A Reliable Seawater Desalination System Based on Membrane Technology and Biotechnology Considering Reduction of the Environmental Impact

Abstract

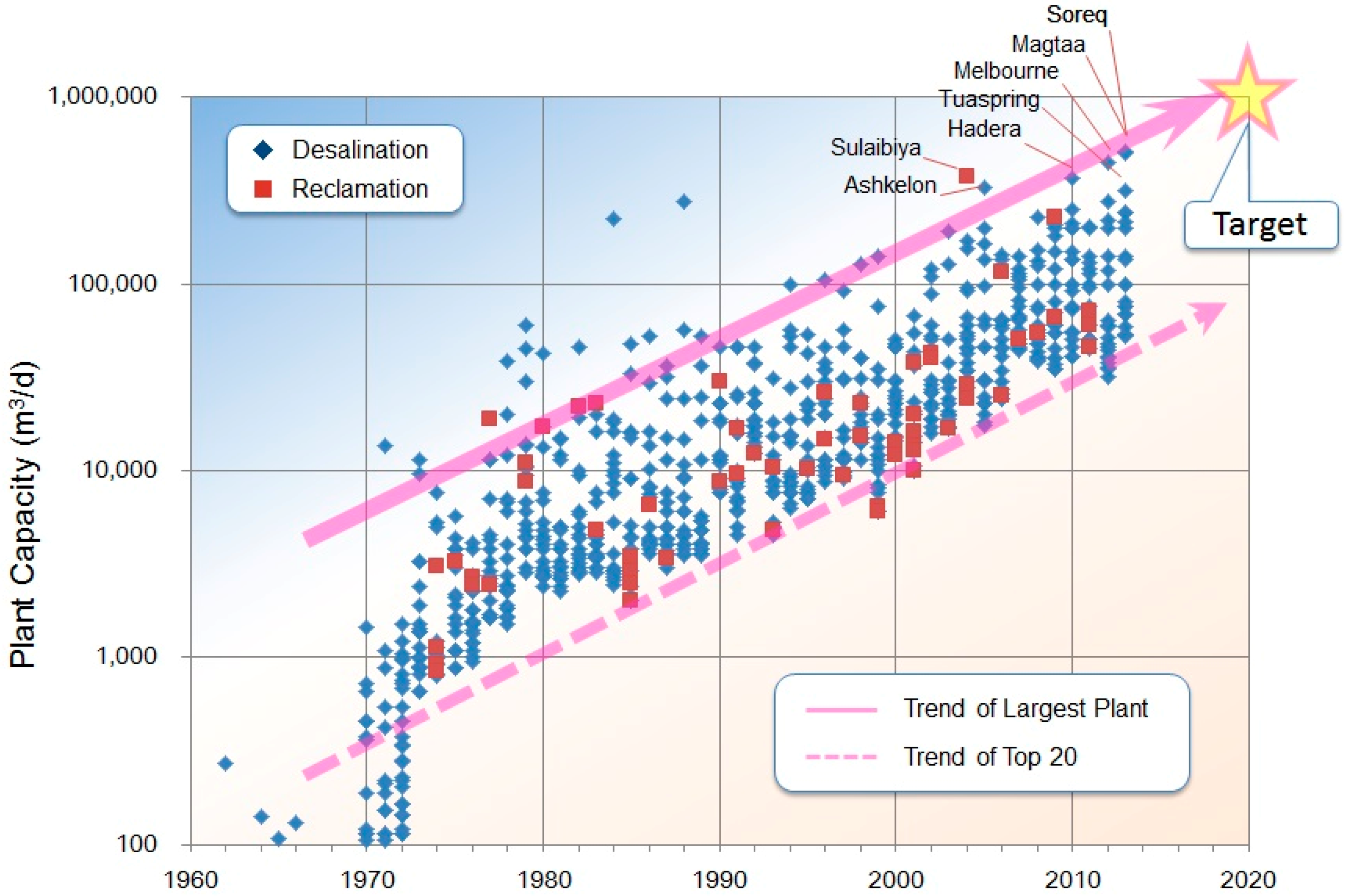

:1. Introduction

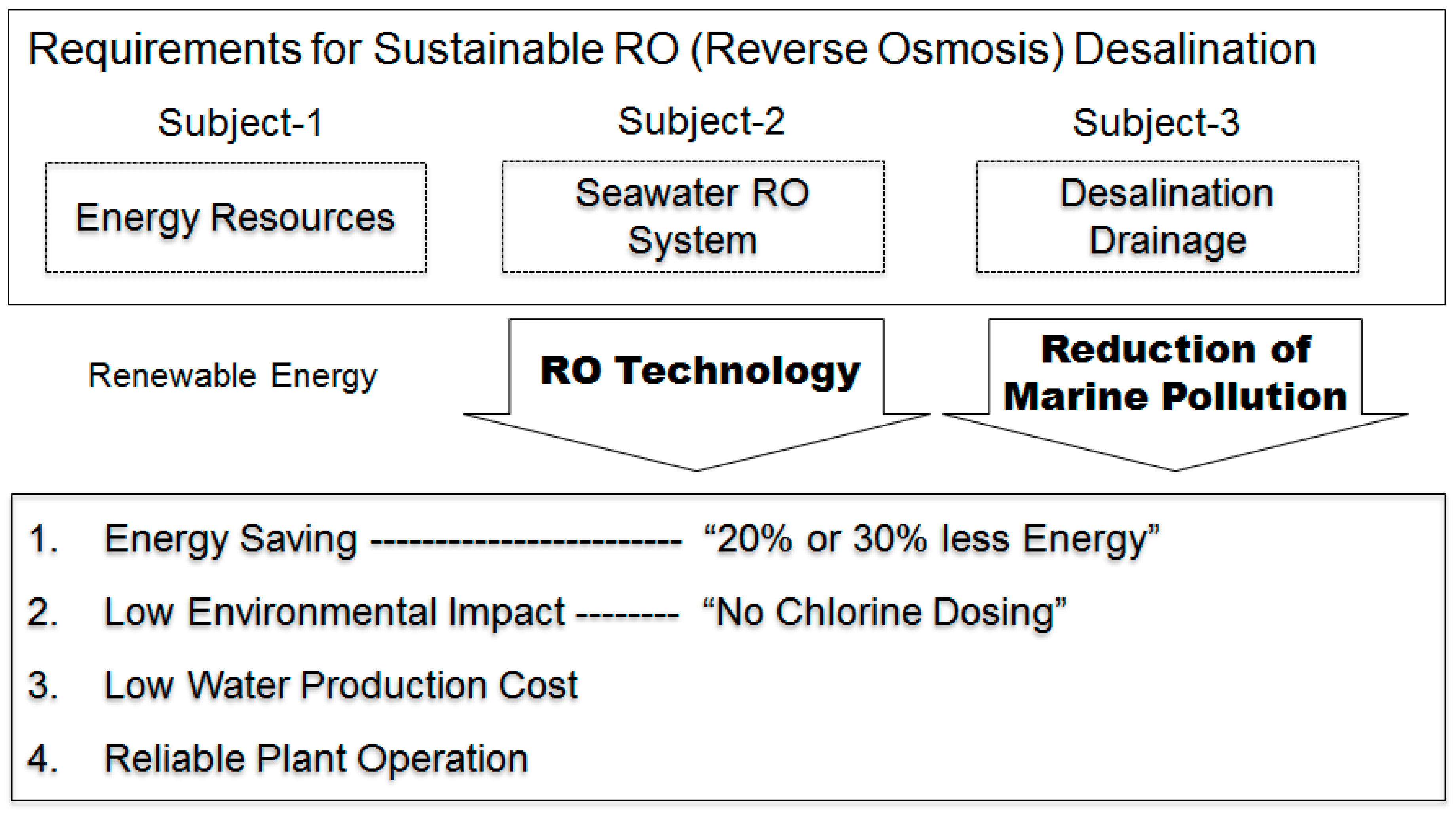

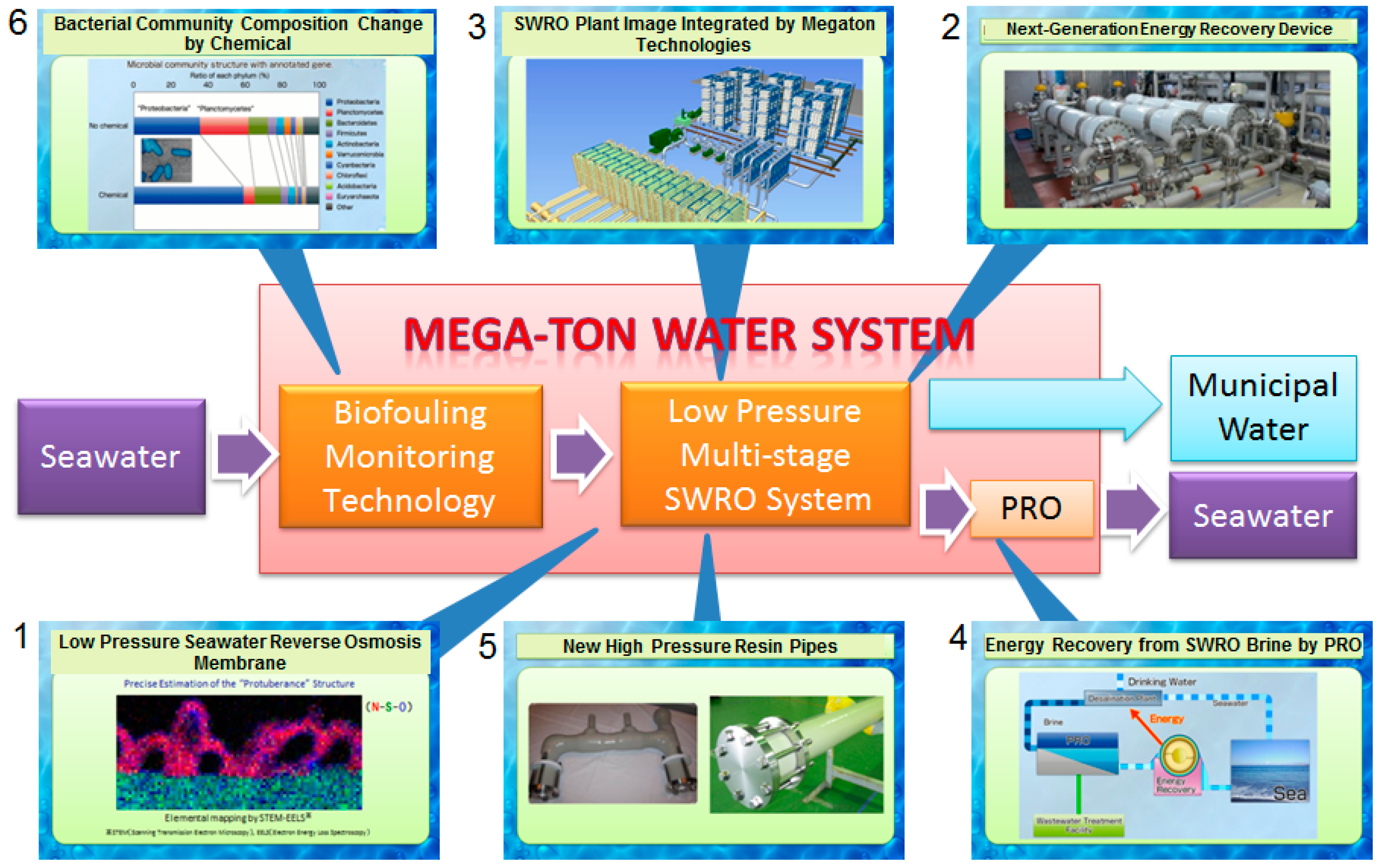

- Low-pressure SWRO membranes.

- Next generation energy recovery devices (ERD).

- Low-pressure multistage SWRO systems (LMS): SWRO Plant Image Integrated by Mega-ton Technologies.

- Energy Recovery from SWRO Brine by PRO (pressure-retarded osmosis)

- New high durability high-pressure resin pipes.

- Biofouling monitoring technology: Bacterial Community Composition Change by Chemical.

2. Results and Discussion

2.1. Reliable Seawater Desalination System for Biofouling

2.1.1. History of Anti-Biofouling Trails for SWRO (Seawater Reverse Osmosis) System

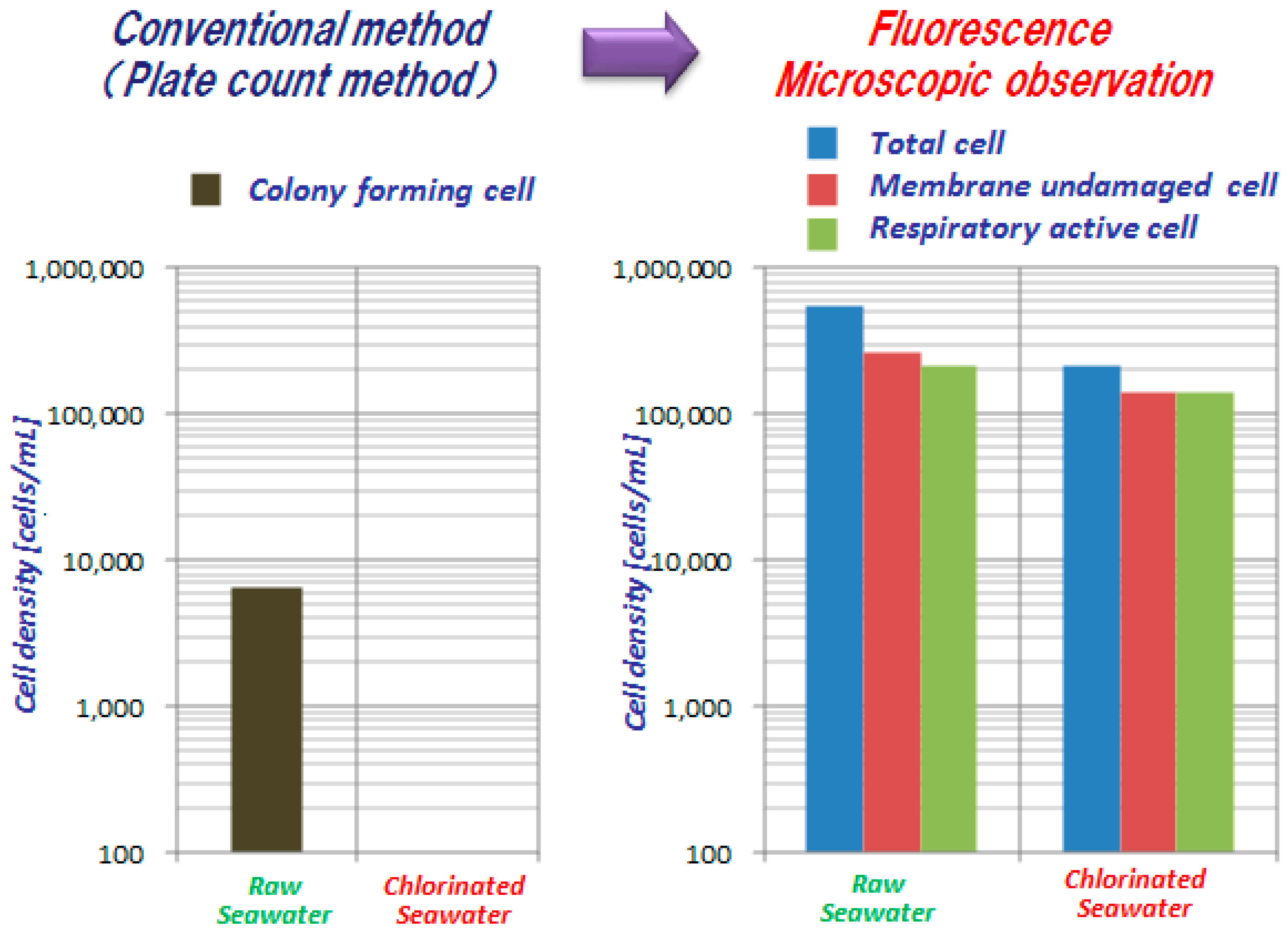

2.1.2. Sterilization Effect by Chlorination on Marine Bacteria is Limited

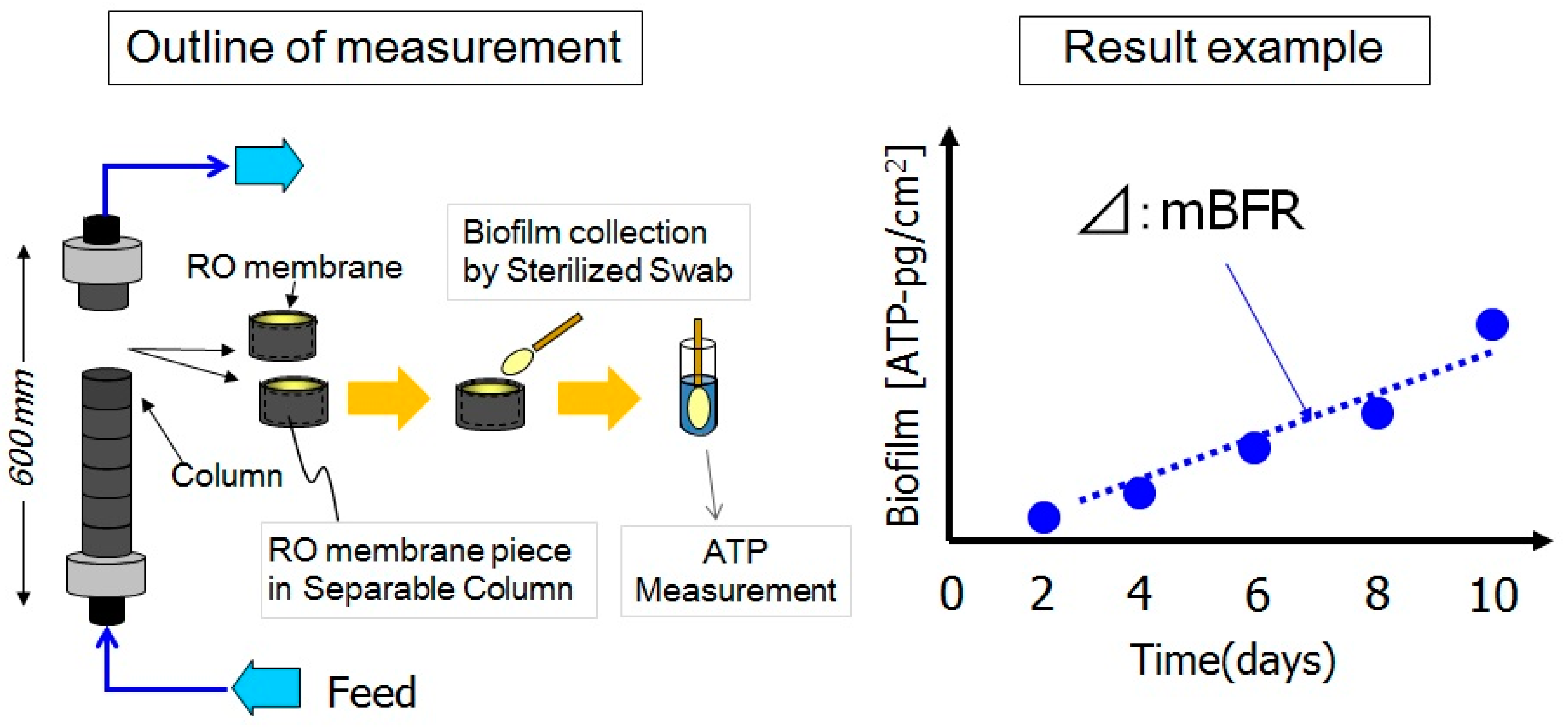

2.1.3. Membrane Biofilm Formation Rate (mBFR)

2.1.4. Chlorine Sterilization Triggers Biofouling

2.1.5. The Effect of Chemical Addition on Microbial Community Structures

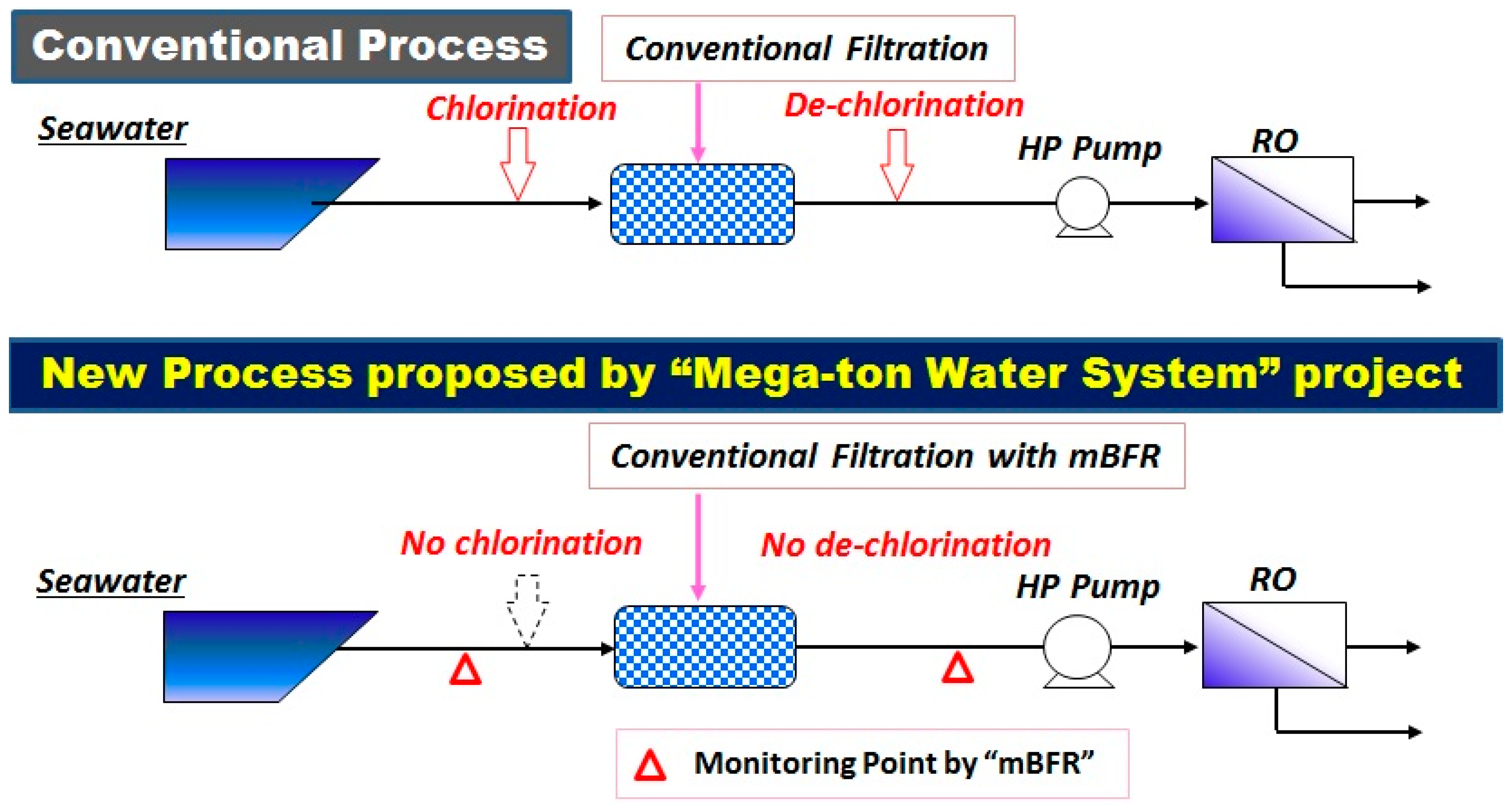

2.1.6. Comparison of Conventional Process and New Process Proposed by “Mega-ton Water System” Project

2.2. Verification of Biofouling Monitoring Technology in Arabian Gulf, Most Severe Biofouling Area and in the Red Sea in Saudi Arabia

- (1)

- (2)

- High-performance system for low-cost seawater using other Mega-ton Technologies are shown in Figure 3 as low-pressure multistage SWRO systems [4].

- (A)

- High water recovery system by two-stage one pass up to 60%.

- (B)

- Flux equalization by optimization of vessel configuration (two elements in one vessel).

- (C)

- High-energy recovery by ERD.

- (D)

- Newly developed polyamide membrane (TM820V-400) by Toray was used in this system.

- (E)

- Pre-treatment is DMF (Dual Media Filter).

2.2.1. Pilot Plant Verification (500 m3/day) in the Arabian Gulf

2.2.2. Full Plant Verification of NEDO-SWCC Demonstration Project (10,000 m3/day) at the Red Sea, Ummluji, Saudi Arabia

- (1)

- Reduce energy consumption by around 20% compared to that of conventional seawater desalination plants applying RO membranes.

- (2)

- Reduce the construction cost by reducing the capacity of the pretreatment facilities, which will be enabled by lowering the seawater intake.

- (3)

- Biofouling monitoring technology using mBFR is applied to this project.

3. Conclusions

- A reliable seawater desalination system based on membrane technology and biotechnology for considering environmental impacts were established as an innovative paradigm shift of the biofouling concept.

- We confirmed that the chemical addition of chlorine and SBS triggers biofouling.

- Biofouling monitoring technology using mBFR was a good indicator of reliable seawater desalination system design and operation.

- This biofouling monitoring technology using mBFR was verified in a pilot test, located in Al Jubail, DTRI and Saudi Arabia during one year.

- The next step of the post-megaton project is the verification of this technology at a full-scale plant-10,000 m3/day in Ummluji, Saudi Arabia.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- International Desalination Association. Global Water Intelligence; DesalData 2016 Plant Inventory Report; International Desalination Association: Oxford, UK, 2016. [Google Scholar]

- Kurihara, M.; Takeuchi, H. Earth-friendly Seawater Desalination System required in 21st Century. Chem. Eng. Technol. 2018, 41, 401–412. [Google Scholar] [CrossRef]

- Kurihara, M.; Hanakawa, M. Mega-ton Water System: Japanese national research and development project on seawater desalination and wastewater reclamation. Desalination 2013, 308, 131–137. [Google Scholar] [CrossRef]

- Kurihara, M.; Takeuchi, H. The Next Generation Energy Efficient Membrane Desalination System with Advanced Key Technologies: “Mega-ton Water System”, Current Trends and Future Development on (Bio-) Membranes 1st Edition—Membrane Desalination System: The Next Generation; Elsevier: Amsterdam, The Netherlands, 2018; eBook ISBN: 9780128135525, Paper ISBN 9780128135518. [Google Scholar]

- Kurihara, M.; Kurokawa, H. Further Progress of “Mega-ton Water System”. In Proceedings of the 12th SWA-APDA Joint Conference, Singapore, 11 July 2018. [Google Scholar]

- Lattemann, S.; Höpner, T. Environmental impact and impact assessment of seawater desalination. Desalination 2008, 220, 1–15. [Google Scholar] [CrossRef]

- Khedr, M.G. Membrane fouling problems in reverse osmosis desalination applications. Int. Desalin. Water Reuse Q. 2000, 10, 259–267. [Google Scholar]

- Baker, J.S.; Dudley, L.Y. Biofouling in membrane systems—A review. Desalination 1998, 118, 81–90. [Google Scholar] [CrossRef]

- Saeed, M.O.; Jamaluddin, A.T.; Tisan, I.A.; Lawrence, D.A.; Al-Amri, M.M.; Chida, K. Biofouling in a seawater reverse osmosis plant on the Red Sea coast, Saudi Arabia. Desalination 2000, 128, 177–190. [Google Scholar] [CrossRef]

- Hamida, A.B.; Moch, I., Jr. Controlling biological fouling in open sea intake RO plants without continuous chlorination. Desalin. Water Reuse 1996, 6, 40–45. [Google Scholar]

- Kimura, T.; Ito, Y.; Nakaoki, Y. Innovative Biofouling Prevention on Seawater Desalination Reverse Osmosis Membrane; International Desalination Association: Oxford, UK, 2001. [Google Scholar]

- Ito, Y.; Hanada, S.; Kitade, T.; Tanaka, Y.; Kurihara, M. Clarification of Impact of Biofouling Triggered by Chemical Addition; IDAWC: Tianjin, China, 2013. [Google Scholar]

- Van der Kooij, D.; Veenendaal, H.R.; Baars-Lorist, C.; Van der Klift, D.; Drost, Y.C. Biofilm formation on surface of glass and teflon exposed to treated water. Water Res. 1995, 29, 1655–1662. [Google Scholar] [CrossRef]

- Van der Kooij, D.; Vrouwenvelder, J.S.; Veenendaal, H.R. Kinetic aspects of biofilm formation on surfaces exposed to drinking water. Water Sci. Technol. 1995, 32, 61–65. [Google Scholar] [CrossRef]

- Vrouwenvelder, J.S.; Van der Kooij, D. Diagnosis, prediction and prevention of biofouling of NF and RO membranes. Desalination 2001, 139, 65–71. [Google Scholar] [CrossRef]

- Ito, Y.; Kantan, S.; Maeda, T.; Okubo, K.; Taniguchi, M. Innovative Biofouling Monitoring Device and its Criteria for Reverse Osmosis plant Operation and Optimization; IDAWC: San Diego, CA, USA, 2015. [Google Scholar]

- Kogure, K. Poster session, Bacterial community structure of RO foulant at phylum level. In Proceedings of the International Symposium on FIRST Program “Mega-ton Water System”, Tokyo, Japan, 21–22 November 2013. [Google Scholar]

- Dhakal, N.; Salinas-Rodriguez, S.; Knops, F.; Schippers, J.; Kennedy, M. Ultrafiltration as a pretreatment for seawater reverse osmosis during algal bloom. In Proceedings of the International Desalination Association (IDA) World Congress 2017, Sao Paulo, Brazil, 15–20 October 2017. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurihara, M.; Takeuchi, H.; Ito, Y. A Reliable Seawater Desalination System Based on Membrane Technology and Biotechnology Considering Reduction of the Environmental Impact. Environments 2018, 5, 127. https://doi.org/10.3390/environments5120127

Kurihara M, Takeuchi H, Ito Y. A Reliable Seawater Desalination System Based on Membrane Technology and Biotechnology Considering Reduction of the Environmental Impact. Environments. 2018; 5(12):127. https://doi.org/10.3390/environments5120127

Chicago/Turabian StyleKurihara, Masaru, Hiromu Takeuchi, and Yohito Ito. 2018. "A Reliable Seawater Desalination System Based on Membrane Technology and Biotechnology Considering Reduction of the Environmental Impact" Environments 5, no. 12: 127. https://doi.org/10.3390/environments5120127

APA StyleKurihara, M., Takeuchi, H., & Ito, Y. (2018). A Reliable Seawater Desalination System Based on Membrane Technology and Biotechnology Considering Reduction of the Environmental Impact. Environments, 5(12), 127. https://doi.org/10.3390/environments5120127