Value Stream Analysis in Military Logistics: The Improvement in Order Processing Procedure

Abstract

1. Introduction

2. Background

2.1. Military Logistics and Processes

2.2. Lean Methodologies and Tools

Value Stream Practices

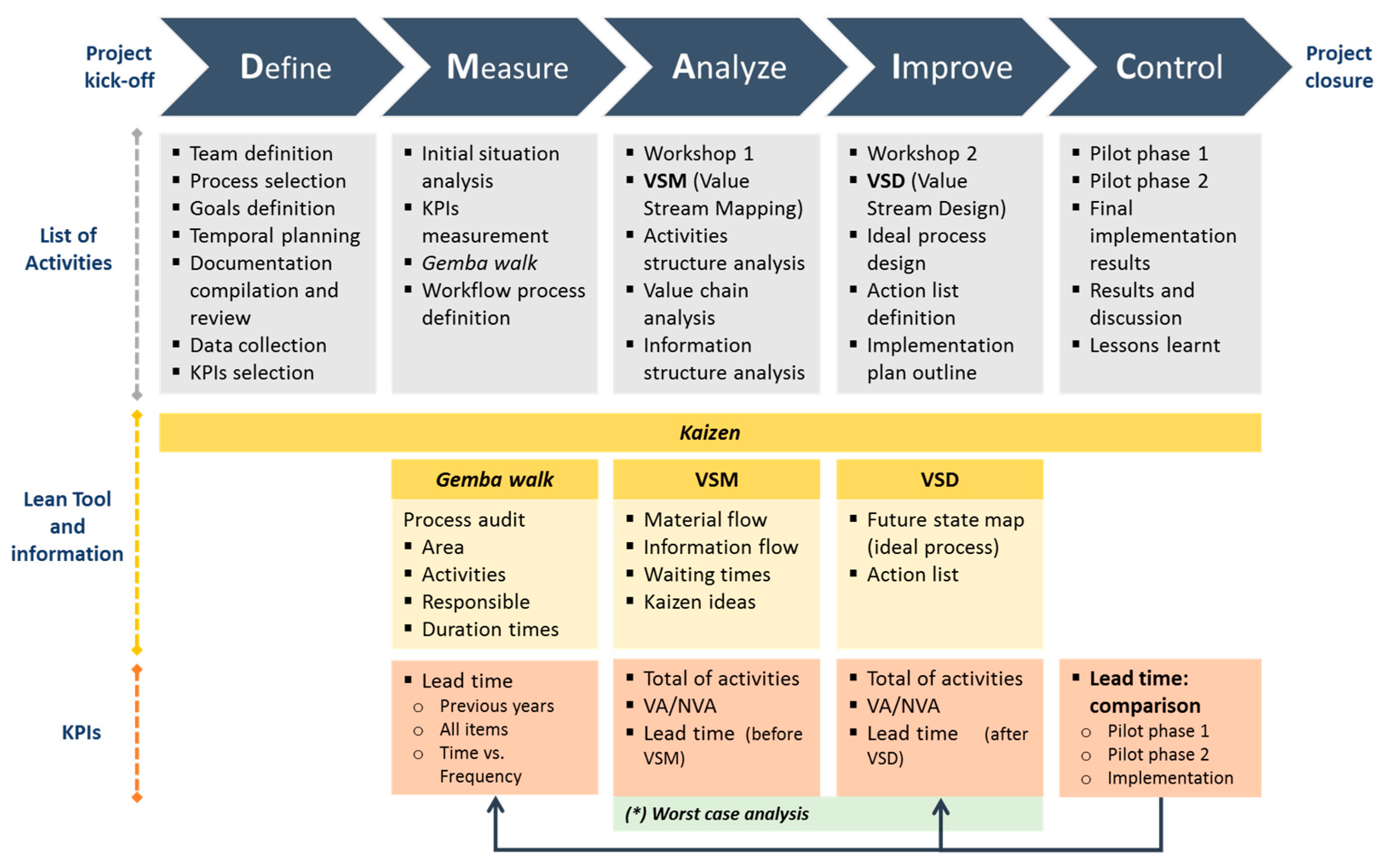

3. Methodology

4. Case Study

- Non-value added activities in the supply process should be identified.

- The affected areas of the process and the required times of their activities should be evaluated.

- General process improvements should be identified and the effectiveness of the actions proposed should be validated.

- The new procedure should be documented by redefining activities, workflow, responsibilities, and layouts.

- The requirements established by their own organization should be guaranteed.

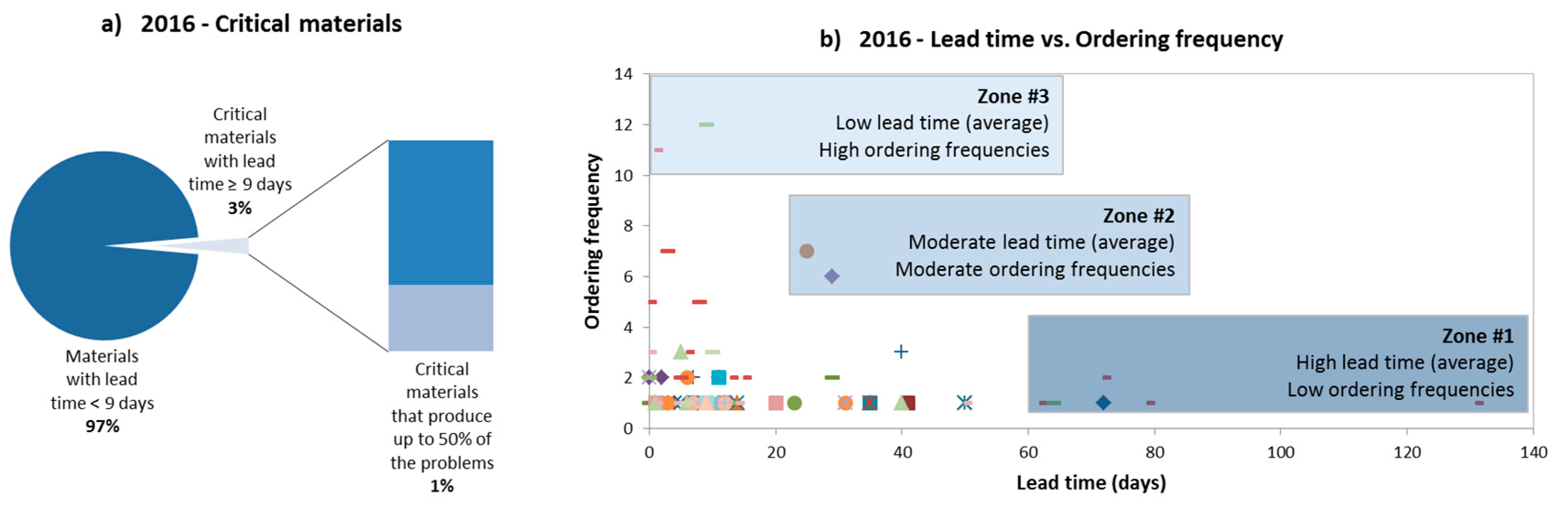

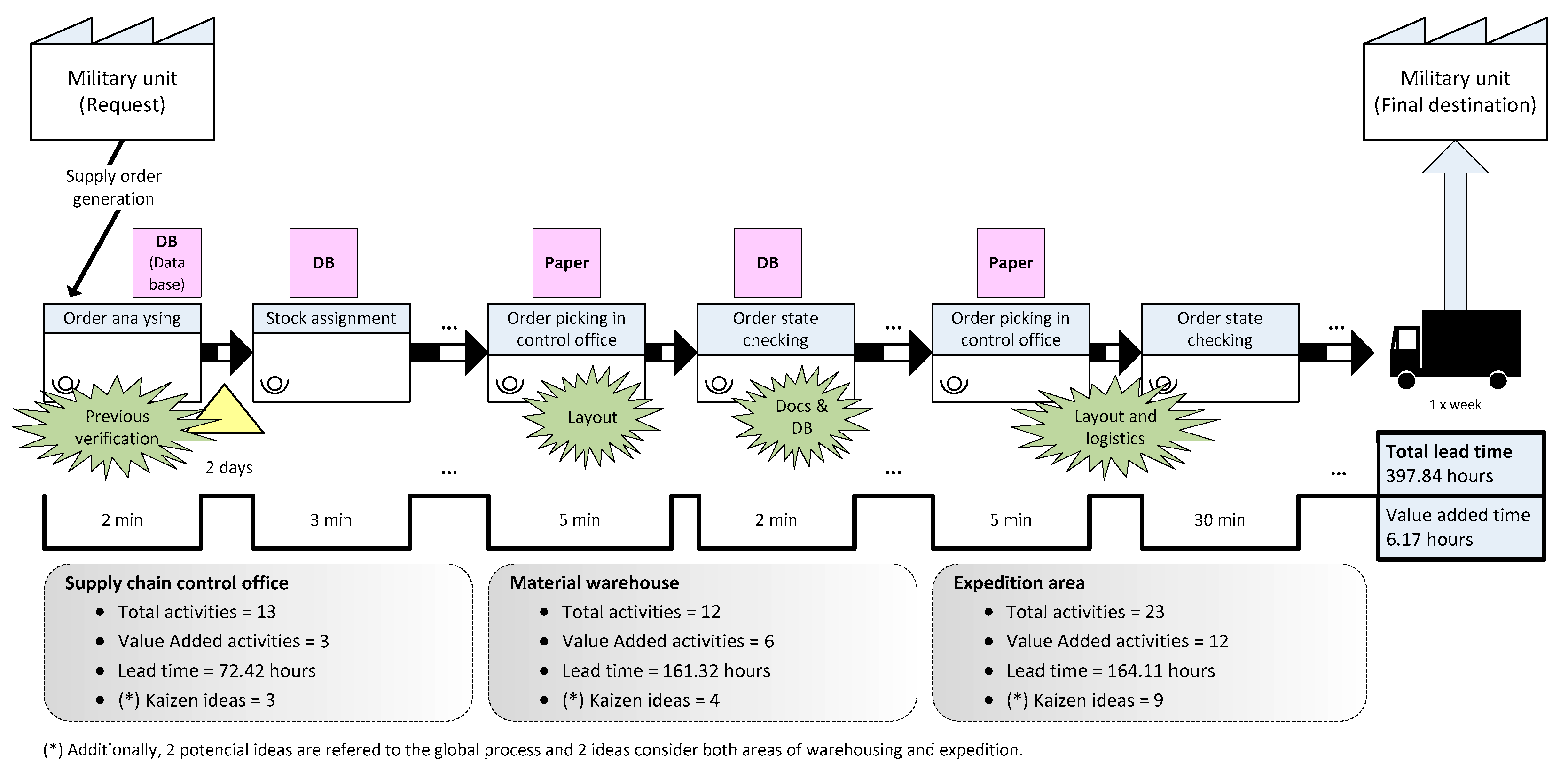

4.1. Current State Map

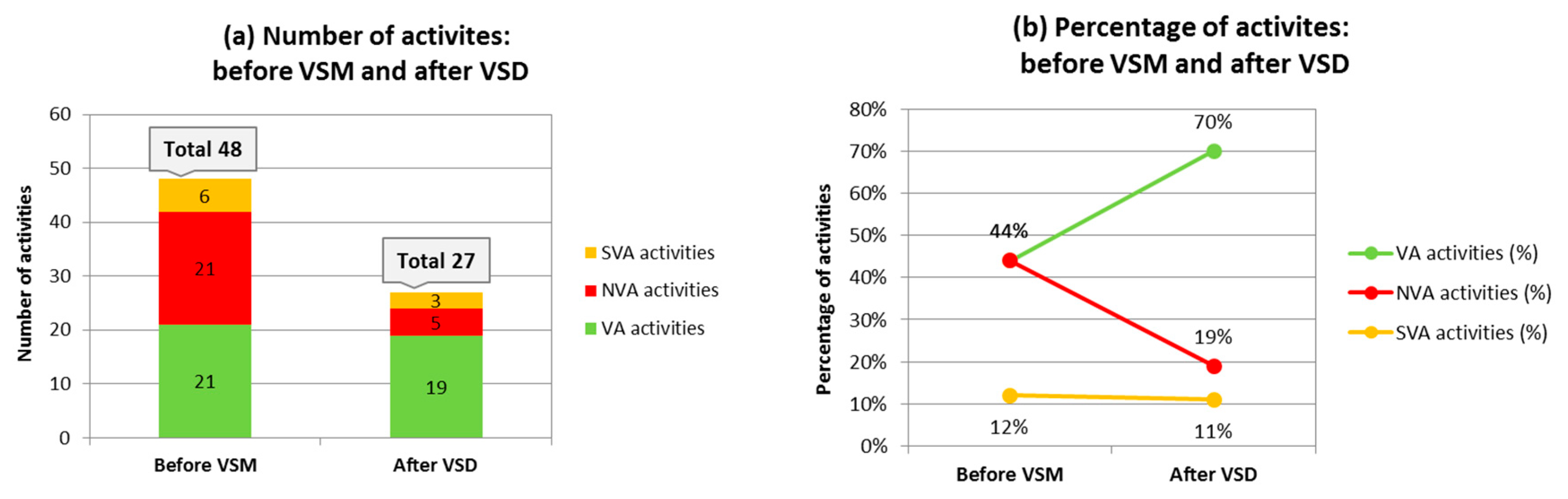

4.2. Future State Map

4.3. Implementation Plan Outline

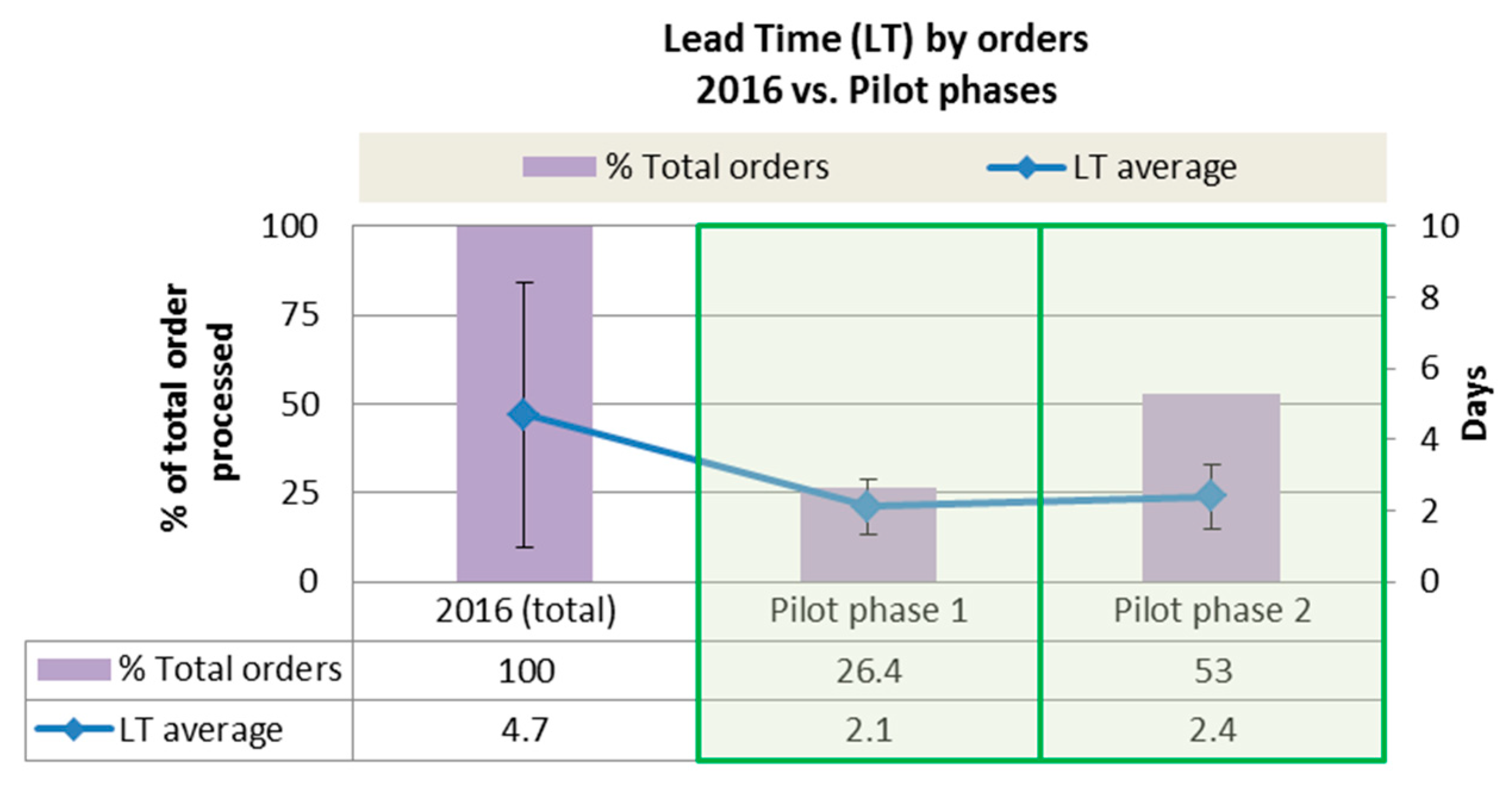

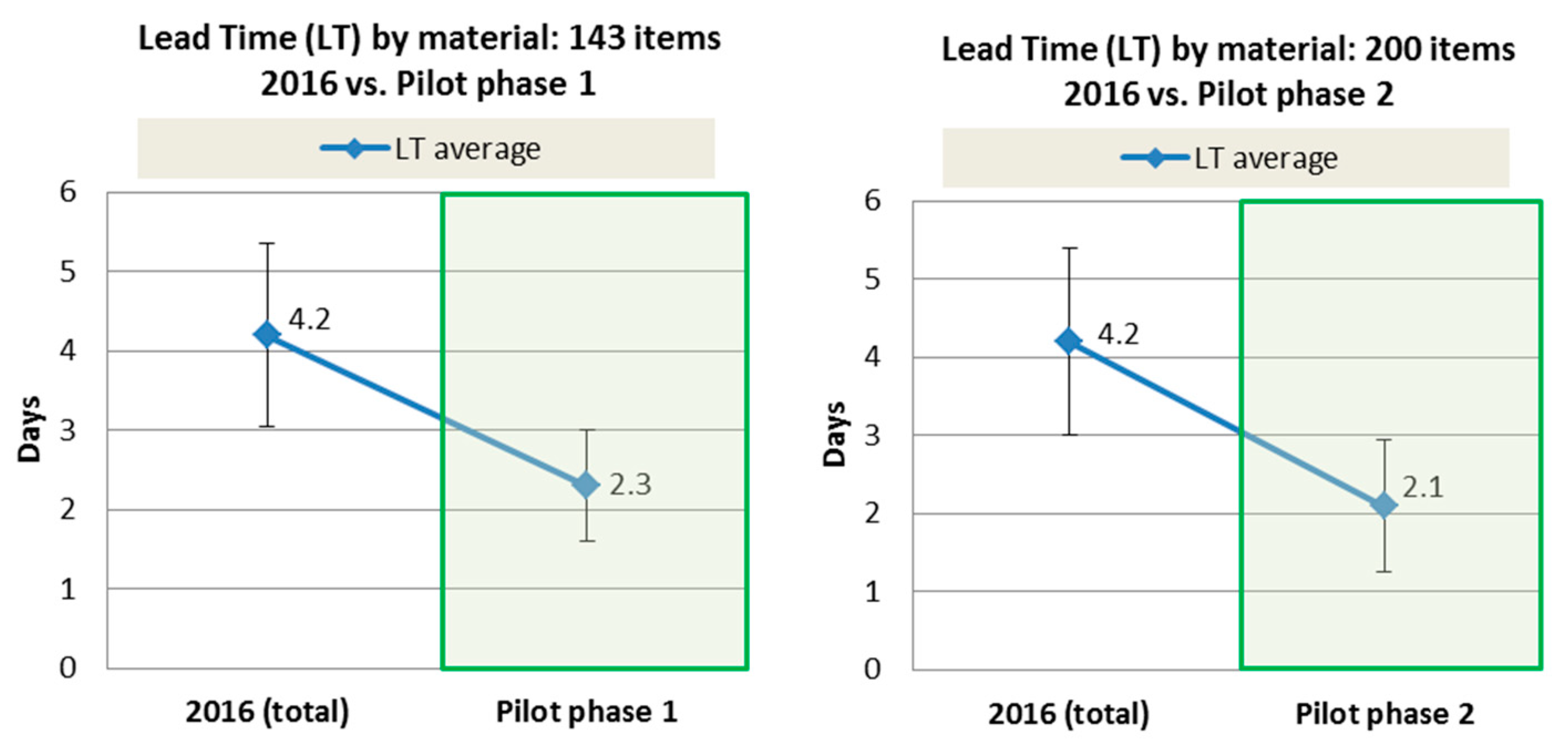

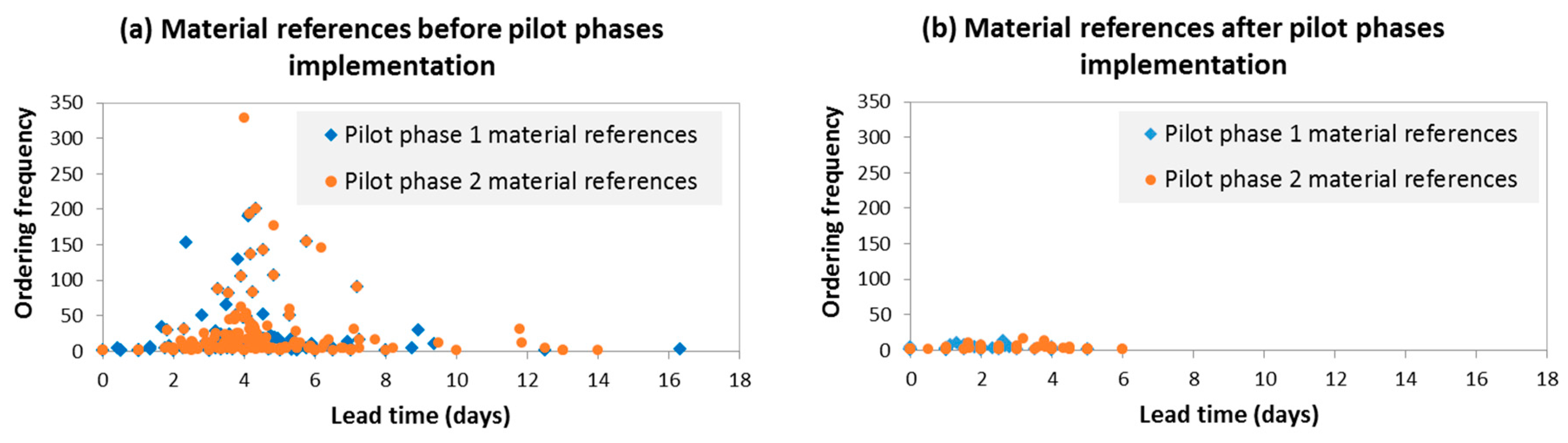

- Pilot phase 1: 11 working days, 26.4% of the total request orders processed with the new process, 143 different types of material references.

- Pilot phase 2: 10 working days, 53.0% of the total request orders processed with the new process, 200 different types of material references.

5. Results

6. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- The Wharton School, University of Pennsylvania. Managing Supply Chains: What the Military Can Teach Business (and Vice Versa). Available online: http://knowledge.wharton.upenn.edu/article/managing-supply-chains-what-the-military-can-teach-business-and-vice-versa/ (accessed on 17 July 2017).

- Lai, E.M. An Analysis of the Department of Defense Supply Chain: Potential Applications of the Auto-ID Center Technology to Improve Effectiveness. Ph.D. Thesis, Department of Mechanical Engineering, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Joint Vision 2020. In America’s Military—Preparing for Tomorrow; US Government Printing Office: Washington, DC, USA, 2000.

- Haraburda, S.; Col, B. Transforming military support processes from logistics to supply chain management. Army Sustain. 2016, 48, 12–15. [Google Scholar]

- Stewart, G. Supply-chain operations reference model (SCOR): The first cross-industry framework for integrated supply-chain management. Logist. Inf. Manag. 1997, 10, 62–67. [Google Scholar] [CrossRef]

- Huan, S.H.; Sheoran, S.K.; Wang, G. A review and analysis of supply chain operations reference (SCOR) model. Supply Chain Manag. Int. J. 2004, 9, 23–29. [Google Scholar] [CrossRef]

- Muckstadt, J.A.; General, T.; Babbitt, G. Military Supply Chains: Five Principles for Managing Uncertainty; PTC Inc.: Boston, MA, USA, 2016. [Google Scholar]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World: The Story of Lean Production; Harper Perennial: New York, NY, USA, 1991. [Google Scholar]

- Liker, J.K. The Toyota Way: 14 Management Principles from the World’s Greatest Manufacturer; McGraw Hill: New York, NY, USA, 2004. [Google Scholar]

- Ohno, T. Toyota Production System: Beyond Large-Scale Production; Productivity Press: New York, NY, USA, 1988. [Google Scholar]

- Shingo, S. Non-Stock Production: The Shingo System of Continuous Improvement; Productivity Press: Cambridge, MA, USA, 1988. [Google Scholar]

- Burt, D.N.; Dobler, D.W.; Starling, S.L. World Class Supply Management: The Key to Supply Chain Management; McGraw-Hill/Irwin: New York, NY, USA, 2003; ISBN 0072290706. [Google Scholar]

- Lysons, K.; Farrington, B. Purchasing and Supply Chain Management, 8th ed.; Pearson Education: London, UK, 2012. [Google Scholar]

- O’Rourke, D. The science of sustainable supply chains. Science 2014, 344, 1124–1127. [Google Scholar] [CrossRef]

- Lamming, R. Beyond Partnership: Strategies for Innovation and Lean Supply; Prentice Hall: Upper Saddle River, NJ, USA, 1993. [Google Scholar]

- Lamming, R. Squaring lean supply with supply chain management. Int. J. Oper. Prod. Manag. 1996, 16, 183–196. [Google Scholar] [CrossRef]

- Pande, P.S.; Neuman, R.P.; Cavanagh, R.R. The Six Sigma Way; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Imai, M. Kaizen: The Key to Japan’s Competitive Success; McGraw-Hill Education: New York, NY, USA, 1986. [Google Scholar]

- Harry, M.; Schroeder, R.R. Six Sigma: The Breakthrough Management Strategy Revolutionizing the World’s Top Corporations; Doubleday Business: New York, NY, USA, 1999. [Google Scholar]

- Arnheiter, E.D.; Maleyeff, J. The integration of lean management and Six Sigma. TQM Mag. 2005, 17, 5–18. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Chiarini, A.; Mokhlis, A.; Benhida, K. The integration of lean manufacturing, Six Sigma and sustainability: A literature review and future research directions for developing a specific model. J. Clean. Prod. 2016, 139, 828–846. [Google Scholar] [CrossRef]

- Tuttle, W., Jr. Defense Logistics for the 21st Century; Naval Institute Press: Annapolis, MD, USA, 2013. [Google Scholar]

- NATO Standardization Agency. NATO Glossary of Terms and Definitions; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2013. [Google Scholar]

- Zhou, W.; Zhang, C.; Wang, Q. Concealment measurement and flow distribution of military supply transportation: A double-entropy model. Eur. J. Oper. Res. 2018, 264, 570–581. [Google Scholar] [CrossRef]

- Kalchschmidt, M.; Zotteri, G.; Verganti, R. Inventory management in a multi-echelon spare parts supply chain. Int. J. Prod. Econ. 2003, 81, 397–413. [Google Scholar] [CrossRef]

- Huiskonen, J. Maintenance spare parts logistics: Special characteristics and strategic choices. Int. J. Prod. Econ. 2001, 71, 125–133. [Google Scholar] [CrossRef]

- Tysseland, B.E. Spare parts optimization process and results: OPUS10 cases in the Norwegian Defence. Int. J. Phys. Distrib. Logist. Manag. 2009, 39, 8–27. [Google Scholar] [CrossRef]

- Gholz, E.; James, A.D.; Speller, T.H. The second face of systems integration: An empirical analysis of supply chains to complex product systems. Res. Policy 2018, 47, 1478–1494. [Google Scholar] [CrossRef]

- Mayr, A.; Weigelt, M.; Kühl, A.; Grimm, S.; Erll, A.; Potzel, M.; Franke, J. Lean 4.0—A conceptual conjunction of lean management and Industry 4.0. Procedia CIRP 2018, 72, 622–628. [Google Scholar] [CrossRef]

- Krafcik, J.F. Triumph of the lean production system. MIT Sloan Manag. Rev. 1988, 30, 41. [Google Scholar]

- Shah, R.; Ward, P.T. Lean manufacturing: Context, practice bundles, and performance. J. Oper. Manag. 2003, 21, 129–149. [Google Scholar] [CrossRef]

- Bhamu, J.; Sangwan, K.S.; Singh Sangwan, K. Lean manufacturing: Literature review and research issues. Int. J. Oper. Prod. Manag. 2014, 34, 876–940. [Google Scholar] [CrossRef]

- Sundar, R.; Balaji, A.N.; Kumar, R.M.S. A Review on Lean Manufacturing Implementation Techniques. Procedia Eng. 2014, 97, 1875–1885. [Google Scholar] [CrossRef]

- Netland, T.H.; Schloetzer, J.D.; Ferdows, K. Implementing corporate lean programs: The effect of management control practices. J. Oper. Manag. 2015, 36, 90–102. [Google Scholar] [CrossRef]

- Pearce, A.; Pons, D. Advancing lean management: The missing quantitative approach. Oper. Res. Perspect. 2019, 6, 100114. [Google Scholar] [CrossRef]

- Wahab, A.N.A.; Mukhtar, M.; Sulaiman, R. A Conceptual Model of Lean Manufacturing Dimensions. Procedia Technol. 2013, 11, 1292–1298. [Google Scholar] [CrossRef]

- Hines, P.; Holweg, M.; Rich, N. Learning to evolve. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Rother, M.; Shook, J. Learning to See: Value Stream Mapping to Add Value and Eliminate Muda; The Lean Enterprise Institute: Brookline, MA, USA, 1998. [Google Scholar]

- Bruce, M.; Daly, L.; Towers, N. Lean or agile: A solution for supply chain management in the textiles and clothing industry? Int. J. Oper. Prod. Manag. 2004, 24, 151–170. [Google Scholar] [CrossRef]

- Christopher, M. The Agile Supply Chain. Ind. Mark. Manag. 2000, 29, 37–44. [Google Scholar] [CrossRef]

- Naylor, J.B.; Naim, M.; Berry, D. Leagility: Integrating the lean and agile manufacturing in the total supply chain. Int. J. Prod. Econ. 1999, 62, 107–118. [Google Scholar] [CrossRef]

- Martin, C.; Towill, D.R. Supply chain migration from lean and functional to agile and customised. Supply Chain Manag. Int. J. 2000, 5, 206–213. [Google Scholar] [CrossRef]

- Minculete, G.; Olar, P. Push and Pull systems in supply chain management. Correlative approaches in the military field. J. Def. Resour. Manag. 2016, 7, 165–172. [Google Scholar]

- Bean, W.L.; Joubert, J.W.; Luhandjula, M.K. Inventory management under uncertainty: A military application. Comput. Ind. Eng. 2016, 96, 96–107. [Google Scholar] [CrossRef]

- Hines, P.; Rich, N. The seven value stream mapping tools. Int. J. Oper. Prod. Manag. 1997, 17, 46–64. [Google Scholar] [CrossRef]

- Forno, A.J.D.; Pereira, F.A.; Forcellini, F.A.; Kipper, L.M. Value Stream Mapping: A study about the problems and challenges found in the literature from the past 15 years about application of Lean tools. Int. J. Adv. Manuf. Technol. 2014, 72, 779–790. [Google Scholar] [CrossRef]

- Singh, B.; Garg, S.K.; Sharma, S.K. Value stream mapping: Literature review and implications for Indian industry. Int. J. Adv. Manuf. Technol. 2011, 53, 799–809. [Google Scholar] [CrossRef]

- Shou, W.; Wang, J.; Wu, P.; Wang, X.; Chong, H.-Y. A cross-sector review on the use of value stream mapping. Int. J. Prod. Res. 2017, 55, 3906–3928. [Google Scholar] [CrossRef]

- Seth, D.; Seth, N.; Dhariwal, P. Application of value stream mapping (VSM) for lean and cycle time reduction in complex production environments: A case study. Prod. Plan. Control 2017, 28, 398–419. [Google Scholar] [CrossRef]

- Wee, H.M.; Wu, S. Lean supply chain and its effect on product cost and quality: A case study on Ford Motor Company. Supply Chain Manag. Int. J. 2009, 14, 335–341. [Google Scholar] [CrossRef]

- Rahani, A.R.; Al-Ashraf, M. Production Flow Analysis through Value Stream Mapping: A Lean Manufacturing Process Case Study. Procedia Eng. 2012, 41, 1727–1734. [Google Scholar] [CrossRef]

- Andrade, P.F.; Pereira, V.G.; Del Conte, E.G. Value stream mapping and lean simulation: A case study in automotive company. Int. J. Adv. Manuf. Technol. 2016, 85, 547–555. [Google Scholar] [CrossRef]

- Venkataraman, K.; Ramnath, B.V.; Kumar, V.M.; Elanchezhian, C. Application of Value Stream Mapping for Reduction of Cycle Time in a Machining Process. Procedia Mater. Sci. 2014, 6, 1187–1196. [Google Scholar] [CrossRef]

- Rohac, T.; Januska, M. Value Stream Mapping Demonstration on Real Case Study. Procedia Eng. 2015, 100, 520–529. [Google Scholar] [CrossRef]

- Hodge, G.L.; Ross, K.G.; Joines, J.A.; Thoney, K. Adapting lean manufacturing principles to the textile industry. Prod. Plan. Control 2011, 22, 237–247. [Google Scholar] [CrossRef]

- Abdulmalek, F.A.; Rajgopal, J. Analyzing the benefits of lean manufacturing and value stream mapping via simulation: A process sector case study. Int. J. Prod. Econ. 2007, 107, 223–236. [Google Scholar] [CrossRef]

- Rohani, J.M.; Zahraee, S.M. Production Line Analysis via Value Stream Mapping: A Lean Manufacturing Process of Color Industry. Procedia Manuf. 2015, 2, 6–10. [Google Scholar] [CrossRef]

- Yang, T.; Kuo, Y.; Su, C.T.; Hou, C.L. Lean production system design for fishing net manufacturing using lean principles and simulation optimization. J. Manuf. Syst. 2015, 34, 66–73. [Google Scholar] [CrossRef]

- Hartmann, L.; Meudt, T.; Seifermann, S.; Metternich, J. Value stream method 4.0: Holistic method to analyse and design value streams in the digital age. Procedia CIRP 2018, 78, 249–254. [Google Scholar] [CrossRef]

- Knoll, D.; Reinhart, G.; Prüglmeier, M. Enabling value stream mapping for internal logistics using multidimensional process mining. Expert Syst. Appl. 2019, 124, 130–142. [Google Scholar] [CrossRef]

- Stadnicka, D.; Litwin, P. Value stream mapping and system dynamics integration for manufacturing line modelling and analysis. Int. J. Prod. Econ. 2019, 208, 400–411. [Google Scholar] [CrossRef]

- Jiménez, E.; Tejeda, A.; Pérez, M.; Blanco, J.; Martínez, E. Applicability of lean production with VSM to the Rioja wine sector. Int. J. Prod. Res. 2012, 50, 1890–1904. [Google Scholar] [CrossRef]

- De Steur, H.; Wesana, J.; Dora, M.K.; Pearce, D.; Gellynck, X. Applying Value Stream Mapping to reduce food losses and wastes in supply chains: A systematic review. Waste Manag. 2016, 58, 359–368. [Google Scholar] [CrossRef]

- Tyagi, S.; Choudhary, A.; Cai, X.; Yang, K. Value stream mapping to reduce the lead-time of a product development process. Int. J. Prod. Econ. 2015, 160, 202–212. [Google Scholar] [CrossRef]

- Kaiser, J.; Urnauer, C.; Metternich, J. A framework for planning logistical alternatives in value stream design. Procedia CIRP 2019, 81, 180–185. [Google Scholar] [CrossRef]

- Ali, N.B.; Petersen, K.; De França, B.B.N. Evaluation of simulation-assisted value stream mapping for software product development: Two industrial cases. Inf. Softw. Technol. 2015, 68, 45–61. [Google Scholar] [CrossRef]

- Grove, A.L.; Meredith, J.O.; Macintyre, M.; Angelis, J.; Neailey, K. Lean implementation in primary care health visiting services in National Health Service UK. Qual. Saf. Health Care 2010, 19, e43. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Torres Romero, J.; Govindan, K.; Cherrafi, A.; Ramanathan, U. A PDCA-based approach to Environmental Value Stream Mapping (E-VSM). J. Clean. Prod. 2018, 180, 335–348. [Google Scholar] [CrossRef]

- Faulkner, W.; Badurdeen, F. Sustainable Value Stream Mapping (Sus-VSM): Methodology to visualize and assess manufacturing sustainability performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- Helleno, A.L.; de Moraes, A.J.I.; Simon, A.T. Integrating sustainability indicators and Lean Manufacturing to assess manufacturing processes: Application case studies in Brazilian industry. J. Clean. Prod. 2017, 153, 405–416. [Google Scholar] [CrossRef]

- Deshkar, A.; Kamle, S.; Giri, J.; Korde, V. Design and evaluation of a Lean Manufacturing framework using Value Stream Mapping (VSM) for a plastic bag manufacturing unit. Mater. Today Proc. 2018, 5, 7668–7677. [Google Scholar] [CrossRef]

- Kasava, N.K.; Yusof, N.M.; Khademi, A.; Saman, M.Z.M. Sustainable domain value stream mapping (SdVSM) framework application in aircraft maintenance: A case study. Procedia CIRP 2015, 26, 418–423. [Google Scholar] [CrossRef]

- Vinodh, S.; Ben Ruben, R.; Asokan, P. Life cycle assessment integrated value stream mapping framework to ensure sustainable manufacturing: A case study. Clean Technol. Environ. Policy 2016, 18, 279–295. [Google Scholar] [CrossRef]

- Edtmayr, T.; Sunk, A.; Sihn, W. An Approach to Integrate Parameters and Indicators of Sustainability Management into Value Stream Mapping. Procedia CIRP 2016, 41, 289–294. [Google Scholar] [CrossRef]

- Haefner, B.; Kraemer, A.; Stauss, T.; Lanza, G. Quality Value Stream Mapping. Procedia CIRP 2014, 17, 254–259. [Google Scholar] [CrossRef]

- Toivonen, T.; Siitonen, J. Value Stream Analysis for Complex Processes and Systems. Procedia CIRP 2016, 39, 9–15. [Google Scholar] [CrossRef]

- Oberhausen, C.; Plapper, P. Cross-enterprise value stream assessment. J. Adv. Manag. Res. 2017, 14, 182–193. [Google Scholar] [CrossRef]

- Roh, P.; Kunz, A.; Wegener, K. Information stream mapping: Mapping, analysing and improving the efficiency of information streams in manufacturing value streams. CIRP J. Manuf. Sci. Technol. 2019, 25, 1–13. [Google Scholar] [CrossRef]

- de Mast, J.; Lokkerbol, J. An analysis of the Six Sigma DMAIC method from the perspective of problem solving. Int. J. Prod. Econ. 2012, 139, 604–614. [Google Scholar] [CrossRef]

- Parast, M.M. The effect of Six Sigma projects on innovation and firm performance. Int. J. Proj. Manag. 2011, 29, 45–55. [Google Scholar] [CrossRef]

- Srinivasan, K.; Muthu, S.; Devadasan, S.R.; Sugumaran, C. Enhancing effectiveness of shell and tube heat exchanger through six sigma DMAIC phases. Procedia Eng. 2014, 97, 2064–2071. [Google Scholar] [CrossRef]

- Nithyanandam, G.K.; Pezhinkattil, R. A Six Sigma approach for precision machining in milling. Procedia Eng. 2014, 97, 1474–1488. [Google Scholar] [CrossRef][Green Version]

- Cunha, C.; Dominguez, C. A DMAIC Project to Improve Warranty Billing’s Operations: A Case Study in a Portuguese Car Dealer. Procedia Comput. Sci. 2015, 64, 885–893. [Google Scholar] [CrossRef]

- Erbiyik, H.; Saru, M. Six Sigma Implementations in Supply Chain: An Application for an Automotive Subsidiary Industry in Bursa in Turkey. Procedia Soc. Behav. Sci. 2015, 195, 2556–2565. [Google Scholar] [CrossRef]

- Hardy, D. An Analysis of Lean Six Sigma in the Army, Navy and Air Force; Naval Postgraduate School: Monterey, CA, USA, 2018. [Google Scholar]

- Baily, A.; Gibson, B.; MacFarlane, J.M.; Hazelbaker, C.; Richards, J.; Lyle, I.; Rawhouser, B. Application of lean six sigma to reduce repeated handling of material at Tobyhanna Army Depot. In Proceedings of the 39th International Annual Conference American Society Engineering Management, ASEM 2018 Bridging Gap between Engineering and Business, Coeur d’Alene, ID, USA, 17–20 October 2018; pp. 691–700. [Google Scholar]

| Indicator | Before VSM | After VSD |

|---|---|---|

| Total activities | 48 | 27 |

| VA activities (%) | 21 (44%) | 19 (70%) |

| NVA activities (%) | 21 (44%) | 5 (19%) |

| SVA activities (%) | 6 (12%) | 3 (11%) |

| VA (hours) | 6.17 | 1.96 |

| NVA (hours) | 391.68 | 4.01 |

| VA/[NVA + SVA] (%) | 1.57% | 48.86% |

| Lead Time (hours) | 397.84 | 5.97 |

| Lead Time (days) | 49.73 | 0.75 |

| Study Groups | t-Test for Equality of Means | t | Freedom Degrees | Sig. (2-Tailed) | Mean Difference | Std. Error Difference |

|---|---|---|---|---|---|---|

| Post-test Experimental group and control group | Equal variances assumed | −3.56 | 608 | 0.000 | −0.614 | 0.172 |

| Equal variances not assumed | −3.50 | 518.9 | 0.001 | −0.614 | 0.176 | |

| Experimental group Pre-test and Post-test | Equal variances assumed | 5.43 | 10939 | 0.000 | 2.243 | 0.413 |

| Equal variances not assumed | 18.18 | 733.2 | 0.000 | 2.243 | 0.123 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Acero, R.; Torralba, M.; Pérez-Moya, R.; Pozo, J.A. Value Stream Analysis in Military Logistics: The Improvement in Order Processing Procedure. Appl. Sci. 2020, 10, 106. https://doi.org/10.3390/app10010106

Acero R, Torralba M, Pérez-Moya R, Pozo JA. Value Stream Analysis in Military Logistics: The Improvement in Order Processing Procedure. Applied Sciences. 2020; 10(1):106. https://doi.org/10.3390/app10010106

Chicago/Turabian StyleAcero, Raquel, Marta Torralba, Roberto Pérez-Moya, and José Antonio Pozo. 2020. "Value Stream Analysis in Military Logistics: The Improvement in Order Processing Procedure" Applied Sciences 10, no. 1: 106. https://doi.org/10.3390/app10010106

APA StyleAcero, R., Torralba, M., Pérez-Moya, R., & Pozo, J. A. (2020). Value Stream Analysis in Military Logistics: The Improvement in Order Processing Procedure. Applied Sciences, 10(1), 106. https://doi.org/10.3390/app10010106