Analysis of the Influence of High Peening Coverage on Almen Intensity and Residual Compressive Stress

Abstract

1. Introduction

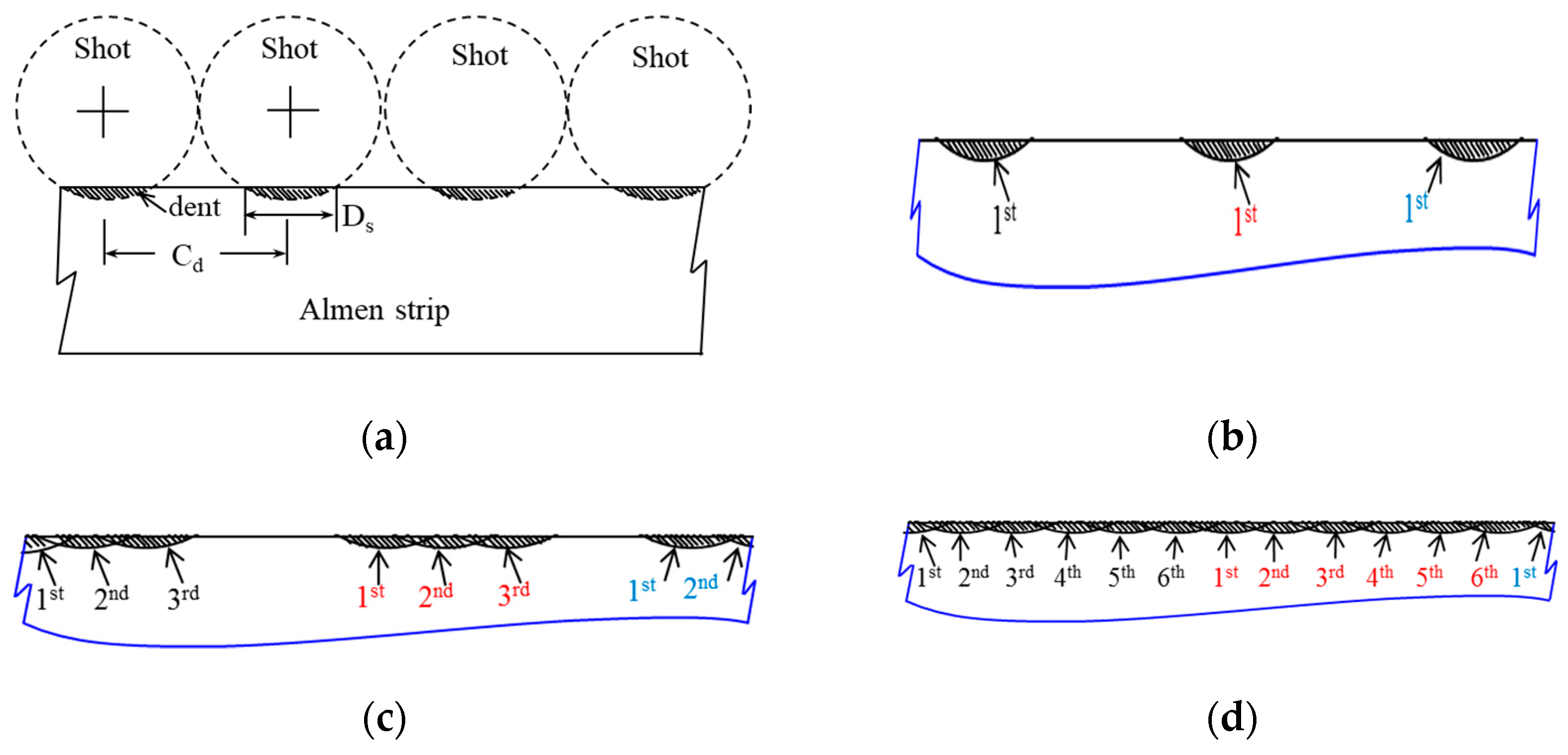

2. A Quantitative Description of the Peening Coverage

3. Comparison of Finite Element Simulation of Almen Test and Almen Test

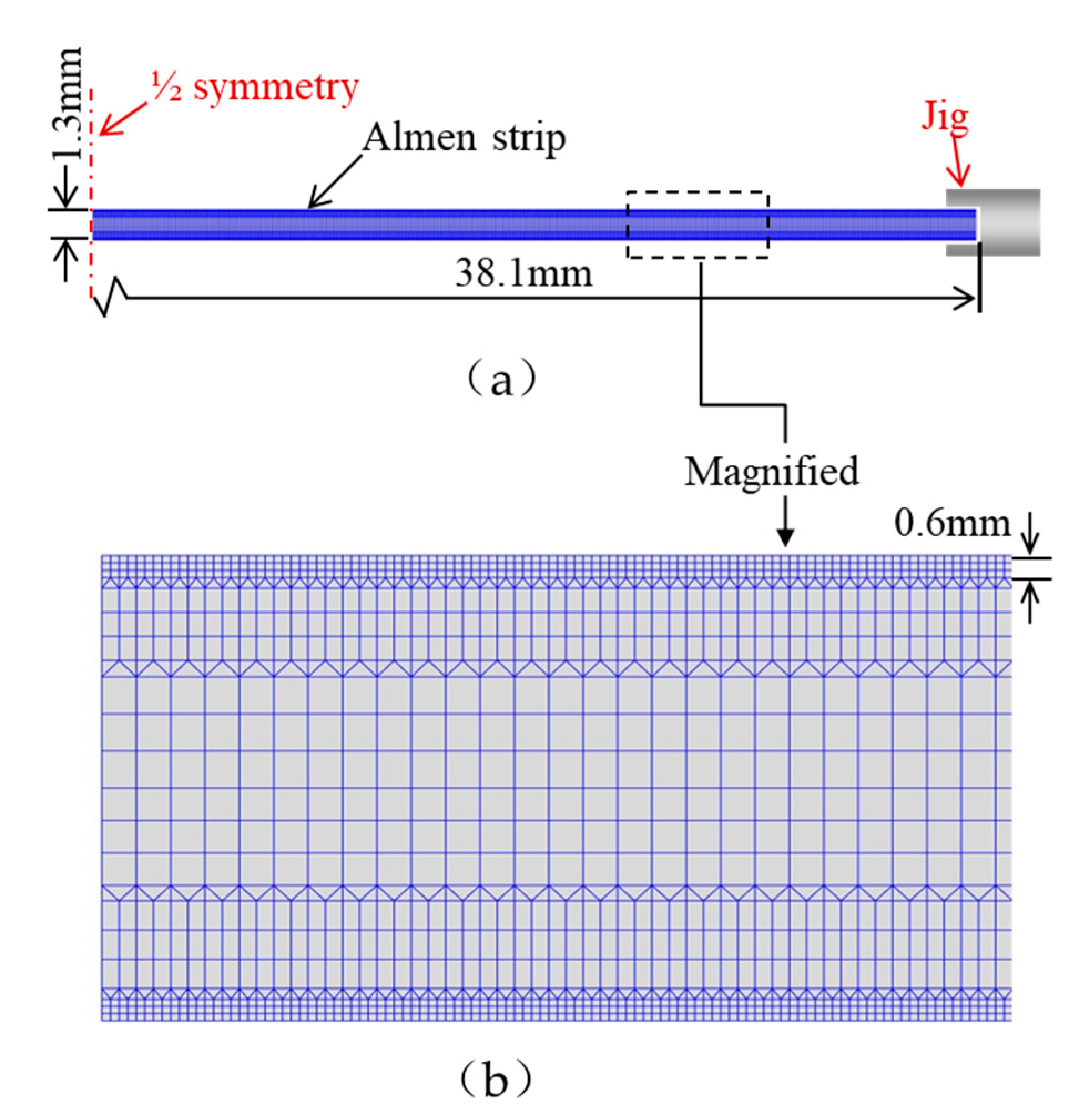

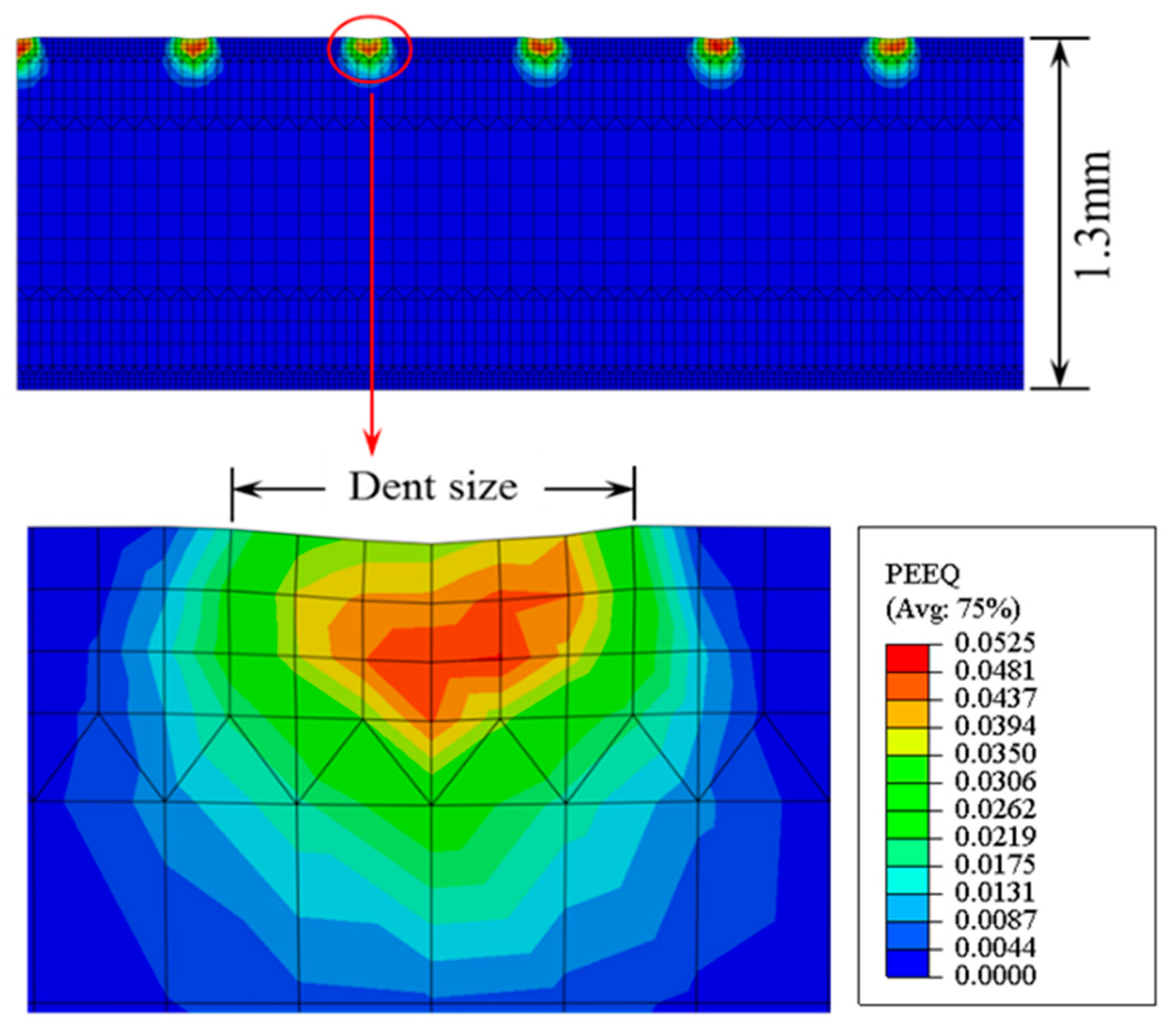

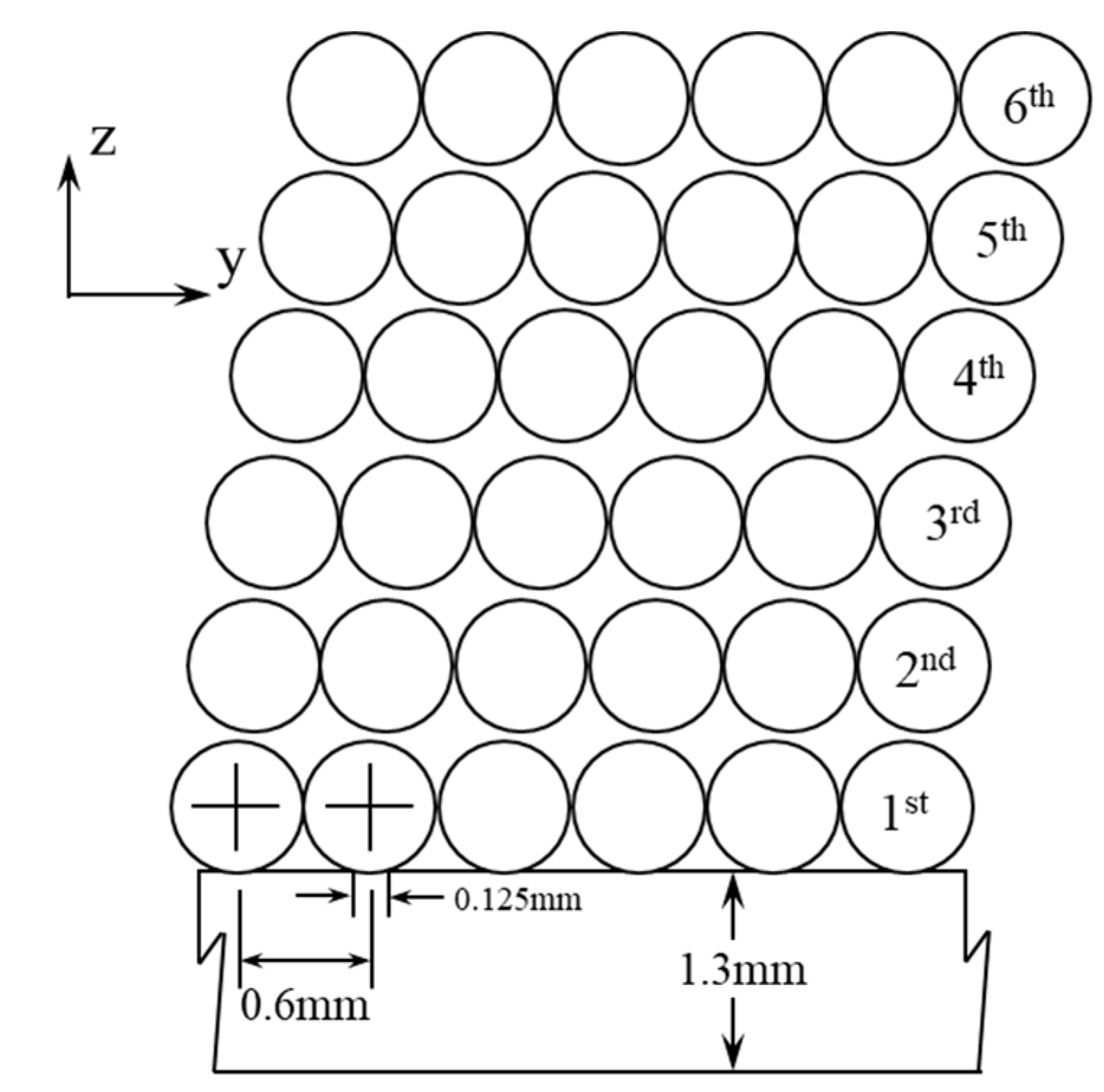

3.1. FE Simulation of Almen Test

3.1.1. Boundary Conditions

3.1.2. Material Model

3.1.3. Mesh Size

3.1.4. Impact Sequence and Position

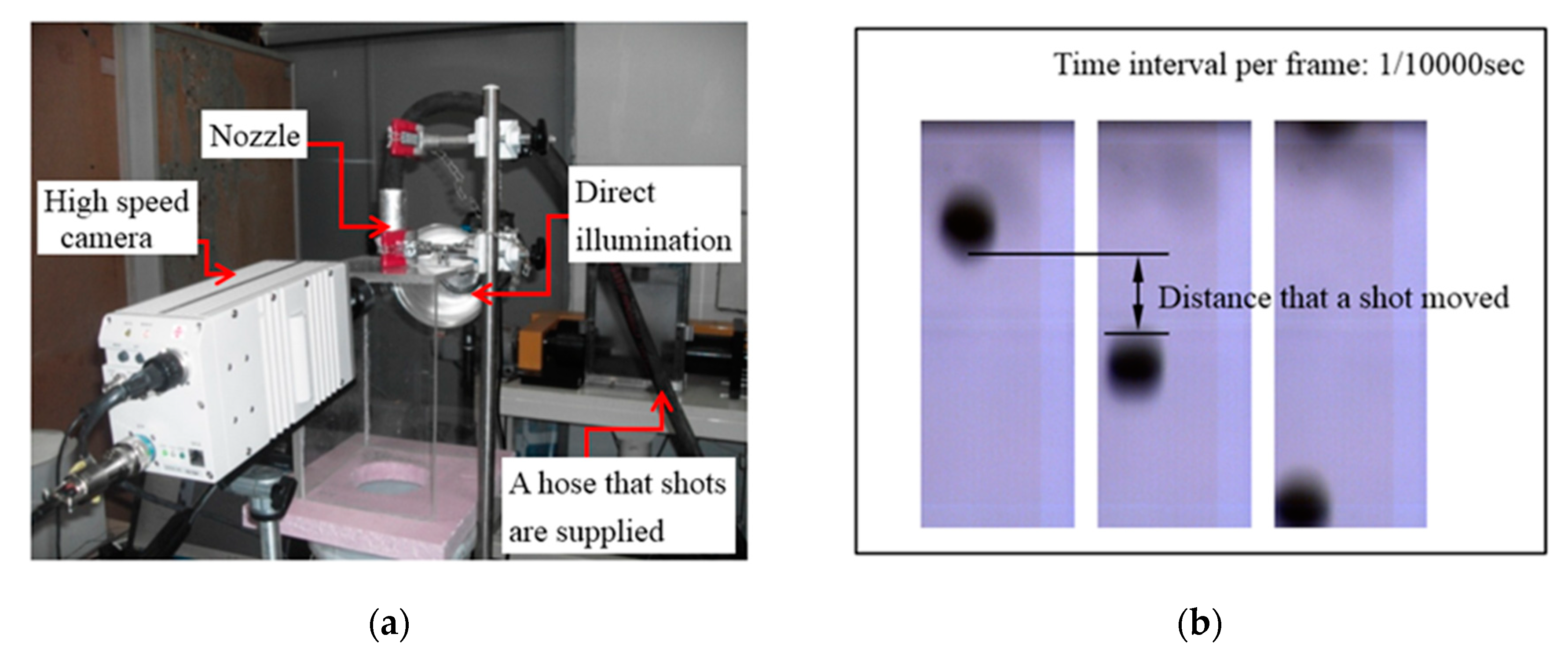

3.2. Almen Test

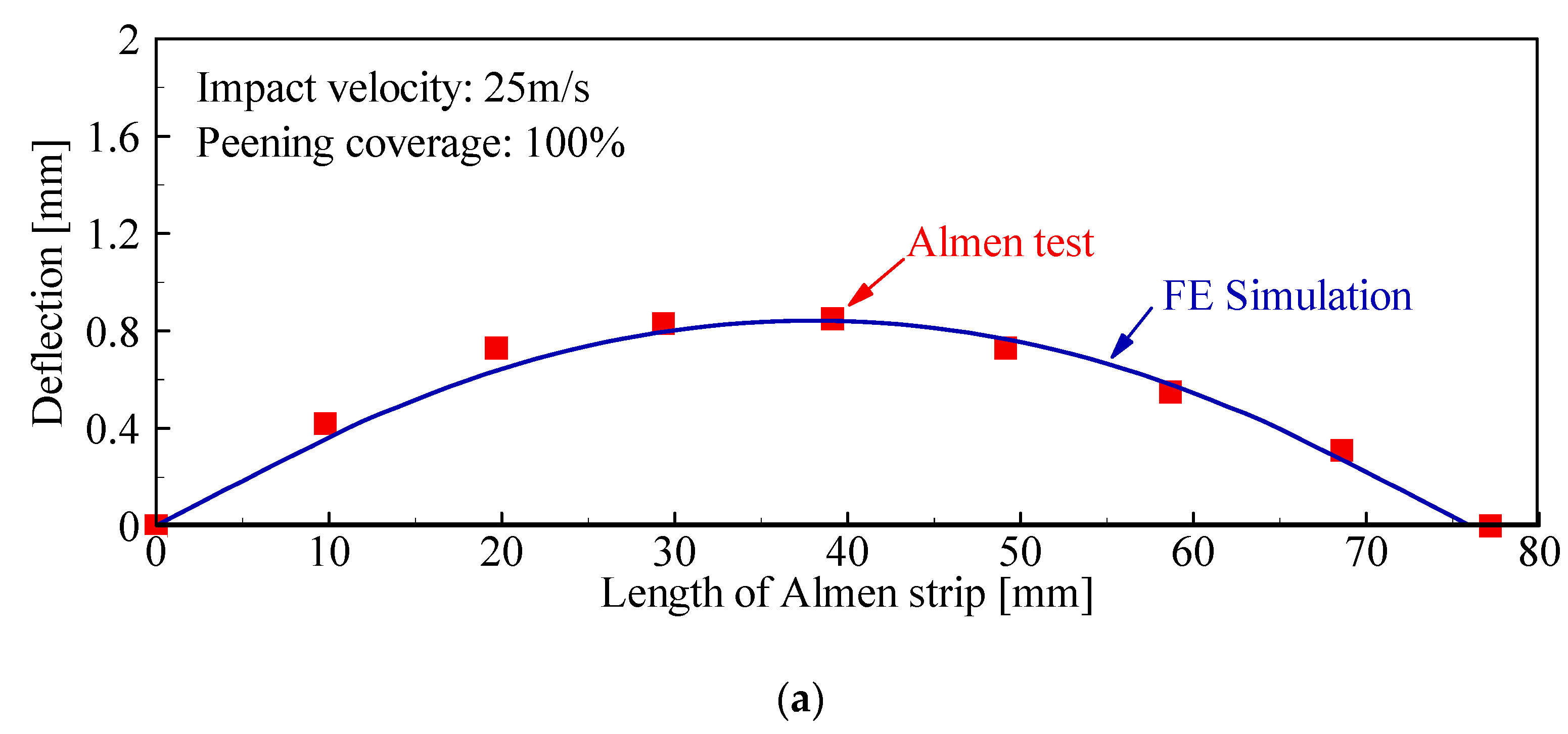

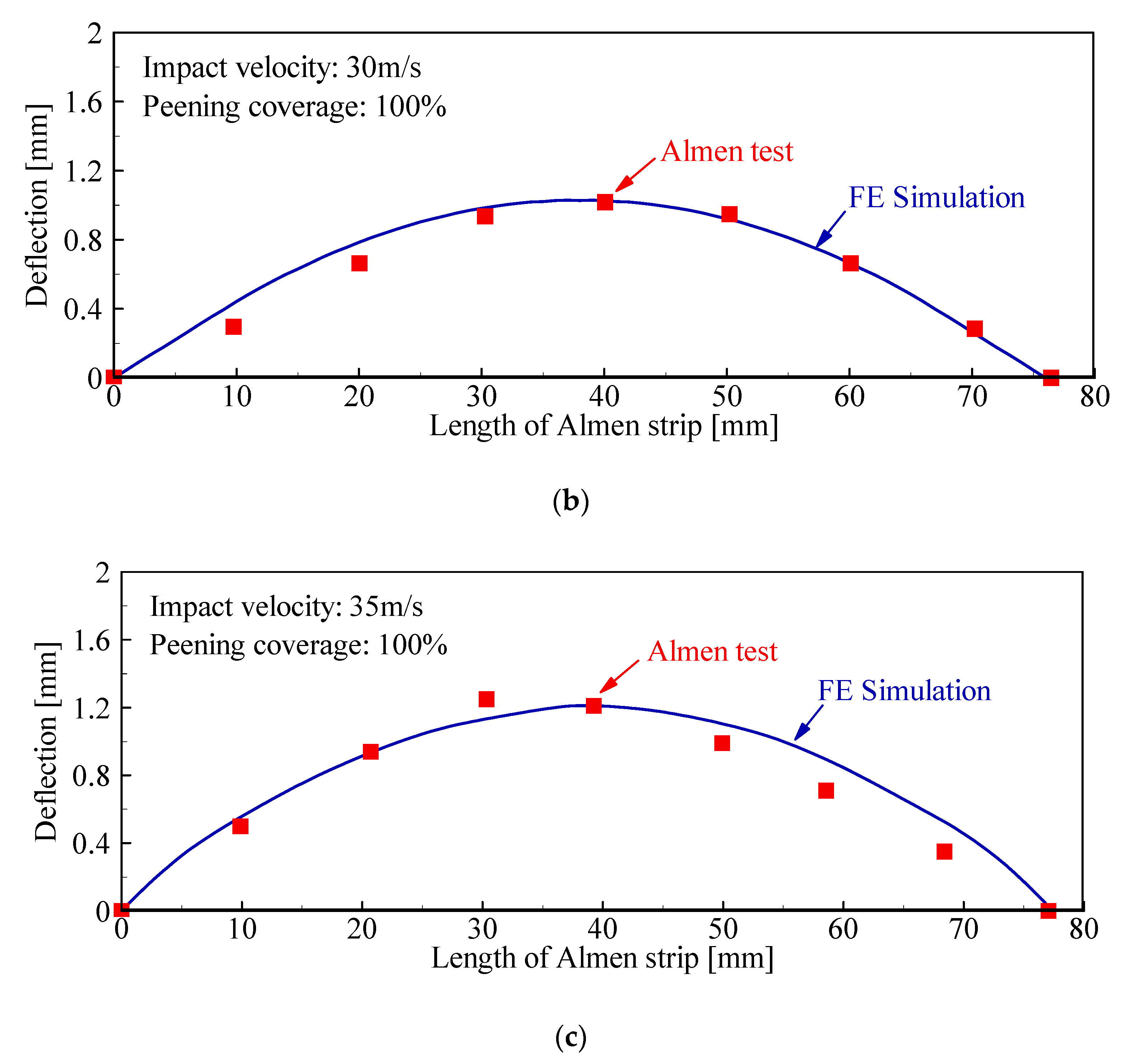

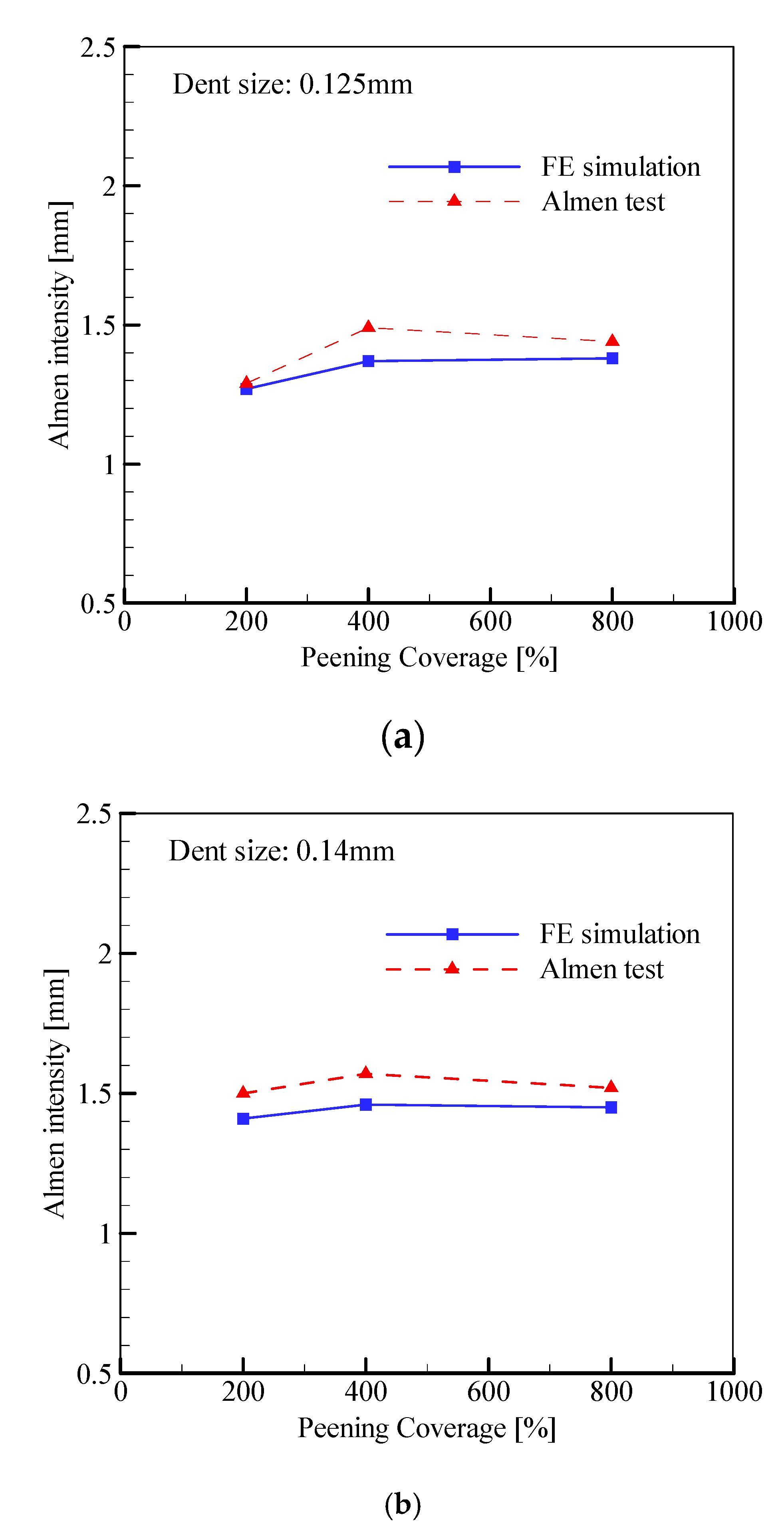

3.3. Comparison of Results of FE Simulation and Almen Test

4. Analysis of the Influence of High Peening Coverage on Almen Intensity and RCS

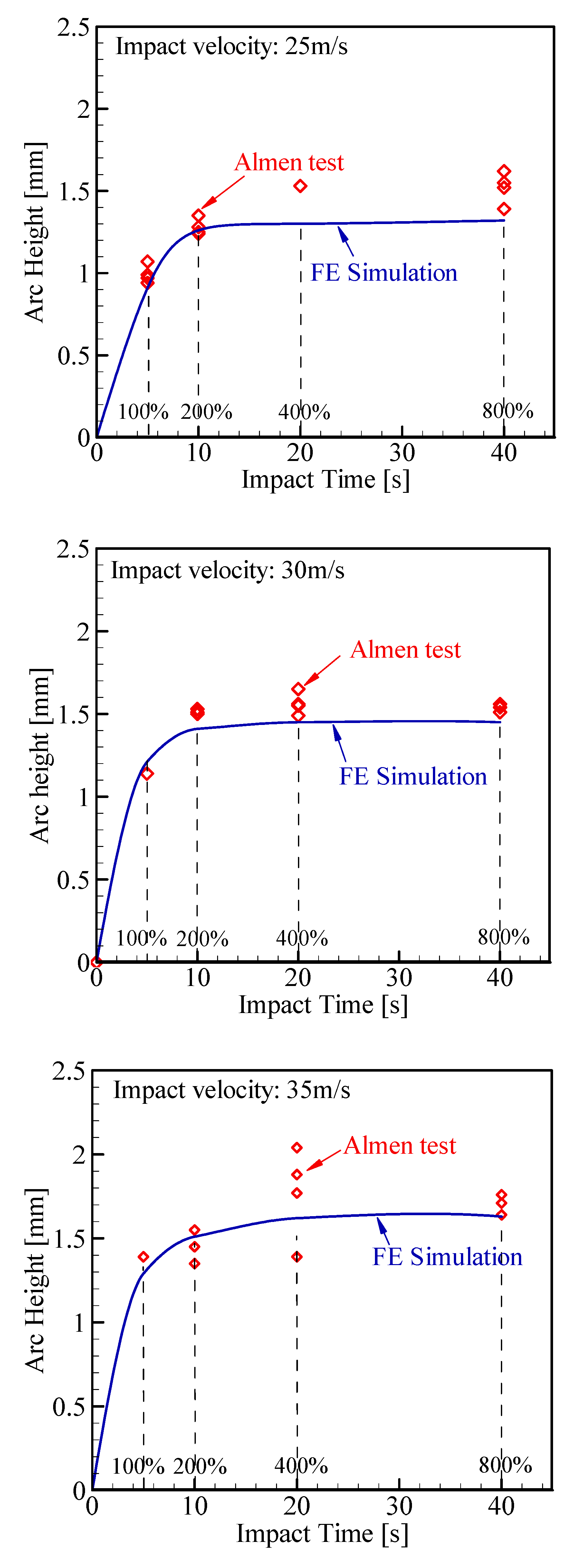

4.1. Influence of High Peening Coverage on Almen Intensity

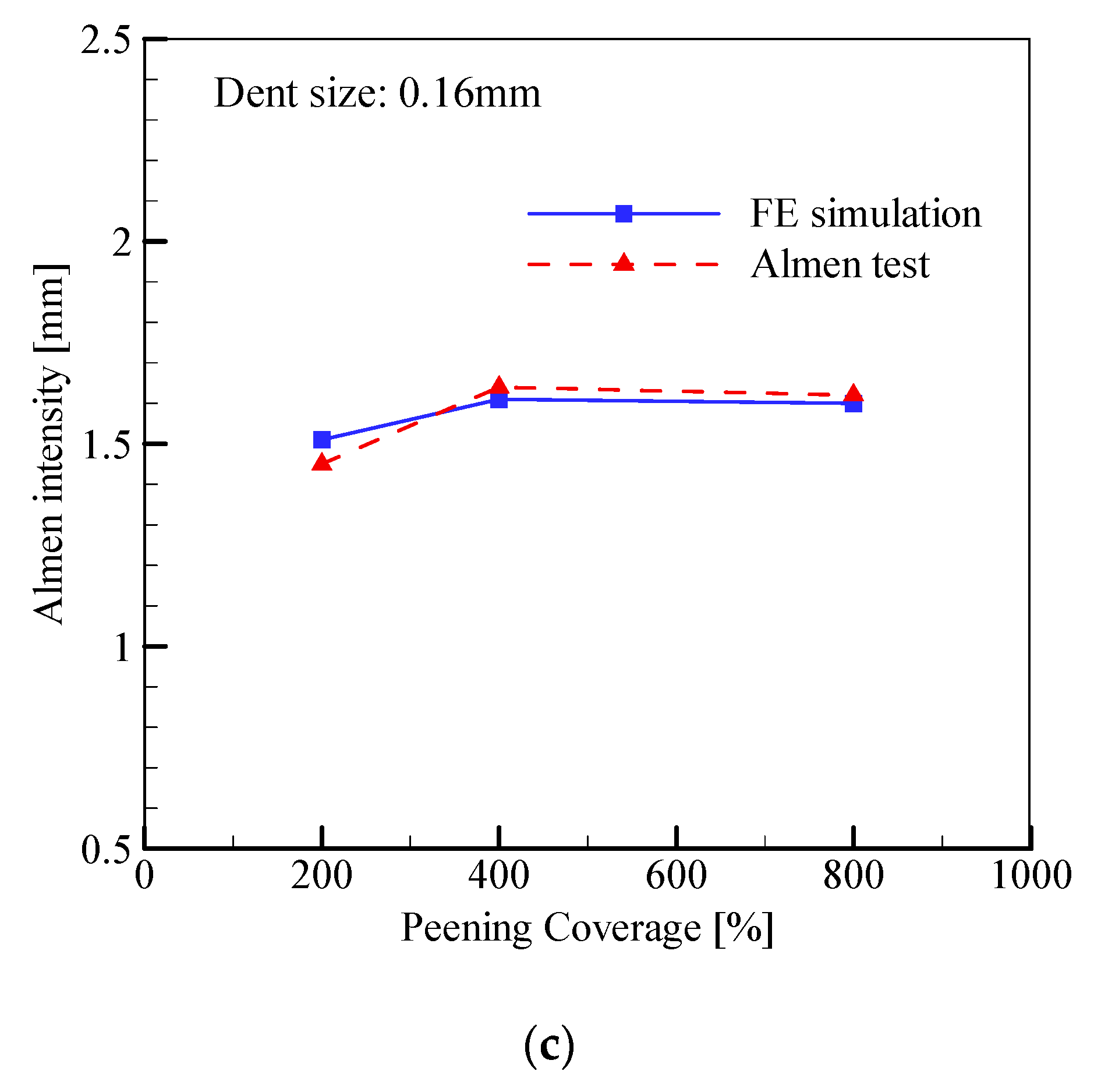

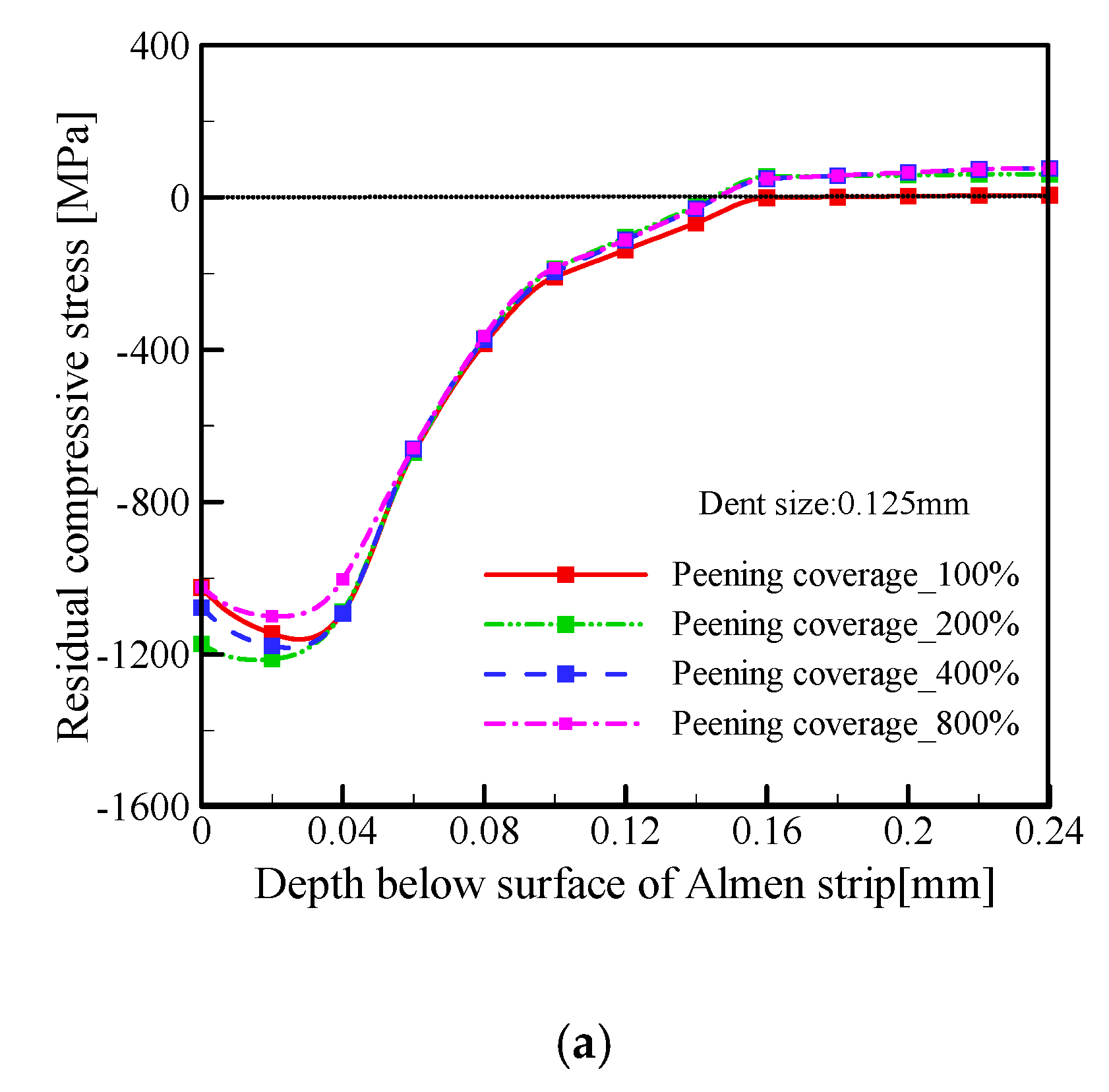

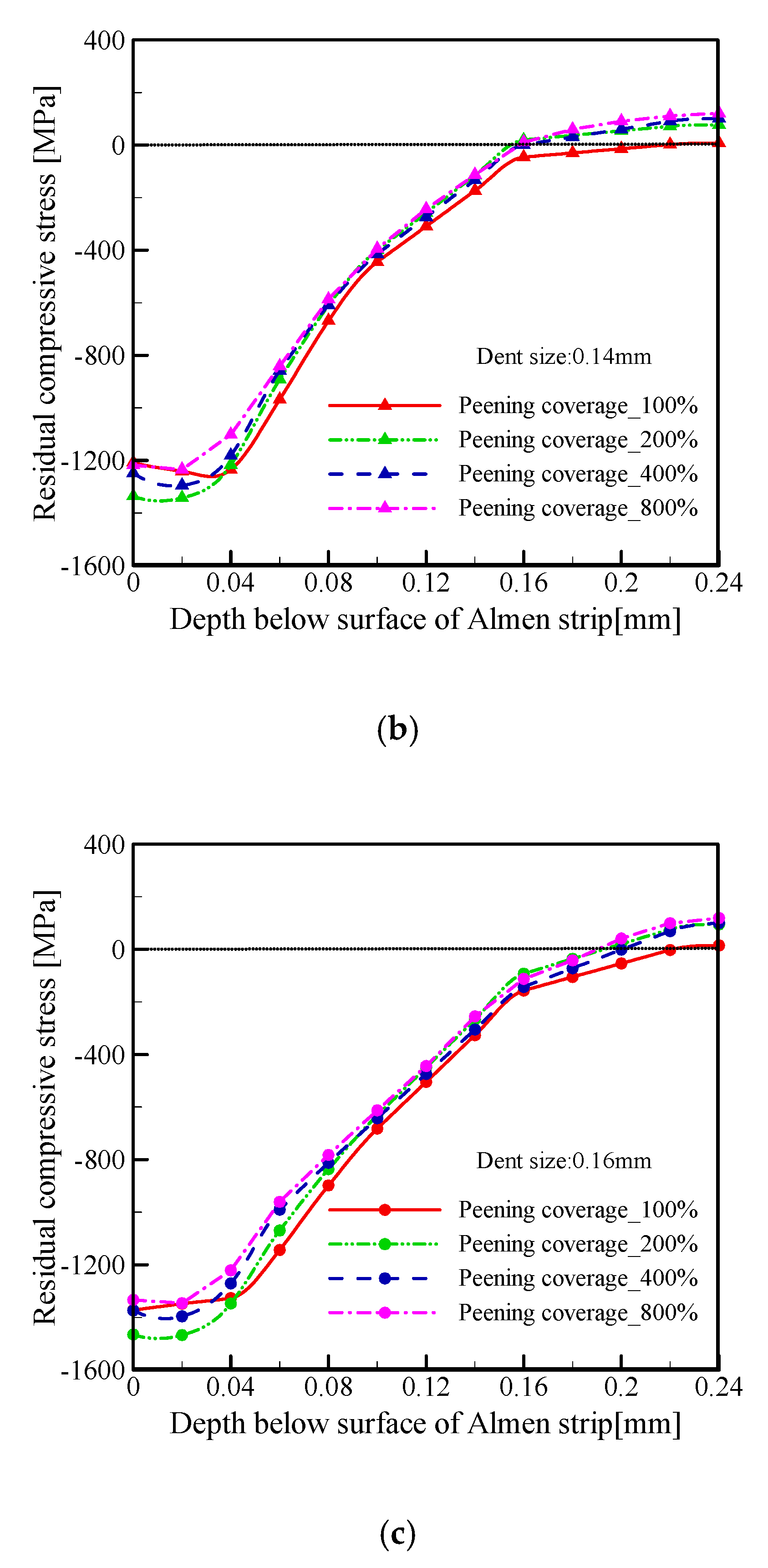

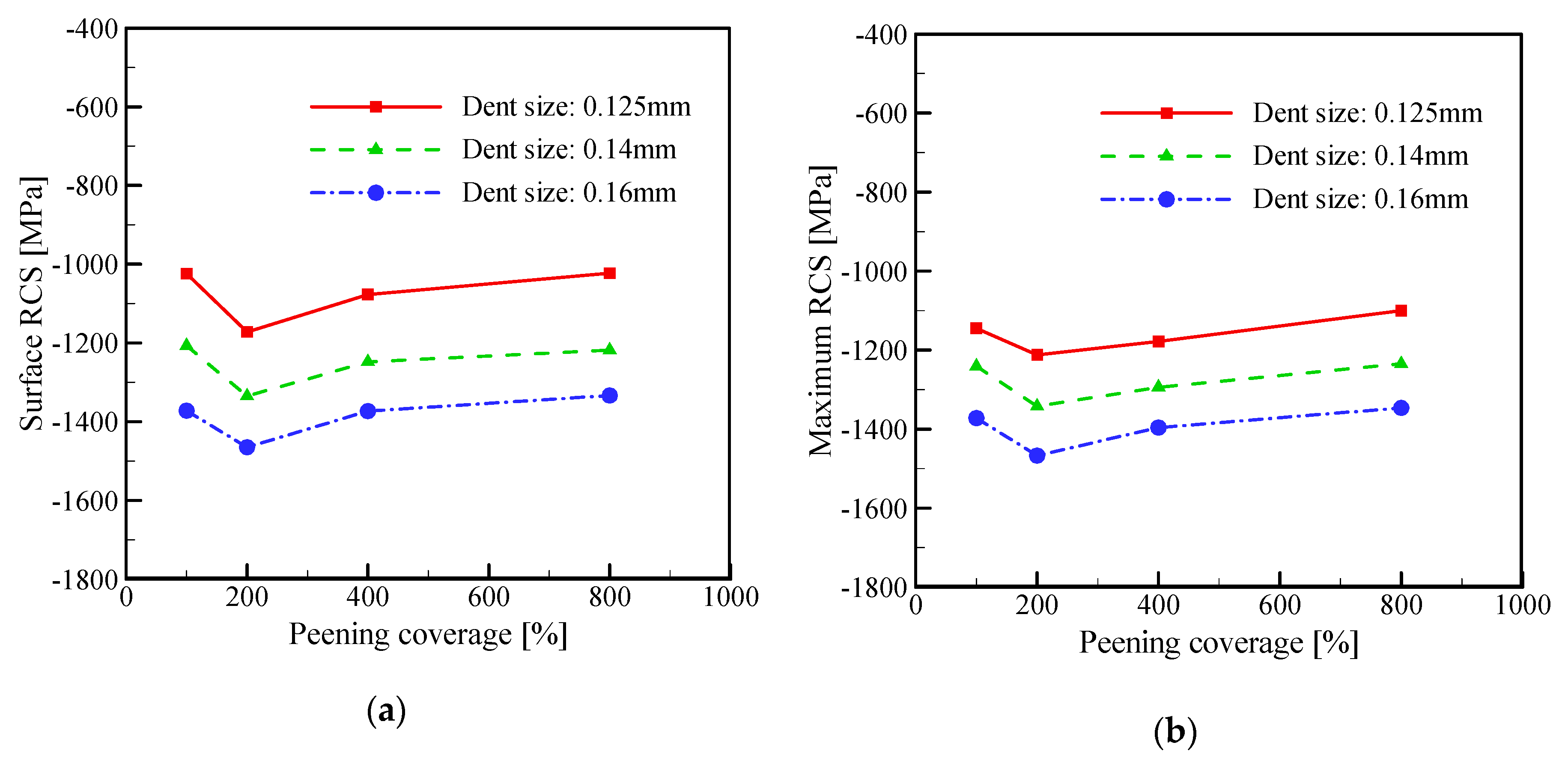

4.2. Influence of High Peening Coverage on RCS

5. Conclusions

- With the same peening coverage, arc height of FE simulation and Almen test agrees well, which indicates that the quantitative description of peening coverage and the FE simulation is effective.

- With dent size of 0.125, 0.14, and 0.16 mm, the Almen intensity all increases firstly and then decreases with the peening coverage increasing, there is a maximum value of Almen intensity, which is very important for shot peening process.

- With dent size of 0.125, 0.14, and 0.16 mm, there is a maximum absolute value of surface RCS and maximum RCS with the peening coverage increasing. With certain peening coverage, the surface RCS and maximum RCS increases as dent size increases.

Author Contributions

Funding

Conflicts of Interest

References

- Dimakos, K.; Mariotto, A.; Giacosa, F. Optimization of the fatigue resistance of nitinol stents through shot peening. Procedia Struct. Integr. 2016, 2, 1522–1529. [Google Scholar] [CrossRef]

- Gholami, M.; Altenberger, I.; Kuhn, H.A.; Wollmann, M.; Wagner, L. Effects of shot peening on the fatigue performance of ultrafine-grained CuNi3Si1Mg. Surf. Eng. 2017, 33, 706–714. [Google Scholar] [CrossRef]

- Segurado, E.; Belzunce, F.J.; Pariente, I.F. Effects of low intensity shot peening treatments applied with different types of shots on the fatigue performance of a high-strength steel. Surf. Coat. Technol. 2018, 340, 25–35. [Google Scholar] [CrossRef]

- Ferreira, N.; Antunes, P.; Ferreira, J.; Costa, J.; Capela, C. Effects of Shot-Peening and Stress Ratio on the Fatigue Crack Propagation of AL 7475-T7351 Specimens. Appl. Sci. 2018, 8, 375. [Google Scholar] [CrossRef]

- John, O.A.; Royal, O.M. Shot Blasting Test. U.S. Patent Office No. 440,987, 25 February 1944. [Google Scholar]

- Miao, H.Y.; Larose, S.; Perron, C.; Lévesque, M. An analytical approach to relate shot peening parameters to Almen intensity. Surf. Coat. Technol. 2010, 205, 2055–2066. [Google Scholar] [CrossRef]

- Guechichi, H.; Castex, L.; Benkhettab, M. An analytical model to relate shot peening Almen intensity to shot velocity. Mech. Based Des. Struct. 2013, 41, 79–99. [Google Scholar] [CrossRef]

- Unal, O.; Varol, R. Almen intensity effect on microstructure and mechanical properties of low carbon steel subjected to severe shot peening. Appl. Surf. Sci. 2014, 290, 40–47. [Google Scholar] [CrossRef]

- Unal, O. Optimization of shot peening parameters by response surface methodology. Surf. Coat. Technol. 2016, 305, 99–109. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Mhaede, M.; Basha, M.; Wollmann, M.; Wagner, L. The effect of shot peening parameters and hydroxyapatite coating on surface properties and corrosion behavior of medical grade AISI 316L stainless steel. Surf. Coat. Technol. 2015, 280, 347–358. [Google Scholar] [CrossRef]

- Jebahi, M.; Gakwaya, A.; Lévesque, J.; Mechri, O.; Ba, K. Robust methodology to simulate real shot peening process using discrete-continuum coupling method. Int. J. Mech. Sci. 2016, 107, 21–33. [Google Scholar] [CrossRef]

- Atig, A.; Sghaier, R.B.; Seddik, R.; Fathallah, R. Probabilistic methodology for predicting the dispersionof residual stresses and Almen intensity considering shot peening process uncertainties. Int. J. Adv. Manuf. Tech. 2018, 94, 2125–2136. [Google Scholar] [CrossRef]

- David, K. Quantification of Shot Peening Intensity Rating. Shot Peener Mag. 2015, 32, 26–34. [Google Scholar]

- Cao, W.; Fathallah, R.; Castex, L. Correlation of Almen arc height with residual stresses in shot peening process. Mater. Sci. Technol. 1995, 11, 967–973. [Google Scholar] [CrossRef]

- Guagliano, M. Relating Almen intensity to residual stresses induced by shot peening: A numerical approach. J. Mater. Process. Technol. 2001, 110, 277–286. [Google Scholar] [CrossRef]

- Bhuvaraghan, B.; Srinivasan, S.M.; Maffeo, B.; Prakash, O. Analytical solution for single and multiple impacts with strain-rate effects for shot peening. Comp. Model. Eng. Sci. 2010, 57, 137. [Google Scholar]

- Bhuvaraghan, B.; Srinivasan, S.M.; Maffeo, B.; McCLain, R.D.; Potdar, Y.; Prakash, O. Shot peening simulation using discrete and finite element methods. Adv. Eng. Softw. 2010, 41, 1266–1276. [Google Scholar] [CrossRef]

- Hu, D.Y.; Gao, Y.; Meng, F.C.; Song, J.; Wang, Y.F.; Ren, M.X.; Wang, R.Q. A unifying approach in simulating the shot peening process using a 3D random representative volume finite element model. Chin. J. Aeronaut. 2017, 30, 1592–1602. [Google Scholar] [CrossRef]

- Marini, M.; Fontanari, V.; Bandini, M.; Benedetti, M. Surface layer modifications of micro-shot-peened Al-7075-T651: Experiments and stochastic numerical simulations. Surf. Coat. Technol. 2017, 321, 265–278. [Google Scholar] [CrossRef]

- Tu, F.; Delbergue, D.; Klotz, T.; Bag, A.; Miao, H.; Bianchetti, C.; Brochu, M.; Bocher, P.; Levesque, M. Discrete element-periodic cell coupling model and investigations on shot stream expansion, Almen intensities and target materials. Int. J. Mech. Sci. 2018, 145, 353–366. [Google Scholar] [CrossRef]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. On the shot peening surface coverage and its assessment by means of finite element simulation: A critical review and some original developments. Appl. Surf. Sci. 2012, 259, 186–194. [Google Scholar] [CrossRef]

- Miao, H.Y.; Larose, S.; Perron, C.; Lévesque, M. On the potential applications of a 3D random finite element model for the simulation of shot peening. Adv. Eng. Softw. 2009, 40, 1023–1038. [Google Scholar] [CrossRef]

- Majzoobi, G.H.; Azizi, R.; Nia, A.A. A three-dimensional simulation of shot peening process using multiple shot impacts. J. Mater. Process. Technol. 2005, 164, 1226–1234. [Google Scholar] [CrossRef]

- Klemenz, M.; Schulze, V.; Rohr, I.; Löhe, D. Application of the FEM for the prediction of the surface layer characteristics after shot peening. J. Mater. Process. Technol. 2009, 209, 4093–4102. [Google Scholar] [CrossRef]

- Kubler, R.F.; Berveiller, S.; Bouscaud, D.; Guiheux, R.; Patoor, E.; Puydt, Q. Shot peening of TRIP780 steel: Experimental analysis and numerical simulation. J. Mater. Process. Technol. 2019, 270, 182–194. [Google Scholar] [CrossRef]

- Mylonas, G.I.; Labeas, G. Numerical modelling of shot peening process and corresponding products: Residual stress, surface roughness and cold work prediction. Surf. Coat. Technol. 2011, 205, 4480–4494. [Google Scholar] [CrossRef]

- Yang, Z.R.; Park, J.S.; Lee, Y. A strip holding system for finite element simulation of Almen strip testing. J. Mech. Sci. Technol. 2014, 28, 2825–2830. [Google Scholar] [CrossRef]

- David, K. The importance of work. Shot Peen. Mag. 2014, 31, 26–36. [Google Scholar]

- Hibbit, H.D.; Karlsson, B.I.; Sorensen, E.P. ABAQUS User Manual; Version 6.12; Simulia: Providence, RI, USA, 2012. [Google Scholar]

- Kim, T.; Lee, J.H.; Lee, H.; Cheong, S.K. An area-average approach to peening residual stress under multi-impacts using a three-dimensional symmetry-cell finite element model with plastic shots. Mater. Des. 2010, 31, 50–59. [Google Scholar] [CrossRef]

- Meo, M.; Vignjevic, R. Finite element analysis of residual stress induced by shot peening process. Adv. Eng. Softw. 2003, 34, 569–575. [Google Scholar] [CrossRef]

- Frija, M.; Hassine, T.; Fathallah, R.; Bouraoui, C.; Dogui, A.; de Génie Mécanique, L. Finite element modelling of shot peening process: Prediction of the compressive residual stresses, the plastic deformations and the surface integrity. Mat. Sci. Eng. A 2006, 426, 173–180. [Google Scholar] [CrossRef]

- Hong, T.; Ooi, J.Y.; Shaw, B.A. A numerical study of the residual stress pattern from single shot impacting on a metallic component. Adv. Eng. Softw. 2008, 39, 743–756. [Google Scholar] [CrossRef]

- Meguid, S.A.; Shagal, G.; Stranart, J.C. 3D FE analysis of peening of strain-rate sensitive materials using multiple impingement model. Int. J. Impact Eng. 2002, 27, 119–134. [Google Scholar] [CrossRef]

- Meguid, S.A.; Maricic, L.A. Finite element modeling of shot peening residual stress relaxation in turbine disk assemblies. J. Eng. Mater. Technol. 2015, 137, 031003. [Google Scholar] [CrossRef]

- Zimmermann, M.; Schulze, V.; Baron, H.U.; Löhe, D. A novel 3D finite element simulation model for the prediction of the residual stress state after shot peening. In Proceedings of the 10th International Conference on Shot Peening, Tokyo, Japan, 15–18 September 2008. [Google Scholar]

- Bagherifard, S.; Ghelichi, R.; Guagliano, M. A numerical model of severe shot peening (SSP) to predict the generation of a nanostructured surface layer of material. Surf. Coat. Technol. 2010, 204, 4081–4090. [Google Scholar] [CrossRef]

- Ullah, H.; Ullah, B.; Muhammad, R. Dynamic numerical simulation of plastic deformation and residual stress in shot peening of aluminum alloy. Struct. Eng. Mech. 2017, 63, 1–9. [Google Scholar]

- SAE. Test. Strip, Holder and Gage for Shot Peening; Society of Automotive Engineers, Inc.: Warrendale, PA, USA, 2004; p. J442. [Google Scholar]

| Property | Value |

|---|---|

| Density | 7800 kg/m3 |

| Poisson’s Ratio | 0.29 |

| Young’s Modulus | 205 GPa |

| Yield Strength | 1268 MPa |

| Ultimate Strength | 1422 MPa |

| Elongation | 8.2% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Lee, Y.; He, S.; Jia, W.; Zhao, J. Analysis of the Influence of High Peening Coverage on Almen Intensity and Residual Compressive Stress. Appl. Sci. 2020, 10, 105. https://doi.org/10.3390/app10010105

Yang Z, Lee Y, He S, Jia W, Zhao J. Analysis of the Influence of High Peening Coverage on Almen Intensity and Residual Compressive Stress. Applied Sciences. 2020; 10(1):105. https://doi.org/10.3390/app10010105

Chicago/Turabian StyleYang, Zhaorui, Youngseog Lee, Shangwen He, Wenzhen Jia, and Jun Zhao. 2020. "Analysis of the Influence of High Peening Coverage on Almen Intensity and Residual Compressive Stress" Applied Sciences 10, no. 1: 105. https://doi.org/10.3390/app10010105

APA StyleYang, Z., Lee, Y., He, S., Jia, W., & Zhao, J. (2020). Analysis of the Influence of High Peening Coverage on Almen Intensity and Residual Compressive Stress. Applied Sciences, 10(1), 105. https://doi.org/10.3390/app10010105