1. Introduction

In the course of the permanently increasing requirements for energy efficiency and careful use of resources, CVJs offer a great potential for optimisation through material savings and efficiency improvement, since they are used in many technical applications for the uniform transmission of rotary motion and torque. However, the current design and optimisation of these joints is largely founded on many years of experience based on analytical design methods for the statically undeflected load case of the joint. Nevertheless, to take dynamic influences on the joint behaviour into account during the development process, complex and cost-intensive test bench investigations are necessary. For this reason, numerical analysis of the CVJ using multi-body simulation is a suitable method to consider dynamic effects and to characterise the joint behaviour under different influencing parameters at an early stage of development.

To analyse the forces acting in a double offset joint (DOJ) and the resulting joint kinematics, Hayama [

1] used the MBS program ADAMS in conjunction with Hertzian contact theory. The contacts are determined internally in ADAMS. However, in his analysis, he neglected the friction between the components at first. Kimata et al. [

2] then considered these frictional forces for fixed and plunging typed joints, which are incorporated into the analytical description of the joint in order to finally solve it numerically via an ordinary differential equation (ODE) solver without a commercial software. They also compared the calculation results with experimental data at test bench for the secondary torque in DOJ [

3]. Serveto et al. [

4] also referred to these results and investigated the influence of friction on the secondary torque occurring in the joint as well. Similar to Kimata et al., they considered frictional forces in proportion to the contact normal forces with the help of Coulomb’s law. They identified possible noise, vibration and harshness (NVH) phenomena by implementing user-defined routines in ADAMS and performing their own measurements. For the analysis of the NVH-effective forces in a front sideshaft consisting of a ball CVJ and a tripod joint, Lim et al. [

5] used a similar approach to Serveto et al., but implemented it in DAFUL software. The contact determination in the ball joint is analytical, but they formulate their model with kinematic constraints, so that the use of a differential algebraic equation (DAE) solver is necessary, which means a higher numerical effort by considering algebraic constraints [

6]. Pennestri and Valentini [

7] chose a fundamentally different approach for the numerical observation of a pilot lever joint, in which they defined sets of curves in the respective tracks, onto which the balls are forced by corresponding force laws. In this way, they presupposed the position of the balls a priori, which is why they cannot be adjusted freely on the basis of the acting forces. In this case, there is a chance of missing out on phenomena that occur in reality. In addition, Valentini [

8] and Pennestri et al. [

9] presented analytical approaches for taking manufacturing deviations in joint analysis into account. Shen [

10] used the MBS program SIMPACK for his analysis of plunging joint with straight tracks, in which a general contact determination between balls and tracks is carried out by applying the polygonal contact model of Hippmann [

11]. Although this approach allows the contact between arbitrary geometries to be checked, it is more computationally intensive due to the general determination of contact, which is disadvantageous for extensive parameter studies in the early development stage. Furthermore, with the mesh size there is an additional numerical parameter, which influences the calculation results and must therefore first be verified.

The listed works deal with different joint geometries in contrast to the plunging joint considered in this paper. It has a track geometry defined by straight tracks and is characterised by a double inclination for each track. This results in crossed track pairs, which are arranged alternately in the inner and outer race. In the cross-section, all tracks have an elliptical contour. However, the field of application for these CVJs is smaller than that of the DOJ, which are used, e.g., in the front sideshaft of vehicles, so that there is no comprehensive version for the kinematic simulation of these joints available so far. The present work is intended to close this gap and to provide a tool that complements the design process of CVJ with straight tracks and allows first numerical analyses to be performed focused on a most efficient variant, which is why an analytical contact determination is chosen. Only free bodies are considered, so that the positions of the individual joint bodies result exclusively from the forces acting in the joint. This also allows the use of an ODE solver, which means less numerical effort compared to a DAE solvers.

2. Theory

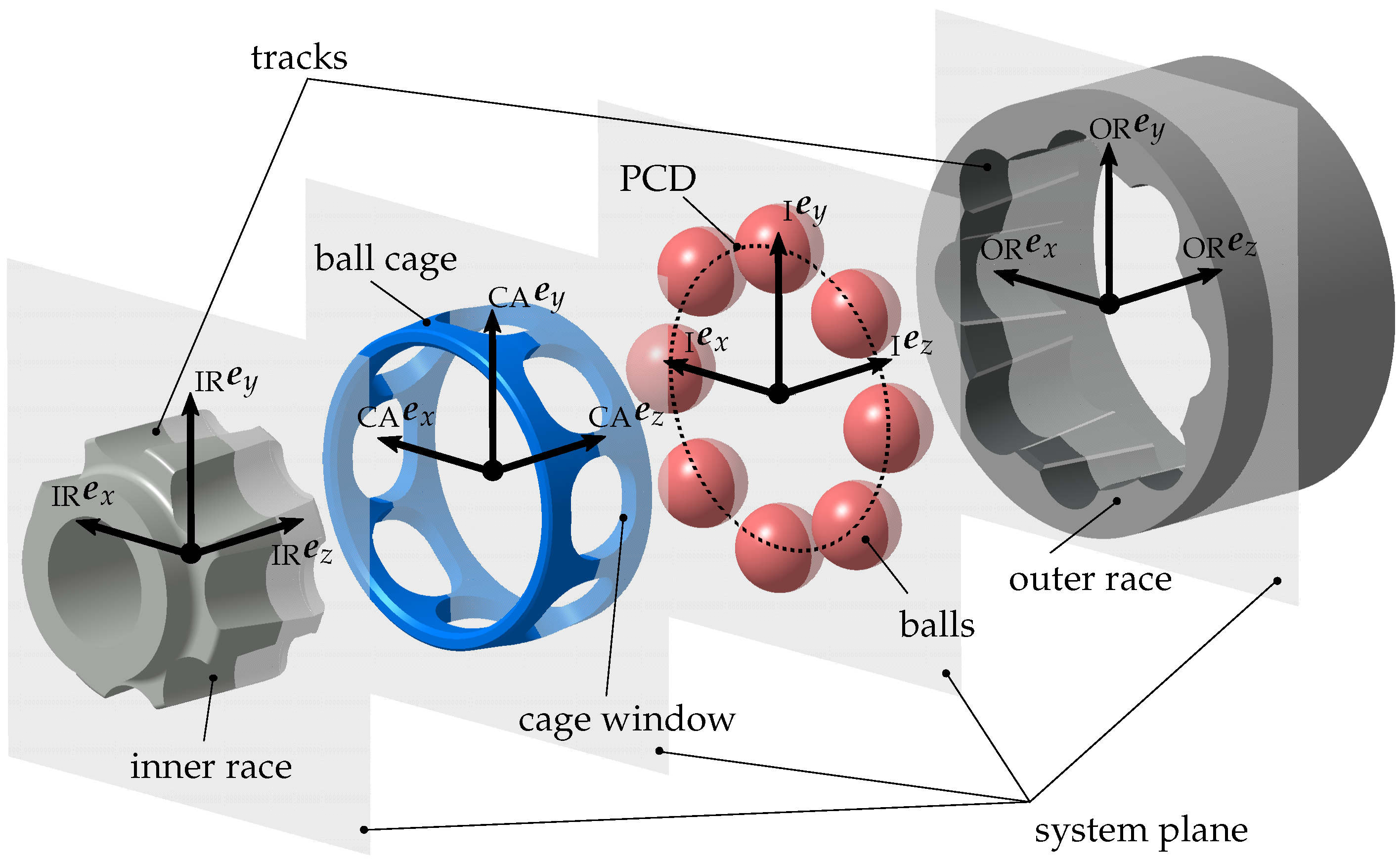

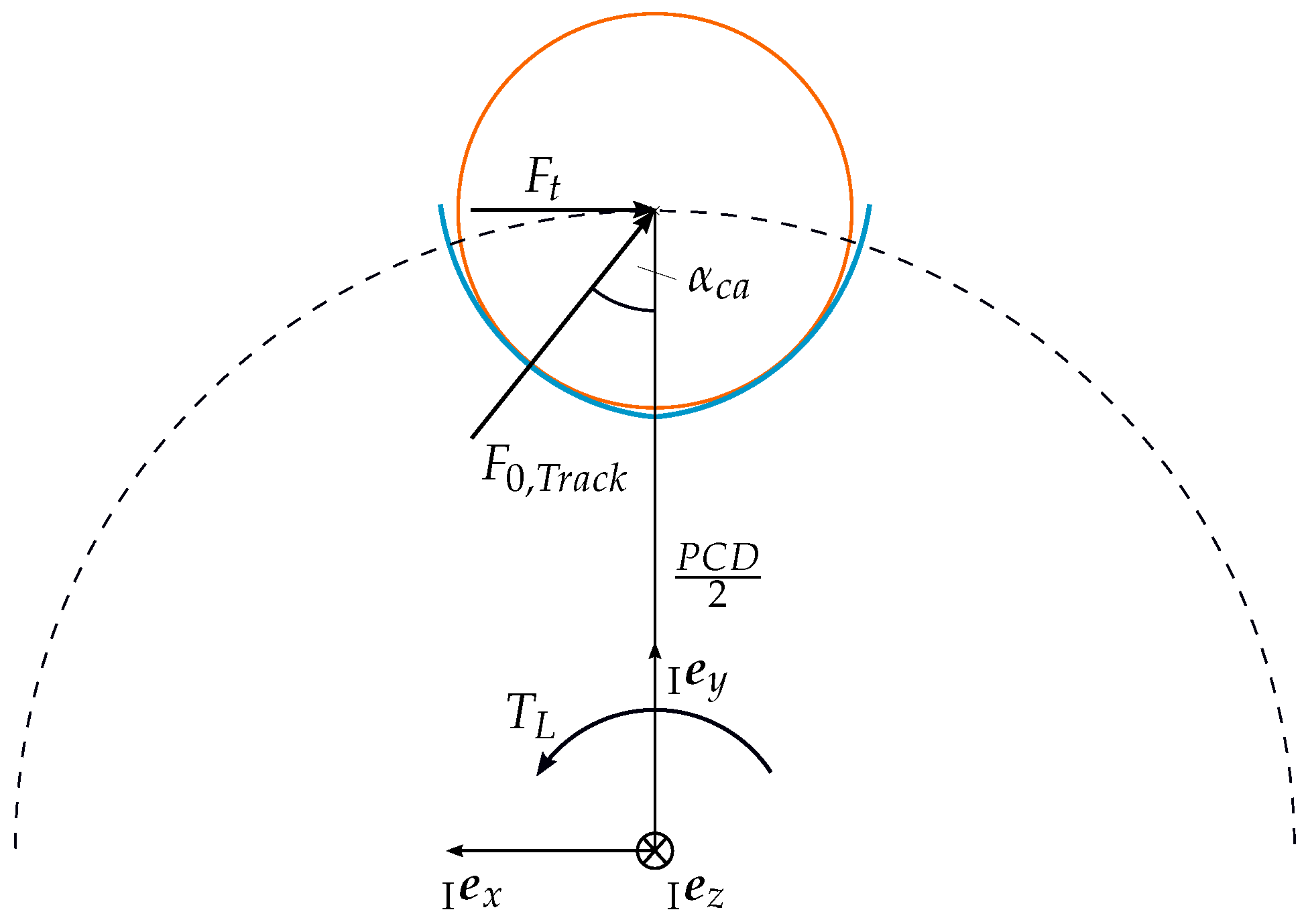

Figure 1 illustrates the basic design of a constant velocity ball joint of this type. The inner race and the outer race are each connected to a rotating shaft and have several tracks, so that a positive transmission of the torque takes place in the joint between the name-giving balls and the tracks. Further, for numerical analysis using multi-body simulation, it is necessary to define fixed coordinate systems for all joint components in addition to the inertial system

, which are also shown in

Figure 1. For the undeflected state of the joint, all ball centres in the system plane are located on the pitch circle diameter (PCD) of the joint. As the joint rotates, the balls are positioned over the ball cage in the bisecting plane to ensure uniform rotary transmission [

12]. For this purpose, it has recesses called cage windows. In addition, the joint is filled with grease to achieve a better tribological behaviour and to reduce wear. Depending on the intended use of the joint, the designs of the track geometries differ.

The analysis of the CVJ is carried out by applying the multi-body simulation under the assumption of rigid bodies. The algorithm was implemented in the MBS software EMD, which was developed at the Institute of Mechanics of the Otto von Guericke University Magdeburg. A detailed description of the functionality can be found in the dissertation of Daniel [

13]. First, the differential equations of motion for spatial dynamics are established

where

is the mass matrix,

is the acceleration vector,

is the vector of external forces and moments and

is the vector of centrifugal, gyroscopic and Coriolis forces. A derivation of the individual components can be found in [

14,

15]. Considering only free bodies, the analysis is performed using an ODE solver for the numerical solution of the differential equation. For this reason, the ODE of second order must be transformed into a differential equation system of first order. For this purpose, the state space vector and its time derivative

are defined, which contain the positions

, the translational velocities

and the accelerations

relative to the inertial system

as well as the orientation parameters

and the angular velocities

and their time derivatives. The translational parameters are specified in Cartesian coordinates

while different forms are implemented for the orientation parameters

. Cardan angles are used to analyse the results, while quaternions are used to solve the system of equations in order to avoid the gimbal lock [

16]

After the transformation into the state space and the conversion according to the unknown time derivative, the equation

results, which can be committed to the solver.

Since the present system has a very stiff numerical behaviour, a stable solution can only be guaranteed by implicit methods [

17,

18]. For this purpose, the implicit trapezoidal method [

18] with an adaptive step size control is used

Here, s is the step size, i is the index for the current time step and j is the respective iteration step within the time step.

The multi-body simulation starts with the current positions and velocities of the corresponding bodies. These are determined by solving the differential equations from the previous time step. For the initial state, a definition of initial conditions is made. Starting from the current positions and velocities, a contact determination between the bodies is performed to determine a possible penetration, which is used to calculate the contact forces acting on the bodies. The coupling of the bodies in the multi-body simulation is done by the vector of external forces . After the contact forces for each body have been determined and entered into the vector of the right hand side, the solution of the differential equation can be done by the procedure described above and the state vector can be calculated for the following time step.

3. Simulation Model

To analyse the joint kinematics using multi-body simulation, it is first necessary to define suitable coordinate systems. Therefore, a Cartesian inertial system is introduced, whose global z-axis corresponds to the rotational axis of the outer race. In addition, body-fixed coordinate systems are defined on the inner race

, the outer race

and the cage

, whose origins lie in the joint system plane (see

Figure 1). Starting from the body-fixed coordinate systems, several coordinate systems are introduced for each track and for each cage window. While the alignment of the coordinate systems in the cage window corresponds to the cage fixed coordinate system, the track coordinate systems

follow the track orientation with the two track angles

and

. The transformation into the track coordinate system is performed sequentially using the matrix

In

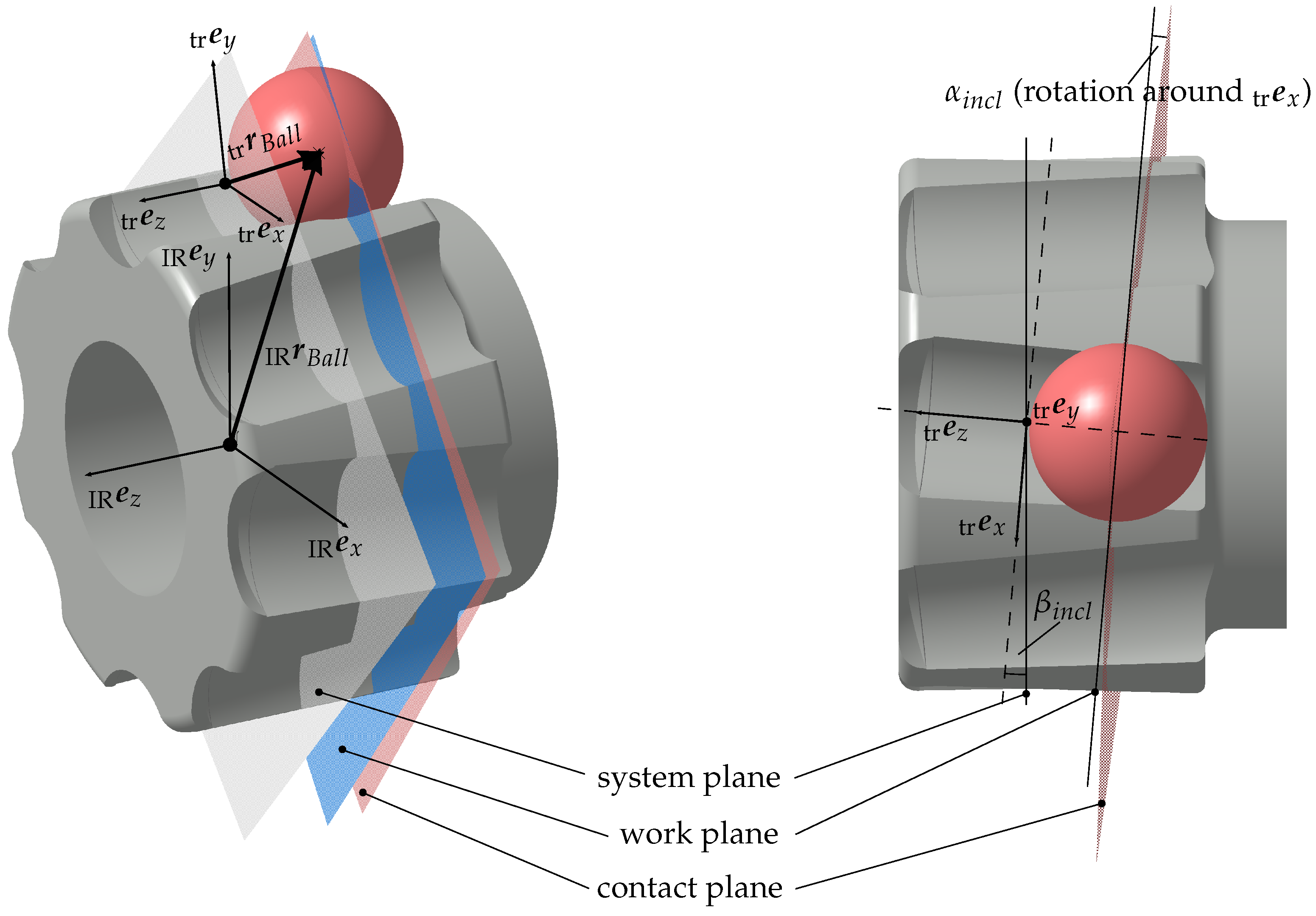

Figure 2, the position of the described track coordinate systems is illustrated using the inner race as an example.

Based on the defined coordinate systems, various coordinate transformations can be carried out to enable analytical contact determination for the entire joint. This applies to the ball track as well as to the ball cage contact, which is explained in detail in the following.

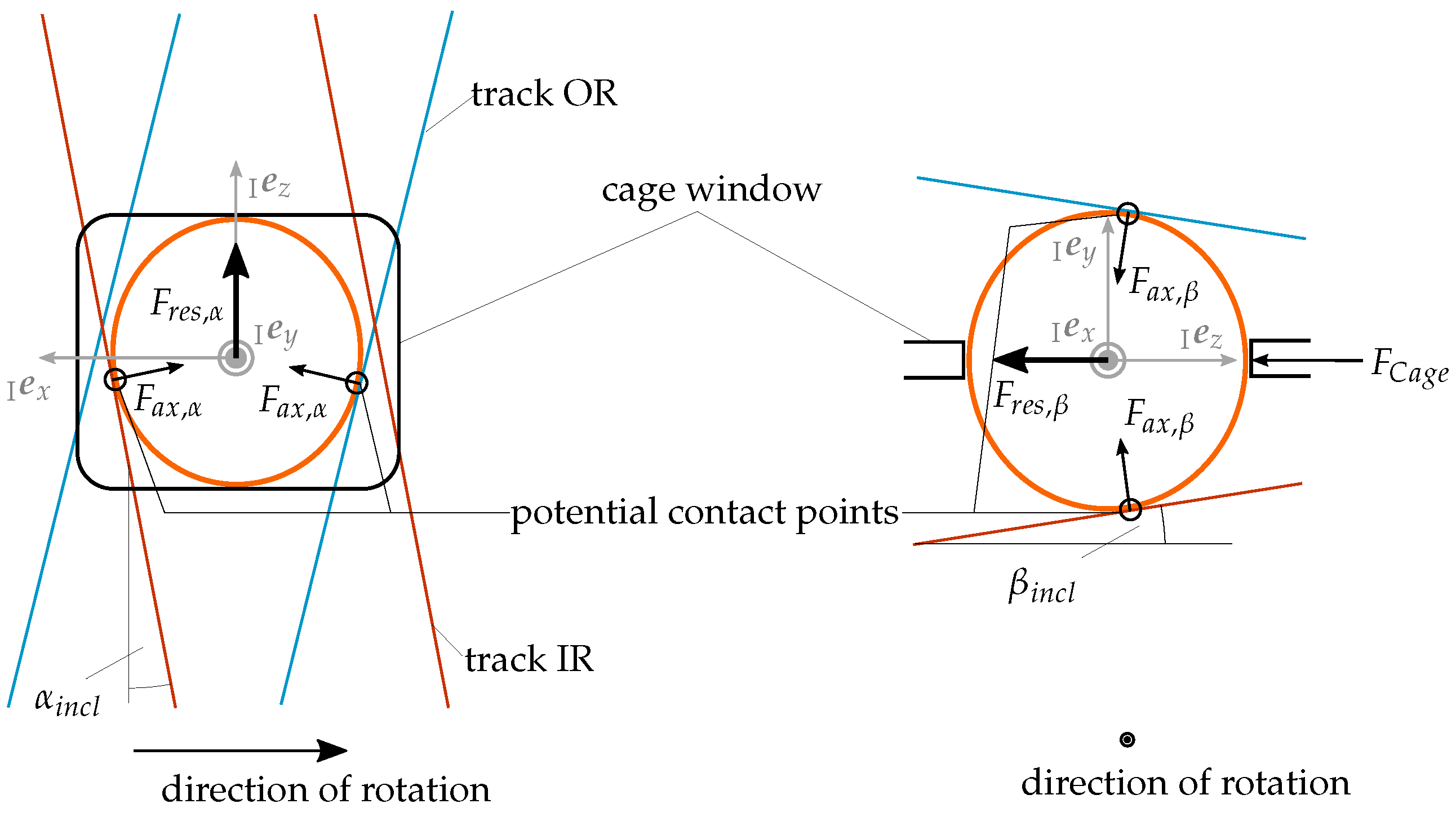

Up to six potential contact points are possible per ball, two per track and two more in the cage window. In the entire joint, therefore, a large number of potential contact points must be evaluated for each time step of the numerical integration, which can lead to high computing times under arbitrary circumstances. The considered track geometry allows implementing an analytical contact determination, which is based on the observation of simple geometric shapes. Thus, a complex three-dimensional contact analysis can be obviated, ensuring a fast and stable contact routine. This also guarantees that an efficient contact routine is maintained for different variations of the track parameters, e.g., the ball size or the PCD. This is necessary because a low computing time with sufficient accuracy is of utmost importance for parameter studies and design optimisation in an early step of the product development process.

The analytical contact determination is derived from the joint system plane for both ball track contact and ball cage contact for the undeflected state of the joint. Based on the considered track angles of each track, the balls move out of the joint system plane as a result of the deflection or axial displacement of the inner race. Hence, both the PCD and the distance between the ball centres along the PCD change. This leads to additional transformation steps.

For ball track contact, the current ball position is evaluated with respect to the track coordinate system

, so that a corresponding contact plane

(red,

Figure 2) can be defined orthogonal to the track axis as a function of the ball position. After the transformation of all necessary coordinates into the contact plane, the two-dimensional contact determination is performed by calculating the distance between the centres of two circles in order to identify the maximum plane penetration

between

and

of the contact bodies along the normal vector

(see

Figure 3a). Subsequently, the identified contact points

on the track and

on the ball surface are transformed into the inertial system and the maximum spatial penetration

is determined for further force calculation

Here, is the centre of the track flank, is the centre of the ball, is the track radius, is the ball radius, is the vectorial penetration between the contact bodies and is the Euclidean norm of it.

An analytical approach is also chosen for the cage ball contact, but this is implemented three-dimensionally (see

Figure 3b). First, a contact plane is defined on the respective window edge by a normal vector

and a receiving point

in the body fixed cage coordinate system

. Then, a potential contact point on the sphere surface

is defined from the normal vector of the plane

, the centre of the sphere

and the radius of the sphere

. After a transformation of the potential contact point on the ball

and the normal vector of the contact plane

into the inertial system

(resulting in

and

), the distance between plane and potential contact point can be determined

Finally, if the contact is positive for

, the contact point in the cage window can be calculated as the point for the force application

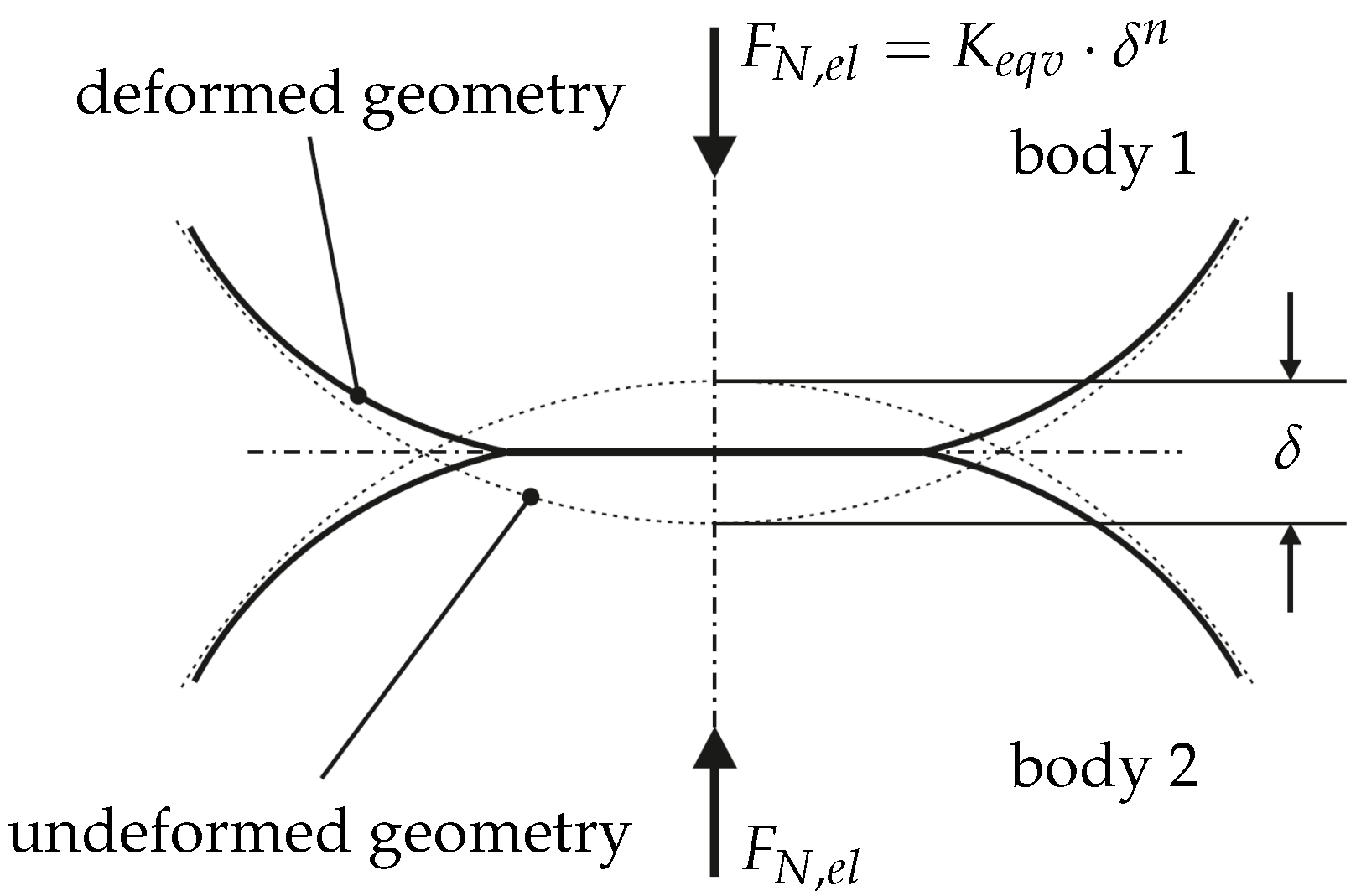

In the present work, a one-dimensional approach is used to calculate the contact forces with high efficiency, since this approach provides sufficient accuracy while maintaining a low level of complexity. In this case, the contact force acts exclusively along a direction vector between two contact points. The elastic component of the contact normal force is therefore calculated with the previously determined penetration based on the Hertzian contact theory [

19], so that the penetration between the bodies can be interpreted as a local elastic deformation (see

Figure 4). Mathematically, this can be described as a power law according to Johnson [

20]. Besides an elastic force component, a simple viscous model for numeric stability is also used, so that the following equation according to Hunt and Crossley [

21] results for calculating the contact normal force

with the equivalent contact stiffness

calculated according to the method of Hamrock and Brewe [

22] for the Hertzian contact theory, the scalar penetration

, the exponent

n, the scalar penetration velocity

, the damping constant

D and the contact normal vector

for the respective contact between ball and track or ball and cage. However, the choice of the damping parameter

D is not exclusively physically motivated. In real systems, damping occurs during the contact process, but this force component can be neglected compared to the elastic force components in the present application, because the elastic force components are significantly larger, which is why the viscous force components have only a minor influence on the kinematics. Rather, the damping component is used for numerical stabilisation during time integration, since in this way oscillations in the contact process are reduced. While the choice of damping constants initially has a negligible influence on the system kinematics within a certain range, it should be noted that, due to the selected force approach, the use of a damping constant that is too high can lead to tensile forces between the contact bodies when they come out of contact, which may result in unphysical system behaviour.

Frictional forces

in the joint are implemented via Coulomb’s friction law [

23] in proportion to the normal contact force

. These forces act in the direction of the resulting tangential velocity

between the two contact bodies,

Here, is the relative velocity between the contact bodies, is the velocity in contact normal direction, is the translational velocity of each contact body, is the rotional velocity of each contact body and is the vector from centre of gravity to the contact point for each contact body.

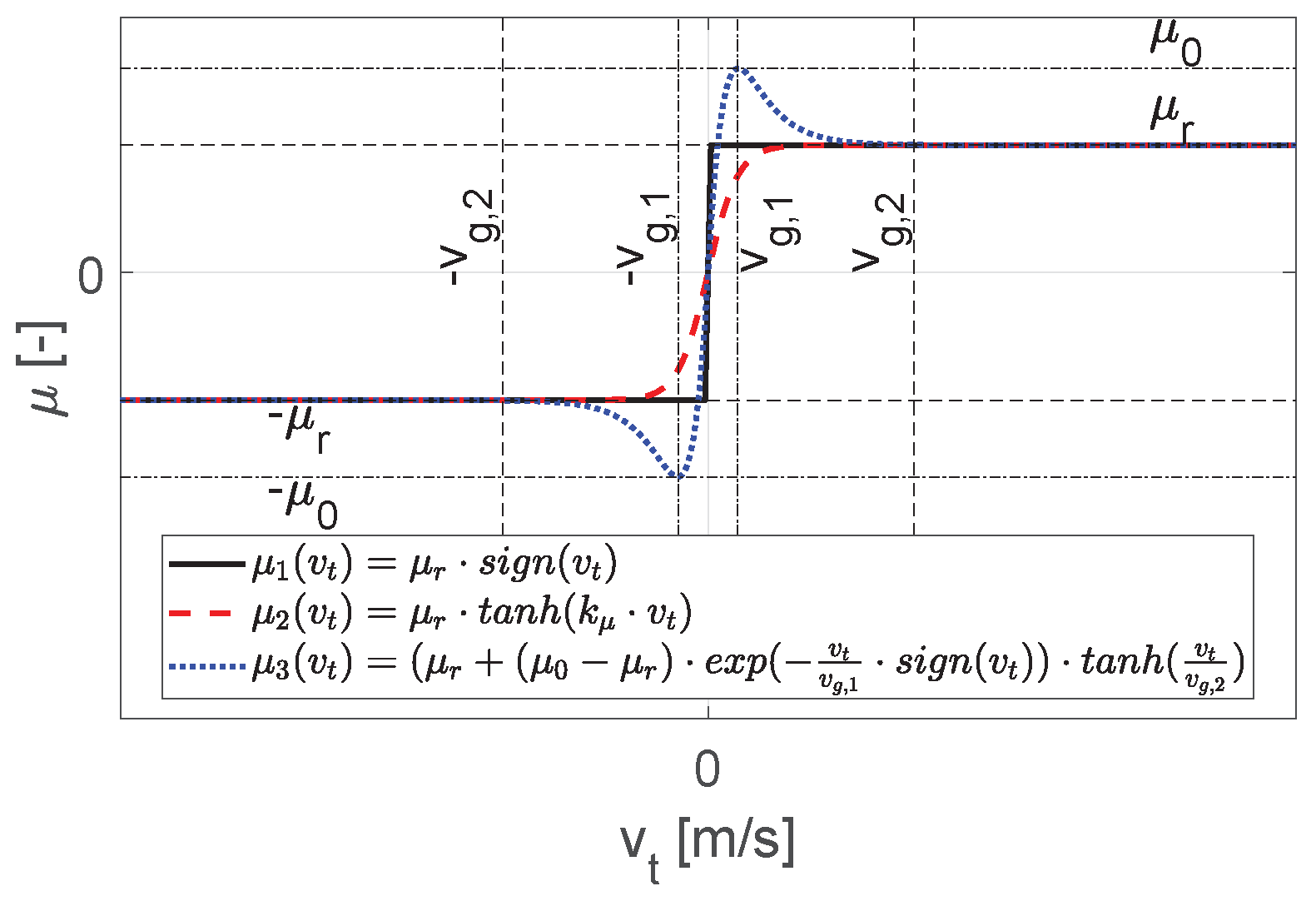

The behaviour of the friction coefficient

is not represented by a simple signum function (see

Figure 5,

), but is approximated for numerical conversion by a continuously differentiable function, so that a discontinuity at

is avoided (see

Figure 5,

). Normally, adhesive forces between the contact bodies are taken into account in the multi-body simulation via switching functions. However, this requires a high numerical effort. To be able to approximate adhesive forces at low relative velocities avoiding switching functions, the following approach according to Daniel [

13] is used

Here, is the coefficient of sliding friction, is the coefficient of static friction, is the first critical velocity and is the second critical velocity.

6. Conclusions

In the present work, a multi-body simulation model for analysing the kinematics and the acting forces within a constant velocity joint (CVJ) is presented. The plunging joint has straight tracks with an elliptical cross-section and two track angles per track, so that an analytical contact determination is possible between balls and tracks as well as between balls and cage.

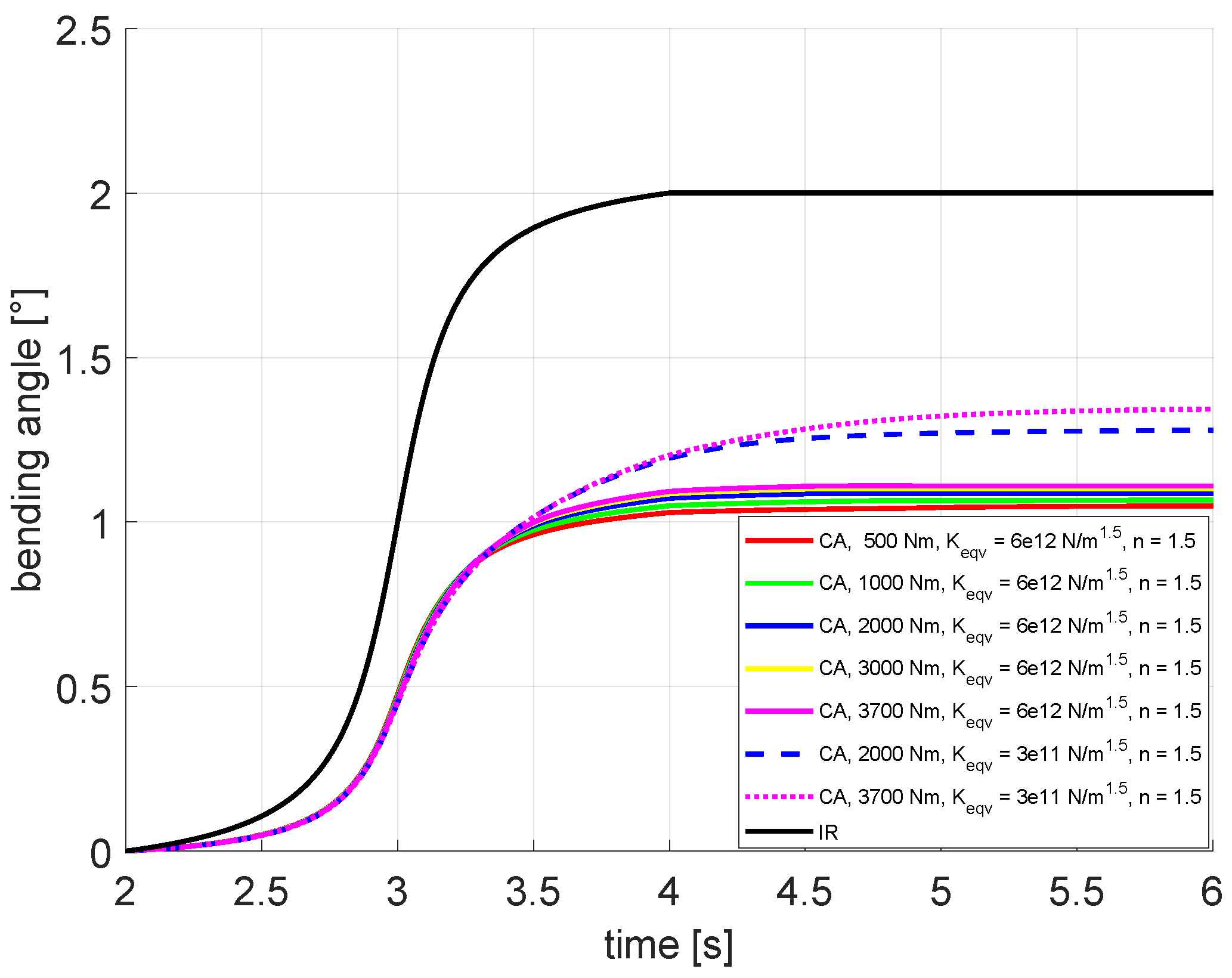

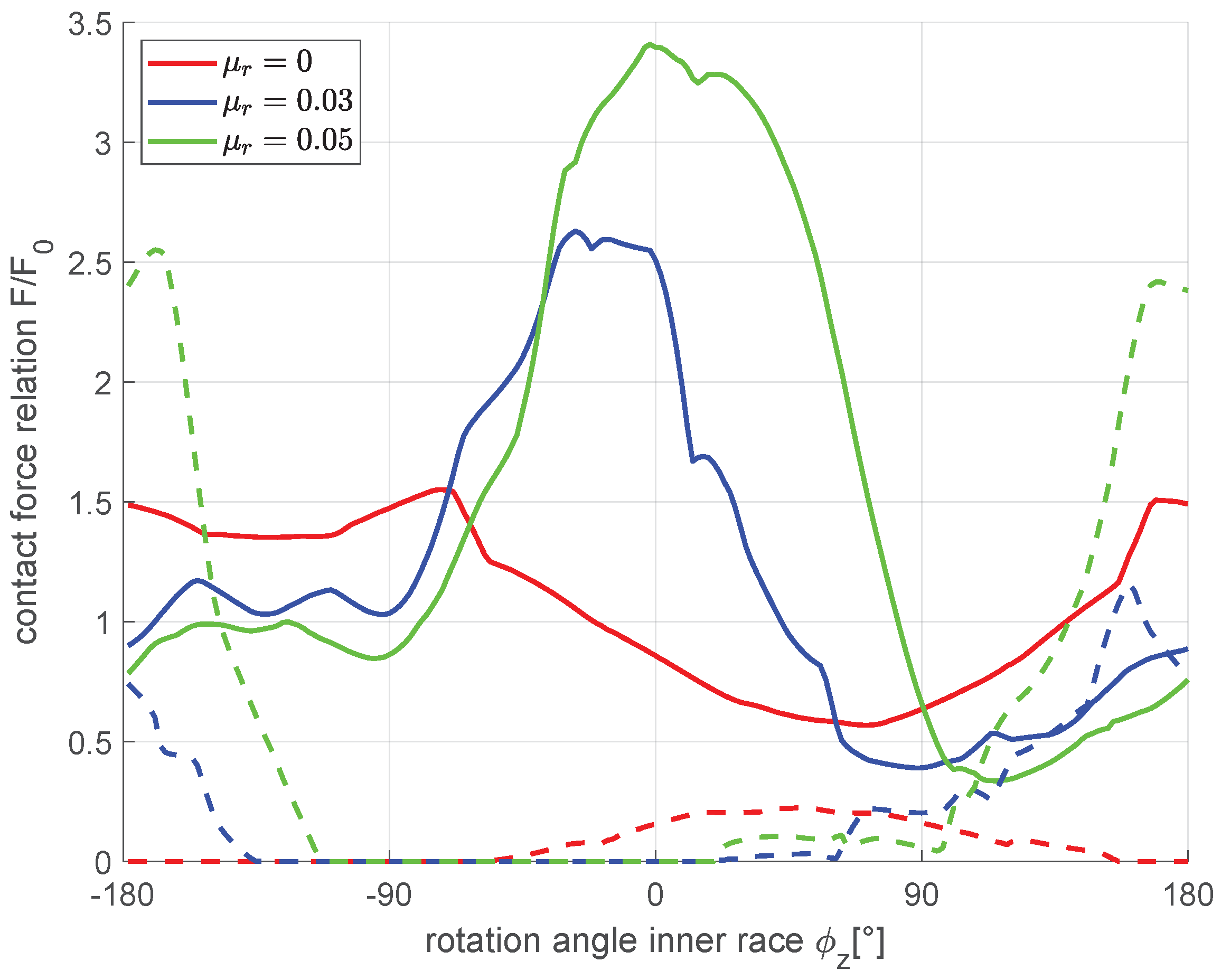

The verification of the CVJ with regard to the homokinetic condition to be fulfilled showed that a significantly higher contact stiffness must be selected than that provided by Hertzian contact theory. This deviation is caused by a relatively large contact area between ball and track with respect to the ball surface. The resulting contact forces were compared for benchmark problems with analytical calculation results and generally showed good agreement. It is noticeable that the cage does not absorb forces for low load torques, since these forces are initially absorbed completely by the track. This can be attributed to the high contact stiffness which was chosen to sufficiently fulfil the homokinetic condition with the analytical approach. Moreover, a clear influence of the friction coefficient on the joint kinematics and the contact forces can be observed, which is shown by the example of the secondary torque.

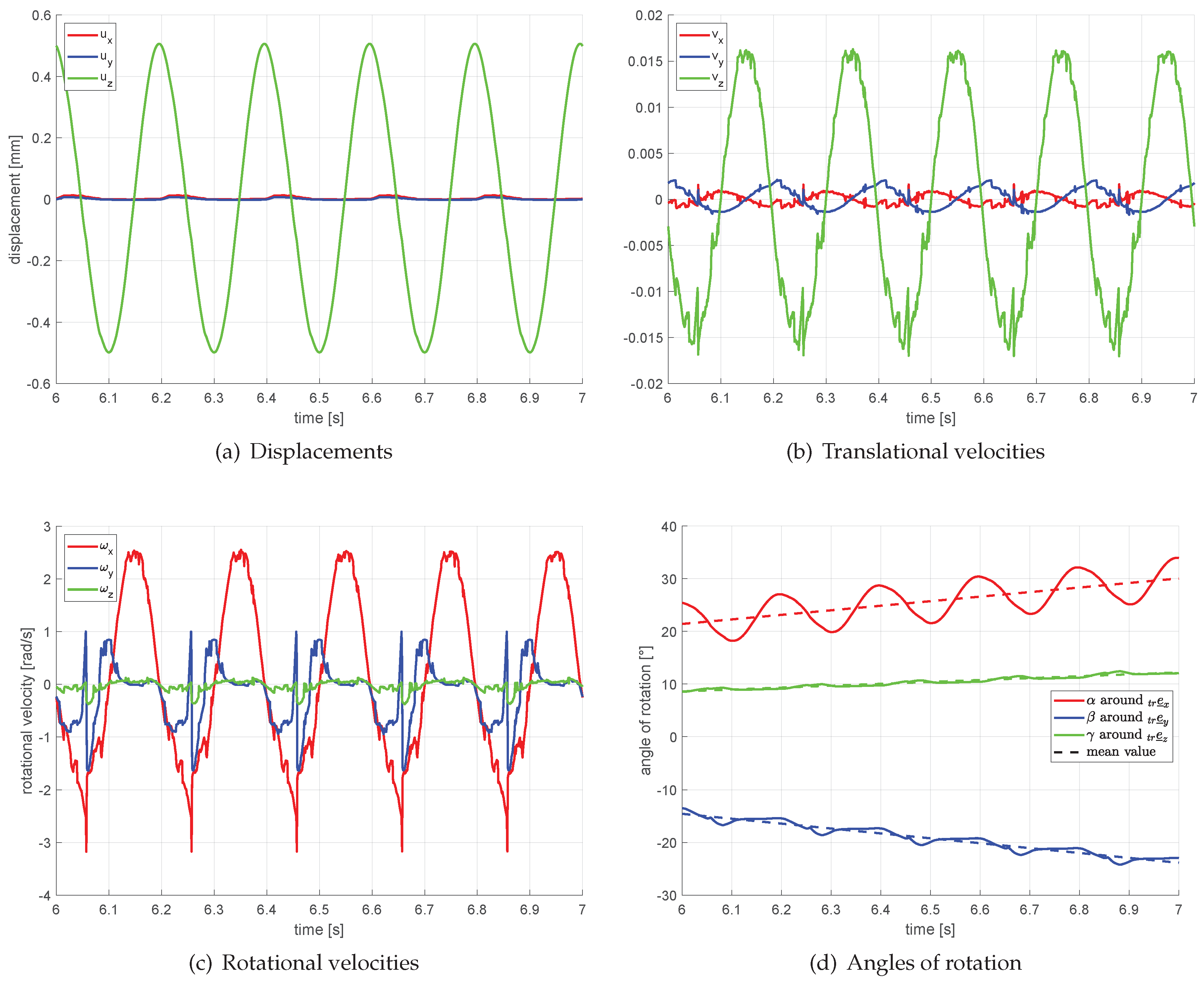

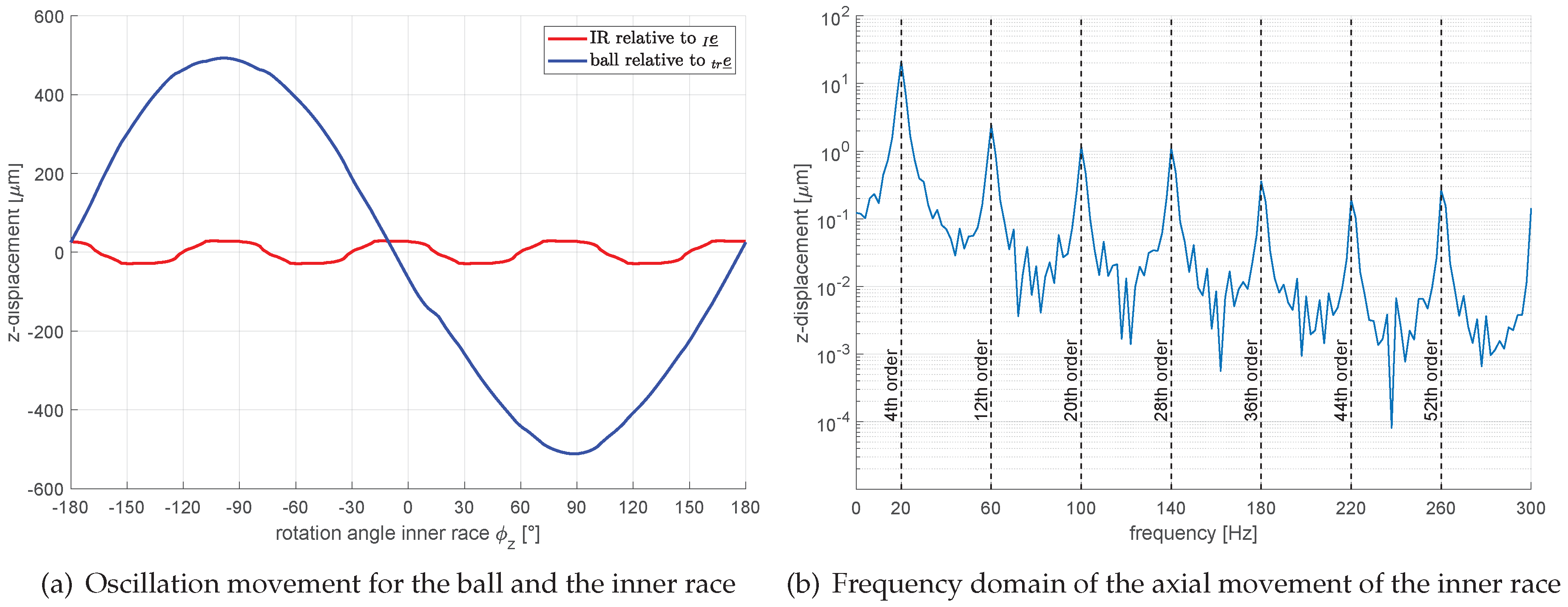

By analysing the ball kinematics and the axial movement in the joint, two examples of usage possibilities of the simulation model are shown. By evaluating the kinematic pathways of the ball, a pure rolling motion of the balls within the track can be excluded. Furthermore, possible NVH influences caused by an axial movement of the inner race can be determined for deflected joint condition, which depend on the application parameters and the joint geometry. In this way, the presented model can be integrated into the development process in addition to analytical methods in order to take into account transient processes and dynamic effects. Finally, the model allows parameter studies for the influence analysis of individual joint parameters on the kinematics, which reduces the scope of real test bench investigations.

In further studies, the contact stiffness in the joint should be validated in test bench investigations by examining the influence of the joint geometry on the fulfilment of the homokinetic condition. In addition, it should be investigated whether another contact model for the contact determination such as a surface model possibly fulfils the homokinetic condition at lower contact stiffnesses. If it is necessary to detail the model at this point, this is accompanied by a significant increase in the numerical effort, whereby the additional effort must be put in proportion to the actual refinement of the calculation results. Supplementarily, it would be useful to measure the analysed forces and kinematics so that the simulation results can be validated. For this purpose, both direct measurement of the contact forces and measurement of the secondary torque are suitable for determining the friction coefficient in the joint tracks. To increase the level of detail of the multi-body simulation, it is also conceivable to make the joint components such as the cage or inner ring elastic. In this way, further influences on the joint kinematics can be investigated. Furthermore, a more precise description of the friction behaviour between ball and track could also be helpful r to characterise the joint behaviour even more precisely in future.