1. Introduction

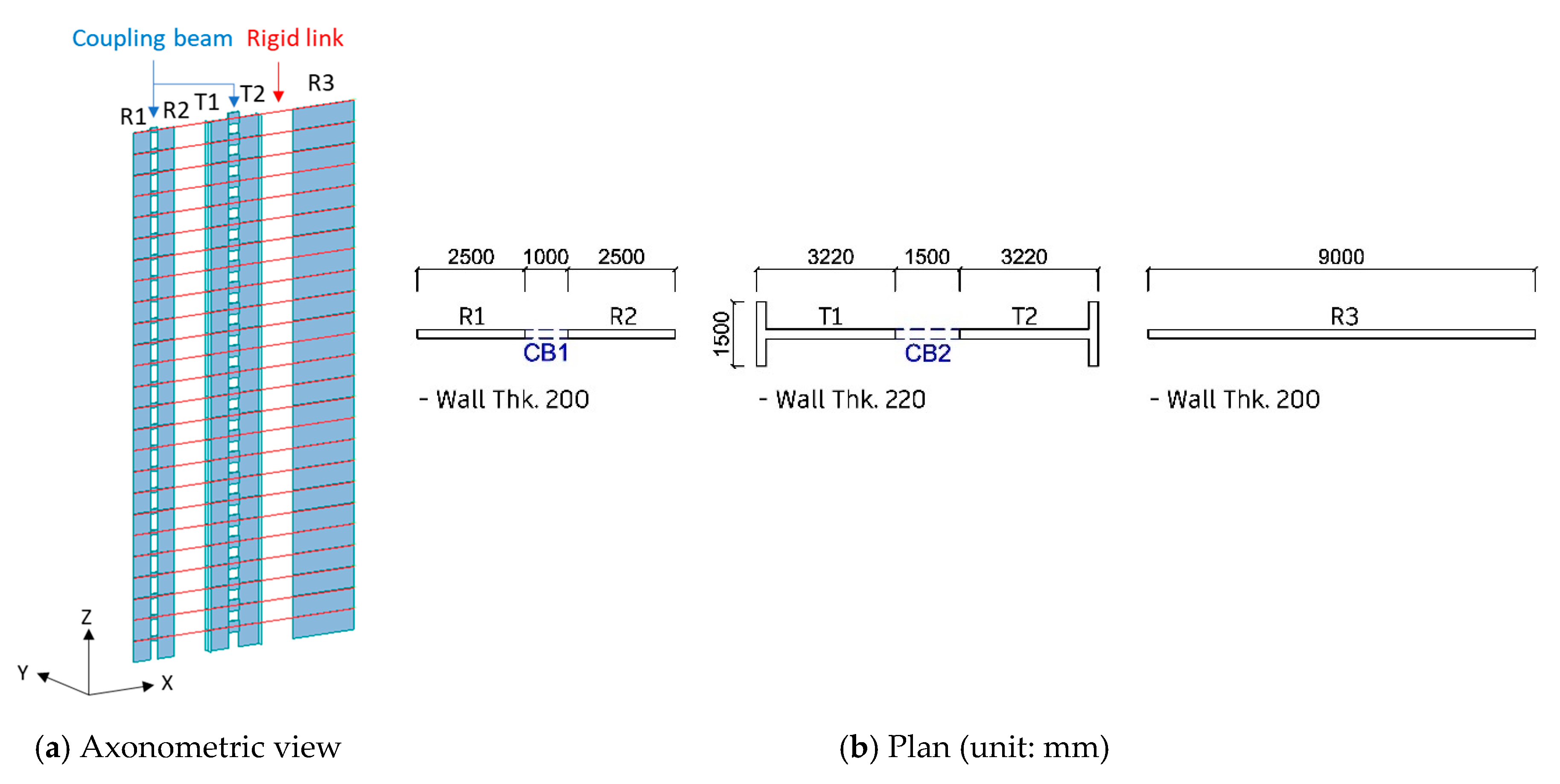

Performance-based seismic design has been applied to high-rise buildings increasingly in South Korea as well as the USA, owing to progress in nonlinear structural analysis techniques and relevant design guidelines. In Korean Building Code (KBC) 2016, the performance-based seismic design is introduced for the first time and defined as a design method to achieve performance objectives using nonlinear analysis considering inelastic deformation capacity and the over-strength of structures more precisely, and it can be applied to structures in which the design coefficients for elastic design are uncertain or structures required to meet various performance objectives [

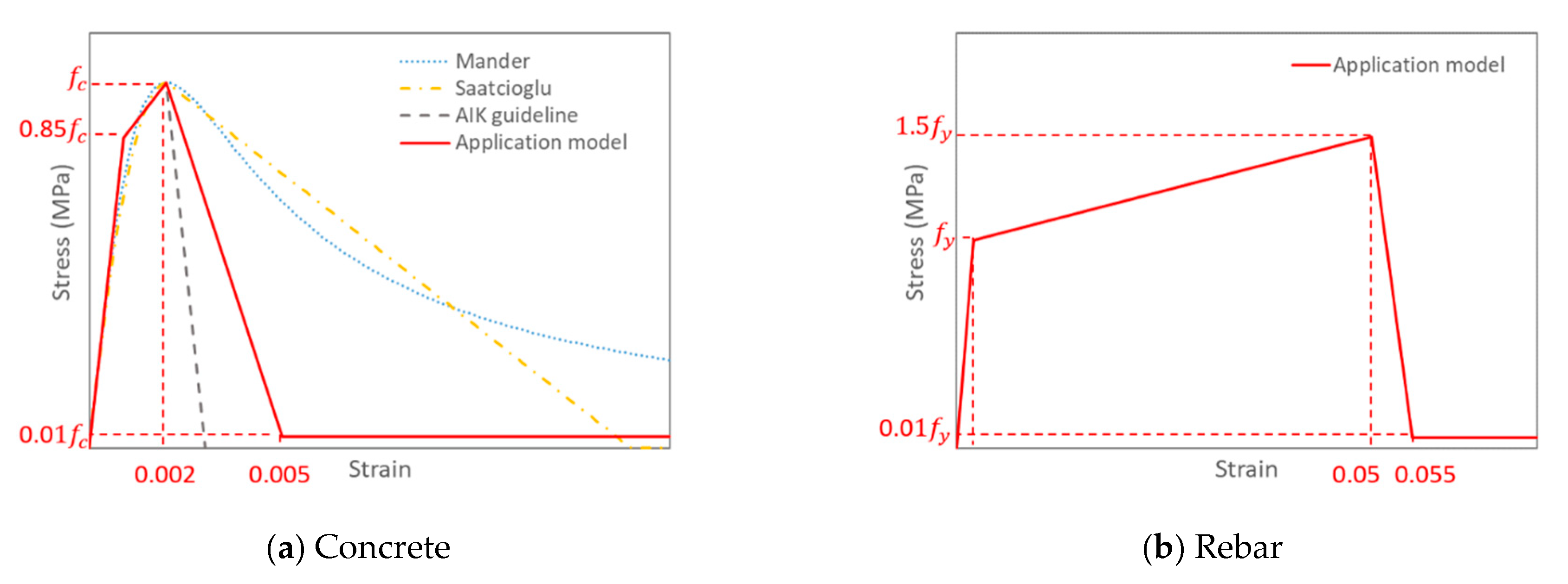

1]. In South Korea, performance-based seismic design is mostly applied to high-rise apartment buildings in which ordinary reinforced concrete (RC) shear walls are used to resist seismic forces. This is because ordinary RC shear walls are not permitted in the elastic design for buildings that belong to seismic design category D and are taller than 60 m. For such conditions, special RC shear walls are used, but strict confinement details are required in boundary elements with a side effect of higher construction cost and time. The “boundary element” designate longitudinal end in the cross section of walls where hoop reinforcement is located to confine concrete in high compression. The special RC wall is avoided, particularly in case of thin walls because the spacing of the hoop reinforcement required to be smaller than one third of the wall thickness, and this requirement causes difficulty in the detailing work and concrete placing in an actual construction field. In order to solve this problem, high-rise ordinary RC shear walls are used, using the performance-based seismic design procedure introduced in KBC 2016. The detailed guidelines for the performance-based seismic design are given in “Guidelines for Performance-Based Seismic Design of Residential Buildings” published by the Architectural Institute of Korea (AIK) [

2].

Although nonlinear dynamic analysis is used for the detailed verification of seismic performance, it is necessary to verify the structural safety of high-rise ordinary RC shear walls, because such walls are subjected to relatively high axial force ratios, which can lead to brittle failure mode due to the lack of confinement in the boundary elements. In accordance with AIK guidelines, nonlinear response history analyses are conducted using seven pairs of horizontal ground motion components within the framework of performance-based seismic design. However, mean peak response-based design without strength reduction factors for a limited number of ground motion records are questionable in respect to reliability. Representative guidelines on the reliability of seismic design are found in (American Society of Civil Engineers) ASCE 7–16, in which a target reliability for structural stability against earthquakes is proposed as 10% in the case of seismic risk category I and II [

3]. FEMA P695 provides a verification methodology for seismic design coefficients in respect to structural stability based on incremental dynamic analysis, by which structures are analyzed repeatedly for earthquakes with increasing intensity measures until structural collapse is identified [

4].

Recently, diverse studies have been conducted to assess the seismic fragility of the RC shear wall. In the study of Chun et al. (2013) [

5], seismic fragility analysis was carried out for both ordinary and special RC shear walls, among which some specimens have simplified confinement details for boundary elements. However, their work presents only RC walls with boundary elements in detail. Gogus and Wallace (2015) [

6,

7] and Rafie Nazari (2017) [

8] evaluated the seismic performance of building frame systems, of which the core walls are ordinary or special RC shear walls. Above all, analytical models for buildings in their research have at most 12 and 10 stories, respectively, which are not so high-risen compared to Korean apartment buildings over 60 m designed in a performance-based methodology. Therefore, existing studies on the seismic performance of bearing wall systems consisting of ordinary RC shear walls over 60 m-tall height are insufficient. In addition, existing studies address shear walls designed using the ultimate strength design method based on elastic analysis rather than the performance-based design based on nonlinear analysis.

In this study, the seismic fragility assessment of high-rise ordinary RC shear walls over 60 m designed through performance-based seismic design is conducted to verify whether those structures have adequate collapse margin ratios. The evaluation of the collapse fragility curve and the assessment of collapse prevention performance are conducted in accordance with FEMA P695. The procedure of FEMA P695 is intended to verify the seismic design coefficients, such as response modification factors and over-strength factors and displacement amplification factors. However, the procedure can be applied to any structure that can be grouped as a single category, such as ordinary RC shear walls higher than 60 m designed in accordance with a single design document. Therefore, three analytical models composed of ordinary RC shear walls typical in South Korea but with different heights are designed in accordance with the AIK guidelines using nonlinear response history analysis using seven pairs of horizontal ground motion components. Then, incremental dynamic analysis (IDA) is performed for those structures using 30 ground motion pairs to calculate the collapse fragility curve. Finally, criteria on the conditional collapse probability and the collapse margin ratio (CMR) are evaluated in accordance with FEMA P695.

3. Seismic Fragility Assessment Procedure

3.1. FEMA P695 Procedure

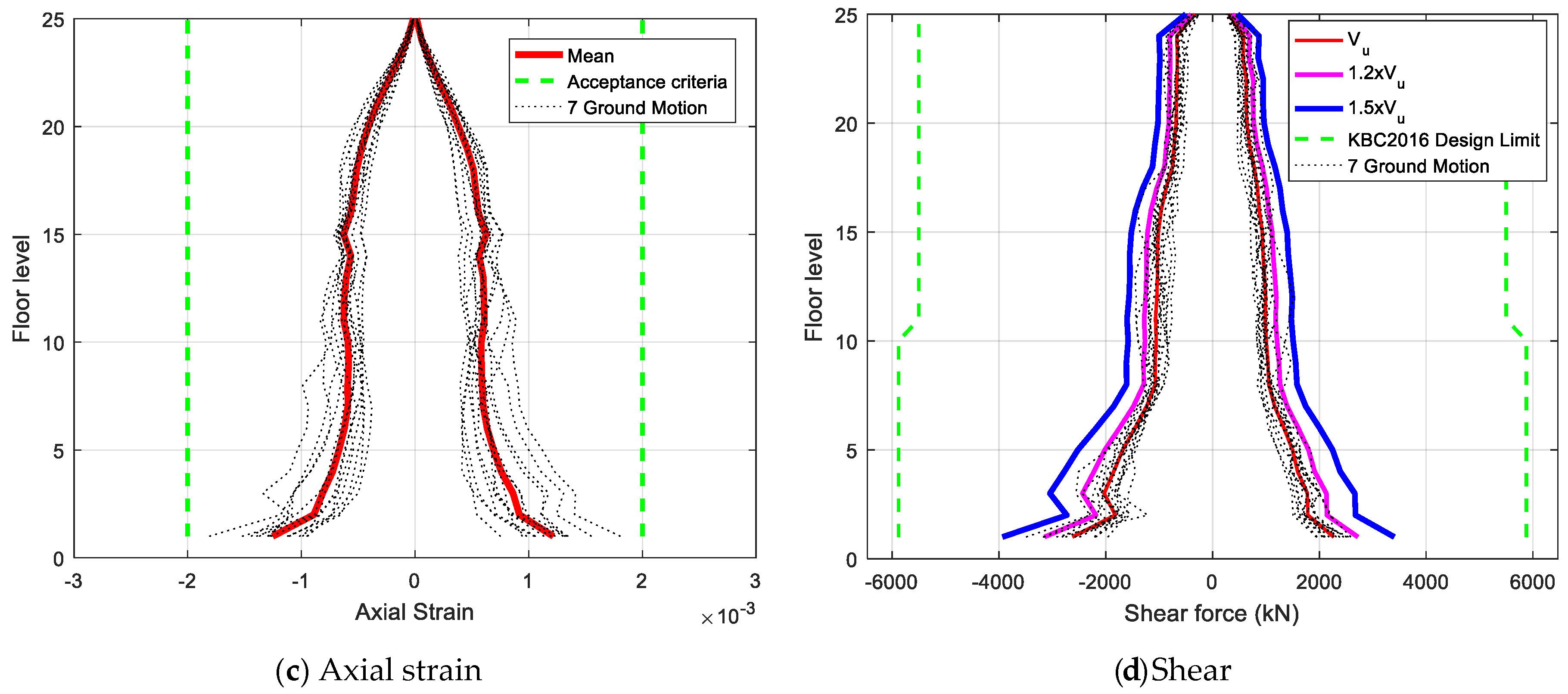

A seismic fragility assessment for three analytical model was conducted using the procedure of FEMA P695, one of the methodologies for evaluating the seismic performance coefficients of structural systems that are not prescribed in the standard. The FEMA P695 procedure verifies if seismic-force-resisting systems have an acceptable probability of collapse and a collapse margin ratio (CMR) for the maximum considered earthquake based on the collapse fragility curve obtained by incremental dynamic analysis (IDA).

The spectral shape of ground motion records is an important factor that influences the result of IDA and the corresponding collapse fragility. Baker and Cornell found that the spectral shape for the MCE level ground motion of the western area of United States and the shape design spectrum shape of ASCE 7-05 are different significantly over a certain period of time [

29,

30,

31]. In addition, the structural analysis for those spectra having such differences showed that there is a considerable difference in collapse prevention performance. Baker and Cornell proposed a conditional spectrum to compensate for that kind of difference. The conditional spectrum has a spectral acceleration corresponding to a specific return period at a control frequency, and spectral accelerations at other periods are determined by a percentile conditional on the spectral acceleration at the control frequency. The conditional spectrum thus provides statistical information about the variability of the spectrum at periods other than the control frequency. In this study, ground motion suites for the IDA were selected and scaled using the conditional spectrum.

In FEMA P695, when the spectral shape of the general structural design standard is used, the CMR is modified to the adjusted collapse margin ratio (ACMR) using a correction factor called the spectral shape factor (SSF) to take into account difference in the spectral shape mentioned above. However, the conditional spectrum was used directly as the target response spectrum for ground motion suites used in the performance evaluation in this study. Therefore, values of ACMR in this study are the same as those of CMR without modification.

The FEMA P695 criteria for collapse prevention require that the CMR be above a specified allowable value and the collapse probability at the MCE level of spectral acceleration be less than 10%. An example of the seismic fragility curve in the form of a cumulative lognormal distribution function is shown in

Figure 7, to illustrate those two collapse prevention criteria. In

Figure 7, the CMR is defined as

, where

is the spectral acceleration corresponding to the fundamental mode period of the analytical model at the MCE level spectrum, and

is the spectral acceleration with 50% collapse probability in the fragility curve. The collapse probability is evaluated at

.

The spectral acceleration at the first mode period

was used to represent the intensity measure (IM) of ground motion suites for IDA and the fragility assessment. Higher-mode contribution and period elongation are important factors in the case of high-rise buildings responding to earthquakes inelastically. An intensity measure, such as an average spectral acceleration for multiple periods including an elongated one, may be a better IM that can reduce dispersion and bias in the prediction of collapse [

32]. Nevertheless,

was adopted for the IM in order to achieve consistency in the seismic hazard between design and fragility evaluation as well as to take into account variability in spectral shape by scaling ground motion records to the distribution of conditional spectra anchored to

.

The standard deviation

of the lognormal distribution to account for uncertainty in the fragility curve was determined in accordance with FEMA P695 [

4].

is calculated by Equation (4).

where

is the record-to-record collapse uncertainty and was calculated based on the dynamic analysis results in this study.

is the design requirements-related collapse uncertainty,

is the test data-related collapse uncertainty, and

is the modeling-related collapse uncertainty. In FEMA P695, values of 0.1 to 0.5 are assigned to

,

, and

according to “Superior” to “Poor” grade of quality ratings for each uncertainty source. In this study, 0.2 was used uniformly for the three standard deviation assuming “Good” grade.

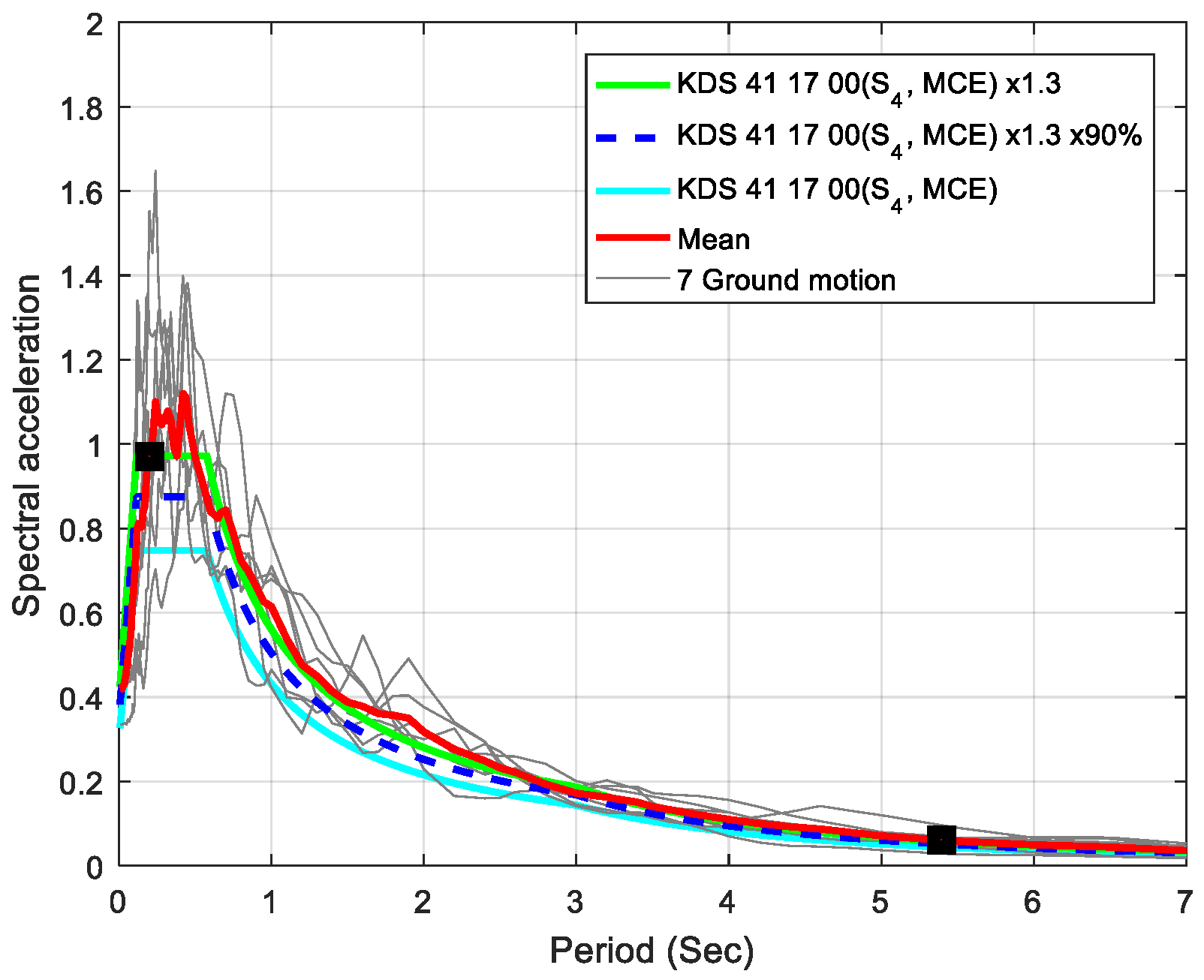

3.2. Ground Motion for Incremental Dynamic Analysis

Three ground motion suites were used in the IDA of each analytical model, respectively. All the selected ground motions in each suite have earthquake magnitudes between 6.0 and 7.0 and epicenter distance between 10 and 50 km. The mean shear wave velocities for the upper 30 m of the site profile at the record station is between 150–420 m/s, which are similar to the condition of site class S

4 applied to the design of the analytical models. Ground motions were chosen from the NGA-West2 ground motion database of the PEER, as in the design [

13]. The ground motion records comprising a single suite were matched to the probability distribution as well as the median of the conditional spectrum by amplitude scaling in accordance with Baker and Lee’s study [

33]. The fundamental mode period of each analysis model was chosen for the control period of the conditional spectra.

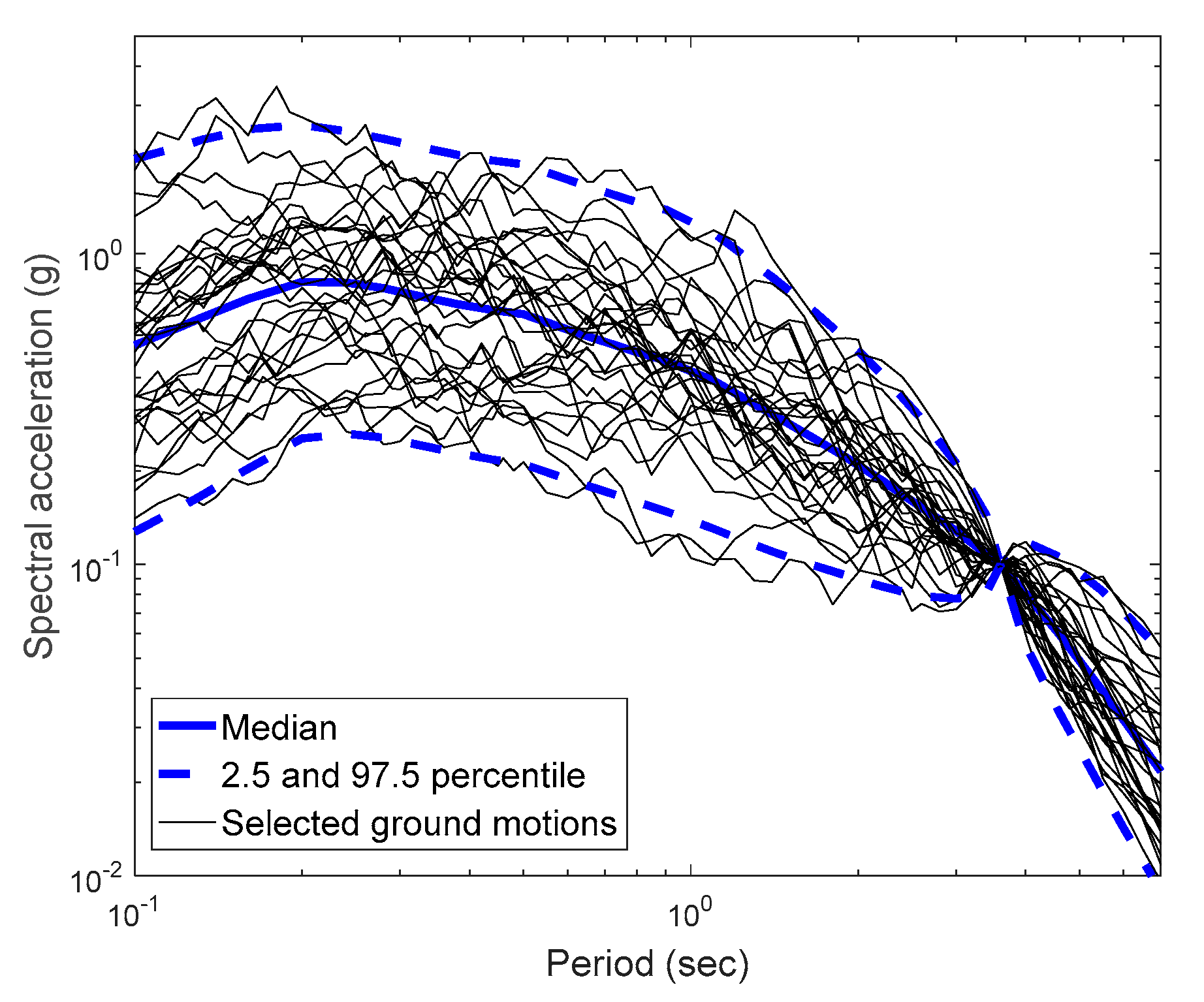

Figure 8 shows the target and matched ground motion spectra for analytical Model B.

The individual ground motion suite is comprised of 30 pairs of horizontal components, much more than the seven pairs used for the design phase. Similar to the design of the analytical models, only the single horizontal component of ground motion was applied to the in-plane horizontal direction in a single IDA. Each component comprising a ground motion pair was applied to the IDA alternately, considering the randomness in the azimuth of ground motion. Therefore, total 60 IDA’s were conducted in the in-plane direction for a total of 60 ground motion components, respectively.

Regarding the number of ground motion records, 22 pairs of horizontal components are used in FEMA P695 [

4]. Baltzopoulos et al. conducted a study on an adequate number of ground motion records necessary to predict the collapse of moment-resisting frames with nonlinear dynamic analysis [

34]. According to their research result, 40 to 100 ground motion records are required to achieve a coefficient of variation below 10% with respect to the result using 200 records. The 60 ground motion components used in this study is a reasonable choice considering both computational efforts and accuracy in collapse probability.

It was assumed that the target spectrum was defined in the direction of the maximum spectral acceleration and GMRotD100 spectrum of each ground motion suite is used in amplitude scaling of each suite. The GMRotD100 spectrum is the 100-percentile of the geometric mean dependent on period [

35,

36].

Figure 9a shows the GMRotD100 spectra of individual ground motion pairs and the target MCE spectrum for the Model B.

Figure 9b,c compare the target spectrum and the individual ground motion spectra for each horizontal component, respectively, for the Model B. The median spectrum and the target MCE spectrum for each direction have considerable difference in the spectral acceleration ordinate, but the difference is only slight at the control period.

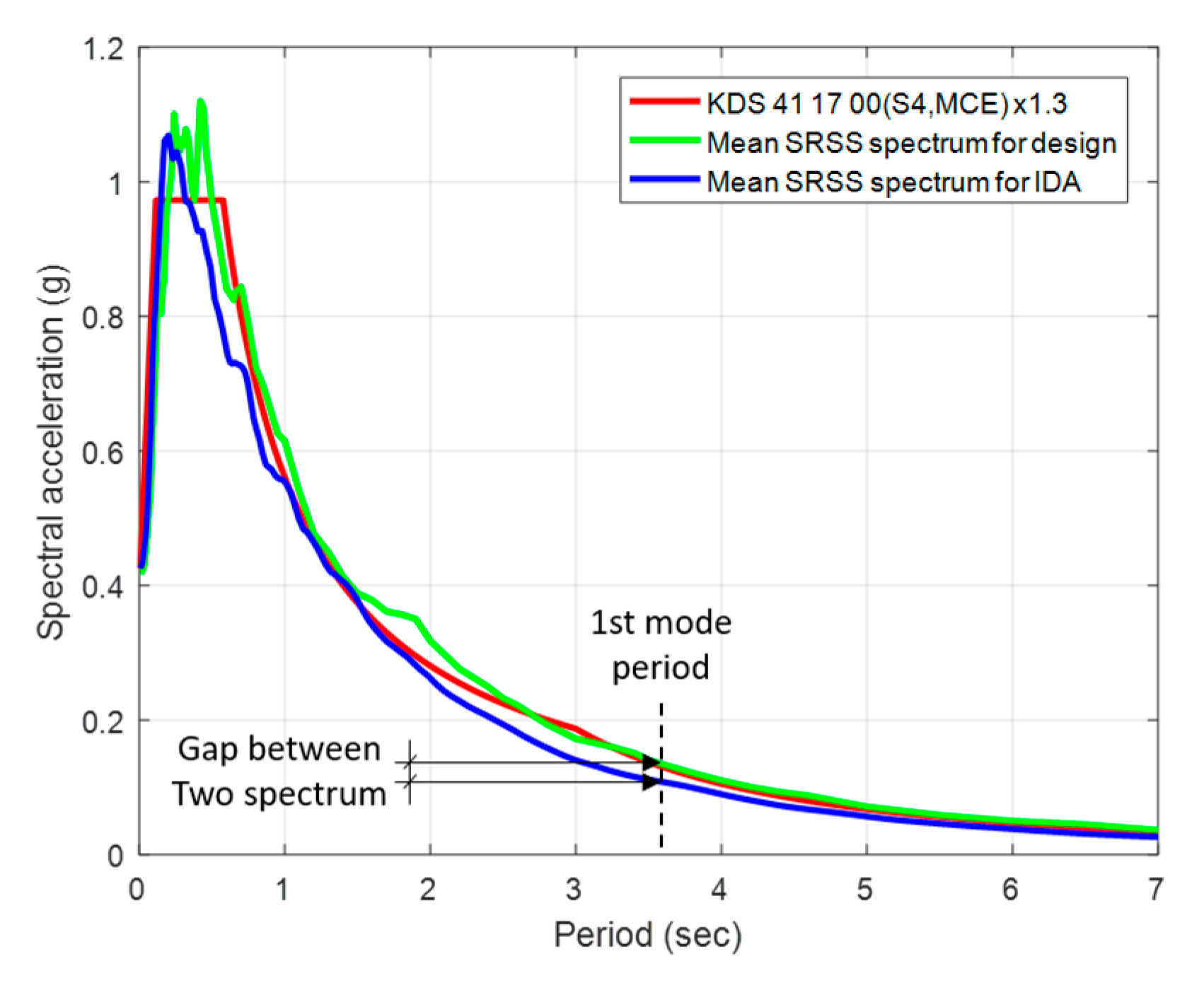

The ground motion suites for the design of the analytical models were scaled so that the mean SRSS spectrum is fit to 1.3 times the MCE spectrum, while those for IDA was scaled so that individual GMRotD100 spectrum has the same Sa(T1) as that of the MCE spectrum itself. The mean SRSS spectra of the ground motion suites for design and IDA is plotted, respectively, and compared to 1.3 times the MCE spectrum in

Figure 10. The mean SRSS spectrum of the ground motion suite for IDA is lower than that for design at most periods longer than 0.2 s. For consistency between the design and performance evaluation,

, the spectral acceleration at

for MCE spectrum itself, is modified into

using a scale factor defined by the ratio of spectral accelerations at

on the mean SRSS spectra for design and IDA. The scale factor for each analytical model and corresponding

are summarized in

Table 8. In the following, the collapse probability and collapse margin of wall group models are calculated for

rather than

.

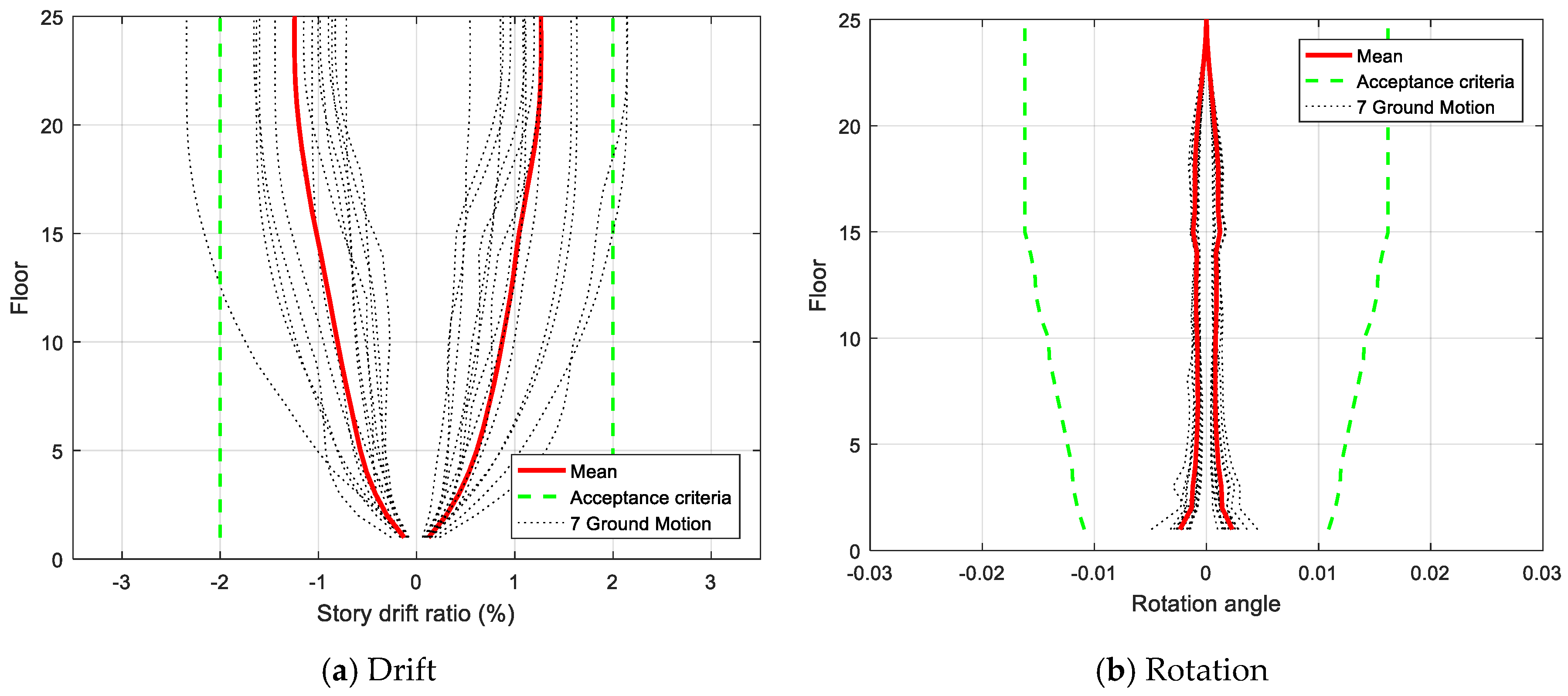

3.3. Engineering Demand Parameter (EDP)

Four EDPs are considered in order to determine the collapse of the structure. Those EDPs include the rapid increase of inter-story drift, exceedance of the acceptable plastic hinge rotation angle, concrete compression failure at the boundary of wall section, and the shear failure, and are described as follows.

Table 9 summarizes the acceptance criteria for the four EDPs and details are given in the following sections.

3.3.1. Inter-Story Drift

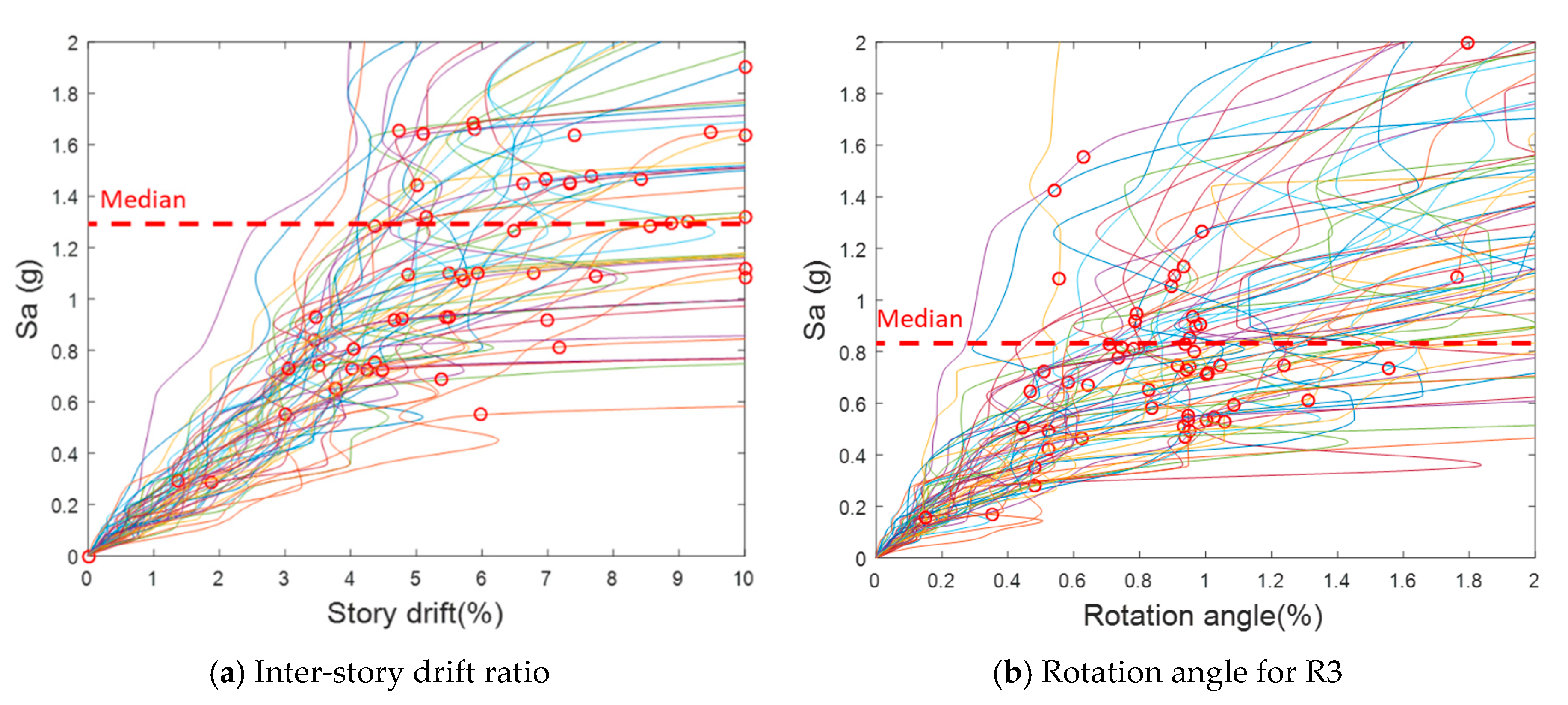

The first EDP is the maximum of the peak inter-story drift for entire stories.

Figure 11a shows IDA curves with the horizontal axis of the inter-story drift and the vertical axis of the first mode spectral acceleration. The collapse of structures is a kind of instability and is identified by the rapid increase of the inter-story drift on the IDA curve. In other words, this is the case when the increase in spectral acceleration is small but the inter-story drift ratio is significantly increased. The collapse in this study is defined as the point on the IDA curve where the slope of the curve decrease to the 20% of the initial slope according to the recommendation by Vamvatsikos and Cornell [

37]. However, when such a point did not occur, the point where the maximum inter-story drift ratio reaches 10%, which is judged to be a sufficient measure of instability, and was defined as the collapse point. The collapse points are marked with circles in

Figure 11a.

3.3.2. Plastic Hinge Rotation Angle

The second EDP is the plastic hinge rotation angle of the wall element. The exceedance of acceptance criteria by at least one shear wall element was deemed collapse. The acceptance criteria for collapse prevention defined in ASCE 41-17 was adopted. The allowable plastic rotation angle is dependent on the extent of confinement at the boundary of the wall section and was determined for each analysis case, considering the axial force ratio and shear force demand determined from the dynamic response analysis results. IDA curves with respect to the plastic hinge rotation angle are plotted in

Figure 11b for the component wall R3 in Model A. The circles represent a point where the EDP reaches the acceptance criteria. Plastic hinge rotation angles at the circles are different because they are dependent on the shear force demand for the wall.

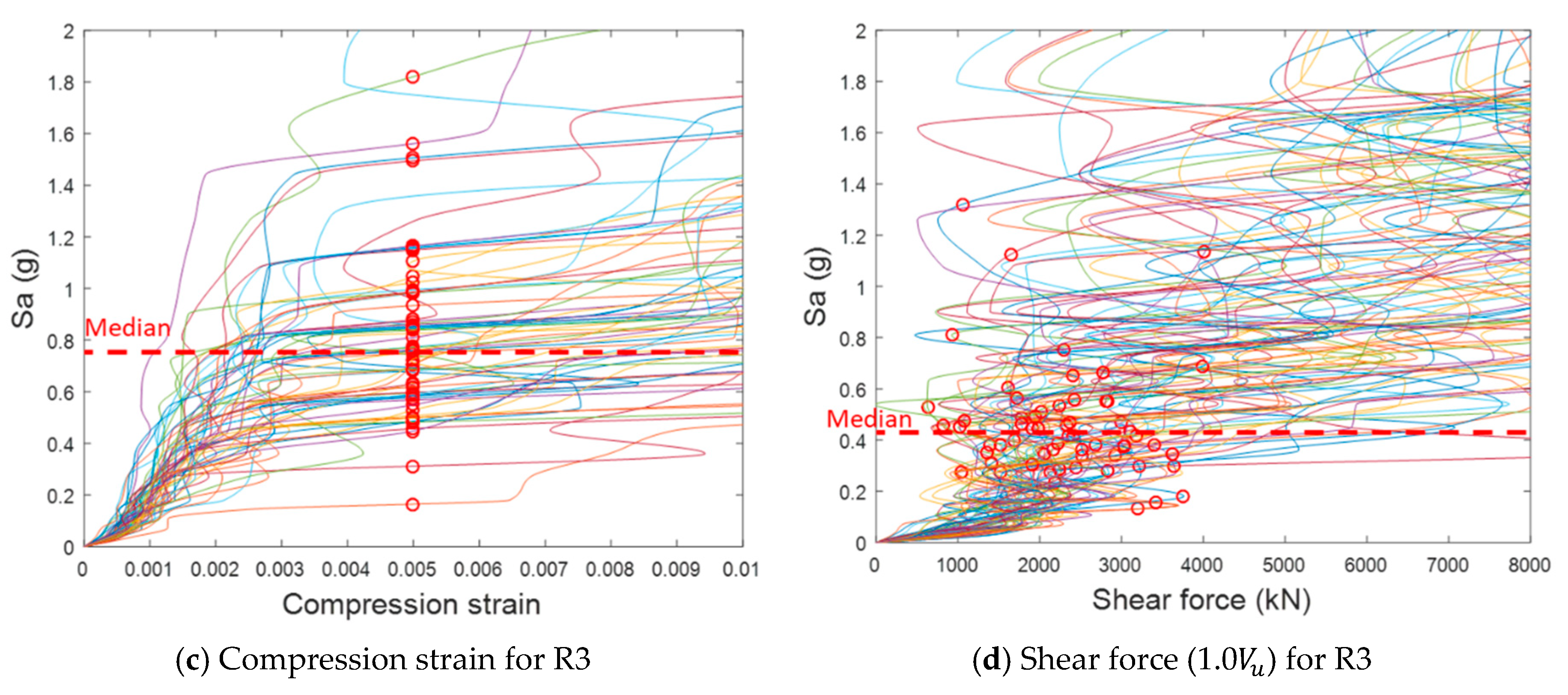

3.3.3. Compression Strain

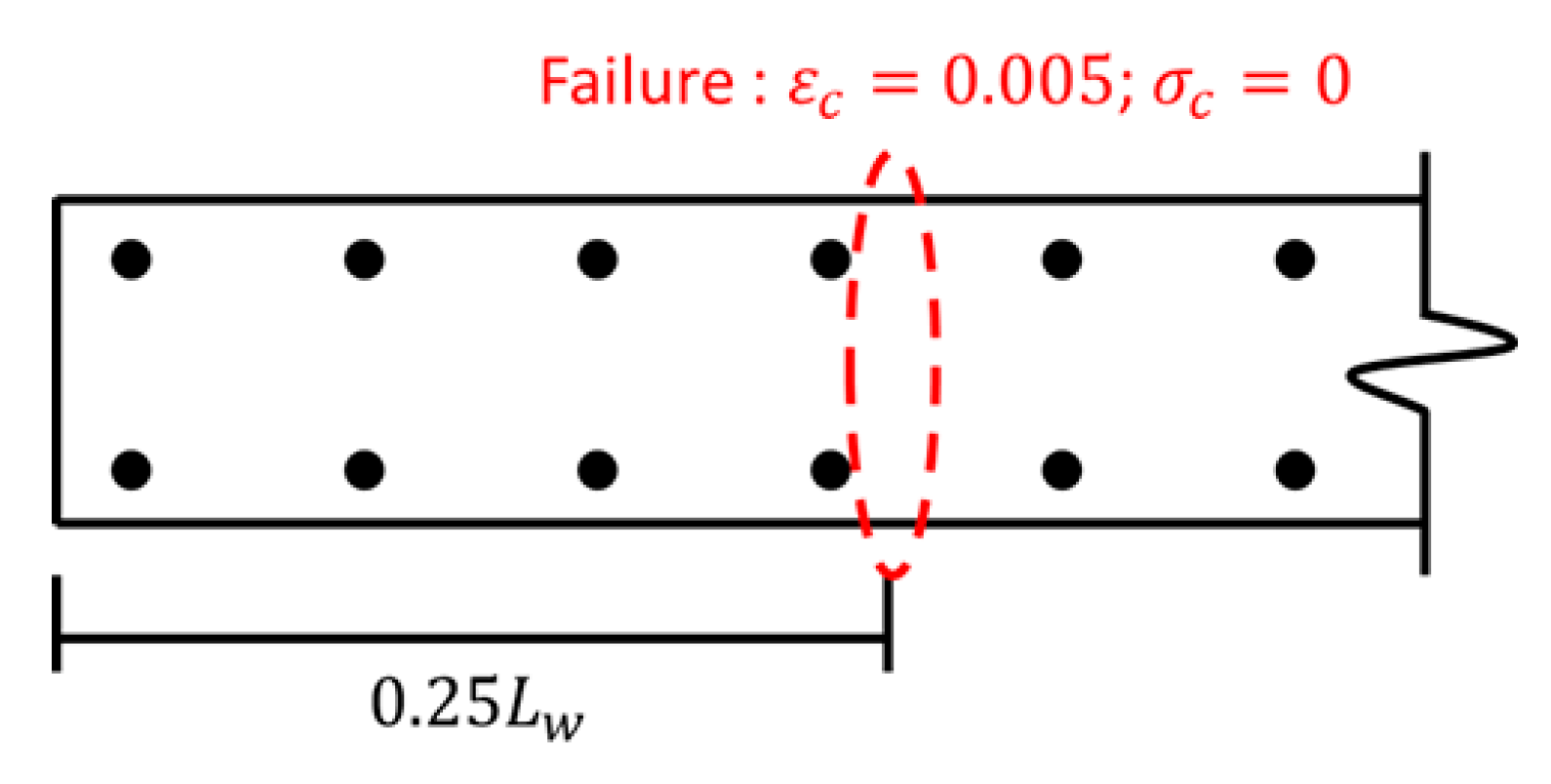

Thirdly, concrete compression failure at the boundary of the wall section can cause instability of the structure. The instability of the wall structure due to concrete compressive failure is assumed to occur when the compressive strain of concrete reaches a value where the stress drops to zero, passing through the peak stress at 25% of the wall length from the compressive extreme of the wall section as shown in

Figure 12, according to the study of Gogus and Wallace and the NIST 10-917-8 report [

6,

7,

38]. This is based on experiences showing that the instability of wall structures occurs in pushover analysis when concrete stress at such a place drops to zero. In this study, pushover analysis for the three analytical models was conducted to examine the adequacy of the acceptance criteria for the compressive strain at the specified location. The concrete model used in this study reaches residual strength (1% of the maximum strength) at the strain of 0.005, as mentioned in the preceding section. The results of the pushover analysis are shown in

Figure 13, in which the roof drifts where the compressive strain reaches 0.005 at the point of 25% wall length, away from the compressive extreme of the section are also represented. As a result of the analysis, it is observed that a sharp drop of strength and the concrete compression failure at the specified location occur simultaneously. Therefore, the concrete compression failure criteria can predict collapse appropriately and included in collapse probability calculation. IDA curves with respect to the compression strain are plotted in

Figure 11c for the component wall R3 in Model A. The circles represent a point where the compression strain reaches the acceptance criteria for the compression strain.

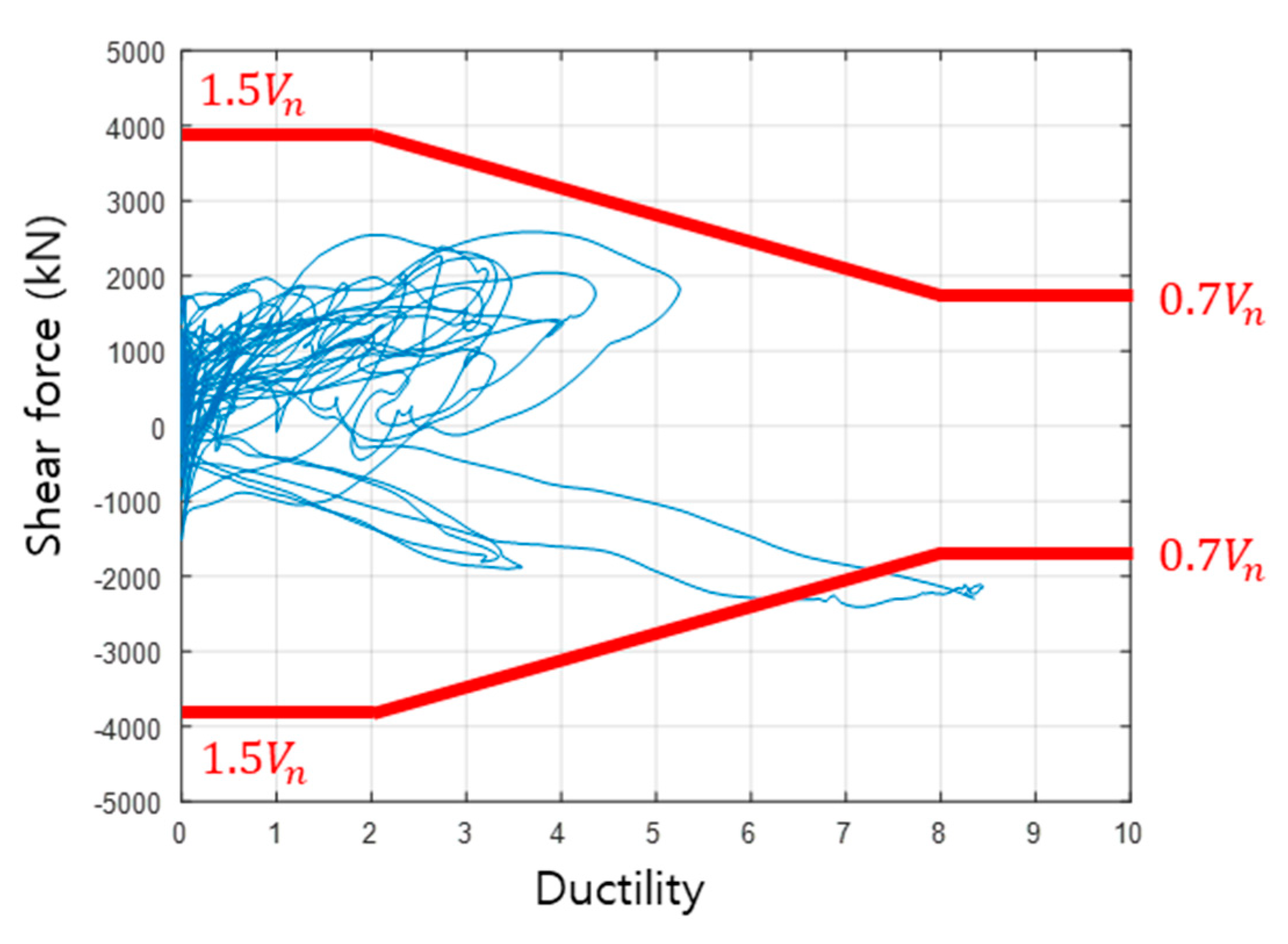

3.3.4. Shear Strength

In literature, decrease in shear strength with respect to flexural ductility was considered in the seismic evaluation based on existing experimental data [

20,

39,

40]. This reduction of shear strength is caused by increasing damage due to flexural deformation. In this study, the envelope of the shear strength with respect to the flexural ductility suggested in the study by Gogus was adopted to examine whether the failure of shear components that are modeled elastically occurs or not after each nonlinear dynamic analysis. An example of shear failure envelope and the history of shear force with respect to flexural ductility is illustrated in

Figure 14. In the illustrated model, 1.5 times the nominal strength is permitted when the flexural ductility is 2 or less, but only 0.7 times the nominal strength is permitted when the flexural ductility reaches 8 or more. When the flexural ductility value is between 2 and 8, linear interpolation is used. IDA curves with respect to the shear force are plotted in

Figure 11d for the component wall R3 in Model A. The circles represent a point where the shear force reaches the acceptance criteria. Shear forces at those circles are different because they are dependent on the flexural ductility of the wall.

3.4. Processing the Result of IDA

The peak value of an EDP was calculated, and the corresponding acceptance criterion was checked for each story and component wall. The most critical story or component wall determined whether the failure occurred or not by the EDP. The collapse of a whole analytical model was determined by the EDP that exceeded the acceptance criteria at the lowest IM in the IDA for a single ground motion record. By fitting the IM–collapse probability relation, the seismic fragility curve for each analytical model was calculated. In a similar way, the seismic fragility curve can be calculated for each component wall.

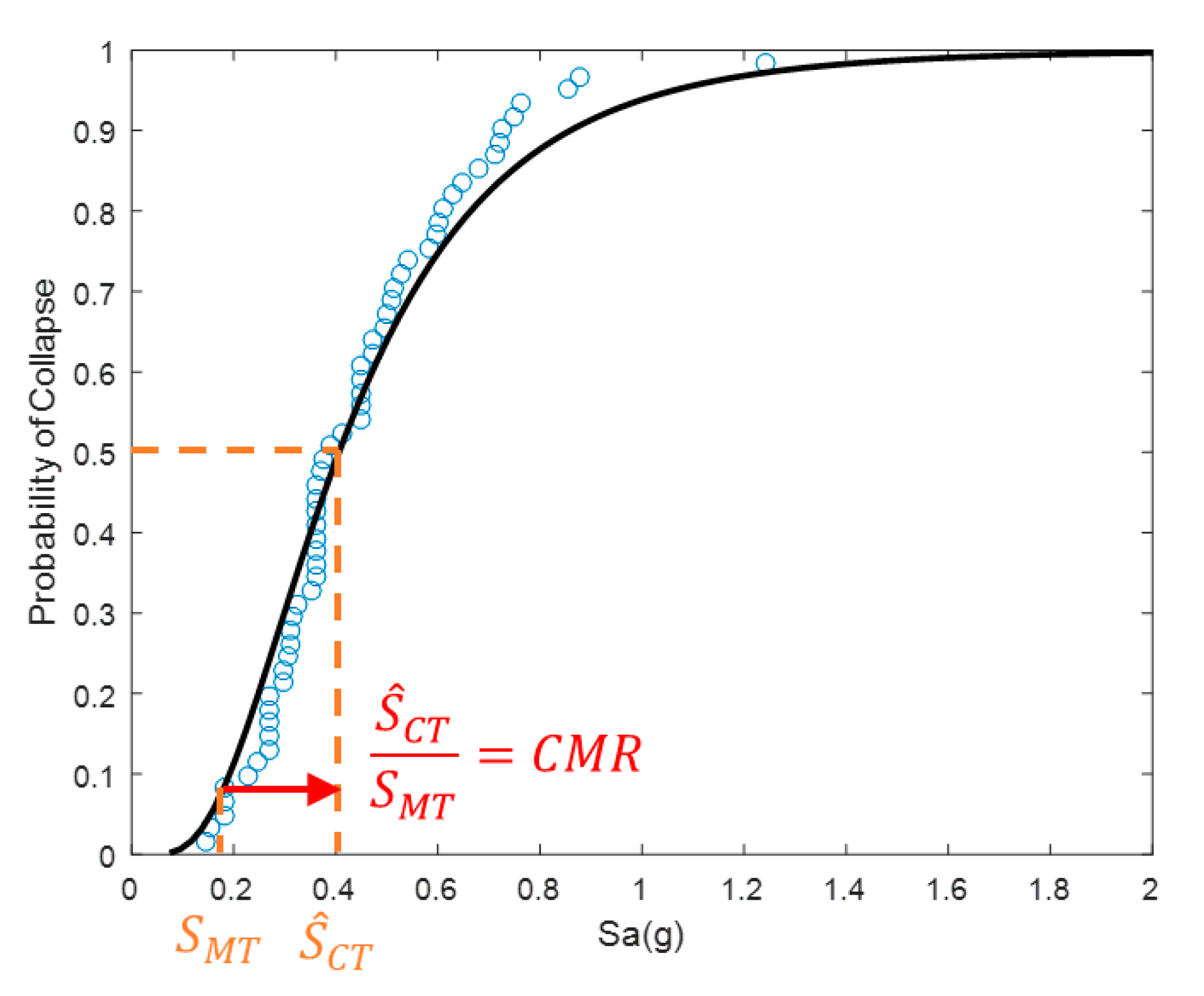

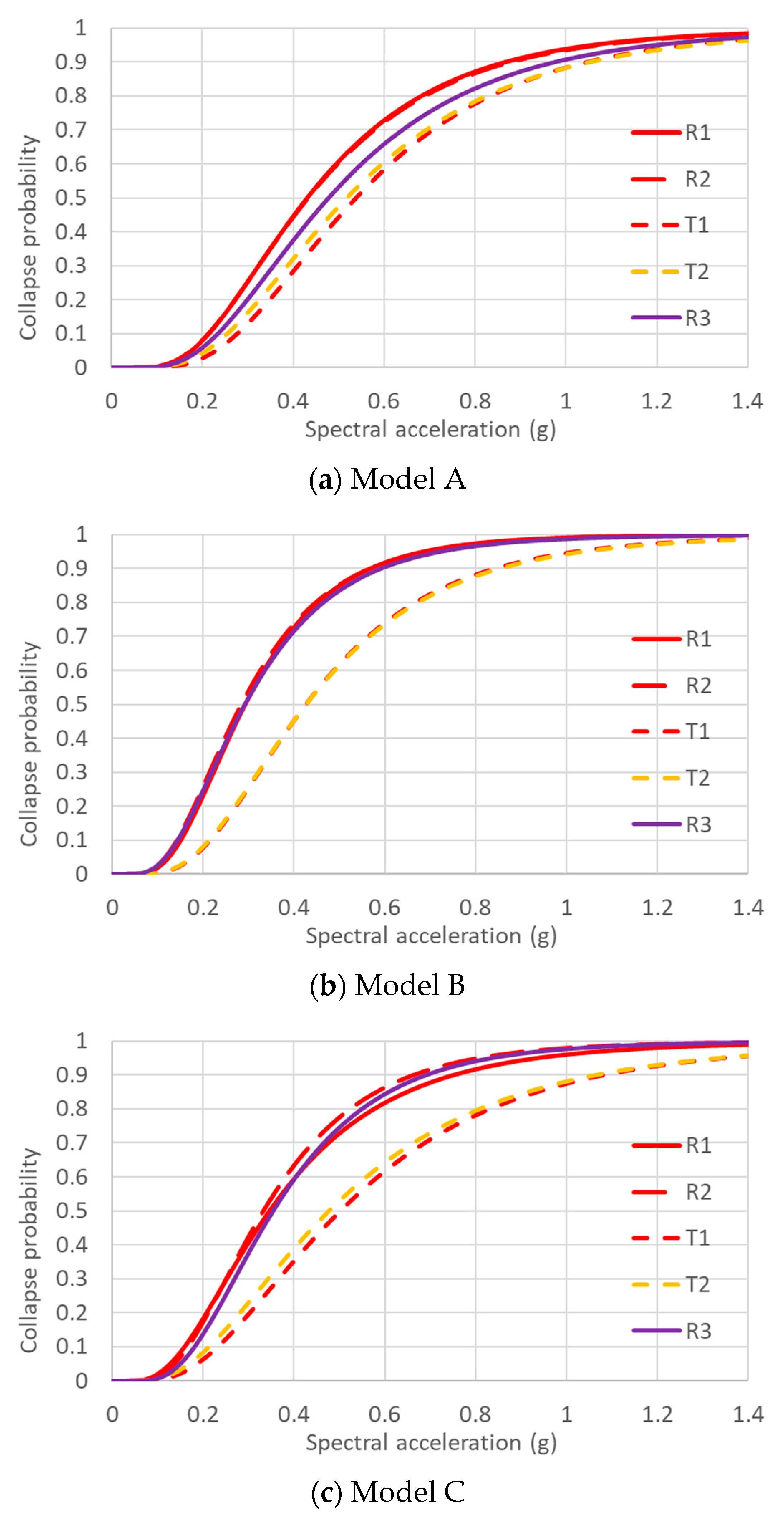

4. Seismic Fragility Assessment Results

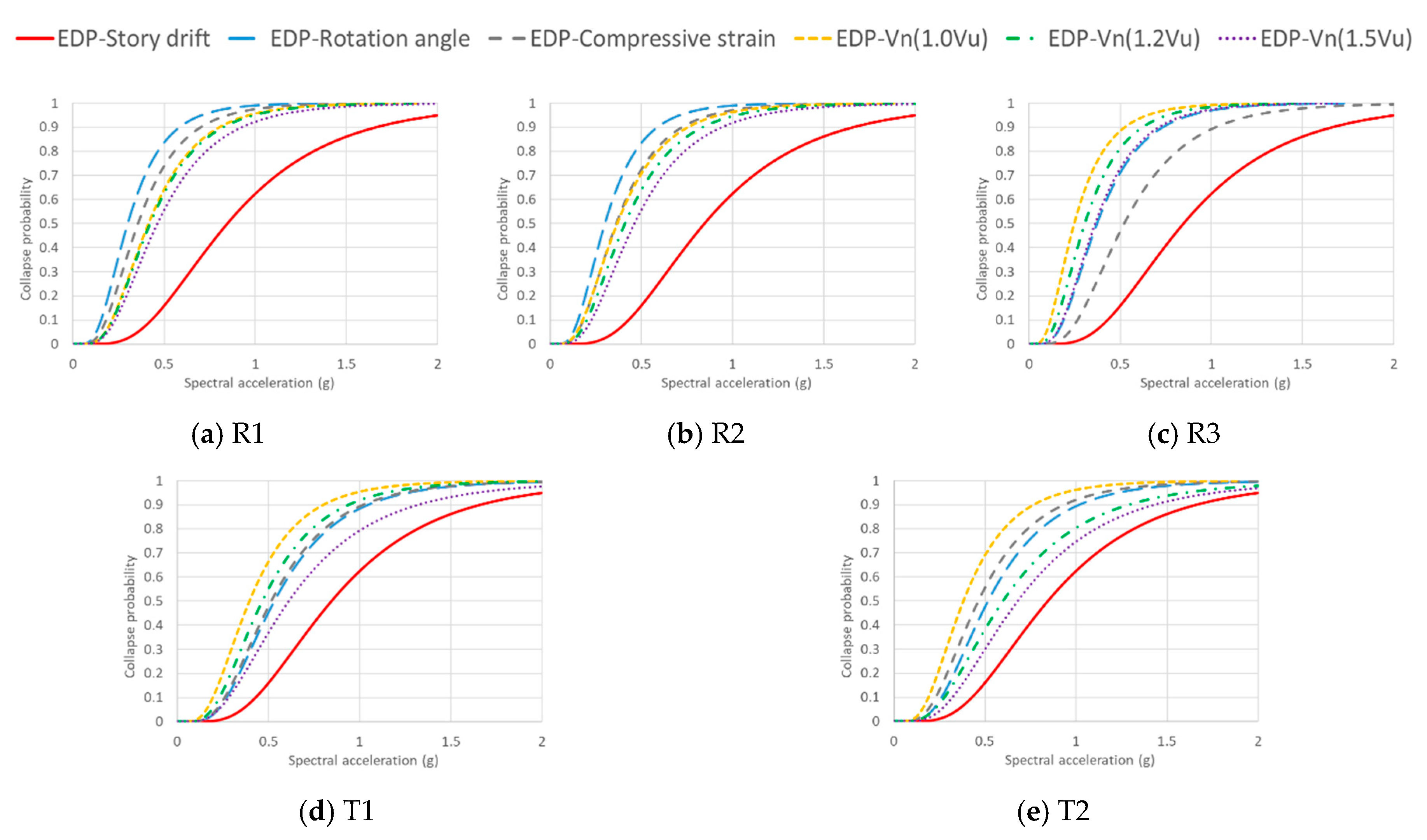

The result of seismic fragility assessment based on IDA is summarized for each component wall of three analytical models in

Figure 15, and

Table 10 and

Table 11. All the shear wall groups were designed to satisfy shear force demand with an amplification factor 1.2 to the mean peak shear force in accordance with the AIK guidelines. The seismic fragility curves in

Figure 15 were constructed based on the failure mode that occurred at the lowest intensity measure among four failure modes investigated in the IDA. That is, if one of the four EDPs does not satisfy its acceptance criteria earlier than others, the corresponding intensity measure was used for the calculation of fragility curves.

FEMA P695 requires the collapse probability of individual building model to be limited below 20%, and the average collapse probability for the performance group comprised of different structural models with the same structural system to be limited below 10%. All the three analytical models have a collapse probability less than 20% in

Table 10 if the maximum collapse probability among the component walls is defined as the collapse probability of the analytical model. Additionally, the average collapse probability among the three analytical models is 8.1%, which is below the 10% limit. As a result, all of the three analytical models satisfy the requirement for collapse prevention as prescribed in FEMA P695.

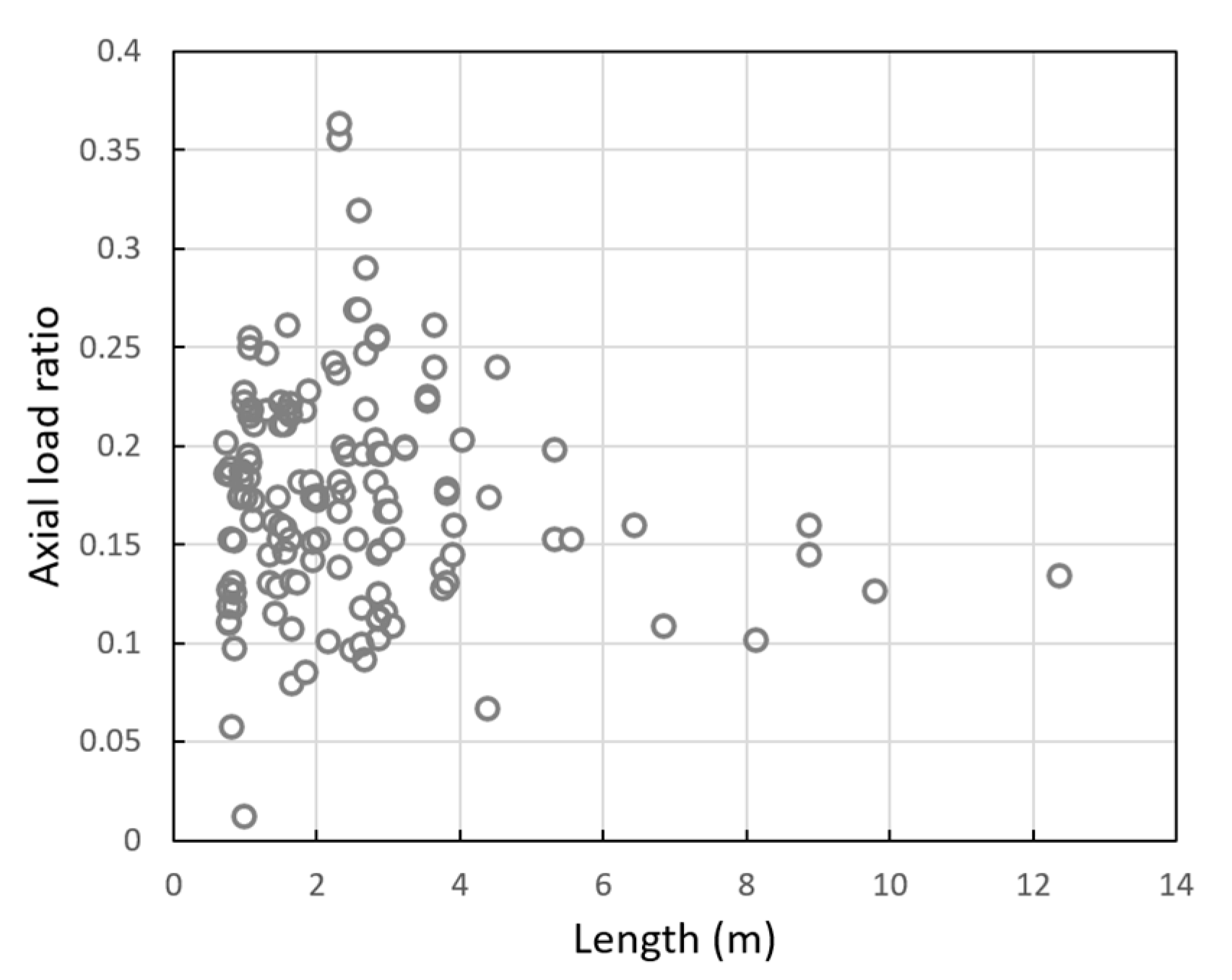

The wall with the highest collapse probability in each wall group model has 2.5 m length and 30% axial force ratio from the observation of Model A, B, and C. In other words, it was found that the component walls with a high risk of collapse are short walls with large axial forces. This is supposed to be the result of the predominant effect of the compression failure at the wall boundary region, rather than shear failure.

ACMR is examined for individual models as well as the performance group comprised of all the three models in comparison with the FEMA P695 criteria ACMR

10% and ACMR

20%, respectively. In

Table 11, it is observed that the lowest ratio of ACMR over ACMR

20% in each wall group model is obtained for the wall with the highest collapse probability, e.g., R2 in Model A. It is observed that the ACMR

20% criteria corresponding to the 20% collapse probability are met for all of the three wall group models. When three wall group models are grouped as a single performance group, the acceptance criteria ACMR

10% corresponding to the 10% collapse probability should be met for the average ACMR. After identifying the ACMR of the most vulnerable wall in each wall group model as a representative ACMR, three ACMRs are averaged and compared with the ACMR

10% acceptance criteria. As shown in the last row of

Table 11, the performance group satisfies the ACMR

10% acceptance criteria.

Table 12 summarizes performance evaluation results for the performance group designed using different shear force amplification factors 1.0, 1.2 and 1.5 to the design shear force considering record-to-record variability. The same procedure and criteria as used in

Table 10 and

Table 11 are used in the performance evaluation. It is observed that the collapse performance criteria of FEMA P695 were satisfied when the amplification factors 1.2 and 1.5 were used. However, the collapse performance criteria was not satisfied when the amplification factor 1.0 was used. In addition, amplification factor 1.5 improved the collapse probability at MCE and ACMR only minorly compared to amplification factor 1.2. Therefore, 1.2 can be a marginal value for the amplification factor of shear force.

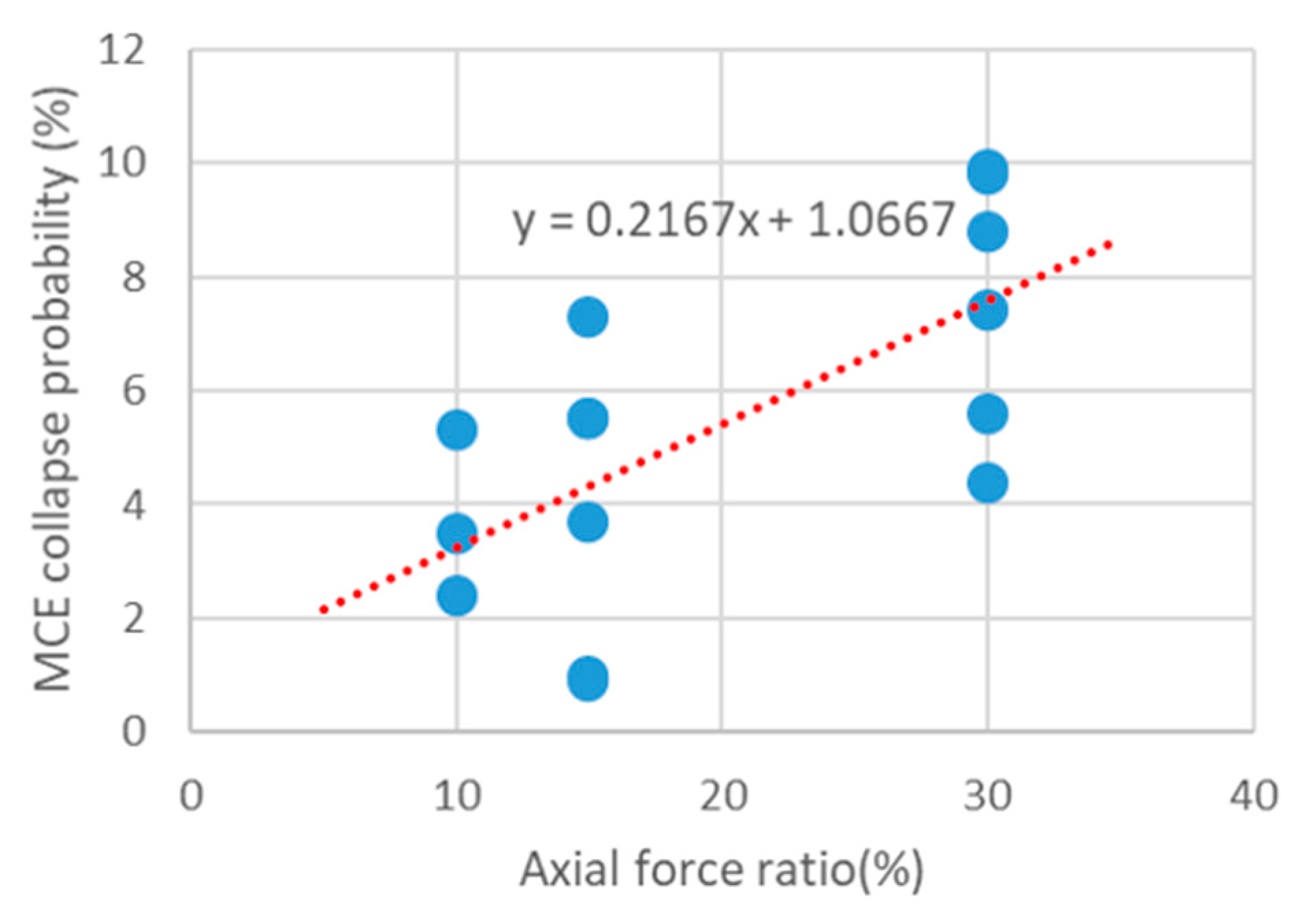

Figure 16 shows relationship between the axial force ratio and the collapse probability of individual component walls shown in

Table 10. Component walls having an axial force ratio of 10% have collapse probabilities from 2.4 to 5.3% while component walls having an axial force ratio of 30% have a collapse probability from 4.4 to 9.9%. Therefore, the collapse probability of shear walls tend to increase as the axial force ratio of those walls increases. This result is consistent with the fact that the deformation capacity of shear walls usually decreases with higher axial force ratio.

In

Figure 17, collapse fragility curves for individual walls comprising Model A are shown as an example. Those fragility curves were calculated for each EDP, respectively.

Table 13 presents failure probabilities at the MCE for each EDP obtained from the collapse fragility curve plotted in

Figure 17. The failure probability for each EDP was calculated for individual walls to determine which EDP is dominant. The EDP with the highest collapse probability among the five individual walls comprising a wall group model was chosen as the primary failure mode of the wall group model and is shown in

Table 13.

For individual component walls of Model A, the plastic hinge rotation angle has the highest collapse probability in most walls, but the highest collapse probability (11.2%) observed in the longest wall (R3) corresponds to the shear failure for amplification factor 1.0. As a result, the primary EDP changes from shear failure to plastic hinge rotation angle failure as the amplification factor to shear increases from 1.0 to 1.2 and 1.5, which reduces the potential of shear failure in the walls. Model B has a tendency similar to Model A, but shear failure is the primary failure mode of T1 and T2 as well as R3, and the transition from shear failure to plastic hinge rotation angle failure occurs at the amplification factor 1.2. In the case of the Model C, unlike the other two models, the wall with the highest collapse probability was R1, of which the failure mode is the compressive axial strain failure without change, in spite of the increasing amplification factor to shear force. This is due to the high axial force ratio of R1 caused by the small cross-section area and the characteristics of high-rise buildings. On the whole, the amplification factor to shear force 1.2 is enough to prevent shear failure from being the primary failure mode of the analytical model.