Abstract

This research aims to develop a conceptual framework and propositions to establish and test the causal relationships between Industry 5.0 readiness (I5.0R), global value chain (GVC) participation, business competitiveness (BC), and sustainable business growth (SBG) of small and medium-sized enterprises (SMEs). This study focuses on Industry 5.0 readiness, evaluated through human-centricity, fairtrade practices, lean management, sustainability practices, and business competitiveness, measured by marketing, resources, production, and finance. Both constructs were developed and tested as higher-order constructs, while GVC participation and sustainable business growth were assessed as lower-order constructs. Data were collected from marine food processing SMEs in Thailand using a purposive sampling technique. This study tested and confirmed the content validity, construct validity, and reliability of both lower and higher-order models. Using partial least squares structural equation modeling (PLS-SEM) with bootstrapping (n = 1000), the results indicated significant positive impacts of Industry 5.0 readiness on GVC participation, Industry 5.0 readiness on business competitiveness, GVC participation on business competitiveness, and business competitiveness on the sustainable business growth of SMEs. Additionally, business competitiveness was found to mediate the relationship between Industry 5.0 readiness and sustainable business growth. These findings contribute to the literature on Industry 5.0, GVCs, and SME business competitiveness, offering practical insights for SMEs and policymakers aiming to enhance sustainable growth through strategic readiness and competitiveness in Industry 5.0 practices. The implications and directions for further research in Industry 5.0 readiness of SMEs are presented.

1. Introduction

Industry 5.0 is the perpetuation of Industry 4.0 with a special focus on human-centricity, sustainability, and the resilience of industries (Industry 5.0—European Commission 2022). Since 2016, the concept has been widely discussed by industry experts and academicians in blogs, websites, social media, conferences, journals, and government reports (Rada 2015; Gotfredsen 2016; ØSTERGAARD 2016; Sachsenmeier 2016; Atwell 2017; Demir and Cicibaş 2017; Rendall 2017; Skobelev and Borovik 2017; European Economic and Social Committee 2018; Özdemir and Hekim 2018; Ozkeser 2018; Rossi 2018; Vollmer 2018; Demir et al. 2019; Nahavandi 2019; Paschek et al. 2019; Pathak et al. 2019; Iftikhar and Iftikhar 2020; Müller 2020; Saptaningtyas and Rahayu 2020). It is a well-known fact that past industrial revolutions have transformed the firms’ business processes. However, the contemporary post-globalized industrial revolutions differ from the pre-globalized industrial revolutions. This is because, in the 21st century, small and medium-sized enterprises (SMEs) play a significant role in the post-globalized modern industrial structure. They contribute a significant share in the growth of national economies by creating new jobs, stimulating the regional economy, and adding value to the products and services. Hence, SMEs play a crucial role in the value chains and are considered inevitable in the success of “Industry 5.0”. Accordingly, better integration, technology implementation, and value generation are indispensable for the sustainable growth of SMEs (Müller 2020).

Over the years, Thailand has been transformed from an agricultural society (Industry 1.0) to a value-based economy (Industry 4.0). Therefore, the Thai Government encourages SMEs to prepare to embrace the challenges in the Thailand 4.0 era and drive the economy towards Thailand 4.0 by boosting SME startups to produce innovative and high-value products (Nantachukra n.d.). However, a survey (SMEs Development Bank of Thailand 2018) with 1219 entrepreneurs revealed that “Entrepreneurs who can upgrade their business into the Thailand 4.0 era by using advanced technology research and innovation” were only 2.87%, followed by 1.97% in the 3.0 era (heavy machinery). All the remaining respondents were working with the technologies from 2.0 (72.33%), and 1.0 (22.82%) eras. Yet, micro, small, and medium enterprises (MSMEs) are considered the backbone of the Thai economy, and they accelerated economic growth by contributing 35.3% of the country’s GDP in 2019. More than 3 million micro, small, and medium-sized enterprises, comprising 99.53% of Thai business enterprises, account for more than 14 million jobs, which is 86% of the total employment (MSME Profile n.d.; Korwatanasakul and Paweenawat 2020). Thus, they are also vital employers in the national economy.

Among the manufacturing sector, marine food processing SMEs significantly contribute to the Thai economy. Thailand’s marine food processing sector is the fifth largest exporter in the world. The competitive advantage of this sector is based on several factors such as geographical location, skilled labor, and the active participation of SMEs (CMU-MOOC | Maritime Clusters and International Digital Marketing n.d.; Sowcharoensuk 2019). The seafood processing sector is classified into two categories: (1) “chilled and frozen” and (2) “canned, prepared, and preserved”. Even though export has been the primary driver of the Thai seafood processing industry, there is also a significant demand in the domestic market (Sowcharoensuk 2019). Thus, a reasonable number of Thai SMEs are engaged in seafood processing. SMEs moving along with the industrial transition has been identified as the solution to overcome the middle-income, inequality, and imbalance traps and upgrade the potential of the country in becoming an upper-income country with sustainable growth (Ministry of Industry 2016). Therefore, assessing the “Industry 5.0 readiness” and its role in the sustainable business growth of SMEs is a vital priority. Also, the causal relationship between Industry 5.0 readiness, global value chain participation, business competitiveness, and the sustainable business growth of SMEs has never been studied from the aspect of marine food processing SMEs in Thailand. Thus, the objective of this study is to develop a conceptual framework and propositions to establish and test the causal relationship between Industry 5.0 readiness, global value chain participation, business competitiveness, and the sustainable business growth of SMEs. Another well-established theory is that business competitiveness leads to sustainable business growth. However, the preceding causal nature of the “Industry 5.0 readiness” on business competitiveness and sustainable business growth remains unknown. One more growing trend is SME participation in the global value chain. Again, the causal relationship between “Industry 5.0 readiness”, global value chain participation, business competitiveness, and sustainable business growth remains unexplored. Thus, the research questions addressed in this research are as follows: (RQ1) What are the variables suitable to assess the “Industry 5.0 readiness”, “Global value chain participation”, “Business competitiveness”, and “Sustainable business growth” of SMEs? (RQ2) What are the causal relationships between the above four factors? The remaining sections of the article are structured as literature review and hypotheses development, methodology, analysis and findings, discussion, conclusion, implications, limitations, and future research directions.

2. Literature Review and Hypotheses Development

The first part of this section focuses on the latent variables’ Industry 5.0 readiness (I5.0R) determinants, global value chain (GVC) participation, business competitiveness (BC), and sustainable business growth (SBG); the second part explores and conceptualizes the causal relationship between I5.0R, GVC, BC, and SBG.

2.1. Industry 5.0 Readiness of SMEs (I5.0R)

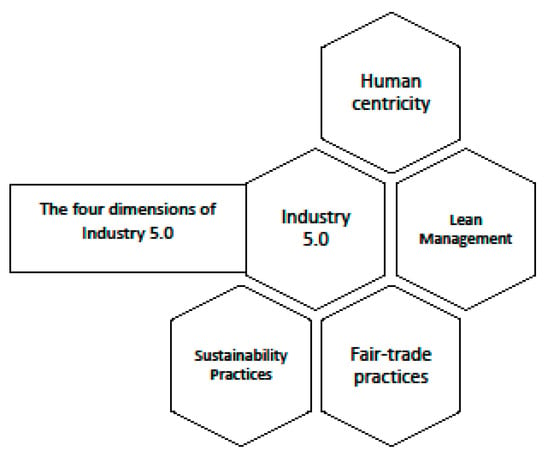

Though it is evident that the Industry 5.0 concept has been discussed by academic and industry experts since 2015, it has received major attention after being embedded into the policy brief of the European Commission (EC) in the year 2021. Industry 5.0 complements Industrial Revolution 4.0 with an additional focus on human-centric aspects and sustainability (Müller 2020). Thus, the concept of Industry 5.0 focuses on building the future of industries and societies with social, environmental, and economic dimensions along with the technological aspects. The evolving definitions of “industry 5.0” insists that the core concept is achieving the goals of the people, planet, and society by shifting the focus from shareholders to stakeholders (Breque et al. 2021). Therefore, the Industry 5.0 readiness can be assessed using the five core elements, namely, human-centricity, sustainability practices, resilience (Rada 2015; Demir and Cicibaş 2017; Müller 2020; Breque et al. 2021; Margherita and Braccini 2021; Xu et al. 2021; Akundi et al. 2022; Carayannis and Morawska-Jancelewicz 2022; Zizic et al. 2022), fairtrade practices (Ozkeser 2018; Paschek et al. 2019; Breque et al. 2021; Margherita and Braccini 2021; Carayannis et al. 2022), and lean management (Rada 2015; Ozkeser 2018; Paschek et al. 2019; Xu et al. 2021; Zizic et al. 2022; Rada 2017; Shelzer 2017). The three elements of Industry 5.0, “human-centricity”, “sustainability”, and “resilience”, were already conceptualized by the EU. However, an earlier study (Madhavan et al. 2024) found that SMEs are not resilient-ready, and they may need Government support during disruptions and economic shocks. Thus, resilience was excluded from this study. “Fairtrade practices (FP)” and “lean management (LM)” were included as the third and fourth dimensions and tested in this study (Figure 1). Thus, to add value to the concept of Industry 5.0 and contribute to the existing knowledge, the Industry 5.0 readiness assessment (I5.0R) scale was developed as a higher-order scale with human-centricity, sustainability, fairtrade practices, and lean management as lower order factors. The literature used to develop the scale and the factors are presented in this section.

Figure 1.

The dimensions of Industry 5.0.

2.1.1. Human-Centricity

The first factor of I5.0R is human-centricity. The core concept of human-centricity is to shift the focus from the technology-driven industrial transition to a human-centric technology-driven industrial transition. Such a human-centric approach is multifaceted and not just limited to human–machine interaction and cooperation. This is because the introduction and integration of technologies may necessitate restructuring workplaces, redesigning the jobs, and rethinking the industry’s business models, which may have several positive and negative impacts on workers and may even put them at risk during the transition. Thus, (a) empowering employees with technology and data-driven decision making (HC1); (b) assuring employees’ wellbeing (physical health, mental health, and work–life balance) (HC2); (c) investing in the reskilling and upskilling of employees to enhance their skills (including digital skills), capabilities, and talents (HC3); (d) maintaining respect and dignity of the employees during the transition (HC4); (e) ensuring the fundamental rights and privacy (HC5); and (f) creating a safe and inclusive working environment (HC6) (Nahavandi 2019; Breque et al. 2021; Margherita and Braccini 2021; Xu et al. 2021; Akundi et al. 2022; Zizic et al. 2022; Priya et al. 2023) were included as variables to assess human-centricity.

2.1.2. Fairtrade Practices

The second factor of I5.0R is fairtrade practices. Fairtrade practices is related to the firms’ commercial practices that focus at the sustainable development of the stakeholders, maintaining transparency with the interested parties and protecting confidentiality of the commercial data (Sitnikov et al. 2021). Open innovation is already on the agenda of the EC for achieving Industry 5.0 (Breque et al. 2021). Furthermore, earlier studies (Breque et al. 2021; Ghobakhloo et al. 2023a, 2023b) have posited that technological advancements, research and development, supportive trade policies, open innovation for creating a shared economy for stakeholders, and environmental success are the required enablers of Industry 5.0 transition. In addition, several studies (Sitnikov et al. 2021; Schmitt 2011; Alemany et al. 2023; Ivanov 2024) have linked fairtrade practices to the SDG12 “Responsible production and consumption” of sustainability. Thus, to gain better understanding of SMEs, this study conceptualized fairtrade practices as the distinct factor and adopted (a) open innovation for creating a shared economy (FP1), (b) using technologies for traceability of the product quality (FP2), (c) mass personalization of products according to customer requirements (FP3), and (d) data security and privacy (FP4) as the key variables (Madhavan et al. 2024) to study the role of fairtrade practices in Industry 5.0 readiness.

2.1.3. Lean Management

The third factor of I5.0R is “Lean Management”. The lean concept, derived from Toyota production systems (TPS—Muda—eight types of waste), has existed for more than seven decades (Womack and Jones 1994; Bozdogan 2010; A Brief History of Lean n.d.) but gained broader attention only since the 1990s (Womack and Jones 1994; Womack et al. 1990) and has been widely discussed in the academic literature within the context of Industry 4.0 and Industry 5.0 (Ozkeser 2018; Mladineo et al. 2021; Alves 2022; Souza et al. 2022; Rahardjo et al. 2024). Lean management from the context of Industry 5.0 is to focus on the firm’s systemic approach towards resource optimization and eliminating waste in all forms (Ozkeser 2018; Rada 2017). Moreover, lean management is attached to the human-centric approach and it is an enabler of Industry 5.0 in SMEs (Mladineo et al. 2021). Thus, considering the importance of lean management, which focuses on efficient resource management and waste reduction to maximize value, this study acknowledges it as a crucial and distinct element of Industry 5.0 readiness for assessing SMEs, Therefore, this study focuses on the lean aspects related to employees, customers, and processes and uses (a) overproduction (LM1), (b) over-processing (LM2), (c) job queues (LM3), (d) defective production (LM4), (e) talent utilization (LM5), (f) investment management (LM6), (g) lead time management (LM7), and (h) preventive maintenance that eliminates non-value added activities (LM8) (Ozkeser 2018; Mladineo et al. 2021; Alves 2022; Ohno 1988; Poppendieck 2011) as variables to assess lean management.

2.1.4. Sustainability Practices

The fourth factor of I5.0R is sustainability practices. To achieve sustainable development, businesses within an industry must respect the planet’s ecosystem. Thus, earlier environmental-sustainability related studies focused on developing circular processes, emphasizing recycling, reusing, and repurposing natural resources, and reducing waste and environmental consequences. However, after the introduction of sustainable development goals (SDGs) at the United Nations Conference on Sustainable Development in 2012 (United Nations 2012) and endorsement of SDGs by the United Nations in 2015, countries around the world have incorporated the concept of sustainability into their national goals. As a result, industries have been primarily concerned with incorporating the three pillars of sustainability (social, economic, and environmental) into their businesses. Thus, the core elements of sustainability with regard to Industry 5.0 emphasize the organizations on (a) using renewable power sources (SP1); (b) developing new business models for reducing the negative impacts on the economy, environment, and society (SP2); (c) efficient use of energy (SP3); (d) efficient use of resources (3Ms: machines, materials, and money) (SP4); (e) reduction in air emissions (SP5); (f) reduction in wastewater disposal (SP6); (g) recycling and reusing resources (SP7); and (h) job opportunities for the local community (SP8) (Demir and Cicibaş 2017; Nahavandi 2019; Paschek et al. 2019; Müller 2020; Breque et al. 2021; Margherita and Braccini 2021; Xu et al. 2021; Akundi et al. 2022; Zizic et al. 2022; Madhavan et al. 2024). Hence, the above eight variables were included in the Industry 5.0 readiness scale to study the sustainability practices.

2.2. Global Value Chain Participation (GVC)

On one hand, trade between countries worldwide has witnessed a remarkable increase since globalization; on the other hand, transportation and communication costs have decreased due to the growth in trade and advancements in transportation, information, and communication technology (Chen 2019). The global economy has been built on GVCs since globalization, resulting in an increase in global trade, employment, and world GDP. The GVCs connect companies, employees, and consumers worldwide. They provide opportunities for internal consumers and firms in developing countries to participate and integrate into the global economy in order to access markets of developed countries and add value to the industries. GVC participation is crucial for economic development, employment opportunities, and poverty reduction, enabling developing countries to compete successfully in the global economy (Gereffi and Fernandez-Stark 2016). The GVCs involve the participation of several firms or actors from different regions at different stages of the product life cycle, in which the participating firms add value to the primary activities through a range of activities from purchasing inputs to distributing outputs (Gereffi and Fernandez-Stark 2016; Brennan and Rakhmatullin 2017). Recently, there were suggestions to include SMEs in the “national, regional and global value chains” to upgrade the economic and social aspects by acquiring competitiveness through technology, knowledge, and skills, leading to increased profits and workforce development (Gereffi and Fernandez-Stark 2016; Lwesya 2022). Studies (Weinberger and Lumpkin 2007; Gereffi and Fernandez-Stark 2016) also claimed that GVC participation of agro-food SMEs in rural areas can alleviate poverty, which addresses the five sustainable development goals (SDGs) 1, 2, 8, 10, and 17 (no poverty, zero hunger, decent work and economic growth, reduced inequalities, and partnership for the goals) (United Nations n.d.).

The four pillars of GVC participation by SMEs are access to market; training; finance; and collaboration and coordination (Gereffi and Fernandez-Stark 2016). On one side, the potential of SMEs can be classified into three categories based on product attributes (quality, price, and delivery), company attributes (financial stability, production capacity, flexibility, certification, ICT level, geographical location, and innovation capacity), and soft strengths (business integrity and corporate social responsibility) for GVC participation (Yuhua 2014). But on the other side, there are certain hidden constraints such as difficulty in achieving product standards and certification and technology costs; increased competition, geographic location, limited access to resources, finance, markets, skilled labor, and training; lack of structure; lack of knowledge and skills, digital skills, know-how, experience, and information about market opportunities; lack of economies of scale; limited knowledge about language and culture and e-market places; and legal issues in exporting that prevent SMEs’ participation in GVCs (Harvie and Charoenrat 2015). From the above literature, this study adopted (a) domestic market competitiveness (GVC1); (b) digital integration of the value chain (GVC2); (c) cross-border digital marketing (GVC3); (d) importing inputs from foreign countries (GVC4); (e) sourcing foreign supplies from domestic markets (GVC5); (f) directly exporting products to foreign countries (GVC6); (g) selling to the foreign market through a domestic distributor (GVC7); and (h) ability to access the market (value chain linkages between producers and buyers) (GVC8) as variables to study the global value chain participation of SMEs (Korwatanasakul and Paweenawat 2020; Gereffi and Fernandez-Stark 2016; Harvie and Charoenrat 2015; Shinozaki 2015; Abe 2015; Asian Development Bank, Asian Development Bank Institute 2015; Mukherjee and Mukherjee 2022; Ge et al. 2020; Nugroho 2022).

2.3. Business Competitiveness (BC)

Competitiveness is defined as the “capability of individuals, firms, industries, regions, and economies” to sustain competition at the domestic or international level (Farhikhteh et al. 2020; Pirau et al. 2013). Also, the competitiveness of a nation or industry can be assessed using Porter’s four-factor diamond model (Farhikhteh et al. 2020; Porter 1990, 209; Tsai et al. 2021). The concept of “business or enterprise competitiveness” refers to the competitiveness of a firm’s product, production efficiencies, and financial status (Ahmedova 2015; Farhikhteh et al. 2020), which indicates the importance of efficient management of firms’ processes and resources when compared to their competitors (Singh et al. 2007). The two well-recognized conventional competitiveness analysis models in strategic management are Michael Porter’s five forces framework and the resource-based model. Porter’s model was drawn from industrial organization economics, which measures the external environmental factors that affect the firms’ competitiveness (Porter 1979). The resource-based model analyses the firms’ internal environment based on their resources and capabilities (Wernerfelt 1984; Barney 1991). Thus, it is crucial for SMEs to understand and analyze the internal environment’s strengths and weaknesses based on the firm’s resources and capabilities to respond to the external environment. Thus, using appropriate “recent technologies” can improve SMEs’ productivity; possessing “manufacturing flexibility or flexible manufacturing systems (FMS)” can help SMEs to meet the international market demand and accommodate customizations; sourcing the “right quality raw materials from right suppliers” can improve SMEs’ performance; conforming “product quality” can increase SMEs’ market share; developing “new products” through innovation and technology, maintaining “on-time delivery performance”, and reducing “costs” can facilitate SMEs in successfully competing in both the domestic and global markets (Singh et al. 2007). Further, internal practices such as innovation, intellectual property, internationalization, and financial accessibility also play a crucial role in the business competitiveness (Ahmedova 2015). Thus, competitiveness has been recognized as a multi-dimensional concept comprising both internal and external factors, where the internal factors include resources (human, finance, technical, and informational) and processes through resources (research, production, commercial, financial, and personnel); whereas the external factors include environmental variables (Ceptureanu 2015). Therefore, variables such as “strategic planning”, “production and operations”, “quality assurance”, “marketing”, “accounting and finance”, “human resources”, “environmental management”, and “information systems” (Ibarra Cisneros et al. 2017; Martínez and Álvarez 2006; Saavedra García 2012); “product quality”, “product delivery”, “product cost”, “product flexibility”, “product design”, “product service”, “communication with customers”, “degree of customer orientation”, “product pricing”, “customer satisfaction”, “proactiveness”, “product innovation”, “knowledge acquisition”, “employee skills”, and “open-mindedness” (Taçoğlu et al. 2019); “product features”, “product differentiation”, “cost”, “value”, “price”, “business reputation”, and “customer experience” (Efendi et al. 2020); “financial performance”, “purchasing costs”, and “technology” (Lopez-Torres 2023) were used to study the business competitiveness of SMEs. We can say these research focus on the functional aspects such as product, production, marketing, distribution, and organizational learning. Also, the literature suggests that due consideration and importance should be given to the capabilities and resources of SMEs while evaluating their competitiveness.

Based on the above discussions and practical importance, this study has categorized SMEs’ business competitiveness into “marketing”, “resource”, “production”, and “finance” (Farhikhteh et al. 2020; Ahmedova 2015; Ibarra Cisneros et al. 2017; Taçoğlu et al. 2019; Efendi et al. 2020; Prasada et al. 2021; Lopez-Torres 2023).

- Marketing competitiveness: The most commonly used 4ps of marketing—(a) product competitiveness (BCM1), (b) price competitiveness (BCM2), (c) place competitiveness (BCM3), and (d) promotion competitiveness (BCM4)—were adopted as variables for measuring the marketing competitiveness.

- Resource competitiveness: Four variables, namely, (a) use of technology and innovation (BCR1); (b) human resources (skilled, creative, talented, and experienced) (BCR2); (c) internal resources (machinery and technology) (BCR3); and (d) suppliers’ competitiveness (BCR4), were included to study the business resource competitiveness.

- Production competitiveness: Three variables for production competitiveness were identified and used—(a) flexible manufacturing (BCP1), (b) lower production cost than competitors (BCP2), and (c) superior quality than competitors for production competitiveness (BCP3).

- Financial competitiveness: Further, three variables, namely, (a) financial strength (BCF1); (b) accessibility to the bank credit facilities (BCF2); and (c) shorter cash-flow cycle (BCF3), were adopted for finance competitiveness, respectively.

2.4. Sustainable Business Growth (SBG)

Sustainable business growth is referred to as the consistent development of firms over a time, achieved through meeting economic, social, and environmental goals (Yusoff et al. 2018). However, from an economics perspective, it can be assessed through annual sales growth and age of the firm (Salojärvi et al. 2005).

Thus, “sustainable business growth” referred to in this study is line with the conceptualization of the study (Yusoff et al. 2018) which is attaining self-sufficient growth through financial objectives and continual performance within the firms’ capabilities while sustaining future objectives without risking their long-term existence. Several studies (Khan and Naeem 2018; Madhavan et al. 2022a; Sharafuddin et al. 2022) have emphasized that achieving only profits or economic aspects alone cannot assure long-term survival although it is a crucial factor, therefore have utilized the three dimensions (economic, social, and environmental) for measuring sustainable growth of the firm. The economic dimension can be measured through the variables “an increase” in ROI, sales, market share, profit, customer satisfaction and retention; the social dimension can be measured through “an increase” in social investment, customer awareness about the company, brand and its products, employee retention, focus on health/safety of employees and local community, and training and skill development of employees (Khan and Naeem 2018; Madhavan et al. 2022a; Sharafuddin et al. 2022; Yoon et al. 2016); and the environmental dimension can be measured through an increase in environmentally friendly usage of facilities and focus on complying with environmental laws, regulations, and policies (Khan and Naeem 2018; Madhavan et al. 2022a). Thus, it is understood that sustainable business growth is a firm’s ability to achieve long-term growth in economic, social, and environmental aspects. However, we have included only the economic (Diabate et al. 2019) and social aspect in sustainable business growth. This is because we have assessed the sustainability practices through the Industry 5.0 readiness scale. Hence, the variables included in this study were adopted from (Khan and Naeem 2018; Madhavan et al. 2022a), which focused on assessing the increase in (a) profit (SBG1); (b) customer satisfaction (SBG2); (c) customer retention (SBG3); (d) social investment (SBG4); (e) brand awareness in the market (SBG5); (f) employee retention (SBG6); (g) training and skill development of employees (SBG7); and (h) focus on the health and safety of employees and local communities (SBG8).

2.5. Proposed Causal Relationship, Hypotheses, and Conceptual Framework

Since research on Industry 5.0 is in the nascent stage, the empirical studies in this context are very limited in number. As per the authors’ knowledge, the studies on Industry 5.0 are progressing and a conceptual framework along with empirical analysis with reference to SMEs is limited in number (Waheed et al. 2022). There are few studies (Saptaningtyas and Rahayu 2020; Botti and Baldi 2024) that have conducted theoretical and qualitative research on the topic “Industry 5.0”. Also, a few more studies (Saptaningtyas and Rahayu 2020; Hussain et al. 2023; Reino-Cherrez et al. 2023) were traced on the topic “industry 5.0 and SMEs”; a few studies (Rajesh 2023; Sharma et al. 2022) analyzed the challenges in implementing Industry 5.0.

2.5.1. Industry 5.0 Readiness (I5.0R) and Sustainable Business Growth (SBG)

There are few pieces of evidence which theoretically conceptualized and suggested the relationships between Industry 5.0 dimensions and sustainable growth. The most noticeable studies are the adoption of Industry 5.0 and sustainable growth of manufacturing SMEs (Hussain et al. 2023); digital technologies and sustainable growth (Hassoun et al. 2022); human-centricity and sustainable growth (Lu et al. 2022); technology skills of employees and economic business sustainability (Hernita et al. 2021); resilience and sustainable growth/sustainable performance (Breque et al. 2021; Madhavan et al. 2022b; Phonthanukitithaworn et al. 2023); innovation capabilities/open innovation and sustainable growth (Khan and Naeem 2018; Yoon et al. 2016; Yun et al. 2020); lean management and sustainable growth (Ozelkan et al. 2013; Minh and Ha 2016; Ballé and Jones 2017; M. P. et al. 2017; Beifert et al. 2018); and sustainability practices on sustainability performance (Gadenne et al. 2012). Further, the moderation effects of Industry 5.0 technologies on the relationship between shared economy and sustainable performance were studied (Waheed et al. 2022). Therefore, the following hypothesis is postulated:

H1:

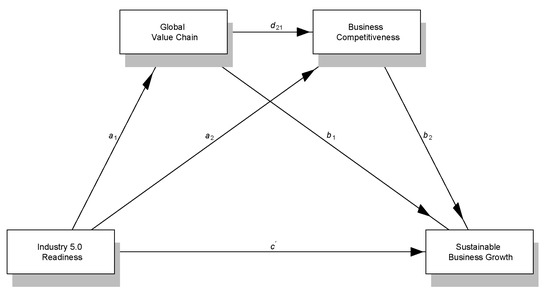

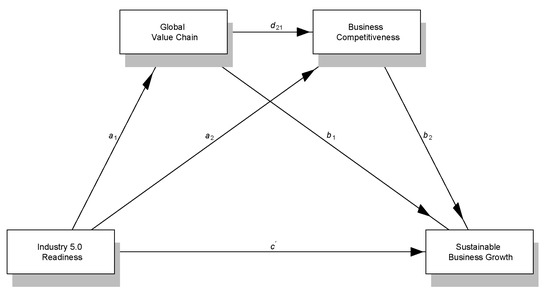

There is a significant impact of Industry 5.0 readiness on the sustainable business growth of SMEs (c`—Figure 2).

Figure 2.

Conceptual framework.

2.5.2. Industry 5.0 Readiness (I5.0R) and Global Value Chain (GVC) Participation

Using technology, data, and AI (artificial intelligence) can provide flexibility in production and build efficient value chains; thus, technology and digitalization can enable SMEs to participate in global value chains (Breque et al. 2021). Though there is limited empirical research on Industry 5.0 and global value chains, and since Industry 5.0 is complementary to Industry 4.0, this study has sought support from the prior studies on Industry 4.0 and global value chains. There are a handful of notable studies on Industry 4.0 and global value chains (Rainnie and Dean 2020; Brun et al. 2019; Dilyard et al. 2021; Opazo-Basáez et al. 2021; Awan et al. 2022; Delera et al. 2022; Nyagadza et al. 2022; Hernández Paz et al. 2023; Kliestik et al. 2023). It was also found that Industry 4.0 could better integrate and coordinate the GVCs (Rainnie and Dean 2020), providing opportunities for the firm to access knowledge and widening their GVC network (Opazo-Basáez et al. 2021). Digital technologies such as cloud computing, AI, and big data support the SME participation in GVCs (Hernández Paz et al. 2023). Hence, based on the prior studies, it is evident that the digitalization and environmental dimensions of sustainability enable manufacturing firms to participate in GVCs; further, this study postulates the following hypothesis:

H2:

There is a significant impact of Industry 5.0 readiness on the global value chain participation of SMEs (a1—Figure 2).

2.5.3. Industry 5.0 Readiness and Business Competitiveness (BC)

There are few studies that have conceptualized Industry 4.0 and 5.0 with business competitiveness (Madhavan et al. 2022b; Alvarez-Aros and Bernal-Torres 2021; Kolaro et al. 2023). It was also evident that implementing Industry 5.0 principles would facilitate manufacturers in gaining competitiveness (Ghobakhloo et al. 2024; Sharma et al. 2022). Hence, the following hypothesis is postulated:

H3:

There is a significant impact of Industry 5.0 readiness on the business competitiveness of SMEs (a2—Figure 2).

2.5.4. Global Value Chain (GVC) Participation and Sustainable Business Growth (SBG)

Initially, GVC analysis was limited to the large enterprises in the manufacturing sector; however, it has lately been broadened to include SMEs, with recommendations for inclusion in regional and global value chains (Gereffi and Fernandez-Stark 2016). The causal relationship between GVC participation and SBG is already proven through a few studies. Participation in forward and backward GVC has a positive impact on the firm performance (Korwatanasakul and Paweenawat 2020) and SMEs participating in GVC gain increase in exports (Charoenrat and Pholphirul 2022), yielding higher profits than those who do not (Deyshappriya and Maduwanthi 2021). Similarly, another study (Mao 2022) found the linkages between GVCs and economic growth and suggested that strengthening the domestic value chain and increasing GVC participation is important for economic growth. SMEs’ GVC participation provides opportunities to achieve sustained economic growth and development (Yuhua 2014; Yuhua and Bayhaqi 2013; Christianty and Hidayati 2017). Thus, the following hypothesis is postulated:

H4:

There is a significant impact of global value chain participation on the sustainable business growth of SMEs (b1—Figure 2).

2.5.5. Global Value Chain (GVC) Participation and Business Competitiveness (BC)

There is a handful of evidence that SMEs’ backward participation (Nugroho 2022) in GVCs can potentially increase their competitiveness in the global markets (Deyshappriya and Maduwanthi 2021). GVC participation by SMEs will improve product attributes, resources, production, and sales, which inevitably enhances their competitiveness in the global market (Christianty and Hidayati 2017). Another study (Mohiuddin and Su 2014) concluded that the competitiveness of SMEs depends on the participation in GVCs. Thus, the following hypothesis is formulated:

H5:

There is a significant impact of global value chain participation on the business competitiveness of SMEs (d21—Figure 2).

2.5.6. Business Competitiveness (BC) and Sustainable Business Growth (SBG)

There are limited studies that have conceptualized the impact of business competitiveness on the sustainable business growth of SMEs (Madhavan et al. 2022b). Competitiveness is considered as a crucial aspect for achieving sustainable competitive advantage, which impacts sustainable business performance (Haseeb et al. 2019; Madhavan et al. 2022a). The firm must possess competitiveness in functional areas of the firm such as marketing, resources, production, and finance to achieve sustainable business growth; however, competitiveness in these aspects are the internal capabilities of the firm developed over a period of time (Bartlett and Ghoshal 2002). Few studies have conceptualized the impact of competitiveness on firm performance, which is subsequently highlighted. Competitiveness of SMEs is regarded as a critical success factor in achieving the firm performance (Abe 2015). Another study (Zanotti et al. 2018) found the significant positive impact of competitiveness on the financial performance of the firm. The study (Le and Ikram 2022) reported a significant and positive relationship between the firm’s competitiveness and firm performance in terms of financial performance, operational performance, and environmental performance. Hence, the hypothesis is postulated as follows:

H6:

There is a significant impact of business competitiveness on the sustainable business growth of SMEs (b2—Figure 2).

2.5.7. Mediation Role of GVC Participation and BC in the Relationship between I5.0R and SBG

Industry 5.0 studies are in the progressing stage; mediation and serial mediation effects with respect to the I5.0 and SBG are not available yet. Based on the above hypothesis postulations, this study attempts to investigate the mediating role of GVC participation and BC in the relationship between I5.0R and SBG. In addition, this study also investigates the serial mediation effects of GVC and BC, as the relationship between GVC participation and business competitiveness is evident (Deyshappriya and Maduwanthi 2021; Mohiuddin and Su 2014). Thus, the following hypotheses were postulated:

H7:

GVC participation significantly mediates the relationship between Industry 5.0 readiness and sustainable business growth.

H8:

Business competitiveness significantly mediates the relationship between Industry 5.0 readiness and sustainable business growth.

H9:

Industry 5.0 readiness significantly impacts the sustainable business growth of SMEs through GVC participation and business competitiveness.

The conceptual framework (Figure 2) and hypotheses were developed based on the existing literature to fill the research gap (Madhavan et al. 2024; Madhavan et al. 2022b), which aims to study the causal relationships of Industry 5.0 readiness with GVC participation, business competitiveness, and sustainable business growth of marine food processing SMEs.

3. Methodology

3.1. Study Population

The target population of this study were the entrepreneurs and managers of the marine food processing SMEs in Thailand. Companies with workforce numbers of 6–50 and 51–200 were classified as small and medium enterprises in Thailand (The Office of SMEs Promotion (OSMEP) n.d.; Definition of MSMEs n.d.). The population frame was generated from the Department of Industrial Works (DIW) website in Thailand. This study included the marine food processing SMEs that are engaged in producing processed seafoods (fish balls, dried shrimps, smoked salmon, oyster sauce, clams, mackerel), and ready-made seafood products (shrimp paste, and canned food). As of 21 April 2023, the results from DIW showed that the population sizes of the SMEs engaged in processed seafood was 252 and ready-made food products was 132. Initially, the total 384 SMEs were screened by considering two aspects: 1. SMEs that have closed their business and 2. SMEs that are operating in multiple locations. To avoid duplication and responses from the same companies, the SMEs with the same name and address located in multiple provinces were reviewed and considered as a single company for this research. Thus, the final study population list consisted of 364 SMEs.

3.2. Sampling Method and Size

This study adopted the purposive sampling approach. The sample frame was drawn from the population list based on three criteria: accessibility of SMEs, business nature of SMEs, and operational status (operating or temporarily closed). Firstly, the researchers ensured that the SMEs’ names were on the list and were accessible with at least one communication mode, either phone number, email address, website, Facebook, or line application to contact them. Secondly, the nature of the SME’s business type was reviewed, and the companies that do not have minimal processing (for example, involved only in washing, peeling, and freezing), companies focused only on cold storage, and company’s products that are not meant for human consumption (for example, collagen powder and animal feed) were excluded. Thirdly, the study also excluded the SMEs that have temporarily shut down their operations due to the Government’s seasonal fishing restrictions. In the above three criteria, the first criteria are the inclusion criteria and the second and third are the exclusion criteria. Thus, the final sample size of 162 SMEs was considered for this study.

3.3. Instrument Development and Content Validity

The theoretical construct based on literature review consisted of six variables for human-centricity, four variables for fairtrade practices, eight variables for lean management, eight variables for sustainability practices, eight variables for global value chain, four variables for marketing competitiveness, four variables for resource competitiveness, three variables for production competitiveness, three variables for financial competitiveness, and eight variables for sustainable business growth. Thus, the theoretical construct with fifty-six variables was distributed to two academicians and two industry experts. Individual face-to-face sessions were held with each academician and expert, and based on feedback, one variable each from fairtrade practices, lean management, and sustainable business growth were removed. Thus, after enhancing the content validity, the final questionnaire consisted of fifty-three variables.

Human-centricity, fairtrade practices, lean management, and sustainability practices were used as the lower-order secondary factors for assessing the latent variable “industry 5.0 readiness level”. Further, business competitiveness was also designed as a higher-order factor with marketing competitiveness, resource competitiveness, production competitiveness, and financial competitiveness as second order factors. The five-point Likert scale of concern for Industry 5.0 readiness and scale of agreement for global value chain, business competitiveness, and sustainable business growth were adopted based on recommendations.

3.4. Data Collection

Out of 162 SMEs, 28 SMEs were reluctant to answer the survey forms. Finally, 76 SMEs answered the survey forms, 73 responses were found to be complete, whereas the remaining 3 incomplete forms were excluded from this study. Thus, the response rate was 45 percent (close to 50%), which exceeded the acceptable level of 30 percent for online surveys (Sekaran and Bougie 2016). Therefore, the sample size was adequate for further evaluating the hypotheses using PLS-SEM. Thus, the collected data were subjected to, reliability, validity, and hypothesis tests.

3.5. Ethical Committee Approval and Data Collection Period

The questionnaire survey was developed in both Thai and English language and obtained human research ethics committee approval on 6 January 2023. The data were collected from the mid of January 2023 to May 2023. The questionnaire was circulated online (via email and social media) and offline (both the hard copy and online links were shared).

4. Analysis and Findings

4.1. The Lower-Order Measurement Model

4.1.1. Indicator Loadings (Indicator Reliability)

Indicator loadings were tested for indicator reliability, and loadings of seven variables (HC4, LM2, SP1, SP3, GVC2, GVC7, and SBG6) were found lower than the threshold value of 0.708 and hence removed from the model for further analysis. The results (Table 1) of the remaining lower-order construct’s indicator loadings above the threshold value of 0.708 (Hair et al. 2019) inferred that they were reliable for proceeding further with the analysis. The loadings range from 0.723 (fairtrade practices (FP2)) to 0.913 (business resource competitiveness (BCR2)). Thus, a total of 46 variables were included for proceeding further with the analysis.

Table 1.

Indicator loadings (indicator reliability).

4.1.2. Internal Consistency (Lower-Order Reliability)

The present study evaluated the measurement model’s internal consistency reliability through Cronbach’s alpha (α) (Cronbach 1951) and composite reliability (CR) values. These indicators measure the degree to which the items within each latent construct (human-centricity, fairtrade practices, lean management, sustainability practices, global value chain, marketing competitiveness, resource competitiveness, production competitiveness, finance competitiveness, sustainable business growth) consistently reflect the underlying concept (Hair et al. 2021).

Cronbach’s Alpha

The results of the reliability test (Table 2) inferred that all lower-order constructs exceeded the recommended threshold of α ≥ 0.70 for acceptable internal consistency (Nunnally and Bernstein 1994). Specifically, the alphas for human-centricity, fairtrade practices, lean management, sustainability practices, global value chain, marketing competitiveness, resource competitiveness, production competitiveness, finance competitiveness, and sustainable business growth were 0.846, 0.737, 0.896, 0.863, 0.897, 0.898, 0.903, 0.723, 0.832, and 0.884, respectively. These findings suggest that the items of human-centricity, fairtrade practices, lean management, sustainability practices, global value chain, marketing competitiveness, resource competitiveness, production competitiveness, finance competitiveness, and sustainable business growth are correlated and reliably measure the constructs.

Table 2.

Lower-order composite reliability (internal consistency) and convergent validity.

Composite Reliability

Composite Reliability (CR) values (Table 2) were also calculated for each lower-order construct (rhoA), providing another estimate of internal consistency while accounting for the weightings of individual indicator loadings (Hair et al. 2023). Consistent with the alpha values, all CRs exceeded the recommended threshold of 0.70 (Bagozzi and Yi 2012). The CR values for human-centricity, fairtrade practices, lean management, sustainability practices, global value chain, marketing competitiveness, resource competitiveness, production competitiveness, finance competitiveness, and sustainable business growth were 0.862, 0.768, 0.899, 0.870, 0.904, 0.903, 0.905, 0.73, 0.857, and 0.885, respectively. These findings further support the reliable measurement of the constructs.

4.1.3. Convergent Validity

Convergent validity assesses the extent to which a construct is measured accurately and consistently by its indicators (Hair et al. 2021). This study employed the average variance extracted (AVE) as a measure of convergent validity. The results (Table 2) inferred that all the constructs exceeded the recommended threshold of 0.50 for AVE values, indicating acceptable convergent validity. Specifically, the AVE values were 0.621, 0.652, 0.657, 0.595, 0.661, 0.767, 0.775, 0.644, 0.751, and 0.634 for human-centricity, fairtrade practices, lean management, sustainability practices, global value chain, marketing competitiveness, resource competitiveness, production competitiveness, finance competitiveness, and sustainable business growth. These findings suggest that the indicators within each construct share a significant amount of variance with the underlying latent construct, thereby supporting the validity of the measurement model.

4.2. Lower-Order Discriminant Validity (Heterotrait–Monotrait Ratio)

Discriminant validity assesses the extent to which the measured constructs are distinct from each other, ensuring that they represent unique concepts rather than overlapping constructs. This study employed the Heterotrait–Monotrait (HTMT) ratio, a widely used indicator of discriminant validity in PLS-SEM (Henseler et al. 2015). The results (Table 3) infer that all HTMT ratios calculated for the present study were below the recommended threshold of 0.90, indicating acceptable discriminant validity between the constructs. Specifically, the HTMT values ranged from (finance competitiveness, global value chain) 0.504 to (sustainability practices, lean management) 0.882. These findings suggest that the measured constructs are sufficiently distinct and not interchangeable.

Table 3.

Lower-order discriminant validity (Heterotrait–Monotrait ratio.).

4.3. Higher-Order Composite Reliability (Internal Consistency) and Convergent Validity

Further, the internal consistency (higher-order reliability), composite reliability, and convergent validity were tested for the higher-order model using Cronbach’s alpha (α) (Cronbach 1951), rhoA, and AVE. The results (Table 4) of the higher-order model inferred that all the higher-order variables met the threshold values for Cronbach’s alpha, rhoA (0.70–0.95), and AVE (>0.5).

Table 4.

Higher-order composite reliability (internal consistency) and convergent validity.

4.4. Higher-Order Discriminant Validity (Heterotrait–Monotrait Ratio)

The results of the higher-order discriminant validity (Table 5) infer that all HTMT ratios calculated for the higher-order model were below the recommended threshold of 0.90 (Henseler et al. 2015), indicating acceptable discriminant validity between the higher-order constructs.

Table 5.

Higher-order discriminant validity (Heterotrait–Monotrait ratio).

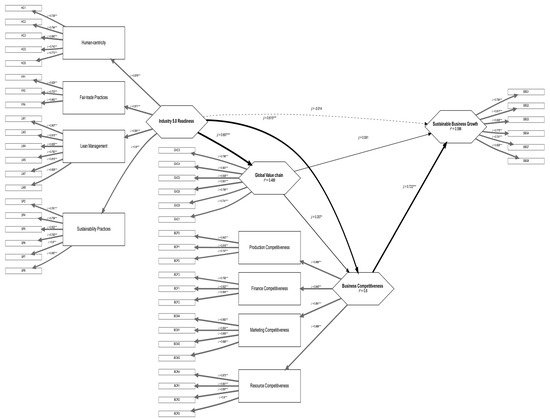

4.5. The Higher-Order Structural Model

Bootstrapping provides a robust approach to hypothesis testing in PLS-SEM by resampling the data and generating confidence intervals for the estimated path coefficients, accounting for potential sampling error (Hair et al. 2023). Thus, this study employed a bootstrapped (n = 1000) higher-order reflective structural model (HOR-SEM) to test the proposed hypotheses regarding the relationships between “Industry 5.0 Readiness”, “Global value chain”, “Business competitiveness”, and “Sustainable business growth”. The results (Table 6 and Figure 3) of the bootstrapped model and the hypotheses are as follows.

Table 6.

Results of structural model (bootstrapped path (n = 1000)).

Figure 3.

Higher-order structural model (Significant at *** 0.001).

Hypothesis 1:

The bootstrapped results did not support the first hypothesis. With an original estimate value of−0.014, bootstrapped mean of −0.016, bootstrapped standard deviation of 0.144, T stat value of −0.099, and 5% CI of −0.261, and 95% CI of 0.204, the findings suggest that there is no significant impact of Industry 5.0 readiness on sustainable business growth.

Hypothesis 2:

The bootstrapped results support the second hypothesis. With an original estimate value of 0.697, bootstrapped mean of 0.696, bootstrapped standard deviation of 0.072, T stat value of 9.738, and 5% CI of 0.565, and 95% CI of 0.803, the findings suggest that there is a significant impact of Industry 5.0 readiness on global value chain participation.

Hypothesis 3:

The bootstrapped results support the third hypothesis. With an original estimate value of 0.615, bootstrapped mean of 0.623, bootstrapped standard deviation of 0.199, T stat value of 6.157, and 5% CI of 0.463, and 95% CI of 0.784, the findings suggest that there is a significant impact of Industry 5.0 readiness on the business competitiveness of SMEs.

Hypothesis 4:

The bootstrapped results did not support the fourth hypothesis. With an original estimate value of 0.091, bootstrapped mean of 0.096, bootstrapped standard deviation of 0.107, T stat value of 0.852, and 5% CI of −0.083, and 95% CI of 0.272, the findings suggest that there is no significant impact of global value chain participation on sustainable business growth.

Hypothesis 5:

The bootstrapped results support the fifth hypothesis. With an original estimate value of 0.207, bootstrapped mean of 0.200, bootstrapped standard deviation of 0.109, T stat value of 1.902, and 5% CI of 0.018, and 95% CI of 0.378, the findings suggest that there is a significant impact of global value chain participation on business competitiveness.

Hypothesis 6:

The bootstrapped results support the sixth hypothesis. With an original estimate value of 0.722, bootstrapped mean of 0.733, bootstrapped standard deviation of 0.111, T stat value of 6.503, and 5% CI of 0.557, and 95% CI of 0.913, the findings suggest that there is a significant impact of business competitiveness on sustainable business growth.

Hypothesis 7:

The bootstrapped results did not support the seventh hypothesis. With an original estimate value of 0.447, bootstrapped mean of 0.051, bootstrapped standard deviation of 0.0634, T stat value of 0.704, and 5% CI of −0.050, and 95% CI of 0.197, the findings suggest that global value chain participation does not mediates the relationship between Industry 5.0 readiness and sustainable business growth.

Hypothesis 8:

The bootstrapped results support the eighth hypothesis. With an original estimate value of 0.548, bootstrapped mean of 0.56, bootstrapped standard deviation of 0.109, T stat value of 4.998, and 5% CI of 0.369, and 95% CI of 0.798, the findings suggest that business competitiveness mediates the relationship between Industry 5.0 readiness and sustainable business growth.

Hypothesis 9:

The bootstrapped results did not support the ninth hypothesis. With an original estimate value of 0.0177, bootstrapped mean of 0.15, bootstrapped standard deviation of 0.23, T stat value of 0.776, and 5% CI of −0.0315, and 95% CI of 0.0632, the findings suggest that there is no serial mediation effects of global value chain and business competitiveness in the relationship between Industry 5.0 readiness and sustainable business growth.

5. Discussion

This study advances the understanding of Industry 5.0 readiness in SMEs by exploring its causal relationships with global value chain (GVC) participation, business competitiveness, and sustainable business growth, addressing significant gaps in the literature identified by prior works (Madhavan et al. 2022b; Madhavan et al. 2024). Specifically, this research evaluates Industry 5.0 readiness across four dimensions: human-centricity, fairtrade practices, lean management, and sustainability practices, while intentionally excluding resilience due to the finding that many SMEs are not resilient (Madhavan et al. 2024). Therefore, this study excluded the sub-dimension “resilience” to measure the Industry 5.0 readiness in SMEs.

The conceptual framework positions Industry 5.0 readiness and business competitiveness as higher-order latent constructs, each encompassing four dimensions. Initial assessments confirmed the reliability and validity of these constructs at both lower and higher orders. The nine proposed hypotheses were tested using partial least squares structural equation modeling (PLS-SEM) with a bootstrapping approach (n = 1000 samples), providing robust insights into the interactions between these constructs.

This study’s findings reveal that Industry 5.0 readiness significantly enhances GVC participation (H2) and business competitiveness (H3). These results are consistent with those of previous studies (Madhavan et al. 2022b; Hernández Paz et al. 2023), which suggests that digitalization enables SMEs to engage in GVCs by fostering trust, transparency, and cross-border information access. Interestingly, the relationship between Industry 5.0 readiness and GVC participation may be bidirectional; while Industry 5.0 readiness can facilitate GVC engagement, participation in GVCs might also drive SMEs to adopt Industry 5.0 practices, such as digitalization, fairtrade, lean management, and sustainability (Delera et al. 2022; Hernández Paz et al. 2023). Future research could explore this potential reverse causality to deepen our understanding of these dynamics.

This study also confirms that GVC participation positively impacts business competitiveness (H5), aligning with prior research (Madhavan et al. 2022b; Deyshappriya and Maduwanthi 2021; Christianty and Hidayati 2017; Mohiuddin and Su 2014) indicating that SMEs involved in GVCs achieve higher profitability and competitiveness. Additionally, business competitiveness significantly contributes to sustainable business growth (H6), supporting earlier findings that found a positive link between firm competitiveness to overall SME performance.

The other two hypotheses, H1 (Industry 5.0 readiness on sustainable business growth) and H4 (GVC participation on sustainable business growth), were not widely studied. While the hypotheses regarding direct effects of Industry 5.0 readiness on sustainable business growth (H1) and GVC participation on sustainable business growth (H4) were not supported, these findings highlight the complexity of these relationships. Industry 5.0 readiness, as a higher-order construct, did not show a significant direct impact on sustainable business growth, nor did GVC participation, despite the theoretical basis from policy-oriented studies (Yuhua 2014; Yuhua and Bayhaqi 2013).

The analysis of indirect effects provided refined insights: Industry 5.0 readiness impacts sustainable business growth through business competitiveness (H8) but not through GVC participation (H7). No evidence was found for serial mediation involving Industry 5.0 readiness, GVC participation, business competitiveness, and sustainable business growth (H9). The significant finding for the path from GVC participation to business competitiveness (H5) underscores the importance of further investigating the reciprocal influences between these factors, as their interplay could have substantial implications for SME strategies and policymaking.

Thus, the findings of this study contribute to a deeper and more detailed understanding of how Industry 5.0 readiness influences various aspects of SME performance, offering valuable implications for researchers, practitioners, and policymakers aiming to enhance the competitiveness and sustainability of SMEs in the evolving global market.

6. Conclusions

The bootstrapped hypothesis testing revealed a mix of significant and non-significant relationships between the constructs of interest. These findings contribute to a more nuanced understanding of how the “industry 5.0 readiness” acts as a preceding factor in determining sustainable business growth and provide valuable insights for SMEs, policymakers, and researchers. This study filled the research gap (Madhavan et al. 2024; Madhavan et al. 2022b) by empirically investigating the causal relationship of Industry 5.0 readiness with the sustainable business growth of SMEs through GVC participation and business competitiveness. Prior works have claimed causal relationships between digitalization and GVC participation (Hernández Paz et al. 2023) and GVC participation and business competitiveness (Deyshappriya and Maduwanthi 2021; Christianty and Hidayati 2017; Mohiuddin and Su 2014); this study also provided similar findings. However, no serial mediation is found between I5.0R and SBG, through GVC and BC. Also, it is evident from this study that it is difficult for SMEs to achieve SBG without acquiring business competitiveness. Thus, this research adds value to the progressing Industry 5.0, GVC, competitiveness, entrepreneurship, and sustainability literature.

7. Implications

The constructs can be used by researchers in various industry settings to measure the I5.0R, GVC, and competitiveness of SMEs. This study provides a major contribution to the food processing SMEs. It is evident from this study that SMEs are aware of technology and human-centric approaches, lean management, and sustainability practices. According to the results, SMEs are ready in certain aspects and already in pace with Industry 5.0 practices in various aspects of their business (Madhavan et al. 2024). Such an experience would enhance their GVC participation and competitiveness in the market, leading to long-term growth in the economic and social aspects of the business. Hence, the entrepreneurs/managers of SMEs could review the Industry 5.0 readiness dimensions and prepare themselves to participate in GVCs and attain long-term competitiveness and growth. Policymakers can adopt the model and study constructs to review the readiness aspects and essentials of GVC participation and facilitate entrepreneurs with training and support for GVC participation to attain competitiveness. By doing so, SMEs can be at pace with Industry 5.0, so that they may not lag behind large-scale enterprises.

8. Limitations and Future Research Directions

This study is limited to marine food processing SMEs and does not cover all food processing SMEs in Thailand. However, the conceptual framework and constructs could be generalized for various manufacturing SMEs. Future research could include all types of manufacturing SMEs to study the I5.0R levels and GVC participation in various industries, and a large representative sample from various industries would provide comparative insights in a big picture. In addition, further studies could design the conceptual framework with reverse effects to gain deeper insights. For example, Industry 5.0 adoption enhances GVC participation, and in other ways, GVC participation enhances Industry 5.0 adoption; GVC participation can enhance competitiveness, and in other ways, competitiveness can enhance GVC participation. Further, a longitudinal study coupled with workshop can update the SMEs’ status and progress in I5.0 readiness and GVC participation.

Author Contributions

Conceptualization, M.M.; Methodology, M.M. and M.A.S.; Investigation, M.M. and M.A.S.; Data curation, M.M. and M.A.S.; Software, M.M. and M.A.S.; Resources, M.M.; Formal analysis, M.M. and M.A.S.; Validation, M.M. and M.A.S.; Funding acquisition, M.M.; Project administration, M.M.; Writing—original draft, M.M. and M.A.S.; Writing—review & editing, M.M., M.A.S. and S.W.; Visualization, M.M. and M.A.S.; Supervision, S.W. All authors have read and agreed to the published version of the manuscript.

Funding

This project is funded by National Research Council of Thailand (NRCT). Capital Name: Research and Innovation Grants for Young Talented Researchers 2021, Contract number: N41A640113. This research was partially supported by Chiang Mai University, Thailand.

Institutional Review Board Statement

The Research Ethics Committee of Chiang Mai University has reviewed and issued the “Certificate of Exemption” (COE No. 002/66, CMUREC Code No. 65/234, Date: 6 January 2023), which was approved based on the international guidelines for human research protection including the Declaration of Helsinki, International Conference on Harmonization in Good Clinical Practice (ICH-GCP), and The Belmont Report.

Informed Consent Statement

Informed consent was obtained from all the respondents who participated in this study. The study and its purpose were explained to all the respondents who participated in this study. The anonymity and confidentiality of the data were maintained at all times.

Data Availability Statement

The data are not publicly available due to privacy and ethical restrictions.

Acknowledgments

We thank National Research Council of Thailand (NRCT) for funding this research (Capital Name: Research and Innovation Grants for Young Talented Researchers 2021. Contract number: N41A640113). Also, we thank Chiang Mai University, Thailand, for partially supporting this research. All the authors thank the participants (seafood processing SMEs of Thailand) for their support and participation in this research. The authors thank the College of Maritime Studies and Management, Chiang Mai University, Samut Sakhon, for their encouragement and support in conducting this research successfully.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- A Brief History of Lean. n.d. Lean Enterprise Institute (blog). Available online: https://www.lean.org/explore-lean/a-brief-history-of-lean/ (accessed on 11 March 2024).

- Abe, Masato. 2015. SME Participation in Global Value Chains: Challenges and Opportunities. In INTEGRATING SMEs INTO GLOBAL VALUE CHAINS. Phillipines: Asian Development Bank, Asian Development Bank Institute. Available online: https://www.adb.org/sites/default/files/publication/175295/smes-global-value-chains.pdf (accessed on 11 August 2022).

- Ahmedova, Sibel. 2015. Factors for Increasing the Competitiveness of Small and Medium-Sized Enterprises (SMEs) in Bulgaria. Procedia—Social and Behavioral Sciences 195: 1104–12. [Google Scholar] [CrossRef]

- Akundi, Aditya, Daniel Euresti, Sergio Luna, Wilma Ankobiah, Amit Lopes, and Immanuel Edinbarough. 2022. State of Industry 5.0—Analysis and Identification of Current Research Trends. Applied System Innovation 5: 27. [Google Scholar] [CrossRef]

- Alemany, Ana Patricia Fanjul, Liliana Herrera, and M. F. Muñoz-Doyague. 2023. Fair Trade and the Sustainable Development Goals: An Opportunity for Sustainable Production and Consumption. In Global Challenges for a Sustainable Society. Edited by José Alberto Benítez-Andrades, Paula García-Llamas, Ángela Taboada, Laura Estévez-Mauriz and Roberto Baelo. Springer Proceedings in Earth and Environmental Sciences. Cham: Springer International Publishing, pp. 223–39. [Google Scholar] [CrossRef]

- Alvarez-Aros, Erick L., and César A. Bernal-Torres. 2021. Technological Competitiveness and Emerging Technologies in Industry 4.0 and Industry 5.0. Anais Da Academia Brasileira de Ciências 93: e20191290. [Google Scholar] [CrossRef] [PubMed]

- Alves, Anabela Carvalho. 2022. Lean Thinking: An Essential Mindset. IEEE Engineering Management Review 50: 127–33. [Google Scholar] [CrossRef]

- Asian Development Bank, Asian Development Bank Institute, ACTIONS IN. 2015. INTEGRATING SMEs INTO GLOBAL VALUE CHAINS. Phillipines: Asian Development Bank, Asian Development Bank Institute. Available online: https://www.adb.org/sites/default/files/publication/175295/smes-global-value-chains.pdf (accessed on 11 August 2022).

- Atwell, Cabe. 2017. Yes, Industry 5.0 Is Already on the Horizon. Machine Design. September 12. Available online: https://www.machinedesign.com/automation-iiot/article/21835933/yes-industry-50-is-already-on-the-horizon (accessed on 12 December 2022).

- Awan, Usama, Ismail Gölgeci, Dilshod Makhmadshoev, and Nishikant Mishra. 2022. Industry 4.0 and Circular Economy in an Era of Global Value Chains: What Have We Learned and What Is Still to Be Explored? Journal of Cleaner Production 371: 133621. [Google Scholar] [CrossRef]

- Bagozzi, Richard P., and Youjae Yi. 2012. Specification, Evaluation, and Interpretation of Structural Equation Models. Journal of the Academy of Marketing Science 40: 8–34. Available online: https://idp.springer.com/authorize/casa?redirect_uri=https://link.springer.com/article/10.1007/s11747-011-0278-x&casa_token=IeBemgTyYTgAAAAA:HQuVSk1InoysciBdGB4Ob43VYGcWLKvsT6CHGBweSlc1l8E34sLB5dvXpribBi85nIw1gztVdXo9shqCAR0 (accessed on 8 April 2024). [CrossRef]

- Ballé, Michael, and Daniel T. Jones. 2017. The Lean Strategy: Using Lean to Create Competitive Advantage, Unleash Innovation, and Deliver Sustainable Growth, 1st ed. New York: McGraw-Hill Education. [Google Scholar]

- Barney, Jay. 1991. Firm Resources and Sustained Competitive Advantage. Journal of Management 17: 99–120. [Google Scholar] [CrossRef]

- Bartlett, Christopher A., and Sumantra Ghoshal. 2002. Managing across Borders: The Transnational Solution. Boston: Harvard Business Press. Available online: https://books.google.com/books?hl=en&lr=&id=KYjHMVuNOAwC&oi=fnd&pg=PA3&dq=C.A.+Bartlett,+S.+Ghoshal+Managing+Across+Borders:+The+Transnational+Solution+Harvard+Business+School+Press,+Boston,+MA+(1989)&ots=MrxXczSM_E&sig=yUyCe4PpSD7PwMP-Ln_2LGfsatQ (accessed on 15 April 2024).

- Beifert, Anatoli, Laima Gerlitz, and Gunnar Prause. 2018. Industry 4.0—For Sustainable Development of Lean Manufacturing Companies in the Shipbuilding Sector. In Reliability and Statistics in Transportation and Communication. Edited by Igor Kabashkin, Irina Yatskiv and Olegas Prentkovskis. Lecture Notes in Networks and Systems. Cham: Springer International Publishing, pp. 563–73. [Google Scholar] [CrossRef]

- Botti, Antonio, and Giovanni Baldi. 2024. Business Model Innovation and Industry 5.0: A Possible Integration in GLAM Institutions. European Journal of Innovation Management. ahead-of-print. [Google Scholar] [CrossRef]

- Bozdogan, Kirkor. 2010. EVOLUTION OF THE LEAN ENTERPRISE SYSTEM: A CRITICAL SYNTHESIS AND AGENDA FOR THE FUTURE+, July. Available online: https://dspace.mit.edu/bitstream/handle/1721.1/82085/100731_Bozdogan_EvolutionofLeanEntSys.pdf (accessed on 11 March 2024).

- Brennan, Louis, and Ruslan Rakhmatullin. 2017. Transnationalizing Smart Specialization Strategy. In Advances in the Theory and Practice of Smart Specialization. Amsterdam: Elsevier, pp. 249–68. Available online: https://www.sciencedirect.com/science/article/pii/B9780128041376000115 (accessed on 13 March 2024).

- Breque, Maija, Lars De Nul, and Athanasios Petridis. 2021. Industry 5.0: Towards a Sustainable, Human Centric and Resilient European Industry. Brussels: Directorate-General for Research and Innovation (European Commission). Available online: https://data.europa.eu/doi/10.2777/308407 (accessed on 13 December 2022).

- Brun, Lukas, Gary Gereffi, and James Zhan. 2019. The “Lightness” of Industry 4.0 Lead Firms: Implications for Global Value Chains. In Transforming Industrial Policy for the Digital Age. Cheltenham: Edward Elgar Publishing, pp. 37–67. Available online: https://www.elgaronline.com/edcollchap/edcoll/9781788976145/9781788976145.00008.xml (accessed on 25 December 2023).

- Carayannis, Elias G., Luca Dezi, Gianluca Gregori, and Ernesto Calo. 2022. Smart Environments and Techno-Centric and Human-Centric Innovations for Industry and Society 5.0: A Quintuple Helix Innovation System View Towards Smart, Sustainable, and Inclusive Solutions. Journal of the Knowledge Economy 13: 926–55. [Google Scholar] [CrossRef]

- Carayannis, Elias G., and Joanna Morawska-Jancelewicz. 2022. The Futures of Europe: Society 5.0 and Industry 5.0 as Driving Forces of Future Universities. Journal of the Knowledge Economy 13: 3445–71. [Google Scholar] [CrossRef]

- Ceptureanu, Sebastian Ion. 2015. Competitiveness of SMES. Business Excellence and Management 5: 55–67. [Google Scholar]

- Charoenrat, Teerawat, and Piriya Pholphirul. 2022. The Industrial Sector Participation in Global Value Chains for Sustainable Development of the Greater Mekong Subregion (GMS). Global Business Review 23: 608–40. [Google Scholar] [CrossRef]

- Chen, Chun-Liang. 2019. Value Creation by SMEs Participating in Global Value Chains under Industry 4.0 Trend: Case Study of Textile Industry in Taiwan. Journal of Global Information Technology Management 22: 120–45. [Google Scholar] [CrossRef]

- Christianty, R., and R. Hidayati. 2017. Strategy to Increase the Competitiveness of SMEs and Their Integration into Global Value Chain. In A New Paradigm in Trade Governance Strengthen Global Competitiveness. The Proceeding of The International Conference and Call for Paper on Trade 5th–6th September 2017. Jakarta: Trade Analysis and Development Agency Ministry of Trade, Republic of Indonesia, vol. 4, pp. 173–88. [Google Scholar]

- CMU-MOOC | Maritime Clusters and International Digital Marketing. n.d. Available online: https://mooc.cmu.ac.th/th/course/848f0dce-2604-47c2-9f98-fafab4b510d4?fbclid=IwAR0HoNaoLIHZJoInH5rru-XR3DM6kBAEGh0JIn7iCjuWXMFpiJoQ2X3zFIg (accessed on 29 July 2022).

- Cronbach, Lee J. 1951. Coefficient Alpha and the Internal Structure of Tests. Psychometrika 16: 297–334. [Google Scholar] [CrossRef]

- Definition of MSMEs. n.d. SME. Available online: https://www.sme.go.th/en/page.php?modulekey=363 (accessed on 2 February 2024).

- Delera, Michele, Carlo Pietrobelli, Elisa Calza, and Alejandro Lavopa. 2022. Does Value Chain Participation Facilitate the Adoption of Industry 4.0 Technologies in Developing Countries? World Development 152: 105788. [Google Scholar] [CrossRef]

- Demir, Kadir Alpaslan, Gözde Döven, and Bülent Sezen. 2019. Industry 5.0 and Human-Robot Co-Working. Procedia Computer Science 158: 688–95. [Google Scholar] [CrossRef]

- Demir, Kadir, and Halil Cicibaş. 2017. Industry 5.0 and a Critique of Industry 4.0. In 4th International Management Information Systems Conference “Industry 4.0”. İstanbul: İstanbul University. [Google Scholar]

- Deyshappriya, NP Ravindra, and B. C. H. Maduwanthi. 2021. Impact of Global Value Chains on the Performance of SMEs in Sri Lanka: Evidence from Sri Lanka. In Enhancing SME Participation in Global Value Chains. Vol. 299, Available online: https://www.researchgate.net/profile/Ravindra-Deyshappriya-2/publication/351618713_Impact_of_Global_Value_Chains_on_the_Performance_of_SMEs_in_Sri_Lanka_Evidence_from_Sri_Lanka_Global_Value_Chain_and_SMEs_Concepts_and_Definitions/links/60a1689792851cfdf33b3546/Impact-of-Global-Value-Chains-on-the-Performance-of-SMEs-in-Sri-Lanka-Evidence-from-Sri-Lanka-Global-Value-Chain-and-SMEs-Concepts-and-Definitions.pdf (accessed on 14 March 2024).

- Diabate, Ardjouman, Hagan Sibiri, Linyu Wang, and Liying Yu. 2019. Assessing SMEs’ Sustainable Growth through Entrepreneurs’ Ability and Entrepreneurial Orientation: An Insight into SMEs in Côte d’Ivoire. Sustainability 11: 7149. Available online: https://www.mdpi.com/2071-1050/11/24/7149 (accessed on 13 March 2024). [CrossRef]

- Dilyard, John, Shasha Zhao, and Jacqueline Jing You. 2021. Digital Innovation and Industry 4.0 for Global Value Chain Resilience: Lessons Learned and Ways Forward. Thunderbird International Business Review 63: 577–84. [Google Scholar] [CrossRef]

- Efendi, Suryono, Edi Sugiono, Eddy Guritno, Sufyati, and Hendryadi. 2020. Building Innovation and Competitiveness for Low Technology Manufacturing SMEs through Imitating Capability and Learning: The Case of Indonesia. Cogent Social Sciences 6: 1803515. [Google Scholar] [CrossRef]

- European Economic and Social Committee. 2018. Industry 5.0 Will Bring about a New Paradigm of Cooperation between Humans and Machines. European Economic and Social Committee. December 6. Available online: https://www.eesc.europa.eu/en/news-media/eesc-info/012019/articles/66151 (accessed on 13 December 2022).

- Farhikhteh, Shirzad, Ali Kazemi, Arash Shahin, and Shafiee Majid Mohammad. 2020. How Competitiveness Factors Propel SMEs to Achieve Competitive Advantage? Competitiveness Review: An International Business Journal 30: 315–38. [Google Scholar] [CrossRef]

- Gadenne, David, Lokman Mia, John Sands, Lanita Winata, and George Hooi. 2012. The Influence of Sustainability Performance Management Practices on Organisational Sustainability Performance. Journal of Accounting & Organizational Change 8: 210–35. [Google Scholar] [CrossRef]

- Ge, Ying, David Dollar, and Xinding Yu. 2020. Institutions and Participation in Global Value Chains: Evidence from Belt and Road Initiative. China Economic Review 61: 101447. [Google Scholar] [CrossRef]

- Gereffi, Gary, and Karina Fernandez-Stark. 2016. Global Value Chain Analysis: A Primer, 2nd Edition. Duke CGGC (Center on Globalization, Governance & Competitiveness). Available online: https://dukespace.lib.duke.edu/server/api/core/bitstreams/fd7a47de-df3b-4a75-9749-e5113e28def3/content (accessed on 25 December 2023).

- Ghobakhloo, Morteza, Mohammad Iranmanesh, Behzad Foroughi, Abderahman Rejeb, Davoud Nikbin, and Ming-Lang Tseng. 2024. A Practical Guide on Strategic Roadmapping for Information and Operations Technology Management: A Case Study on Industry 5.0 Transformation. Journal of Industrial and Production Engineering, 1–25. [Google Scholar] [CrossRef]

- Ghobakhloo, Morteza, Mohammad Iranmanesh, Manuel E. Morales, Mehrbakhsh Nilashi, and Azlan Amran. 2023a. Actions and Approaches for Enabling Industry 5.0-Driven Sustainable Industrial Transformation: A Strategy Roadmap. Corporate Social Responsibility and Environmental Management 30: 1473–94. [Google Scholar] [CrossRef]

- Ghobakhloo, Morteza, Mohammad Iranmanesh, Ming-Lang Tseng, Andrius Grybauskas, Alessandro Stefanini, and Azlan Amran. 2023b. Behind the Definition of Industry 5.0: A Systematic Review of Technologies, Principles, Components, and Values. Journal of Industrial and Production Engineering 40: 432–47. [Google Scholar] [CrossRef]

- Gotfredsen, Shermine. 2016. Bringing Back the Human Touch: Industry 5.0 Concept Creating Factories of the Future’. Manufacturers Monthly. June 15. Available online: https://www.manmonthly.com.au/features/bringing-back-the-human-touch-industry-5-0-concept-creating-factories-of-the-future/ (accessed on 12 December 2022).

- Hair, Joseph F., G. Tomas M. Hult, Christian M. Ringle, Marko Sarstedt, Nicholas P. Danks, and Soumya Ray. 2021. Partial Least Squares Structural Equation Modeling (PLS-SEM) Using R: A Workbook. Classroom Companion: Business. Cham: Springer International Publishing. [Google Scholar] [CrossRef]

- Hair, Joseph F., Jeffrey J. Risher, Marko Sarstedt, and Christian M. Ringle. 2019. When to Use and How to Report the Results of PLS-SEM. European Business Review 31: 2–24. [Google Scholar] [CrossRef]

- Hair, Joseph F., Joe Hair, Marko Sarstedt, Christian M. Ringle, and Siegfried P. Gudergan. 2023. Advanced Issues in Partial Least Squares Structural Equation Modeling. Thousand Oaks: Sage publications. [Google Scholar]

- Harvie, Charles, and Teerawat Charoenrat. 2015. SMEs and the Rise of Global Value Chains. In INTEGRATING SMEs INTO GLOBAL VALUE CHAINS. Phillipines: Asian Development Bank, Asian Development Bank Institute. Available online: https://www.adb.org/sites/default/files/publication/175295/smes-global-value-chains.pdf (accessed on 11 August 2022).

- Haseeb, Muhammad, Hafezali Iqbal Hussain, Sebastian Kot, Armenia Androniceanu, and Kittisak Jermsittiparsert. 2019. Role of Social and Technological Challenges in Achieving a Sustainable Competitive Advantage and Sustainable Business Performance. Sustainability 11: 3811. [Google Scholar] [CrossRef]

- Hassoun, Abdo, Nour Alhaj Abdullah, Abderrahmane Aït-Kaddour, Mohamed Ghellam, Ayşegül Beşir, Oscar Zannou, Begüm Önal, Rana Muhammad Aadil, Jose M. Lorenzo, Amin Mousavi Khaneghah, and et al. 2022. Food Traceability 4.0 as Part of the Fourth Industrial Revolution: Key Enabling Technologies. Critical Reviews in Food Science and Nutrition 64: 873–889. [Google Scholar] [CrossRef] [PubMed]

- Henseler, Jörg, Christian M. Ringle, and Marko Sarstedt. 2015. A New Criterion for Assessing Discriminant Validity in Variance-Based Structural Equation Modeling. Journal of the Academy of Marketing Science 43: 115–35. [Google Scholar] [CrossRef]

- Hernández Paz, Virginia, Antonio Javier Revilla Torrejón, and Alicia Rodríguez Márquez. 2023. Disruptive Data-Related Technologies and Global Value Chain: Insights from SMEs in Emerging Markets. Disruptive Technologies in International Business. Challenges and Opportunities for Emerging Markets, 5–16. Available online: https://e-archivo.uc3m.es/handle/10016/39858 (accessed on 14 March 2024).

- Hernita, Hernita, Batara Surya, Iwan Perwira, Herminawaty Abubakar, and Muhammad Idris. 2021. Economic Business Sustainability and Strengthening Human Resource Capacity Based on Increasing the Productivity of Small and Medium Enterprises (SMEs) in Makassar City, Indonesia. Sustainability 13: 3177. [Google Scholar] [CrossRef]