Influence of Loading Orientation and Knitted Versus Woven Transversal Connections in 3D Textile Reinforced Cement (TRC) Composites

Abstract

1. Introduction

2. Materials and Methods

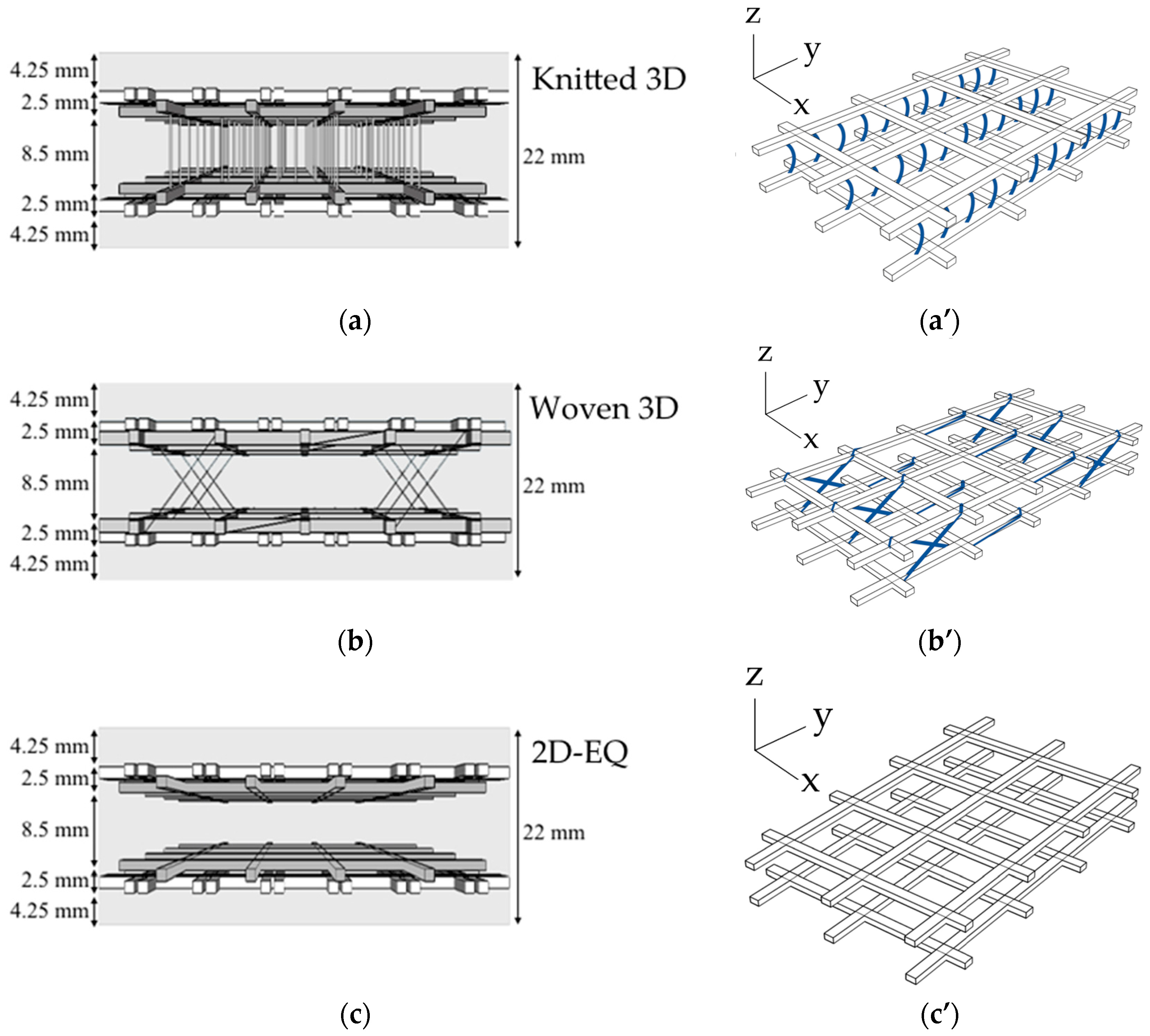

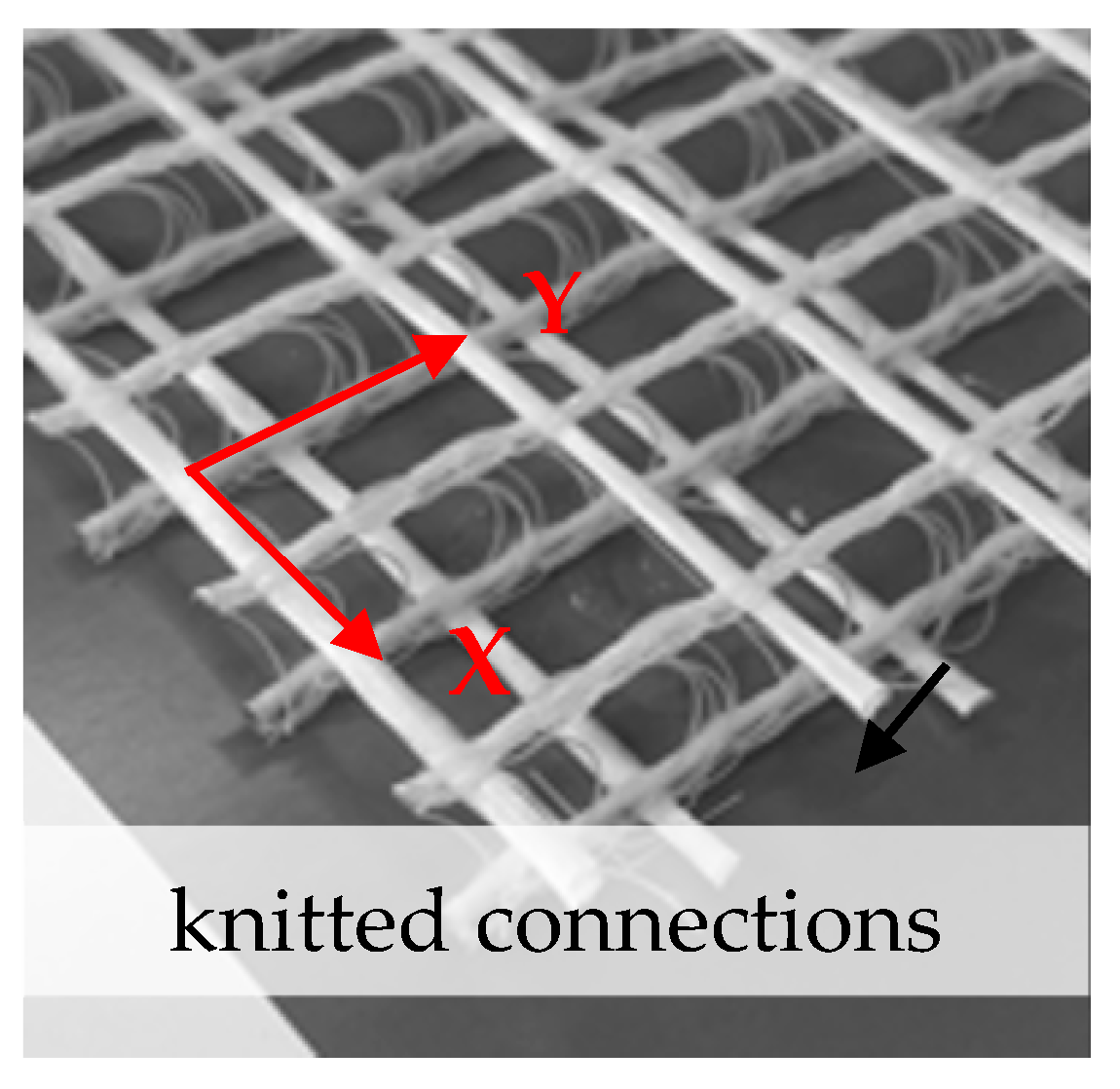

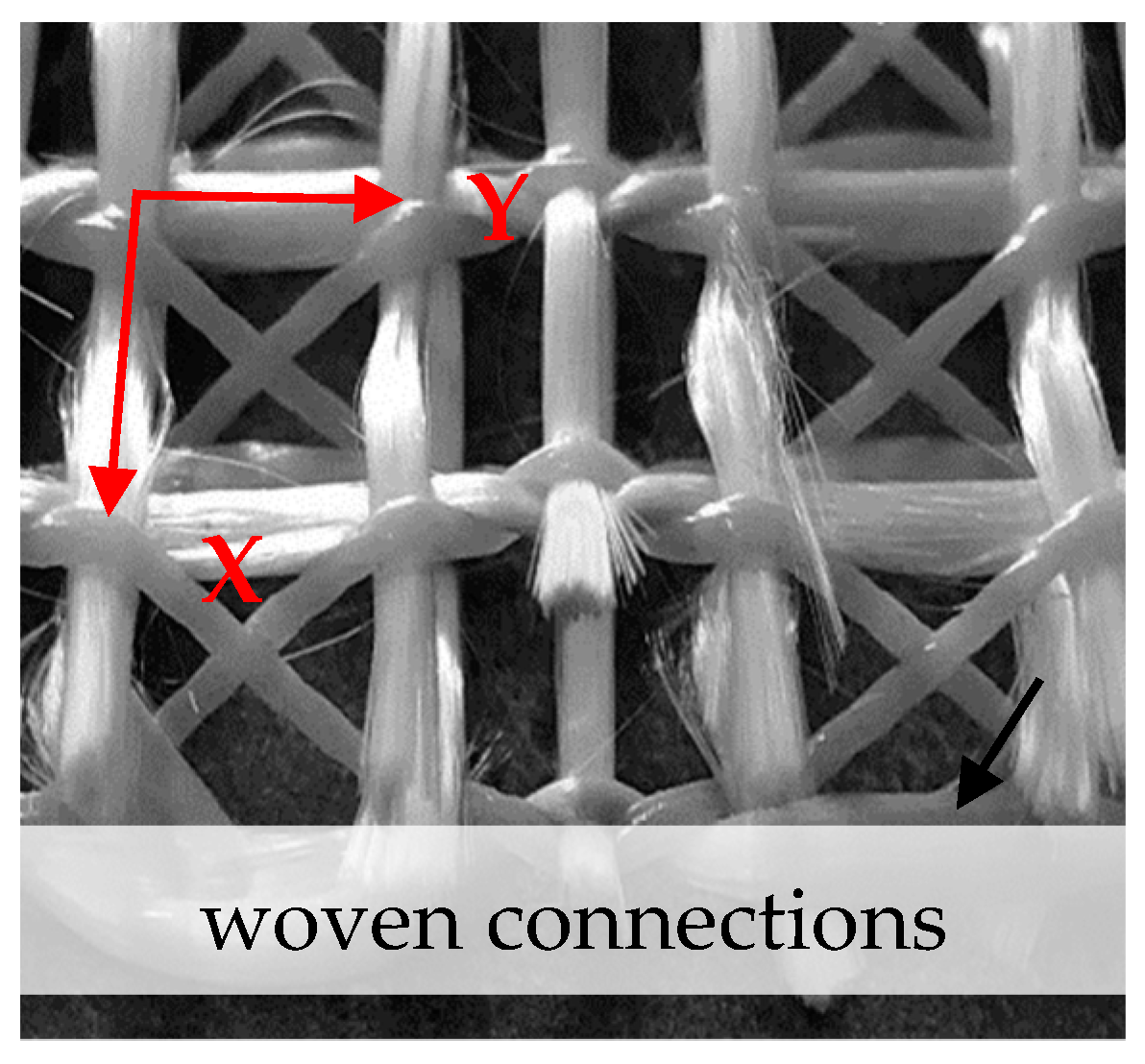

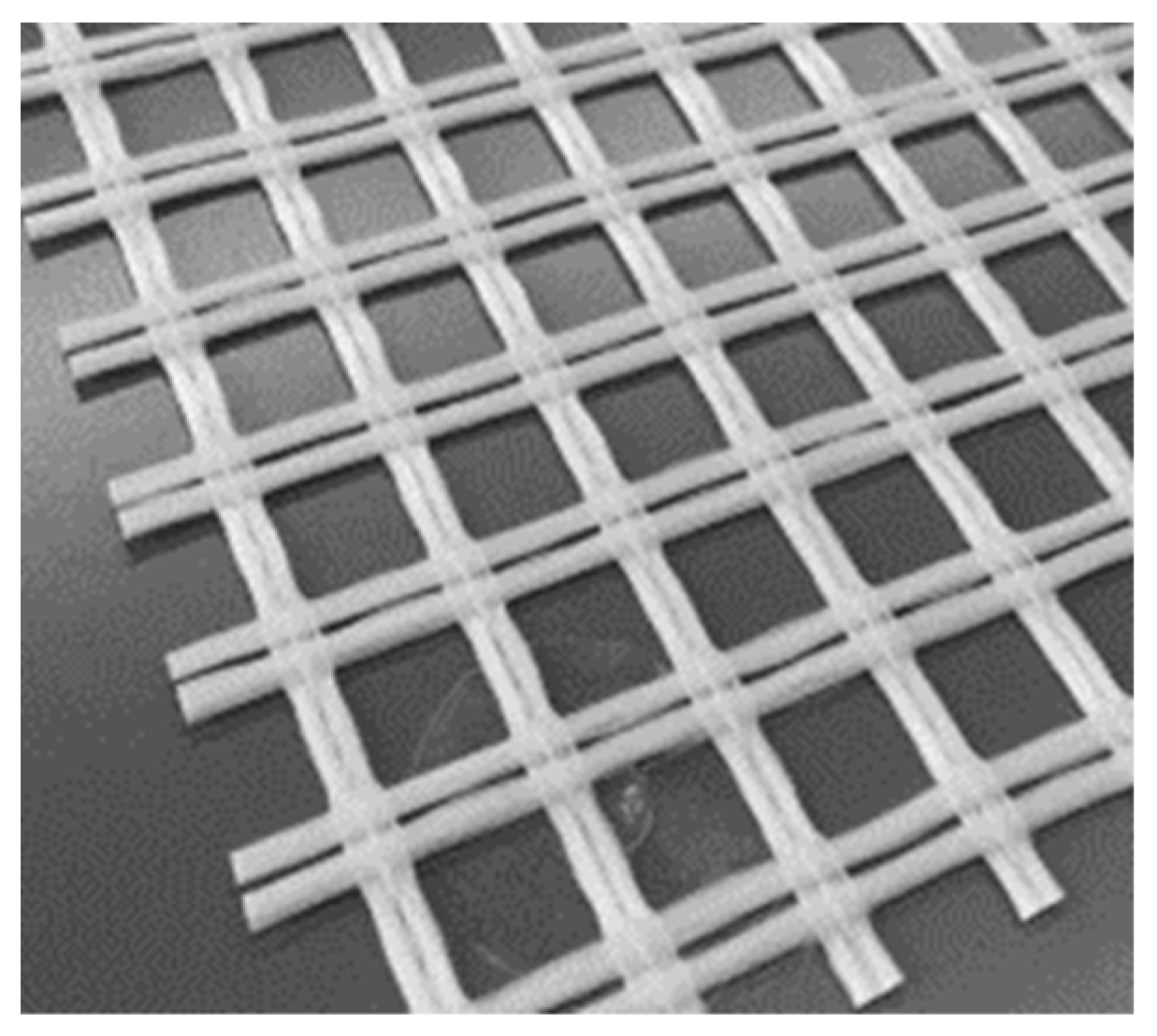

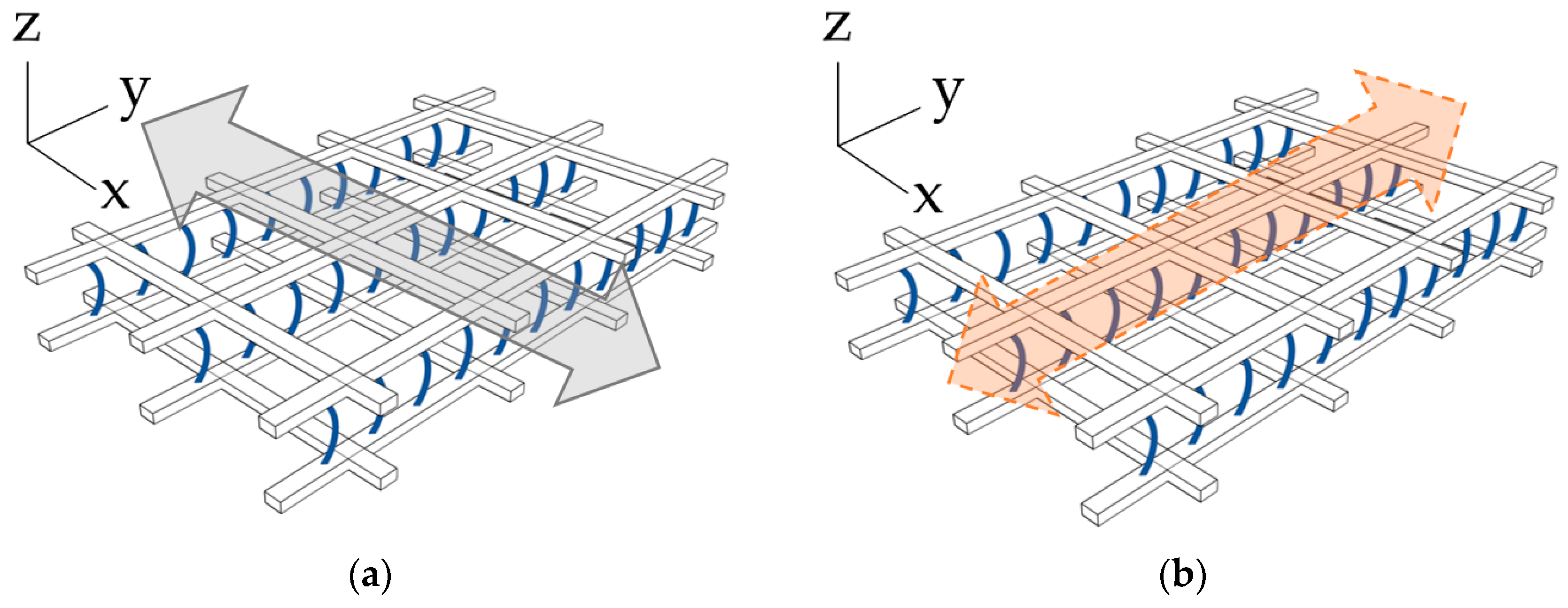

2.1. Properties of Selected Textiles, Considered Layups and Matrix

2.2. TRC Manufacturing Process

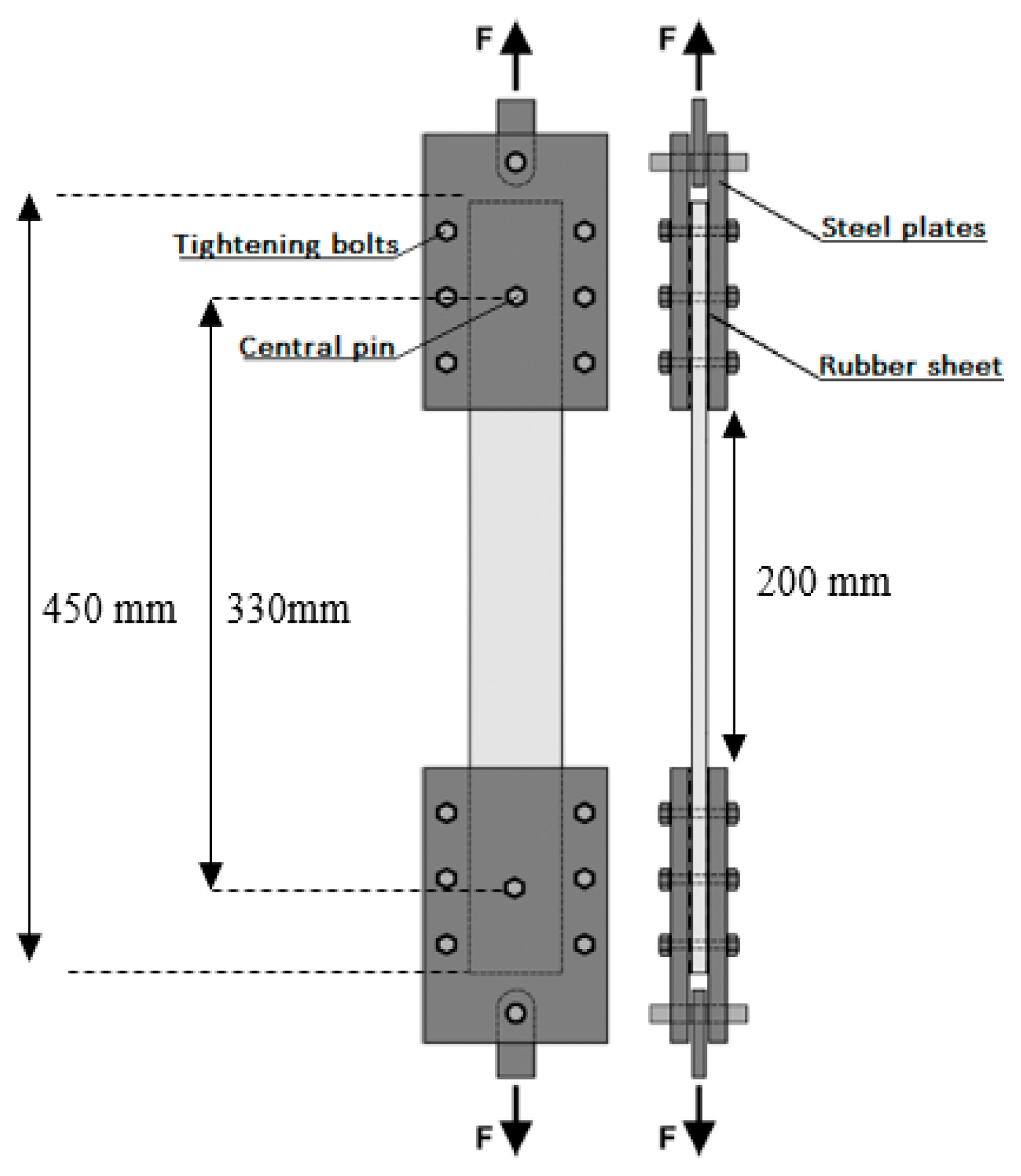

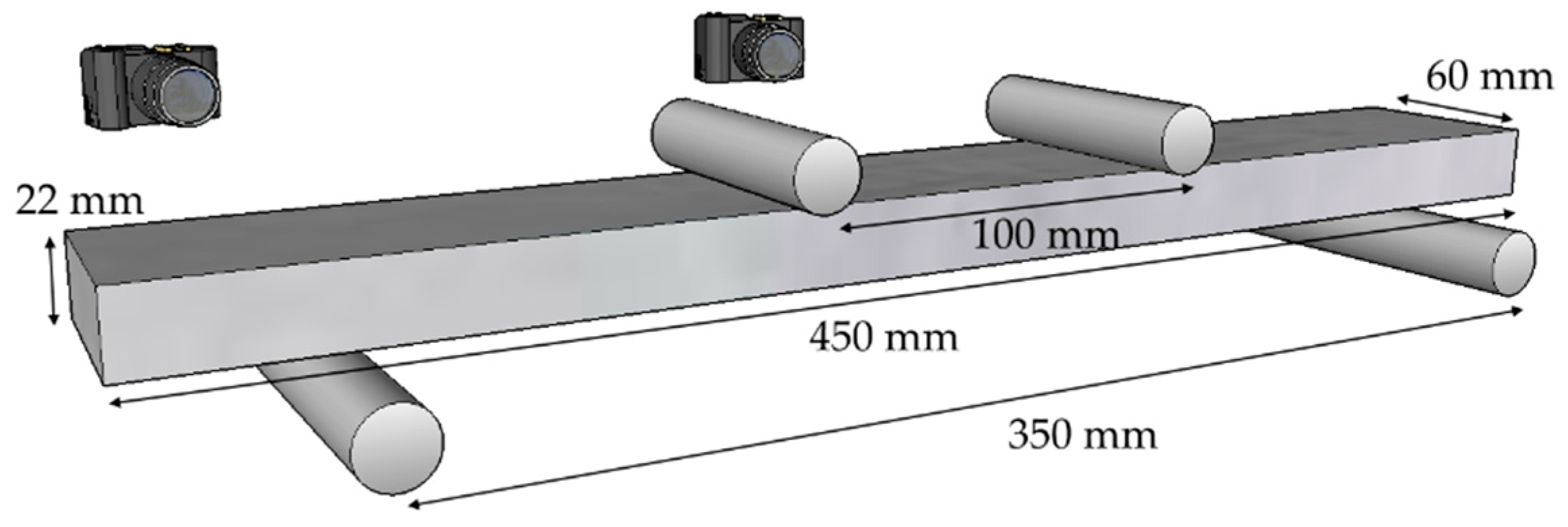

2.3. Tensile and Flexural Experimental Test Setup

3. Experimental Results and Discussion

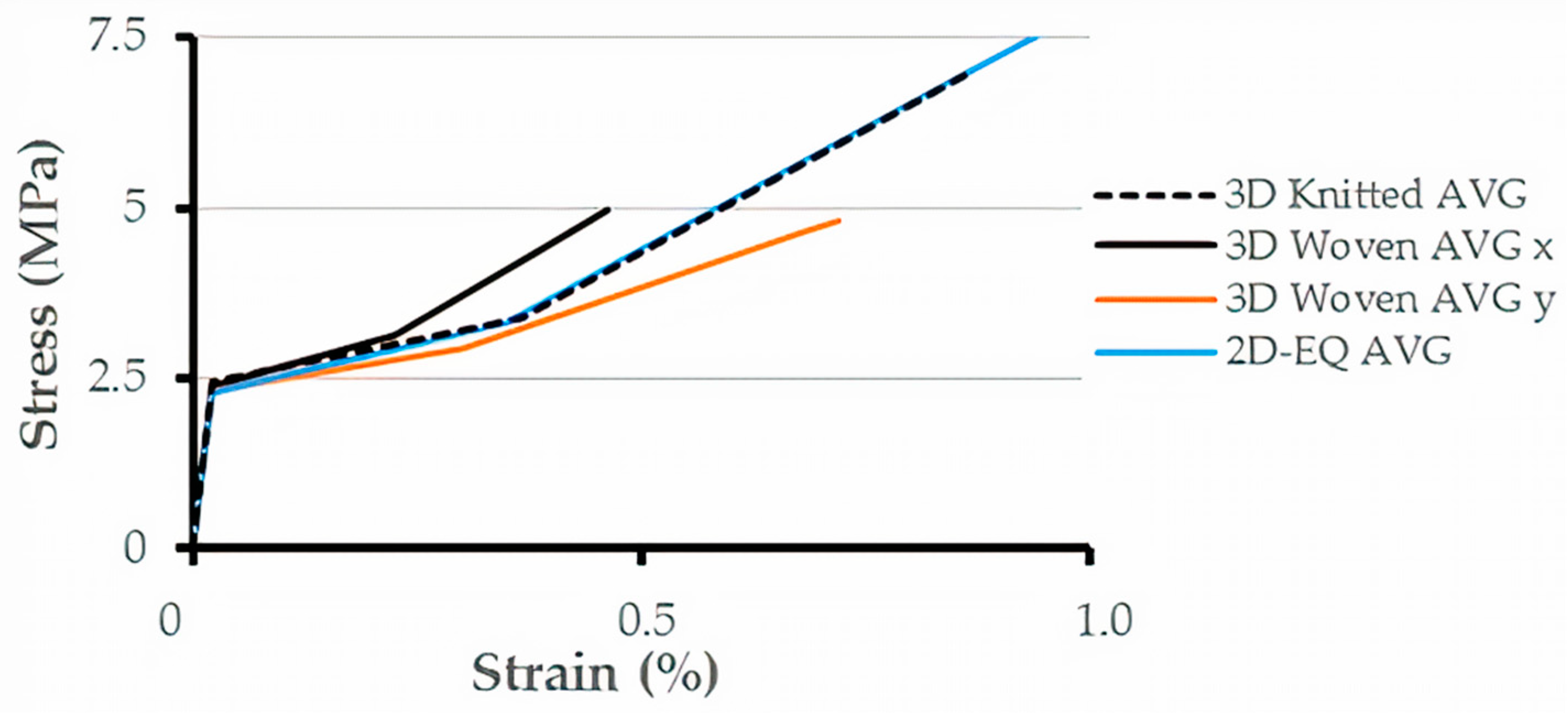

3.1. Tensile Experimental Results

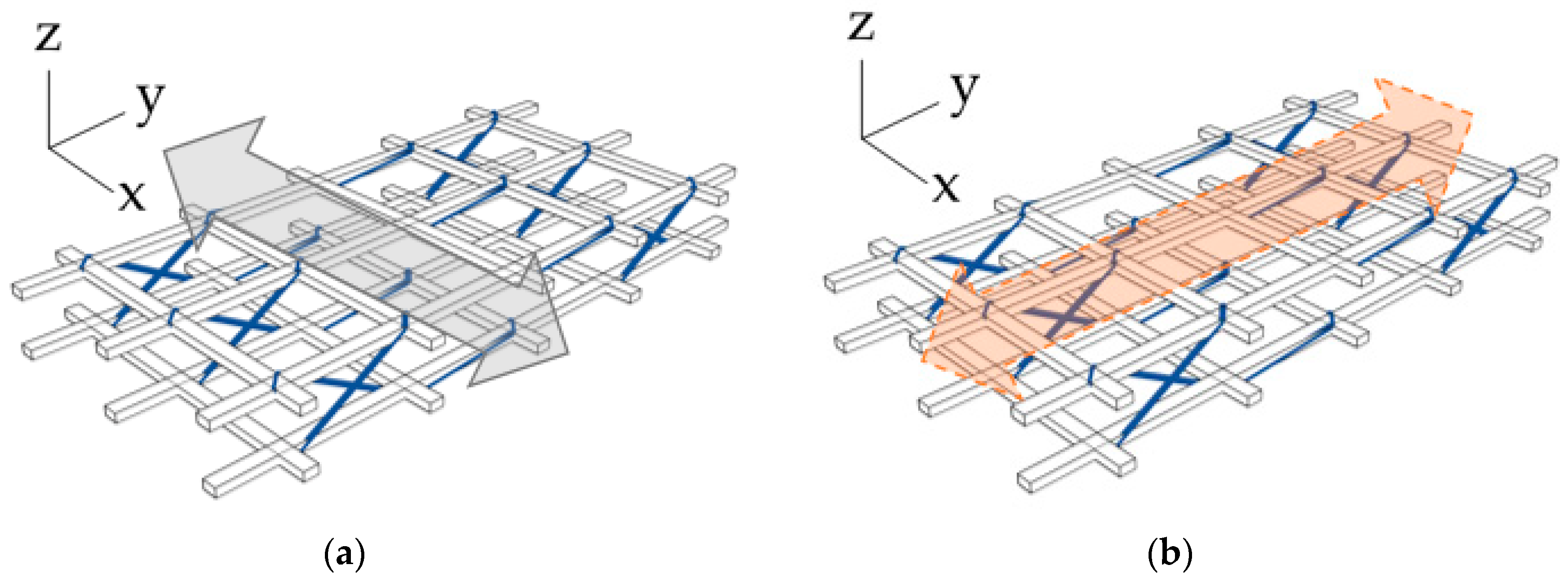

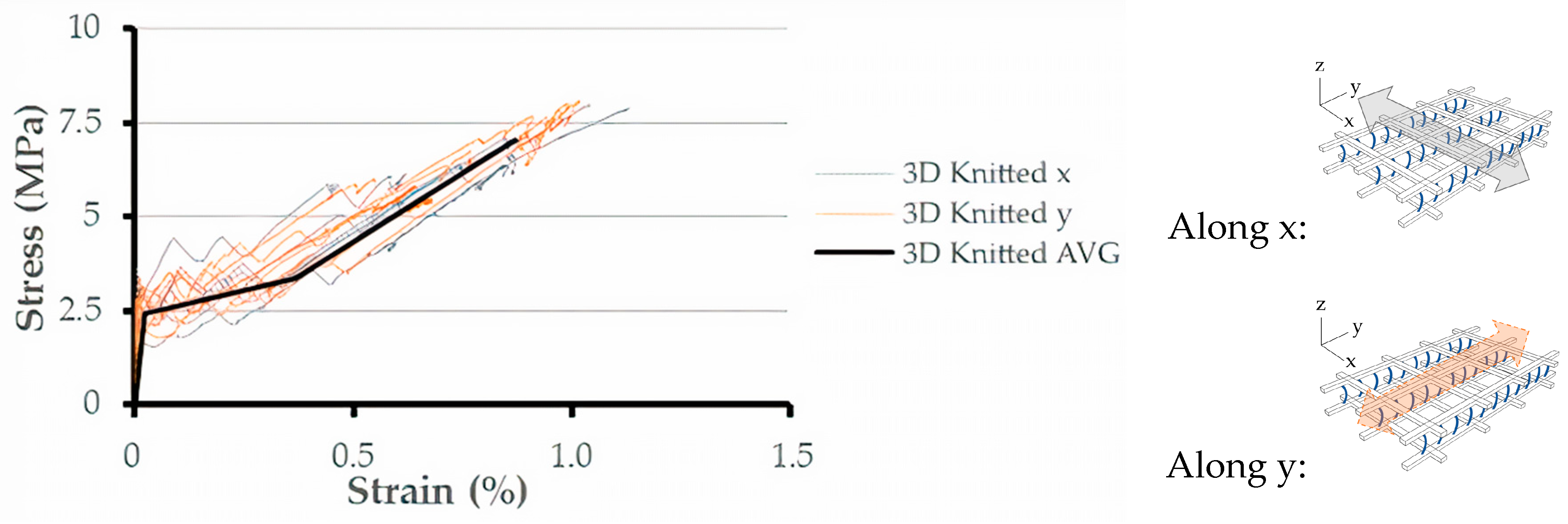

3.1.1. Knitted 3D TRC

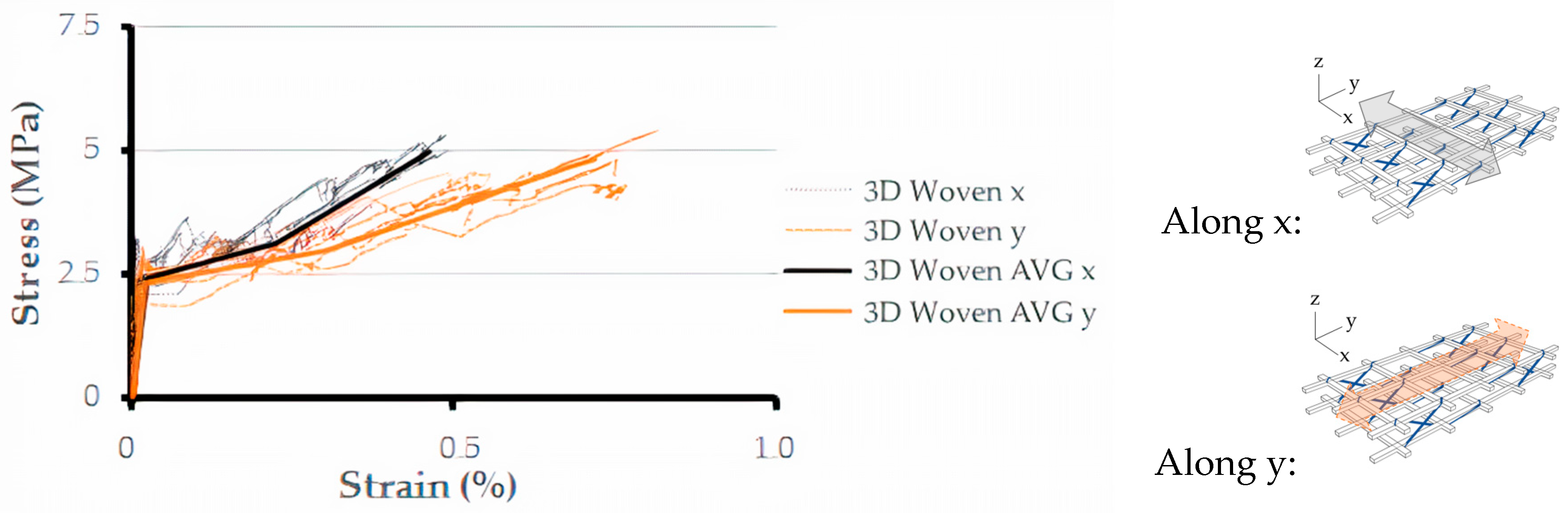

3.1.2. Woven 3D TRC

3.2. Flexural Experimental Results

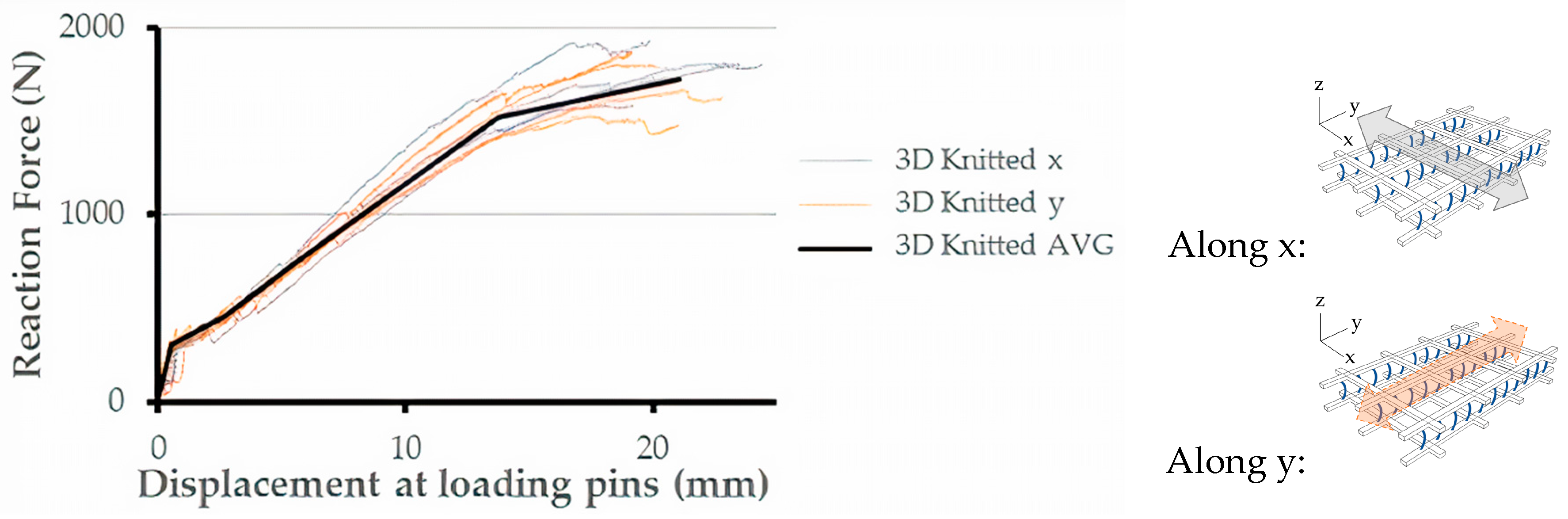

3.2.1. Knitted 3D TRC

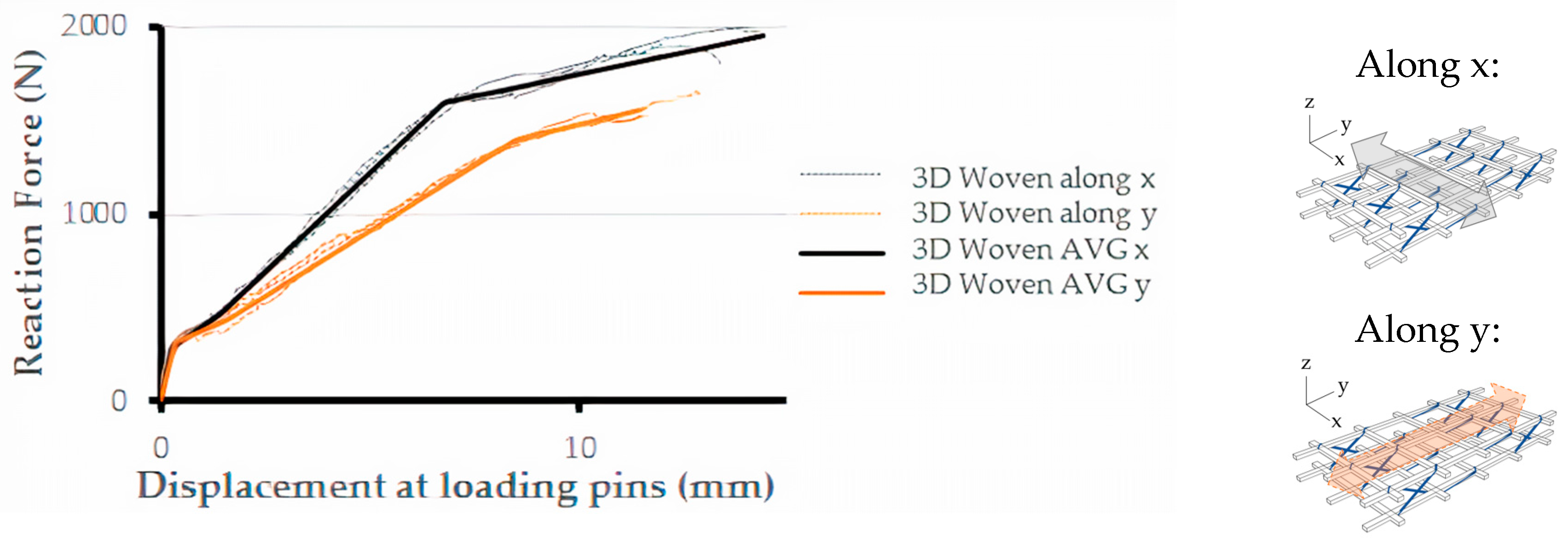

3.2.2. Woven 3D TRC

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Brameshuber, W. Textile Reinforced Concrete: State of the Art Report. RILEM Technical Committee 201-TRC, 1st ed.; RILEM Publications: Aachen, Germany, 2006. [Google Scholar]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; Taylor and Francis: New York, NY, USA, 2007; 601p. [Google Scholar]

- Aveston, J.; Cooper, G.A.; Kelly, A. Single and Multiple Fracture. In Proceedings of the Properties of Fibre Composites, London, UK, November 1971. [Google Scholar]

- Hegger, J.; Kulas, C.; Horstmann, M. Spatial Textile Reinforcement Structures for Ventilated and Sandwich Facade Elements. Adv. Struct. Eng. 2016, 15, 665–675. [Google Scholar] [CrossRef]

- Triantafillou, T.; Papanicolaou, C.G. Shear Strengthening of Reinforced Concrete Members with Textile Reinforced Mortar (TRM) Jackets. Mater. Struct. 2006, 39, 93–103. [Google Scholar] [CrossRef]

- Brückner, A.; Ortlepp, R.; Curbach, M. Anchoring of Shear Strengthening for T-Beams Made of Textile Reinforced Concrete (TRC). Mater. Struct. 2008, 41, 407–418. [Google Scholar] [CrossRef]

- Contamine, R.; Si Larbi, A.; Hamelin, P. Identifying the Contributing Mechanisms of Textile Reinforced Concrete (TRC) in the Case of Shear Repairing Damaged and Reinforced Concrete Beams. Eng. Struct. 2013, 46, 447–458. [Google Scholar] [CrossRef]

- Si Larbi, A.; Agbossou, A.; Hamelin, P. Experimental and Numerical Investigations about Textile-Reinforced Concrete and Hybrid Solutions for Repairing And/or Strengthening Reinforced Concrete Beams. Compos. Struct. 2013, 99, 152–162. [Google Scholar] [CrossRef]

- Verbruggen, S.; Remy, O.; Wastiels, J.; Tysmans, T. Stay-in-Place Formwork of TRC Designed as Shear Reinforcement for Concrete Beams. Adv. Mater. Sci. Eng. 2013, 2013, 1–9. [Google Scholar] [CrossRef]

- Peled, A.; Bentur, A.; Mobasher, B. Textile Reinforced Concrete; Taylor and Francis: New York, NY, USA, 2017. [Google Scholar]

- Hegger, J.; Horstmann, M.; Zell, M. Applications for TRC. In Proceedings of the 15th International Congress of the International Glassfibre Reinforced Concrete Association (GRCA), Prague, Czech Republic, April 2008. [Google Scholar]

- Tysmans, T.; Adriaenssens, S.; Cuypers, H.; Wastiels, J. Structural Analysis of Small Span Textile Reinforced Concrete Shells with Double Curvature. Compos. Sci. Technol. 2009, 69, 1790–1796. [Google Scholar] [CrossRef]

- Scholzen, A.; Chudoba, R.; Hegger, J. Thin-walled shell structures made of textile-reinforced concrete Part I: Structural design and construction. Struct. Concr. 2015, 16, 106–114. [Google Scholar] [CrossRef]

- Verwimp, E.; Tysmans, T.; Mollaert, M.; Berg, S. Experimental and numerical buckling analysis of a thin TRC dome. Thin-Walled Struct. 2015, 94, 89–97. [Google Scholar] [CrossRef]

- Cuypers, H.; Wastiels, J. Analysis and Verification of the Performance of Sandwich Panels with Textile Reinforced Concrete Faces. J. Sandw. Struct. Mater. 2011, 13, 589–603. [Google Scholar] [CrossRef]

- Vervloet, J.; Tysmans, T.; El Kadi, M.; De Munck, M.; Panagiotis, P.; Van Itterbeek, P.; Wastiels, J.; Van Hemelrijck, D. Validation of a Numerical Bending Model for Sandwich Beams with Textile-Reinforced Cement Faces by Means of Digital Image Correlation. Appl. Sci. 2019, 9, 1253. [Google Scholar] [CrossRef]

- Helbig, T.; Rempel, S.; Unterer, K.; Kulas, C.; Hegger, J. Fuß- und Radwegbrücke aus Carbonbeton in Albstadt-Ebingen. Die weltweit erste ausschließlich carbonfaserbewehrte Betonbrücke. Beton-und Stahlbetonbau 2016, 111, 676–685. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Almusallam, T.H.; Alsayed, S.H.; Al-Salloum, Y.A. Flexural strengthening of RC beams using textile reinforced mortar - Experimental and numerical study. Compos. Struct. 2013, 97, 40–55. [Google Scholar] [CrossRef]

- Zhu, D.; Mobasher, B.; Peled, A. Experimental study of dynamic behavior of cement-based composites. Constr. Build. Mater. 2011, 2, 1–12. [Google Scholar] [CrossRef]

- Amzaleg, E.; Peled, A.; Janetzko, S.; Gries, T. Flexural Behaviour of Cement Based Element Reinforced with 3D Fabric. In Proceedings of the VIII International Conference on Fracture Mechanics of Concrete and Concrete Structures, Toledo, Spain, 11 March 2013. [Google Scholar]

- El Kadi, M.; Tysmans, T.; Verbruggen, S.; Vervloet, J.; De Munck, M.; Wastiels, J.; Van Hemelrijck, D. Experimental study and benchmarking of 3D textile reinforced cement composites. Cem. Concr. Compos. 2019, 104, 1–10. [Google Scholar] [CrossRef]

- Peled, A.; Haik, R.; Sasi, E.A. Influence of three-dimensional (3D) fabric orientation on flexural properties of cement-based composites. Cem. Concr. Compos. 2017, 80, 1–9. [Google Scholar]

- Dvorkin, D.; Poursaee, A.; Peled, A.; Weiss, W.J. Influence of bundle coating on the tensile behavior, bonding, cracking and fluid transport of fabric cementbased composites. Cem. Concr. Compos. 2013, 42, 9–19. [Google Scholar] [CrossRef]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical properties of FRCM using carbon fabrics with different coating treatments. Compos. Part B Eng. 2016, 88, 220–228. [Google Scholar] [CrossRef]

- Signorini, C.; Nobili, A.; Sola, A.; Messori, M. Designing epoxy viscosity for optimal mechanical performance of coated Glass Textile Reinforced Mortar (GTRM) composites. Constr. Build. Mater. 2020, 233, 1–12. [Google Scholar] [CrossRef]

- El Kadi, M.; Tysmans, T.; Verbruggen, S.; Wastiels, J.; Vervloet, J.; De Munck, M.; Van Hemelrijck, D. A layered-wise, composite modelling approach for fibre textile reinforced cementitious composites. Cem. Concr. Compos. 2018, 94, 107–115. [Google Scholar] [CrossRef]

- Sika. Sikagrout 217, Note de Produit. Available online: https://www.sika.com/ (accessed on 28 June 2020).

- Fraas, V. Technical Datasheet SitGrid701. Available online: https://www.solutions-in-textile.com (accessed on 28 June 2020).

- Ghekiere, P. 3D Weaving, Strong in Development. Available online: https://www.3dweaving.com (accessed on 28 June 2020).

- Fraas, V. Technical Datasheet SitGrid200. Available online: https://www.solutions-in-textile.com (accessed on 28 June 2020).

- Brameshuber, W. Uniaxial Tensile Test: Test Methods and Design of Textile Reinforced Concrete. Mater. Struct./Mater. et Constr. 2016, 49, 4923–4927. [Google Scholar]

- Sutton, M.A.; Orteu, J.-J.; Schreier, H.W. Image Correlation for Shape, Motion and Deformation Measurements; Springer Science + Business Media: New York, NY, USA, 2009. [Google Scholar]

| Textile | Material | Grid Size (mm × mm) | Textile Density (g/m²) | Equivalent Thickness (mm) | Yarn Stiffness (GPa) | Textile Max Stress (MPa) | Transversal Connection |

|---|---|---|---|---|---|---|---|

| Knitted 3D | AR-glass 2400 tex | 22.5 × 22.5 | 536 | 0.105 | 67 | 496 | knitted polyester |

| Woven 3D | AR-glass 1200 tex | 9.1 × 9.1 | 527 | 0.103 | 67 | 512 | woven polyester |

| 2D | AR-glass 2400 tex | 17.5 × 17.5 | 568 | 0.223 | 67 | 526 | / |

| Aggregate Size. (mm) | Compressive strength (28d) (MPa) | Modulus of Rupture (28d) (MPa) | Density after Mixing (kg/m³) | Young’s Modulus (GPa) | Water/Mortar Ratio (-) |

|---|---|---|---|---|---|

| 0–1.6 | 70 | 12 | 2010 | 9 | 0.15 |

| Knitted 3D TRC, along x, Vf = 1.49% | |||

| ε0 (%) | 0 | σ0 (MPa) | 0 |

| εc (%) | 0.022 | σc (MPa) | 2.47 |

| εmc (%) | 0.365 | σmc (MPa) | 3.40 |

| εf (%) | 0.880 | σf (MPa) | 7.03 |

| E1 (MPa) | 11,027 ± 541 | ||

| E2 (MPa) | 271 ± 73 | ||

| E3 (MPa) | 710 ± 45 | ||

| Knitted 3D TRC, along y, Vf = 1.49% | |||

| ε0 (%) | 0 | σ0 (MPa) | 0 |

| εc (%) | 0.022 | σc (MPa) | 2.41 |

| εmc (%) | 0.369 | σmc (MPa) | 3.36 |

| εf (%) | 0.840 | σf (MPa) | 7.01 |

| E1 (MPa) | 10,919 ± 532 | ||

| E2 (MPa) | 275 ± 77 | ||

| E3 (MPa) | 738 ± 48 | ||

| Knitted 3D TRC, all, Vf = 1.49% | |||

| ε0 (%) | 0 | σ0 (MPa) | 0 |

| εc (%) | 0.022 | σc (MPa) | 2.44 |

| εmc (%) | 0.367 | σmc (MPa) | 3.38 |

| εf (%) | 0.860 | σf (MPa) | 7.02 |

| E1 (MPa) | 10,973 ± 534 | ||

| E2 (MPa) | 273 ± 74 | ||

| E3 (MPa) | 724 ± 46 | ||

| Knitted 3D AVG | Woven 3D AVG x | Woven 3D AVG y | 2D-EQ AVG | |

|---|---|---|---|---|

| E1 (MPa) | 10,973 | 10,903 | 10,957 | 10,736 |

| E2 (MPa) | 273 | 365 | 229 | 318 |

| E3 (MPa) | 724 | 761 | 446 | 710 |

| Woven 3D TRC, Along x, Vf = 1.49% | Woven 3D TRC, Along y, Vf = 1.49% | ||||||

|---|---|---|---|---|---|---|---|

| ε0 (%) | 0 | σ0 (MPa) | 0 | ε0 (%) | 0 | σ0 (MPa) | 0 |

| εc (%) | 0.022 | σc (MPa) | 2.40 | εc (%) | 0.021 | σc (MPa) | 2.31 |

| εmc (%) | 0.225 | σmc (MPa) | 3.14 | εmc (%) | 0.301 | σmc (MPa) | 2.95 |

| εf (%) | 0.464 | σf (MPa) | 4.96 | εf (%) | 0.719 | σf (MPa) | 4.82 |

| E1 (MPa) | 10,903 ± 705 | E1 (MPa) | 10,957 ± 812 | ||||

| E2 (MPa) | 365 ± 64 | E2 (MPa) | 229 ± 38 | ||||

| E3 (MPa) | 761 ± 44 | E3 (MPa) | 446 ± 35 | ||||

| Knitted 3D TRC, All Specimens, Vf = 1.49% | |||

|---|---|---|---|

| d0 (mm) | 0 | F0 (N) | 0 |

| dc (mm) | 0.562 | Fc (N) | 310 |

| dmc (mm) | 2.711 | Fmc (N) | 460 |

| df (mm) | 14.045 | Ff (N) | 1503 |

| K1 (N/mm) | 551 ± 48 | ||

| K2 (N/mm) | 70 ± 12 | ||

| K3 (N/mm) | 92 ± 7 | ||

| Equivalent 2D TRC, All Specimens, Vf = 1.49% | |||

|---|---|---|---|

| d0 (mm) | 0 | F0 (N) | 0 |

| dc (mm) | 0.555 | Fc (N) | 306 |

| dmc (mm) | 1.848 | Fmc (N) | 395 |

| df (mm) | 16.503 | Ff (N) | 1456 |

| K1 (N/mm) | 552 ± 42 | ||

| K2 (N/mm) | 68 ± 19 | ||

| K3 (N/mm) | 72 ± 3 | ||

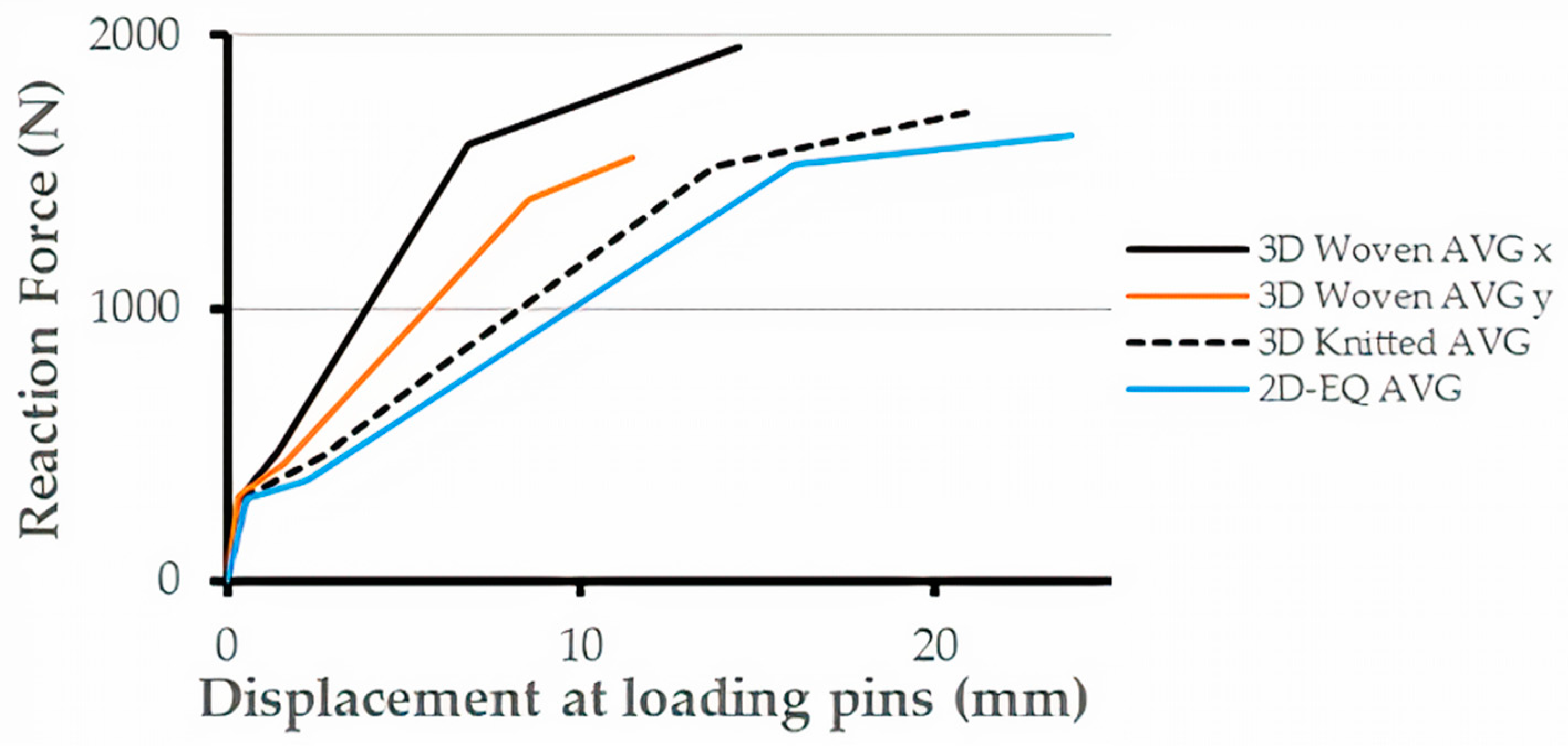

| Knitted 3D AVG | Woven 3D AVG x | Woven 3D AVG y | 2D-EQ AVG | |

|---|---|---|---|---|

| K1 (N/mm) | 551 | 536 | 558 | 552 |

| K2 (N/mm) | 70 | 166 | 103 | 68 |

| K3 (N/mm) | 92 | 218 | 143 | 72 |

| Woven 3D TRC, Along x, Vf = 1.49% | Woven 3D TRC, Along y, Vf = 1.49% | ||||||

|---|---|---|---|---|---|---|---|

| d0 (mm) | 0 | F0 (N) | 0 | d0 (mm) | 0 | F0 (N) | 0 |

| dc (mm) | 0.542 | Fc (N) | 290 | dc (mm) | 0.561 | Fc (N) | 313 |

| dmc (mm) | 1.661 | Fmc (N) | 476 | dmc (mm) | 1.713 | Fmc (N) | 432 |

| df (mm) | 6.806 | Ff (N) | 1598 | df (mm) | 8.504 | Ff (N) | 1401 |

| K1 (N/mm) | 536 ± 44 | K1 (N/mm) | 558 ± 49 | ||||

| K2 (N/mm) | 166 ± 16 | K2 (N/mm) | 103 ± 11 | ||||

| K3 (N/mm) | 218 ± 16 | K3 (N/mm) | 143 ± 10 | ||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Kadi, M.; Kapsalis, P.; Van Hemelrijck, D.; Wastiels, J.; Tysmans, T. Influence of Loading Orientation and Knitted Versus Woven Transversal Connections in 3D Textile Reinforced Cement (TRC) Composites. Appl. Sci. 2020, 10, 4517. https://doi.org/10.3390/app10134517

El Kadi M, Kapsalis P, Van Hemelrijck D, Wastiels J, Tysmans T. Influence of Loading Orientation and Knitted Versus Woven Transversal Connections in 3D Textile Reinforced Cement (TRC) Composites. Applied Sciences. 2020; 10(13):4517. https://doi.org/10.3390/app10134517

Chicago/Turabian StyleEl Kadi, Michael, Panagiotis Kapsalis, Danny Van Hemelrijck, Jan Wastiels, and Tine Tysmans. 2020. "Influence of Loading Orientation and Knitted Versus Woven Transversal Connections in 3D Textile Reinforced Cement (TRC) Composites" Applied Sciences 10, no. 13: 4517. https://doi.org/10.3390/app10134517

APA StyleEl Kadi, M., Kapsalis, P., Van Hemelrijck, D., Wastiels, J., & Tysmans, T. (2020). Influence of Loading Orientation and Knitted Versus Woven Transversal Connections in 3D Textile Reinforced Cement (TRC) Composites. Applied Sciences, 10(13), 4517. https://doi.org/10.3390/app10134517