Influence of Cracking on Oxygen Transport in UHPFRC Using Stainless Steel Sensors

Abstract

1. Introduction

- Gaseous materials, such as CO2, water and acid vapor, may take part in transport in cracks up to a few tenths of micrometer (i.e., 0.1, 0.2 microns).

- Liquid materials, such as water, solutions of acids, might be of minor importance in microcracks below 1 micron.

2. Materials and Methods

2.1. Mix Design

2.2. Concrete Characterization

2.2.1. Slump and Compressive Strength

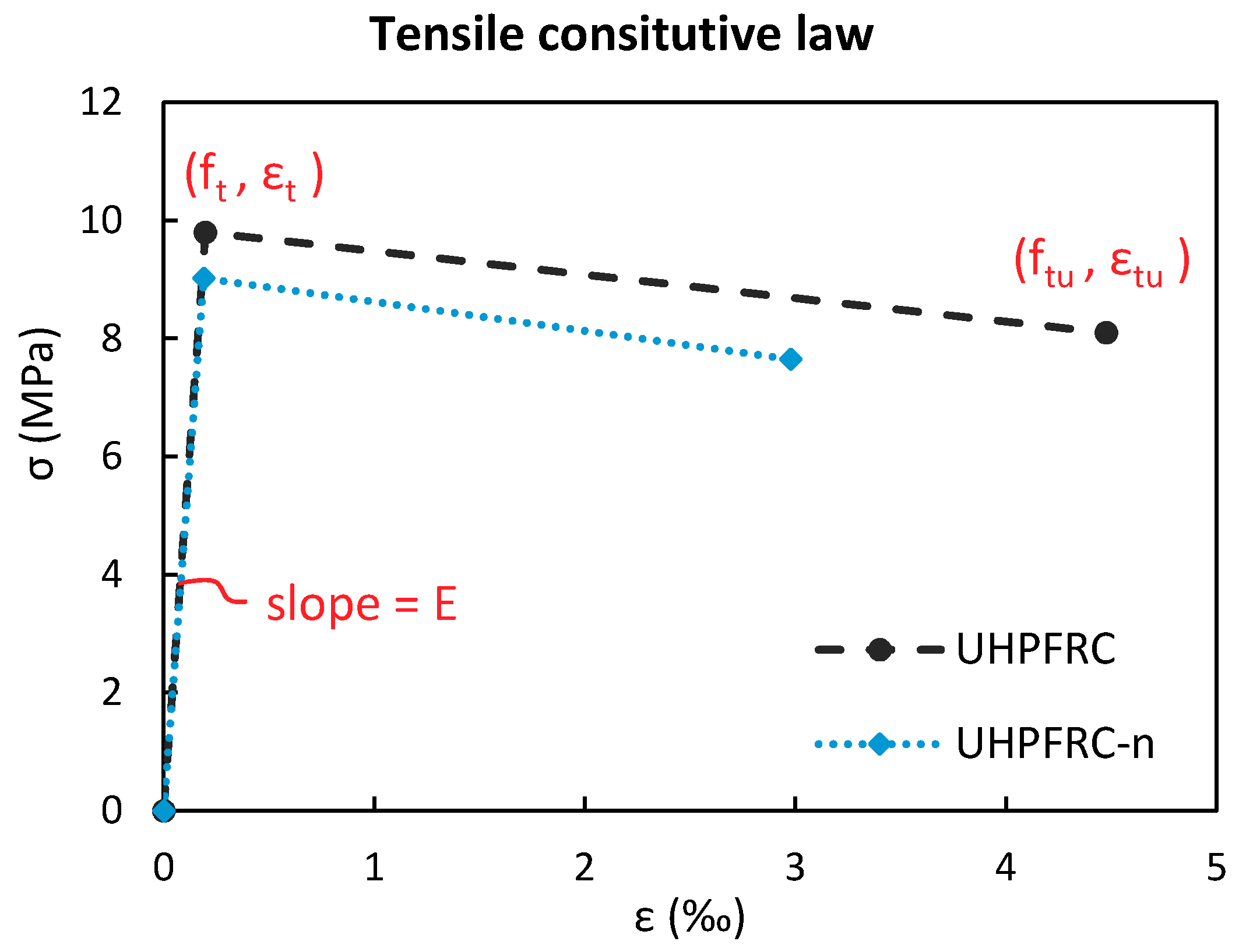

2.2.2. Flexural—Tensile Strength of UHFPRCs

2.2.3. Air Permeability, Absorption, and Porosity Accessible to Water

2.3. Methodology and Experimental Program in Cracked State

2.3.1. Concept and Experimental Program

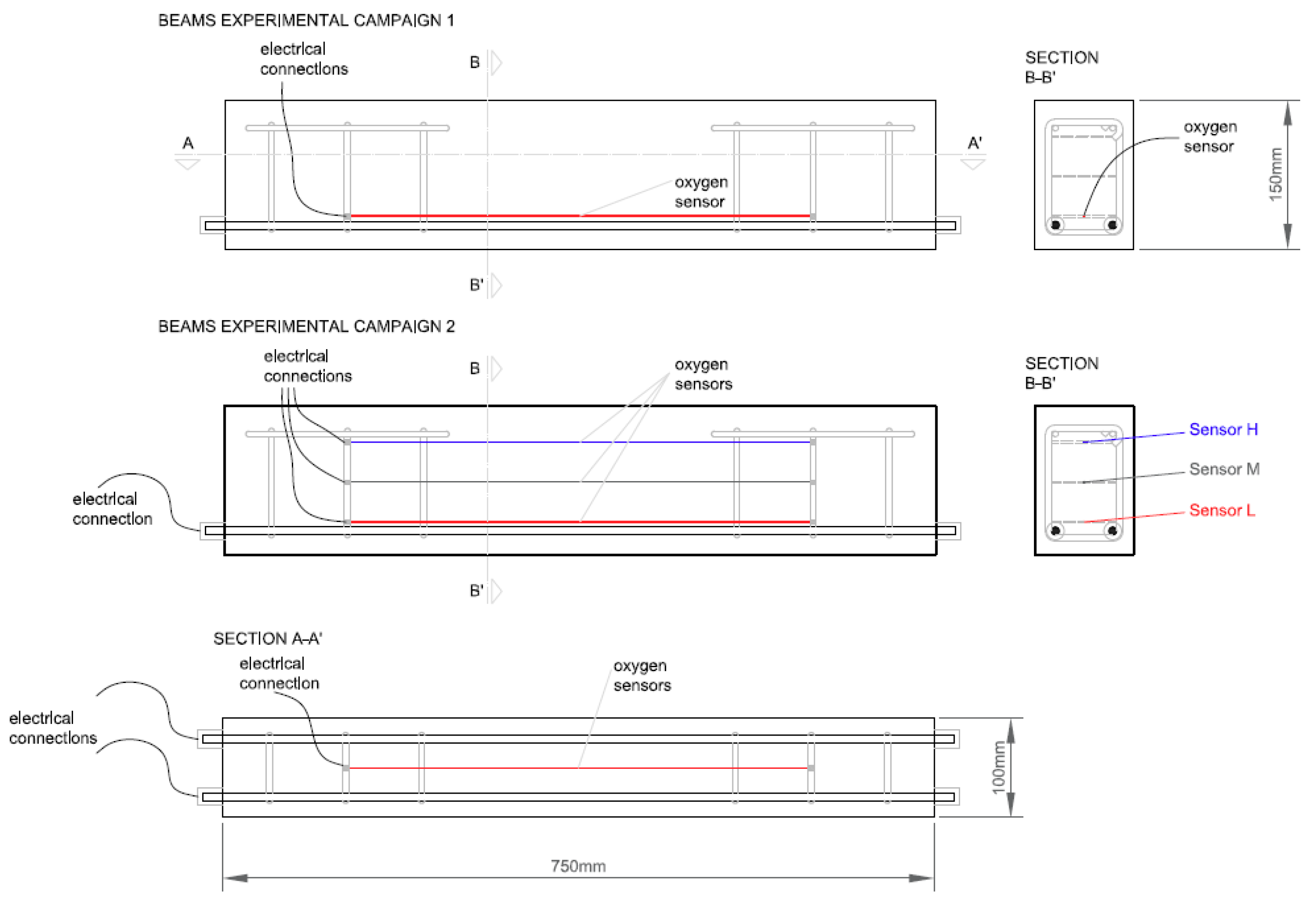

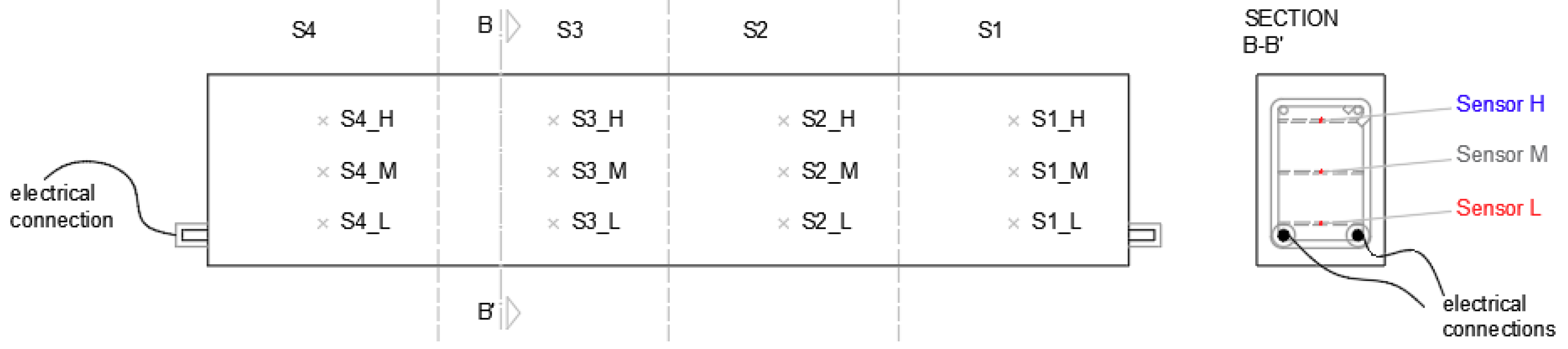

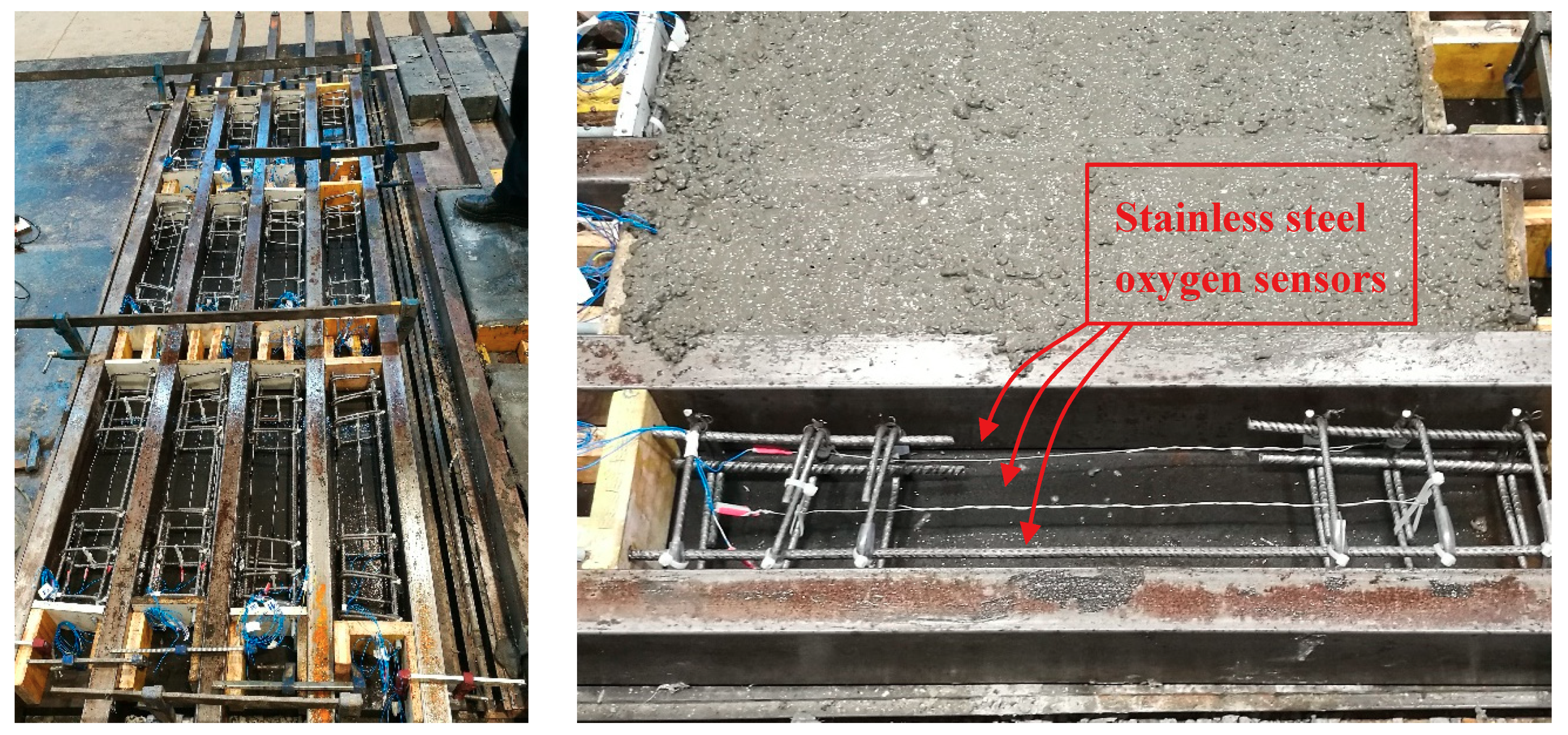

2.3.2. Preparation of the Beams and Casting

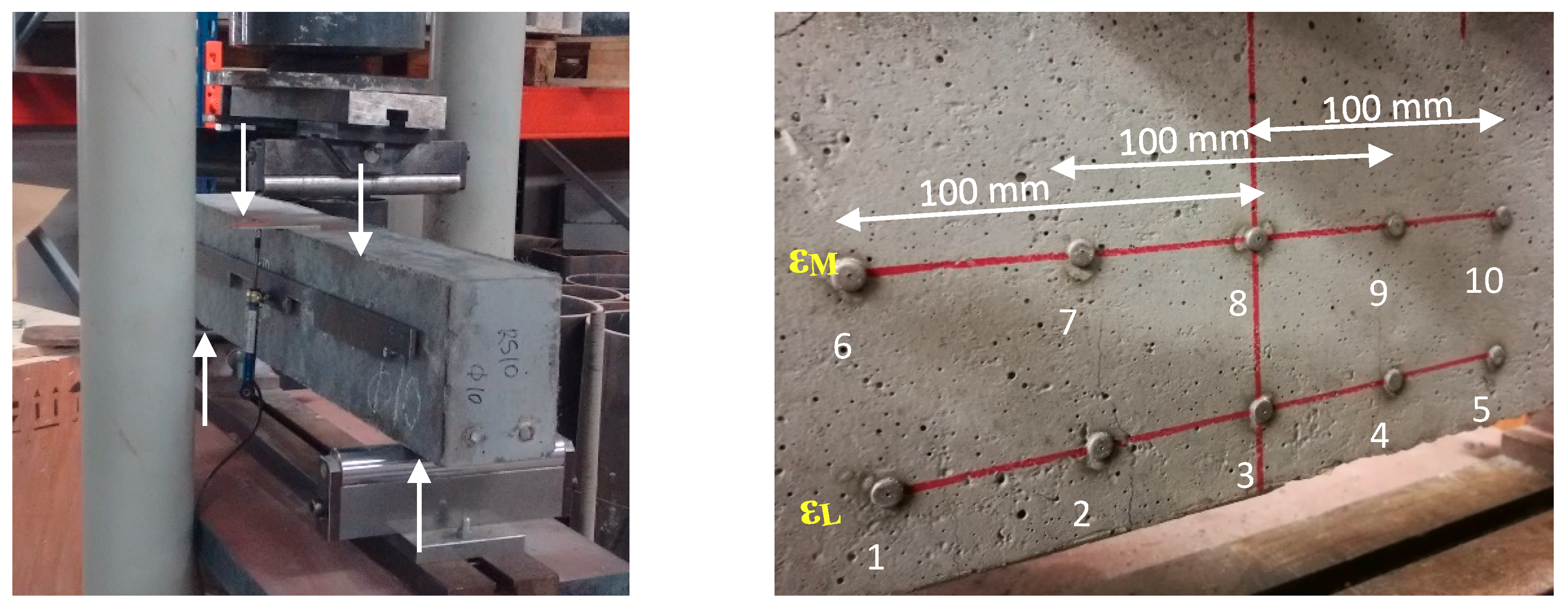

2.3.3. Pre-Cracking Procedure

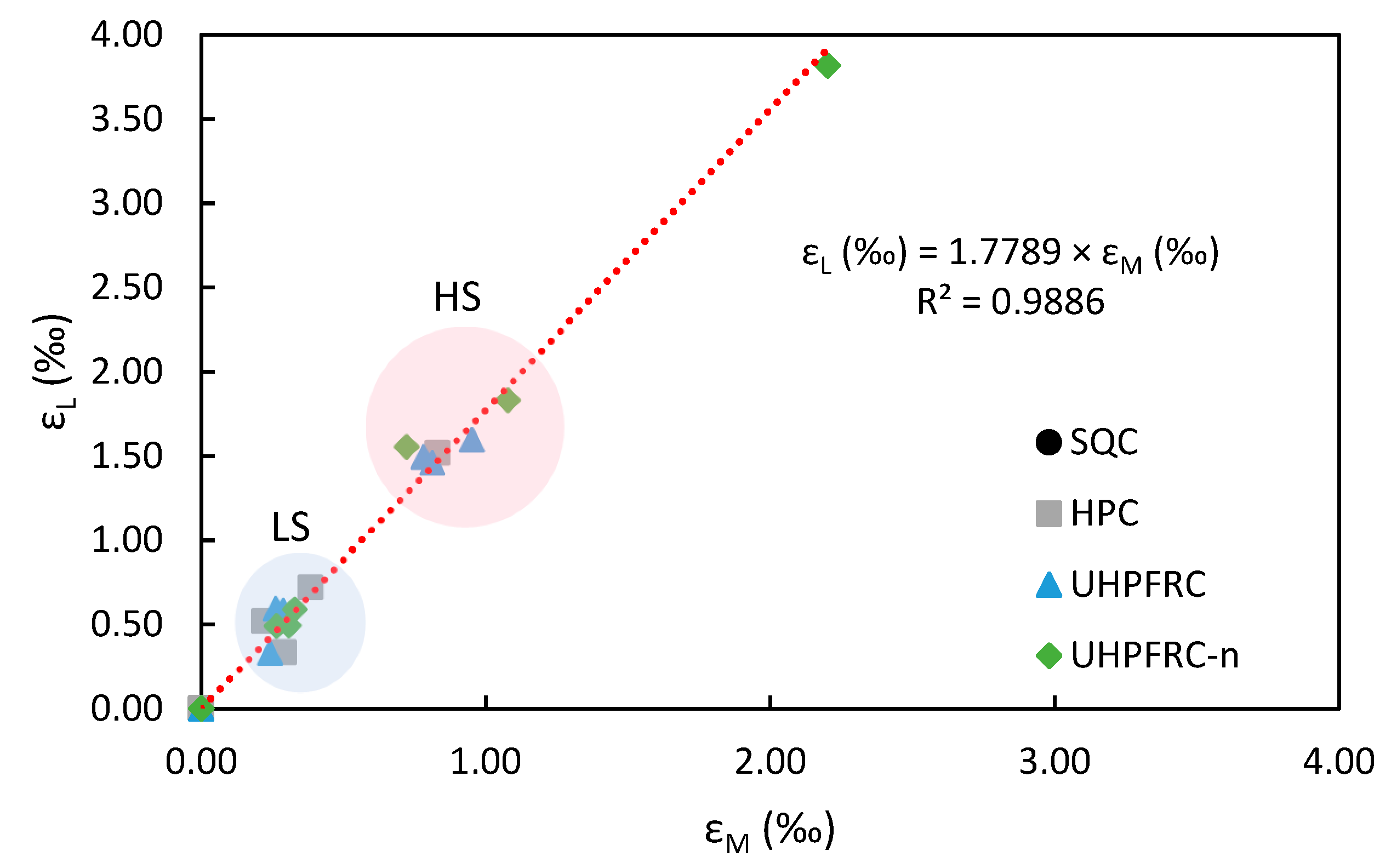

- Low Strain level (LS): average strain εM,avg at middle height of the beam around 0.5‰ as measured in loaded conditions. This level represents a condition inside the service limit state, in which a crack has been produced and it has been closed afterwards. This level produced one or two localized cracks of widths below 0.1 mm in traditional concretes and a series of very closed micro-crack of 10–15 microns in UHPFRCs at the reinforcement level.

- High Strain level (HS): average strain εL,avg at the reinforcement level between 1‰ and 2‰ as measured after unloading. The condition used in practice was when the averaged strain of the three intervals exceeded the value of 1.5‰, since strain was measured between three intervals. This level represents a condition beyond the service limit state, with yielded or almost yielded rebars. This level produced localized cracks between 0.2–0.3 mm in traditional concretes and multiple micro-cracks of 25–50 microns in UHPFRCs at the reinforcement level. This cracking level represents a highly demanding condition, which is common for concrete structures in aggressive environments.

2.3.4. Voltammetry Analysis to Detect Cracks

3. Results and Discussion

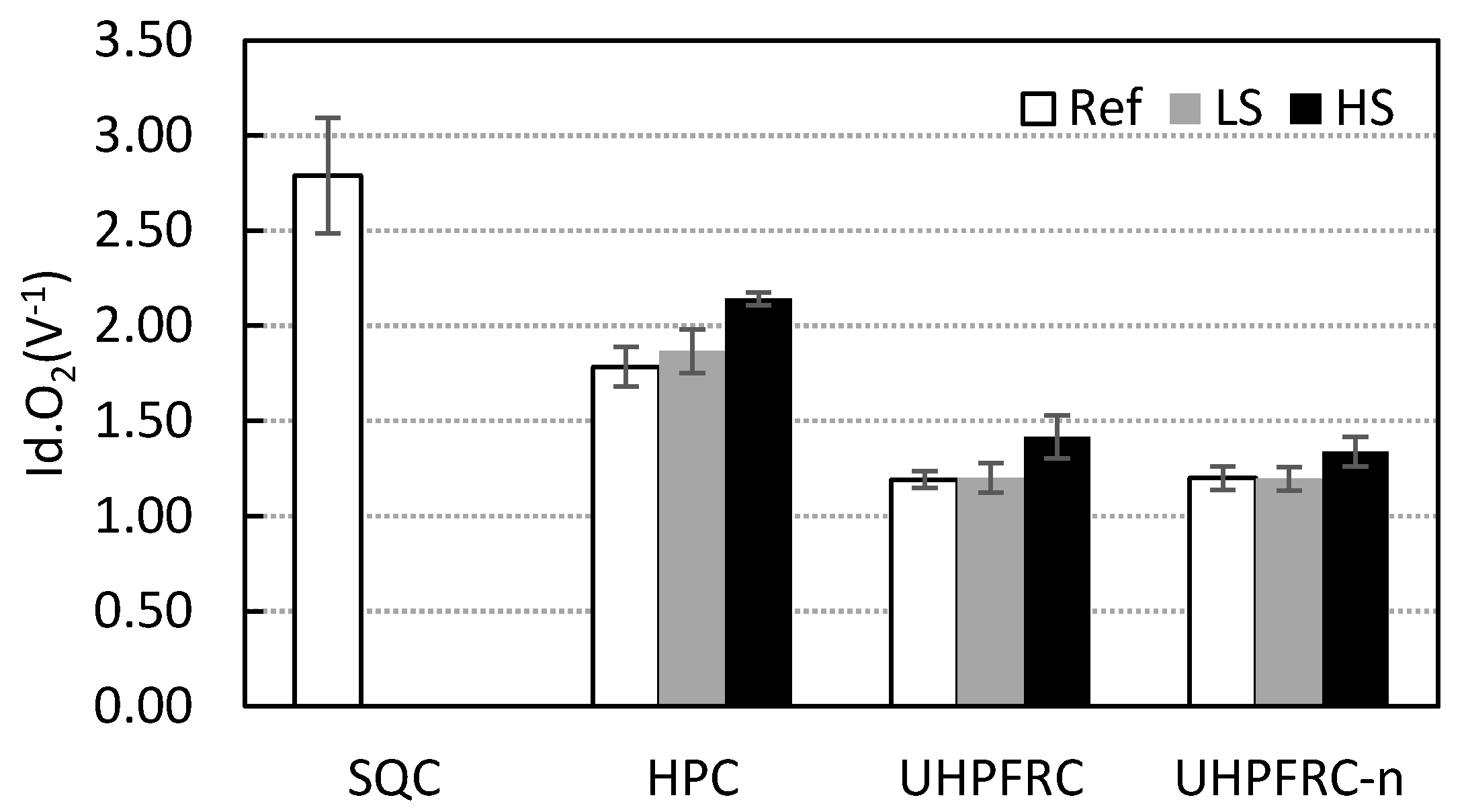

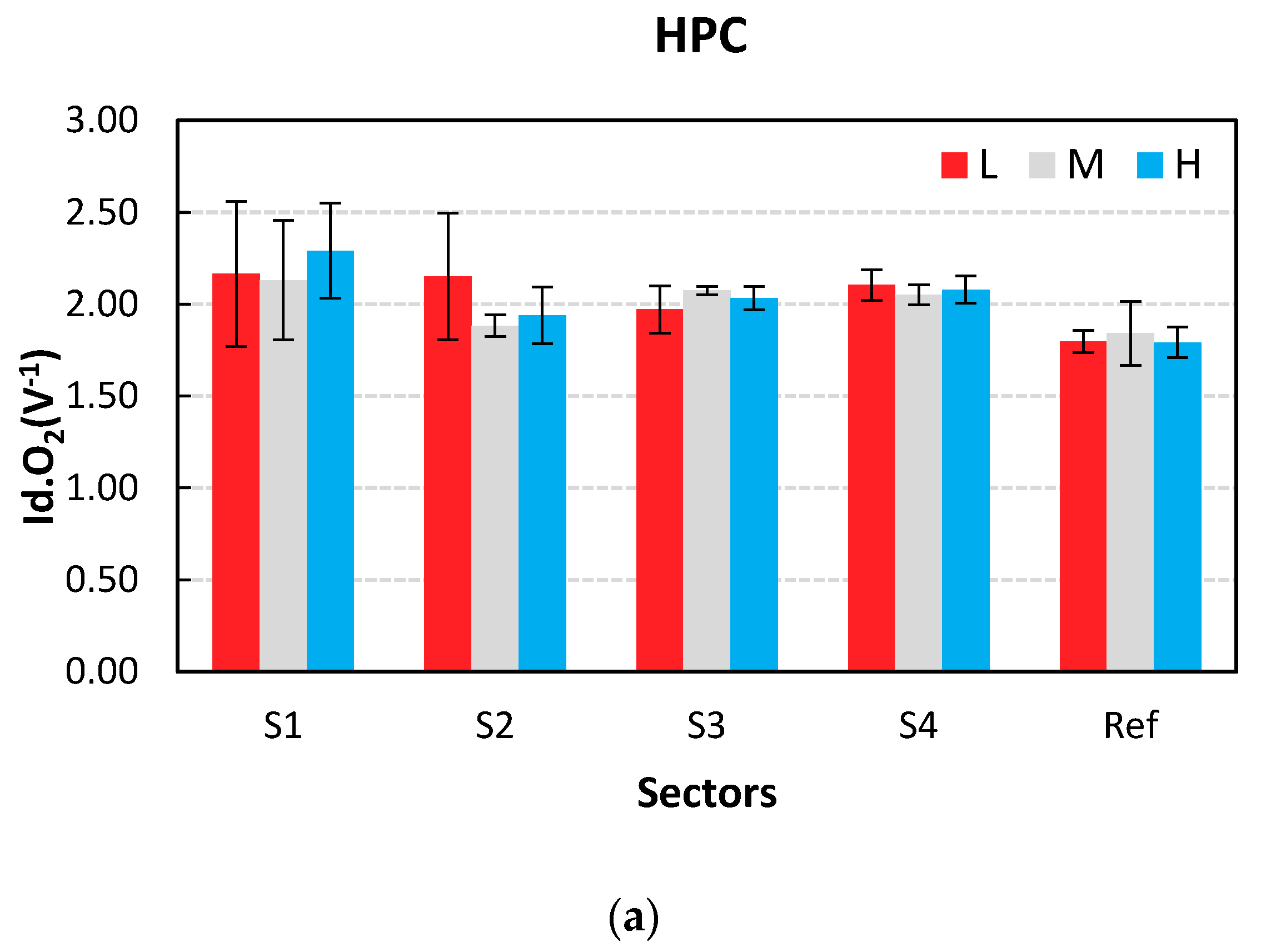

3.1. Experimental Campaign 1: Effect of Concrete Type on Cracking through Oxygen Availability

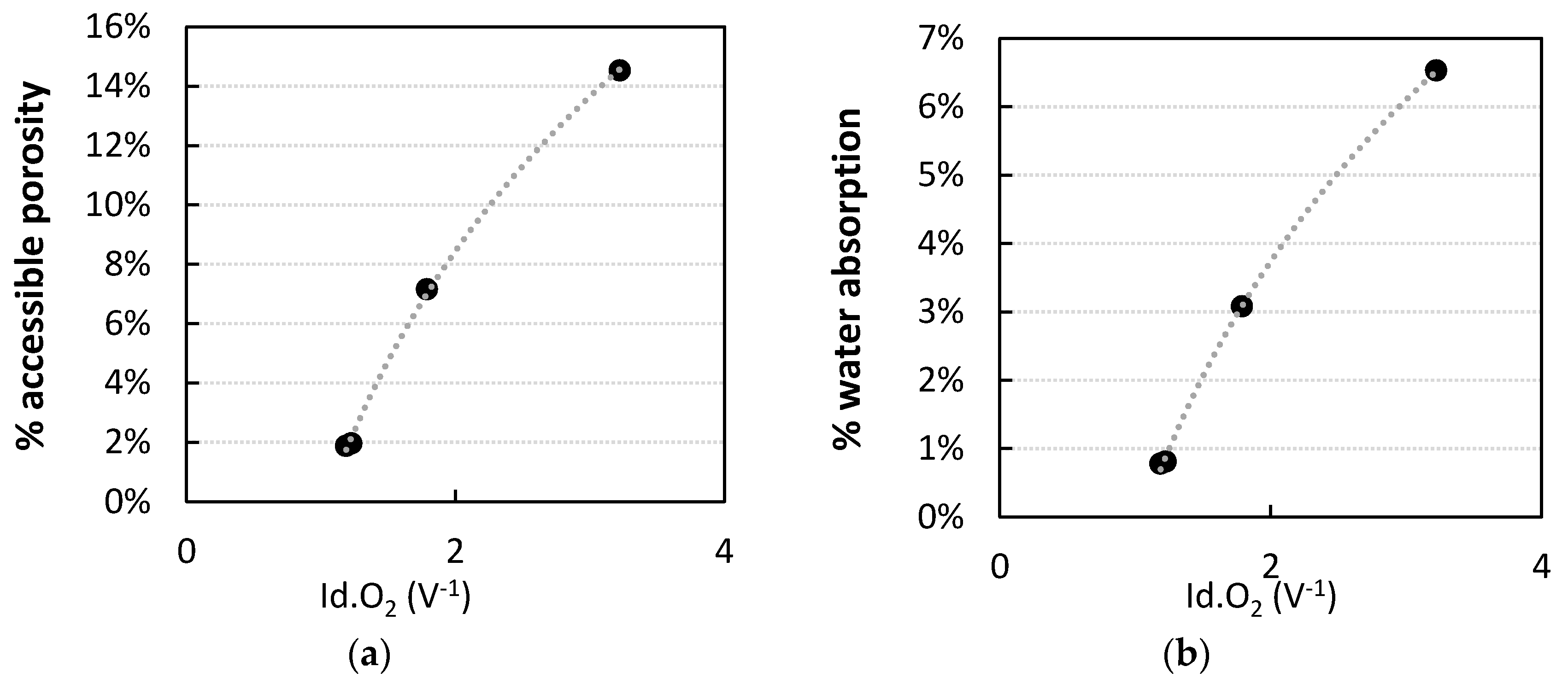

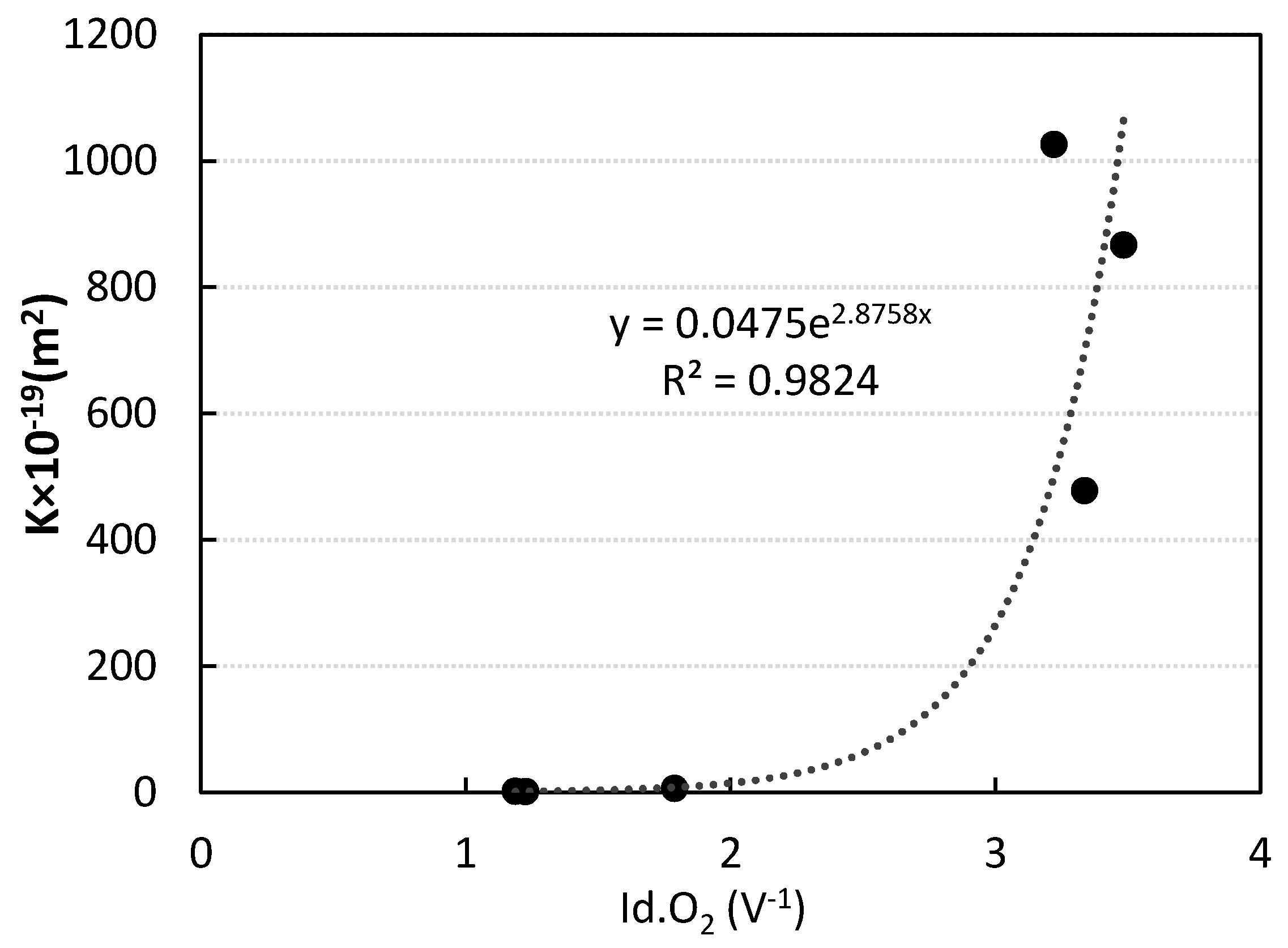

3.2. Discussion: Oxygen Availability Relation with Porosity and Permeability

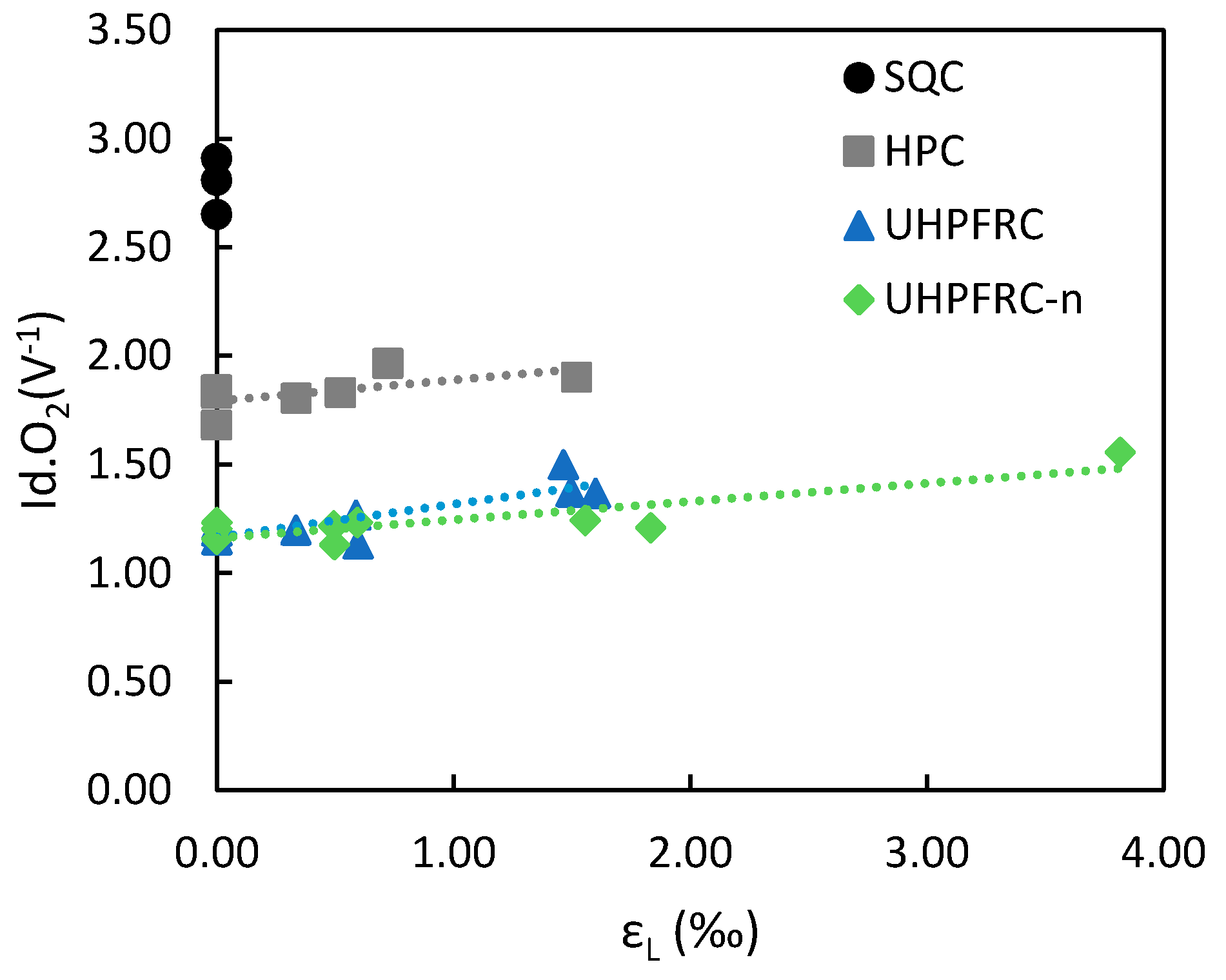

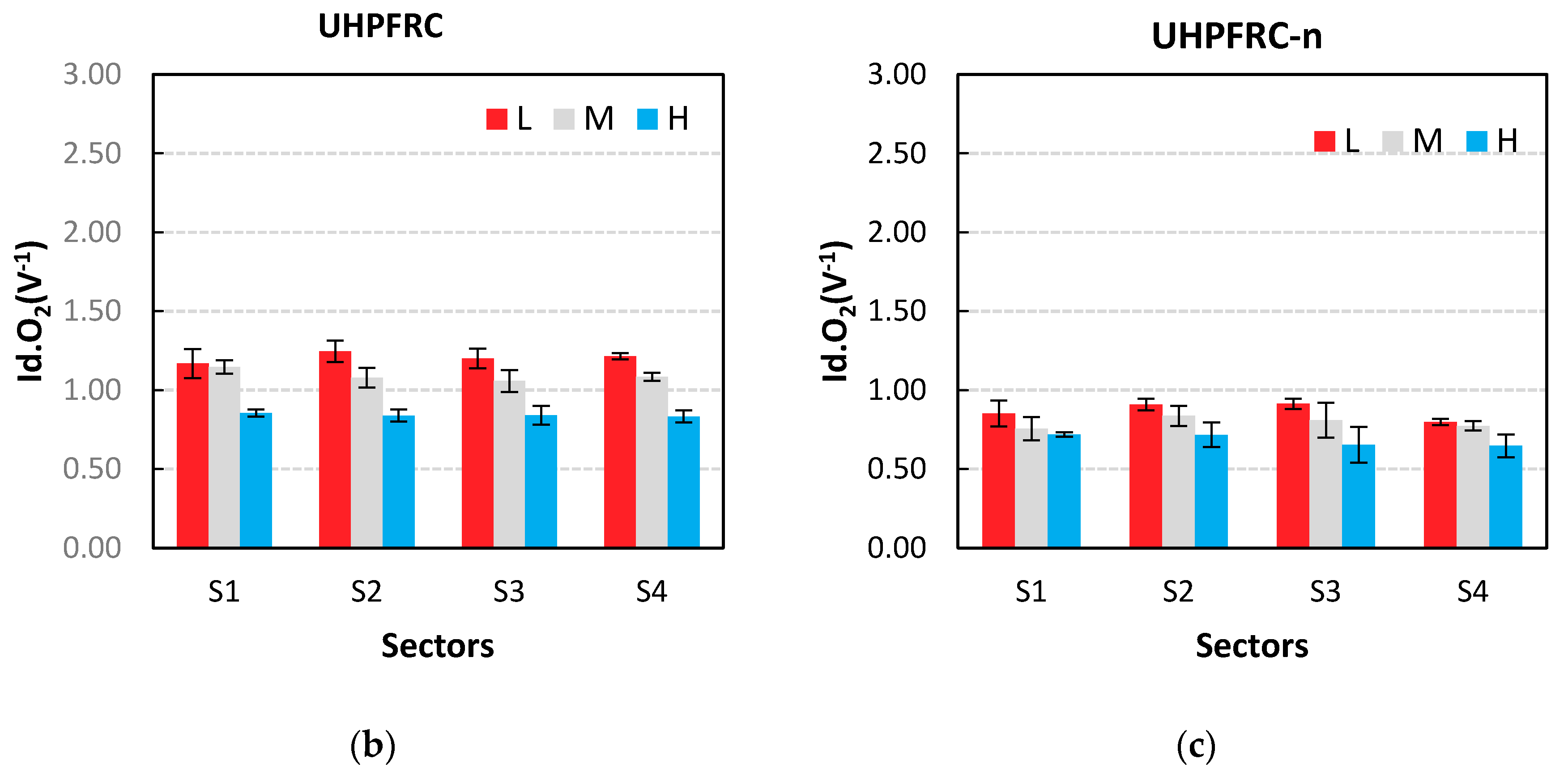

3.3. Experimental Campaign 2: Sensitivity of the Sensor at Different Locations

4. Conclusions

- The stainless steel voltammetric sensor used in this work and the Id.O2 parameter were able to detect variations in the availability of oxygen and, thus, detect differences in size of cracks produced in reinforced concrete in the range of 0.1–0.3 mm, as well as smaller cracks in the range of microns. This sensor was also able to detect differences in crack pattern for a same concrete type, depending on the zone that is measured. The study of the sensitivity of the sensor at different locations in UHPFRCs shows that oxygen availability decreased while going towards the upper part of the beam, as the crack width was thinner.

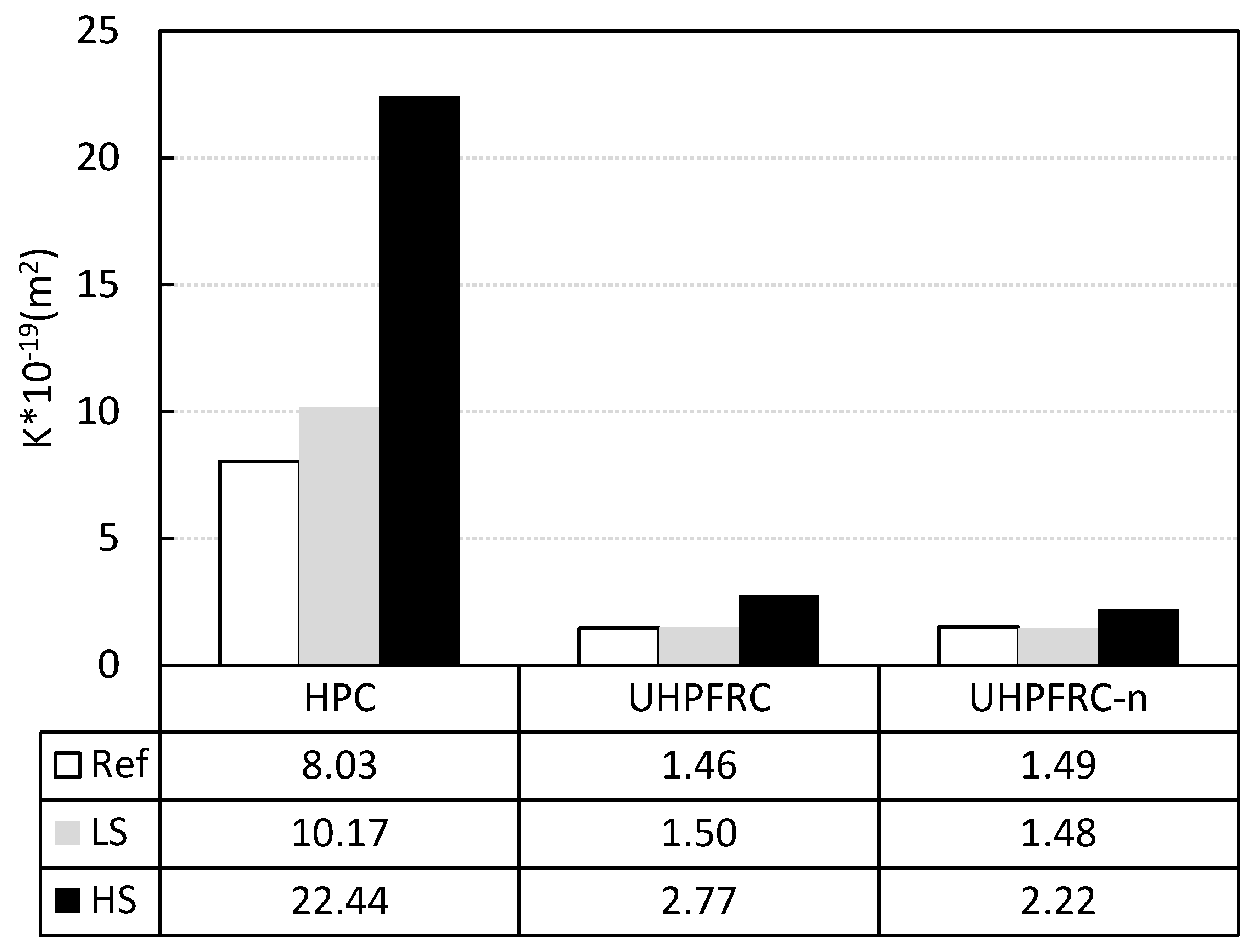

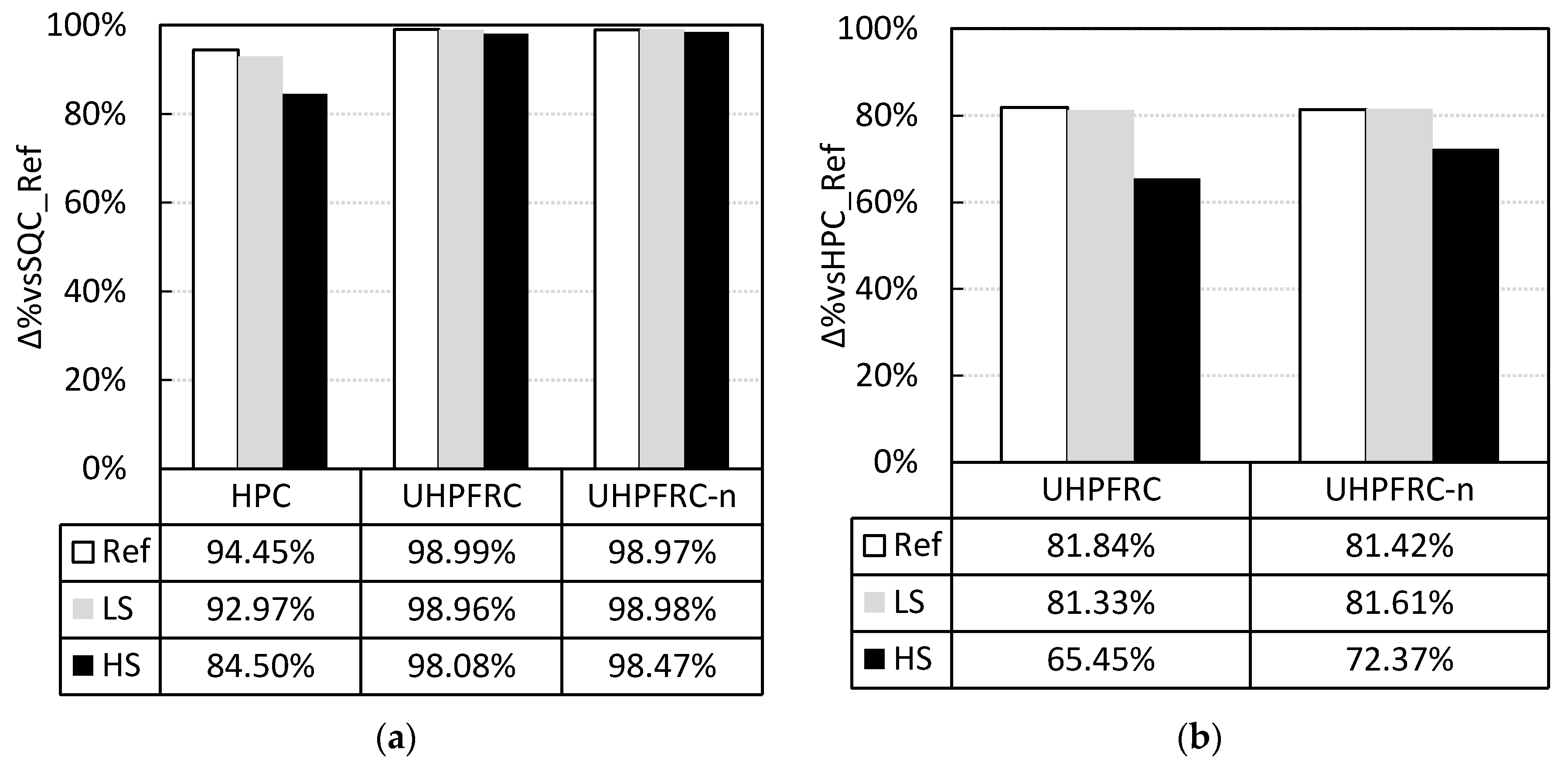

- In uncracked conditions, HPC and UHPFRCs improved the air permeability coefficient by three orders of magnitude, and the absorption and porosity to water by one order of magnitude. For cracked conditions, the air permeability coefficient for cracked concrete has been estimated through a correlation model. The obtained results show that cracked UHPFRCs improved 65–80% the values of uncracked HPC and 98–99% the values of uncracked SQC. This improvement is produced by the compacity of UHPFRCs matrices and their diffused micro-crack pattern.

- Oxygen availability, as measured in UHPFRC and UHPFRC-n with the stainless steel sensor, indicates that cracked UHPFRCs registered improvements in the Id.O2 parameter in the range of 20–30% comparing to uncracked HPC and 50–60% when comparing to uncracked SQC.

- Increasing the damage level or strain in HPC beams increased the presence of oxygen in 5% for LS and 20% for HS when compared to the uncracked level. In the case of UHPFRCs, the beams cracked to LS conditions showed the same oxygen availability than uncracked beams. However, the beams cracked at the HS level experienced increments between 11 and 19% for UHPFRC and UHPFRC-n.

- This work demonstrates that multi-cracking patterns are more beneficial in terms of air transport than single crack patterns for a comparable strain level, especially for small strain levels, and that using these concretes in construction will potentially produce high durability structures with an extended service life, even after suffering cracks.

Author Contributions

Funding

Conflicts of Interest

References

- Du Beton, F.I. International Federation for Structural Concrete (fib). In Fib Model Code for Concrete Structures 2010; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Ahlborn, T.; Misson, D.; Peuse, E.; Gilbertson, C. Durability and strength characterization of ultra-high performance concrete under variable curing regimes. In Proceedings of the Second International Symposium on Ultra High Performance Concrete, Kassel, Germany, 5–7 March 2008; ISBN 978-3-89958-376-2. [Google Scholar]

- van Zijl, G.; Wittmann, F. Durability of Strain-Hardening Fibre-Reinforced Cement-Based Composites (SHCC). Rilem State Art Rep. 2011. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites (ECC) A Review of the Material and Its Applications. J. Adv. Concr. Technol. 2003, 1, 215–230. Available online: http://hdl.handle.net/2027.42/84703 (accessed on 28 December 2019). [CrossRef]

- Asgari, M.A.; Mastali, M.; Dalvand, A.; Abdollahnejad, Z. Development of deflection hardening cementitious composites using glass fibres for flexural repairing/strengthening concrete beams: Experimental and numerical studies. Eur. J. Environ. Civ. Eng. 2019, 23, 916–944. [Google Scholar] [CrossRef]

- Derucher, K.N. ‘Failure mechanism of concrete’ in Composite Materials: Testing and Design (Fifth Conference). In ASTM STP 674; Tsai, S.W., Ed.; American Society for Testing and Materials: Philadelphia, PA, USA, 1982; pp. 664–679. [Google Scholar]

- Ravindrarajah, R.S.; Swamy, R.N. Load effects on fracture of concrete. Mater. Struct. 1989, 22, 15–22. [Google Scholar] [CrossRef]

- Bascoul, A. State of the art report—Part 2: Mechanical micro-cracking of concrete. Mater. Struct. 1996, 29, 67–78. [Google Scholar] [CrossRef]

- Damgaard-Jensen, A.; Chatterji, S. State of the art report on micro-cracking and lifetime of concrete—Part I. Mater. Struct. 1996, 29, 3–8. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Löfgren, I.; Lundgren, K.; Görander, N.; Halldén, C. Characterisation of bending cracks in R/FRC using image analysis. Cem. Concr. Res. 2016, 90, 104–116. [Google Scholar] [CrossRef]

- Correia, M.J.; Pereira, E.; Salta, M.; Fonseca, I. Sensor for oxygen evaluation in concrete. Cem. Concr. Compos. 2006, 28, 226–232. [Google Scholar] [CrossRef]

- Yoon, I.-S. Comprehensive Approach to Calculate Oxygen Diffusivity of Cementitious Materials Considering Carbonation. Int. J. Concr. Struct. Mater. 2018, 12, 16. [Google Scholar] [CrossRef]

- Banthia, N.; Zanotti, C.; Sappakittipakorn, M. Sustainable fiber reinforced concrete for repair applications. Constr. Build. Mater. 2014, 67, 405–412. [Google Scholar] [CrossRef]

- Berrocal, L.I.; G, C.; Lundgren, K. The effect of fibres on steel bar corrosion and flexural behaviour of corroded RC beams. Eng. Struct. 2018, 163, 409–425. [Google Scholar] [CrossRef]

- Zamora, J.R. Sistema de Sensores Embebidos para Monitorizar la Corrosión en Estructuras de Hormigón Armado. Fundamentos, Metodología y Aplicaciones. Ph.D. Thesis, Universitat Politècnica de València, València, Spain, 2018. [Google Scholar]

- Martínez-Ibernón, A.; Gandía-Romero, J.; Lliso-Ferrando, J.; Soto, J. Determination of oxygen availability in concrete by means of voltammetric sensors. In Proceedings of the EUROCORR 2019, Sevilla, Spain, 8–13 September 2019. [Google Scholar]

- Sisomphon, K.; Copuroglu, O.; Koenders, E. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Carsana, M. A “fracture testing” based approach to assess crack healing of concrete with and without crystalline admixtures. Constr. Build. Mater. 2014, 68, 535–551. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Pirritano, F.; Serna, P.; Ferrara, L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr. Build. Mater. 2016, 114, 447–457. [Google Scholar] [CrossRef]

- López, J.Á.; Serna, P.; Navarro-Gregori, J.; Camacho, E. An inverse analysis method based on deflection to curvature transformation to determine the tensile properties of UHPFRC. Mater. Struct. 2015, 48, 3703–3718. [Google Scholar] [CrossRef]

- Martínez, J.L. Characterisation of the Tensile Behaviour of UHPC by Means of Four-Point Bending Tests. Ph.D. Thesis, Universitat Politècnica de València, València, Spain, 2017. [Google Scholar]

- Lopez, J.A.; Serna, P.; Camacho, E.; Coll, H.; Navarro-Gregori, J. First ultra-high-performance fibre-reinforced concrete footbridge in Spain: Design and construction. Struct. Eng. Int. 2014, 24, 101–104. [Google Scholar] [CrossRef]

- Resplendino, J.; Petitjean, J. French recommendations for ultra-high performance fiber-reinforced concretes. In Proceedings of the International RILEM Workshop on Test and Design Methods for Steel Fibre Reinforced Concrete, Bochum, Germany, 20–21 March 2003. [Google Scholar]

- Negrini, A.; Roig-Flores, M.; Mezquida-Alcaraz, E.; Ferrara, L.; Serna, P. Effect of crack pattern on the self-healing capability in traditional, HPC and UHPFRC concretes measured by water and chloride permeability. In Proceedings of the 7th International Conference on Concrete Repair, Cluj Napoca, Romania, 30 September–2 October 2019; Volume 289. [Google Scholar] [CrossRef]

- AFGC Groupe de travail BFUP. Bétons fibrés à ultra-hautes performances. In Recommandations—Ultra High Performance Fibre-Reinforced Concretes; AFGC Groupe de travail BFUP: Paris, France, 2013. [Google Scholar]

| Kg/m3 | SQC | HPC | UHPFRC | UHPFRC-n |

|---|---|---|---|---|

| Cement I 42.5 R-SR5 | 350 | 450 | 800 | 800 |

| Silica Fume | 50 | 175 | 175 | |

| Water | 192 | 160 | 160 | 165.0 |

| w/c | 0.591 | 0.356 | 0.200 | 0.206 |

| w/b | 0.591 | 0.320 | 0.164 | 0.169 |

| Aggregate 7/12 | 600 | 200 | ||

| Aggregate 4/7 | 300 | 600 | ||

| Natural sand | 950 | 950 | ||

| Limestone filler | 60 | |||

| Siliceous sand–medium 0/1.6 mm | 565 | 565 | ||

| Siliceous sand–fine 0/0.5 mm | 302 | 302 | ||

| Siliceous sand–flour (<50 μm) | 225 | 225 | ||

| Short steel fibers 13/0.2 | 160 | 160 | ||

| Superplasticizer A | 0.7 | |||

| Superplasticizer B | 5.5 | 30 | 30 | |

| Crystalline admixture | 7.8 | |||

| Alumina nanofibers | 2.438 | |||

| Slump or [slump flow] (mm) | 180 | 190 | 700 | 620 |

| Compressive strength at 28d (MPa) | 40.2 | 79.8 | 144.7 | 133.6 |

| Concrete Type | Spec. | Constitutive Tensile Law | ||||

|---|---|---|---|---|---|---|

| ft (MPa) | ftu (MPa) | εtu (‰) | E (MPa) | ωo (mm) | ||

| UHPFRC | avg. | 9.80 | 8.10 | 4.48 | 49,639 | 2.87 |

| CV | 6.74% | 17.72% | 24.86% | 4.77% | 16.46% | |

| UHPFRC-n | avg. | 9.02 | 7.65 | 2.98 | 47,517 | 2.49 |

| CV | 11.28% | 11.79% | 52.63% | 1.72% | 14.69% | |

| Air Permeability coef. (10−19 m2) | CV | % Porosity Accessible to Water | CV | % Water Absorption | CV | |

|---|---|---|---|---|---|---|

| SQC | 1030 | 11.07% | 14.53% | 3.00% | 6.53% | 3.53% |

| HPC | 6.23 | 29.96% | 7.15% | 3.20% | 3.08% | 3.25% |

| UHPFRC | 1.38 | 26.48% | 1.96% | 3.56% | 0.81% | 3.63% |

| UHPRFC-n | 1.94 | 30.10% | 1.87% | 13.18% | 0.78% | 13.11% |

| Experimental Campaign 1 | Experimental Campaign 2 | |||||||

|---|---|---|---|---|---|---|---|---|

| Single Crack Pattern | Multiple Cracks Pattern | |||||||

| Concrete | Crack Level | No. | Concrete | Crack Level | No. | Concrete | Crack Level | No. |

| SQC | Uncracked | 3 | UHPFRC | Uncracked | 3 | HPC | High Strain | 1 |

| HPC | Uncracked | 3 | Low Strain | 3 | UHPFRC | High Strain | 1 | |

| Low Strain | 3 | High Strain | 3 | UHPFRC-n | High Strain | 1 | ||

| High Strain | 1 | |||||||

| UHPFRC-n | Uncracked | 3 | ||||||

| Low Strain | 3 | |||||||

| High Strain | 3 | |||||||

| Δ% vs. SQC_Ref | Δ% vs. HPC_Ref | ||||

|---|---|---|---|---|---|

| HPC | UHPFRC | UHPFRC-n | UHPFRC | UHPFRC-n | |

| Ref | 36.05% | 57.32% | 57.03% | 33.26% | 32.81% |

| LS | 33.10% | 56.97% | 57.16% | 32.71% | 33.01% |

| HS | 23.24% | 49.30% | 52.09% | 20.72% | 25.07% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martínez-Ibernón, A.; Roig-Flores, M.; Lliso-Ferrando, J.; Mezquida-Alcaraz, E.J.; Valcuende, M.; Serna, P. Influence of Cracking on Oxygen Transport in UHPFRC Using Stainless Steel Sensors. Appl. Sci. 2020, 10, 239. https://doi.org/10.3390/app10010239

Martínez-Ibernón A, Roig-Flores M, Lliso-Ferrando J, Mezquida-Alcaraz EJ, Valcuende M, Serna P. Influence of Cracking on Oxygen Transport in UHPFRC Using Stainless Steel Sensors. Applied Sciences. 2020; 10(1):239. https://doi.org/10.3390/app10010239

Chicago/Turabian StyleMartínez-Ibernón, Ana, Marta Roig-Flores, Josep Lliso-Ferrando, Eduardo J. Mezquida-Alcaraz, Manuel Valcuende, and Pedro Serna. 2020. "Influence of Cracking on Oxygen Transport in UHPFRC Using Stainless Steel Sensors" Applied Sciences 10, no. 1: 239. https://doi.org/10.3390/app10010239

APA StyleMartínez-Ibernón, A., Roig-Flores, M., Lliso-Ferrando, J., Mezquida-Alcaraz, E. J., Valcuende, M., & Serna, P. (2020). Influence of Cracking on Oxygen Transport in UHPFRC Using Stainless Steel Sensors. Applied Sciences, 10(1), 239. https://doi.org/10.3390/app10010239