Abstract

The search for more sustainable construction materials, capable of complying with quality standards and current innovation policies, aimed at saving natural resources and reducing global pollution, is one of the greatest present societal challenges. In this study, an innovative recycled aggregate concrete (RAC) is designed and produced based on the use of a coarse recycled aggregate (CRA) crushing concrete with electric arc furnace slags as aggregate. These slags are a by-product of the steelmaking industry and their use, which avoids the use of natural aggregates, is a new trend in concrete and pavement technology. This paper has investigated the effects of incorporating this type of CRA in concrete at several replacement levels (0%, 20%, 50% and 100% by volume), by means of the physical, mechanical and durability characterization of the mixes. The analysis of the results has allowed the benefits and disadvantages of these new CRAs to be established, by comparing them with those of a natural aggregate concrete (NAC) mix (with 0% CRA incorporation) and with the data available in the literature for concrete made with more common CRA based on construction and demolition waste (CDW). Compared to NAC, similar compressive strength and tensile strength values for all replacement ratios have been obtained. The modulus of elasticity, the resistance to chloride penetration and the resistance to carbonation are less affected by these CRA than when CRA from CDW waste is used. Slight increases in bulk density over 7% were observed for total replacement. Overall, functionally good mechanical and durability properties have been obtained.

1. Introduction

Approximately 90% of construction and demolition wastes (CDW) are currently going to landfills even though they are potentially recyclable [1]. The use of this waste should be a priority to achieve the sustainable development objectives set by the European Commission, although this action is hindered due to lack of facilities and standards, lack of support from governments or lack of users’ confidence [1,2]. The use of CDW as aggregates in concrete production, mostly coarse recycled aggregates (CRA), not only means a saving of natural resources derived from the extraction of aggregate, but also economic savings. Analogously, concrete with electric arc furnace slags (EAFS) as aggregate is based on the use of waste (from the steel industry) that would otherwise be deposited in landfills. In this case, the reduction of CO2 emissions in the processes without taking into account the transport and manufacturing of the materials can be as high as 35% [3]. On the other hand, CO2 emissions induced by concrete crushing are not very different from those generated in the production of natural aggregates [4].

To improve the understanding of the paper, the acronyms used and their meaning are shown in Table 1.

Table 1.

Acronyms used in the article.

Most CRA are produced by crushing concrete that has ended its service life, i.e., they are composed mainly of natural stone and attached mortar. Typically, CRA are materials with lower density and porosity than natural aggregates (NA) because the attached mortar is less dense and more porous than the natural aggregate that it covers. The average density can be 8% lower and the average water absorption 5–6 times those of the natural aggregates [5,6]. According to the current Spanish concrete standards, the aggregates’ water absorption must be less than 5% to be used in structural concrete [7,8]. According to Etxeberría et al. [9], the shape index of NA is 25% and 28% for CRA produced in quarries, although its value depends on the crushing process. Typically, laboratory-produced CRA are made with a single crushing stage (usually a jaw crusher), whilst NA are produced with multiple crushing (primary, secondary and sometimes tertiary). De Brito et al. [10] found that when CRA go through the same crushing process as NA their shape index is expected to be lower than that of NA. The water absorption and the shape index are vital for the calculation of the compensation water to determine the total water/cement (w/c) ratio [11].

There are many studies on the use of recycled aggregate (RA) in the production of structural concrete. Most of them only consider replacement of the coarse fraction of the aggregates, because the fine fraction has a great cohesion and water absorption that make it difficult to control the quality of the aggregates [12] and reduce the workability in the fresh state [13]. The risk of contamination of the finer fraction is also higher [14].

The use of CRA is more common also because it has less porosity and adhered paste. Typically, CRA concrete is around 4%–8% less dense [15,16,17], although this effect can be the opposite for high density CRA (e.g., CRA based on EAFS). The water absorption of these CRA concretes can be 500% higher than that of NA concrete (NAC) [18,19], although it tends to decrease due to the crystallization of hydration products, depending on the crushing age of the source concrete and curing conditions [20,21,22]. The fresh workability with CRA is lower than that of NAC for equal w/c effective ratios, so it is important to correct the water content to achieve similar slump without the help of admixtures [16,23,24,25,26,27,28].

One of the main characteristics of this concrete is the presence of three interfacial transition zone (ITZ). One is between the original aggregate of CRA and the cement paste in the source concrete and it is formed by dense hydrates, and in the case of EAFS concrete is of higher quality than with NA [29]. Another is between the old cement paste and the new paste, and the third ITZ is between the NA of the recycled aggregate and the new cement paste. The two ITZs between recycled aggregate (stone and mortar) and the new paste are where the chemical reactions between both generate loose and pore interfaces [30,31]. These ITZs are thus weaker and limit the mechanical properties of CRA [30]. Concrete with 100% CRA shows a loss in compressive strength with respect to coarse NA at 28 days, for the same effective w/c ratio and amount of cement, from 10% to 37% [9,17,27,32,33,34], approximately proportional to the replacement level [35,36] and depending on the relative strength of the new paste and CRA [37]. This decrease in compressive strength may make it necessary to use about 5% more cement to achieve the same strength as with NA, thus compromising the cost-effectiveness and sustainability of CRA [9,12]. From 28 to 91 days, the relative increase in compressive strength with recycled aggregate concrete (RAC) is sometimes greater than with NA due to the hydration of unhydrated cement grains [37]. The splitting tensile strength is typically lower but often not by as much as compressive strength, but there are studies where the tensile strength can even be higher with CRA than with NA [9,38], while the modulus of elasticity can decrease by 15% for 30% replacement and 45% for 100% replacement [35,39]. This reduction is because CRA has a lower modulus of elasticity than NA and due to the increase in the effective w/c ratio to maintain workability constant. Reductions in the modulus of elasticity result in increases in the peak strain of concrete under monotonic compression—[32] reports an increase of 20% for aggregate replacement of 100%. It is also known that the use of CRA but also the new cement paste affect the fatigue behaviour of concrete, reducing the fatigue limit and fatigue life [40,41]. Other authors have shown that the multi-recycling of the concrete that contain CRA is limited and that after three recycling cycles, CRA are mostly composed of mortar and new NA are needed in the mix design [42].

The drying shrinkage of concrete with CRA can be 50% higher [43] than with coarse NA, while chloride ions’ penetration can reach up to 150% increases [24,44] due to the high permeability of this concrete. Resistance to carbonation is linked to the porosity of concrete [15] and, therefore, to the porosity of CRA, although it is also strongly linked to the chemical composition of concrete [24]. The high porosity of CRA makes carbonation depths increase between 22%–187% for 100% replacement [24,33,45] in comparison to NAC. Some authors propose the use of more crushing stages to eliminate the attached mortar and thus obtain rounder and less porous aggregates [45,46], the use of acids or heat to disaggregate the mortar of RCA [47,48], thermo-mechanical processes [49,50] or the use of several mechanical systems for on-site processing [51]. Another solution presented by the literature is the use of crushed bricks or steel slag [13,52] to compensate the loss of strength and durability, due to their pozzolanicity. However, these beneficiation techniques add new steps to the aggregate production process and increase production costs and the environmental impact of CRA production.

Currently, there is an increasing trend towards the use of steel slag in concrete [23]. The use of EAFS as CRA in concrete is a novelty (to the best of the authors’ knowledge, it has never been done before) and its use is justified by the potential benefits of this aggregate and by the boom of its use in recent years mostly in road pavements or hydraulic structures [53]. The characteristics of the source concrete determine the behaviour of the recycled aggregates concrete. Concrete with EAFS offers an improvement in compressive strength by 50% compared to concrete with NA, a slightly higher modulus [54] and a generalized improvement in durability (low water absorption and permeability) [55,56], whereas the roughness of the aggregates allows improving the quality of the new ITZ of CRA. The quality of the CRA from EAFS concrete will compensate the loss of mechanical and durability properties that more common CRA provides, saving natural resources. This concrete has potential applications in foundations, plain concrete walls, or structures where a high self-weight is important (e.g., radiation-proof structures). The results of the physical-mechanical and durability tests, for concrete with coarse replacements of 0%, 20%, 50% and 100% by CRA, will be analysed and discussed, establishing the suitability of their use.

2. Materials and Methods

2.1. Materials

In this research, the NA used were: limestone gravel (2/6, 6/12 and 12/20 mm), and silica sand (0/2 and 0/4 mm) to produce the reference concrete. For the manufacture of RAC, CRA obtained from the crushing of concrete with EAFS (using a jaw crusher) 2 months old has been used. The resulting crushing material has a range of grading of 0/25 mm. This EAFS concrete has been manufactured with cement (CEM) I 52.5 R and a w/c ratio of 0.47. This source material presents at 28 days a compressive strength of 88 MPa, a modulus of elasticity of 52 GPa and an oxygen permeability of 6.48 × 10−18 m2. The physical properties of both the NA and RA are shown in Table 2, after performing a measurement. The specific gravity and the water absorption have been determined according to EN 1097-6, the shape index was obtained following the EN 933-4 and Los Angeles wear has been determined according to EN 1097-2. The Portland cement used in RAC is CEM I 42.5 R (European standard), whose density is 3.15 g/cm3 according to UNE 80103, and the mix has been made with tap water.

Table 2.

Characterization of the aggregates.

The obtained water absorption of the CRA meets the requirements of the Spanish standard EHE-08 for structural concrete [7] and is more than twice that of coarse NA. However, this value is very small compared to more common CRA that normally exceeds 5% [5,33,57], although it depends on the size range. The shape index of the CRA is slightly lower than that of the NA and approximately one and a half times the values obtained by Etxeberría et al. [9] for conventional CRA. In terms of workability, these aggregates show a low shape index, but EAFS exposed surface is very cavernous and cause mesh between aggregates, demanding an extra volume of cement paste or mortar to fill the holes in their surface. However, the solid fraction of EAFS is generally much less absorbent than that of NA. Due to its properties, good mechanical and durability properties are expected [39].

2.2. Mix Design

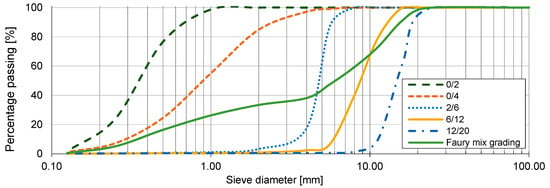

The design of the mix has been made using the Faury method, to obtain maximum compactness. The maximum aggregate size has been set at 20 mm, in accordance with EHE-08. The coarse aggregates (>4 mm, EN 13139) of the reference concrete (NAC) have been replaced at several ratios (20%, 50%, and 100% vol.) with CRA. The content of cement has been set at 350 kg/m3 and the effective w/c ratio of the reference concrete (NAC) at 0.5. The total w/c ratio has been determined by adding compensation water equal to that estimated for the mixing time (10 min) from the water absorption over time test, according to the method proposed by Rodrigues et al. [58]. The strength class of concrete has been defined as C30/37 in accordance with EN 1992-1-1. The slump has been defined as 70 ± 10 mm (S2) according to EN 12350-2 and without plasticizers (in order not to introduce more variables) for all replacement ratios. To maintain the same slump in all the mixes, the effective w/c has been slightly modified. RAC has been manufactured from the theoretical curve of NAC (Figure 1), maintaining between mixes the same volume of aggregates of each sieve fraction, so the mix grading for NAC and for RAC is the same. The mix proportions used are shown in Table 3.

Figure 1.

Theoretical curve and grading of the different aggregates according to EN 933-1.

Table 3.

Concrete mix proportions.

The aggregates were dried at 100 ± 2 °C until constant weight before mixing and the mixing process consisted of a sequence of 4 min with the coarse aggregates and 2/3 of the water, 2 more minutes after adding the fine aggregates and a further 4 min after adding the cement and 1/3 of the water. The concrete was demoulded after 24 h of manufacture and it has been cured in a humidity chamber at 20 ± 2 °C and 95 ± 2% humidity (except for drying shrinkage testing specimens).

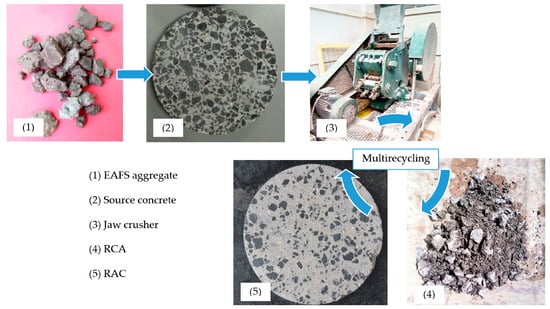

A scheme illustrating the successive steps of RAC’s manufacturing process is shown in Figure 2. The process describes the possible multi-recycling of RAC.

Figure 2.

Recycled aggregate concrete (RAC) manufacturing process.

2.3. Physical Properties Tests

The concrete’s absorption by capillarity has been determined on four cylindrical specimens with 150 mm diameter and 100 mm in length per mix proportion, after 28 days of curing in a humidity chamber and 14 days in an oven at 60 ± 5 °C. The test consists of measuring the mass evolution after 3, 6, 24 and 72 h of immersion, according to LNEC (National Laboratory for Civil Engineering) standards following the LNEC E-393. The absorption by immersion has been determined on four 100 mm cubic samples after 28 days of curing in a humidity chamber according to LNEC E-394. In addition, the apparent bulk, bulk, and saturated surface dry (SSD) density have been determined according to EN 12390-7 and the open porosity according to UNE 83980, for all the mixes produced.

2.4. Mechanical Properties Tests

The compressive strength () has been obtained on 150 mm cubic samples (EN 12390-1) per mix at ages of 7, 28 and 91 days. The test specimens have been tested using a load application rate of 0.6 MPa/s in a servo-hydraulic press of 3000 kN capacity and in accordance with EN 12390-3. The ultrasonic pulse velocity test has been performed on the specimens intended for the compressive strength test, prior to testing the compressive strength and just after their surface is dry. The measurement has been carried out according to EN 12504-4 with the transducers in direct transmission placed in collinear directions between two parallel faces with Vaseline on the contact surface between transducers and the concrete surface. The pulse velocity is calculated as the ratio. The compressive modulus of elasticity (E) has been determined in a servo-hydraulic press of 250 kN capacity, on three cylindrical specimens with 150 mm and 300 mm in length per mix, after 28 days of curing in a humidity chamber. The upper and lower faces of the test specimens have been levelled before the test and a compressometer/extensometer equipped with high precision displacement transducers is used to measure the micro-deformation. Four loading/unloading cycles have been used, applying an initial stress of 1 MPa (17.6 kN) and a load application speed of 0.5 MPa/s (8.8 kN), using a maximum load of according to LNEC E-397. The splitting tensile strength has been determined on the three specimens used in the modulus of elasticity test, for all mixes. A servo-hydraulic press of 3000 kN capacity and a load rate of 0.05 MPa/s (3.5 kN/s) was used, according to EN 12390-6.

2.5. Durability Tests

The resistance to chloride-ion penetration was determined by calculating the diffusion coefficient by means of the depth of chlorides penetration into concrete, according to LNEC E-463. Three cylindrical specimens with 100 mm diameter and 50 mm in length per mix have been used for each of the ages (28 and 91 days) and mixes. The specimens were cured in a wet chamber and moved to a dry chamber (20 ± 2 °C and 60 ± 5% relative humidity) in the last 14 days before testing. Carbonation resistance of the concrete was determined on three cylindrical specimens with 100 diameter and 50 mm in length per mix and per exposure time, stored 14 days in a humidity chamber followed by 14 days in a dry chamber (20 ± 2 °C and 60 ± 5% humidity) before being placed for 7, 28, or 91 days in the carbonation chamber. The conditions of the carbonation chamber and the test methodology are those proposed by LNEC E-391 (temperature of 23 ± 3 °C, relative humidity of 60 ± 5%, and CO2 concentration of 5.0 ± 0.1%). The determination of the carbonation depth was carried out with the help of a pH indicator (1% phenolphthalein solution in ethanol), cutting the specimen in quarters, spraying the solution and measuring the depth of carbonation penetration (the average depth measured in the eight contact surfaces of the broken specimen). Drying shrinkage was measured on two 100 × 100 × 500 mm prismatic specimens per mix and according to LNEC E-398, from 24 h to 91 days of age. The specimens were placed in a chamber at 20 ± 2 °C and 55 ± 5% relative humidity after demoulding and during the 91 days of testing.

3. Results and Discussion

3.1. Physical Properties

Table 4 shows the average physical properties of all the mixes produced and their standard deviation. All densities increase as the replacement does, since CRA has a bulk density 0.3 g/cm3 higher than that of NA (Table 2). The increase in bulk density is close to 7% for 100% replacement and opposite to that obtained by other authors using more common RCA [20,21,22]. This increase in density allows a saving of volume with respect to NAC in applications where self-weight is important (i.e., bridge counterweights or seawalls). To compare the amount of voids in mixes with different density, the property to be analyzed is open porosity, since the water absorption is the ratio and hence depends on the bulk density of the material. Open porosity increases by 18% for 100% replacement, which is approximately 70% of the relative increase obtained by Thomas et al. [15] for more common RCA mixes with a w/c ratio of 0.5. The increase in open porosity with respect to the NAC is due to RA being on average 160% more porous than coarse NA (Table 2) and coarse aggregate represents 44% of RAC’s volume. This large increase is due to the porous nature of the source concrete mortar. Analogously, the increase in porosity obtained is relatively low because the source concrete has a low water/cement ratio (0.47).

Table 4.

Physical properties of hardened concrete mixes.

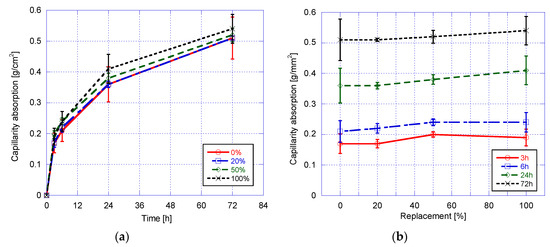

Figure 3 shows the capillarity absorption over time for the different replacement ratios used.

Figure 3.

Capillarity absorption vs. time (a) and capillarity absorption vs. replacement ratio (b).

Capillarity absorption increases with immersion time (Figure 3a) and the level of replacement (Figure 3b). For 20% replacement, the variation in absorption with respect to NAC is negligible for any immersion time, while for 100% replacement the values may increase by 9% at 72 h of immersion. For replacement of 50%, intermediate capillary absorption increases of around 4% are obtained. For total replacement and 72 h immersion, other authors obtained increases of around 30% for both current RAC [19] and high-quality precast concrete RAC [10]. The higher absorption shown by RAC is due to the high porosity of RCA, which contains more and longer capillaries than NAC’s. Figure 3a shows that the capillarity absorption difference is maximum at 24 h between 0% and 100% replacement and the difference is reduced at 72 h. This happens because the mix with 100% replacement has larger pores size (larger capillary pores saturate the first). The low water absorption of the study concrete is compatible with the minimum capillarity absorption obtained, which shows a loss very similar to that of ultrasonic pulse velocity, strongly related to the mechanical properties of the hardened concrete.

3.2. Mechanical Properties

There are several factors that positively and negatively affect the compressive strength of the study RAC: porosity of the cement paste, the new ITZ’s quality and characteristics of the RCA. Porosity negatively affects strength. The greater porosity of RAC is due to the porosity of RCA and to that generated in the ITZ between RCA and the new paste [59]. This porosity largely depends on the w/c ratio of both the source concrete and RAC. This strength loss is not high for this RAC, since the porosity of mixes with a 100% replacement is only 18% higher than of NAC, because the source concrete has a low w/c ratio and RAC mixes have a lower effective w/c ratio than the source concrete. A lower quality ITZ has been reported by various authors [30,31] as the main cause of the strength loss of RAC, justifying that this element is the weakest link of the chain. The shape of the EAFS aggregates in RCA and the high compressive strength and stiffness of the source concrete minimize this effect. On the other hand, compared with NA, RCA’s shape index is 23% lower and, even having a greater roughness, these aggregates allow using slightly lower effective w/c ratios to obtain the same workability, generating lower pores in the mortar and reducing the strength loss.

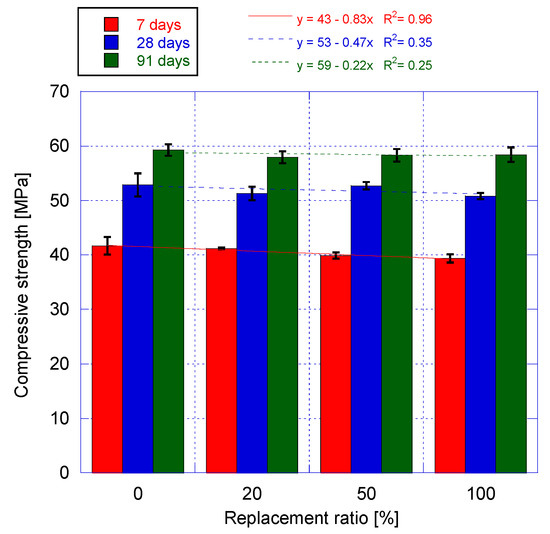

The result of these effects on the compressive strength is shown in Figure 4 where the evolution over time of the compressive strength for all mixes is shown.

Figure 4.

Compressive strength of all mixes at different ages.

At 7 days, the compressive strength decreases slightly and linearly as replacement increases. For 100% replacement, the strength loss with respect to NAC is 5.5%. At 28 days, the concrete class for all replacement is C35/45, exceeding the C30/37 class proposed at the design phase. At 28 days, a strength loss or gain depending on the replacement cannot be clearly defined, but a relative 7-day strength increase of 21% for NAC and 23% for RAC with 100% of RA is observed. This slightly higher relative increase for high replacement could be due to a hydration of the unhydrated cement grains of the old mortar, thus improving the bond in the ITZ with the new mortar. So the curing age is an important factor to check the effectiveness of these concrete mixes. At 91 days, the replacement level does not affect compressive strength. The slope of the linear adjustment is practically 0 and the standard deviation close to 1 for all replacements, proving an increase in compressive strength with age and replacement ratio, because the old mortar is still hydrating. In any case, the compressive strength obtained is much lower than that of the source concrete, although relatively higher than that obtained in other studies for current CDW [9,17,27,32,33,34] which on average lose around 10% compressive strength at 28 days with respect to NAC. This is due to the high quality of the RCA used in the present study, namely the high strength of the attached mortar of these CRA (due to the strength of the source concrete) and its low shape index.

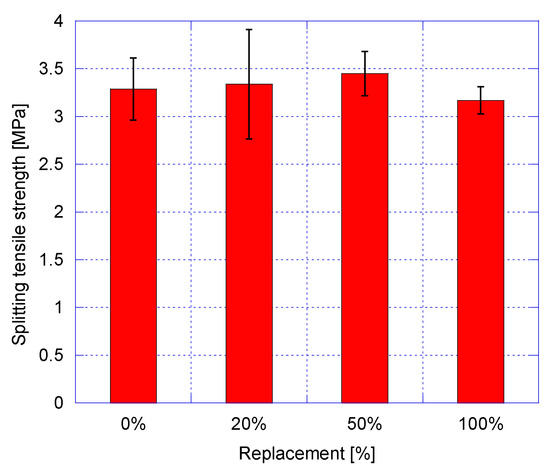

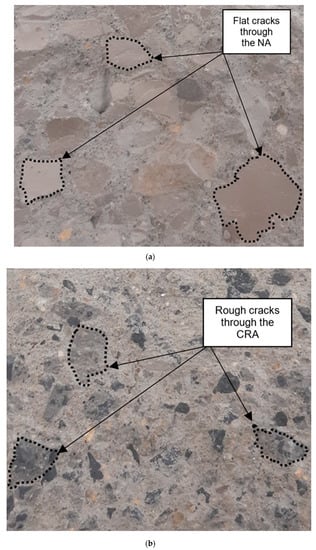

The results of the splitting tensile strength tests are shown in Figure 5. The high standard deviation, which is typical of splitting tensile strength tests [33], and the similar mean values obtained show that the behaviour of RAC is very similar to NAC’s for any replacement ratio. This happens because there is a good bond strength between RCA and the new paste, due to the higher roughness of RCA. This greater roughness seems to compensate for the weaker mortar surface generated in the crushing stage and exposed in the new ITZ. It also compensates for RAC not benefitting from the bond produced by the chemical interaction between calcium hydroxide and the calcareous aggregate [59] in NAC. As seen in Figure 6, fracture surfaces propagate through the aggregates (good bond strength in the ITZ), both for NAC and RAC. In the case of NAC, the crack surface is flatter, favored by the crystalline structure of calcite, while the fracture surface produced in CRA is irregular or lumpy with a smooth transition to the new mortar paste. Most of the macro-cracks present in RCA are produced in the mortar phase of the source concrete, even though sometimes they are also produced through the EAFS aggregate.

Figure 5.

Tensile strength of all mixes at 28 days.

Figure 6.

Crack patterns of test specimens subjected to tensile strength test for 0% (a) and 100% (b) replacement ratio.

The splitting tensile strength values obtained by other authors for RAC produced with CDW are variable depending on the quality of RA. According to the classification proposed by Silva et al. [14], RA are classified in four classes according to their intrinsic properties (bulk density, water absorption and Los Angeles wear). For the most demanding category (Class A), the loss of tensile strength should be around 10% with respect to NAC [60]. The RA used in the present study, even though not complying with the water absorption requirements described for Class A, shows a tensile strength similar to NAC’s.

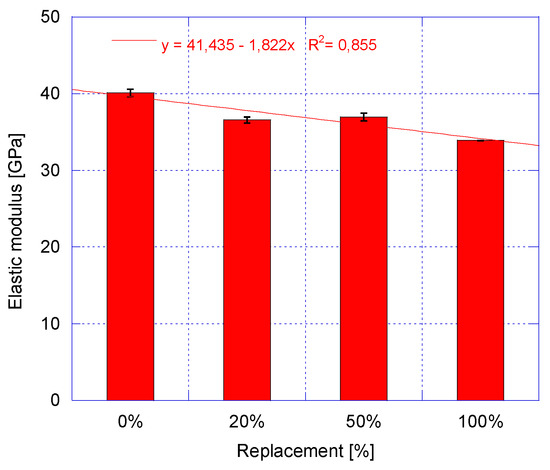

Figure 7 shows the compressive modulus of elasticity for all mixes produced. Using a linear trend line, an inverse relationship between modulus of elasticity and replacement level can be established. While NAC shows a 40 GPa modulus of elasticity, the 100% replacement mix shows values around 33 GPa, 17% lower and with standard deviations not exceeding 0.5 MPa. This reduction is lower than that commonly reported and is related to the properties of the source concrete. The source concrete used to produce RCA has low w/c ratio, a modulus of elasticity greater than 50 GPa and a low porosity close to 10%. For similar w/c ratios and cement contents, other authors reported reductions from 15% to more than 40% [15,35,61] using RCA produced from common concrete waste.

Figure 7.

Modulus of elasticity of all mixes at 28 days.

Traditionally, density is a factor directly related to the modulus of elasticity because it is linked to the porosity of concrete [59]. The aggregate used is 7% denser than NA, but this is due more to the iron nature of RA than to the very slight increase of w/c ratio. The porosity of RCA influences its stiffness and hence the stiffness of concrete, since its increase allows greater deformations per unit of applied load.

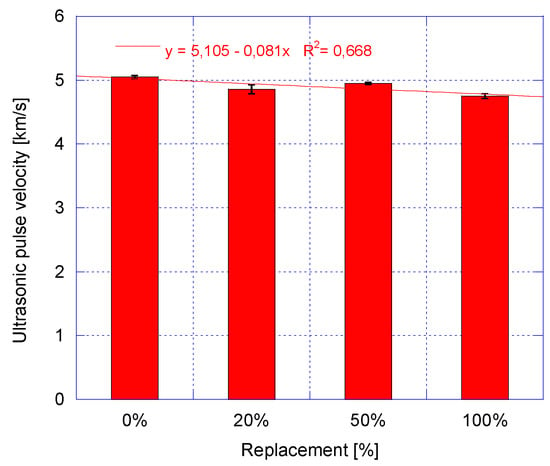

Ultrasonic pulse velocity is intrinsically related to the modulus of elasticity and density. The ultrasonic pulse velocity obtained for all the mixes produced is shown in Figure 8. Following the trend line, it is observed that the pulse velocity decreases as the replacement ratio increases. There is a maximum loss of 6% for 100% replacement, slightly less than 9% determined by Khatib [52] for current RAC with the same w/c ratio. It should be remarked that the source concrete showed an ultrasonic pulse velocity of 5.22 km/s at the same age. On the other hand, the maximum loss obtained is similar to that obtained by de Brito et al. [10] for RAC produced from concrete precast rejects, which demonstrates the homogeneity of RAC and the high quality of the RCA used. The RCA used in this study has a density 10% and 20% higher than NA and of current RCA respectively, which a priori favours an increase in the ultrasonic pulse velocity. On the other hand, the porosity of the source concrete mortar allows RAC to strain more under sustained loads, obtaining smaller modulus of elasticity and lower ultrasonic pulse velocity than NAC, due to the discontinuities generated by the pores.

Figure 8.

Ultrasonic pulse velocity at 28 days.

3.3. Durability

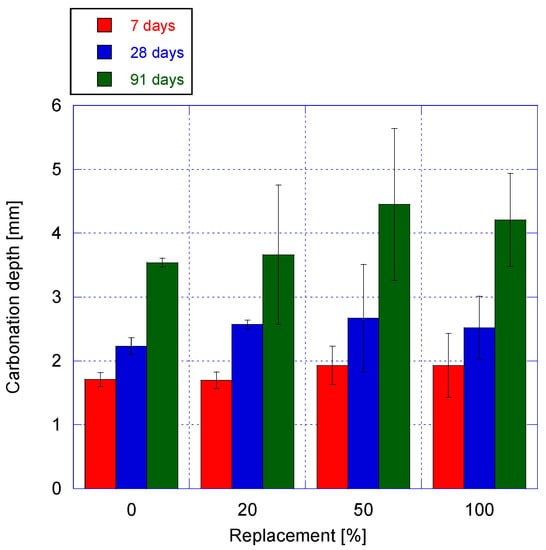

Carbonation is a phenomenon that alters the alkaline behaviour of concrete. When CO2 from the atmosphere diffuses into the concrete matrix, it reacts with water forming carbonic acid and the latter reacts with portlandite forming calcium carbonate. This process reduces the pH of concrete, depassivating the reinforcement. Figure 9 shows the evolution of the carbonation depth over time of all mixes. At 7 days, the carbonation depth is very small due to the low w/c ratio of the mixes. The test scatter caused by reading tolerances is relevant but mixes with 100% and 50% replacements appear to be slightly less durable. However, at 28 days, a slight increase in carbonation depth with the increase in CRA incorporation can be observed, which can reach about 10% for total replacement. This trend continues at 91 days, when carbonation becomes more noticeable for higher replacements: 50 and 100%. For total replacement, carbonation depths can be 15% higher than for reference concrete.

Figure 9.

Carbonation depth for all mixes and ages.

The general increase in carbonation depth with replacement ratio and age is due to several causes. CRA is composed of the source concrete mortar, hence part of this cement is already carbonated. Another relevant fact is that the open porosity of RAC is 18% higher than that of NAC, which favours the increase of permeability and hence the diffusion of CO2 through the cement matrix, since there is easier access to more paste surface. On the other hand, by having a greater volume of total mortar, there is also a greater amount of total portlandite compared to the reference concrete (a greater amount of calcium carbonate can be generated) and hence a greater amount of CO2 is required for the same carbonation depth.

Other authors have also obtained increases in carbonation depth as the replacement level increases. For similar mixes and 100% replacement, de Brito et al. [10] obtained a marginal increase of the depth of carbonation for rejected high-quality precast concrete at all ages tested. Ryu et al. [62] obtained a slight increase in carbonation depth for similar mixes and similar compressive strengths, namely an increment of 14% for total replacement. Finally, in the review of Silva et al. [45], it is found that, for total replacement, the average carbonation depth may increase by a factor of 2 with respect to the control concrete, establishing the permeability of concrete, which depends directly on the water absorption (and therefore on the open porosity) of RCA, as a key factor.

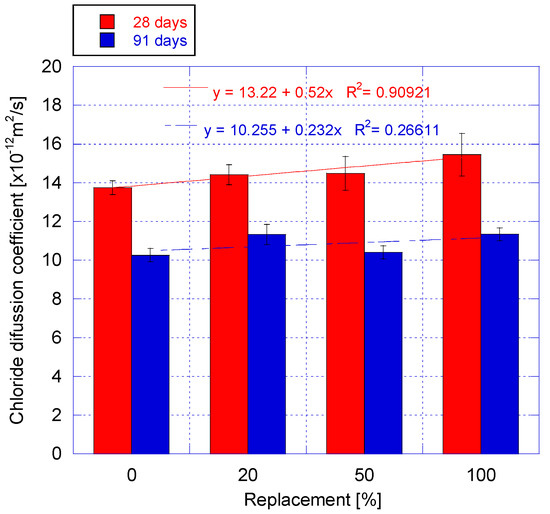

Chlorides negatively affect concrete, reacting with tricalcium aluminate forming Friedel’s salt (bound chlorides) and oxidizing the reinforcement after penetrating concrete (free chlorides) [63]. The resistance to the penetration of chlorides is shown in Figure 10. The chlorides diffusion coefficient increases with replacement ratio and decreases with age. At 28 days, there is a quasi linear increase in this coefficient, reaching 11% for total replacement. At 91 days, the increase is 9.5% for total replacement, due to the extra contribution of mortar from the source concrete that continues to hydrate. On the other hand, there is a large reduction in chlorides diffusion coefficient with age, a reduction greater than 25% for all replacements.

Figure 10.

Chloride diffusion coefficient for all mixes and ages.

Chlorides penetration in concrete (an advective-diffusive phenomenon) largely depends on its porosity and the tortuosity of its capillary framework [64]. A strong correlation has been obtained between the chlorides diffusion coefficient and both open porosity (R2 = 0.73) and capillarity absorption (R2 = 0.89). Critical variables such as the content or type of cement remain constant, so it seems consistent that the higher ingress of chlorides in RAC with larger replacement is due to the increase in open porosity, owing to the higher volume of voids in RCA.

The incorporation of EAFS usually improves the chloride diffusion coefficient relative to the reference concrete by about 10% [56], so it is expected that the behaviour of RAC with RCA based on EAFS can show an improvement over mixes with current RCA. Likewise, concrete with current RCA generally have higher chloride diffusion coefficient than concrete produced with NA. Bravo et al. [24] obtained average increases of more than 40% in the chlorides diffusion coefficient for total replacement of CRA produced from unsorted CDW. Other studies, however, argue that this property is unrelated with the RA replacement level [10], stating that it depends mostly on the quality of CRA.

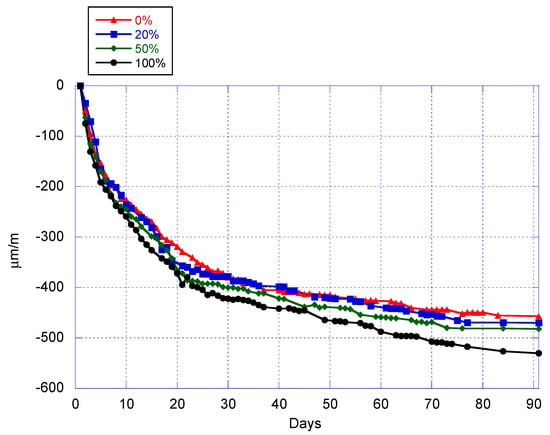

Drying shrinkage is a significant phenomenon during cement hydration. The difference in relative humidity between the environment and the specimen causes the water adsorbed to the hydrated paste to pass into the atmosphere following Fick’s law. Drying the specimen involves a reduction in volume that can cause cracking of the paste in severe cases. The evolution of drying shrinkage for the different mixes is shown in Figure 11. The drying shrinkage obtained for RAC with total replacement is about 530 μm/m at 91 days, while for NAC it is 457 μm/m, so there is an increase of 13%.

Figure 11.

Mean drying shrinkage over time for all mixes.

It is well known that there is a strong relationship between drying shrinkage and modulus of elasticity in concrete [65]. The shape and texture of aggregates are variables that affect the drying shrinkage, although modulus of elasticity (or any of the variables that affect the latter) is the parameter that most affects the former [59]. An increase in modulus of elasticity generates a greater restriction against strain, i.e., stiffer aggregates more efficiently oppose the strain generated by shrinkage than more deformable ones. As stated before, the modulus of elasticity drops with increase of the replacement ratio (17% for full replacement) and drying shrinkage decreases similarly. Another factor to keep in mind is that RCA is still shrinking, especially if the source concrete is young concrete, while NA do not shrink. Recycling concrete that has already reached the end of its service life is not a problem, but in the case of laboratory-produced concrete (the case here) it is something to keep in mind. Shrinkage measured from RAC with laboratory-produced source concrete is thus expected to overestimate the shrinkage of RAC. Losses for total RCA replacement range from 10% [10] to 50% [43], the latter being the value established in the Xuping review as a typical value for RAC.

4. Conclusions

In this study, a new concrete based on the use of concrete waste has been tested. The concrete waste used incorporates a by-product of the steelmaking industry (EAFS), thus waste production and natural aggregate consumption are reduced. The physical, mechanical and durability properties of the new material have been characterized and compared with the results of a reference conventional concrete with the same mix design of the recycled aggregate concrete tested. Moreover, experiments from other authors on the properties of concrete with recycled aggregates from other sources were also compared with those of this experiment. The following conclusions were drawn:

- The use of RCA with a water absorption twice that of NA requires compensation water, but the rounded shape of the RCA produced from concrete with EAFS (shape index 20% lower than NAC) makes it possible to use slightly lower effective w/c ratio to obtain the same workability;

- The replacement level affects the physical properties of RAC. Bulk density increased by 7%, unlike in current RAC (typically density decreases), due to the iron present in this recycled aggregate. Both porosity and capillarity slightly increase (18% and 9% for full replacement respectively) as replacement increases due to the porosity of the source concrete mortar;

- Compressive strength is not affected by the replacement level for ages over 28 days due to the hydration of the unhydrated cement grains of the source concrete and to a good bond strength between RCA and the new mortar. This good bond, favoured by the cavernous form of EAFS in the source concrete, allows tensile strength to be very similar to that of NAC. On the other hand, the modulus of elasticity is the property most affected by the replacement of RCA, showing losses that can reach 17% with respect to NAC. Typical decreases of the modulus of elasticity caused by full recycled aggregate incorporation are higher than this value;

- Durability properties are negatively but slightly affected. Carbonation depths and chlorides diffusion coefficients are 15% and 25% higher respectively for full replacement at 91 days. Both properties are linked to the porosity of RAC and hence with the quality of the RCA used, which is reflected in a low w/c ratio and a good bond between aggregate and paste;

- Drying shrinkage values 13% higher for total replacements have been obtained at 91 days, consistent with the modulus of elasticity obtained;

- The mechanical and durability tests results obtained are satisfactory, usually near the lower limit of the interval of change found in the literature and sometimes showing a behaviour very similar to that of the reference NAC;

- Concrete designed by recycling an EAFS-based concrete has potential applications as a structural material and can also be used in applications where its self-weight is important, as in bridge counterweights, seawalls or radiation-proof structures.

Author Contributions

Data curation, J.d.B.; Formal analysis, P.T., J.P., C.T. and J.d.B.; Funding acquisition, C.T. and J.R.; Investigation, P.T., J.P. and C.T.; Methodology, C.T.; Project administration, C.T.; Resources, J.R.; Writing-original draft, P.T. and J.P.; Writing-review & editing, C.T. and J.d.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-financed by the European Regional Development Fund (ERDF) and the Ministry of Economy, Industry and Competitiveness (MINECO) within the framework of the project RTC-2016-5637-3 and in collaboration with the company INGECID and the department LADICIM (University of Cantabria).

Acknowledgments

The authors gratefully acknowledge the support of the CERIS Research Unit, IST, University of Lisbon and of FCT.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tam, V.W.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of aggregates from recycled construction and demolition waste in concrete, Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Faleschini, F.; De Marzi, P.; Pellegrino, C. Recycled concrete containing EAF slag: Environmental assessment through LCA. Eur. J. Environ. Civ. Eng. 2014, 18, 1009–1024. [Google Scholar] [CrossRef]

- Braymand, S.; Feraille, A.; Serres, N.; Feugeas, F. Benchmarking of materials composition and transportation influences on Life Cycle Assessment of Recycled Aggregate Concrete. In Proceedings of the 5th International Conference on Sustainable Solid Waste Management, Athens, Greece, 21–24 June 2017; pp. 1–3. [Google Scholar]

- McNeil, K.; Kang, T.H.-K. Recycled Concrete Aggregates: A Review. Int. J. Concr. Struct. Mater. 2013, 7, 61–69. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Performance and properties of structural concrete made with recycled concrete aggregate. Mater. J. 2003, 100, 371–380. [Google Scholar]

- Ministerio de Fomento de España. EHE-08: Instrucción de Hormigón Estructural. 2008. Available online: http://www.fomento.gob.es/MFOM/LANG_CASTELLANO/ORGANOS_COLEGIADOS/CPH/instrucciones/EHE08INGLES/ (accessed on 22 December 2019).

- UNE-EN 12620:2003+A1:2009. In Áridos Para Hormigón; Normalización Española: Madrid, Spain, 2009.

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- De Brito, J.; Ferreira, J.; Pacheco, J.; Soares, D.; Guerreiro, M. Structural, material, mechanical and durability properties and behaviour of recycled aggregates concrete. J. Build. Eng. 2016, 6, 1–16. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Establishing a relationship between modulus of elasticity and compressive strength of recycled aggregate concrete. J. Clean. Prod. 2016, 112, 2171–2186. [Google Scholar] [CrossRef]

- Marinkovic, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Anastasiou, E.; Filikas, K.G.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J.; Dhir, R. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; Sánchez De Juan, M. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Topcu, I.B.; Sengel, S. Properties of concretes produced with waste concrete aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Fiol, F.; Thomas, C.; Muñoz, C.; Ortega-López, V.; Manso, J.M. The influence of recycled aggregates from precast elements on the mechanical properties of structural self-compacting concrete. Constr. Build. Mater. 2018, 182, 309–323. [Google Scholar] [CrossRef]

- Matias, D.; de Brito, J.; Rosa, A.; Pedro, D. Durability of concrete with recycled coarse aggregates: Influence of superplasticizers. J. Mater. Civ. Eng. 2013, 26, 6014011. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.; Cimentada, A.; Medina, C. Influence of curing conditions on recycled aggregate concrete. Constr. Build. Mater. 2018, 172, 618–625. [Google Scholar] [CrossRef]

- Thomas, C.; Cimentada, A.; Polanco, J.A.; Setién, J.; Méndez, D.; Rico, J. Influence of recycled aggregates containing sulphur on properties of recycled aggregate mortar and concrete, Compos. Part B Eng. 2013, 45, 474–485. [Google Scholar] [CrossRef]

- Gómez-Soberón, J.M.V. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- de Brito, J.; Agrela, F. New Trends in Eco-Efficient and Recycled Concrete; Woodhead Publishing: Cambridge, UK, 2018. [Google Scholar]

- Bravo, M.; De Brito, J.; Pontes, J.; Evangelista, L. Durability performance of concrete with recycled aggregates from construction and demolition waste plants. Constr. Build. Mater. 2015, 77, 357–369. [Google Scholar] [CrossRef]

- Barra, M.; Vazquez, E. Properties of concretes with recycled aggregates: Influence of properties of the aggregates and their interpretation. In Sustainable Construction: Use of Recycled Concrete Aggregate: Proceedings of the International Symposium organised by the Concrete Technology Unit, University of Dundee and held at the Department of Trade and Industry Conference Centre, London, UK on 11–12 November 1998; Thomas Telford Publishing: London, UK, 2018; pp. 18–30. [Google Scholar]

- Ajdukiewicz, A.; Alina, K. Influence of recycled aggregates on mechanical properties of HS/HPC. Cem. Concr. Compos. 2002, 24, 269–279. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Arribas, I.; Vegas, I.; San-José, J.; Manso, J.M. Durability studies on steelmaking slag concretes. Mater. Des. 2014, 63, 168–176. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Li, W.; Xiao, J.; Sun, Z.; Kawashima, S.; Shah, S.P. Interfacial transition zones in recycled aggregate concrete with different mixing approaches. Constr. Build. Mater. 2012, 35, 1045–1055. [Google Scholar] [CrossRef]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Alexandridou, C.; Angelopoulos, G.N.; Coutelieris, F.A. Mechanical and durability performance of concrete produced with recycled aggregates from Greek construction and demolition waste plants. J. Clean. Prod. 2018, 176, 745–757. [Google Scholar] [CrossRef]

- Pacheco, J.; De Brito, J.; Chastre, C.; Evangelista, L. Experimental investigation on the variability of the main mechanical properties of concrete produced with coarse recycled concrete aggregates. Constr. Build. Mater. 2019, 201, 110–120. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Xiao, J.; Li, W.; Poon, C. Recent studies on mechanical properties of recycled aggregate concrete in China—A review. Sci. China Technol. Sci. 2012, 55, 1463–1480. [Google Scholar] [CrossRef]

- Pacheco, J.; De Brito, J.; Chastre, C.; Evangelista, L. Scatter of Constitutive Models of the Mechanical Properties of Concrete: Comparison of Major International Codes. J. Adv. Concr. Technol. 2019, 17, 102–125. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Thomas, C.; Carrascal, I.; Setién, J.; Polanco, J.A. Determinación del límite a fatiga en hormigones reciclados de aplicación estructural—Determining the fatigue limit recycled concrete structural application. An. Mecánica La Fract. 2009, 1, 283–289. (In Spanish) [Google Scholar]

- Thomas, C.; Setién, J.; Polanco, J.A.; Lombillo, I.; Cimentada, A.I. Fatigue limit of recycled aggregate concrete. Constr. Build. Mater. 2014, 52, 146–154. [Google Scholar] [CrossRef]

- Thomas, C.; De Brito, J.; Gil, V.; Sainz-Aja, J.; Cimentada, A. Multiple recycled aggregate properties analysed by X-ray microtomography. Constr. Build. Mater. 2018, 166, 171–180. [Google Scholar] [CrossRef]

- Li, X. Recycling and reuse of waste concrete in China: Part I. Material behaviour of recycled aggregate concrete. Resour. Conserv. Recycl. 2008, 53, 36–44. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Silva, R.V.; Neves, R.; De Brito, J.; Dhir, R.K. Carbonation behaviour of recycled aggregate concrete. Cem. Concr. Compos. 2015, 62, 22–32. [Google Scholar] [CrossRef]

- de Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Qian, X.; Chen, P.; Xu, Y.; Guo, J. An environmentally friendly method to improve the quality of recycled concrete aggregates. Constr. Build. Mater. 2017, 144, 432–441. [Google Scholar] [CrossRef]

- Shima, H.; Tateyashiki, H.; Matsuhashi, R.; Yoshida, Y. An Advanced Concrete Recycling Technology and its Applicability Assessment through Input-Output Analysis. J. Adv. Concr. Technol. 2005, 3, 53–67. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Kalinowska-Wichrowska, K.; Bołtryk, M.; Jiménez, J.R.; Fernández, J.M. The Influence of Heat and Mechanical Treatment of Concrete Rubble on the Properties of Recycled Aggregate Concrete. Materials 2019, 12, 367. [Google Scholar] [CrossRef] [PubMed]

- Braymand, S.; Roux, S.; Fares, H.; Déodonne, K.; Feugeas, F. Separation and quantification of attached mortar in recycled concrete aggregates. Waste Biomass Valorization 2017, 8, 1393–1407. [Google Scholar] [CrossRef]

- Lotfi, S.; Eggimann, M.; Wagner, E.; Mróz, R.; Deja, J. Performance of recycled aggregate concrete based on a new concrete recycling technology. Constr. Build. Mater. 2015, 95, 243–256. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Papayianni, I.; Anastasiou, E. Utilization of electric arc furnace steel slags in concrete products. In 6th European Slag Conference: Proceedings Ferrous Slag-Resource Development for an Environmentally Sustainable World; EUROSLAG Publication: Madrid, Spain, 2010; pp. 319–334. [Google Scholar]

- Monosi, S.; Ruello, M.L.; Sani, D. Electric arc furnace slag as natural aggregate replacement in concrete production. Cem. Concr. Compos. 2016, 66, 66–72. [Google Scholar] [CrossRef]

- Abu-Eishah, S.I.; El-Dieb, A.S.; Bedir, M.S. Performance of concrete mixtures made with electric arc furnace (EAF) steel slag aggregate produced in the Arabian Gulf region. Constr. Build. Mater. 2012, 34, 249–256. [Google Scholar] [CrossRef]

- Faleschini, F.; Fernández-Ruíz, M.A.; Zanini, M.A.; Brunelli, K.; Pellegrino, C.; Hernández-Montes, E. High performance concrete with electric arc furnace slag as aggregate: Mechanical and durability properties. Constr. Build. Mater. 2015, 101, 113–121. [Google Scholar] [CrossRef]

- Fonseca, N.; De Brito, J.; Evangelista, L. The influence of curing conditions on the mechanical performance of concrete made with recycled concrete waste. Cem. Concr. Compos. 2011, 33, 637–643. [Google Scholar] [CrossRef]

- Rodrigues, F.; Evangelista, L.; De Brito, J. A new method to determine the density and water absorption of fine recycled aggregates. Mater. Res. 2013, 16, 1045–1051. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete microstructure, Properties and Materials. 2017. Available online: http://matteopro.com/images/materiali-non-convenzionali/Concrete_microstrutture_-_book.pdf (accessed on 22 December 2019).

- Silva, R.V.; De Brito, J.; Dhir, R.K. Tensile strength behaviour of recycled aggregate concrete. Constr. Build. Mater. 2015, 83, 108–118. [Google Scholar] [CrossRef]

- Kou, S.-C.; Poon, C.-S.; Wan, H.-W. Properties of concrete prepared with low-grade recycled aggregates. Constr. Build. Mater. 2012, 36, 881–889. [Google Scholar] [CrossRef]

- Ryu, J.S. An experimental study on the effect of recycled aggregate on concrete properties. Mag. Concr. Res. 2002, 54, 7–12. [Google Scholar] [CrossRef]

- Suryavanshi, A.K.; Narayan Swamy, R. Stability of Friedel’s salt in carbonated concrete structural elements. Cem. Concr. Res. 1996, 26, 729–741. [Google Scholar] [CrossRef]

- Maekawa, K.; Ishida, T.; Kishi, T. Multi-scale Modeling of Concrete Performance. J. Adv. Concr. Technol. 2003, 1, 91–126. [Google Scholar] [CrossRef]

- Fédération Internationale du Bétom. Code-Type Models for Structural Behaviour of Concrete; Fédération Internationale du Béton: Bulletin, Lausanne, Switzerland, 2013. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).