Influence of Pressure on Gas/Liquid Interfacial Area in a Tray Column

Abstract

1. Introduction

Studying the Effect of Pressure on Gas/Liquid Interfacial Area

- (1)

- To experimentally investigate the effect of the pressure on gas/liquid interfacial area and its effect on the performance of the absorber; an absorber test rig was constructed and operated.

- (2)

- To assemble a property package for a rate-based model by applying Aspen Plus software for simulation of CO2 absorption using water as an absorbent.

- (3)

- To validate the mathematical model against experimental data at different operation points.

- (4)

- To investigate the effect of pressure on the gas/liquid interfacial area for mass transfer and its impact on the performance of a sieve tray absorber for capturing CO2 by using water as an absorbent.

2. Experimental

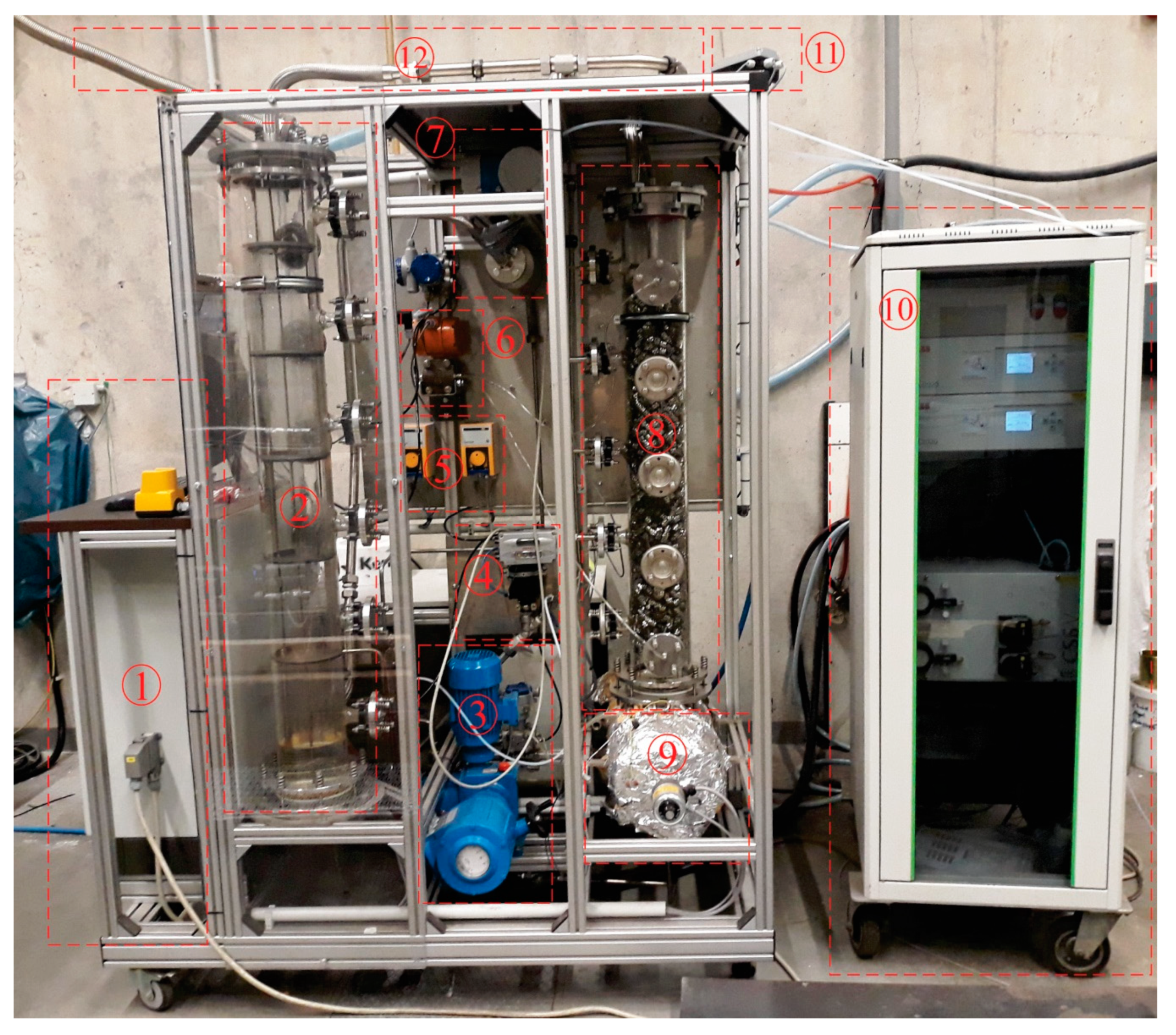

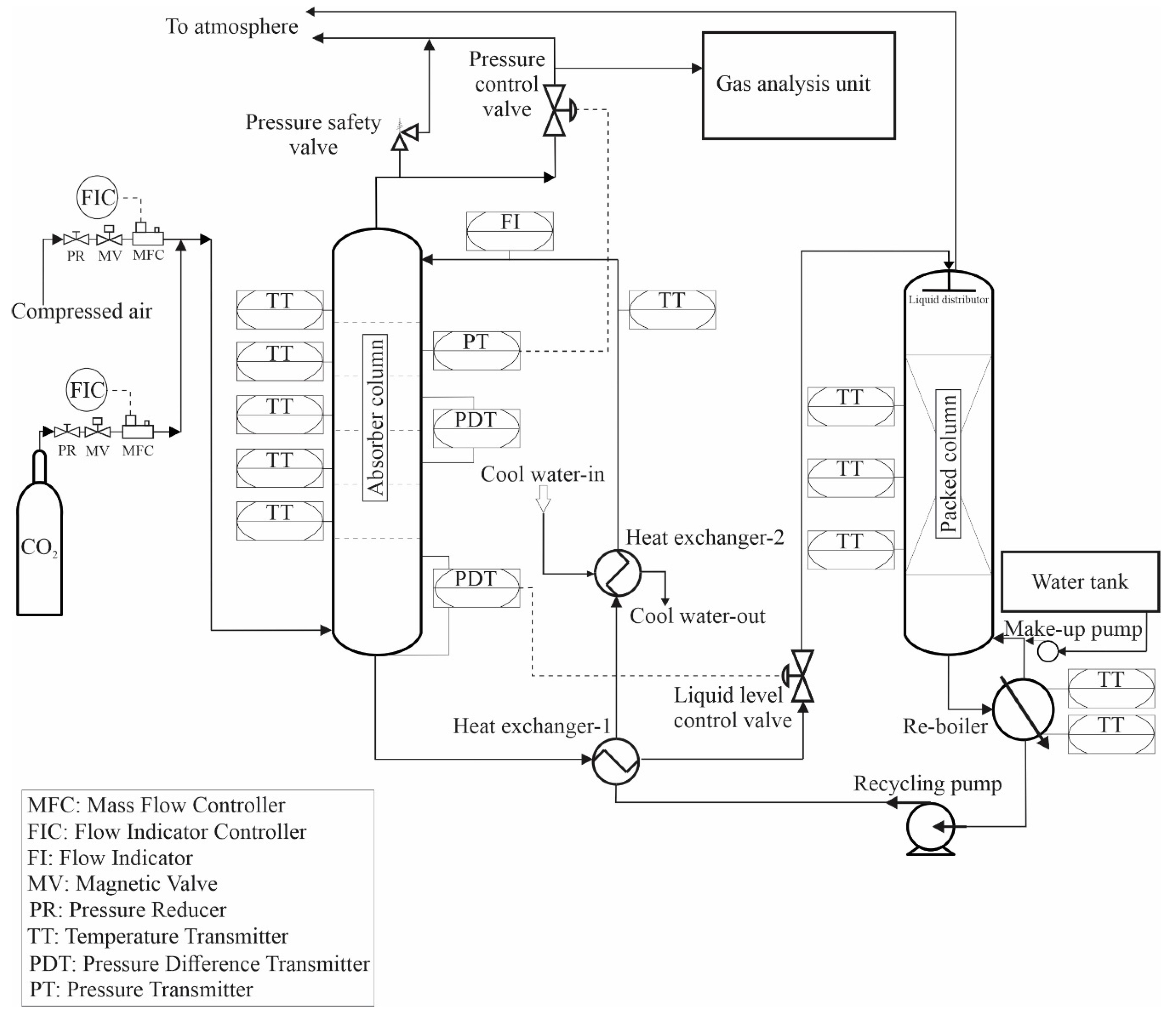

2.1. Test Rig Setup

2.2. Instrumentation and Control Equipment of the Test Rig

2.3. Test Procedure

3. Modeling Approach for Tray Column

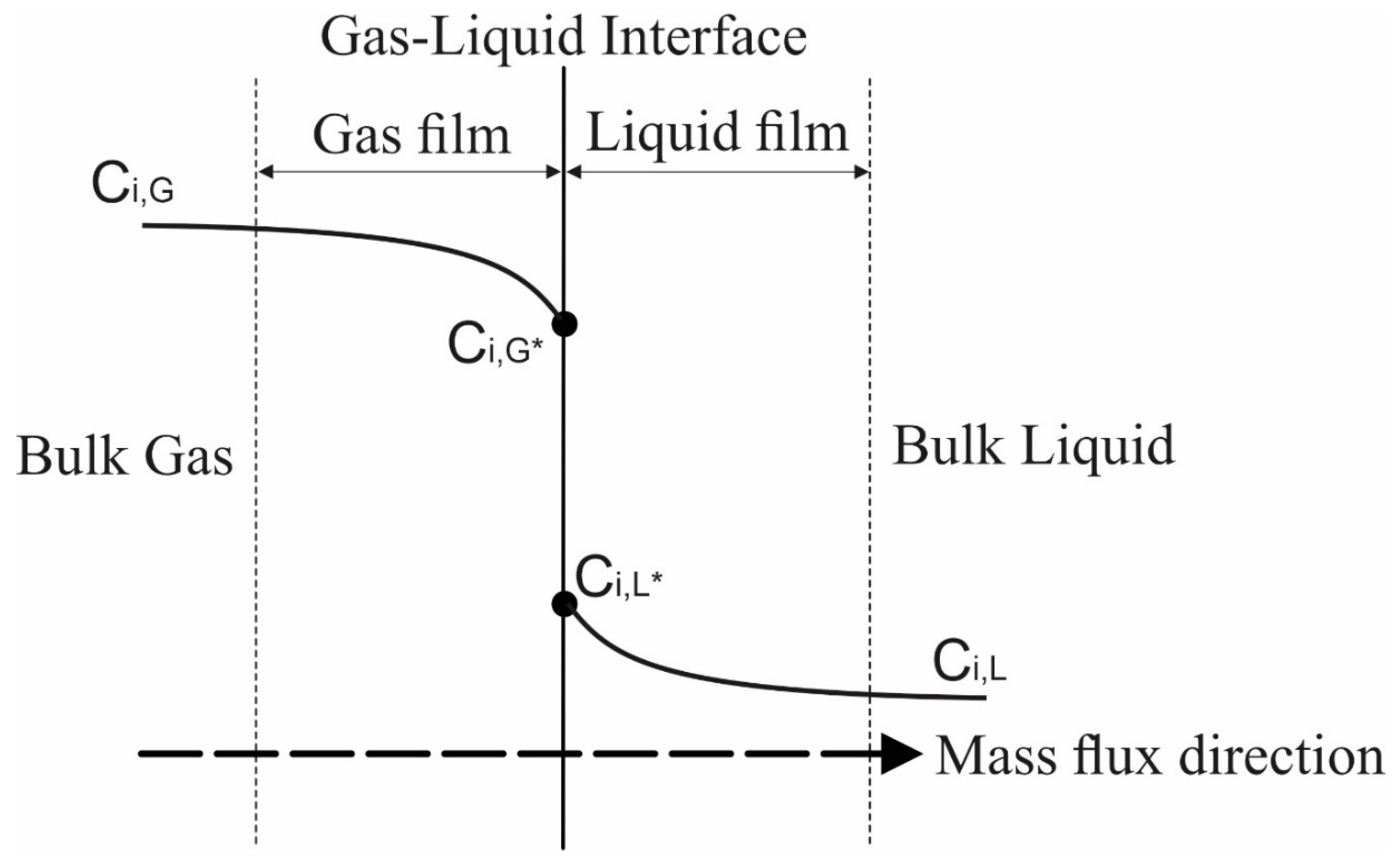

3.1. Rate-Based Modelling for CO2 Absorption

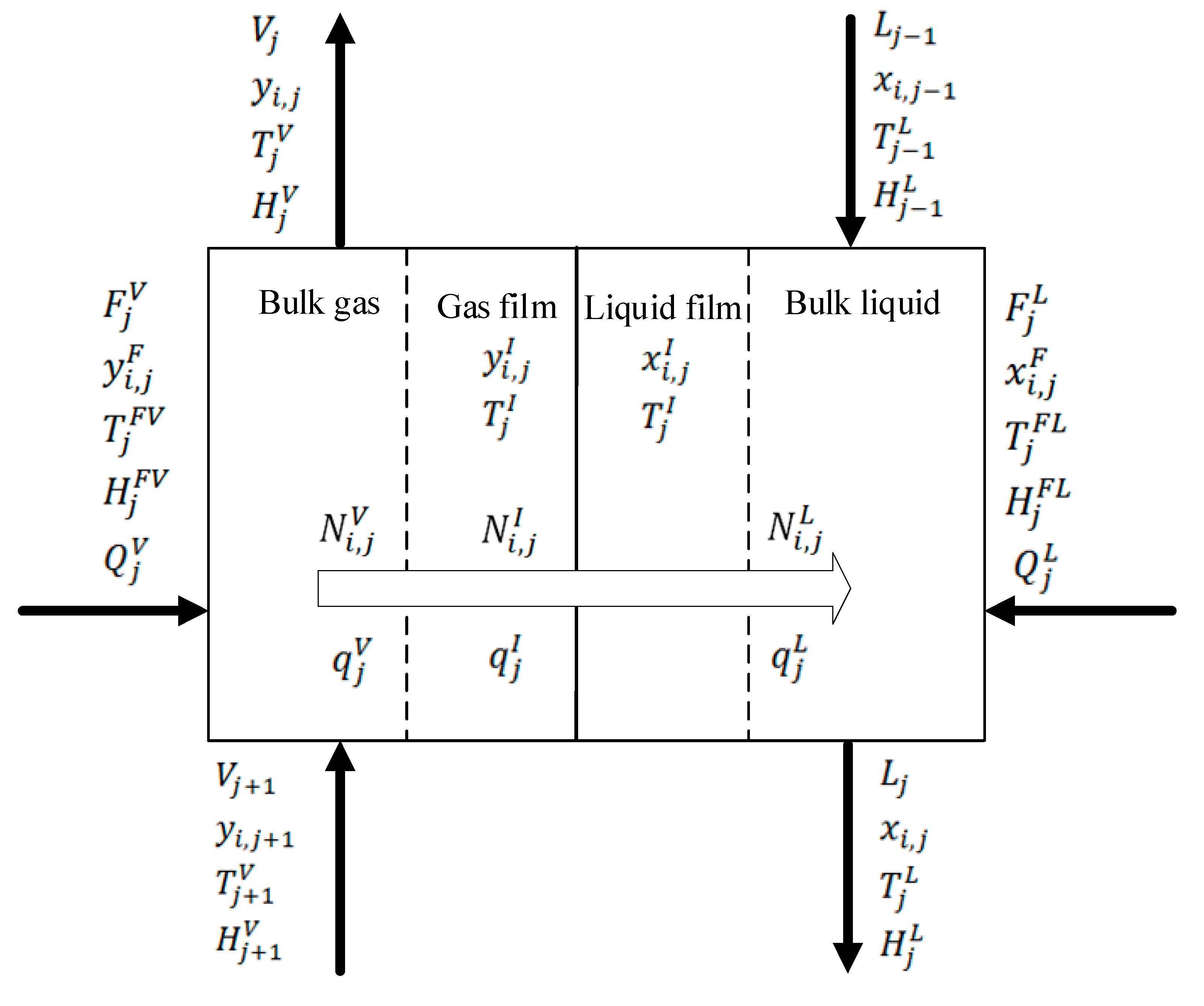

3.2. Tray Column Simulation

- The absorption column is assumed to be adiabatic.

- There is diffusion resistance in film.

- There are no reactions in the film.

- The liquid is well mixed, and the vapor is a plug flow; changes in concentration and temperature in the radial direction are negligible.

- The interfacial surface area is identical for both heat and mass transfer.

- The interface temperature is identical to the bulk liquid temperature since the liquid-side heat transfer resistance is small and balanced to the gas phase (Afkhamipour and Mofarahi 2013) [19].

- Both liquid and gas phases are formally handled as non-ideal mixtures.

4. Results and Discussion

4.1. Model Validation

4.2. Estimation of the Gas/Liquid Interfacial Area

4.3. Studying the Effect of Pressure on the Performance of the Absorber

5. Conclusions

- (1)

- It shows that the pressure influences the gas/liquid interfacial area. By increasing the pressure, the gas/liquid interfacial area slightly decreases at a low inlet gas flow rate. At a higher inlet gas flow rate, the gas/liquid interfacial area was significantly decreased.

- (2)

- Decreased gas/liquid interfacial area when the pressure is increased has a significant influence on decreasing the absorption rate of CO2.

- (3)

- This study highlights the point of the effect of increasing pressure at a high inlet gas flow rate since it decreases the gas/liquid interfacial area.

Author Contributions

Funding

Conflicts of Interest

Nomenclatures

| L | molar flow rate of liquid, |

| V | molar flow rate of vapor |

| F | molar flow rate of feed, |

| N | molar transfer rate, |

| K | equilibrium ratio, |

| r | reaction rate, |

| H | Enthalpy, |

| Q | heat input to a stage, |

| q | heat transfer rate, |

| T | temperature, |

| x | liquid mole fraction [−] |

| y | vapor mole fraction [−] |

| specific molar heat capacity, | |

| molecular weight of the liquid phase | |

| λ | Thermal conductivity, |

| h | Heat transfer coefficient |

| D | diffusion coefficient, |

| rate of mass transfer of component i through the gas boundary, | |

| rate of mass transfer of component i through the liquid boundary, | |

| The interfacial area between gas and liquid phases, | |

| concentration of component i in gas bulk, | |

| concentration of component i in liquid bulk, | |

| concentration of component i in the interface from the gas side, | |

| concentration of component i in the interface from the liquid side, | |

| binary mass transfer coefficient for vapor, | |

| binary mass transfer coefficient for liquid, | |

| diffusivity of the vapor, | |

| diffusivity of the liquid, | |

| superficial F-factor, | |

| average residence time for the liquid (per pass), s | |

| total molar flow rate of, liquid, vapor, | |

| total molar flow rate of, liquid, vapor, | |

| total interfacial area for mass transfer, | |

| molar density of vapor, | |

| molar density of liquid | |

| fractional approach to flooding, - | |

| relative froth density, -, Equation (18) | |

| total active bubbling area on the tray, | |

| superficial velocity for the vapor, | |

| superficial velocity for the liquid, | |

| superficial velocity of vapor at flooding, | |

| density of the vapor, | |

| density of the liquid, | |

| average weir length (per liquid pass), m | |

| volumetric flow rate for the liquid, vapor, | |

| volumetric flow rate for the liquid, vapor, | |

| liquid surface tension | |

| flow parameter, - | |

| fractional hole area per unit bubbling area on the tray, - | |

| clear liquid height, m | |

| average weir height, m | |

| total active bubbling area on the tray, m2 | |

| number of liquid flow passes, - | |

| sieve tray hole pitch, m, Equation (24) | |

| Subscripts | |

| L | liquid |

| V | vapor |

| F | feed |

| G | gas |

| m3/h | cubic meter per hour |

| i | component |

| n | number of components |

| I | interface |

| f | film |

| j | stage number |

| Abbreviations | |

| NRTL | non-random two-liquid model |

| Nm3/h | cubic meter of gas per hour at the normal temperature and pressure |

| Aspen PLUS | simulation software program |

| MERSHQ | equations of material, energy balances, rate of mass and heat transfer, summation of composition, hydraulic, and equilibrium |

| MEA | 2-aminoethano |

| DEA | 2,2′-iminodiethanol |

| MDEA | N-methyl-2,2′-iminodiethanol |

| IPMEA | 2-(isopropylamino) ethanol |

| TBMEA | 2-(tert-butylamino) ethanol |

| PID controller | proportional–integral–derivative controller |

| MFC | mass flow controller |

References

- Wilk, A. Solvent selection for CO2 capture from gases with high carbon dioxide concentration. Korean J. Chem. Eng. 2017, 34, 2275–2283. [Google Scholar] [CrossRef]

- Yamada, H. Comparison of solvation effects on CO2 capture with aqueous amine solutions and amine-functionalized ionic liquids. J. Phys. Chem. B 2016, 120, 10563–10568. [Google Scholar] [CrossRef] [PubMed]

- Barzagli, F.; Lai, S.; Mani, F. Novel non-aqueous amine solvents for reversible CO2 capture. Energy Proced. 2014, 63, 1795–1804. [Google Scholar] [CrossRef]

- Sanna, A.; Vega, F.; Navarrete, B.; Maroto-Valer, M.M. Accelerated MEA degradation study in hybrid CO2 capture systems. Energy Proced. 2014, 63, 745–749. [Google Scholar] [CrossRef]

- Kling, G. Über die dynamik der Blasenbildung beim begasen von Flüssigkeiten unter druck. Int. J. Heat Mass Transf. 1962, 5, 211–223. [Google Scholar] [CrossRef]

- Oyevaar, M.H.; Westerterp, K.R. Mass transfer phenomena and hydrodynamics in agitated gas—Liquid reactors and bubble columns at elevated pressures: State of the art. Chem. Eng. Process. Process Intensif. 1989, 25, 85–98. [Google Scholar] [CrossRef][Green Version]

- LaNauze, R.D. Gas bubble formation at elevated system pressures. Trans. Inst. Chem. Eng. 1974, 52, 337–348. [Google Scholar]

- Bier, K.; Gorenflo, D.; Kemmade, J. Bubble formation and interfacial area during injection of gases into liquids through single orifices. Wärme Und Stoffübertragung 1978, 11, 217–228. [Google Scholar] [CrossRef]

- Idogawa, K. Formation and flow of gas bubbles in a pressurized bubble column with a single orifice or nozzle gas distributor. Chem. Eng. Commun. 1987, 59, 201–212. [Google Scholar] [CrossRef]

- Oyevaar, M.H.; De La Rie, T.; Van der Sluijs, C.L.; Westerterp, K.R. Interfacial areas and gas hold-ups in bubble columns and packed bubble columns at elevated pressures. Chem. Eng. Process. Process Intensif. 1989, 26, 1–14. [Google Scholar] [CrossRef]

- Badssi, A.; Bugarel, R.; Blanc, C.; Peytavy, J.L.; Laurent, A. Influence of pressure on the gas-liquid interfacial area and the gas-side mass transfer coefficient of a laboratory column equipped with cross-flow sieve trays. Chem. Eng. Process. Process Intensif. 1988, 23, 89–97. [Google Scholar] [CrossRef]

- Benadda, B.; Otterbein, M.; Kafoufi, K.; Prost, M. Influence of pressure on the gas/liquid interfacial area a and the coefficient in a counter-current packed column. Chem. Eng. Process. Process Intensif. 1996, 35, 247–253. [Google Scholar] [CrossRef]

- Molga, E.J.; Westerterp, K.R. Gas-liquid interfacial area and holdup in a cocurrent upflow packed bed bubble column reactor at elevated pressures. Ind. Eng. Chem. Res. 1997, 36, 622–631. [Google Scholar] [CrossRef]

- Lewis, W.K.; Whitman, W.G. Principles of gas absorption. Ind. Eng. Chem. 1924, 16, 1215–1220. [Google Scholar] [CrossRef]

- Whitman, W.G. The two film theory of gas absorption. Int. J. Heat Mass Transf. 1962, 5, 429–433. [Google Scholar] [CrossRef]

- Doran, P.M. Bioprocess Engineering Principles, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 379–444. [Google Scholar]

- Ngo, T.H. Gas Absorption into Emulsions. Ph.D. Thesis, Technical University of Braunschweig, Braunschweig, Germany, 5 March 2013. [Google Scholar]

- Pandya, J. Adiabatic gas absorption and stripping with chemical reaction in packed towers. Chem. Eng. Commun. 1983, 19, 343–361. [Google Scholar] [CrossRef]

- Afkhamipour, M.; Mofarahi, M. Comparison of rate-based and equilibrium-stage models of a packed column for post-combustion CO2 capture using 2-amino-2-methyl-1-propanol (AMP) solution. Int. J. Greenh. Gas Control 2013, 15, 186–199. [Google Scholar] [CrossRef]

- Taylor, R.; Krishna, R. Multicomponent Mass Transfer; John Wiley & Sons: Hoboken, NJ, USA, 1993. [Google Scholar]

- Contributors American Institute of Chemical Engineers. Bubble-Tray Design Manual; Contributors American Institute of Chemical Engineers: New York, NY, USA, 1958. [Google Scholar]

- Chan, H.; Fair, J.R. Prediction of point efficiencies on sieve trays. 2. Multicomponent systems. Ind. Eng. Chem. Process Des. Dev. 1984, 23, 820–827. [Google Scholar] [CrossRef]

- Zuiderweg, F.J. Sieve trays: A view on the state of the art. Chem. Eng. Sci. 1982, 37, 1441–1464. [Google Scholar] [CrossRef]

- Švandová, Z.; Markoš, J.; Jelemenský, L. Impact of mass transfer on modelling and simulation of reactive distillation columns. In Mass Transfer in Multiphase Systems and Its Applications; Slovak University of Technology: Bratislava, Slovakia, 2011. [Google Scholar]

- Simon, L.L.; Elias, Y.; Puxty, G.; Artanto, Y.; Hungerbuhler, K. Rate based modeling and validation of a carbon-dioxide pilot plant absorbtion column operating on monoethanolamine. Chem. Eng. Res. Des. 2011, 89, 1684–1692. [Google Scholar] [CrossRef]

| Number of the Experiment | The Total Inlet Gas Flow Rate (Nm3/h) | Pressure (MPa) |

|---|---|---|

| 1 | 15 | 0.2 |

| 2 | 15 | 0.21 |

| 3 | 15 | 0.22 |

| 4 | 15 | 0.23 |

| 5 | 15 | 0.24 |

| 6 | 15 | 0.25 |

| 7 | 15 | 0.26 |

| 8 | 15 | 0.27 |

| 9 | 15 | 0.28 |

| 10 | 15 | 0.29 |

| 11 | 15 | 0.3 |

| 12 | 20 | 0.2 |

| 13 | 20 | 0.21 |

| 14 | 20 | 0.22 |

| 15 | 20 | 0.23 |

| 16 | 20 | 0.24 |

| 17 | 20 | 0.25 |

| 18 | 20 | 0.26 |

| 19 | 20 | 0.27 |

| 20 | 20 | 0.28 |

| 21 | 20 | 0.29 |

| 22 | 20 | 0.3 |

| Pressure (MPa) | Inlet Gas Flow Rate (15 Nm3/h) | Inlet Gas Flow Rate (20 Nm3/h) |

| 0.2 | 1.195% | 0.262% |

| 0.21 | 0.856% | 0.018% |

| 0.22 | 0.711% | 0.308% |

| 0.23 | 0.551% | 0.511% |

| 0.24 | 0.591% | 0.764% |

| 0.25 | 0.6182% | 1.063% |

| 0.26 | 0.528% | 1.379% |

| 0.27 | 0.104% | 1.678% |

| 0.28 | 0.008% | 1.785% |

| 0.29 | 0.085% | 2.017% |

| 0.3 | 0.062% | 2.271% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almoslh, A.; Alobaid, F.; Heinze, C.; Epple, B. Influence of Pressure on Gas/Liquid Interfacial Area in a Tray Column. Appl. Sci. 2020, 10, 4617. https://doi.org/10.3390/app10134617

Almoslh A, Alobaid F, Heinze C, Epple B. Influence of Pressure on Gas/Liquid Interfacial Area in a Tray Column. Applied Sciences. 2020; 10(13):4617. https://doi.org/10.3390/app10134617

Chicago/Turabian StyleAlmoslh, Adel, Falah Alobaid, Christian Heinze, and Bernd Epple. 2020. "Influence of Pressure on Gas/Liquid Interfacial Area in a Tray Column" Applied Sciences 10, no. 13: 4617. https://doi.org/10.3390/app10134617

APA StyleAlmoslh, A., Alobaid, F., Heinze, C., & Epple, B. (2020). Influence of Pressure on Gas/Liquid Interfacial Area in a Tray Column. Applied Sciences, 10(13), 4617. https://doi.org/10.3390/app10134617