Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review

Abstract

1. Introduction

2. Supplementary Cementitious Material (SCM)

2.1. Limestone-Calcined Clay Cement (LC3)

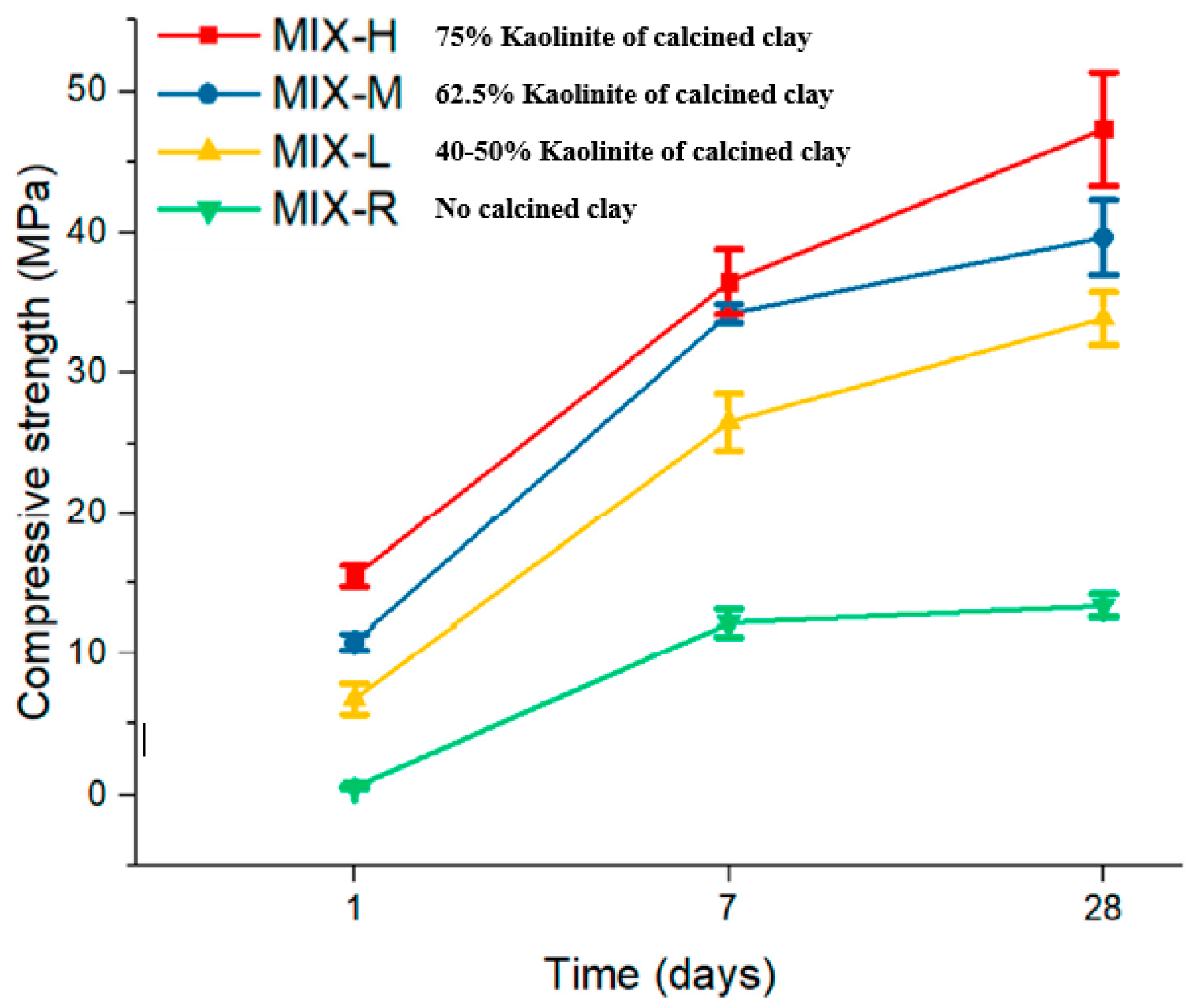

2.1.1. Mechanical Properties of LC3 Cement Binder

2.1.2. Durability and Microstructure of LC3 Cement Binder

3. Fiber-Reinforced Concrete (FRC)

3.1. Natural-Fiber-Reinforced Concrete (NFRC)

3.1.1. Mechanical Properties of NFRC

3.1.2. Durability of Bio Fiber-Reinforced Concrete

3.2. Kenaf Fiber-Reinforced Concrete (KFRC)

4. Discussion and Conclusions

Funding

Conflicts of Interest

References

- Naqi, A.; Jang, J.; Naqi, A.; Jang, J.G. Recent Progress in Green Cement Technology Utilizing Low-Carbon Emission Fuels and Raw Materials: A Review. Sustainability 2019, 11, 537. [Google Scholar] [CrossRef]

- Hasanbeigi, A.; Price, L.; Lu, H.; Lan, W. Analysis of energy-efficiency opportunities for the cement industry in Shandong Province, China: A case study of 16 cement plants. Energy 2010, 35, 3461–3473. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Valipour, M.; Yekkalar, M.; Shekarchi, M.; Panahi, S. Environmental assessment of green concrete containing natural zeolite on the global warming index in marine environments. J. Clean. Prod. 2014, 65, 418–423. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation of natural fiber in ternary blended cement composites containing metakaolin and montmorillonite. Corros. Sci. 2017, 120, 42–60. [Google Scholar] [CrossRef]

- Hakamy, A.; Shaikh, F.U.A.; Low, I.M. Effect of calcined nanoclay on microstructural and mechanical properties of chemically treated hemp fabric-reinforced cement nanocomposites. Constr. Build. Mater. 2015, 95, 882–891. [Google Scholar] [CrossRef]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H. Chapter 5—Effect of Supplementary Cementitious Materials on Reduction of CO2 Emissions from Concrete. In Handbook of Low Carbon Concrete; Nazari, A., Sanjayan, J., Eds.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 89–110. ISBN 978-0-12-804524-4. [Google Scholar]

- Crossin, E. The greenhouse gas implications of using ground granulated blast furnace slag as a cement substitute. J. Clean. Prod. 2015, 95, 101–108. [Google Scholar] [CrossRef]

- Li, C.; Sun, H.; Li, L. A review: The comparison between alkali-activated slag (Si + Ca) and metakaolin (Si + Al) cements. Cem. Concr. Res. 2010, 40, 1341–1349. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-activated binders: A review: Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Golewski, G.L. Green concrete composite incorporating fly ash with high strength and fracture toughness. J. Clean. Prod. 2018, 172, 218–226. [Google Scholar] [CrossRef]

- Tahanpour Javadabadi, M.; De Lima Kristiansen, D.; Bayene Redie, M.; Baghban, M.H. Sustainable Concrete: A Review. Int. J. Struct. Civ. Eng. Res. 2019, 8, 126–132. [Google Scholar]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Chatterji, S.; Thaulow, N.; Christensen, P. Puzzolanic activity of byproduct silica-fume from ferro-silicom production. Cem. Concr. Res. 1982, 12, 781–784. [Google Scholar] [CrossRef]

- Mehta, P.K.; Gjørv, O.E. Properties of portland cement concrete containing fly ash and condensed silica-fume. Cem. Concr. Res. 1982, 12, 587–595. [Google Scholar] [CrossRef]

- Diamond, S. The utilization of flyash. Cem. Concr. Res. 1984, 14, 455–462. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 2007, 21, 1534–1541. [Google Scholar] [CrossRef]

- Rodríguez de Sensale, G. Effect of rice-husk ash on durability of cementitious materials. Cem. Concr. Compos. 2010, 32, 718–725. [Google Scholar] [CrossRef]

- Zain, M.F.M.; Islam, M.N.; Mahmud, F.; Jamil, M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 798–805. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. Development of corn cob ash blended cement. Constr. Build. Mater. 2009, 23, 347–352. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. A study of the permeability and acid attack of corn cob ash blended cements. Constr. Build. Mater. 2010, 24, 403–409. [Google Scholar] [CrossRef]

- Sigvardsen, N.M.; Kirkelund, G.M.; Jensen, P.E.; Geiker, M.R.; Ottosen, L.M. Impact of production parameters on physiochemical characteristics of wood ash for possible utilisation in cement-based materials. Resour. Conserv. Recycl. 2019, 145, 230–240. [Google Scholar] [CrossRef]

- Vejmelková, E.; Koňáková, D.; Kulovaná, T.; Keppert, M.; Žumár, J.; Rovnaníková, P.; Keršner, Z.; Sedlmajer, M.; Černý, R. Engineering properties of concrete containing natural zeolite as supplementary cementitious material: Strength, toughness, durability, and hygrothermal performance. Cem. Concr. Compos. 2015, 55, 259–267. [Google Scholar] [CrossRef]

- Villar-Cociña, E.; Morales, E.V.; Santos, S.F.; Savastano, H.; Frías, M. Pozzolanic behavior of bamboo leaf ash: Characterization and determination of the kinetic parameters. Cem. Concr. Compos. 2011, 33, 68–73. [Google Scholar] [CrossRef]

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes—A review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Kroehong, W.; Sinsiri, T.; Jaturapitakkul, C. Effect of Palm Oil Fuel Ash Fineness on Packing Effect and Pozzolanic Reaction of Blended Cement Paste. Procedia Eng. 2011, 14, 361–369. [Google Scholar] [CrossRef]

- Lim, N.H.A.S.; Ismail, M.A.; Lee, H.S.; Hussin, M.W.; Sam, A.R.M.; Samadi, M. The effects of high volume nano palm oil fuel ash on microstructure properties and hydration temperature of mortar. Constr. Build. Mater. 2015, 93, 29–34. [Google Scholar] [CrossRef]

- Rajak, M.A.A.; Majid, Z.A.; Ismail, M. Morphological Characteristics of Hardened Cement Pastes Incorporating Nano-palm Oil Fuel Ash. Procedia Manuf. 2015, 2, 512–518. [Google Scholar] [CrossRef]

- Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z. Mechanical and fresh properties of sustainable oil palm shell lightweight concrete incorporating palm oil fuel ash. J. Clean. Prod. 2016, 115, 307–314. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Tangpagasit, J.; Songmue, S.; Kiattikomol, K. Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr. Build. Mater. 2011, 25, 4287–4293. [Google Scholar] [CrossRef]

- Jaturapitakkul, C.; Kiattikomol, K.; Tangchirapat, W.; Saeting, T. Evaluation of the sulfate resistance of concrete containing palm oil fuel ash. Constr. Build. Mater. 2007, 21, 1399–1405. [Google Scholar] [CrossRef]

- Wi, K.; Lee, H.-S.; Lim, S.; Ismail, M.A.; Hussin, M.W. Effect of Using Micropalm Oil Fuel Ash as Partial Replacement of Cement on the Properties of Cement Mortar. Adv. Mater. Sci. Eng. 2018, 2018, 1–8. [Google Scholar] [CrossRef]

- Khodabakhshian, A.; Ghalehnovi, M.; de Brito, J.; Asadi Shamsabadi, E. Durability performance of structural concrete containing silica fume and marble industry waste powder. J. Clean. Prod. 2018, 170, 42–60. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Gallucci, E.; Scrivener, K. Influence of limestone on the hydration of Portland cements. Cem. Concr. Res. 2008, 38, 848–860. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Wang, X.; Rao, S.; Shui, Z. A novel Self-Compacting Ultra-High Performance Fibre Reinforced Concrete (SCUHPFRC) derived from compounded high-active powders. Constr. Build. Mater. 2018, 158, 883–893. [Google Scholar] [CrossRef]

- Avet, F.; Scrivener, K. Hydration Study of Limestone Calcined Clay Cement (LC3) Using Various Grades of Calcined Kaolinitic Clays. In Calcined Clays for Sustainable Concrete; Springer: Dordrecht, The Netherlands, 2018; pp. 35–40. [Google Scholar]

- Avet, F.; Boehm-Courjault, E.; Scrivener, K. Investigation of C-A-S-H composition, morphology and density in Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2019, 115, 70–79. [Google Scholar] [CrossRef]

- Sharaky, I.A.; Megahed, F.A.; Seleem, M.H.; Badawy, A.M. The influence of silica fume, nano silica and mixing method on the strength and durability of concrete. SN Appl. Sci. 2019, 1, 575. [Google Scholar] [CrossRef]

- Meddah, M.S.; Ismail, M.A.; El-Gamal, S.; Fitriani, H. Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr. Build. Mater. 2018, 166, 400–412. [Google Scholar] [CrossRef]

- Saha, A.K. Effect of class F fly ash on the durability properties of concrete. Sustain. Environ. Res. 2018, 28, 25–31. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.P.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaraman, R.; Mudali, U.K.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 187, 448–459. [Google Scholar] [CrossRef]

- King, D. The effect of silica fume on the properties of concrete as defined in concrete society report 74, cementitious materials. In Proceedings of the 37th Conference on Our World in Concrete and Structures, Singapore, 29–31 August 2012; pp. 29–31. [Google Scholar]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined clay limestone cements (LC3). Cem. Concr. Res. 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Snellings, R. Assessing, Understanding and Unlocking Supplementary Cementitious Materials. Rilem Tech. Lett. 2016, 1, 50. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- Shi, Z.; Ferreiro, S.; Lothenbach, B.; Geiker, M.R.; Kunther, W.; Kaufmann, J.; Herfort, D.; Skibsted, J. Sulfate resistance of calcined clay—Limestone—Portland cements. Cem. Concr. Res. 2019, 116, 238–251. [Google Scholar] [CrossRef]

- Taylor-Lange, S.C.; Lamon, E.L.; Riding, K.A.; Juenger, M.C.G. Calcined kaolinite–bentonite clay blends as supplementary cementitious materials. Appl. Clay Sci. 2015, 108, 84–93. [Google Scholar] [CrossRef]

- Fernandez, R.; Martirena, F.; Scrivener, K.L. The origin of the pozzolanic activity of calcined clay minerals: A comparison between kaolinite, illite and montmorillonite. Cem. Concr. Res. 2011, 41, 113–122. [Google Scholar] [CrossRef]

- Garg, N.; Skibsted, J. Thermal Activation of a Pure Montmorillonite Clay and Its Reactivity in Cementitious Systems. J. Phys. Chem. C 2014, 118, 11464–11477. [Google Scholar] [CrossRef]

- Antoni, M.; Rossen, J.; Martirena, F.; Scrivener, K. Cement substitution by a combination of metakaolin and limestone. Cem. Concr. Res. 2012, 42, 1579–1589. [Google Scholar] [CrossRef]

- Tafraoui, A.; Escadeillas, G.; Lebaili, S.; Vidal, T. Metakaolin in the formulation of UHPC. Constr. Build. Mater. 2009, 23, 669–674. [Google Scholar] [CrossRef]

- Souza, P.S.L.; Dal Molin, D.C.C. Viability of using calcined clays, from industrial by-products, as pozzolans of high reactivity. Cem. Concr. Res. 2005, 35, 1993–1998. [Google Scholar] [CrossRef]

- Ding, J.-T.; Li, Z. Effects of metakaolin and silica fume on properties of concrete. Mater. J. 2002, 99, 393–398. [Google Scholar]

- Chen, Y.; Chaves Figueiredo, S.; Yalçinkaya, Ç.; Çopuroğlu, O.; Veer, F.; Schlangen, E. The Effect of Viscosity-Modifying Admixture on the Extrudability of Limestone and Calcined Clay-Based Cementitious Material for Extrusion-Based 3D Concrete Printing. Materials 2019, 12, 1374. [Google Scholar] [CrossRef] [PubMed]

- Hassan, A.A.A.; Mayo, J.R. Influence of mixture composition on the properties of SCC incorporating metakaolin. Mag. Concr. Res. 2014, 66, 1036–1050. [Google Scholar] [CrossRef]

- Alvarez, G.L.; Nazari, A.; Bagheri, A.; Sanjayan, J.G.; De Lange, C. Microstructure, electrical and mechanical properties of steel fibres reinforced cement mortars with partial metakaolin and limestone addition. Constr. Build. Mater. 2017, 135, 8–20. [Google Scholar] [CrossRef]

- Avet, F.; Snellings, R.; Alujas Diaz, A.; Ben Haha, M.; Scrivener, K. Development of a new rapid, relevant and reliable (R3) test method to evaluate the pozzolanic reactivity of calcined kaolinitic clays. Cem. Concr. Res. 2016, 85, 1–11. [Google Scholar] [CrossRef]

- Sánchez Berriel, S.; Favier, A.; Rosa Domínguez, E.; Sánchez Machado, I.R.; Heierli, U.; Scrivener, K.; Martirena Hernández, F.; Habert, G. Assessing the environmental and economic potential of Limestone Calcined Clay Cement in Cuba. J. Clean. Prod. 2016, 124, 361–369. [Google Scholar] [CrossRef]

- Huang, W.; Kazemi-Kamyab, H.; Sun, W.; Scrivener, K. Effect of replacement of silica fume with calcined clay on the hydration and microstructural development of eco-UHPFRC. Mater. Des. 2017, 121, 36–46. [Google Scholar] [CrossRef]

- Arbi, K.; Nedeljković, M.; Zuo, Y.; Ye, G. A Review on the Durability of Alkali-Activated Fly Ash/Slag Systems: Advances, Issues, and Perspectives. Ind. Eng. Chem. Res. 2016, 55, 5439–5453. [Google Scholar] [CrossRef]

- Almenares, R.S.; Vizcaíno, L.M.; Damas, S.; Mathieu, A.; Alujas, A.; Martirena, F. Industrial calcination of kaolinitic clays to make reactive pozzolans. Case Stud. Constr. Mater. 2017, 6, 225–232. [Google Scholar] [CrossRef]

- Ferreiro, S.; Herfort, D.; Damtoft, J.S. Effect of raw clay type, fineness, water-to-cement ratio and fly ash addition on workability and strength performance of calcined clay—Limestone Portland cements. Cem. Concr. Res. 2017, 101, 1–12. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Z.; Chaves Figueiredo, S.C.; Çopuroğlu, O.; Veer, F.; Schlangen, E.; Chen, Y.; Li, Z.; Chaves Figueiredo, S.; Çopuroğlu, O.; et al. Limestone and Calcined Clay-Based Sustainable Cementitious Materials for 3D Concrete Printing: A Fundamental Study of Extrudability and Early-Age Strength Development. Appl. Sci. 2019, 9, 1809. [Google Scholar] [CrossRef]

- Maraghechi, H.; Avet, F.; Wong, H.; Kamyab, H.; Scrivener, K. Performance of Limestone Calcined Clay Cement (LC3) with various kaolinite contents with respect to chloride transport. Mater. Struct. 2018, 51, 125. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Sakthivel, T.; Santhanam, M.; Gettu, R.; Pillai, R.G. Mechanical properties and durability performance of concretes with Limestone Calcined Clay Cement (LC3). Cem. Concr. Res. 2018, 107, 136–151. [Google Scholar] [CrossRef]

- Pillai, R.G.; Gettu, R.; Santhanam, M.; Rengaraju, S.; Dhandapani, Y.; Rathnarajan, S.; Basavaraj, A.S. Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3). Cem. Concr. Res. 2019, 118, 111–119. [Google Scholar] [CrossRef]

- Steenberg, M.; Herfort, D.; Poulsen, S.L.; Skibsted, J.; Damtoft, J.S. Composite cement based on Portland cement clinker, limestone and calcined clay. In Proceedings of the Xiii International Congress on the Chemistry of Cement, Madrid, Spain, 3–8 July 2011. [Google Scholar]

- Baghban, M.H.; Hovde, P.J.; Jacobsen, S. Effect of internal hydrophobation, silica fume and w/c on water sorption of hardened cement pastes. In Proceedings of the International Conference on Durability of Building Materials and Components, Porto, Portugal, 12–15 April 2011. [Google Scholar]

- Baghban, M.H. Water Sorption of Hardened Cement Pastes. Cem. Based Mater. 2018. [Google Scholar] [CrossRef]

- Justnes, H.; Østnor, T.; Barnils Vila, N. Vegetable oils as water repellents for mortars. In Proceedings of the 1st International Conference of Asian Concrete Federation, Chiang Mai, Thailand, 28–29 October 2004; pp. 28–29. [Google Scholar]

- Baghban, M.; Hovde, P.; Jacobsen, S. Effect of internal hydrophobation, silica fume and w/c on compressive strength of hardened cement pastes. World J. Eng. 2012, 9, 7–12. [Google Scholar] [CrossRef]

- Baghban, M.H.; Holvik, O.K.; Hesselberg, E.; Javadabadi, M.T. Cementitious Composites with Low Water Permeability through Internal Hydrophobicity. Key Engineering Materials. 2018, 779, 37–42. [Google Scholar] [CrossRef]

- Favier, A.; Scrivener, K. Alkali Silica Reaction and Sulfate Attack: Expansion of Limestone Calcined Clay Cement. In Calcined Clays for Sustainable Concrete; Springer: Dordrecht, The Netherlands, 2018; pp. 165–169. [Google Scholar]

- Carpinteri, A.; Cadamuro, E.; Ventura, G. Fiber-reinforced concrete in flexure: A cohesive/overlapping crack model application. Mater. Struct. 2015, 48, 235–247. [Google Scholar] [CrossRef]

- Oh, B.H.; Kim, J.C.; Choi, Y.C. Fracture behavior of concrete members reinforced with structural synthetic fibers. Eng. Fract. Mech. 2007, 74, 243–257. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Mobasher, B. Mechanics of Fiber and Textile Reinforced Cement Composites; CRC Press: New York, NY, USA, 2011; ISBN 9780429131387. [Google Scholar]

- Choe, G.; Kim, G.; Kim, H.; Hwang, E.; Lee, S.; Nam, J. Effect of amorphous metallic fiber on mechanical properties of high-strength concrete exposed to high-temperature. Constr. Build. Mater. 2019, 218, 448–456. [Google Scholar] [CrossRef]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Al-Oraimi, S.K.; Seibi, A.C. Mechanical characterisation and impact behaviour of concrete reinforced with natural fibres. Compos. Struct. 1995, 32, 165–171. [Google Scholar] [CrossRef]

- De Gutiérrez, R.M.; Díaz, L.N.; Delvasto, S. Effect of pozzolans on the performance of fiber-reinforced mortars. Cem. Concr. Compos. 2005, 27, 593–598. [Google Scholar] [CrossRef]

- Mobasher, B.; Li, C.Y. Effect of interfacial properties on the crack propagation in cementitious composites. Adv. Cem. Based Mater. 1996, 4, 93–105. [Google Scholar] [CrossRef]

- Alberti, M.G.; Enfedaque, A.; Gálvez, J.C. On the mechanical properties and fracture behavior of polyolefin fiber-reinforced self-compacting concrete. Constr. Build. Mater. 2014, 55, 274–288. [Google Scholar] [CrossRef]

- Fujikake, K. Impact Performance of Ultra-High Performance Fiber Reinforced Concrete Beam and its Analytical Evaluation. Int. J. Prot. Struct. 2014, 5, 167–186. [Google Scholar] [CrossRef]

- Soroushian, P.; Marikunte, S. Moisture effects on flexural performance of wood fiber-cement composites. J. Mater. Civ. Eng. 1992, 4, 275–291. [Google Scholar] [CrossRef]

- Soroushian, P.; Marikunte, S. Moisture Sensitivity of Cellulose Fiber Reinforced Cement. In Proceedings of the Durability of Concrete: Second International Conference, Montreal, QC, Canada, 4 August 1991; Volume II, pp. 821–835. [Google Scholar]

- Soroushian, P.; Marikunte, S. Reinforcement of cement-based materials with cellulose fibers. Spec. Publ. 1990, 124, 99–124. [Google Scholar]

- Mansur, M.A.; Aziz, M.A. A study of jute fibre reinforced cement composites. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 75–82. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Sanginabadi, K.; Mostofinejad, D.; Abtahi, S.M.; Fashandi, H. The effect of specific surface area of macro fibers on energy absorption capacity of concrete. J. Text. Inst. 2019, 110, 707–714. [Google Scholar] [CrossRef]

- Hasan, A.; Maroof, N.; Ibrahim, Y. Effects of Polypropylene Fiber Content on Strength and Workability Properties of Concrete. Polytech. J. 2019, 9, 7–12. [Google Scholar] [CrossRef]

- Lam, T.F.; Yatim, J.M. Mechanical properties of kenaf fiber reinforced concrete with different fiber content and fiber length. J. Asian Concr. Fed. 2015, 1, 11. [Google Scholar] [CrossRef]

- Ramaswamy, H.S.; Ahuja, B.M.; Krishnamoorthy, S. Behaviour of concrete reinforced with jute, coir and bamboo fibres. Int. J. Cem. Compos. Lightweight Concr. 1983, 5, 3–13. [Google Scholar] [CrossRef]

- Hasan, N.M.S.; Sobuz, H.R.; Sayed, M.S.; Islam, M.S. The Use of Coconut Fibre in the Production of Structural Lightweight Concrete. J. Appl. Sci. 2012, 12, 831–839. [Google Scholar]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Vajje, S.; Murthy, N.R.K. Study On Addition Of The Natural Fibers Into Concrete. Int. J. Sci. Technol. Res. 2013, 2, 213–218. [Google Scholar]

- Güneyisi, E.; Gesoğlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined effect of steel fiber and metakaolin incorporation on mechanical properties of concrete. Compos. Part B Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Uzomaka, O.J. Characteristics of akwara as a reinforcing fibre. Mag. Concr. Res. 1976, 28, 162–167. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T. Impact strength of a few natural fibre reinforced cement mortar slabs: A comparative study. Cem. Concr. Compos. 2005, 27, 547–553. [Google Scholar] [CrossRef]

- Merta, I.; Tschegg, E.K. Fracture energy of natural fibre reinforced concrete. Constr. Build. Mater. 2013, 40, 991–997. [Google Scholar] [CrossRef]

- Banthia, N.; Zanotti, C.; Sappakittipakorn, M. Sustainable fiber reinforced concrete for repair applications. Constr. Build. Mater. 2014, 67, 405–412. [Google Scholar] [CrossRef]

- Zhou, X.; Ghaffar, S.H.; Dong, W.; Oladiran, O.; Fan, M. Fracture and impact properties of short discrete jute fibre-reinforced cementitious composites. Mater. Des. 2013, 49, 35–47. [Google Scholar] [CrossRef]

- Wang, X.D.; Zhang, C.; Huang, Z.; Chen, G.W. Impact Experimental Research on Hybrid Bamboo Fiber and Steel Fiber Reinforced Concrete. Appl. Mech. Mater. 2013, 357–360, 1049–1052. [Google Scholar] [CrossRef]

- Wang, W.; Chouw, N. The behaviour of coconut fibre reinforced concrete (CFRC) under impact loading. Constr. Build. Mater. 2017, 134, 452–461. [Google Scholar] [CrossRef]

- Page, J.; Khadraoui, F.; Boutouil, M.; Gomina, M. Multi-physical properties of a structural concrete incorporating short flax fibers. Constr. Build. Mater. 2017, 140, 344–353. [Google Scholar] [CrossRef]

- Toledo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Mohr, B.J.; Biernacki, J.J.; Kurtis, K.E. Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites. Cem. Concr. Res. 2007, 37, 1531–1543. [Google Scholar] [CrossRef]

- Harper, S. Developing asbestos-free calcium silicate building boards. Composites 1982, 13, 123–128. [Google Scholar] [CrossRef]

- Bergström, S.G.; Gram, H.-E. Durability of alkali-sensitive fibres in concrete. Int. J. Cem. Compos. Lightweight Concr. 1984, 6, 75–80. [Google Scholar] [CrossRef]

- Sivaraja, M.; Velmani, N.; Pillai, M.S. Study on durability of natural fibre concrete composites using mechanical strength and microstructural properties. Bull. Mater. Sci. 2010, 33, 719–729. [Google Scholar] [CrossRef]

- Omoniyi, T.; Akinyemi, B. Durability based suitability of bagasse cement composite for roofing sheets. J. Civ. Eng. Const. Tech. 2012. [Google Scholar] [CrossRef]

- Ramakrishna, G.; Sundararajan, T.; Kothandaraman, S. Evaluation of durability of natural fibre reinforced cement mortar composite-a new approach. ARPN J. Eng. Appl. Sci. 2010, 5, 44–51. [Google Scholar]

- Javadi, A.; Srithep, Y.; Pilla, S.; Lee, J.; Gong, S.; Turng, L.S. Processing and characterization of solid and microcellular PHBV/coir fiber composites. Mater. Sci. Eng. C 2010, 30, 749–757. [Google Scholar] [CrossRef]

- Bilba, K.; Arsene, M.-A. Silane treatment of bagasse fiber for reinforcement of cementitious composites. Compos. Part Appl. Sci. Manuf. 2008, 39, 1488–1495. [Google Scholar] [CrossRef]

- Cooke, A.M. Durability of Autoclaved Cellulose Fiber Cement Composites. In Proceedings of the 7th Inorganic-Bonded Wood and Fibre Conference, Sun Valley, ID, USA, 25–27 September 2000; Available online: www.fibrecementconsulting.com/publications/990925.durabilitypaper.pdf (accessed on 15 October 2019).

- Claramunt, J.; Ardanuy, M.; García-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Pehanich, J.L.; Blankenhorn, P.R.; Silsbee, M.R. Wood fiber surface treatment level effects on selected mechanical properties of wood fiber–cement composites. Cem. Concr. Res. 2004, 34, 59–65. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Mohammadkazemi, F.; Doosthoseini, K.; Ganjian, E.; Azin, M. Manufacturing of bacterial nano-cellulose reinforced fiber−cement composites. Constr. Build. Mater. 2015, 101, 958–964. [Google Scholar] [CrossRef]

- Mohammadhosseini, H.; Yatim, J.M.; Sam, A.R.M.; Awal, A.S.M.A. Durability performance of green concrete composites containing waste carpet fibers and palm oil fuel ash. J. Clean. Prod. 2017, 144, 448–458. [Google Scholar] [CrossRef]

- Sharman, W.R.; Vautier, B.P. Durability Studies on Wood Fibre Reinforced Cement Sheet; Building Research Association of New Zealand: Rochdale, UK, 1986. [Google Scholar]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Marikunte, S.; Soroushian, P. Statistical evaluation of long-term durability characteristics of cellulose fiber reinforced cement composites. Mater. J. 1995, 91, 607–616. [Google Scholar]

- Zaveri, M.D. Absorbency Characteristics of Kenaf Core Particles. Ph.D. Thesis, North Carolina State University, Raleigh, NC, USA, 2004. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites; CRC Press: Boca Raton, FL, USA, 2005; ISBN 0203508203. [Google Scholar]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Raftari, M. Characteristics of continuous unidirectional kenaf fiber reinforced epoxy composites. Mater. Des. 2014, 64, 640–649. [Google Scholar] [CrossRef]

- Kumar, K.K.; Karunakar, C.; ChandraMouli, B. Development and Characterization of Hybrid Fibres Reinforced Composites Based on Glass and Kenaf Fibers. Mater. Today Proc. 2018, 5, 14539–14544. [Google Scholar] [CrossRef]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.M.; Zulkarnain, N.A.; Raftari, M. The Use of Kenaf Fiber Reinforced Polymer to Confine the Concrete Cylinder. Mater. Today Proc. 2016, 3, 459–463. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S.; Abu Bakar, A. Mechanical performance of oil palm empty fruit bunches/jute fibres reinforced epoxy hybrid composites. Mater. Sci. Eng. A 2010, 527, 7944–7949. [Google Scholar] [CrossRef]

- Jarukumjorn, K.; Suppakarn, N. Effect of glass fiber hybridization on properties of sisal fiber-polypropylene composites. Compos. Part B Eng. 2009, 40, 623–627. [Google Scholar] [CrossRef]

- Joseph, K.; Varghese, S.; Kalaprasad, G.; Thomas, S.; Prasannakumari, L.; Koshy, P.; Pavithran, C. Influence of interfacial adhesion on the mechanical properties and fracture behaviour of short sisal fibre reinforced polymer composites. Eur. Polym. J. 1996, 32, 1243–1250. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–87. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Ranakoti, L.; Pokhriyal, M.; Kumar, A. Natural fibers and biopolymers characterization: A future potential composite material. Bratisl. J. Mech. Eng. Stroj. Časopis 2018, 68, 33–50. [Google Scholar]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Parija, S.; Nayak, S.K.; Tripathy, S.S. Studies on mechanical performance of biofibre/glass reinforced polyester hybrid composites. Compos. Sci. Technol. 2003, 63, 1377–1385. [Google Scholar] [CrossRef]

- Nabi, S.D.; Jog, J.P. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Kumaran, M.G.; Thomas, S. Oil palm fibers: Morphology, chemical composition, surface modification, and mechanical properties. J. Appl. Polym. Sci. 1997, 66, 821–835. [Google Scholar] [CrossRef]

- Mahjoub, R.; Bin Mohamad Yatim, J.; Mohd Sam, A.R. A review of structural performance of oil palm empty fruit bunch fiber in polymer composites. Adv. Mater. Sci. Eng. 2013, 2013. [Google Scholar] [CrossRef]

- Davoodi, M.M.; Sapuan, S.M.; Ahmad, D.; Ali, A.; Khalina, A.; Jonoobi, M. Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Mater. Des. 2010, 31, 4927–4932. [Google Scholar] [CrossRef]

- Park, J.K.; Cho, D.; Kang, T.J. A comparison of the interfacial, thermal, and ablative properties between spun and filament yarn type carbon fabric/phenolic composites. Carbon 2004, 42, 795–804. [Google Scholar] [CrossRef]

- Huang, C.; Chen, T.; Feng, S. Finite element analysis of fatigue crack growth in CFRP-repaired four-point bend specimens. Eng. Struct. 2019, 183, 398–407. [Google Scholar] [CrossRef]

- Babatunde Ogunbode, E.; Mohamad Yatim, J.; Yunus Ishak, M.; Abdul Hamid, H. An Evaluation of the Interfacial Bond Strength of Kenaf Fibrous Concrete and Plain Concrete Composite Cleaner and Sustainable Housing View Project Strength, Durability and Microstructural properties of concrete composites View project. Int. J. Built Environ. Sustain. 2019, 6, 1–6. [Google Scholar] [CrossRef]

| Chemical Composition and Physical Properties | Ordinary Portland Cement | SF | FA | Limestone | Metakaolin | Calcined Clay (50.3 wt.% Kaolinite Content) |

|---|---|---|---|---|---|---|

| SiO2 (%) | 19.2–21.63 | 90–95 | 46.44–50.96 | 0.1–0.8 | 51.8–57.37 | 44.9 |

| Al2O3 (%) | 4.18–4.27 | 0.25–1.2 | 25.88–38.01 | 0.3 | 38.63–42.4 | 32.3 |

| Fe2O3 (%) | 3.32–3.45 | 0.15–1.3 | 3.12–8.25 | 0.3 | 0.77–4.15 | 15.4 |

| TiO2 (%) | --- | --- | 1.36 | --- | 1.07 | 2.4 |

| CaO (%) | 63.25–64.93 | 0.36–1.5 | 2.15–7.5 | 55–58 | 0.03–0.071 | 1.3 |

| MgO (%) | 1.61–2.77 | 0.47–2 | 0.23–2.60 | 1.8–0.2 | 0.07 | 0.8 |

| Na2O (%) | 0.09 | 0.13–0.5 | 0.33–1.26 | 0.01–0.1 | 0.39 | 0.4 |

| MnO (%) | --- | 0.02–0.07 | --- | --- | --- | 0.1 |

| K2O (%) | 0.78 | 0.2–0.84 | 0.88–2.65 | 0.01 | 0.218–0.49 | 0.2 |

| SO3 (%) | 2.02–3.35 | 0.69 | 0.65–0.69 | 0.05 | 0.105–0.15 | 0.1 |

| P2O5 (%) | 0.09 | 0.04–0.17 | 0.06–0.35 | 0.61 | 0.4 | |

| Loss of ignition (%) | 1.24–2.49 | 2.29–3 | 2.79–3.2 | 42.6–43.4 | 1.04 | 1.7 |

| Specific gravity (g/cm3) | 3.2 | 1.9–2.15 | 2.14 | --- | 2.59 | --- |

| Specific surface (cm2/g) | 3280–9000 | 2730 | 3640 | 18,000 | --- | 45,700 |

| Bulk density (kg/m3) | --- | 300–660 | --- | --- | --- | --- |

| Name of Natural Fiber + SCM | Deteriorating Environment | Duration | Type of Mechanical Properties | Percentage of Changes Compared to Conventional Concrete | Notes | Reference |

|---|---|---|---|---|---|---|

| Sisal fiber | Alkaline solution | 28 days of immersion | Impact strength | About−2% | The impact strength of 2% sisal NFRC was about 2 times more than plain mortar. | [114] |

| Sisal fiber + 30% SF | Water bath (Alkalinity of binder) | 730 days of aging | Flexural strength | +28% | The flexural strength increased after aging period due to using 30% SF. | [111] |

| Sisal fiber | Outdoors | 322 days | Flexural strength | −70% | The first crack strength increased by about 53% due to the use of sisal fiber. | [108] |

| Sisal fiber + 45% MK + 5% montmorillonite | Wetting and drawing cycle | 30 cycles | Tensile strength of fiber embedded | +500% | The positive effects of MK on the mitigation of alkalinity was proved. | [6] |

| Hemp fiber + 1% calcined Nano clay | N/A | N/A | Flexural strength | +38% | ------- | [7] |

| Coir fiber | Sulfate attack | 2 years of immersion | Compressive strength | −14% | The deterioration value for conventional concrete was 54%. | [112] |

| Sugarcane fiber | Sulfate attack | 2 years of immersion | Compressive strength | −20% | The deterioration value for conventional concrete was 54%. | [112] |

| Coir fiber | Freezing and thawing | 300 cycles | Modulus of elasticity | −10% | The deterioration value for conventional concrete was 8%. | [112] |

| Sugarcane fiber | Freezing and thawing | 300 cycles | Modulus of elasticity | −14% | The deterioration value for conventional concrete was 8%. | [112] |

| Fiber | Elastic Modulus (GPa) | Tensile Strength (MPa) | Elongation at Break (%) | Density (g/cm3) | Reference (s) |

|---|---|---|---|---|---|

| Kenaf | 40 | 731.64 | 1.8 | 1.2 | [120,129] |

| Jute | 26.5 | 393–773 | 1.5–1.8 | 1.3 | [133] |

| Sisal | 9–22 | 400–700 | 2.0–2.5 | 1.43–1.5 | [134,135] |

| Flax | 27.6–65.5 | 345–1500 | 1.86–3.2 | 1.5 | [107,136] |

| Hemp | 70 | 690 | 1.6–4.0 | 1.47 | [136,137,138] |

| Pineapple | 34.5–82.5 | 170–1627 | 1–3 | 1.44–1.56 | [139,140,141] |

| Cotton | 5.5–12.6 | 400 | 7.0–8.0 | 1.5–1.6 | [140] |

| Oil Palm | 0.48–9 | 24.9–550 | 4–18 | 0.7–1.55 | [142,143] |

| E–glass | 70–71 | 2000–3500 | 0.5–3.4 | 2.5–2.55 | [120,137,144] |

| Carbon | 224–240 | 2650–4000 | 1.4–1.8 | 1.4–1.75 | [145,146] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baghban, M.H.; Mahjoub, R. Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Appl. Sci. 2020, 10, 357. https://doi.org/10.3390/app10010357

Baghban MH, Mahjoub R. Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Applied Sciences. 2020; 10(1):357. https://doi.org/10.3390/app10010357

Chicago/Turabian StyleBaghban, Mohammad Hajmohammadian, and Reza Mahjoub. 2020. "Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review" Applied Sciences 10, no. 1: 357. https://doi.org/10.3390/app10010357

APA StyleBaghban, M. H., & Mahjoub, R. (2020). Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Applied Sciences, 10(1), 357. https://doi.org/10.3390/app10010357