Two Birds with One Stone: Bioplastics and Food Waste Anaerobic Co-Digestion

Abstract

:1. Introduction

| Polymer | Monomer/Subunit | Common Feedstocks | Biodegradable | Chemical Structure | Bioplastic Market Share | Ref. |

|---|---|---|---|---|---|---|

| bio-PET | Ethanol (EtOH) and terephthalic acid (TPA) | Corn, sugar beet, sugarcane, wheat (EtOH) and fossil-based (TPA) | N |  | 19.0% | [8,15,16] |

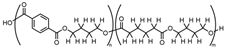

| PLA | Lactic acid | Corn, sugarcane | Y † |  | 16.2% | [8,15,16] |

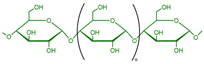

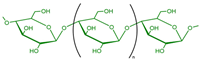

| Starch-based polymer | Starch (α-linked D-glucose) | Corn, potato, wheat, cassava, sugarcane | Y |  | 15.8% | [8,15,16] |

| bio-PE | EtOH | Corn, sugar beet, sugar cane, wheat | N |  | 9.1% | [8,15,16] |

| PBAT | Adipic acid, 1,4-butanediol (BD) and dimethyl-terephthalate | Fossil based # | Y |  | 7.7% | [8,16,17] |

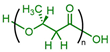

| PH3B (PHA) § | Hydroxy-alkanoate | Corn, vegetable oils, food waste, wastewater (through microbial fermentation) | Y |  | 4.5% | [8,18] |

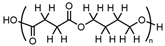

| PBS | Succinic acid and BD | Fossil based # | Y |  | 3.8% | [8,16,17] |

| Cellulose-based polymer | Cellulose (ß-linked D-glucose) | Wood pulp | Y |  | <1% | [8,15] |

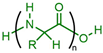

| Protein-based polymer | Amino acid | Wheat gluten, soy protein, milk casein | Y |  | <1% | [8,15] |

2. Status Quo: Organic Waste Management in the Bioeconomy

2.1. Anaerobic Digestion for Food Waste Recycling

2.2. Integrating Biodegradable Bioplastics into Organics Recycling

3. Relevant Study Designs for Biodegradable Bioplastic Anaerobic Degradation

3.1. Co-Digestion Substrates

3.2. Feedstock Ratios

3.3. Hydraulic Retention Time

3.4. Polymer Pre-Treatment

3.5. Polymer Properties

3.6. Microbial Communities

4. The Bigger Picture: Solutions beyond the Technosphere

4.1. Legislative, Economic and Environmental Challenges

4.2. Plastic Consumption and Consumer Behaviour

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- D’ambrières, W. Plastics recycling worldwide: Current overview and desirable changes. Field Actions Sci. Rep. 2019, 19, 12–21. [Google Scholar]

- PlasticsEurope. Plastics—The Facts 2016; PlasticsEurope: Brussels, Belgium, 2016. [Google Scholar]

- Vanapalli, K.R.; Sharma, H.B.; Ranjan, V.P.; Samal, B.; Bhattacharya, J.; Dubey, B.K.; Goel, S. Challenges and strategies for effective plastic waste management during and post COVID-19 pandemic. Sci. Tot. Environ. 2021, 750, 141514. [Google Scholar] [CrossRef] [PubMed]

- Schyns, Z.O.G.; Shaver, M.P. Mechanical recycling of packaging plastics: A review. Macromol. Rapid Commun. 2021, 42, 2000415. [Google Scholar] [CrossRef]

- Brockhaus, S.; Petersen, M.; Kersten, W. A crossroads for bioplastics: Exploring product developers’ challenges to move beyond petroleum-based plastics. J. Clean. Prod. 2016, 127, 84–95. [Google Scholar] [CrossRef]

- Kakadellis, S.; Harris, Z.M. Don’t scrap the waste: The need for broader system boundaries in bioplastic food packaging life-cycle assessment–a critical review. J. Clean. Prod. 2020, 274, 122831. [Google Scholar] [CrossRef]

- European Bioplastics. What Are Bioplastics? Material Types, Terminology, and Labels: An. Introduction; European Bioplastics: Berlin, Germany, 2016. [Google Scholar]

- European Bioplastics. Bioplastics Market Data. Available online: https://www.european-bioplastics.org/market/ (accessed on 8 March 2021).

- Briassoulis, D.; Pikasi, A.; Hiskakis, M. End-of-waste life: Inventory of alternative end-of-use recirculation routes of bio-based plastics in the European Union context. Crit. Rev. Env. Sci. Technol. 2019, 49, 1835–1892. [Google Scholar] [CrossRef]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to assess biodegradation of bioplastics during aerobic composting and anaerobic digestion: A review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quecholac-Piña, X.; Hernández-Berriel, M.d.C.; Mañón-Salas, M.d.C.; Espinosa-Valdemar, R.M.; Vázquez-Morillas, A. Degradation of plastics under anaerobic conditions: A short review. Polymers 2020, 12, 109. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Biodegradable Waste. Available online: https://ec.europa.eu/environment/topics/waste-and-recycling/biodegradable-waste_en (accessed on 8 March 2021).

- Narancic, T.; Verstichel, S.; Reddy Chaganti, S.; Morales-Gamez, L.; Kenny, S.T.; De Wilde, B.; Babu Padamati, R.; O’Connor, K.E. Biodegradable plastic blends create new possibilities for end-of-life management of plastics but they are not a panacea for plastic pollution. Environ. Sci. Technol. 2018, 52, 10441–10452. [Google Scholar] [CrossRef]

- Stagner, J. Methane generation from anaerobic digestion of biodegradable plastics–a review. Int. J. Environ. Stud. 2016, 73, 462–468. [Google Scholar] [CrossRef]

- Karan, H.; Funk, C.; Grabert, M.; Oey, M.; Hankamer, B. Green bioplastics as part of a circular bioeconomy. Trends Plant. Sci. 2019, 24, 237–249. [Google Scholar] [CrossRef]

- Folino, A.; Karageorgiou, A.; Calabrò, P.S.; Komilis, D. Biodegradation of wasted bioplastics in natural and industrial environments: A review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

- Zaaba, N.F.; Jaafar, M. A review on degradation mechanisms of polylactic acid: Hydrolytic, photodegradative, microbial, and enzymatic degradation. Polym. Eng. Sci. 2020, 60, 2061–2075. [Google Scholar] [CrossRef]

- Tsang, Y.F.; Kumar, V.; Samadar, P.; Yang, Y.; Lee, J.; Ok, Y.S.; Song, H.; Kim, K.-H.; Kwon, E.E.; Jeon, Y.J. Production of bioplastic through food waste valorization. Environ. Int. 2019, 127, 625–644. [Google Scholar] [CrossRef] [PubMed]

- De Paula, F.C.; de Paula, C.B.C.; Contiero, J. Prospective Biodegradable Plastics from Biomass Conversion Processes. In Biofuels—State of Development; Biernat, K., Ed.; IntechOpen: London, UK, 2018. [Google Scholar]

- Bátori, V.; Åkesson, D.; Zamani, A.; Taherzadeh, M.J.; Horváth, I.S. Anaerobic degradation of bioplastics: A review. Waste Manag. 2018, 80, 406–413. [Google Scholar] [CrossRef] [PubMed]

- Gómez, E.F.; Michel, F.C. Biodegradability of conventional and bio-based plastics and natural fiber composites during composting, anaerobic digestion and long-term soil incubation. Polym. Degrad. Stabil. 2013, 98, 2583–2591. [Google Scholar] [CrossRef]

- European Commission. Being Wise with Waste: The EU’s Approach to Waste Management; Publications Office of the European Union: Luxembourg, Luxembourg, 2019. [Google Scholar]

- FUSIONS. Food Waste Quantification Manual to Monitor Food Waste Amounts and Progression; FUSIONS: Neuilly-sur-Seine, France, 2016. [Google Scholar]

- European Environment Agency. Bio-Waste in Europe—Turning Challenges into Opportunities; European Environment Agency: Copenhagen, Denmark, 2020. [Google Scholar]

- European Commission. Circular Economy Action Plan.—For a Cleaner and More Competitive Europe; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- World Biogas Association. WBA Global Bioenergy Statistics 2018; World Biogas Association: London, UK, 2018. [Google Scholar]

- Ju, M.; Bae, S.; Kim, J.Y.; Lee, D.-H. Solid recovery rate of food waste recycling in South Korea. J. Mater. Cycles Waste Manag. 2016, 18, 419–426. [Google Scholar] [CrossRef]

- Awasthi, S.K.; Sarsaiya, S.; Awasthi, M.K.; Liu, T.; Zhao, J.; Kumar, S.; Zhang, Z. Changes in global trends in food waste composting: Research challenges and opportunities. Bioresour. Technol. 2020, 299, 122555. [Google Scholar] [CrossRef]

- Rockström, J.; Steffen, W.; Noone, K.; Persson, Å.; Chapin, F.S., III; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef]

- DEFRA. Anaerobic Digestion Strategy and Action Plan. Annual Report 2014; HM Government: London, UK, 2015. [Google Scholar]

- WRAP. The Impact of Household Food Waste Collections on Household Food Waste Arisings; WRAP: Banbury, UK, 2019. [Google Scholar]

- ADBA. Biomethane—The Pathway to 2030; ADBA: London, UK, 2020. [Google Scholar]

- Dilkes-Hoffman, L.S.; Lane, J.L.; Grant, T.; Pratt, S.; Lant, P.A.; Laycock, B. Environmental impact of biodegradable food packaging when considering food waste. J. Clean. Prod. 2018, 180, 325–334. [Google Scholar] [CrossRef]

- WRAP. New Markets for Digestate from Anaerobic Digestion; WRAP: Banbury, UK, 2011. [Google Scholar]

- Trabold, T.; Babbitt, C.W. (Eds.) Sustainable Food Waste-to-Energy Systems; Academic Press: Cambridge, UK, 2018. [Google Scholar]

- BBIA. BBIA Position Paper on the Resource and Waste Strategy; BBIA: Ware, UK, 2019. [Google Scholar]

- CIC. Annual Report on Biowaste Recycling; CIC: Rome, Italy, 2017. [Google Scholar]

- Nemat, B.; Razzaghi, M.; Bolton, K.; Rousta, K. The potential of food packaging attributes to influence consumers’ decisions to sort waste. Sustainability 2020, 12, 2234. [Google Scholar] [CrossRef] [Green Version]

- Allison, A.L.; Lorencatto, F.; Michie, S.; Miodownik, M. Barriers and Enablers to Buying Biodegradable and Compostable Plastic Packaging. Sustainability 2021, 13, 1463. [Google Scholar] [CrossRef]

- Kakadellis, S.; Woods, J.; Harris, Z.M. Friend or foe: Stakeholder attitudes towards biodegradable plastic packaging in food waste anaerobic digestion. Resour. Conserv. Recycl. 2021, 169, 105529. [Google Scholar] [CrossRef]

- Hedge, S.; Diaz, C.A.; Dell, E.D.; Trabold, T.A.; Lewis, C.L. Investigation of process parameters on the anaerobic digestion of a poly (hydroxyalkonate) film. Eur. Polym. J. 2021, 148, 110349. [Google Scholar]

- Briassoulis, D.; Dejean, C.; Picuno, P. Critical review of norms and standards for biodegradable agricultural plastics part II: Composting. J. Polym. Environ. 2010, 18, 364–383. [Google Scholar] [CrossRef]

- Grima, S.; Bellon-Maurel, V.; Feuilloley, P.; Silvestre, F. Aerobic biodegradation of polymers in solid-state conditions: A review of environmental and physicochemical parameter settings in laboratory simulations. J. Polym. Environ. 2000, 8, 183–195. [Google Scholar] [CrossRef]

- Kale, G.; Auras, R.; Singh, S.P.; Narayan, R. Biodegradability of polylactide bottles in real and simulated composting conditions. Polym. Test. 2007, 26, 1049–1061. [Google Scholar] [CrossRef]

- Hobbs, S.R.; Parameswaran, P.; Astmann, B.; Devkota, J.P.; Landis, A.E. Anaerobic Codigestion of Food Waste and Polylactic Acid: Effect of Pretreatment on Methane Yield and Solid Reduction. Adv. Mat. Sci. Eng. 2019, 2019, 4715904. [Google Scholar] [CrossRef] [Green Version]

- Samitthiwetcharong, S.; Chavalparit, O. Enhancement of methane production from alkaline pretreated polylactic acid waste by the co-digestion process. Int. J. GEOMATE 2019, 16, 171–176. [Google Scholar] [CrossRef]

- Lim, J.W.; Ting, D.W.Q.; Loh, K.C.; Ge, T.; Tong, Y.W. Effects of disposable plastics and wooden chopsticks on the anaerobic digestion of food waste. Waste Manag. 2018, 79, 607–614. [Google Scholar] [CrossRef]

- Peng, W.; Wang, Z.; Shu, Y.; Lü, F.; Zhang, H.; Shao, L.; He, P. Fate of a biobased polymer via high-solid anaerobic co-digestion with food waste and following aerobic treatment: Insights on changes of polymer physicochemical properties and the role of microbial and fungal communities. Bioresour. Technol. 2022, 343, 126079. [Google Scholar] [CrossRef]

- Bandini, F.; Frache, A.; Ferrarini, A.; Taskin, E.; Cocconcelli, P.S.; Puglisi, E. Fate of biodegradable polymers under industrial conditions for anaerobic digestion and aerobic composting of food waste. J. Polym. Environ. 2020, 28, 2539–2550. [Google Scholar] [CrossRef]

- Wang, F.; Hidaka, T.; Tsuno, H.; Tsubota, J. Co-digestion of polylactide and kitchen garbage in hyperthermophilic and thermophilic continuous anaerobic process. Bioresour. Technol. 2012, 112, 67–74. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Heaven, S.; Banks, C.J. Degradation of some EN13432 compliant plastics in simulated mesophilic anaerobic digestion of food waste. J. Polym. Degrad. Stab. 2018, 147, 76–88. [Google Scholar] [CrossRef] [Green Version]

- Cucina, M.; De Nisi, P.; Trombino, L.; Tambone, F.; Adani, F. Degradation of bioplastics in organic waste by mesophilic anaerobic digestion, composting and soil incubation. Waste Manag. 2021, 134, 67–77. [Google Scholar] [CrossRef]

- Vasmara, C.; Marchetti, R. Biogas production from biodegradable bioplastics. Environ. Eng. Manag. J. 2016, 15, 2041–2048. [Google Scholar] [CrossRef]

- Okoro-Shekwaga, C.K.; Suruagy, M.V.T.; Ross, A.; Camargo-Valero, M.A. Particle size, inoculum-to-substrate ratio and nutrient media effects on biomethane yield from food waste. Renew. Energy 2020, 151, 311–321. [Google Scholar] [CrossRef]

- Zhang, W.; Torrella, F.; Banks, C.J.; Heaven, S. Data related to anaerobic digestion of bioplastics: Images and properties of digested bioplastics and digestate, synthetic food waste recipe and packaging information. Data Brief. 2019, 25, 103990. [Google Scholar] [CrossRef] [PubMed]

- Angelonidi, E.; Smith, S.R. A comparison of wet and dry anaerobic digestion processes for the treatment of municipal solid waste and food waste. Water Environ. J. 2015, 29, 549–557. [Google Scholar] [CrossRef]

- Rocamora, I.; Wagland, S.T.; Villa, R.; Simpson, E.W.; Fernández, O.; Bajón-Fernández, Y. Dry anaerobic digestion of organic waste: A review of operational parameters and their impact on process performance. Bioresour. Technol. 2020, 299, 122681. [Google Scholar] [CrossRef] [PubMed]

- Battista, F.; Frison, N.; Bolzonella, D. Can bioplastics be treated in conventional anaerobic digesters for food waste treatment? Environ. Technol. Innov. 2021, 22, 101393. [Google Scholar] [CrossRef]

- Banks, C.J.; Heaven, S.; Zhang, Y.; Baier, U. Food Waste Digestion: Anaerobic Digestion of Food Waste for a Circular Economy; IEA Task 37; Murphy, J.D., Ed.; IEA Bioenergy: Paris, France, 2018. [Google Scholar]

- Zhang, W.; Werner, J.J.; Agler, M.T.; Angenent, L.T. Substrate type drives variation in reactor microbiomes of anaerobic digesters. Bioresour. Technol. 2014, 151, 397–401. [Google Scholar] [CrossRef]

- Pathak, V.M. Review on the current status of polymer degradation: A microbial approach. Bioresour. Bioprocess. 2017, 4, 15. [Google Scholar] [CrossRef]

- Danso, D.; Chow, J.; Streit, W.R. Plastics: Environmental and biotechnological perspectives on microbial degradation. Appl. Environ. Microbiol. 2019, 85, e01095-19. [Google Scholar] [CrossRef] [Green Version]

- Dickson, I. Sequencing the Unculturable Majority (S6); Springer Nature: New York, NY, USA, 2021. [Google Scholar]

- Rahman, M.S.; Hoque, M.N.; Puspo, J.A.; Islam, M.R.; Das, N.; Siddique, M.A.; Hossain, M.A.; Sultana, M. Microbiome signature and diversity regulates the level of energy production under anaerobic condition. Sci. Rep. 2021, 11, 19777. [Google Scholar] [CrossRef]

- Leipold, S.; Petit-Boix, A. The circular economy and the bio-based sector-Perspectives of European and German stakeholders. J. Clean. Prod. 2018, 201, 1125–1137. [Google Scholar] [CrossRef]

- Kakadellis, S.; Rosetto, G. Achieving a circular economy for plastics. Science 2021, 373, 49–50. [Google Scholar] [CrossRef] [PubMed]

- FAO & UNEP. Global Assessment of Soil Pollution—Summary for Policy Makers; FAO: Rome, Italy, 2021. [Google Scholar]

- Macleod, M.; Arp, H.P.H.; Tekman, M.B.; Jahnke, A. The global threat from plastic pollution. Science 2021, 373, 61–65. [Google Scholar] [CrossRef] [PubMed]

- Scarlat, N.; Dallemand, J.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Herbes, C.; Beuthner, C.; Ramme, I. Consumer attitudes towards biobased packaging—A cross-cultural comparative study. J. Clean. Prod. 2018, 194, 203–218. [Google Scholar] [CrossRef]

- Taufik, D.; Reinders, M.J.; Molenveld, K.; Onwezen, M.C. The paradox between the environmental appeal of bio-based plastic packaging for consumers and their disposal behaviour. Sci. Total Environ. 2020, 705, 135820. [Google Scholar] [CrossRef] [PubMed]

- Dilkes-Hoffman, L.; Ashworth, P.; Laycock, B.; Pratt, S.; Lant, P. Public attitudes towards bioplastics–knowledge, perception and end-of-life management. Resour. Conserv. Recycl. 2019, 151, 104479. [Google Scholar] [CrossRef]

- Napper, I.; Thompson, R. Environmental deterioration of biodegradable, oxo-biodegradable, compostable, and conventional plastic carrier bags in the sea, soil, and open-air over a 3-year period. Environ. Sci. Technol. 2019, 53, 4775–4783. [Google Scholar] [CrossRef] [PubMed]

| Material Targeted | By 2023 | By 2025 | By 2030 | By 2035 |

|---|---|---|---|---|

| Plastic packaging recycled | - | 50% | 55% | - |

| Municipal waste recycled | - | 55% | 60% | 65% |

| Municipal waste landfilled | - | - | - | ≤10% |

| Household food waste | Separate collection and landfill ban | - | - | - |

| Technology | Process Description | Advantages | Disadvantages | |

|---|---|---|---|---|

| Anaerobic digestion (AD) | Degradation of organic waste by microorganisms in the absence of oxygen in a closed chamber |

|

| |

| Composting | In-vessel composting (IVC) | Degradation of organic waste by microorganisms in the presence of oxygen in a silo or concrete-lined chamber |

|

|

| Windrow composting (WC) | Degradation of organic waste by microorganisms in the presence of oxygen in windrow (i.e., heaps laid out to dry outdoors) |

| ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kakadellis, S.; Lee, P.-H.; Harris, Z.M. Two Birds with One Stone: Bioplastics and Food Waste Anaerobic Co-Digestion. Environments 2022, 9, 9. https://doi.org/10.3390/environments9010009

Kakadellis S, Lee P-H, Harris ZM. Two Birds with One Stone: Bioplastics and Food Waste Anaerobic Co-Digestion. Environments. 2022; 9(1):9. https://doi.org/10.3390/environments9010009

Chicago/Turabian StyleKakadellis, Sarah, Po-Heng Lee, and Zoe M. Harris. 2022. "Two Birds with One Stone: Bioplastics and Food Waste Anaerobic Co-Digestion" Environments 9, no. 1: 9. https://doi.org/10.3390/environments9010009

APA StyleKakadellis, S., Lee, P.-H., & Harris, Z. M. (2022). Two Birds with One Stone: Bioplastics and Food Waste Anaerobic Co-Digestion. Environments, 9(1), 9. https://doi.org/10.3390/environments9010009