Decarbonization Potential of Alternative Fuels in Container Shipping: A Case Study of the EVER ALOT Vessel

Abstract

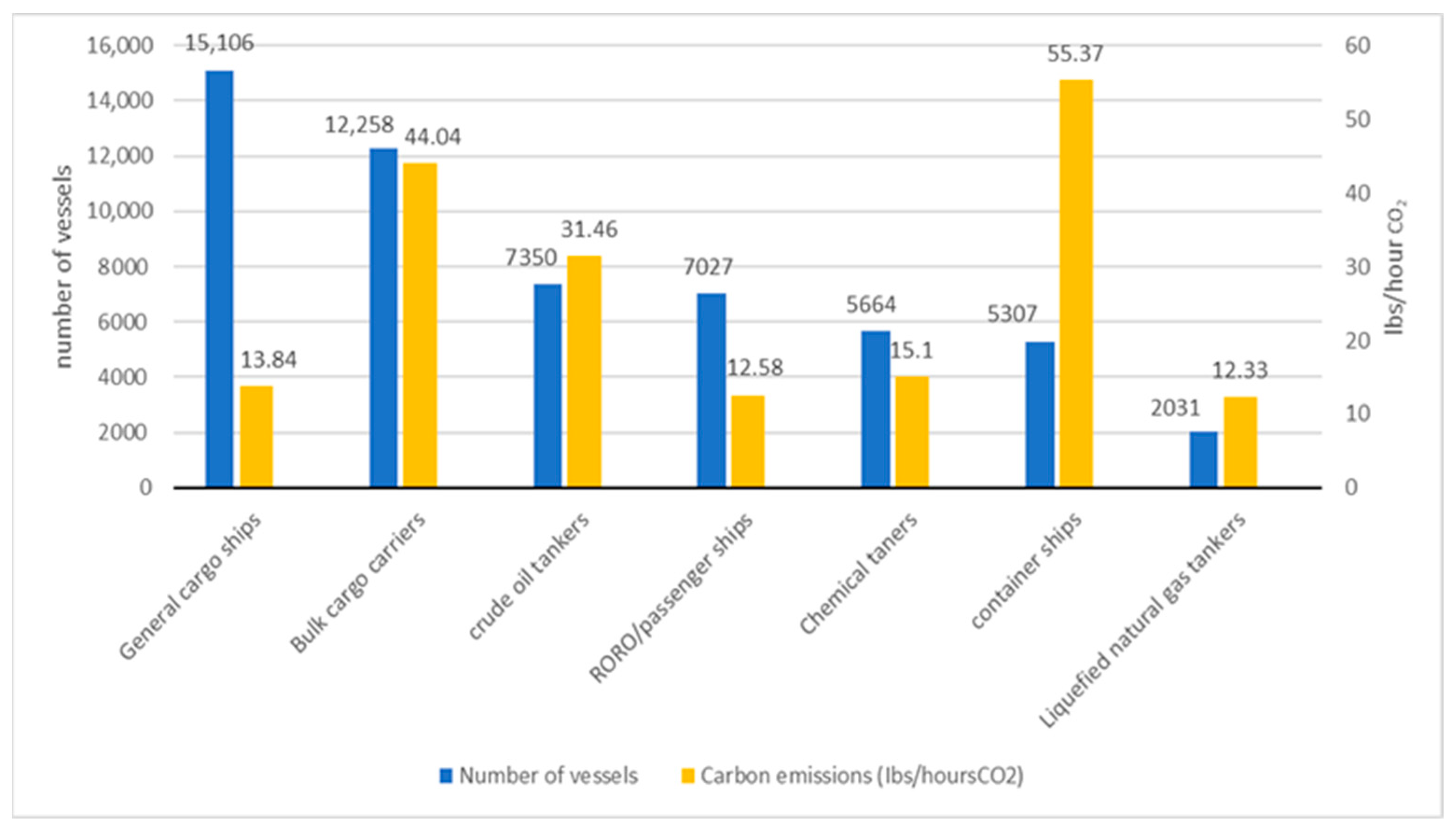

1. Introduction

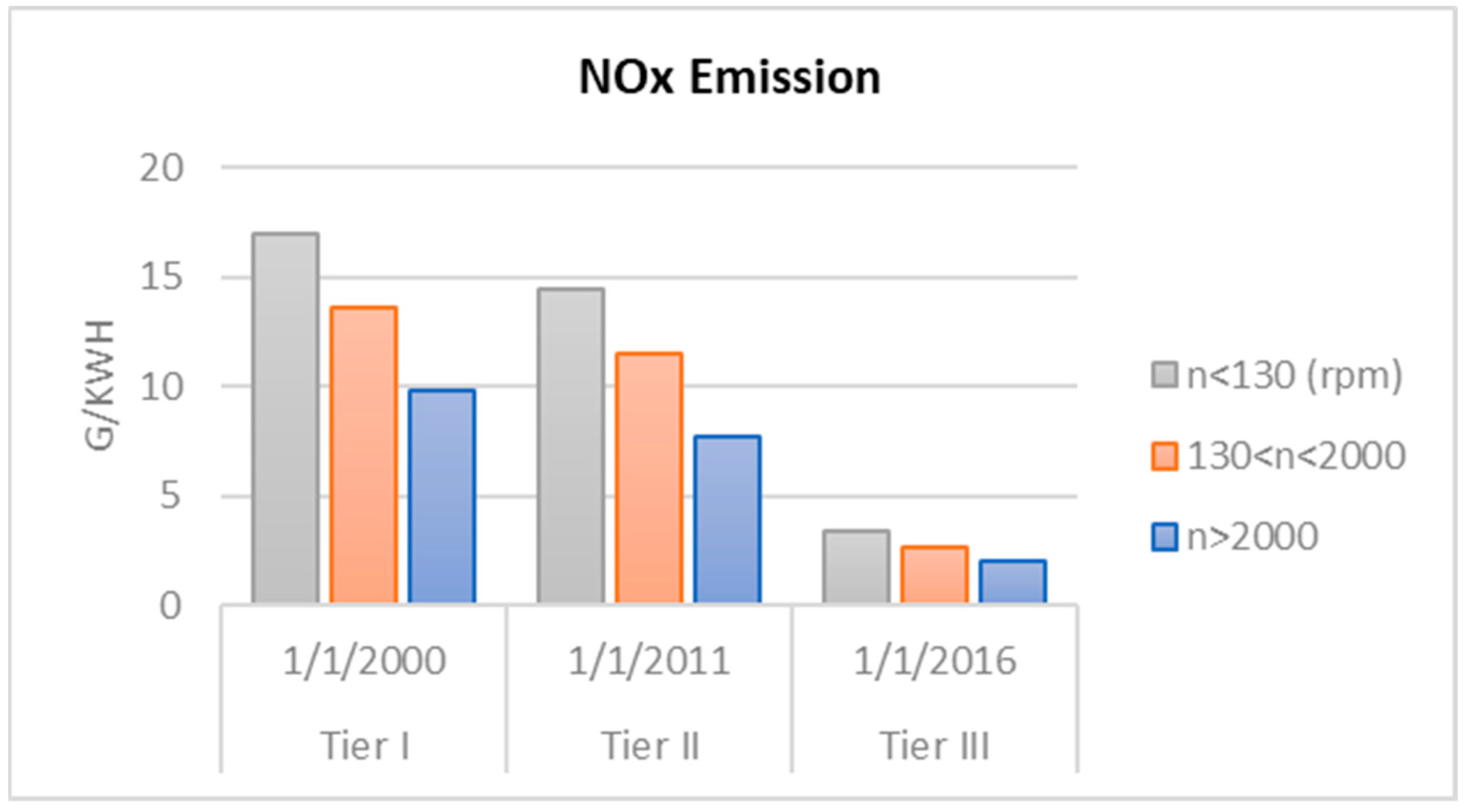

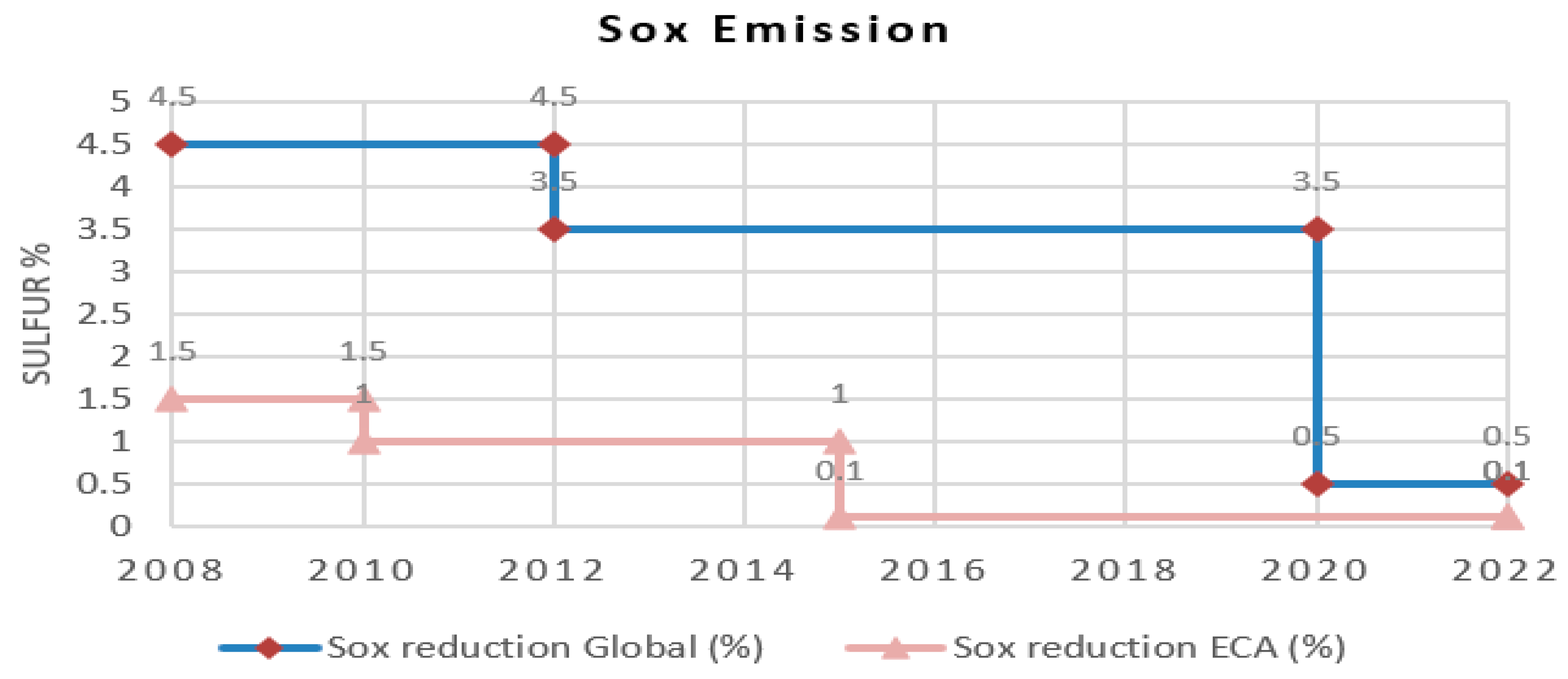

2. IMO Regulations

3. Methodology

3.1. Alternative Fuel Storage on Board Ship

3.2. Environmental Analysis Methodology

3.3. Energy Efficiency Design Index Estimation

3.4. Energy Efficiency Operational Indicator (EEOI) Assessment

4. Case Study

5. Results and Discussion

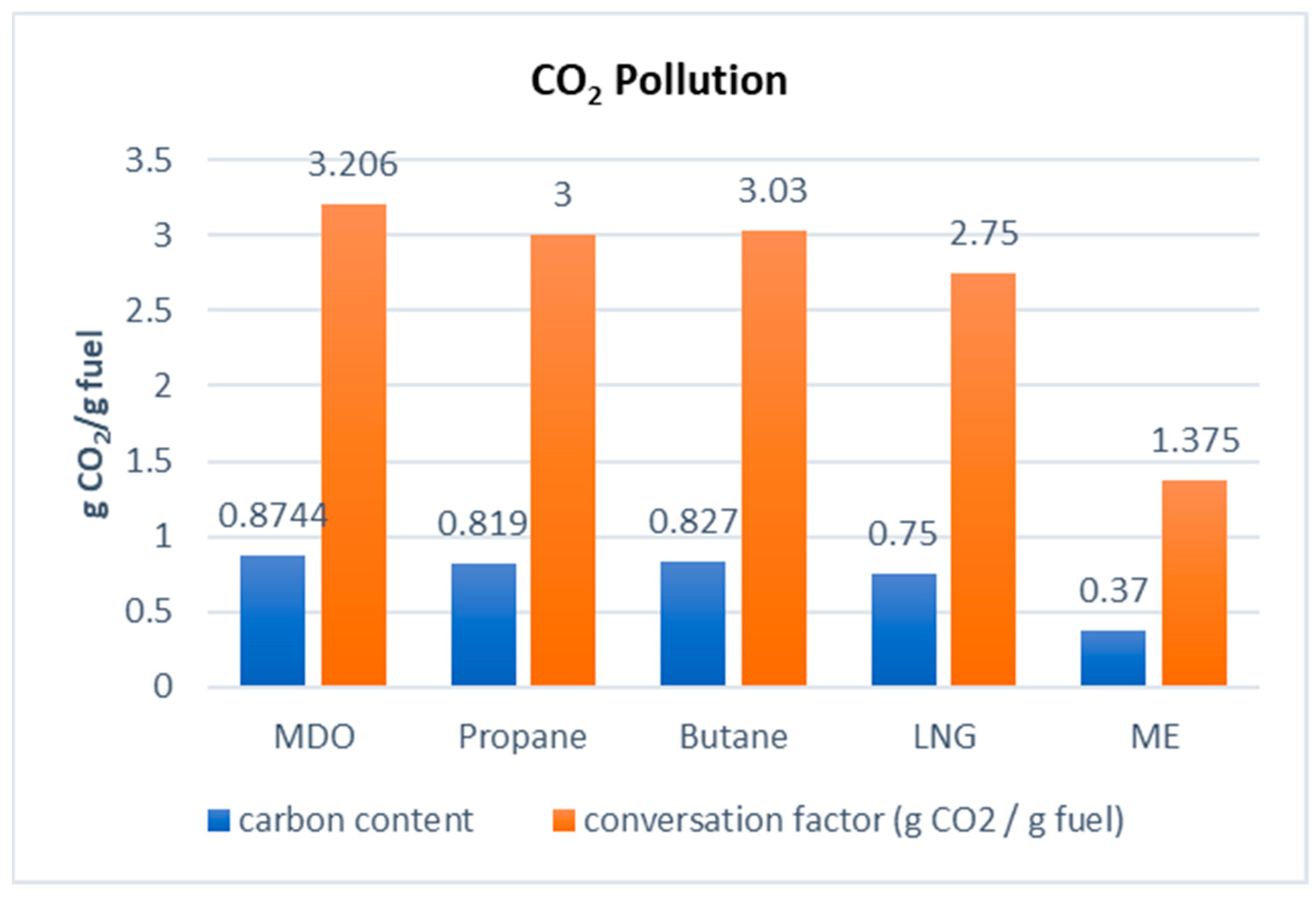

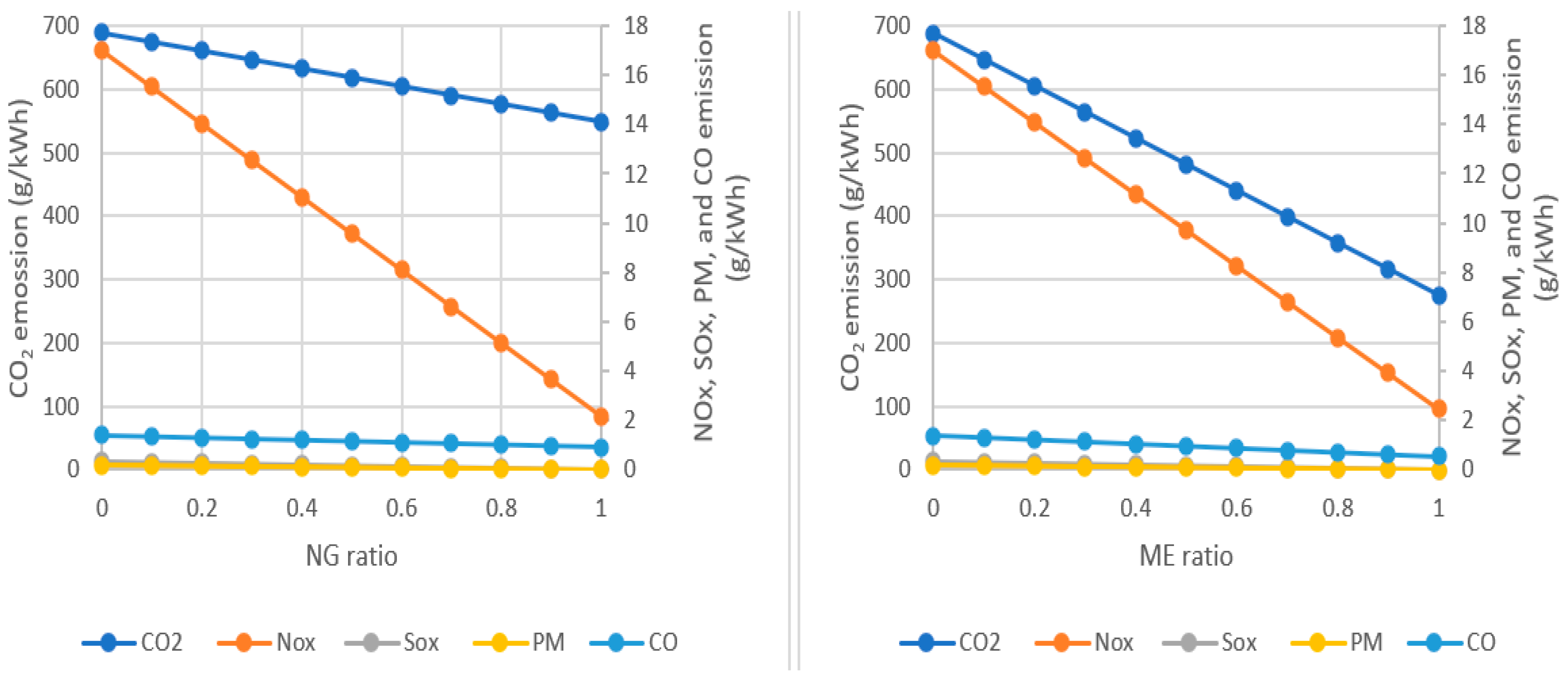

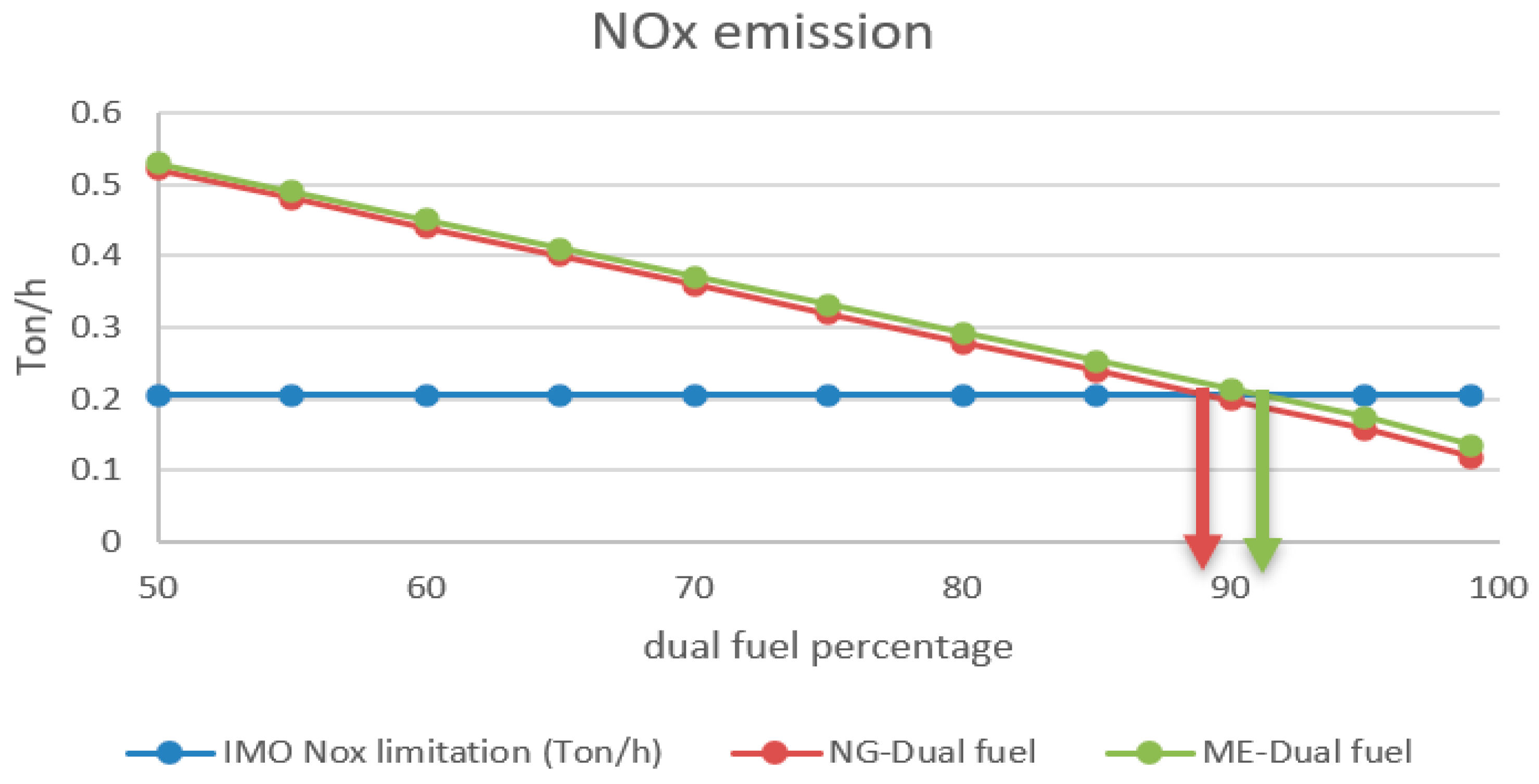

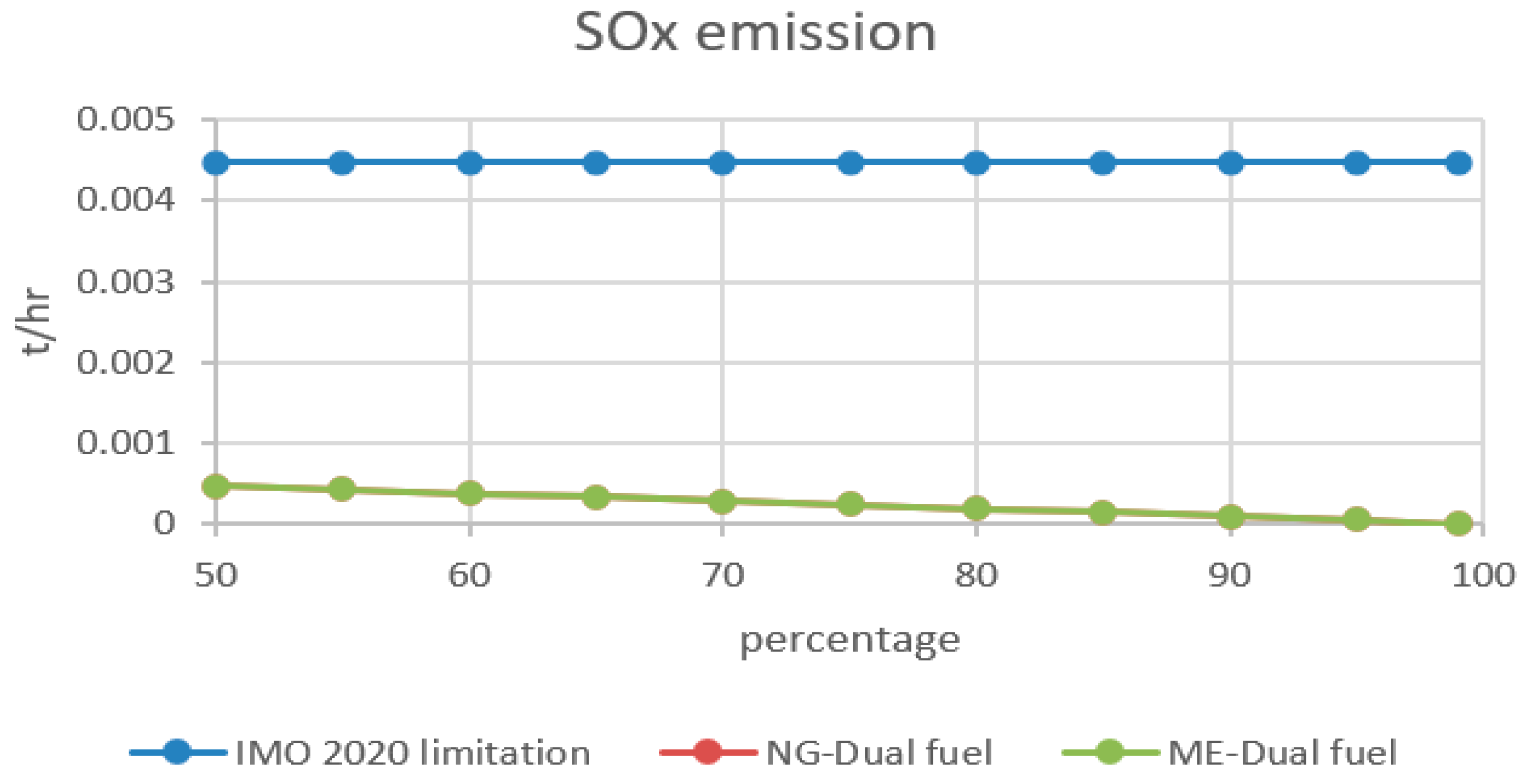

5.1. Environmental Assessment of Alternative Fuels

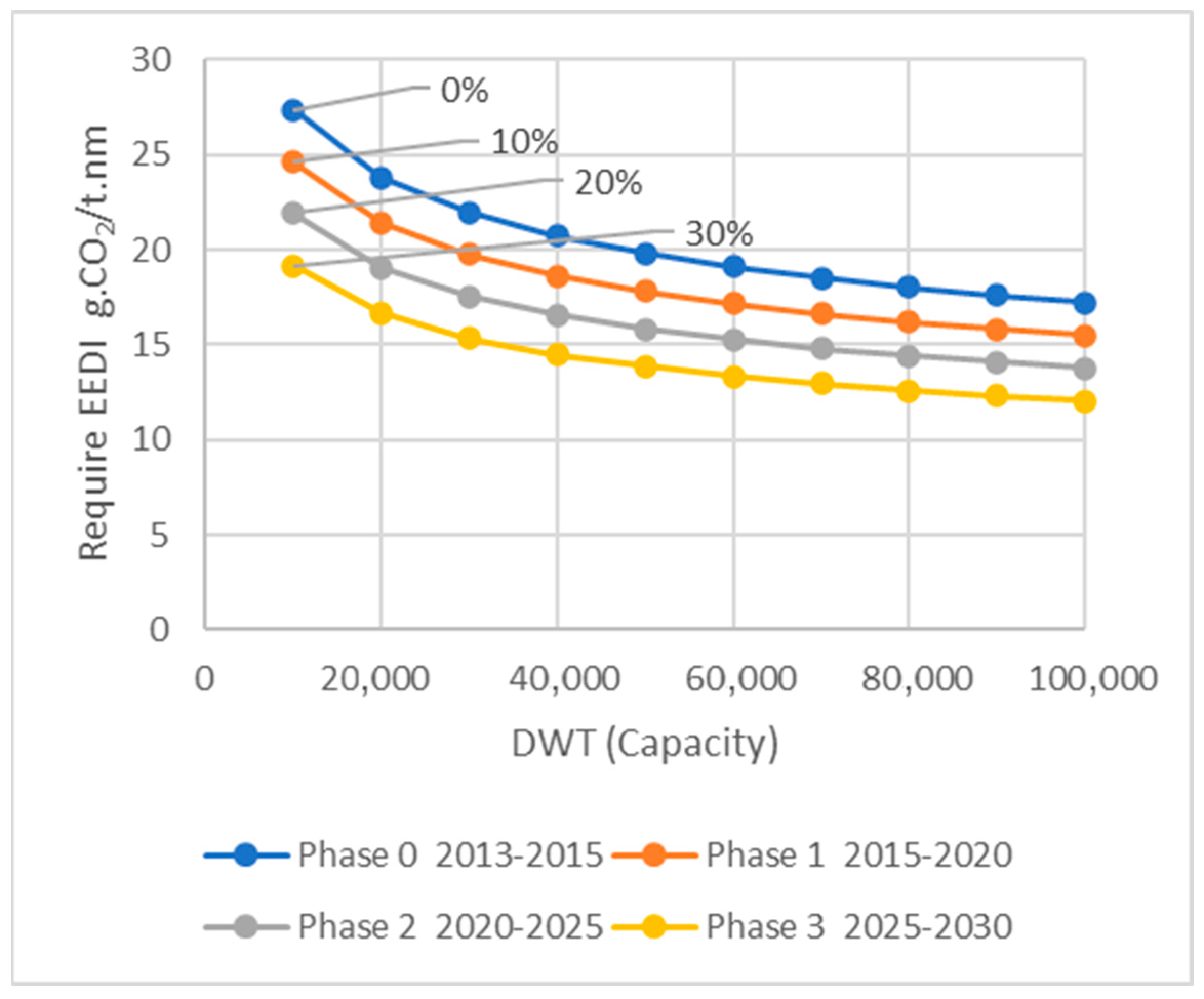

5.2. Energy Efficiency Assessment

6. Conclusions

- From an environmental perspective, the findings indicate that utilizing dual-fuel engines with a mix of 89% natural gas and 11% MDO results in reductions of NOx, SOx, CO2, PM, and CO emissions by 77.69%, 89%, 18.17%, 89%, and 30.51%, respectively. In contrast, using 91% methanol as a dual fuel achieves emission reductions of 77.78%, 91%, 54.67%, 91%, and 55.9%, respectively. Furthermore, replacing conventional diesel engines with dual-fuel systems operating on natural gas or methanol will meet IMO 2016 and 2020 emission standards for NOx and SOx, assuming marine diesel oil content remains below 10%.

- From an energy efficiency perspective, based on the Energy Efficiency Design Index (EEDI) criteria, dual-fuel engines operating on either (89% NG and 11% MDO) or (91% ME and 9% MDO) are expected to comply with IMO targets. The EEDI reference value for the third phase was 10.1021 gCO2/ton-nm, while the calculated EEDI for dual-fuel systems using natural gas and methanol was 11.388 gCO2/ton-nm and 6.263 gCO2/ton-nm, respectively. Moreover, both 89% natural gas and 91% methanol configurations fulfill current IMO EEDI limits and show potential to satisfy future standards, especially with ongoing progress in fuel efficiency and technology.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Elmallah, M.; Elgohary, M.M.; Shouman, M.R. The effect of air chamber geometrical design for enhancing the output power of oscillating water column wave energy converter. Mar. Technol. Soc. J. 2023, 57, 122–129. [Google Scholar] [CrossRef]

- Elmallah, M. The Impact of Livestock Emissions on the Maritime Sector. 30 December 2024. Available online: https://www.jmr.unican.es/index.php/jmr/article/view/610 (accessed on 1 April 2025).

- Elmallah, M.; Shouman, M.; Elgohary, M. Numerical Study on Enhancing the Performance of Air Turbines in Oscillating Water Column Wave Energy Converters. 30 August 2024. Available online: https://www.jmr.unican.es/index.php/jmr/article/view/1026 (accessed on 1 April 2025).

- Elmallah, M.; Shouman, M.; Elgohary, M. Reduction of the Methane Emissions on Livestock Ships to Mitigate Greenhouse Gas Emissions and Promote Future Maritime Transport Sustainability. Nativa 2024, 12, 551–558. [Google Scholar] [CrossRef]

- Elmallah, M.; Shouman, M.; Elgohary, M.M. Reducing methane emissions on livestock ships in order to mitigate greenhouse gas emissions and promote future maritime sustainability. TransNav Int. J. Mar. Navig. Saf. Sea Transp. 2024, 18, 797–804. [Google Scholar] [CrossRef]

- Shouman, M.; Elmallah, M.; Madariaga-Domíngues, E.; González-Almeida, J.A. The Feasibility of Utilizing Hydrogen Fuel Cells in Livestock Ships to Mitigate Greenhouse Gas Emissions. Nativa 2025, 13, 138–143. [Google Scholar] [CrossRef]

- Yoo, S.H.; Lee, K.; Park, H. Greenhouse gas reduction potential of low-carbon alternative marine fuels. Environ. Sci. Pollut. Res. 2023, 30, 21395–21408. [Google Scholar]

- Bouman, E.A.; Lindstad, E.; Rialland, A.I.; Strømman, A.H. State-of-the-art technologies, measures, and potential for reducing GHG emissions from shipping—A review. Transport. Resear. Part D Transport. Environ. 2017, 52, 408–421. [Google Scholar] [CrossRef]

- Saadeldin, M.A.; Elgohary, M.M.; Abdelnaby, M.M.; Shouman, M.R. Advanced simulation and environmental impact assessment of combustion in maritime energy systems. Mar. Technol. Soc. J. 2024, 58, 36–55. [Google Scholar] [CrossRef]

- Saadeldin, M.A.; Elgohary, M.M.; Abdelnaby, M.; Shouman, M.R. Effects of Direct Water Injection on the Nitrogen Oxide Emission Characteristics of Marine Diesel Engines. J. Mar. Sci. Technol. 2023, 31, 6. [Google Scholar] [CrossRef]

- Psaraftis, H.N. On shipping decarbonization [Conference presentation]. HIAS 2023 Symposium: Interdisciplinary Approaches to Sustainability and Climate Change, Hiroshima, Japan. Available online: https://orbit.dtu.dk/files/328694064/Psaraftis_HIAS_keynote_07_07_2023.pdf (accessed on 1 April 2025).

- Olmer, N.; Comer, B.; Roy, B.; Mao, X.; Rutherford, D. Greenhouse Gas Emissions from Global Shipping, 2013–2015 (Report); International Council on Clean Transportation: Washington, DC, USA, 2017. [Google Scholar]

- Bilgili, L. Comparative assessment of alternative marine fuels in life cycle perspective. Renew. Sustain. Energy Rev. 2020, 144, 110985. [Google Scholar] [CrossRef]

- Perčić, M.; Vladimir, N.; Fan, A. Life-cycle cost assessment of alternative marine fuels to reduce the carbon footprint in short-sea shipping: A case study of Croatia. Appl. Energy 2020, 279, 115848. [Google Scholar] [CrossRef]

- Čampara, L.; Hasanspahić, N.; Vujičić, S. Overview of MARPOL ANNEX VI regulations for prevention of air pollution from marine diesel engines. SHS Web Conf. 2018, 58, 1004. [Google Scholar] [CrossRef]

- Herdzik, J. Emissions from marine engines versus IMO certification and requirements of tier 3. J. KONES 2011, 18, 161–167. [Google Scholar]

- Zannis, T.C.; Katsanis, J.S.; Christopoulos, G.P.; Yfantis, E.A.; Papagiannakis, R.G.; Pariotis, E.G.; Rakopoulos, D.C.; Rakopoulos, C.D.; Vallis, A.G. Marine Exhaust Gas Treatment Systems for Compliance with the IMO 2020 Global Sulfur Cap and Tier III NOx Limits: A Review. Energies 2022, 15, 3638. [Google Scholar] [CrossRef]

- Rehmatulla, N.; Calleya, J.; Smith, T. The implementation of technical energy efficiency and CO2 emission reduction measures in shipping. Ocean Eng. 2017, 139, 184–197. [Google Scholar] [CrossRef]

- Sadek, I.; Elgohary, M. Assessment of renewable energy supply for green ports with a case study. Environ. Sci. Pollut. Res. 2020, 27, 5547–5558. [Google Scholar] [CrossRef] [PubMed]

- Kesieme, U.; Pazouki, K.; Murphy, A.; Chrysanthou, A. Biofuel as an alternative shipping fuel: Technological, environmental and economic assessment. Sustain. Energy Fuels 2019, 3, 899–909. [Google Scholar] [CrossRef]

- Paulauskiene, T.; Bucas, M.; Laukinaite, A. Alternative fuels for marine applications: Biomethanol-biodiesel-diesel blends. Fuel 2019, 248, 161–167. [Google Scholar] [CrossRef]

- Spoof-Tuomi, K.; Niemi, S. Environmental and economic evaluation of fuel choices for short sea shipping. Clean Technol. 2020, 2, 34–52. [Google Scholar] [CrossRef]

- Mao, Y.; Su, H.; Chen, H.; Wu, J. Experimental study of combustion and emission characteristics in low-pressure dual-fuel marine engines with pre-chamber ignition. Energy Convers. Manag. 2022, 259, 115609. [Google Scholar] [CrossRef]

- Aymelek, M.; Boulougouris, E.K.; Turan, O.; Konovessis, D. Challenges and opportunities for LNG as a ship fuel source and an application to bunkering network optimisation. In Maritime Technology and Engineering; CRC Press: Boca Raton, FL, USA, 2014; pp. 767–776. [Google Scholar]

- Ammar, N.R. An environmental and economic analysis of methanol fuel for a cellular container ship. Transp. Res. Part D Transp. Environ. 2019, 69, 66–76. [Google Scholar] [CrossRef]

- Ammar, N.R. Energy- and cost-efficiency analysis of greenhouse gas emission reduction using slow steaming of ships: Case study RO-RO cargo vessel. Ships Offshore Struct. 2018, 13, 868–876. [Google Scholar] [CrossRef]

- Saadeldin, M.A.N.; Elgohary, M.M.; Abdelnaby, M.; Shouman, M.R. Biofuels and Electrofuels as Alternative Green Fuels for Marine Applications: A Review. Mar. Technol. Soc. J. 2023, 57, 51–68. [Google Scholar] [CrossRef]

- Andersson, K.; Salazar, C.M. Methanol as a Marine Fuel Report; FC Business Intelligence Ltd.: London, UK, 2015; Available online: http://www.methanol.org/wp-content/uploads/2018/03/FCBI-Methanol-Marine-Fuel-Report-Final-English.pdf (accessed on 1 April 2025).

| Emissions | Type of Operation | |

|---|---|---|

| SOx emissions | Switching to fuels with low sulfur content (e.g., marine gas oil or compliant heavy fuel oil) And scrubber systems | |

| NOx emissions | Pre-combustion | Water injection into the air and adjusting combustion parameters to reduce NOx formation. |

| Combustion | (EGR) Redirecting a portion of exhaust gases back into the engine to lower combustion temperature and NOx formation. | |

| After treatment | A post-combustion treatment that uses urea to convert NOx into nitrogen and water. | |

| CO2 emissions | Concerning Design | Enhancing hull design, propulsion systems, and voyage planning to reduce fuel consumption |

| Engine modifications | Waste heat recovery, engine modifications, and auxiliary system modification such as improving pump efficiency | |

| Operational measures | Implementing slow steaming, optimized routing, and energy-saving practices. | |

| New technologies | Carbon Capture Storage (CCS), Replacing conventional marine fuels with LNG, methanol, biofuels, or hydrogen. | |

| Model | Pressure (bar) | Weight (kg) | Length (m) | Height (m) | Width (m) | Capacity (Gross) |

|---|---|---|---|---|---|---|

| ISO VAC 40-LNG | 10 | 12,670 | 12.192 | 2.591 | 2.438 | 43,500 Ltr |

| ISO VAC 20-LNG | 17 | 7875 | 6.058 | 2.591 | 2.438 | 20,000 Ltr |

| Type | Container Ship |

|---|---|

| Ship’s Name | EVER ALOT |

| Year built | 2022 |

| IMO No. | 9893955 |

| Flag | Panama |

| Length over all (m) | 400 |

| Breadth over all (m) | 61.5 |

| Draught (Avg/Min/Max) (m) | 13.2/3.5/25.5 |

| Speed (kn) | 20.1 |

| Power (kW) | 60,400 at 70 rpm |

| TEU | 24,000 |

| Deadweight (tons) | 241,000 |

| Gross Tonnage (GRT) | 236,228 |

| Main engine | CMD-WinGD 11X92-B |

| Generators (kW) | 5 × 4300 |

| Type of Emission | Emission Factor (g/kwh) | Emission Rate During Operation (kg/h) | Emission Rate During Maneuvering (kg/h) | Emission Rate During Standby (kg/h) | |

|---|---|---|---|---|---|

| 89% (NG) dual fuel | NOx | 3.7924 | 264.0079 | 62.11951 | 15.52988 |

| SOx | 0.0396 | 2.756754 | 0.648648 | 0.162162 | |

| CO2 | 563.6649 | 39,239.53 | 9232.831 | 2308.208 | |

| PM | 0.0209 | 1.454954 | 0.342342 | 0.085586 | |

| CO | 0.9728 | 67.72147 | 15.93446 | 3.983616 | |

| HC | 1.312 | 91.33488 | 21.49056 | 5.37264 | |

| 91% Methanol (ME) dual fuel | NOx | 3.7777 | 262.9846 | 61.87873 | 15.46968 |

| SOx | 0.0324 | 2.255526 | 0.530712 | 0.132678 | |

| CO2 | 312.2411 | 21,736.66 | 5114.509 | 1278.627 | |

| PM | 0.0171 | 1.190417 | 0.280098 | 0.070025 | |

| CO | 0.6174 | 42.9803 | 10.11301 | 2.528253 | |

| HC | 0.891655 | 62.07256 | 14.60531 | 3.651327 |

| Emission | Fuel Type | Emission t/Trip | Emission t/Year | Reduction t/Year | % of Reduction/Year |

|---|---|---|---|---|---|

| NOx | Diesel fuel | 1102.7016 | 8821.613 | ||

| NG dual fuel | 245.993 | 1967.946 | 6853.667 | 77.69% | |

| ME dual fuel | 245.040 | 1960.318 | 6861.295 | 77.78% | |

| SOx | Diesel fuel | 23.351 | 186.811 | ||

| NG dual fuel | 2.569 | 20.549 | 166.261 | 89.00% | |

| ME dual fuel | 2.102 | 16.813 | 169.998 | 91.00% | |

| CO2 | Diesel fuel | 44,678.226 | 357,425.805 | ||

| NG dual fuel | 36,562.01101 | 292,496.088 | 64,929.717 | 18.17% | |

| ME dual fuel | 20,253.457 | 162,027.652 | 195,398.153 | 54.67% | |

| PM | Diesel fuel | 12.324 | 98.594 | ||

| NG dual fuel | 1.356 | 10.845 | 87.749 | 89.00% | |

| ME dual fuel | 1.109 | 8.874 | 89.721 | 91.00% | |

| CO | Diesel fuel | 90.811 | 726.486 | ||

| NG dual fuel | 63.100 | 504.804 | 221.682 | 30.51% | |

| ME dual fuel | 40.048 | 320.380 | 406.106 | 55.90% | |

| HC | Diesel fuel | 38.919 | 311.351 | ||

| NG dual fuel | 85.103 | 680.821 | −369.470 | ||

| ME dual fuel | 57.837 | 462.696 | −151.345 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elmallah, M.; Madariaga, E.; Almeida, J.A.G.; Alghaffari, S.; Saadeldin, M.A.; Ghoneim, N.I.; Shouman, M. Decarbonization Potential of Alternative Fuels in Container Shipping: A Case Study of the EVER ALOT Vessel. Environments 2025, 12, 306. https://doi.org/10.3390/environments12090306

Elmallah M, Madariaga E, Almeida JAG, Alghaffari S, Saadeldin MA, Ghoneim NI, Shouman M. Decarbonization Potential of Alternative Fuels in Container Shipping: A Case Study of the EVER ALOT Vessel. Environments. 2025; 12(9):306. https://doi.org/10.3390/environments12090306

Chicago/Turabian StyleElmallah, Mamdouh, Ernesto Madariaga, José Agustín González Almeida, Shadi Alghaffari, Mahmoud A. Saadeldin, Nourhan I. Ghoneim, and Mohamed Shouman. 2025. "Decarbonization Potential of Alternative Fuels in Container Shipping: A Case Study of the EVER ALOT Vessel" Environments 12, no. 9: 306. https://doi.org/10.3390/environments12090306

APA StyleElmallah, M., Madariaga, E., Almeida, J. A. G., Alghaffari, S., Saadeldin, M. A., Ghoneim, N. I., & Shouman, M. (2025). Decarbonization Potential of Alternative Fuels in Container Shipping: A Case Study of the EVER ALOT Vessel. Environments, 12(9), 306. https://doi.org/10.3390/environments12090306