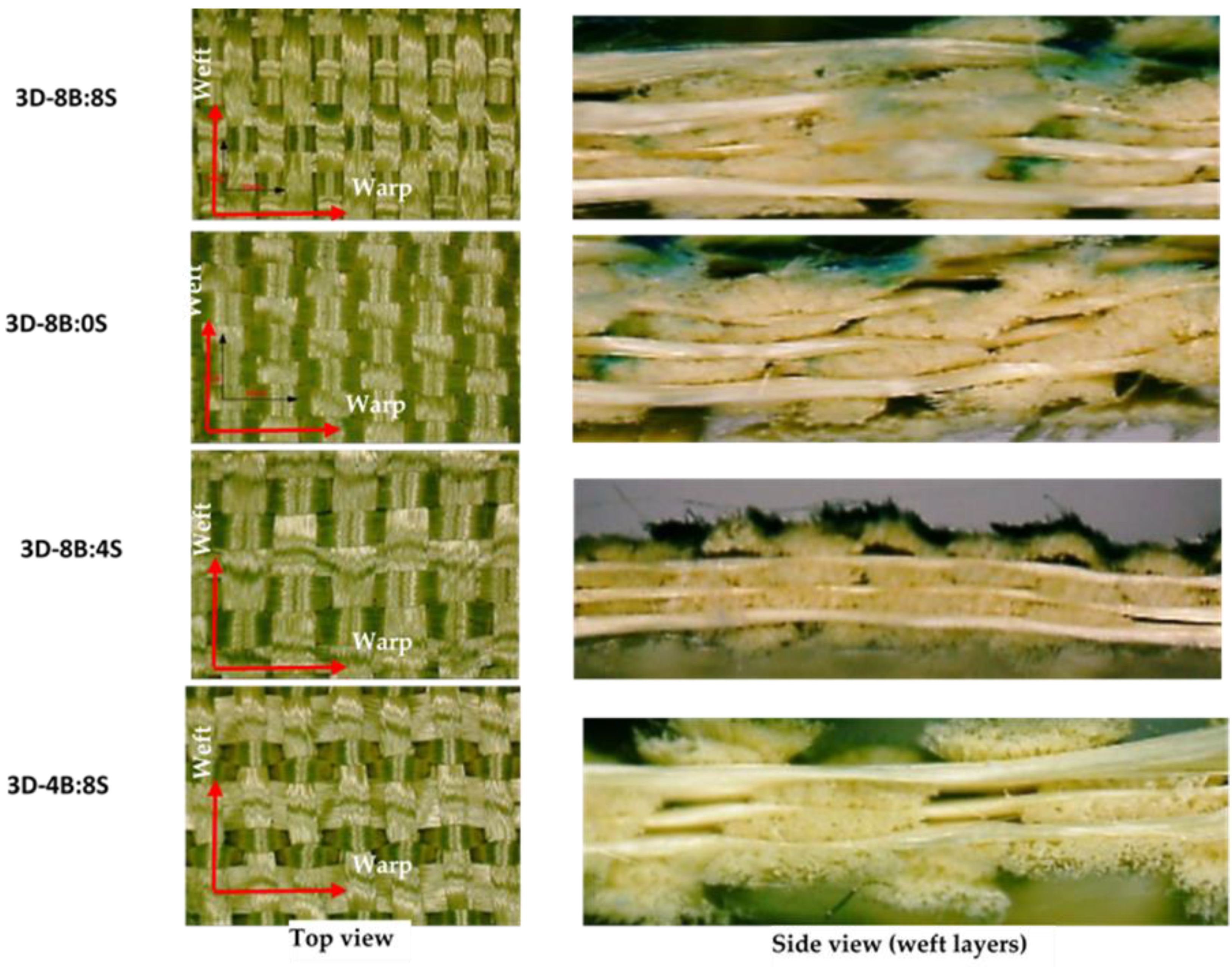

2.1.1. 3D warp Interlock Fabrics Design and Manufacturing Process

3D Warp Interlock Fabrics Design

3D Warp Interlock Fabrics Production

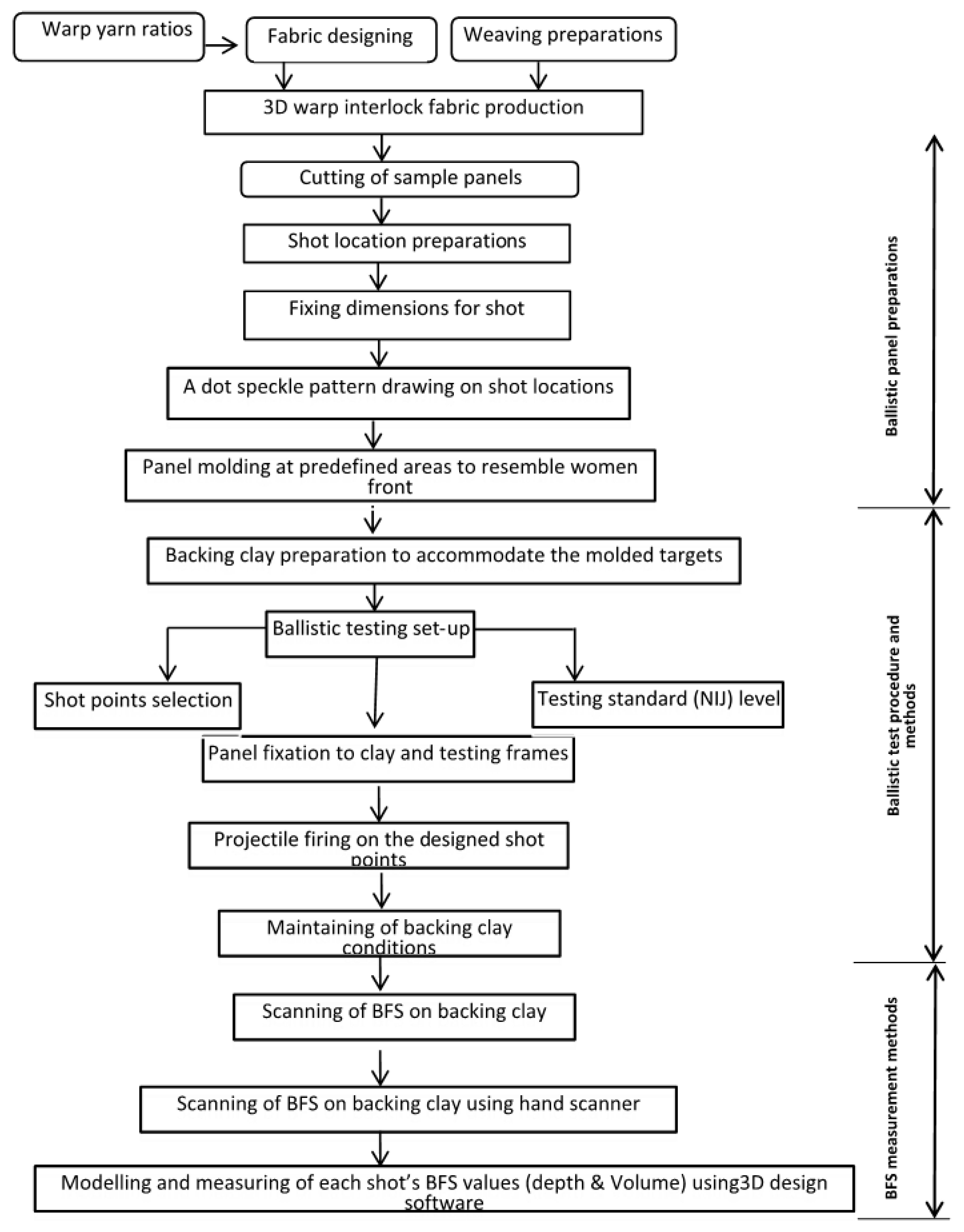

2.2. Ballistic Panel Preparation, Ballistic-testing Procedure and Backface Signature Values

Ballistic Target Panels Preparations

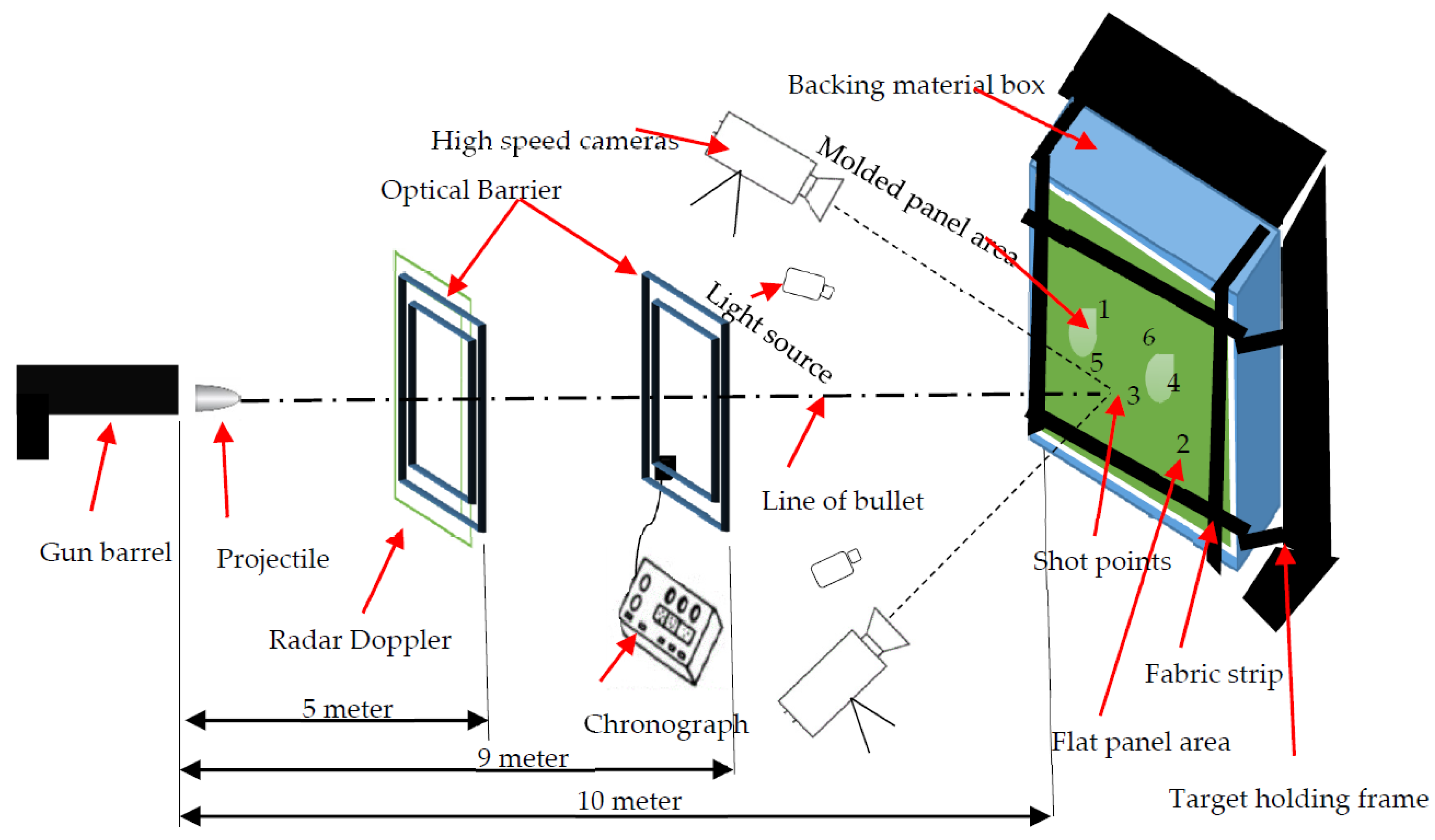

2.3. Ballistic-testing Procedure and Methods

Ballistic Impact Testing

2.4. Measurements of Backface Signature Depth, Diameter and Volumes

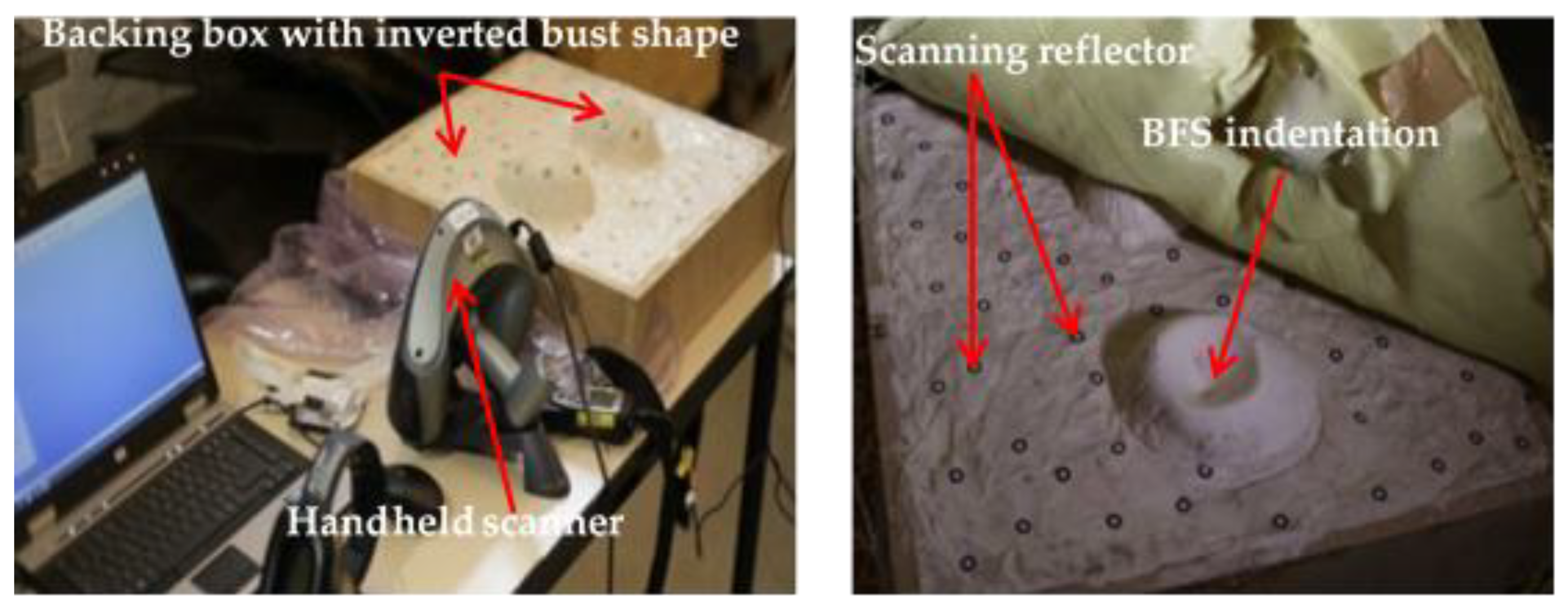

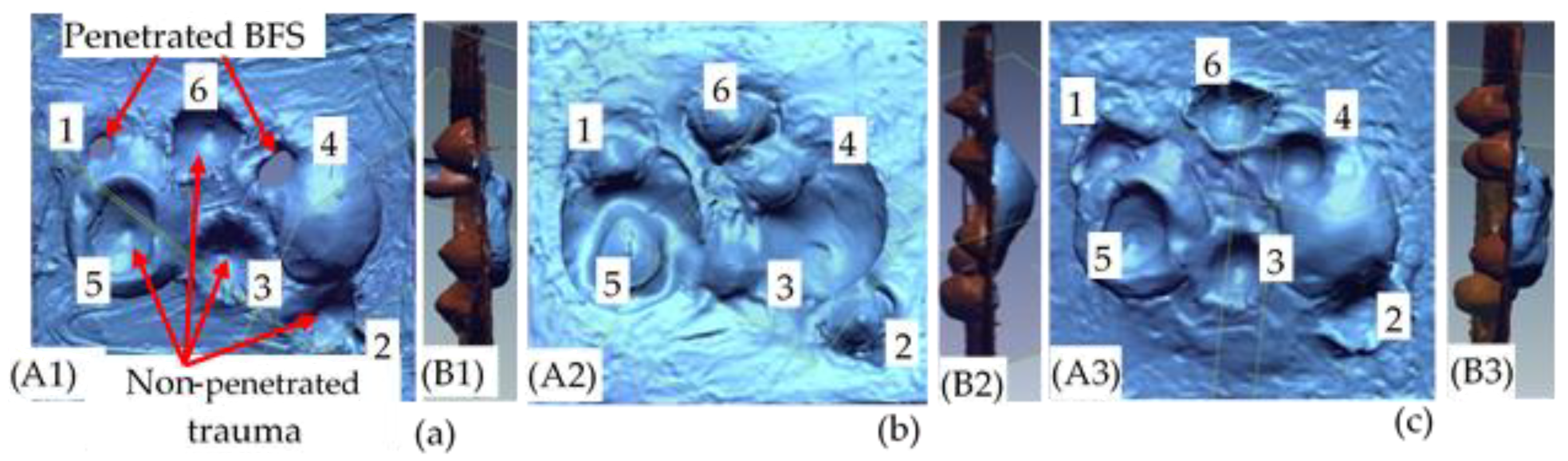

2.4.1. Scanning of Backface Signature at the Back of Plastilina

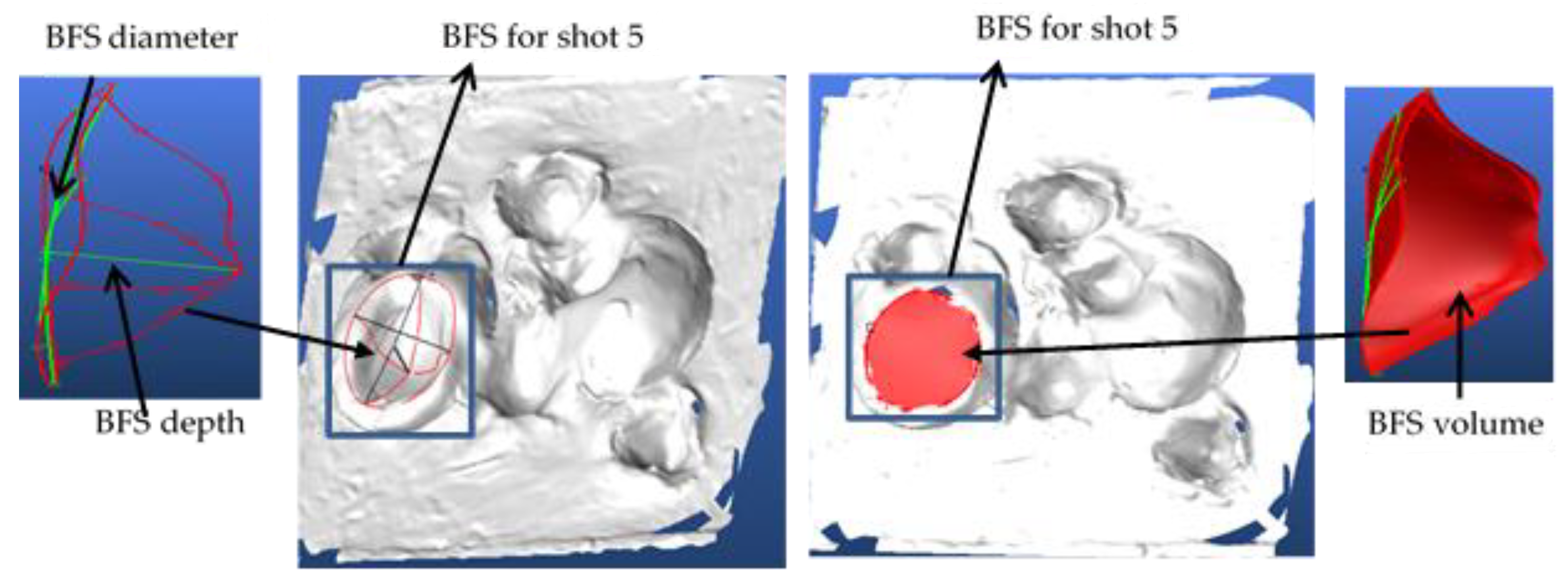

2.4.2. Modeling and Measurements of Backface Signature Values

3. Results and Discussions

3.1. Ballistic Performances of the 3D Warp Interlock Fabrics

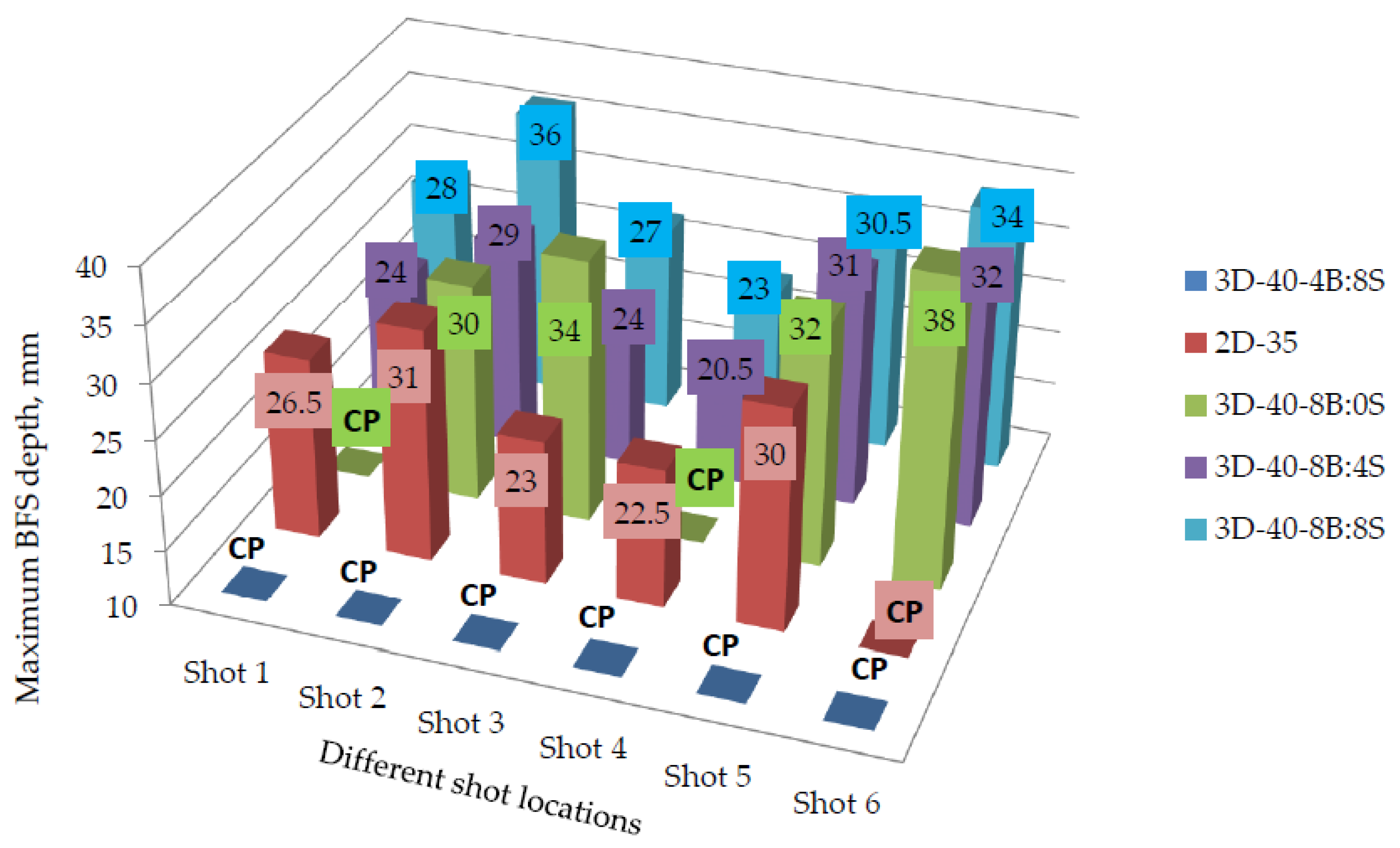

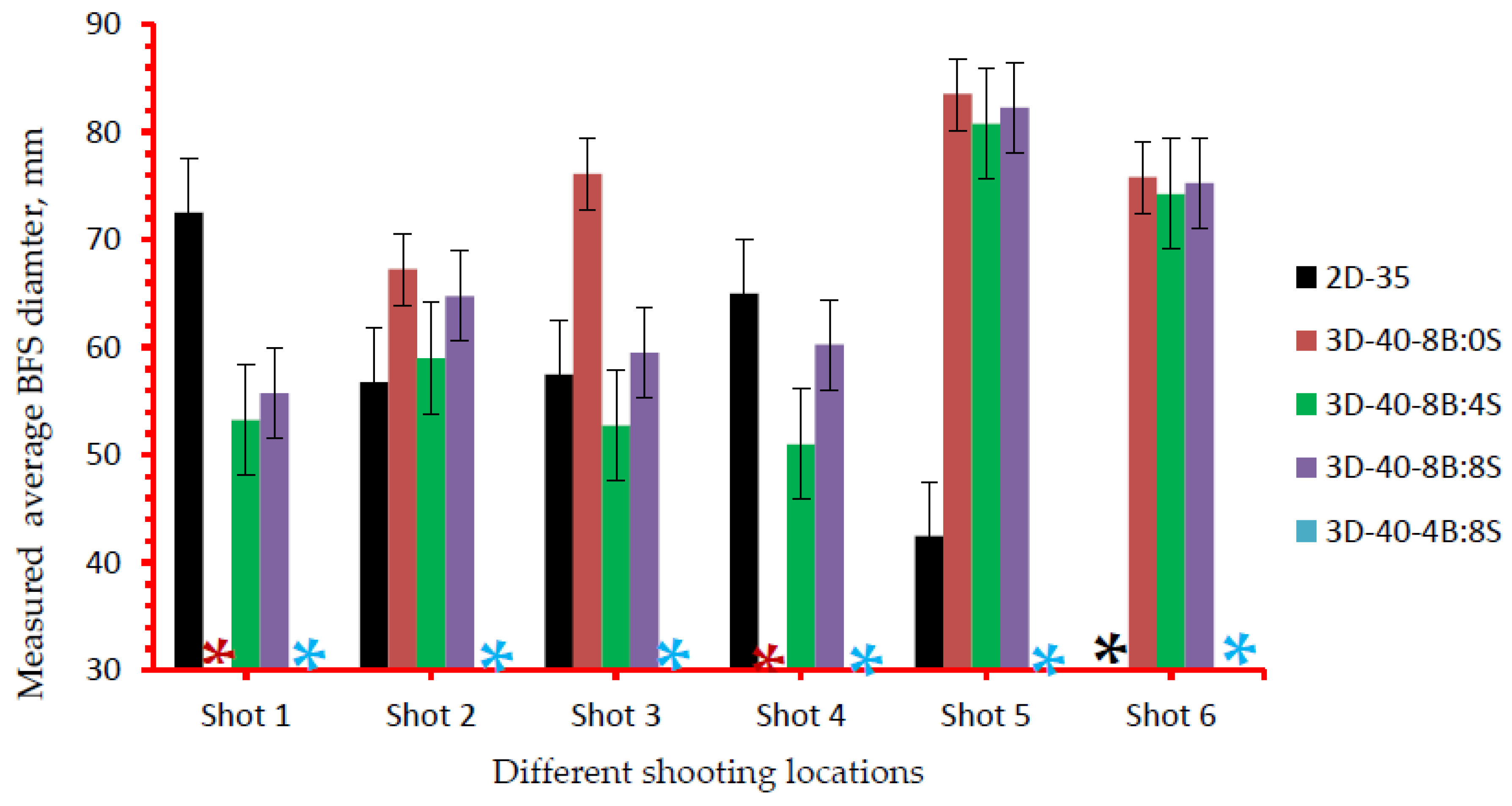

3.1.1. Analysis of Backface Signature Depth and Diameter Values.

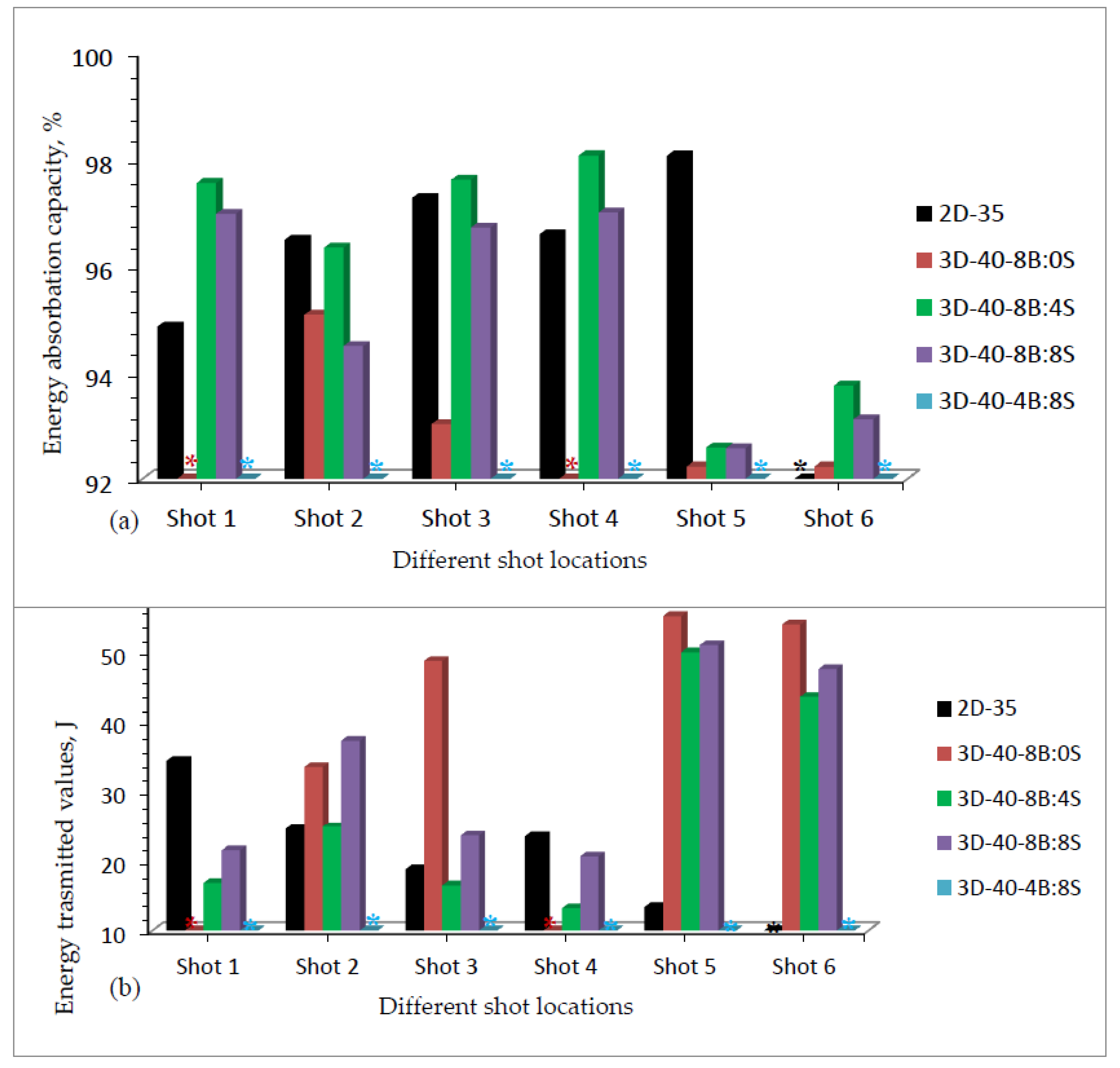

3.1.2. Energy Absorption Capabilities of 3D Warp Interlock Fabrics

- m is the projectile mass (kg);

- vi is the impact velocity of the projectile (m/s);

- ve is the exit velocity of the projectile (m/s);

- vp is the penetration velocity of the projectile (m/s);

- Em is the projectile energy loss (joule).

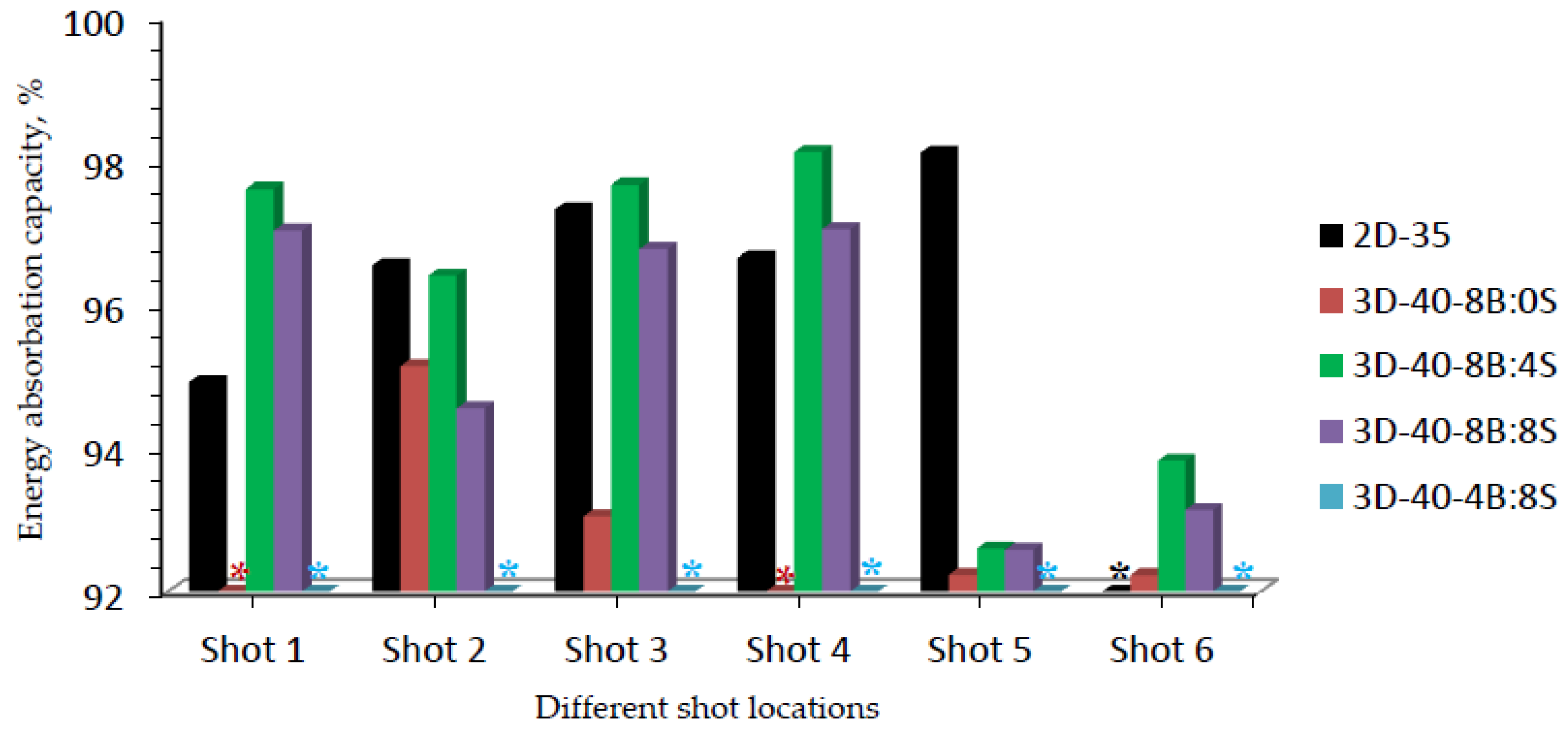

3.1.3. Normalizations of Energy Absorption Capabilities of 3D Warp Interlock Fabrics

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- El Messiry, M.; El-tarfawy, S. Performance of Weave Structure Multi-Layer Bulletproof Flexible Armor. In Proceedings of the 3rd Conference of the National Campaign for Textile Industries, NRC Cairo, “Recent Manufacturing Technologies and Human and Administrative Development”, Cairo, Egypt, 9–10 March 2015; pp. 218–225. [Google Scholar]

- Othman, A.R.; Hassan, M.H. Effect of different construction designs of aramid fabric on the ballistic performances. Mater. Des. 2013, 44, 407–417. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Female seamless soft body armor pattern design system with innovative reverse engineering approaches. Int. J. Adv. Manuf. Technol. 2018, 98, 2271–2285. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. A systematic pattern generation system for manufacturing customized seamless multi-layer female soft body armour through dome-formation (moulding) techniques using 3D warp interlock fabrics. J. Manuf. Syst. 2018, 49, 61–74. [Google Scholar] [CrossRef]

- Chen, X.; Yang, D. Use of Three-dimensional Angle-interlock Woven Fabric for Seamless Female Body Armor: Part II: Mathematical Modeling. Text. Res. J. 2010, 80, 1589–1601. [Google Scholar] [CrossRef]

- Mahbub, R.; Wang, L.; Arnold, L. Design of knitted three-dimensional seamless female body armour vests. Int. J. Fash. Des. Technol. Educ. 2014, 7, 198–207. [Google Scholar] [CrossRef]

- Abtew, M.A.; Bruniaux, P.; Boussu, F.; Loghin, C.; Cristian, I.; Chen, Y. Development of comfortable and well-fitted bra pattern for customized female soft body armor through 3D design process of adaptive bust on virtual mannequin. Comput. Ind. 2018, 100, 7–20. [Google Scholar] [CrossRef]

- Cunniff, P.M. An Analysis of the System Effects in Woven Fabrics Under Ballistic Impact. Text. Res. J. 1992, 62, 495–509. [Google Scholar] [CrossRef]

- Karahan, M.; Jabbar, A.; Karahan, N. Ballistic impact behavior of the aramid and ultra-high molecular weight polyethylene composites. J. Reinf. Plast. Compos. 2015, 34, 37–48. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Arvidson, B.; Pataki, W. Lightweight Ballistic Composites, Military and Law-Enforcement Applications; Woodhead Publishing: Cambridge, UK, 2006; pp. 213–214. [Google Scholar]

- Cork, C.R.; Foster, P.W. The ballistic performance of narrow fabrics. Int. J. Impact Eng. 2007, 34, 495–508. [Google Scholar] [CrossRef]

- Yavaşa, M.O.; Avcıa, A.; Şimşirb, M.; Akdemir, A. Ballistic performance of Kevlar49/UHMW-PEHB26 Hybrid Layered- Composite. Int. J. Eng. Res. Dev. 2015, 7, 1–20. [Google Scholar] [CrossRef][Green Version]

- Wang, Y.; Chen, X.; Young, R.; Kinloch, I.; Garry, W. An Experimental study of ply orientation on ballistic impact resistance of multi-ply fabric panels. Compos. B Eng. 2015, 68, 259–265. [Google Scholar] [CrossRef]

- Zee, R.H.; Hsieh, C.Y. Energy absorption processes in fibrous composites. Mater. Sci. Eng. A 1998, 246, 161–168. [Google Scholar] [CrossRef]

- Zhang, Y.D.; Wang, Y.L.; Huang, Y.; Wan, Y.Z. Preparation and Properties of Three-dimensional Braided UHMWPE Fiber Reinforced PMMA Composites. J. Reinf. Plast. Compos. 2006, 25, 1601–1609. [Google Scholar] [CrossRef]

- Tan, V.B.C.; Tay, T.E.; Teo, W.K. Strengthening fabric armour with silica colloidal suspensions. Int. J. Solids Struct. 2005, 42, 1561–1576. [Google Scholar] [CrossRef]

- Dong, Z.; Sun, C.T. Testing and modeling of yarn pull-out in plain woven Kevlar fabrics. Compos. A Appl. Sci. Manuf. 2009, 40, 1863–1869. [Google Scholar] [CrossRef]

- Das, S.; Jagan, S.; Shaw, A.; Pal, A. Determination of inter-yarn friction and its effect on ballistic response of para-aramid woven fabric under low velocity impact. Compos. Struct. 2015, 120, 129–140. [Google Scholar] [CrossRef]

- Yang, C.C.; Ngo, T.; Tran, P. Influences of weaving architectures on the impact resistance of multi-layer fabrics. Mater. Des. 2015, 85, 282–295. [Google Scholar] [CrossRef]

- Karahan, M. Comparison of Ballistic Performance and Energy Absorption Capabilities of Woven and Unidirectional Aramid Fabrics. Text. Res. J. 2008, 78, 718–730. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Y.; Chen, L.; Zhang, S.; Pan, N. Influence of fabric structure and thickness on the ballistic impact behavior of Ultrahigh molecular weight polyethylene composite laminate. Mater. Des. 2014, 54, 315–322. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Vetiyatil, L.; Ahmad, S. The effect of hybridization on the ballistic impact behavior of hybrid composite armors. Compos. B Eng. 2015, 76, 300–319. [Google Scholar] [CrossRef]

- Nguyen, L.H.; Ryan, S.; Cimpoeru, S.J.; Mouritz, A.P.; Orifici, A.C. The effect of target thickness on the ballistic performance of ultra high molecular weight polyethylene composite. Int. J. Impact Eng. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Sun, D.; Chen, X. Three-dimensional textiles for protective clothing. In Advances in 3D Textiles; Elsevier: Amsterdam, The Netherlands, 2015; pp. 341–360. [Google Scholar]

- Kadir Bilisik, A.; Turhan, Y. Multidirectional Stitched Layered Aramid Woven Fabric Structures and their Experimental Characterization of Ballistic Performance. Text. Res. J. 2009, 79, 1331–1343. [Google Scholar] [CrossRef]

- Bilisik, K.; Korkmaz, M. Multilayered and Multidirectionally-stitched aramid Woven Fabric Structures: Experimental Characterization of Ballistic Performance by Considering the Yarn Pull-out Test. Text. Res. J. 2010, 80, 1697–1720. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Ballistic impact mechanisms–A review on textiles and fibre-reinforced composites impact responses. Compos. Struct. 2019, 223, 110966. [Google Scholar] [CrossRef]

- Abtew, M.A.; Loghin, C.; Cristian, I.; Boussu, F.; Bruniaux, P.; Chen, Y.; Wang, L. Mouldability and its recovery properties of 2D plain woven para-aramid fabric for soft body armour applications. Fibres Text. East. Eur. 2019, 27, 54–62. [Google Scholar] [CrossRef]

- Abtew, M.A.; Loghin, C.; Cristian, I.; Boussu, F.; Bruniaux, P.; Chen, Y.; Wang, L. Two Dimensional (2D) P-Aramid Dry Multi-Layered Woven Fabrics Deformational Behaviour for Technical Applications. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 1–12. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Forming characteristics and surface damages of stitched multi-layered para-aramid fabrics with various stitching parameters for soft body armour design. Compos. A Appl. Sci. Manuf. 2018, 109, 517–537. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Influences of fabric density on mechanical and moulding behaviours of 3D warp interlock para-aramid fabrics for soft body armour application. Compos. Struct. 2018, 204, 402–418. [Google Scholar] [CrossRef]

- Boussu, F.; Cristian, I.; Nauman, S. General definition of 3D warp interlock fabric architecture. Compos. B Eng. 2015, 81, 171–188. [Google Scholar] [CrossRef]

- Legrand, X.; Boussu, F.; Nauman, S.; Cristian, I.; Lapeyronnie, P.; Le Grognec, P.; Binetruy, C. Forming behaviour of warp interlock composite. Int. J. Mater. Form. 2009, 2, 177–180. [Google Scholar] [CrossRef]

- Zhong, T.; Hu, H. Formability of weft-knitted fabrics on a hemisphere. Autex Res. J. 2007, 7, 245–251. [Google Scholar]

- Ha-Minh, C.; Boussu, F.; Kanit, T.; Crépin, D.; Imad, A. Effect of Frictions on the Ballistic Performance of a 3D Warp Interlock Fabric: Numerical Analysis. Appl. Compos. Mater. 2012, 19, 333–347. [Google Scholar] [CrossRef]

- Yang, D.; Chen, X.; Sun, D.; Zhang, S.; Yi, C.; Gong, X.; Zhou, Y.; Chen, Y. Ballistic performance of angle-interlock woven fabrics. J. Text. Inst. 2017, 108, 586–596. [Google Scholar] [CrossRef]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Engineering of 3D warp interlock p-aramid fabric structure and its energy absorption capabilities against ballistic impact for body armour applications. Compos. Struct. 2019, 225, 111179. [Google Scholar] [CrossRef]

- Byun, J.H.; Chou, T.W. Elastic Properties of Three-dimensional Angle-interlock Fabric Preforms. J. Text. 1990, 81, 538–548. [Google Scholar] [CrossRef]

- Bilisik, K. Three-dimensional braiding for composites: A review. Text. Res. J. 2013, 83, 1414–1436. [Google Scholar] [CrossRef]

- Bilisik, K.; Karaduman, N.S.; Bilisik, N.E.; Bilisik, H.E. Three-dimensional fully interlaced woven preforms for composites. Text. Res. J. 2013, 83, 2060–2084. [Google Scholar] [CrossRef]

- Chen, X.; Yang, D. Use of 3D Angle-Interlock Woven Fabric for Seamless Female Body Armour: Part I: Ballistic Evaluation. Text. Res. J. 2010, 80, 1581–1588. [Google Scholar] [CrossRef]

- Lefebvre, M.; Boussu, F. High energy absorption of warp interlock fabrics: Application to high speed impact of fragments. In DYMAT International Conferences; EDP Sciences: Les Ulis, France, 2009; pp. 429–435. [Google Scholar]

- Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I.; Chen, Y.; Wang, L. Ballistic impact performance and surface failure mechanisms of two-dimensional and three-dimensional woven p-aramid multi-layer fabrics for lightweight women ballistic vest applications. J. Ind. Text. 2019, 1–3. [Google Scholar] [CrossRef]

- Mukasey, M.B.; Sedgwick, J.L.; Hagy, D.W. Ballistic Resistance of Body Armor, NIJ Standard-0101.06; US Department of Justice: Washington, DC, USA, 2000; pp. 1–67.

- Chen, X.; Lo, W.-Y.; Tayyar, A.E. Mouldability of Angle-Interlock Woven Fabrics for Technical Applications. Text. Res. J. 2002, 72, 195–200. [Google Scholar] [CrossRef]

| Fabric Designation | Fiber and Yarn Properties | Fabric Properties | |||

|---|---|---|---|---|---|

| Tenacity at Break (mN/tex) | Strength at Break (N) | Elongation at Break (%) | Theoretical Fabric Weight (g/m2) | Average Fabric Thickness (mm) | |

| 3D-8B:0S | 2.35 | 225 | 3.45 | 970/panel | 1.42 |

| 3D-8B:4S | 2.35 | 225 | 3.45 | 970/panel | 1.44 |

| 3D-8B:8S | 2.35 | 225 | 3.45 | 970/panel | 1.52 |

| 3D-4B:8S | 2.35 | 225 | 3.45 | 970/panel | 1.63 |

| 2D-plain | 2.35 | 225 | 3.45 | 200/layer | 1.5 |

| Panel Designation | Panel Fabric Description | Number of Layer (panel) Used | Total Target Panel Thickness (mm) | Total Target Panel Weight (kg) |

|---|---|---|---|---|

| 3D-40-8B:0S | 3D fabric with 100% binding yarn | 40 layers (8 panels) | 11.36 | 1.82 |

| 3D-40-8B:4S | 3D fabric with 66% binding & 33% stuffer | 40 layers (8 panels) | 11.52 | 1.76 |

| 3D-40-8B:8S | 3D fabric with 50% binding & 50% stuffer | 40 layers (8 panels) | 12.16 | 1.72 |

| 3D-40-4B:8S | 3D fabric with 33% binding & 66% stuffer | 40 layers (8 panels) | 13.04 | 1.78 |

| 2D-35 | 2D plain weave fabric | 35 layers | 10.5 | 1.75 |

| Target Panel Designations | Plastilina Temperature of at 1st and 6th Shot (°C) | Test Condition Temp. (°C) and RH (%) |

|---|---|---|

| 2D-35 | 32.8/30.8 | 25/34 |

| 3D-40-8B:0S | 39/35.8 | 22.9/45.5 |

| 3D-40-8B:4S | 39.7/37.8 | 22.9/37.5 |

| 3D-40-8B:8S | 39.3/37.8 | 22.2/45.5 |

| 3D-40-4B:8S | 38.2/37.2 | 22.7/43.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abtew, M.A.; Boussu, F.; Bruniaux, P.; Loghin, C.; Cristian, I. Enhancing the Ballistic Performances of 3D Warp Interlock Fabric Through Internal Structure as New Material for Seamless Female Soft Body Armor Development. Appl. Sci. 2020, 10, 4873. https://doi.org/10.3390/app10144873

Abtew MA, Boussu F, Bruniaux P, Loghin C, Cristian I. Enhancing the Ballistic Performances of 3D Warp Interlock Fabric Through Internal Structure as New Material for Seamless Female Soft Body Armor Development. Applied Sciences. 2020; 10(14):4873. https://doi.org/10.3390/app10144873

Chicago/Turabian StyleAbtew, Mulat Alubel, Francois Boussu, Pascal Bruniaux, Carmen Loghin, and Irina Cristian. 2020. "Enhancing the Ballistic Performances of 3D Warp Interlock Fabric Through Internal Structure as New Material for Seamless Female Soft Body Armor Development" Applied Sciences 10, no. 14: 4873. https://doi.org/10.3390/app10144873

APA StyleAbtew, M. A., Boussu, F., Bruniaux, P., Loghin, C., & Cristian, I. (2020). Enhancing the Ballistic Performances of 3D Warp Interlock Fabric Through Internal Structure as New Material for Seamless Female Soft Body Armor Development. Applied Sciences, 10(14), 4873. https://doi.org/10.3390/app10144873