Environmental Risks and Uncertainty with Respect to the Utilization of Recycled Rolling Stocks

Abstract

:1. Introduction

2. Methods and Materials

2.1. Rolling Stock Types

2.1.1. Freight Trains

Component Analysis of Freight Trains

2.1.2. Passenger Rail Cars

Component Analysis for Passenger Trains

2.1.3. High-Speed Rail

Component Analysis for High Speed Trains

3. Materials Deterioration Mechanisms and Analysis

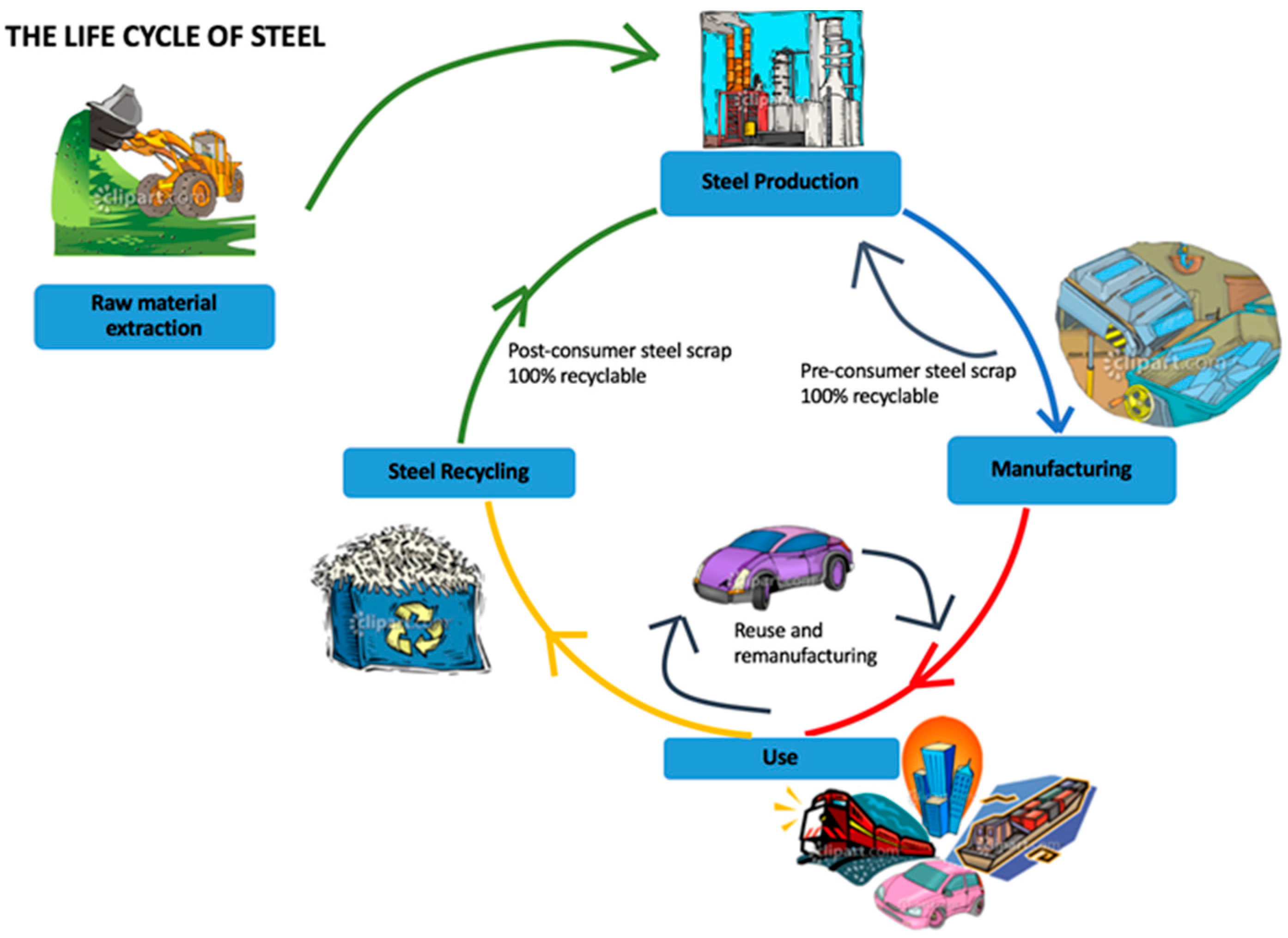

3.1. Steel

3.2. Aluminum

3.3. Copper

3.4. Polymer and Plastic

3.5. Glass

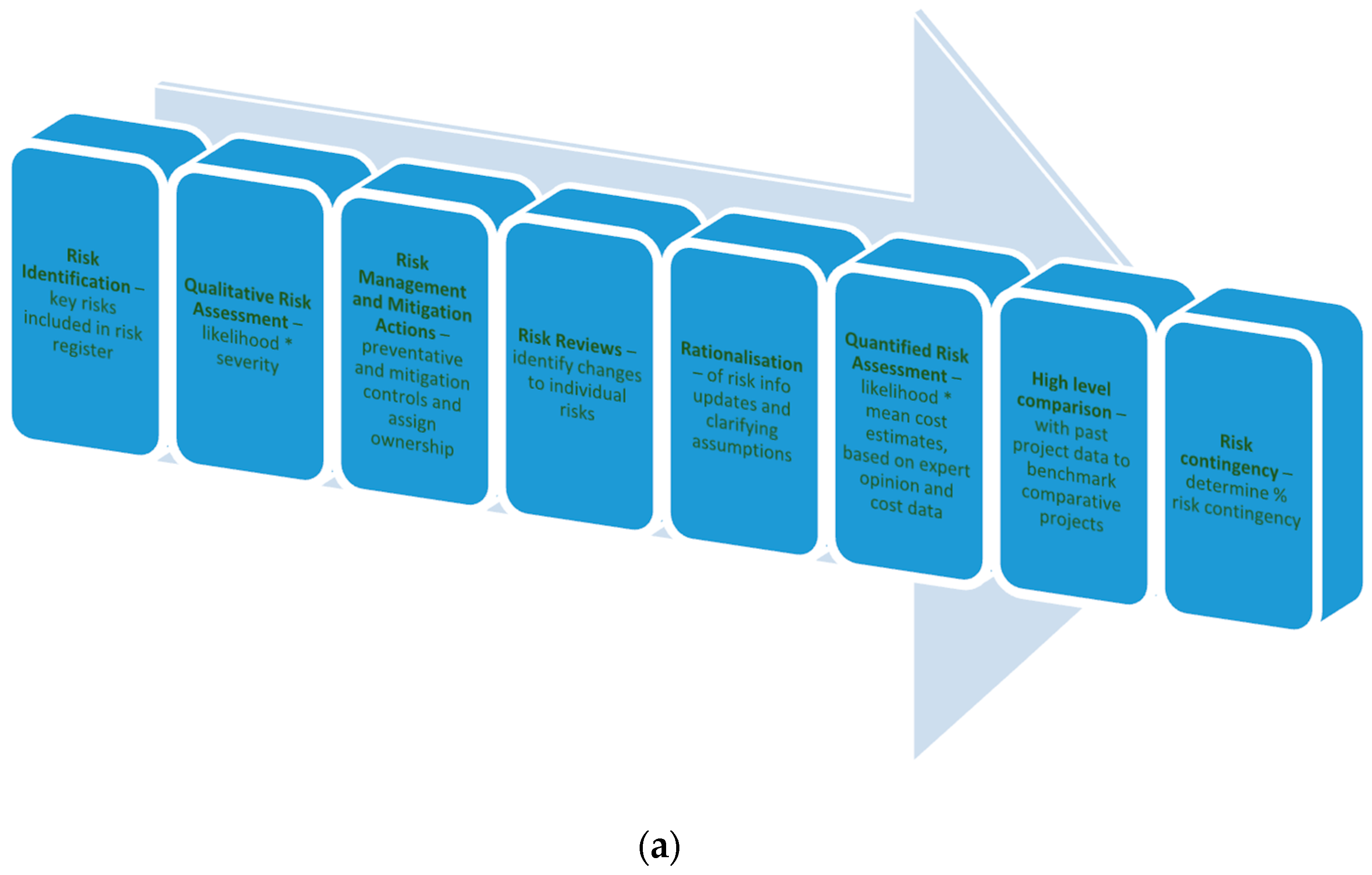

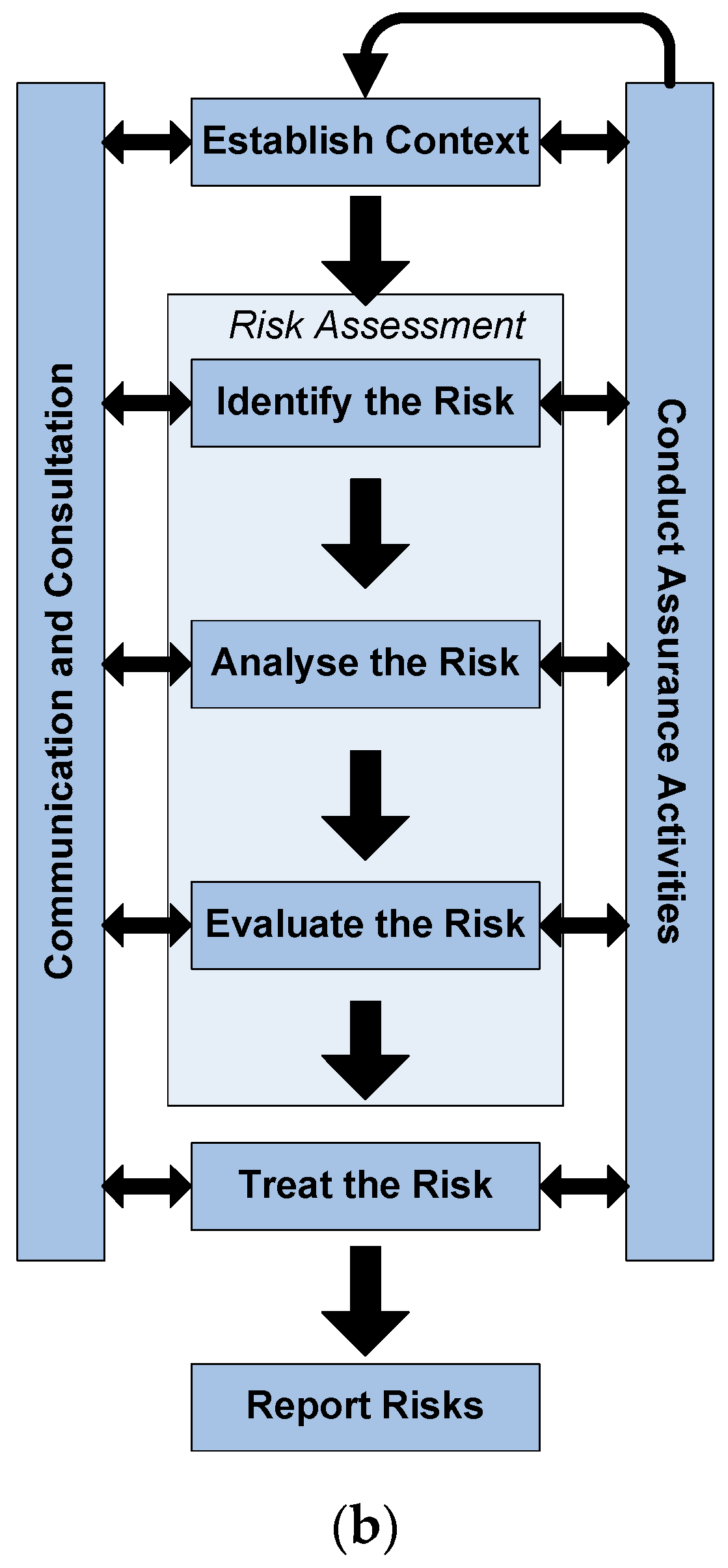

4. Risk Analysis Results

- electrical equipment;

- construction (such as roofing and plumbing), and;

- industrial machinery (such as heat exchangers).

5. Discussions

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Office of Energy Efficiency and Renewable Energy Energy-Consumption and Carbon-Emission Analysis of Vehicle and Component Manufacturing. Available online: https://www.osti.gov/scitech/biblio/993394 (accessed on 12 October 2010).

- International Union of Railways (UIC). The Worldwide Organisation of Cooperation for Railway Companies. Available online: http://www.uic.org (accessed on 29 June 2016).

- Bartl, A. Moving from recycling to waste prevention: A review of barriers and enables. Waste Manag. Res. 2014, 32, 3–18. [Google Scholar] [CrossRef] [PubMed]

- Brebbia, C.; Tomii, N.; Tzieropoulos, P.; Mera, J. Computers in Railways XIV; WIT Press: Southampton, UK, 2014. [Google Scholar]

- Castella, P.; Blanc, I.; Gomez Ferrer, M.; Ecabert, B.; Wakeman, M.; Manson, J.; Emery, D.; Han, S.; Hong, J.; Jolliet, O. Integrating life cycle costs and environmental impacts of composite rail car-bodies for a Korean train. Int. J. Life Cycle Assess. 2009, 14, 429–442. [Google Scholar] [CrossRef]

- Merkisz-Guranowska, A.; Merkisz, J.; Jacyna, M.; Pyza, D.; Stawecka, H. Rail Vehicles Recycling. Available online: http://www.witpress.com/Secure/elibrary/papers/CR14/CR14035FU1.pdf (accessed on 29 June 2016).

- International Standard Organisation (ISO). ISO TC269/WG4 Recyclability and Recoverability Calculation Method of Rolling Stock (Draft); ISO: Geneva, Switzerland, 2016. [Google Scholar]

- Berzi, L.; Delogu, M.; Giorgetti, A.; Pierini, M. On-field investigation and process modelling of end-of-Life Vehicles treatment in the context of Italian craft-type Authorized Treatment Facilities. Waste Manag. 2013, 33, 892–906. [Google Scholar] [CrossRef] [PubMed]

- Berzi, L.; Delogu, M.; Pierini, M.; Romoli, F. Evaluation of the end-of-life performance of a hybrid scooter with theapplication of recyclability and recoverability assessment methods. Resour. Conserv. Recycl. 2016, 108, 140–155. [Google Scholar] [CrossRef]

- Santini, A.; Morselli, L.; Passarini, F.; Vassura, I.; Di Carlo, S.; Bonino, F. End-of-life vehicles management: Italian material and energy recovery efficiency. Waste Manag. 2011, 31, 489–494. [Google Scholar] [CrossRef] [PubMed]

- Del Pero, F.; Delogu, M.; Pierini, M.; Bonaffini, D. Life cycle assessment of a heavy metro train. J. Clean. Prod. 2015, 87, 787–799. [Google Scholar] [CrossRef]

- Viachakis, C. Railway Transport. Available online: http://cargogroup.gr/services/forwarding/train-transport-4.html (accessed on 12 June 2016).

- Siemens Mobility. Available online: https://www.mobility.siemens.com/mobility/global/de/Seiten/siemens-mobility.aspx (accessed on 29 June 2016).

- Gubler, D. Railway Technical Web Pages. Available online: http://www.railway-technical.com (accessed on 29 June 2016).

- iTV. Virgin Passenger “Caught Short” in Train Loo Invited to Birmingham HQ after Tweets Go Viral. Available online: http://www.itv.com/news/central/2015-01-07/virgin-passenger-caught-short-in-train-loo-invited-to-birmingham-hq-after-tweets-go-viral/ (accessed on 13 June 2016).

- Jones, R.C. Railway Photographs 2014. Available online: http://www.robertcjones.co.uk/index.html (accessed on 13 June 2016).

- Silva, R.F.; Kaewunruen, S. Recycling of Rolling Stocks. Environments 2017, 4, 39. [Google Scholar] [CrossRef]

- Duley, R. The Pennsylvania Railroad GG1: The Pantograph. Available online: http://www.steamlocomotive.com/GG1/pantograph.php (accessed on 16 June 2016).

- Wang, Y. Taiwan High Speed Rail 700T. Available online: http://trainoftheweek.blogspot.co.uk/2010/10/taiwan-high-speed-rail-700t.html (accessed on 24 July 2016).

- Tiller, C.; Nottara, Y. Under the Hood of a TGV. Available online: http://www.railfaneurope.net/tgv/motrice.html (accessed on 29 June 2016).

- United Nation. UN Environment Metal Recycling. Opportunities, Limits, Infrastructure. Available online: http://wedocs.unep.org/handle/20.500.11822/8423 (accessed on 21 August 2016).

- Ohno, H.; Matsubae, K.; Nakajima, K.; Kondo, Y.; Nakamura, S.; Nagasaka, T. Toward the efficient recycling of alloying elements from end of life vehicle steel scrap. Resour. Conserv. Recycl. 2015, 100, 11–20. [Google Scholar] [CrossRef]

- Bijen, J. Durability Of Engineering Structures: Design, Repair And Maintenance; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- World Steel Association. Steel Statistical Year Book. Available online: https://www.worldsteel.org (accessed on 16 June 2016).

- Bull, J. The Increasing Cost of Bakerloo Trains. Available online: http://www.londonreconnections.com/2015/no-do-nothing-option-the-increasing-cost-of-the-bakerloos-trains/ (accessed on 20 June 2016).

- Ciacii, L.; Chen, W.; Passarini, F.; Eckelman, M.; Vassura, I.; Morselli, L. Historical evolution of anthropogenic aluminum stocks and flows in Italy. Resour. Conserv. Recycl. 2013, 72, 1–8. [Google Scholar] [CrossRef]

- Müller, U. Introduction to Structural Aluminium Design; Whittles Publishing: Dunbeath, UK, 2011. [Google Scholar]

- Bastidas, D. Copper deterioration: Causes, diagnosis and risk minimisation. Int. Mater. Rev. 2010, 55, 99–127. [Google Scholar] [CrossRef]

- Matsuoka, S. Recyclability of stainless steel railway vehicles. Proc. Inst. Mech. Eng. F 2003, 217, 279–284. [Google Scholar] [CrossRef]

- American Galvanizers Association. Corrosion Protection. Available online: http://www.galvanizeit.org/hot-dip-galvanizing/why-specify-galvanizing/corrosion-protection (accessed on 25 June 2016).

- Sydney Trains. System Requirement ST ERM-SR-01: Enterprise Risk Management; Sydney Trains: Sydney, Australia, 2013. [Google Scholar]

- Sydney Trains. Risk Management Policy; Sydney Trains: Sydney, Australia, 2013. [Google Scholar]

- Sydney Trains. System Guide ST ERM-GD-03: ERM Risk Identification and Assessment; Sydney Trains: Sydney, Australia, 2013. [Google Scholar]

- Network Rail. Annual Report 2013—Principal Risks and Uncertainties. Available online: http://www.glencore.com/assets/who-we-are/doc/GLEN-2013-Annual-Report-Principal-risks-and-uncertainties.pdf (accessed on 14 August 2017).

- Kaewunruen, S. Risks in NSW Rail Business; MBA Risk Management Report: Sydney, Australia, 2014. [Google Scholar]

- AS/NZ ISO 31000:2009 Risk Management—Principles and Guidelines. Available online: https://www.finance.gov.au/sites/default/files/COV_216905_Risk_Management_Fact_Sheet_FA3_23082010_0.pdf (accessed on 14 August 2017).

- Alamy Ltd. Old Wenford Railway Rolling Stock Being Renovated at the Former British Railways Bodmin Motor Power Depot, Bodmin, Cornwall, UK. Available online: http://www.alamy.com/stock-photo-old-wenford-railway-rolling-stock-being-renovated-at-the-former-british-2625112.html (accessed on 25 June 2016).

- Grupta, D.; Saladino, L. Metal Toxicity in Plants; Springer: Berlin, Germany, 2012. [Google Scholar]

- Jula, T.F. Environmental Aspects of Heavy Metal Toxicity. Boston College Environmental Affairs Law Review. Available online: http://lawdigitalcommons.bc.edu/cgi/viewcontent.cgi?article=2026&context=ealr (accessed on 14 August 2017).

- Buekens, A.; Zhou, X. Recycling plastics from automotive shredder residues: A review. J. Mater. Cycles Waste Manag. 2014, 16, 398–414. [Google Scholar] [CrossRef]

- Miller, L.; Soulliere, K.; Sawyer-Beaulieu, S.; Tseng, S.; Tam, E. Challenges and Alternatives to Plastics Recycling in the Automotive Sector. Materials 2014, 7, 5883–5902. [Google Scholar] [CrossRef] [PubMed]

- Ito, M.; Nagai, K. Degradation behavior and application of recycled PVC sheet made of floor sheet for railway vehicle. Polym. Degrad. Stab. 2007, 92, 1692–1699. [Google Scholar] [CrossRef]

- US Environmental Protection Agency. Health Effects Notebook for Hazardous Air Pollutants. Available online: https://www.epa.gov/haps/health-effects-notebook-hazardous-air-pollutants (accessed on 21 August 2016).

- Lee, C. Assessing environmentally friendly recycling methods for composite bodies of railway rolling stock using life-cycle analysis. Transp. Res. D Transp. Environ. 2010, 15, 197–203. [Google Scholar] [CrossRef]

- Veolia Ltd. More than 80% of WEEE Recycled in Angers. Available online: http://www.veolia.in/more-80-weee-recycled-angers (accessed on 16 August 2016).

- Vermeuulen, I.; Block, C.; Van Caneghem, J.; Sikdar, S.; Vandecasteele, C. Sustainability assessment of industrial waste treatment processes: The case of automotive shredder residue. Resour. Conserv. Recycl. 2012, 69, 17–28. [Google Scholar] [CrossRef]

- Chester, M.V.; Horvath, A. Environmental assessment of passenger transportation should include infrastructure and supply chains. Environ. Res. Lett. 2009, 4, 237–266. [Google Scholar] [CrossRef]

- Chester, M.V.; Horvath, A. Life-cycle assessment of high-speed rail: The case of California. Environ. Res. Lett. 2010, 5, 123–129. [Google Scholar] [CrossRef]

- Boughton, B.; Horvath, A. Environmental assessment of shredder residue management. Res. Conserv. Recycl. 2006, 47, 1–25. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Lee, C.K. Sustainability Challenges in Managing End-of-Life Rolling Stocks. Front. Built Environ. 2017, 3. [Google Scholar] [CrossRef]

- Setsobhonkul, S.; Kaewunruen, S.; Sussman, J.M. Lifecycle assessments of railway bridge transitions exposed to extreme climate events. Front. Built Environ. 2017. [Google Scholar] [CrossRef]

- European Commission, 2000, Directive 2000/53/EC on End-of-Life Vehicles. Brussels, Belgium. Available online: http://ec.europa.eu/environment/waste/pdf/guidance_doc.pdf (accessed on 14 August 2017).

- Kaewunruen, S.; Sussman, J.M.; Matsumoto, A. Grand Challenges in Transportation and Transit Systems. Front. Built Environ. 2016, 2. [Google Scholar] [CrossRef]

| Freight Train Components | |||

|---|---|---|---|

| Components of Train [12,13,14,15,16,17] | Type of Material | Recovery Rate (%) | Percentage (% by Mass) |

| Diesel Engine (large cylinder block) | Cast iron/aluminum alloys | 80–90/80–95 | 4.22 |

| Main Alternator | Steel | 90–98 | 0.21 |

| Auxiliary Alternator | Steel | 90–98 | 0.14 |

| Motor Blower | Cast iron/aluminum alloys/steel | 80–90/80–95/90–98 | 0.18 |

| Air Intakes | steel/aluminum | 90–98/80–95 | 0.11 |

| Rectifiers/Inverters | Heavy-gauge aluminum sheet metals with powder-coated or anodized and stainless fittings | 80–95 | 0.49 |

| Battery | Polypropylene, polyethylene or plastic-coated steel | 50–70 | 0.09 |

| Traction Motor | Steel | 90–98 | 0.70 |

| Pinion/Gear | Steel | 90–98 | 0.56 |

| Fuel Tank | Steel/aluminum | 90–98/80–95 | 0.35 |

| Air Reservoirs | Steel/aluminum | 90–98/80–95 | 0.09 |

| Air Compressor | Aluminum | 80–95 | 0.98 |

| Drive Shaft | Aluminum alloys | 80–95 | 0.60 |

| Gearbox | Steel | 90–98 | 2.32 |

| Radiator and Radiator Fan | Aluminum, brass or copper cores | Aluminum (80–95), brass or copper cores (60–80) | 0.02 |

| Turbo Charging | Cast aluminum | 80–95 | 0.11 |

| Truck Frame or Bogie Frame | Steel plate/cast steel | 90–98 | 18.98 |

| Wheels | Steel R7 (carbon content % <0.52) | 90–98 | 20.02 |

| Roof | Steel | 90–98 | 2.11 |

| Door | Aluminum/Steel | 80–95/90–98 | 0.53 |

| Car body/tumblehome | Steel | 90–98 | 45.67 |

| Sand Box | Cast iron | 80–90 | 0.53 |

| Battery Box | CRCA (cold rolled close annealed) sheet and rolled sections of carbon steel | CRCA sheet and rolled sections of carbon steel (90–98) | 0.18 |

| Brake Control Unit | Aluminum/cast iron/reinforced carbon-carbon | 80–95/80–90 | 0.08 |

| Brake Cylinder | Aluminum | 80–95 | 0.34 |

| Condenser | Copper, brass, aluminum, or stainless steel | Copper (60–80), brass, aluminum (80–95), or stainless steel (80–90) | 0.42 |

| Passenger Train Components | |||

|---|---|---|---|

| Components of Train [17,18,19] | Type of Material | Recovery Rate (%) | Percentage (% by mass) |

| Wheels | Steel R7 (carbon content % <0.52) | 90–98 | 13.48 |

| Window | Glass | 50–100 | 0.37 |

| Roof | Aluminum/steel | 80–95/90–98 | 4.30 |

| Table | Polypropylene, polyethylene | 50–70 | 0.22 |

| Seat | Polypropylene, polyethylene | 50–70 | 1.87 |

| Door | Aluminum/steel | 80–95/90–98 | 1.80 |

| Battery Box | CRCA sheet and rolled sections of carbon steel | CRCA sheet and rolled sections of carbon steel (90–98) | 0.09 |

| Pantograph | High-strength tubular steel or alloy frame; alloy of carbon, copper | High-strength tubular steel or alloy frame (90–98); alloy of carbon, copper (60–80) | 0.04 |

| Car body/frame/tumblehome | Aluminum/steel | 80–95/90–98 | 54.42 |

| Brake Control Unit | Aluminum/cast iron/reinforced carbon-carbon | 80–95/80–90 | 0.39 |

| Condenser | Copper, brass, aluminum, or stainless steel | Copper (60–80), brass, aluminum (80–95), or stainless steel (80–90) | 0.11 |

| Compressor | Aluminum | 80–95 | 0.22 |

| Coupler | Steel or composites | 90–98 | 0.45 |

| Gangway Bellows | Silicone-coated fabric | 50–70 | 5.24 |

| Electrical Auxiliary Equipment | |||

| Battery | Polypropylene, polyethylene or plastic-coated steel | 50–70 | 0.15 |

| Generator | Magnetic steel and copper | Magnetic steel (90–98) and copper (60–80) | 0.13 |

| Alternator | Steel | 90–98 | 0.03 |

| Converter | Silicon carbide | 50–70 | 0.08 |

| Bogie Components | |||

| Bogie Frame | Steel plate/cast steel | 90–98 | 7.49 |

| Bogie Transom | Steel plate/cast steel | 90–98 | 3.37 |

| Brake Cylinder | Aluminum | 80–95 | 0.75 |

| Primary Suspension Coil | Steel | 90–98 | 0.30 |

| Motor Suspension Tube | Steel | 90–98 | 0.28 |

| Gearbox | Steel | 90–98 | 1.68 |

| Motor | Steel | 90–98 | 2.62 |

| Secondary Suspension Air Bag | Textile-reinforced rubber | 50–70 | 0.09 |

| High Speed Train Components | |||

|---|---|---|---|

| Components of Train [17,18,19,20,21] | Type of Material | Recovery Rate (%) | Percentage (% by mass) |

| Wheels | Steel R7 (carbon content % <0.52) | 90–98 | 16.63 |

| Window | Glass | 50–100 | 1.85 |

| Roof | Aluminum/steel | 80–95/90–98 | 5.31 |

| Seat | Polypropylene, polyethylene | 50–70 | 3.00 |

| Table | Polypropylene, polyethylene | 50–70 | 0.28 |

| Door | Aluminum/steel | 80–95/90–98 | 2.77 |

| Battery Box | CRCA sheet and rolled sections of carbon steel | CRCA sheet and rolled sections of carbon steel (90–98) | 0.12 |

| “Grand Plongeur Unique” Pantograph | High-strength tubular steel or alloy frame; alloy of carbon, copper | High-strength tubular steel or alloy frame (90–98); alloy of carbon, copper (60–80) | 0.92 |

| Main Transformer | Steel/aluminum | 90–98/80–95 | 0.74 |

| Thyristor controlled-rectifier bridge | Silicon steel | 90–98 | 0.09 |

| Traction Inverters | Aluminum | 80–95 | 0.60 |

| Synchronous AC traction motor | Steel | 90–98 | 1.85 |

| Mechanical Transmission | Aluminum alloys/steel | 80–95/90–98 | 0.92 |

| Impact absorption block | Aluminum | 80–95 | 2.13 |

| Car body/tumblehome | Aluminum/steel | 80–95/90–98 | 7.83 |

| Brake Control Unit | Aluminum/cast iron/reinforced carbon–carbon | 80–95/80–90 | 36.96 |

| Condenser | Copper, brass, aluminum, or stainless steel | Copper (60–80), brass, aluminum (80–95), or stainless steel (80–90) | 0.33 |

| Compressor | Aluminum | 80–95 | 0.08 |

| Signaling Antennas | Aluminum | 80–95 | 0.01 |

| Coupler | Steel | 90–98 | 0.81 |

| Gangway Bellows | Silicone-coated fabric | 50–70 | 3.23 |

| Electrical Auxiliary Equipment | |||

| Battery | Polypropylene, polyethylene or plastic-coated steel | 50–70 | 0.23 |

| Braking Rheostat/Dynamic Brake | Aluminum/steel | 80–95/90–98 | 0.43 |

| Common Block/DC circuit breaker and the main filter capacitor | Insulation sheet, bimetallic strip, silver point, ceramic RFI/EMI suppression capacitors [Note: EMI is Electromagnetic Interference), which is also called RFI (Radio Frequency Interference)] | 60–85 | 0.09 |

| Generator | Magnetic steel and copper | Magnetic steel (90–98) and copper (60–80) | 0.55 |

| Alternator | Steel | 90–98 | 0.15 |

| Converter | Silicon carbide | 50–70 | 0.25 |

| Bogie Components | |||

| Bogie Frame | Steel plate/cast steel | 90–98 | 8.32 |

| Bogie Transom | Steel plate/cast steel | 90–98 | 3.70 |

| Brake Cylinder | Aluminum | 80–95 | 0.92 |

| Primary Suspension Coil | Steel | 90–98 | 0.37 |

| Motor Suspension Tube | Steel | 90–98 | 0.35 |

| Gearbox | Steel | 90–98 | 2.08 |

| Motor | Steel | 90–98 | 3.23 |

| Secondary Suspension Air Bag | Textile-reinforced rubber | 50–70 | 0.12 |

| Key Stakeholders | Scale | Impact |

|---|---|---|

| Train manufacturers, Train repair/refurbish, modification | Medium | The method does not impose penalty to manufacturers. It encourages the uses of recyclable materials and more accurate data records. |

| Train designers, Rolling Stock designers, Procurement officers, Train Operators, Asset Owners | High | The public awareness of rolling stock recycling encourages them to use more recyclable materials. However, there is no environmental legislation to impose any limit or minimal level to railway sector at this stage. It is noted that European Directive (2005) currently imposes in Article 7(3) [52] for automobile recycling targets: min. 95% reuse and recovery and min. 85% reuse and recycling by 2015. This directive could apply to rail sector later in the future. |

| Infrastructure Managers | High | Infrastructure managers need to provide some effort to help increase recycling potentials. They need to identify risks of the utilization and manage them to assure that there is no harm to staff, neighborhoods in rail corridor and the environment. |

| Rail regulators, Governments | Medium | New contracts, incentives and assurance process for rolling stock recycling should be developed. At the same time, environmental risk assurance must be included in the sustainability-based contractual process. |

| Rail passengers | Low | New trains and infrastructure will be more environmental friendly. They will be more motivated to use public transports and play a key role in the contribution towards the reduction of carbon emission. |

| Material | Risk | Description |

|---|---|---|

| Steel | Corrosion | If corroded steel is used as a sub-product such as in a pipe networks or in bridges, it can contaminate the water it contacts. |

| Re-melting process | Many pollutions can be released from coke ovens such as coke oven gas, naphthalene, ammonium compounds, crude light oil and sulfur. | |

| Water, which is used to cool the coke at the end of the re-melting process can be contaminated. | ||

| Copper | Toxicity | Worn material can contaminate water that passes through the pipes and flows into rivers. |

| Acid rain | The copper enters the air, through any process that can release it, remaining in the air until it starts to rain and, then, will penetrate the soil and ground water. | |

| Aggregates | - | It can be comparatively safely reused with low risk to the environment. |

| Aluminum | Acidic precipitation | Aquatic and terrestrial ecosystems are affected, taking into consideration acidic precipitation and contamination of the soil and freshwater. |

| Toxicity | In addition, if used as kitchen utensils, there are also some risks to human health. Aluminum is known as a complex compound and can release significant amounts of toxicity directly into the food and the drinkable or running water. | |

| Glass | - | - |

| Plastics | Toxicity | About 60% of polychlorinated biphenyls (PCB) sources are related to closed fluids and heat transfer fluids [26]. PCBs have been indicated to bring about cancer and non-cancer health effects. |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serrano, L.P.d.S.; Lewandrowski, T.; Liu, P.; Kaewunruen, S. Environmental Risks and Uncertainty with Respect to the Utilization of Recycled Rolling Stocks. Environments 2017, 4, 62. https://doi.org/10.3390/environments4030062

Serrano LPdS, Lewandrowski T, Liu P, Kaewunruen S. Environmental Risks and Uncertainty with Respect to the Utilization of Recycled Rolling Stocks. Environments. 2017; 4(3):62. https://doi.org/10.3390/environments4030062

Chicago/Turabian StyleSerrano, Luca Póvoas de Souza, Tomasz Lewandrowski, Ping Liu, and Sakdirat Kaewunruen. 2017. "Environmental Risks and Uncertainty with Respect to the Utilization of Recycled Rolling Stocks" Environments 4, no. 3: 62. https://doi.org/10.3390/environments4030062

APA StyleSerrano, L. P. d. S., Lewandrowski, T., Liu, P., & Kaewunruen, S. (2017). Environmental Risks and Uncertainty with Respect to the Utilization of Recycled Rolling Stocks. Environments, 4(3), 62. https://doi.org/10.3390/environments4030062